Installation method of large watertight door

An installation method and watertight door technology, applied in the field of shipbuilding, can solve the problems of uncontrollable, large deformation, unfavorable door frame precision, etc., and achieve the effect of saving installation time and preventing structural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

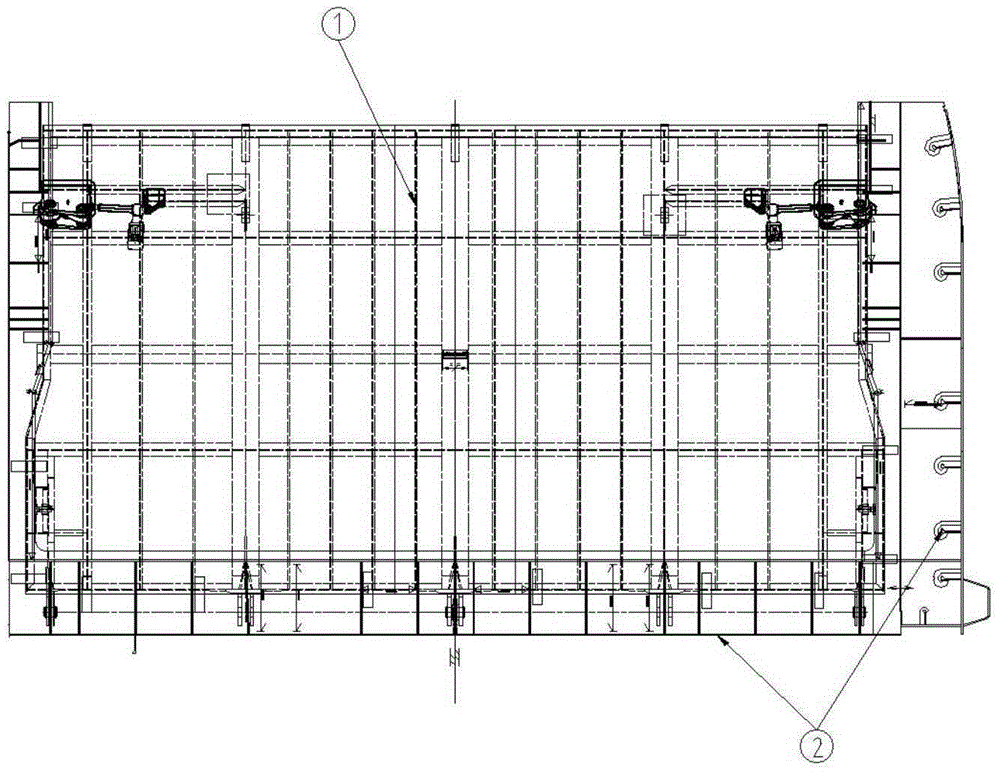

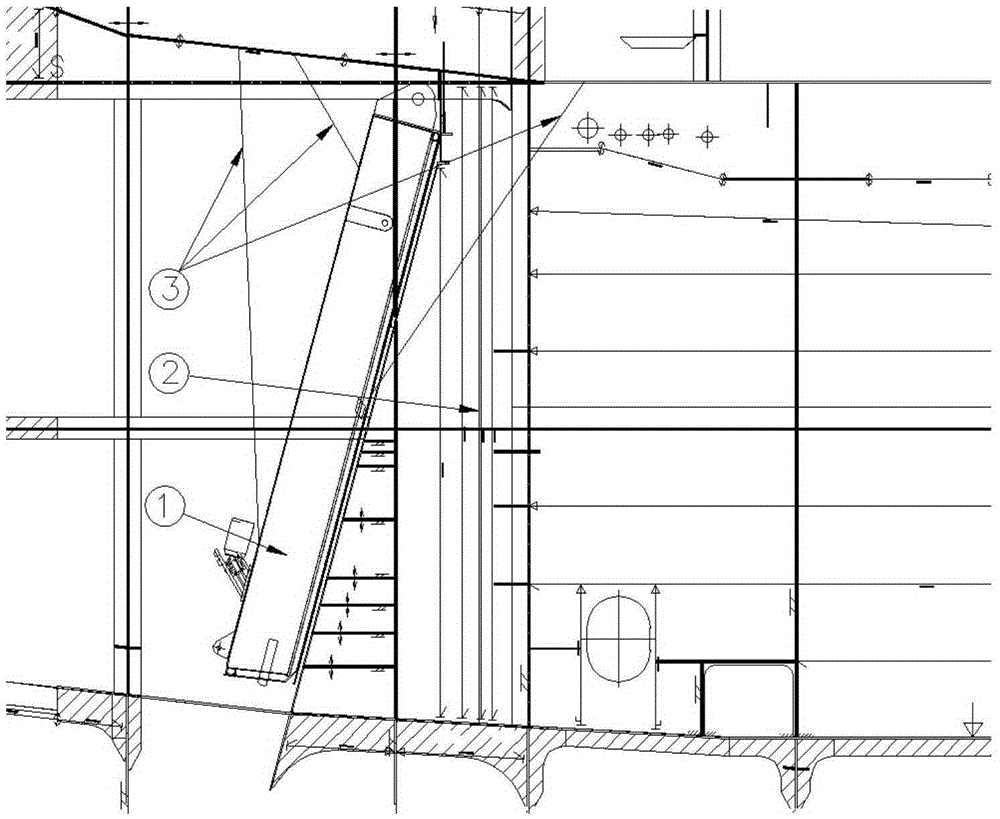

[0032] The method for installing a large watertight door of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

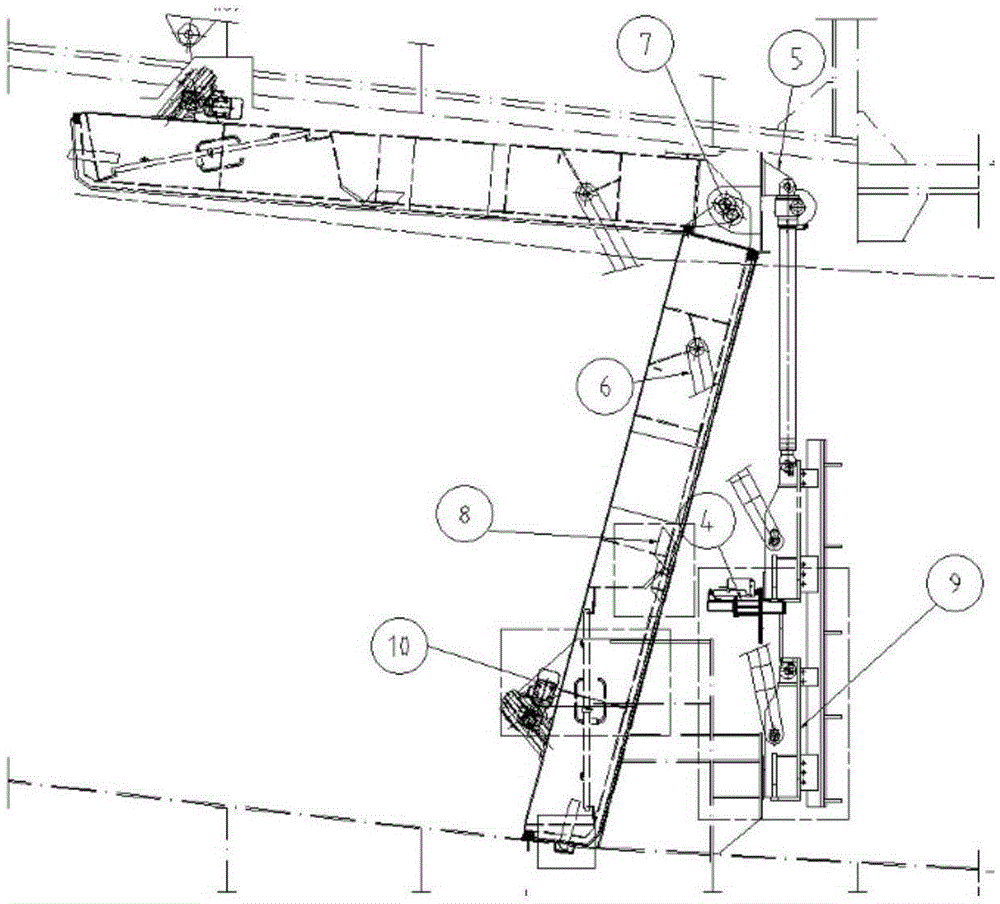

[0033] The watertight door in the large watertight door installation method of the present invention is in figure 1 Draw the reference line and perform anti-state pre-installation in the state. After the watertight door and the general hull section are turned over and carried together, use the hoist and wire rope to fine-tune in situ. Position all attachments according to the guides. Then open the watertight door, install the compression strip, and weld the compression strip after confirming that the watertightness is correct.

[0034] The specific steps are as Figure 4 as shown, Figure 4 It is a flow chart of the installation method of the large watertight door of the present invention. As can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com