Engine airtight detection rapid plugging head

An air tightness detection and engine technology, which is applied to the sealing of engines, engine components, and liquid tightness measurement using liquid/vacuum degree. Time and other issues, to achieve the effect of improving plugging efficiency, shortening installation time, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments:

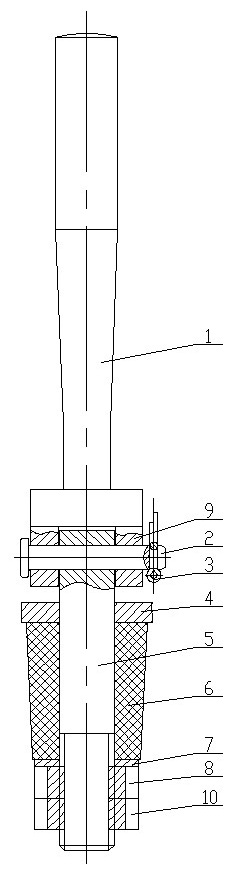

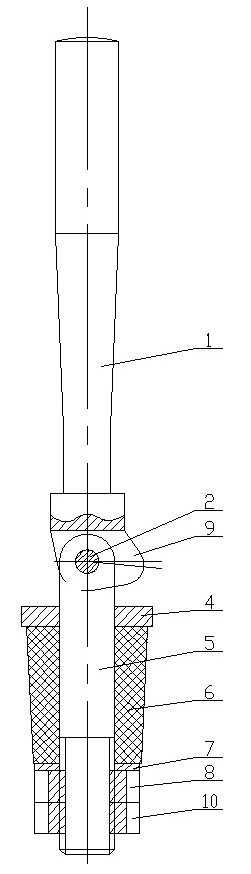

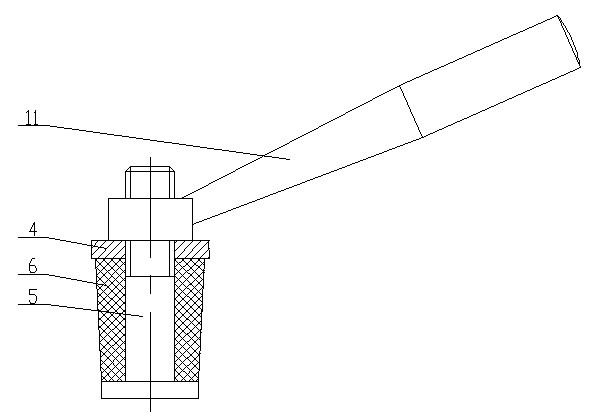

[0019] Such as figure 1 , figure 2 As shown, the present invention is composed of a cam handle 1, a cylindrical pin 2, a split pin 3, an upper washer 4, a tie rod 5, a rubber sleeve 6, a lower washer 7, a first nut 8, a cam 9 and a second nut 10, wherein the tie rod 5 It is a linear round rod structure, and threads are machined on the circumferential surface of the lower end of the tie rod 5. The threaded section at the lower end of the tie rod 5 is fitted with a first nut 8 and a second nut 10 through threaded fit, and the first nut 8 is located at the second Above the nut 10, the two are close together. An upper gasket 4, a rubber sleeve 6 and a lower gasket 7 are also sleeved on the pull rod 5. The upper gasket 4 is located above the rubber sleeve 6, and the bottom surface of the upper gasket 4 is in contact with the top surface of the rubber sleeve 6. The rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com