Patents

Literature

194results about How to "Reduced risk of collapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

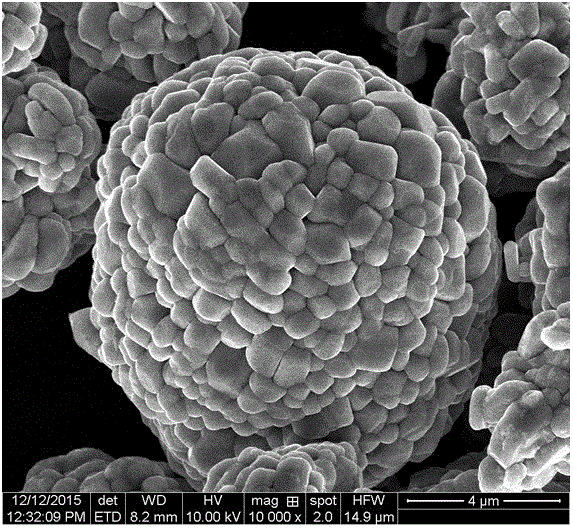

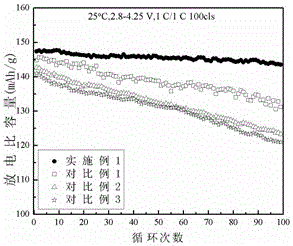

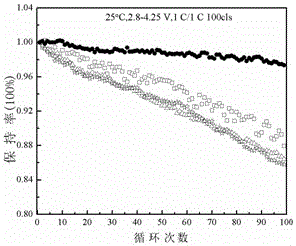

Element co-doping modified ternary lithium ion battery cathode material, and preparation method thereof

ActiveCN106395920AImprove electrochemical cycle performanceHigh magnificationCell electrodesSecondary cellsManganesePhysical chemistry

The invention discloses an element co-doping modified ternary lithium ion battery cathode material, and a preparation method thereof. According to the preparation method, compounds of two kinds of metals Me<1> and Me<2> are respectively selected based on the difference of ion radiuses of lithium ion and transition metal ions in the lithium nickel cobalt manganese ternary material, and are subjected to high temperature sintering with a nickel cobalt manganese precursor, wherein the ion radius of the metal Me<1> ion is close to that of lithium ion, and the metal Me<1> ion is one or a mixture of ions selected from Zn2+ and Zr4+, the radius of the metal Me<2> ion is close to that of transition metal ion Co3+ or Mn4+, and the metal Me<2> is one or a mixture of ions selected from Al3+, V5+, and Ge4+; and then a primary product obtained via high temperature sintering is subjected to second cladding so as to obtain the element co-doping modified ternary lithium ion battery cathode material. The element co-doping modified ternary lithium ion battery cathode material is capable of achieving synergistic effects of two metal elements fully, and improving cycle performance of lithium ion batteries effectively.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

