Reinforcement cage and manufacturing method thereof

A technology of reinforcement cages and steel bars, which is applied in the direction of foundation structure engineering, structural elements, sheet pile walls, etc., to achieve the effect of reducing sediment thickness, less specifications, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

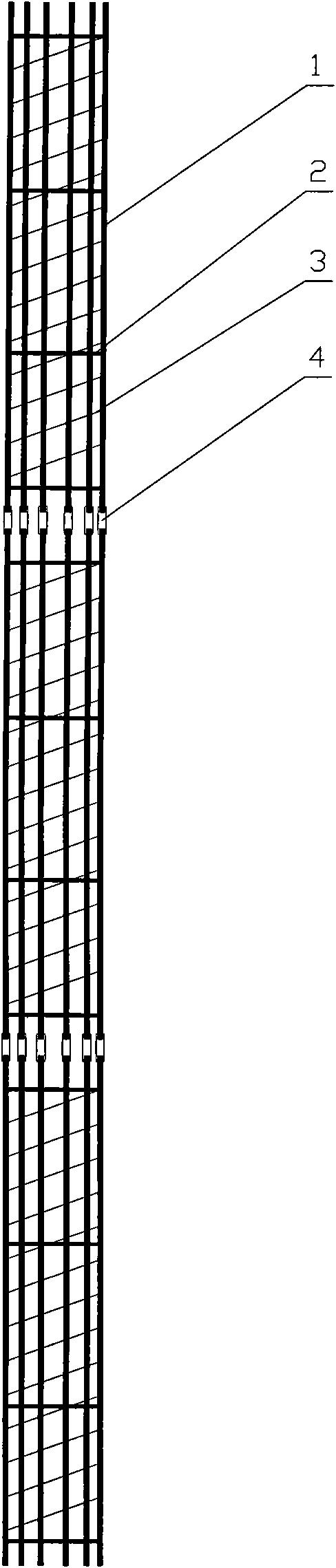

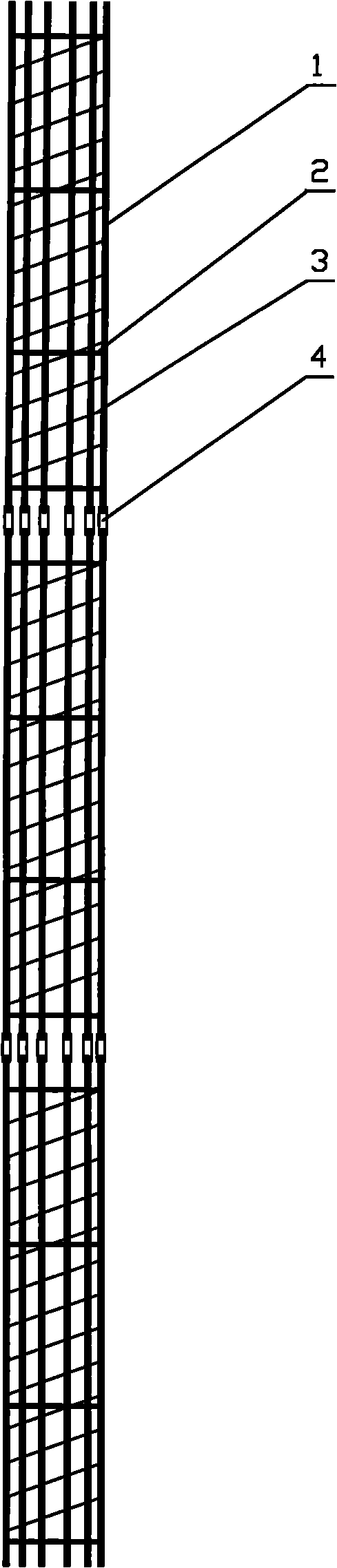

[0064]The underground excavation section of a North Station of a subway line 2 is located under the North Railway Station Road in front of the North Railway Station. The design adopts the "PBA" hole pile method for underground excavation construction, and it needs to be excavated in a small pilot tunnel with a width of 3.5m and a height of 4.5m Construction pile length 17.5m, diameter 1.0m and bored pile with pile length 17.5m, diameter 0.8m. According to the height of the small pilot hole, the maximum processing length of a single-section reinforcement cage shall not exceed 3.0m, and the reinforcement cage of each pile shall be divided into 6 sections and 5 assembly joints. How to complete the steel cage installation quickly and with high quality has become a key issue in construction.

[0065] After research, it was decided to use the mold method to process each section of the steel cage with high precision and assemble it at the opening in the small guide hole.

[0066] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com