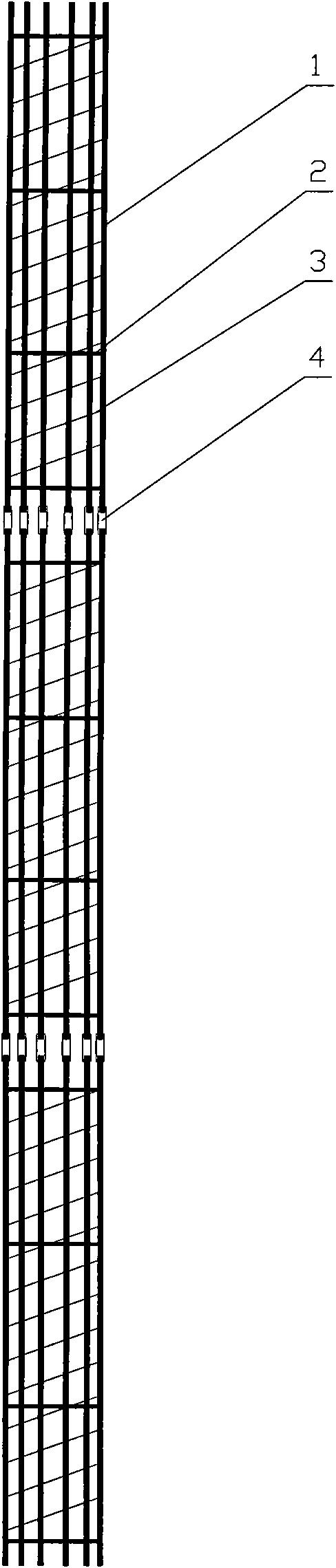

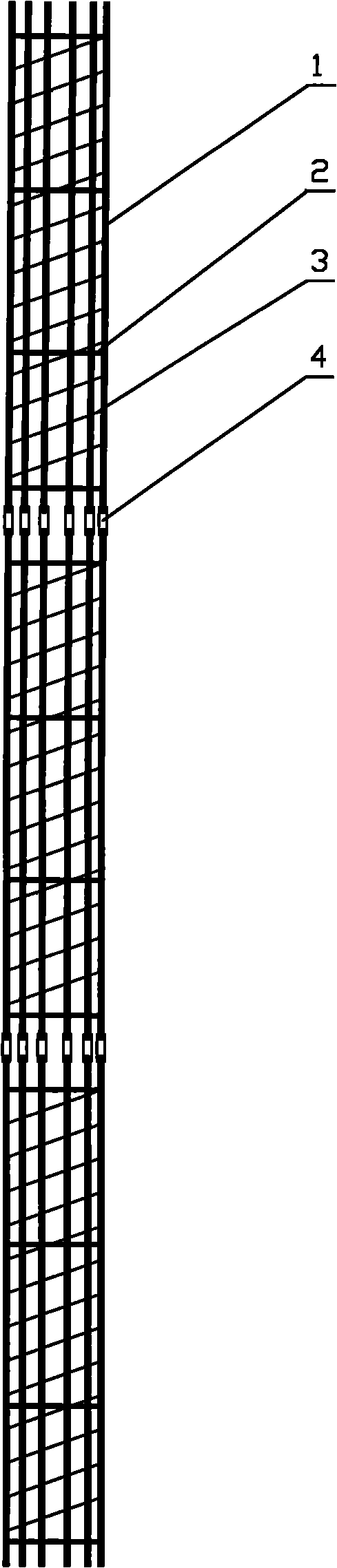

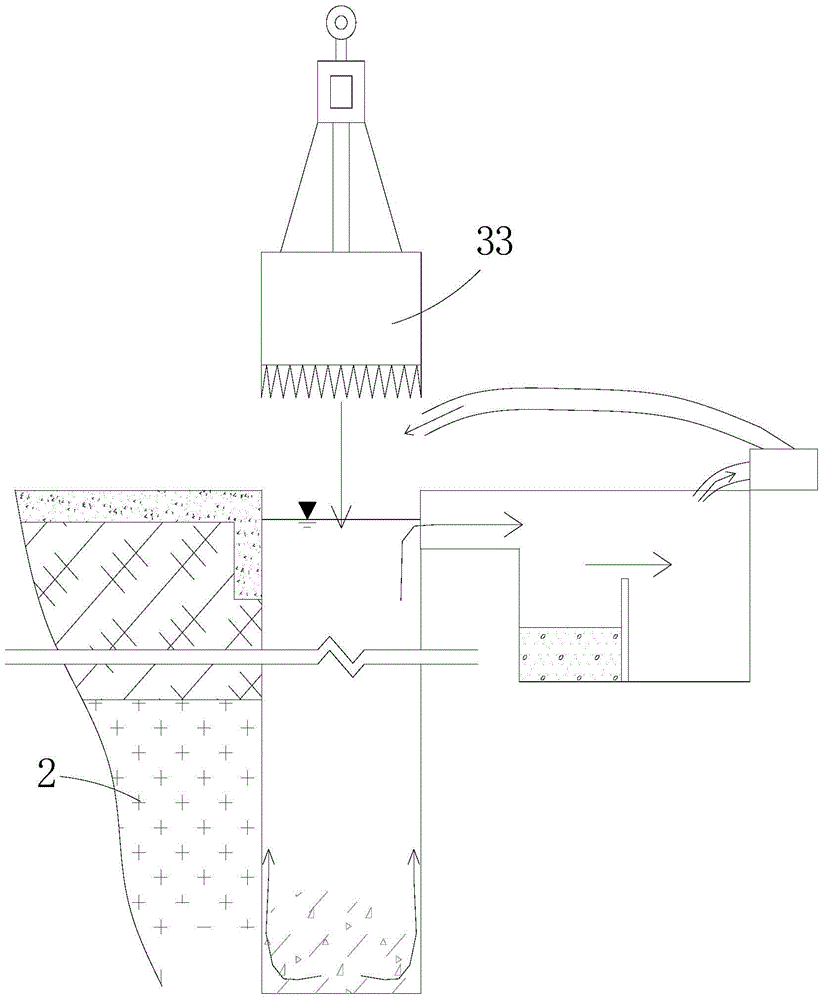

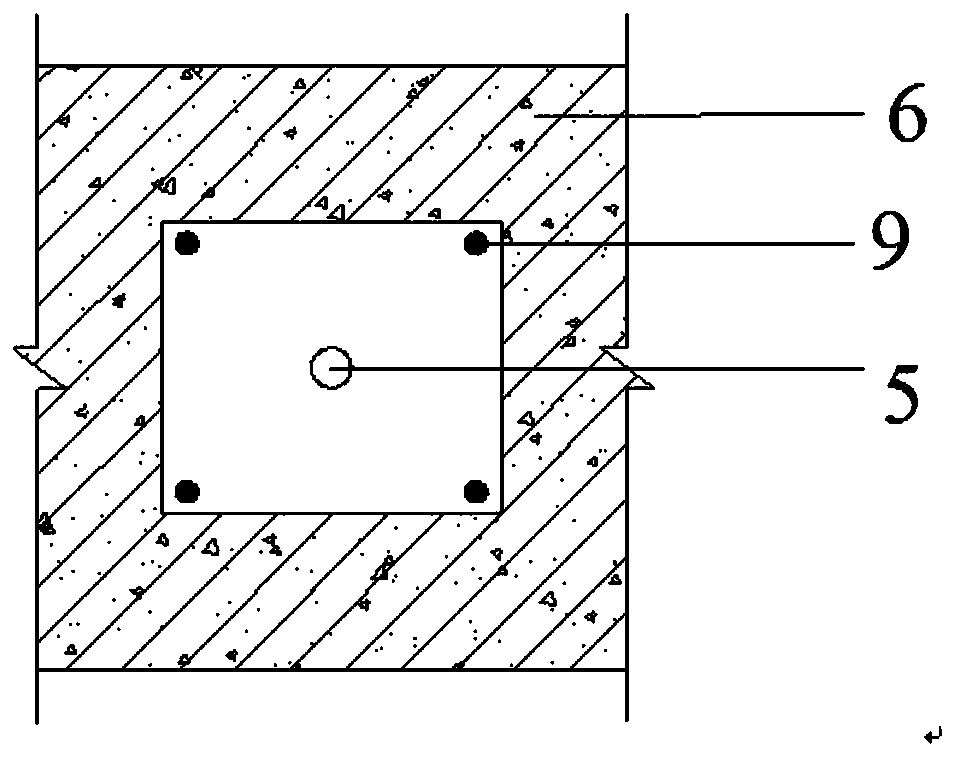

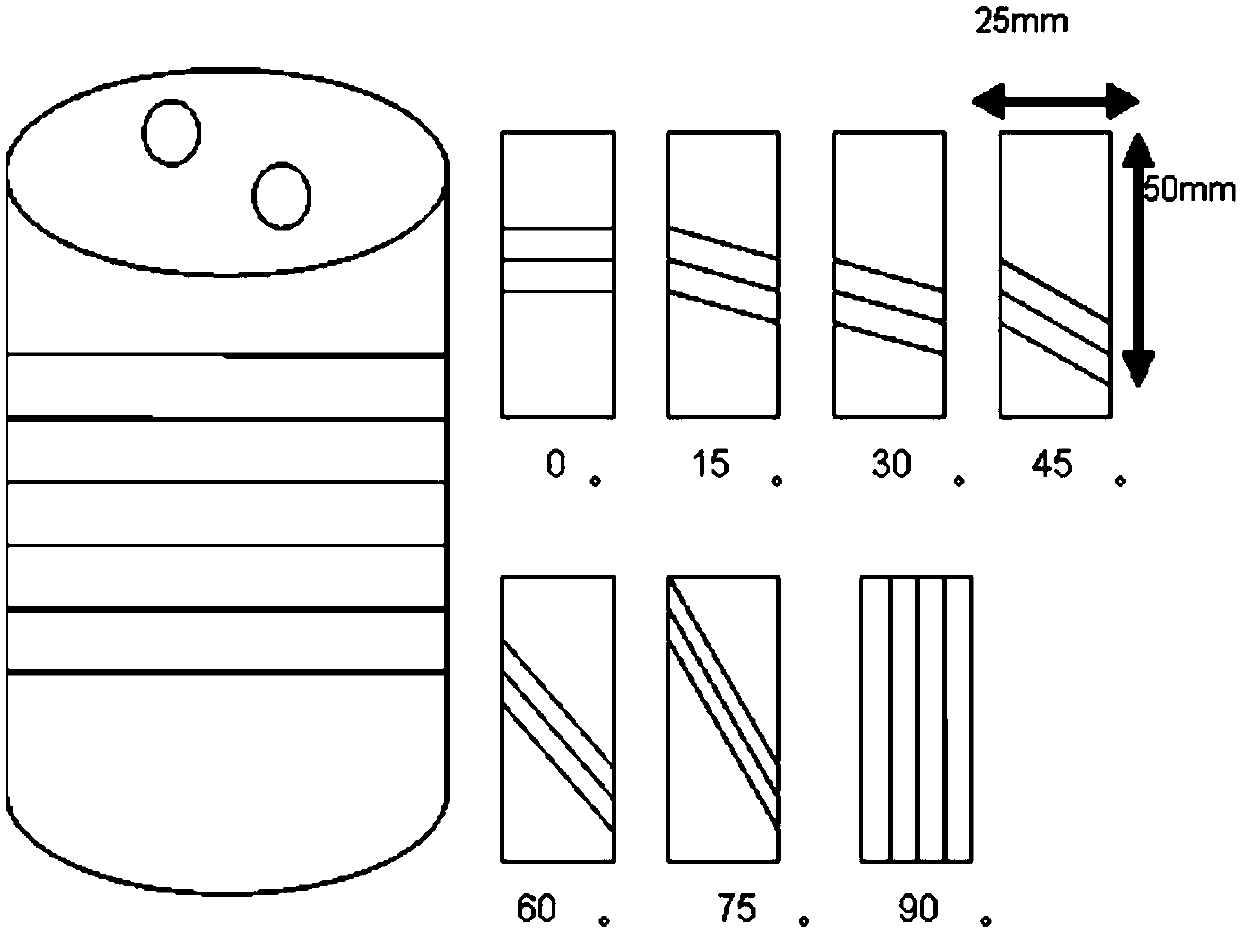

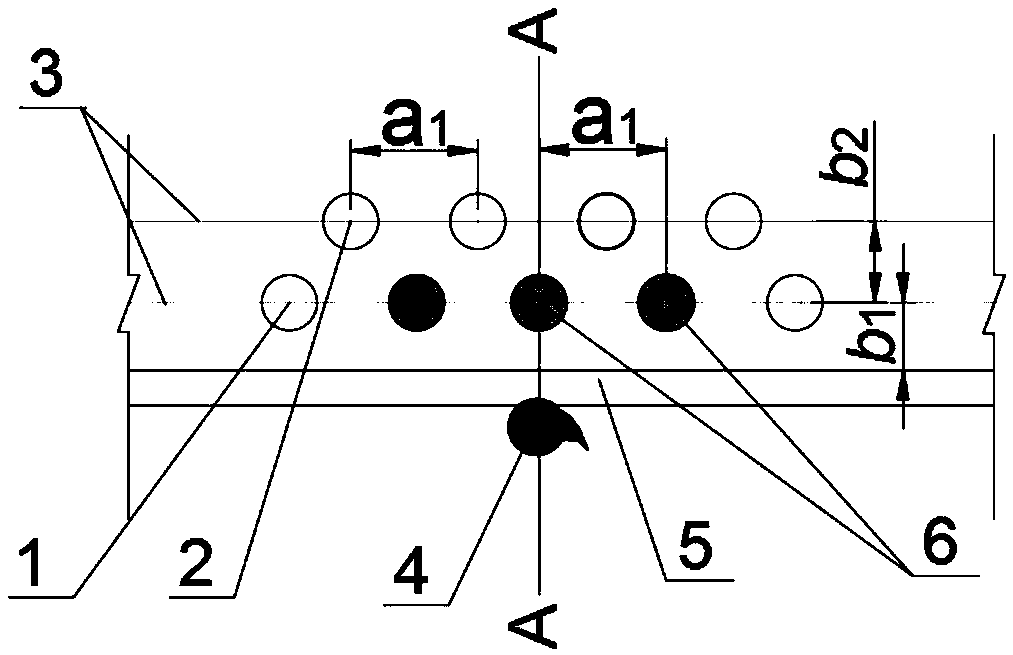

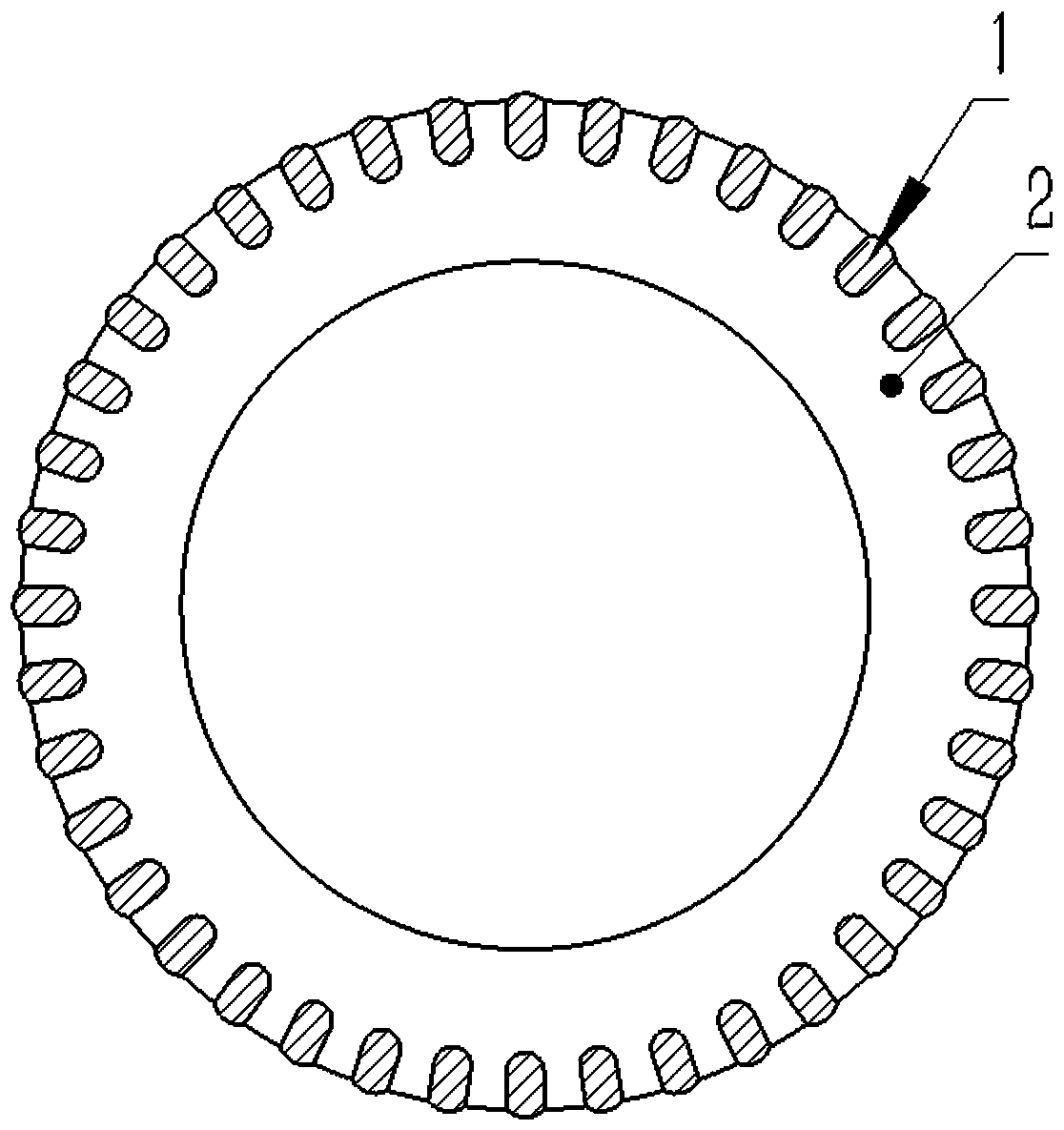

Reinforcement cage and manufacturing method thereof

InactiveCN101967825AQuality improvementImprove machining accuracyBuilding reinforcementsBulkheads/pilesEngineeringRebar

The invention relates to a reinforcement cage and a manufacturing method thereof. The reinforcement cage comprises main reinforcements; the reinforcement cage is divided into a plurality of sections; the main reinforcements, an inner locating stirrup and an outer locating stirrup are arranged in each section of reinforcement cage; the length of the main reinforcements is the same; one ends of the main reinforcements are half wires, and one ends of the reinforcements are full wires; a main reinforcement joint between each section of reinforcement cage is provided with straight thread connectors; and the main reinforcements in each section of reinforcement cage are connected in one-to-one correspondence. The manufacturing method comprises the following steps of: blanking the reinforcements; performing thread rolling on the reinforcement cages; processing the reinforcement cages; storing and delivering the reinforcement cages; splicing the reinforcement cages, preassembling on a spot, putting the processed reinforcement cages end to end according to the sequence of the divided sections into a straight line, sequentially splicing from one end to another end, screwing the connectors one by one, and sequentially arranging the rest reinforcement cages; splicing orifices; and detecting. The invention solves the problem that the reinforcement cage needs to be divided into a plurality of sections for processing and splicing due to the limitation of construction condition. The invention has the characteristics that: the manufacturing method is simple to operate, and the reinforcement cage has high precision and installation rate.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

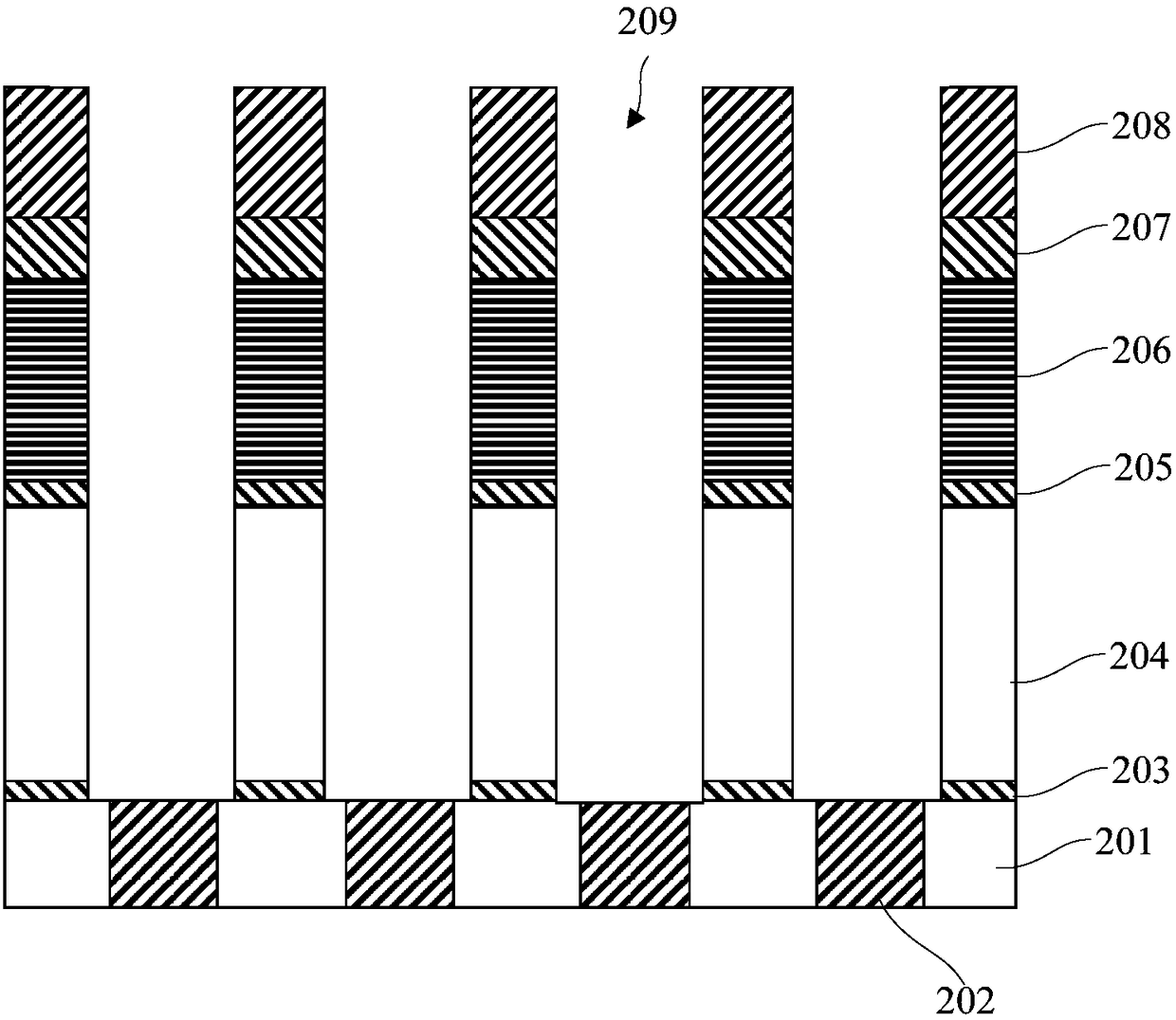

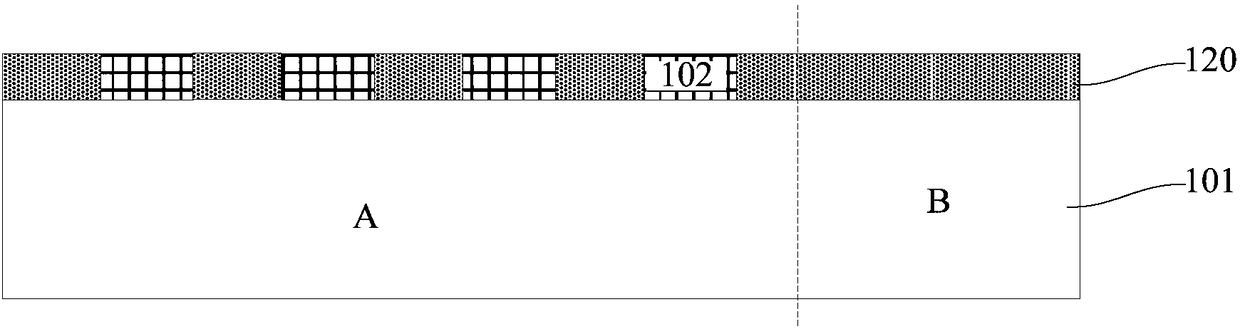

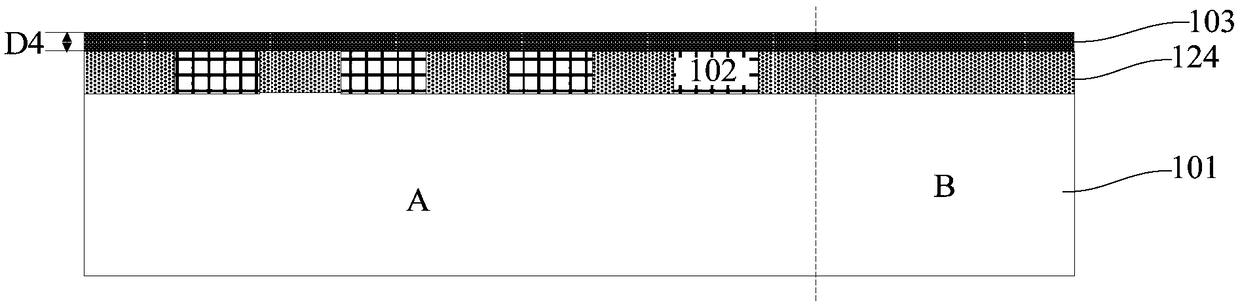

Semiconductor capacitor device and manufacture method thereof

PendingCN108538822AIncrease capacitanceImprove structural strengthTransistorSemiconductor/solid-state device detailsBlock layerCapacitance

The invention provides a semiconductor capacitor device and a manufacture method thereof. The manufacture method includes that a laminated structure comprising a first sacrificial layer, a first support layer, a second sacrificial layer, a second support layer, a third sacrificial layer and a third support layer is adopted for improving the height of the capacitor; the structural strength of the laminated structure during a capacitor hole etching process is improved through two-process settlement for the formation of a lower layer and a higher layer of each of the first sacrificial layer and the second sacrificial layer, wherein the proportion of boron in the upper layer of each sacrifice layer is lower than that in the lower layer of each sacrifice layer and thus the rigidity of the upperlayers is higher than the lower layers. During a process of adopting a chemical mechanical grinding technique for removing a blocking layer, the removal rate of the blocking layer is greater than that of a first conducting layer, so that the first conducting layer is provided with a protruding part protruding from the third support layer. Therefore, the area of a lower electrode of the double-face capacitor is further improved and the integral capacitance value is increased.

Owner:CHANGXIN MEMORY TECH INC

Immovable string hydraulic sandblasting fracture annulus pressure control method for gas field horizontal well

InactiveCN104632172AEnsure wellbore stabilityReduced risk of borehole collapseFluid removalFlushingConstruction designWellhead

The invention provides an immovable string hydraulic sandblasting fracture annulus pressure control method for a gas field horizontal well, and belongs to the technical field of gas field horizontal well sectional improvement. An immovable string hydraulic sandblasting fracture technique string of the gas field horizontal well is laid in the gas field horizontal well, and ejectors are aligned to planned improvement positions; a throttle valve is installed at a wellhead sleeving and releasing outlet, and a sleeving and releasing pipeline is connected into a slurry pond; sandblasting and perforation are carried out on target sections according to construction design, an annulus is opened during sandblasting and perforation, and annulus pressure is controlled through the throttle valve; after perforation, displacement is increased, jet flow pressurization is improved, the annulus pressure is adjusted through the throttle valve, a stratum is pressed open and then a sleeve gate is closed for main fracture construction, and liquid nitrogen is injected in the whole process of main fracture construction of each section; a next layer hydraulic sandblasting fracture tool is opened in a ball throwing mode for next layer perforation and fracture construction; after pressing, the aims that liquid is quickly discharged, the flowback rate is increased, and construction risk is lowered are achieved.

Owner:PETROCHINA CO LTD

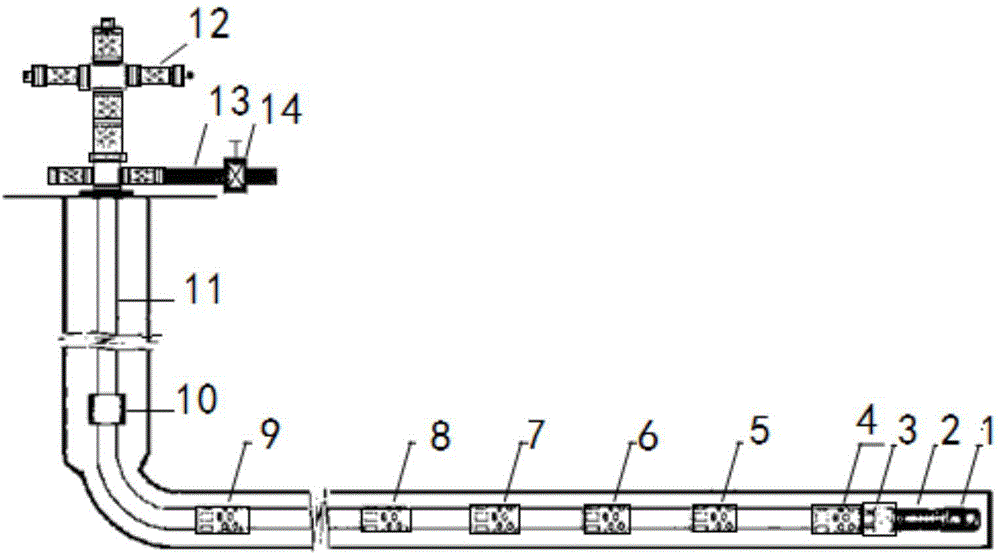

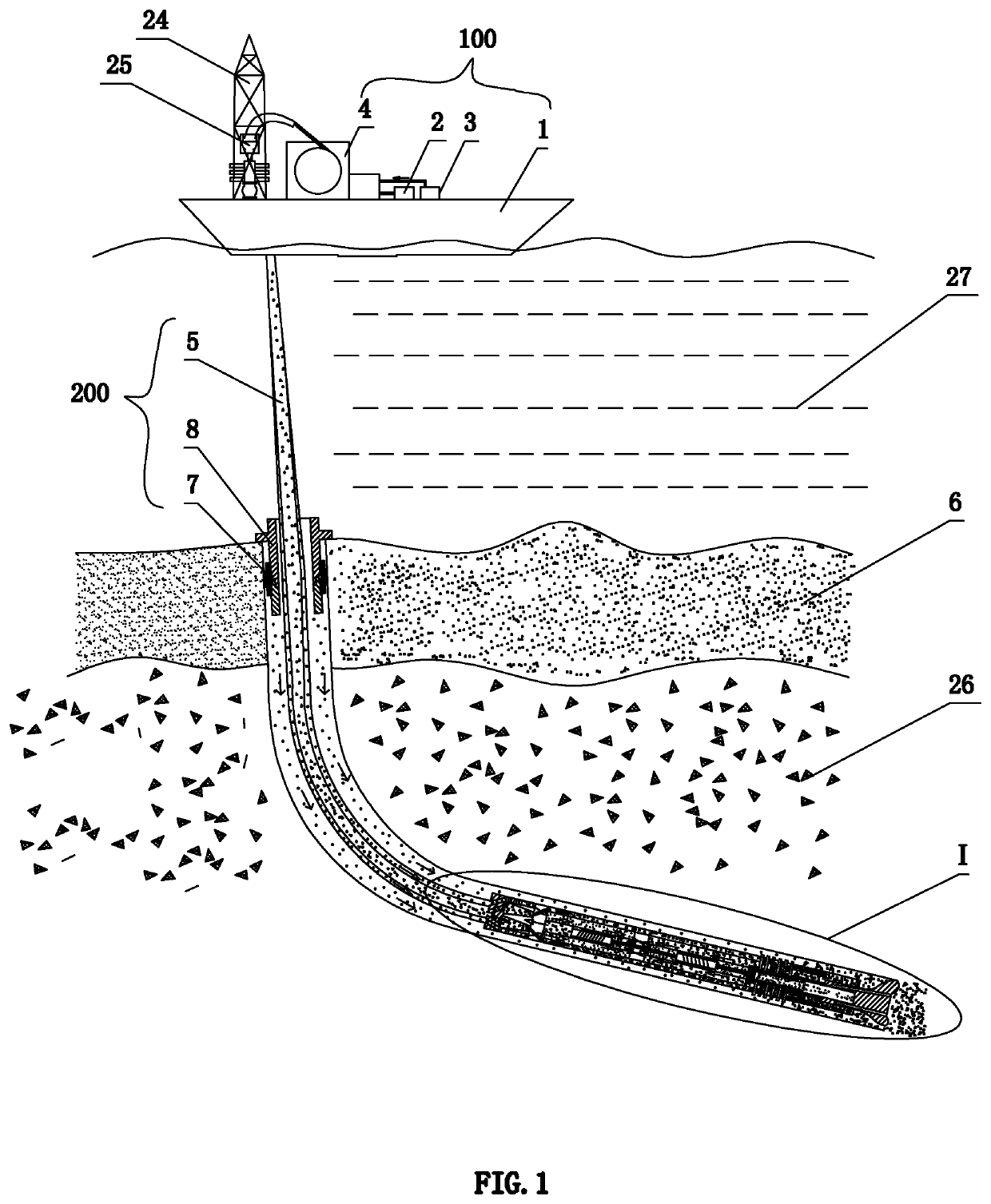

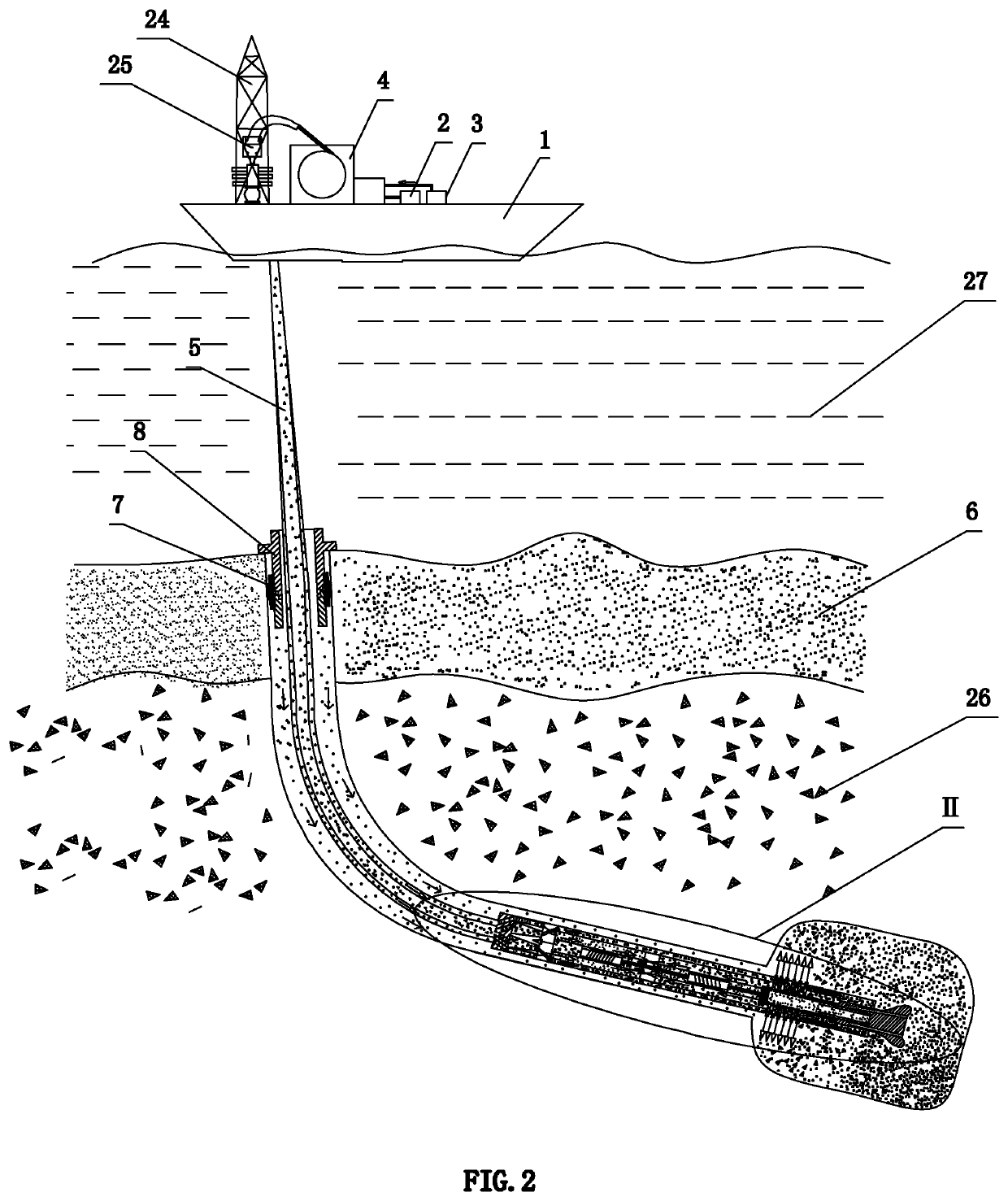

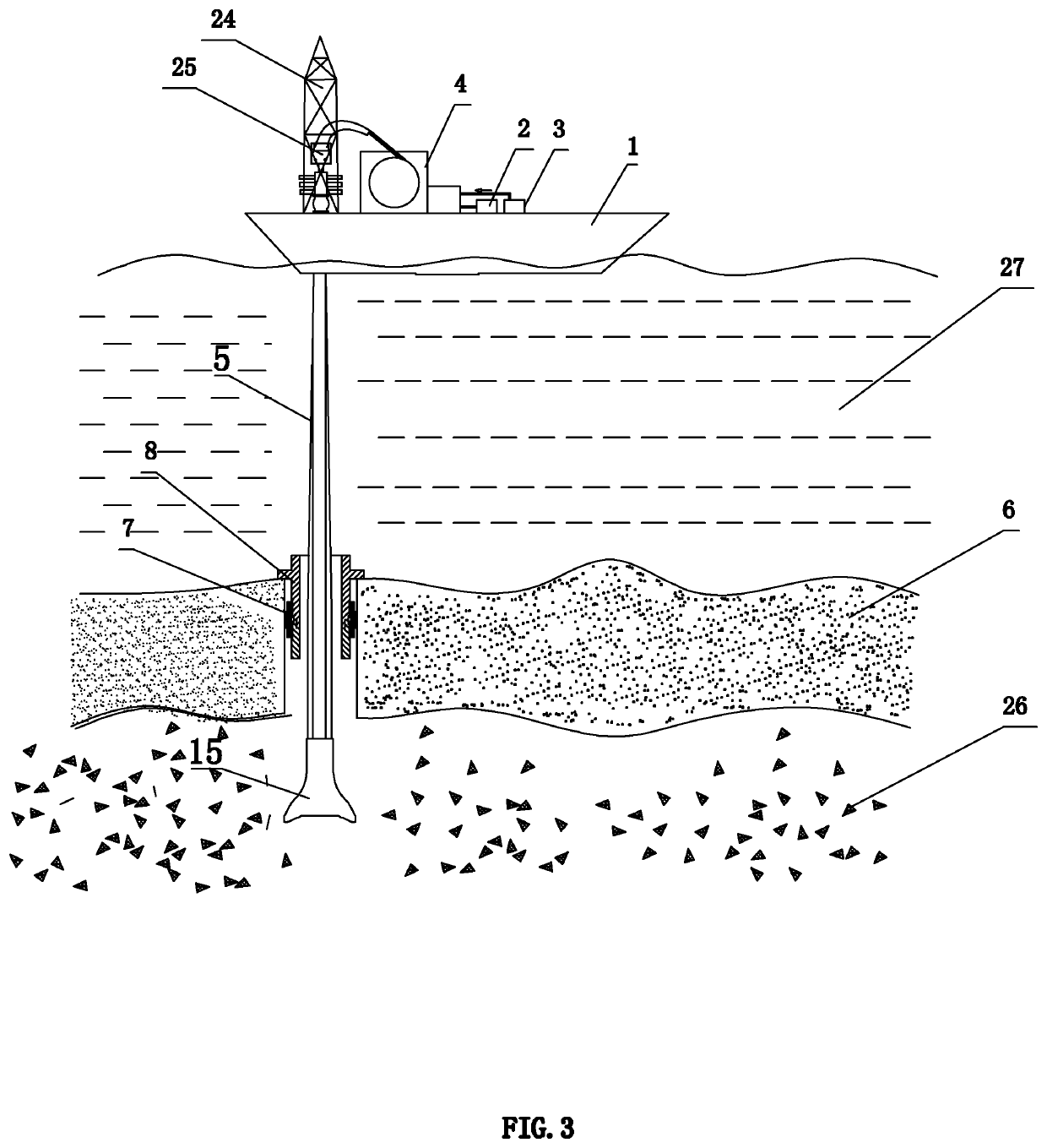

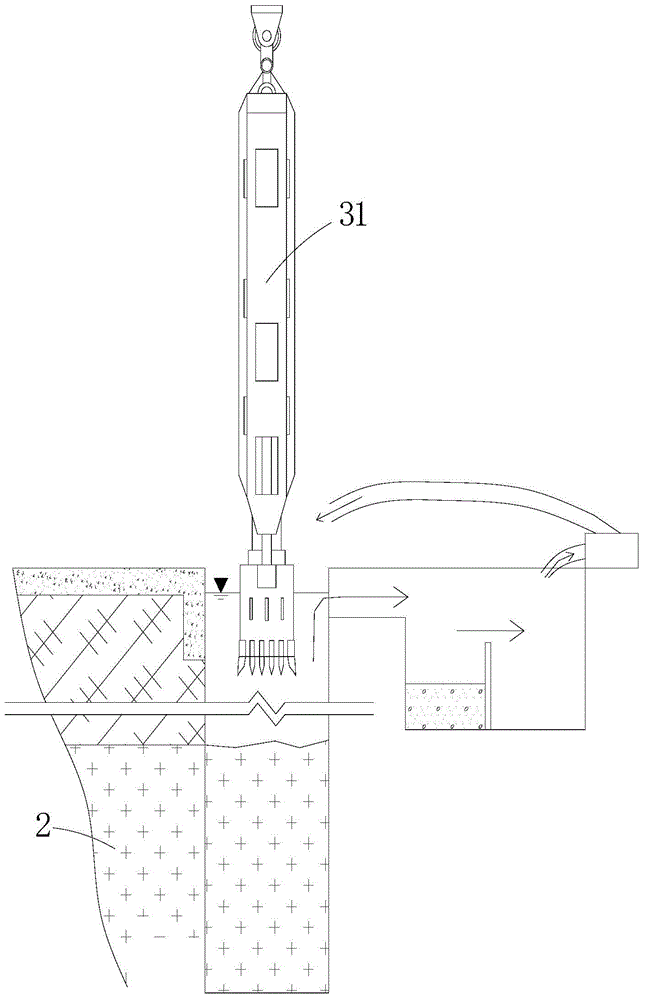

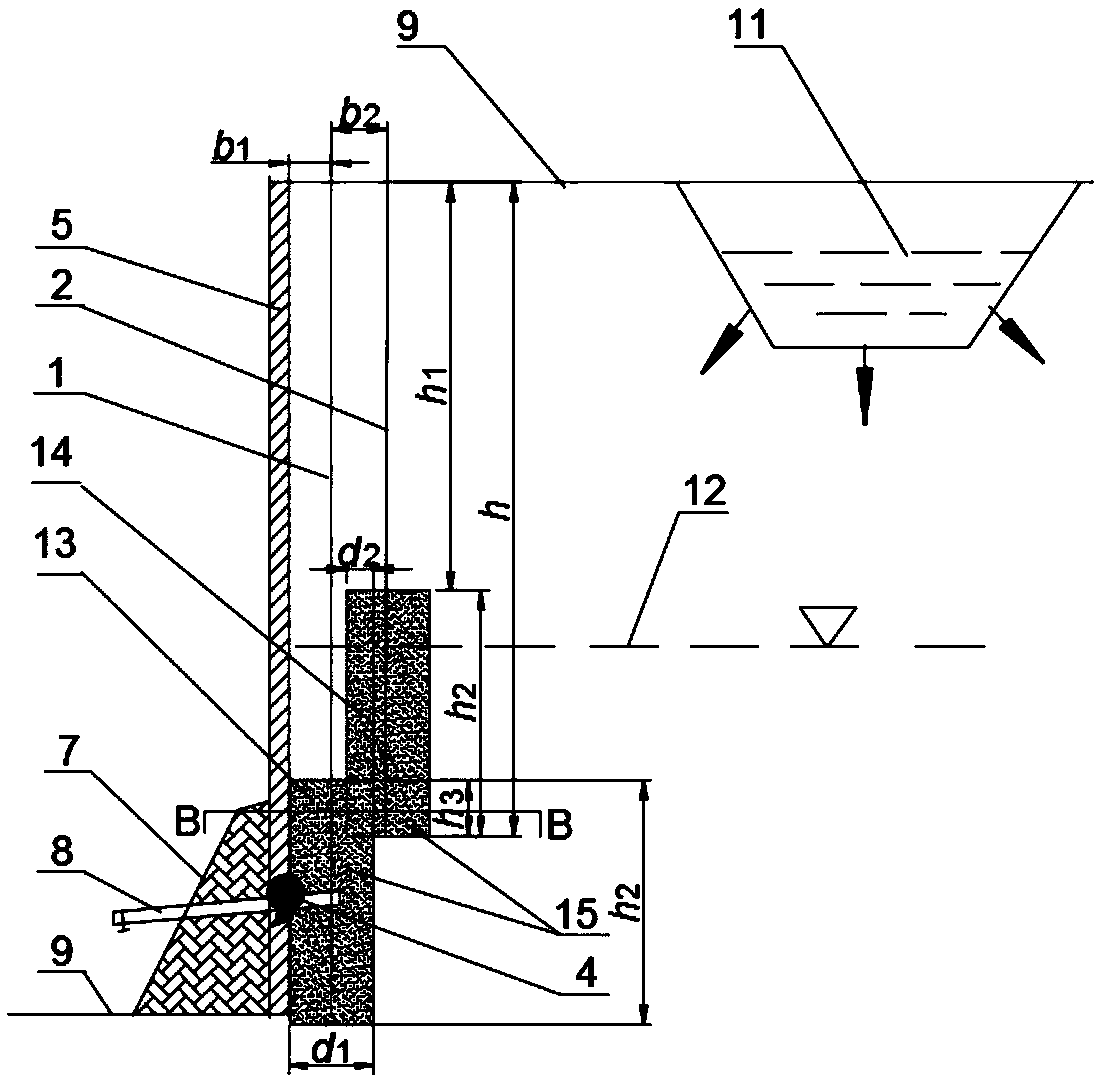

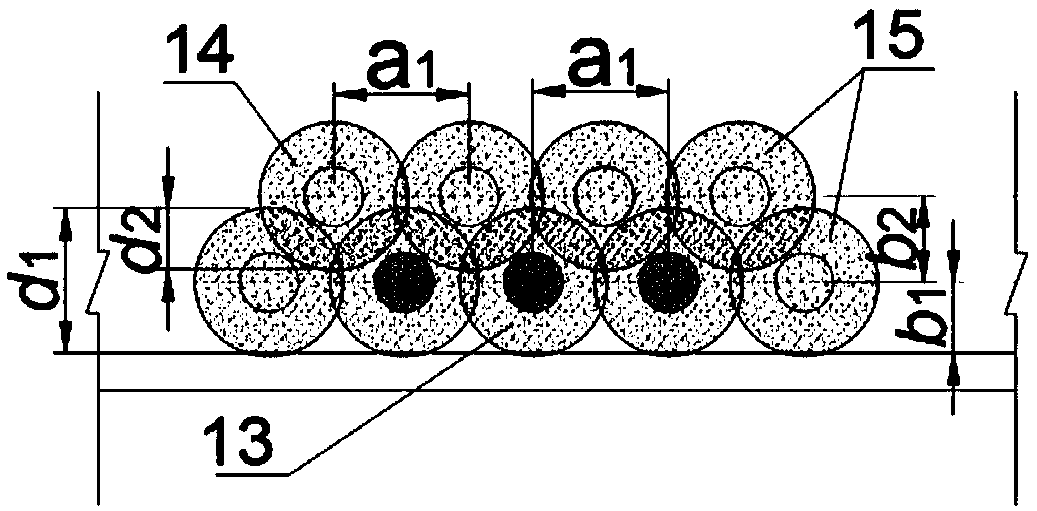

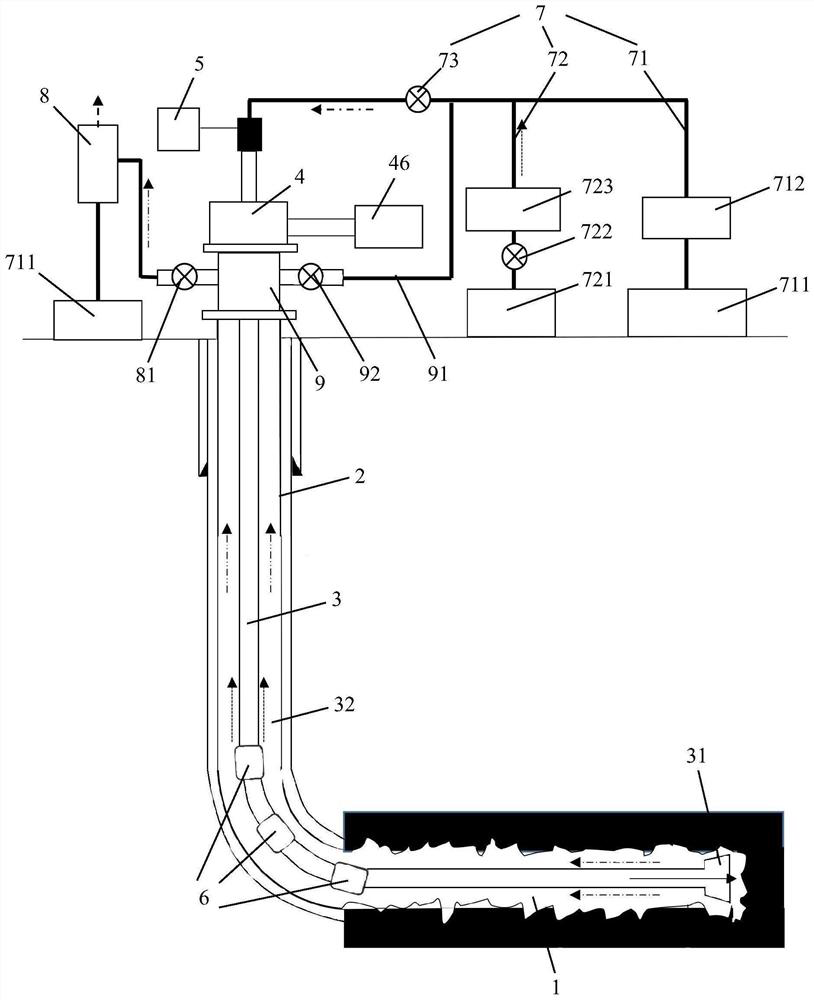

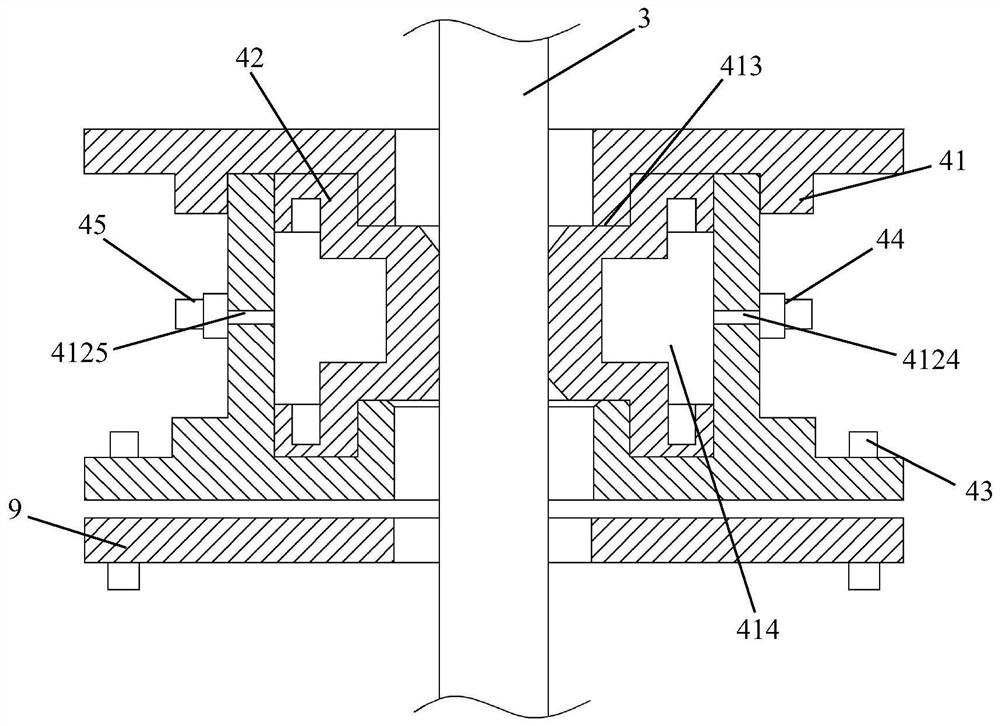

Device and method for solid-state fluidized mining of natural gas hydrates in shallow seabed

ActiveUS20200040710A1Reduced risk of collapseEfficient ejectionDrilling rodsConstructionsSlurryScrew pump

Disclosed is a device for solid-state fluidized mining of natural gas hydrates in a shallow seabed, including: a sea surface support system, a pipeline delivery system, and an undersea drilling system. The sea surface support system includes a hydrate drilling vessel floating on seawater. The pipeline delivery system includes a continuous double-layer oil pipe, a recyclable conduit installed in a sediment cover, an open-hole steering packer installed outside the recyclable conduit. The undersea drilling system includes a hydrate slurry separator, a single screw pump, a hydraulic motor, a jet head and a differential pressure sliding sleeve close to the hydrate drill bit. The present invention has the following beneficial effects. The device achieves a multi-directionally horizontal drilling and production in the hydrate reservoir with a single well head, improving the drilling efficiency and single well production.

Owner:SOUTHWEST PETROLEUM UNIV

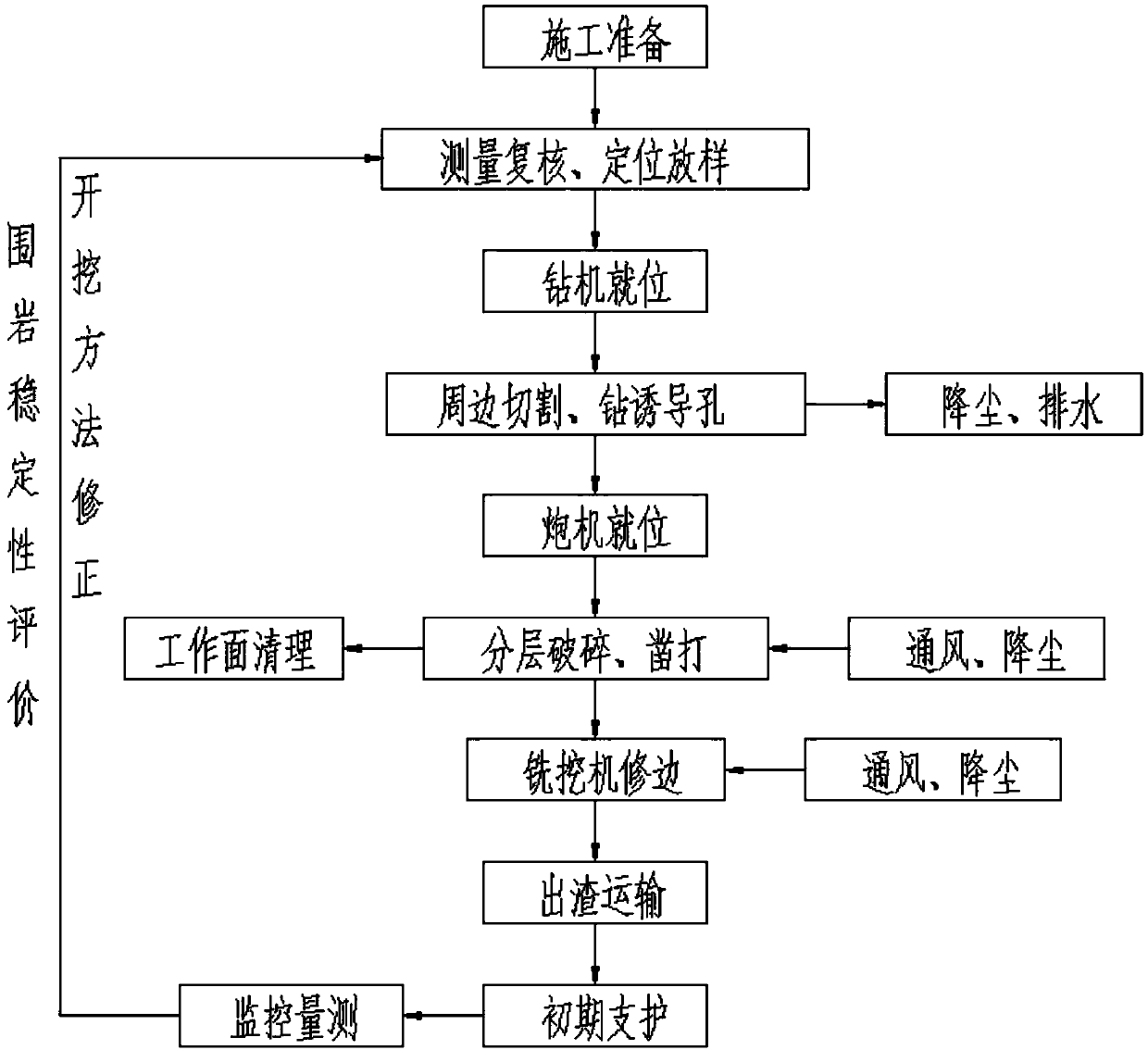

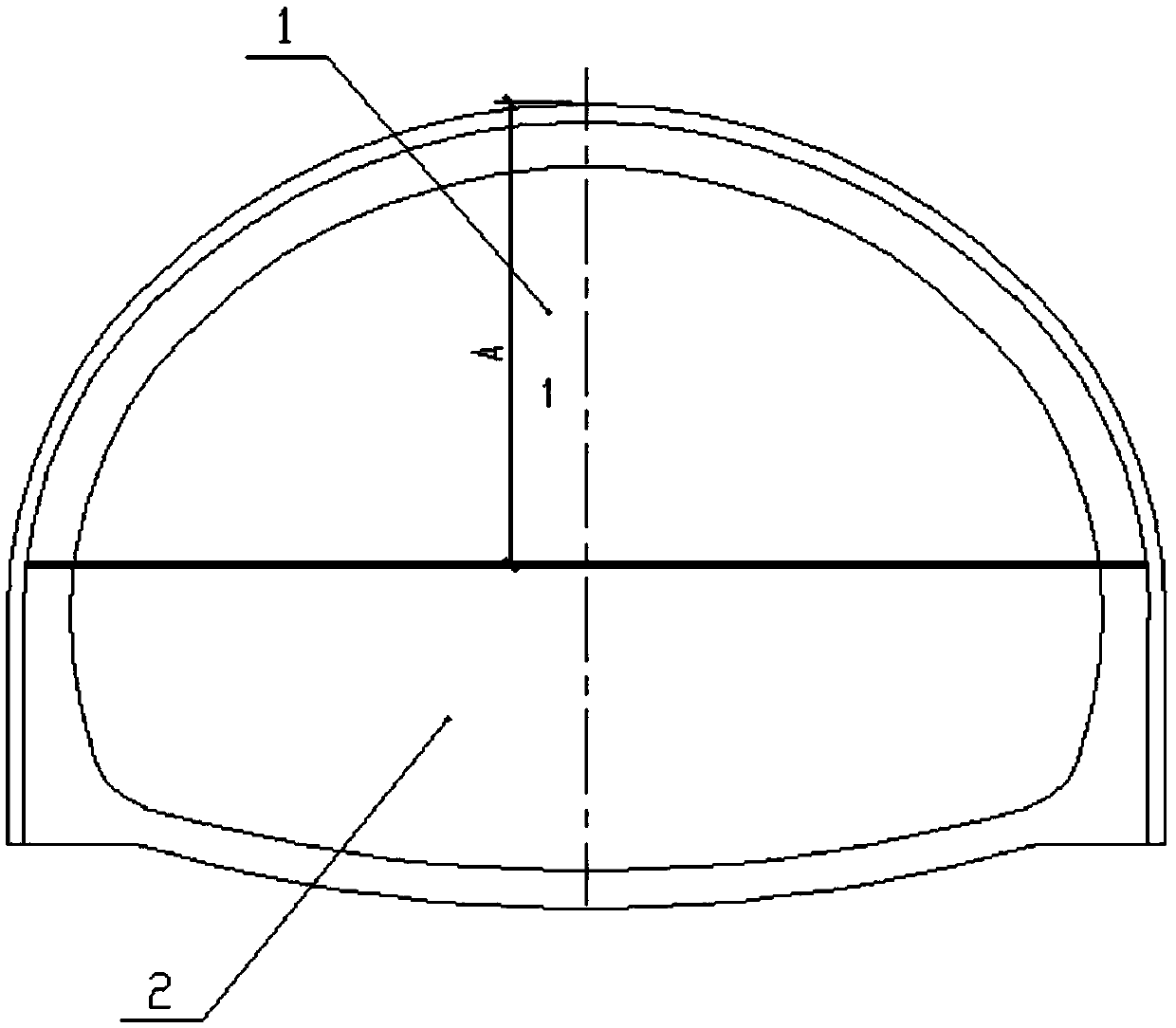

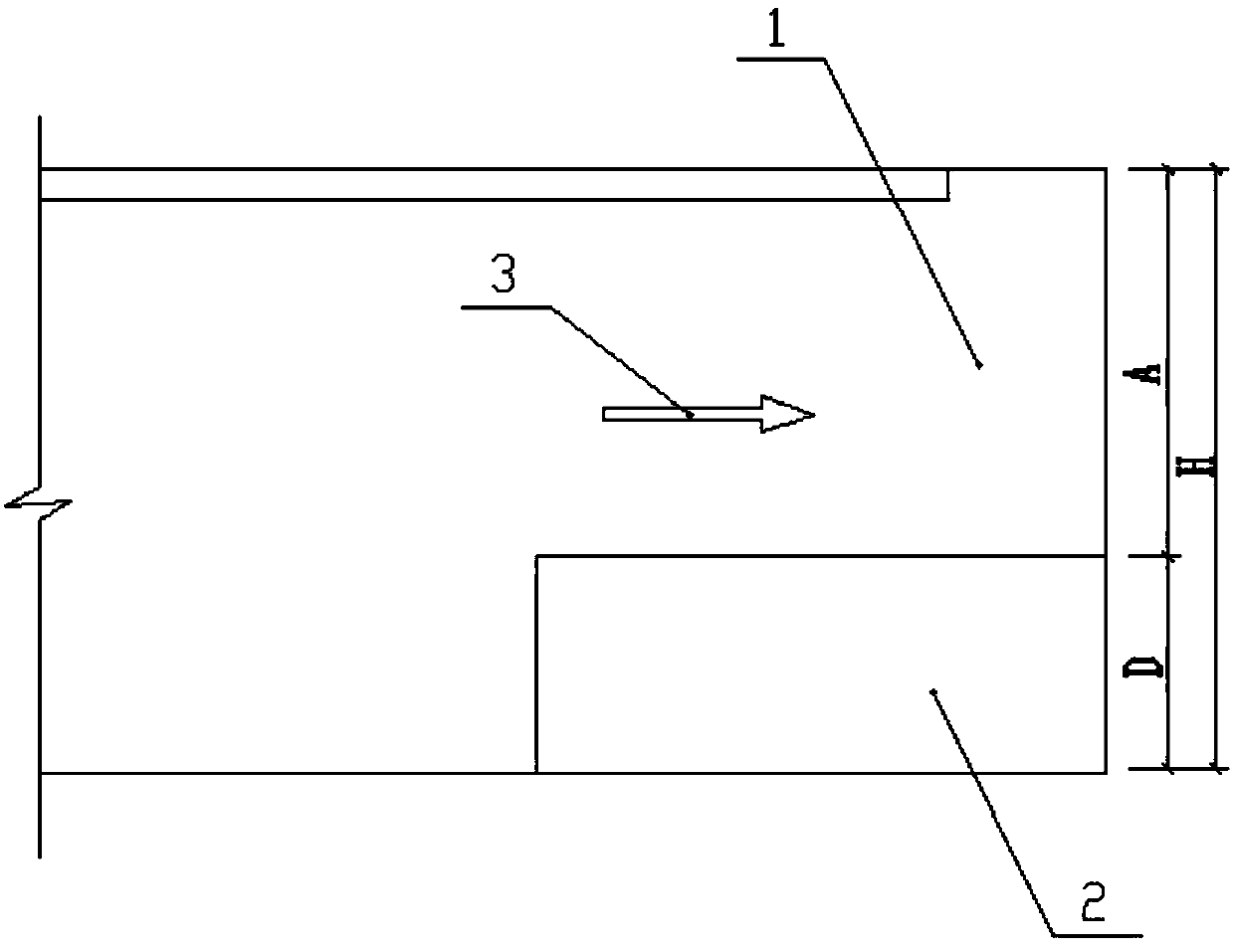

City tunnel drilling and milling machinery combination non-exploding excavation technique

InactiveCN107842368AReduce disturbanceSmall overall deformationUnderground chambersTunnel liningSlagEarth surface

The invention discloses a city tunnel drilling and milling machinery combination non-exploding excavation technique. The city tunnel drilling and milling machinery combination non-exploding excavationtechnique is implemented according to the following steps that (1), construction measuring is conducted; (2), mechanical drilling is conducted, specifically, during upper bench tunneling construction, drilling is conducted by adopting a drilling machine to form a free face, an arched wall is subjected to drilling cutting along an excavation side line, and cannon head induction holes are drilled in the tunnel face; (3), tunneling excavation is conducted, specifically, excavation is conducted on the tunnel face through a bench method; (4), milling excavation trimming is conducted, specifically,trimming is conducted through a milling excavation machine, under-excavation bodies are subjected to milling excavation, residues are cut, and broken rock mass on the arch crown and the tunnel face are cleared; (5), tunnel slag discharging is conducted; and (6), preliminary supporting and secondary lining are conducted, specifically, after each ring of tunnel tunneling is completed and the tunnelface is cleaned up, preliminary supporting construction is conducted in time, and surrounding rock is solidified and sealed through the mode of combination of anchoring, netting, pushing and spraying. According to the construction method, blasting shaking damage is completely eradiated from the source, disturbance on the surrounding rock and earth surface buildings is reduced, and the risks of earth surface sedimentation and tunnel collapse are reduced.

Owner:CHONGQING URBAN CONSTR HLDG GRP +1

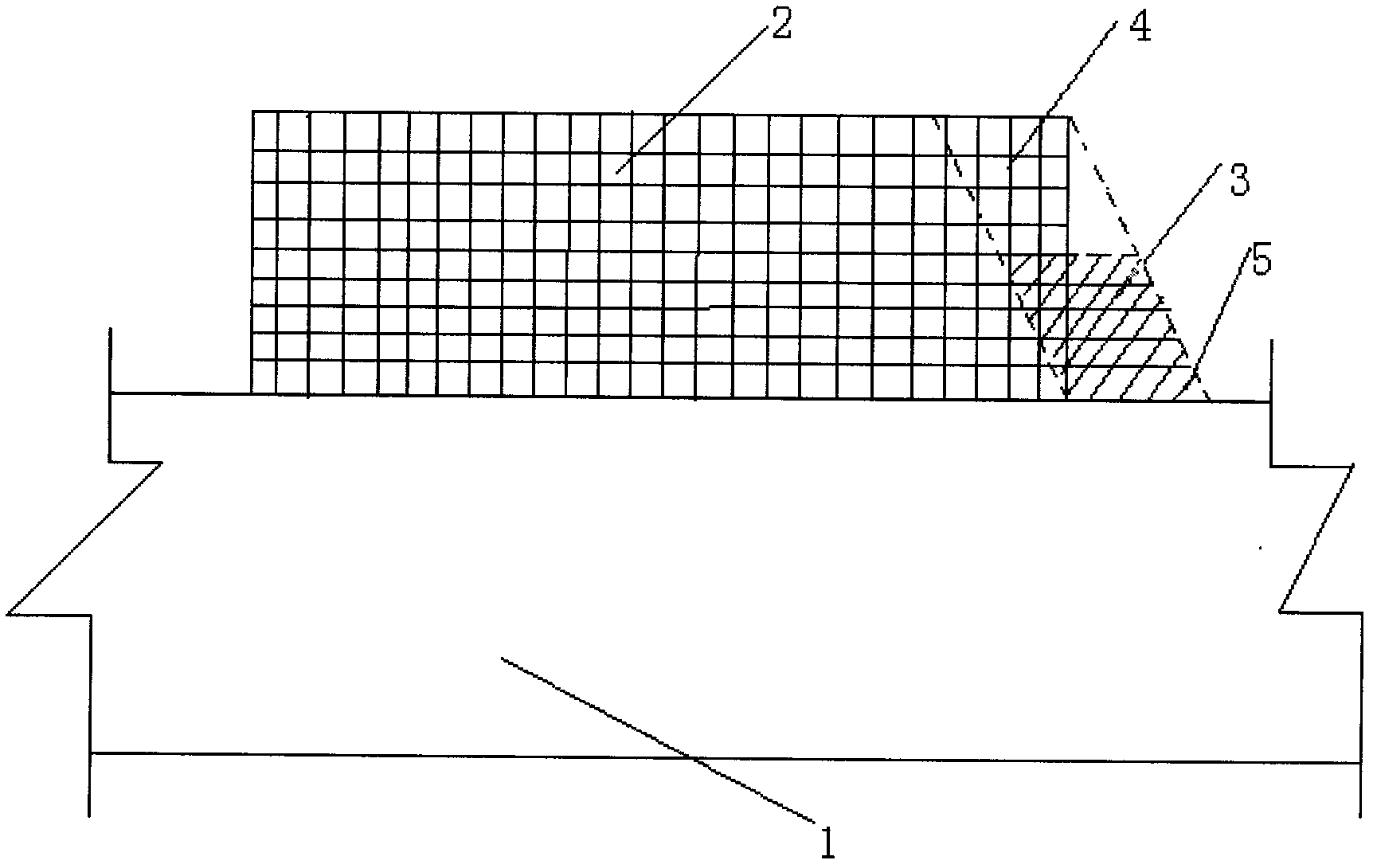

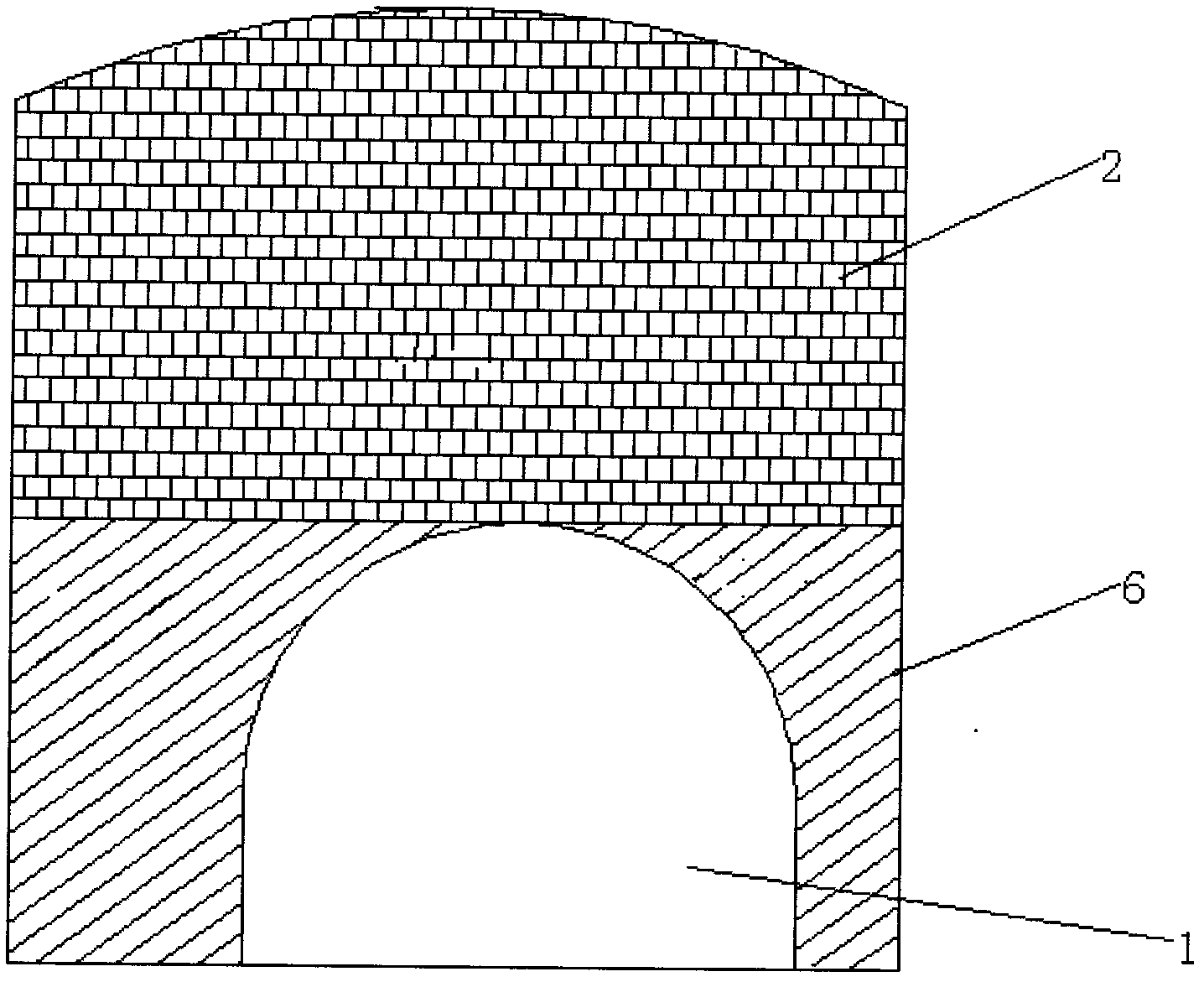

Mechanical breaking construction method for use as shield tunneling machine reached tunnel portal

ActiveCN1995701AReduced risk of collapseShorten the lengthTunnelsArchitectural engineeringShield tunneling

The invention relates to a mechanical breaking construction method for shield machine achieving tunnel portal, comprising following procedures that when the shield machine achieves the outside of shield receiving well and the tip of fish cutter on the cutter head is against the outside of protective mechanism, the shield machine stops digging temporarily; the gun for chiseling the portal is hung into the shield well from the ground by mechanism, and then the gun is used to chisel the protective structure in portal range mechanically; when the portal is chiseled, the gun is hung from the shield well by mechanism and the shield machine achieves receiving well. In the invention, because the mechanical breaking construction method is used and the gun is used to chisel the protective structure in portal range directly, it is safe and rapid, the danger of portal collapse is decreased, the construction period is only one day or two days, rapid and simple process is ensured, there is no need to move in reducing speed when the shield machine achieves and tunnel construction progress is quickened. After the chiseling for portal is finished the shield machine can enter into the shield machine achieving well directly so as to achieve the purpose of invention.

Owner:CHINA TUNNEL CONSTR GUANGDONG

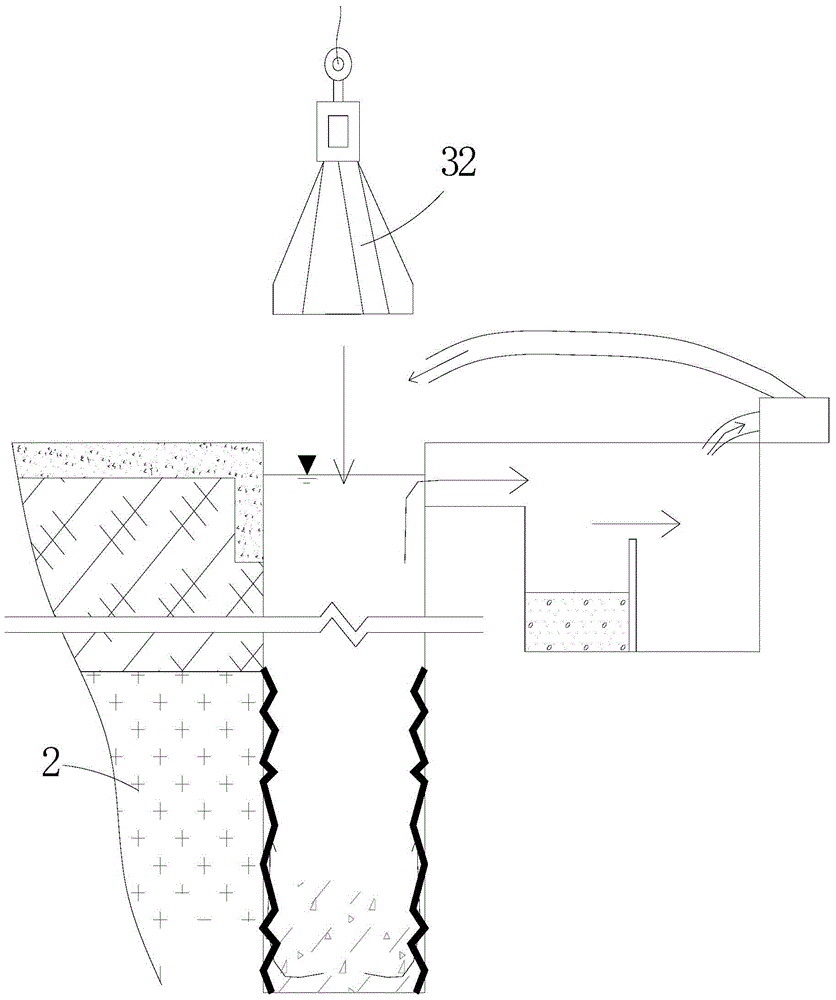

Grooving construction method for embedding underground continuous wall into rock

The invention relates to the technical field of embedding underground continuous walls into rock and grooving of the underground continuous walls and discloses a grooving construction method for embedding an underground continuous wall into rock. The method includes the steps that firstly, a grab bucket is used for excavating soil so that a groove can be formed, and a residual soil layer is reserved between the groove bottom and a rock face; secondly, a rotary excavating drilling tube is used for drilling holes in the residual soil layer and a seriously-weathered layer, a cutting-tooth drilling tube is used for drilling medium-weathered rock and micro-weathered rock, and rock entering holes in bed rock are formed; thirdly, the second step is repeated, and a plurality of rock entering holes are formed in the length extension direction of a groove segment; fourthly, a plane set-hammer is used for clearing away hard rock tooth edges. According to the construction method, the grooving speed is high, and on-site general layout and civilized construction are facilitated; meanwhile, the cutting-tooth drilling tube is used for performing rotary excavation and entering the rock to take a core, and impacting vibration is avoided; due to the fact that the grooving construction period is short, the exposing time of the groove wall is relatively short, the risk that groove wall soil collapses is reduced, the groove wall is stable, and construction cost is indirectly reduced; the residual soil layer is reserved on the rock face of the bed rock, the rotary excavating drilling tube plays a guiding role in the hole forming process, and the situation that because the inner rock face of the groove segment is inclined, hole drilling deflects is prevented.

Owner:SHENZHEN SUNHUI MECHANICAL CO LTD

Construction method for opening off small-section underground chamber of coal mine rock roadway into large-section underground chamber

The invention relates to a construction method for opening off a small-section underground chamber of a coal mine rock roadway into a large-section underground chamber. The construction method comprises the following steps of: drilling and blasting on the top of the rock roadway at a design starting position of the underground chamber at an angle of 70 degrees tilting relative to the longitudinal direction; layering and roof-ripping; clearing by using a scraper loader; brushing the wall while spraying slurry; and the like. The construction method has the advantages of optimizing construction processes, greatly increasing the production efficiency, reducing the labor intensity of workers and increasing the safety coefficient during construction. The construction has high adaptability; the small-section underground chamber can be opened off into the large-section underground chamber on the basis of the conventional small-section rock roadway; the time is saved; and the resource waste is also avoided.

Owner:李菊菊

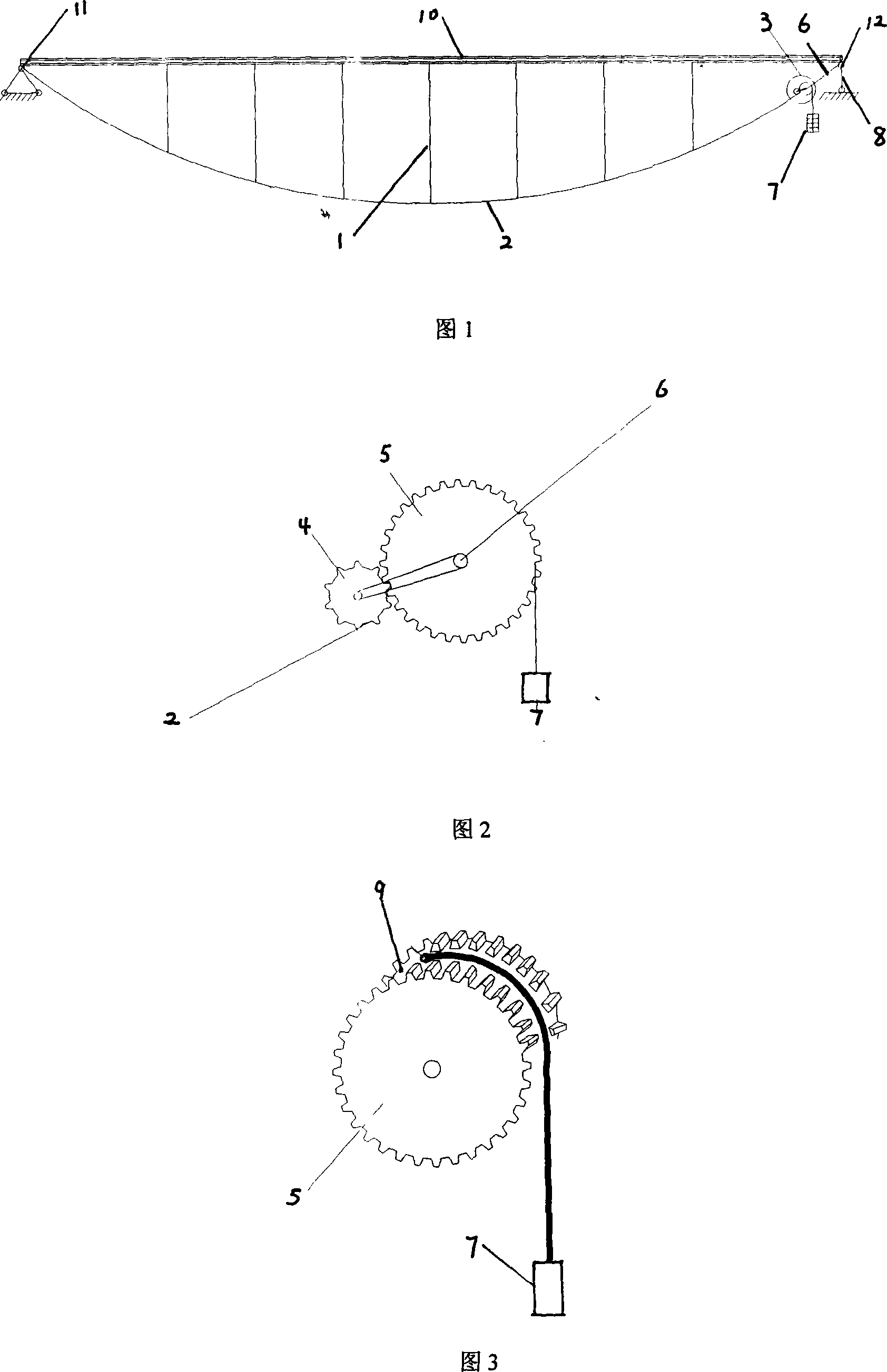

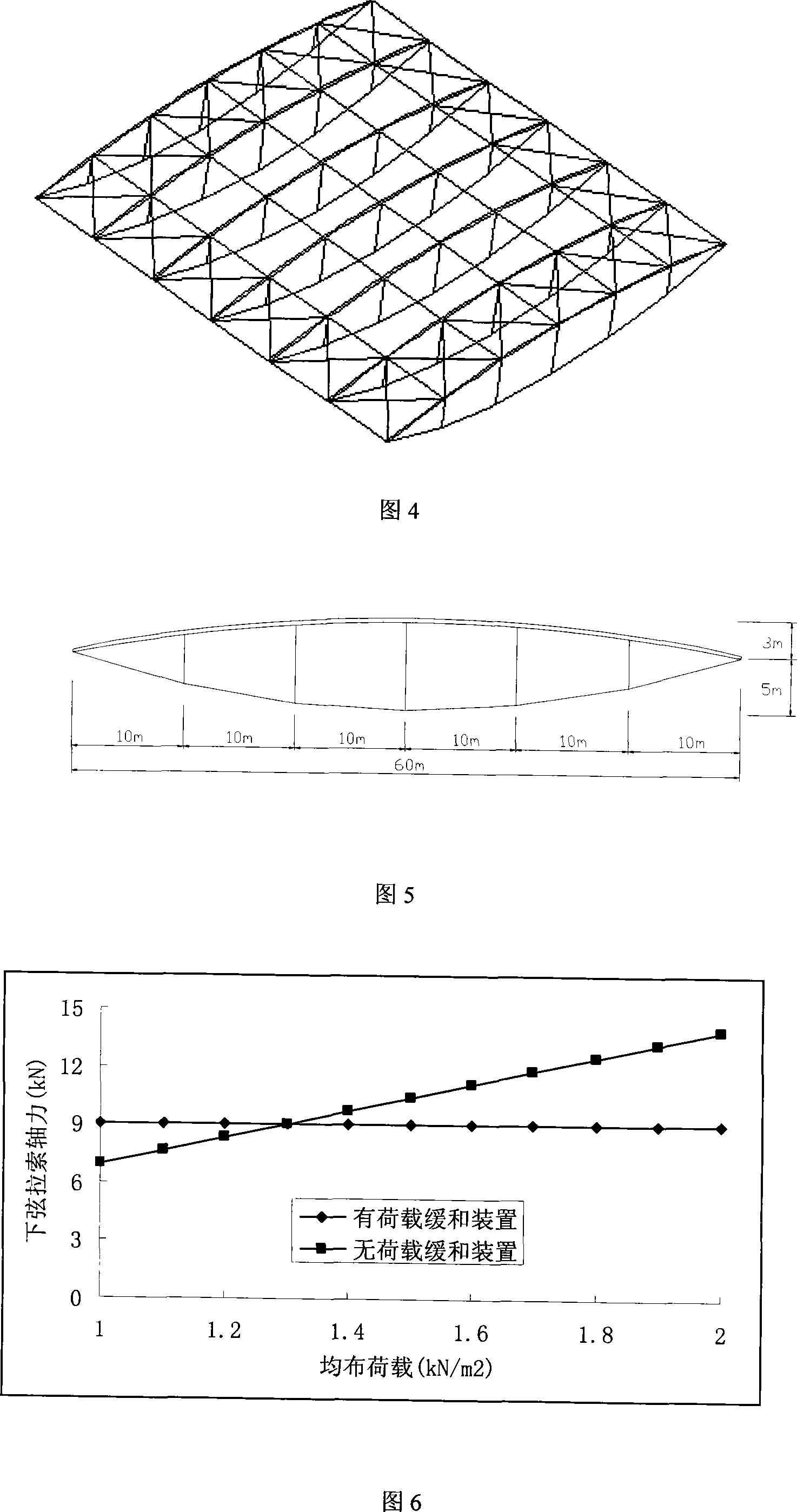

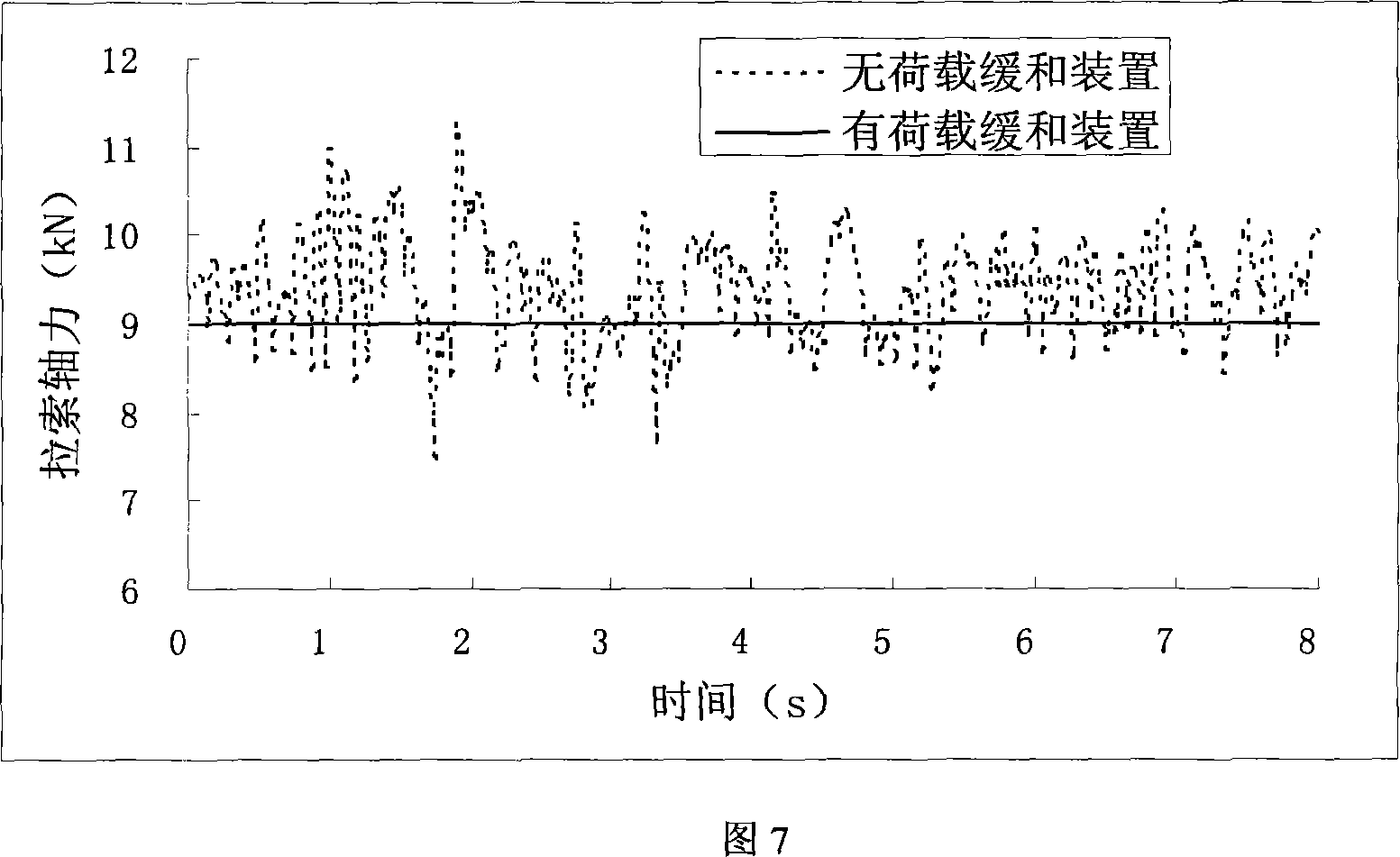

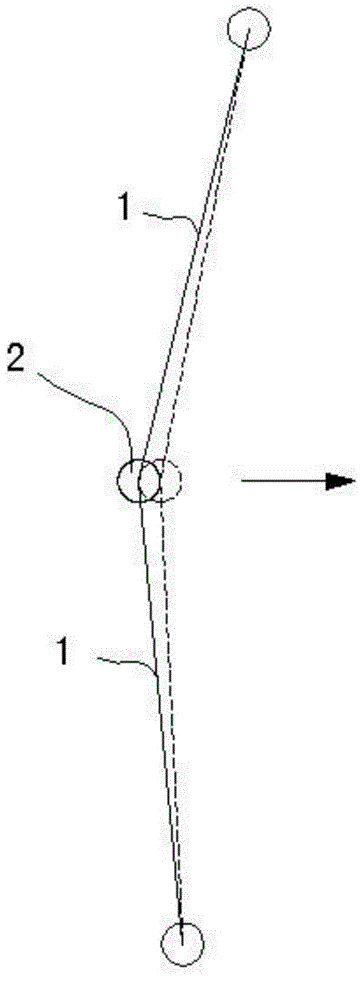

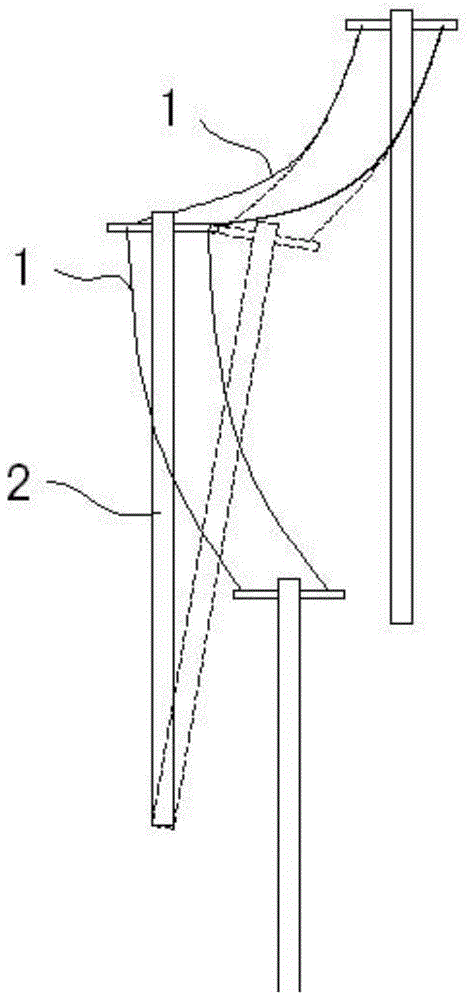

Beam string structure having load alleviation function and implementing method

Owner:ZHEJIANG BADA CONSTR GRP

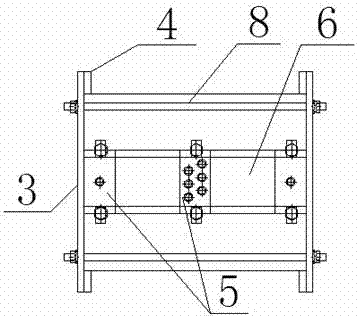

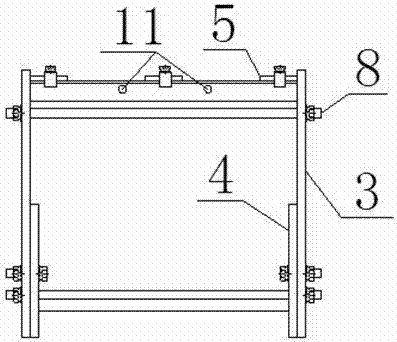

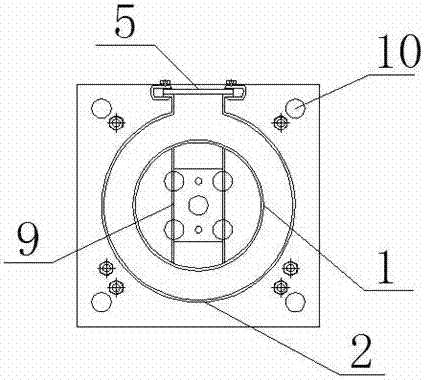

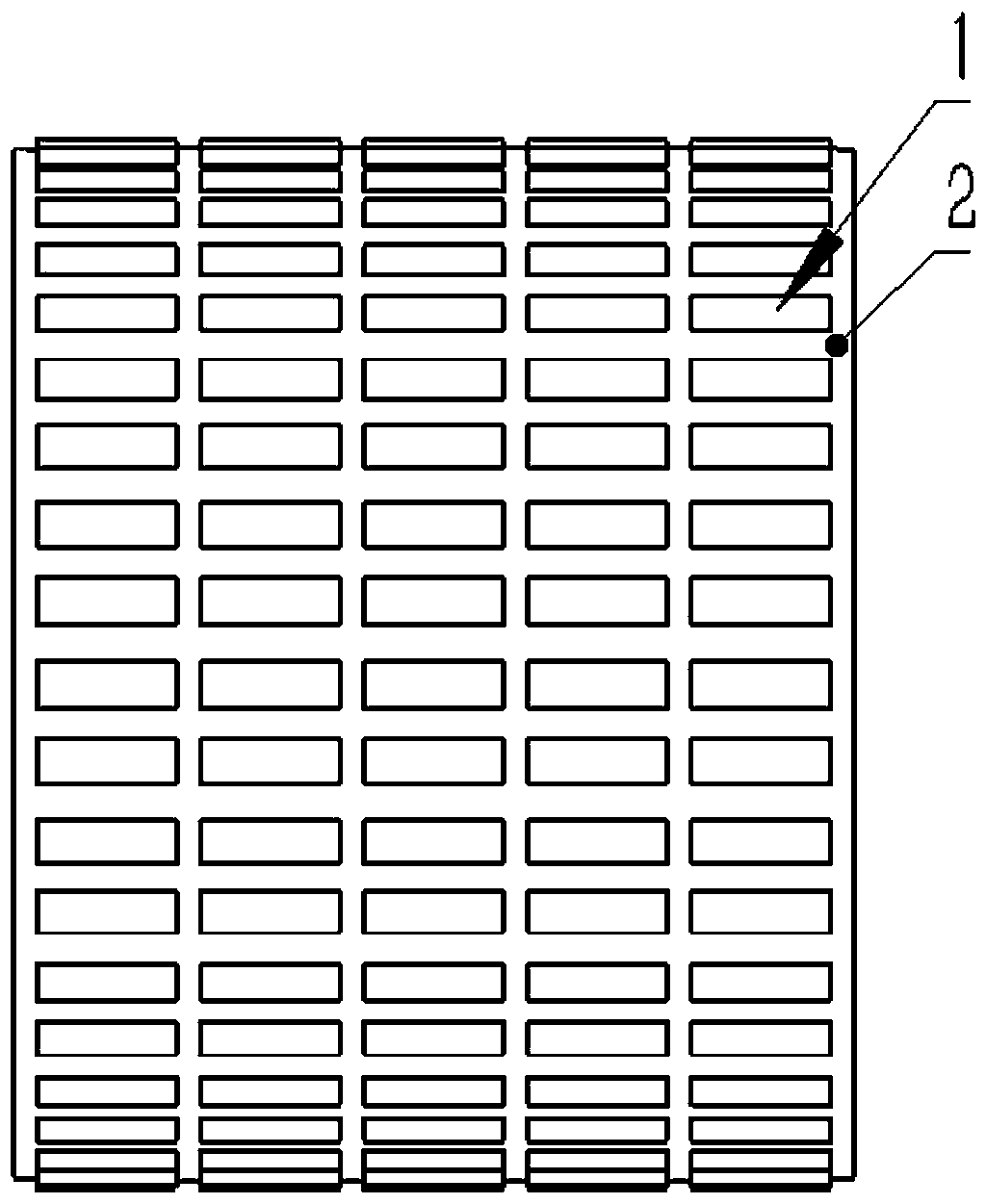

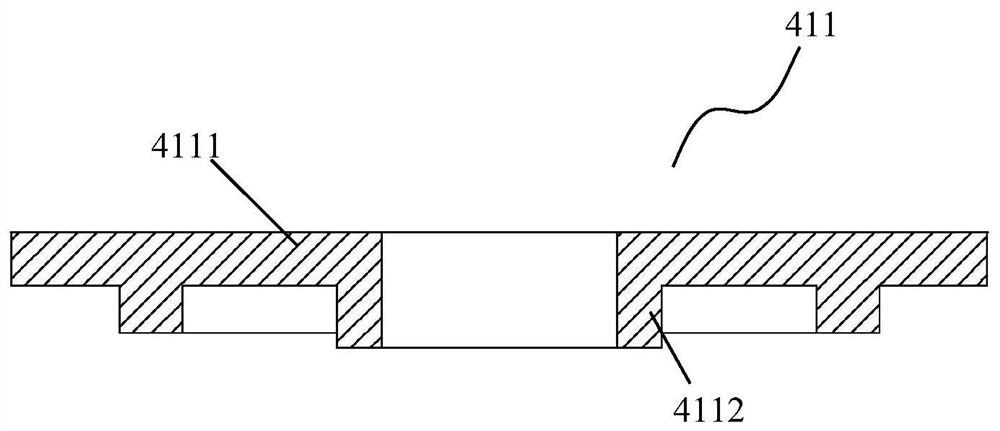

Horizontal casting mold and casting method for high-voltage coil of dry transformer

ActiveCN106935394AIncrease contact areaEnhanced effect of diffusing gasCoils manufacturePartial dischargeAir bubble

The invention discloses a horizontal casting mold and a casting method for a high-voltage coil of a dry transformer. The horizontal casting mold comprises a coil casting inner mold, a coil casting outer mold, an end positioning and fixing support plate, an outer mold lining plate and a connection terminal fixing plate, wherein the coil casting inner mold and the coil casting outer mold are transversely arranged. The horizontal casting mold is good in air dispersity, so that casting is faster, air bubbles are not easily generated, the local discharge amount of the dry transformer is reduced and the operation reliability of the dry transformer is improved. A coil does not need to be erected, so that the possibility of collapse of the coil is reduced and a product is more reliable in quality and safer; the height of the cast coil can reach the height required by the drawings, and the end part is smooth and does not need to be cut, so that the horizontal casting mold is free of dust pollution and environment-friendly. Due to the small height, capital input of a casting tank can be reduced and the cost is lowered.

Owner:山东泰开箱变有限公司

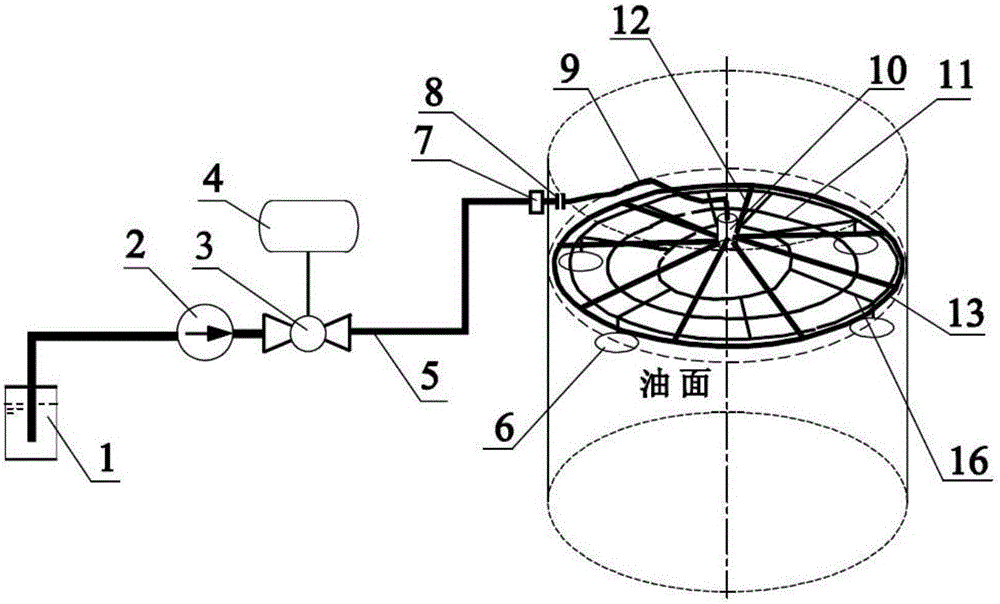

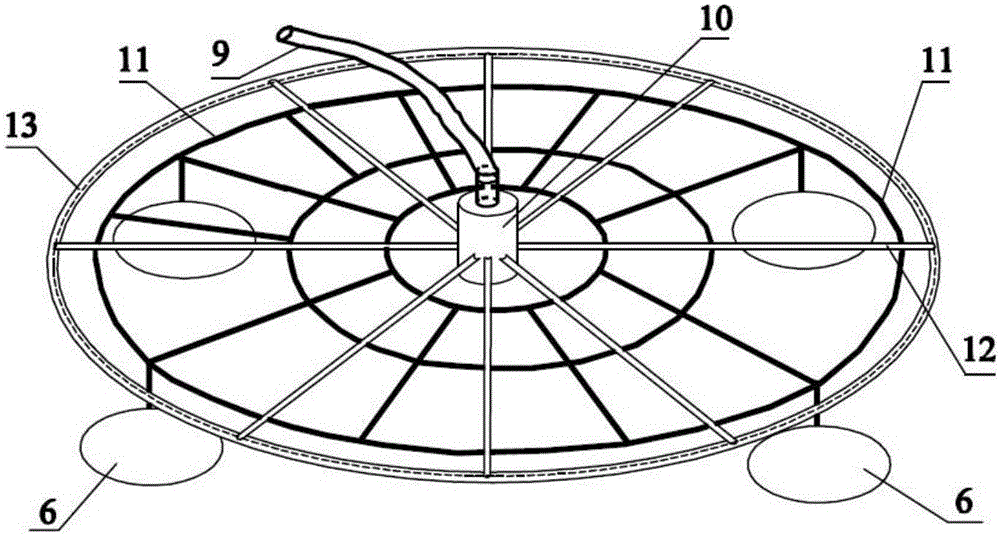

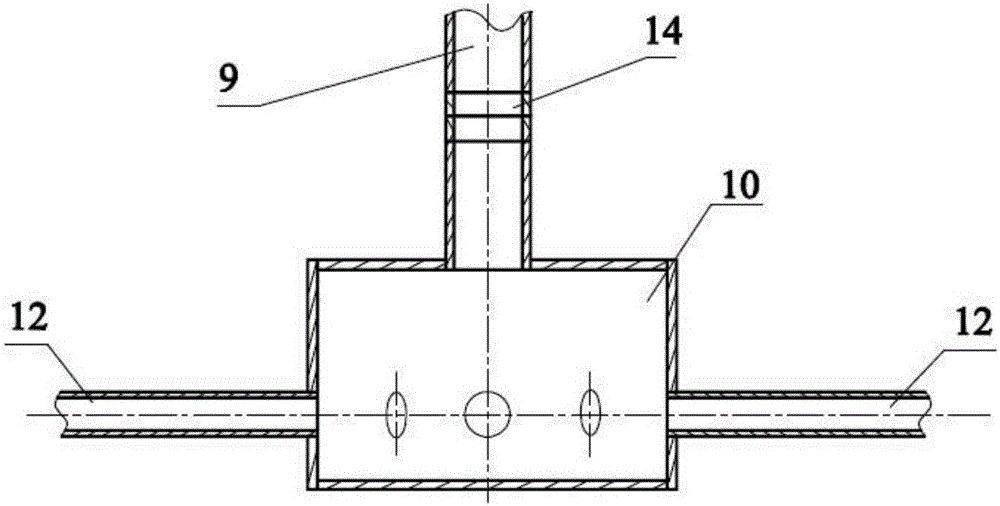

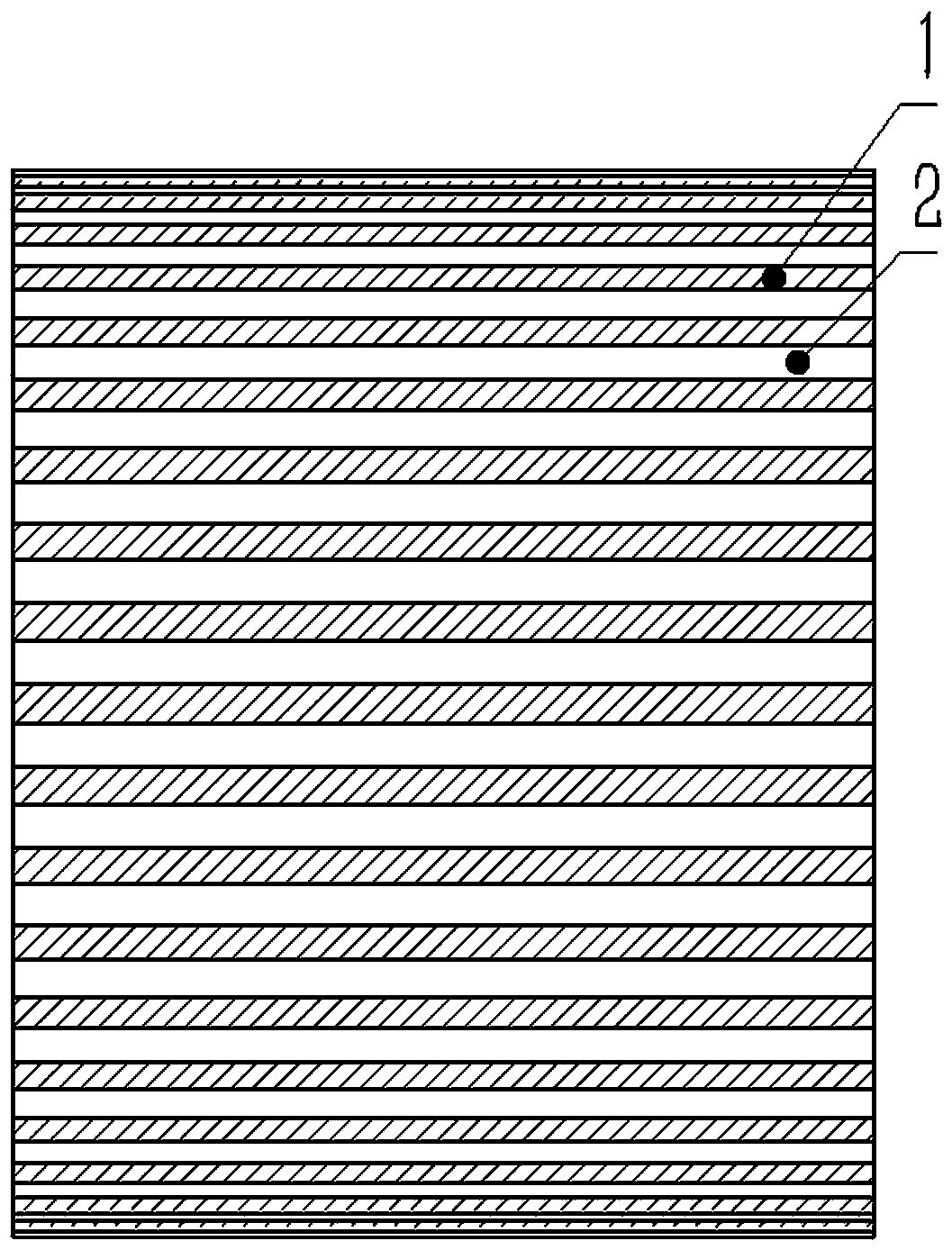

Annular foam fire extinguishing system of oil storage tank

InactiveCN105727475ASpread fastImprove fire extinguishing efficiencyFire rescueFirefighting foamAlloy

The invention discloses an annular foam fire extinguishing system of an oil storage tank. The annular foam fire extinguishing system is characterized in that a buoyancy bracket floating on the oil surface and a fire extinguishing foam spraying device are arranged inside the oil storage tank; the fire extinguishing foam spraying device communicates with a fire extinguishing foam feeding device at the outer part of the oil storage tank through a pipeline; supporting floating balls are arranged at the bottom of the buoyancy bracket; the fire extinguishing foam spraying device comprises a foam buffer collector arranged at the circle center part of an aluminum alloy ring and eight fire extinguishing foam conveying tubes which are uniformly and radially distributed on the periphery of the foam buffer collector; the eight fire extinguishing foam conveying tubes are positioned in the same plane; the near-ends of the fire extinguishing foam conveying tubes communicate with the foam buffer collector, and the far-ends of the fire extinguishing foam conveying tubes communicate with an annular fire extinguishing foam tube; and a plurality of fire extinguishing foam outflow holes are uniformly formed in the annular fire extinguishing foam tube in the circumferential direction. According to the annular foam fire extinguishing system, fire extinguishing foam outlets always keep constant distance with the liquid surface, so that the purpose that the fire extinguishing foam is effectively saved is achieved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

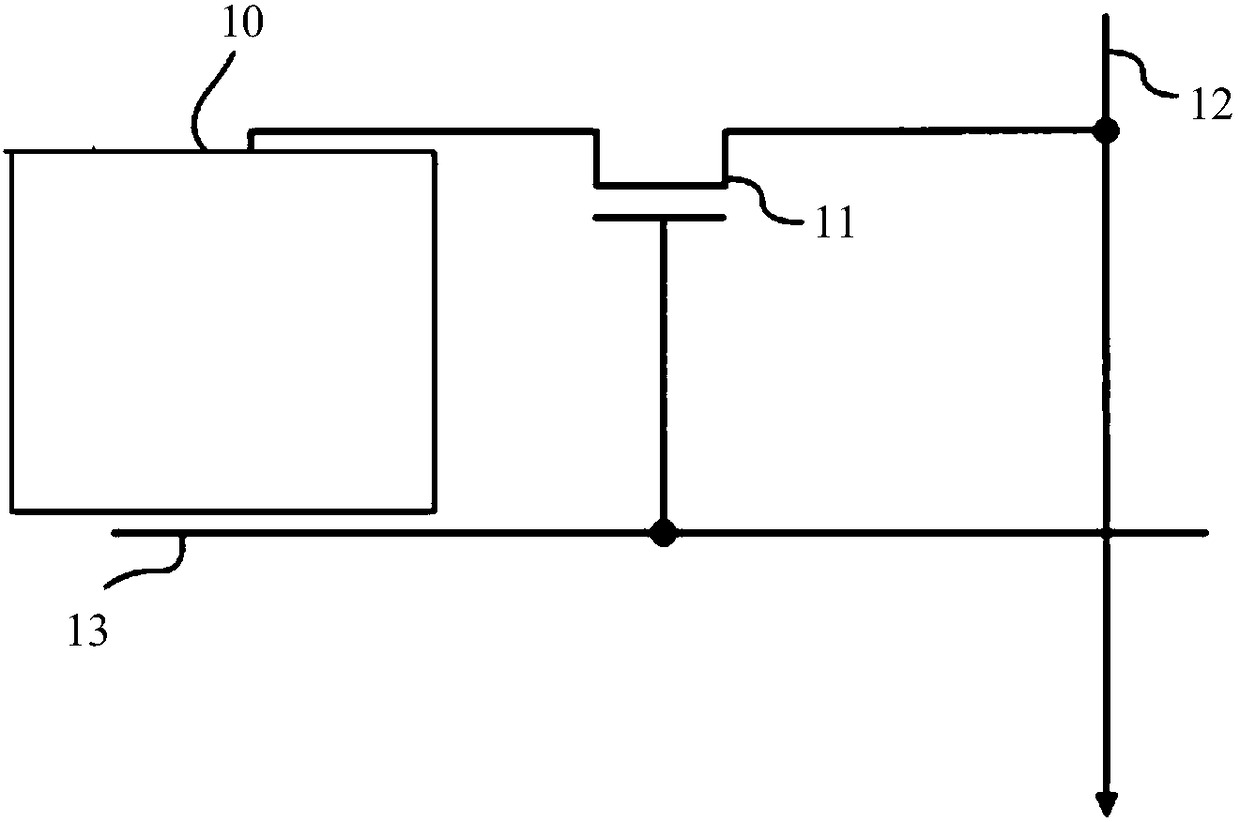

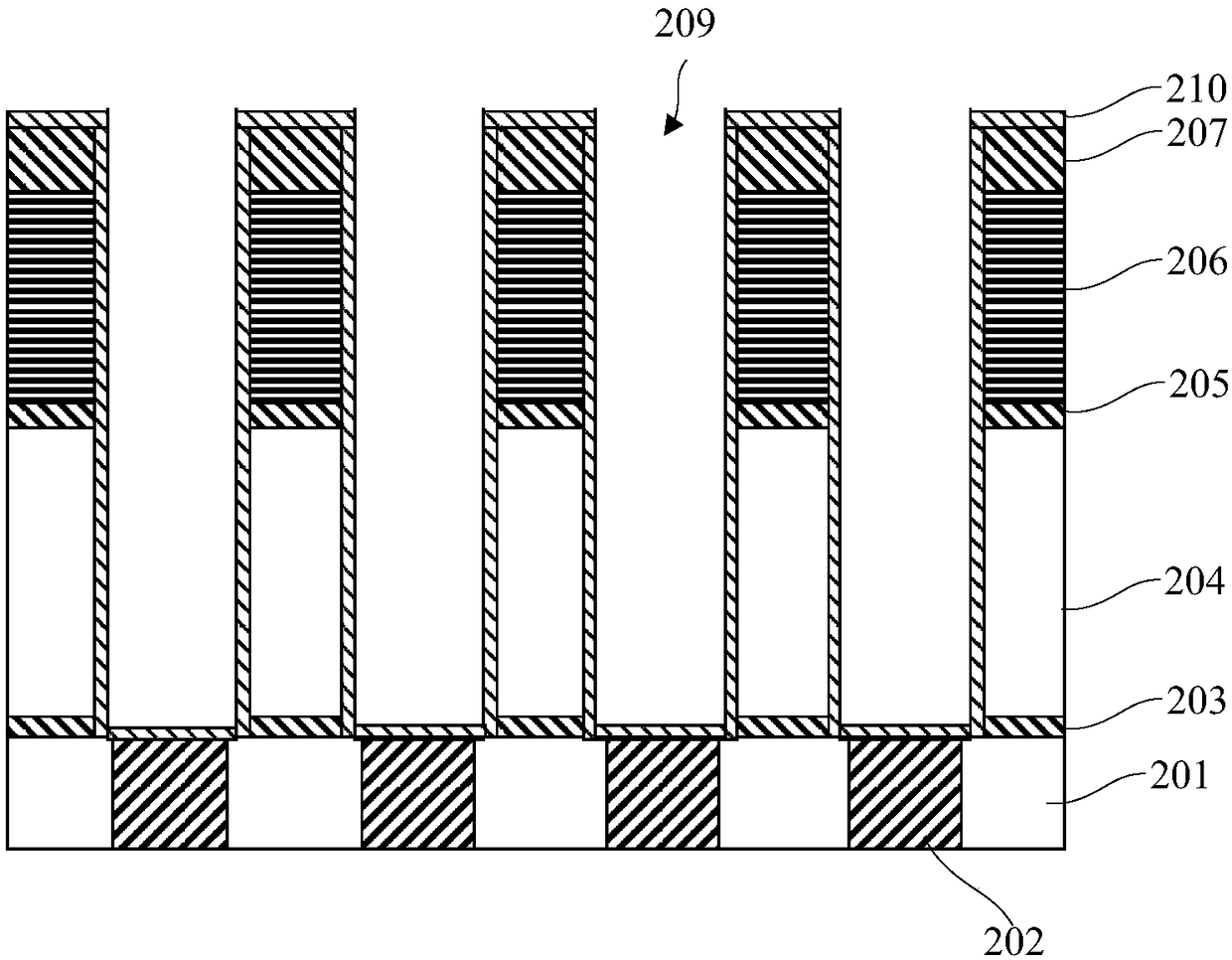

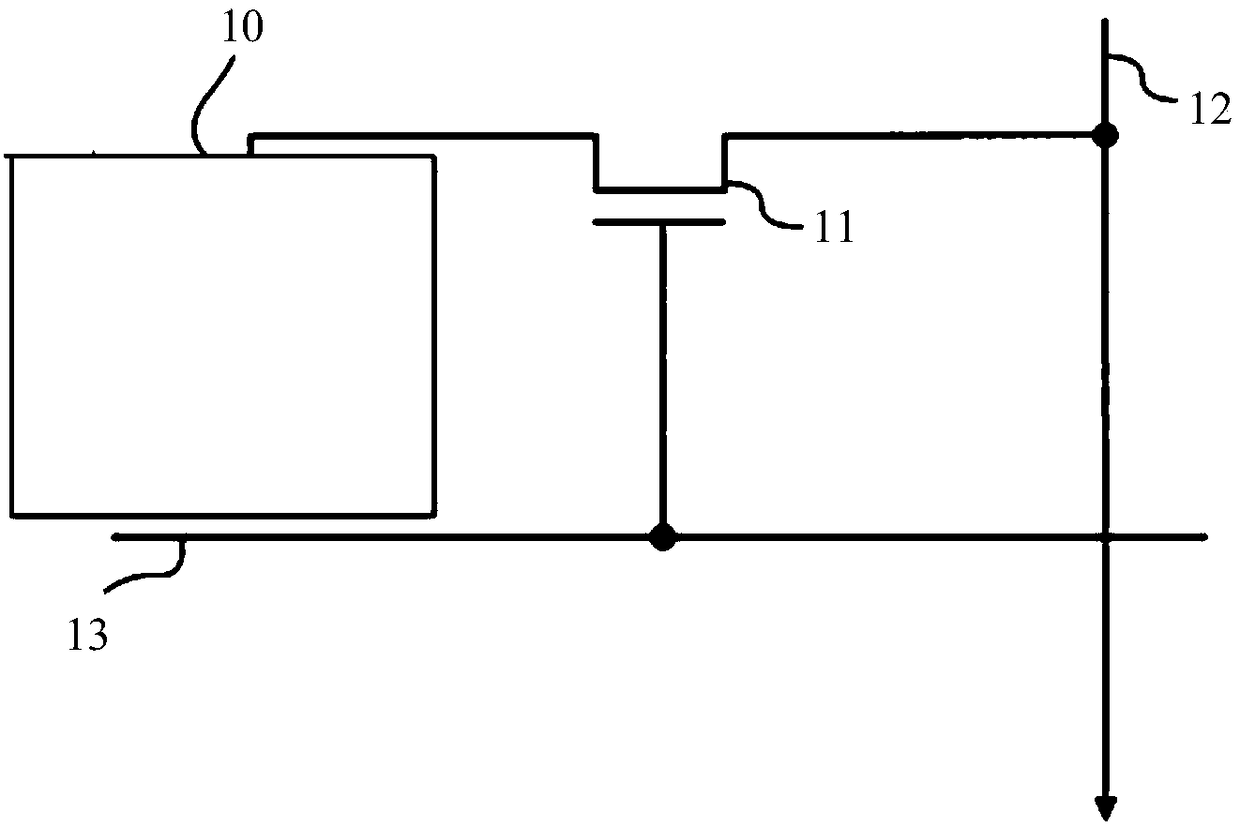

Capacitor device of semiconductor integrated circuit and fabrication method of capacitor device

PendingCN108550569AIncrease capacitanceIncrease etch stopTransistorSemiconductor/solid-state device detailsIntegrated circuitCapacitance

The invention provides a capacitor device of a semiconductor integrated circuit and a fabrication method of the capacitor device. The device adopts a lamination structure of three sacrificial layers and three support layers; after the sacrificial layers are removed, a first top support assistance layer and a second top support assistance layer are deposited before openings of the support layers are opened by etching to increase etching obstruction; and the residual thickness of the support layers is increased. The heights of capacitor holes can be effectively increased, so that the vertical capacitor height is increased; the surface area of a plate electrode is increased; and a higher capacitance value can be obtained in the same unit area. The support layers with the residual thickness of10-50nm can be obtained; a vertical capacitor structure is more steady; and a risk of collapse of a higher capacitor is greatly reduced.

Owner:CHANGXIN MEMORY TECH INC

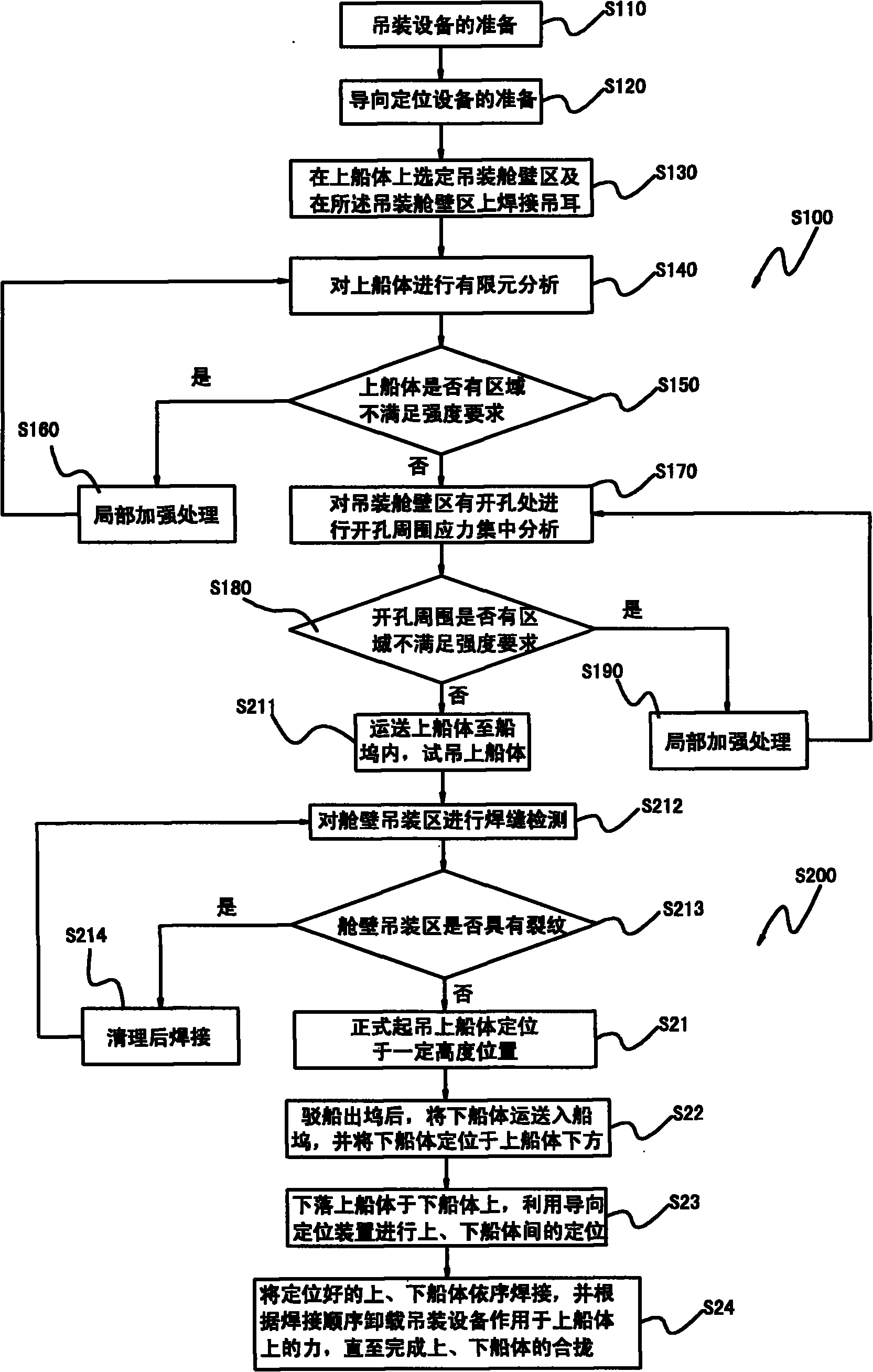

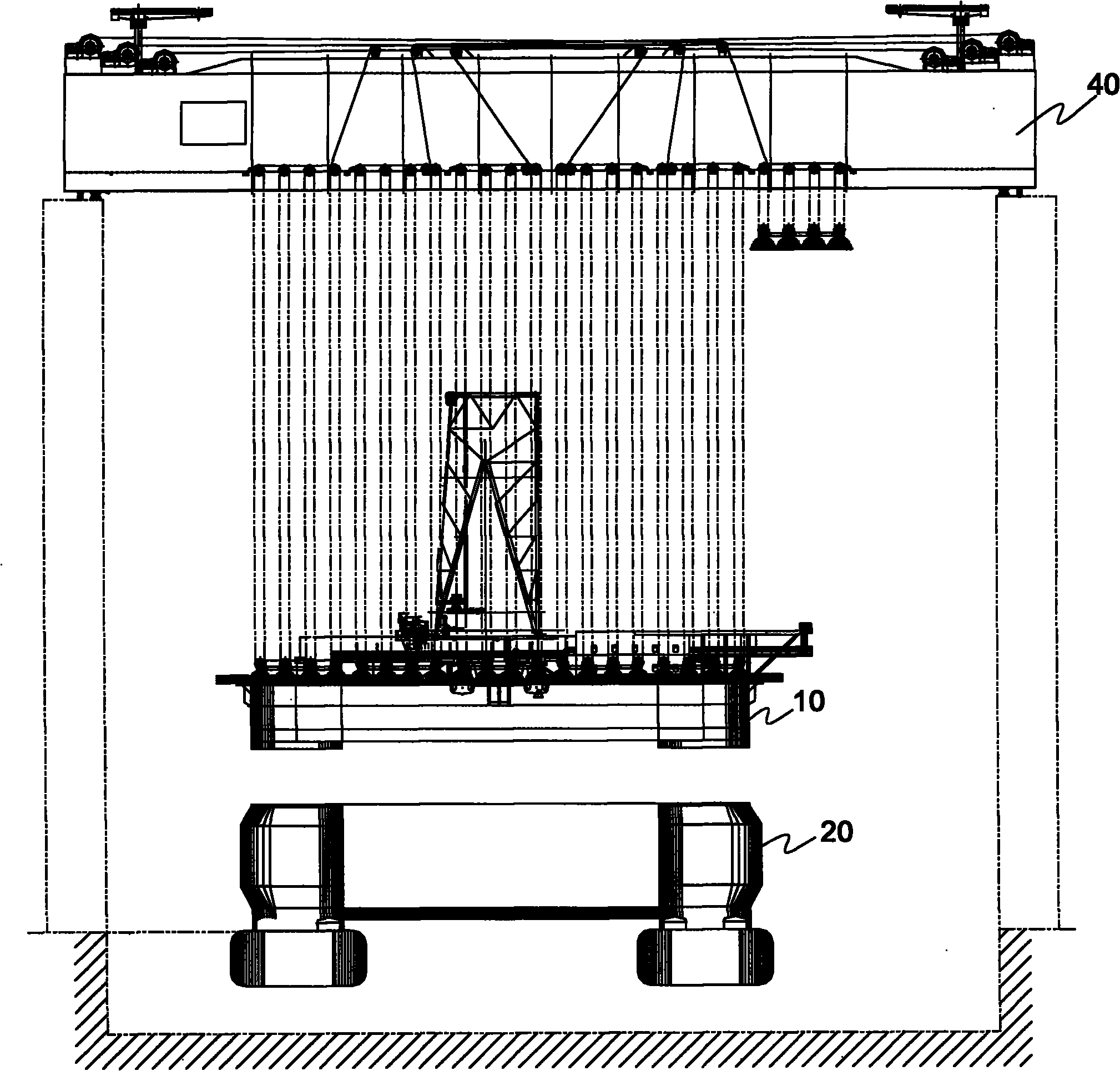

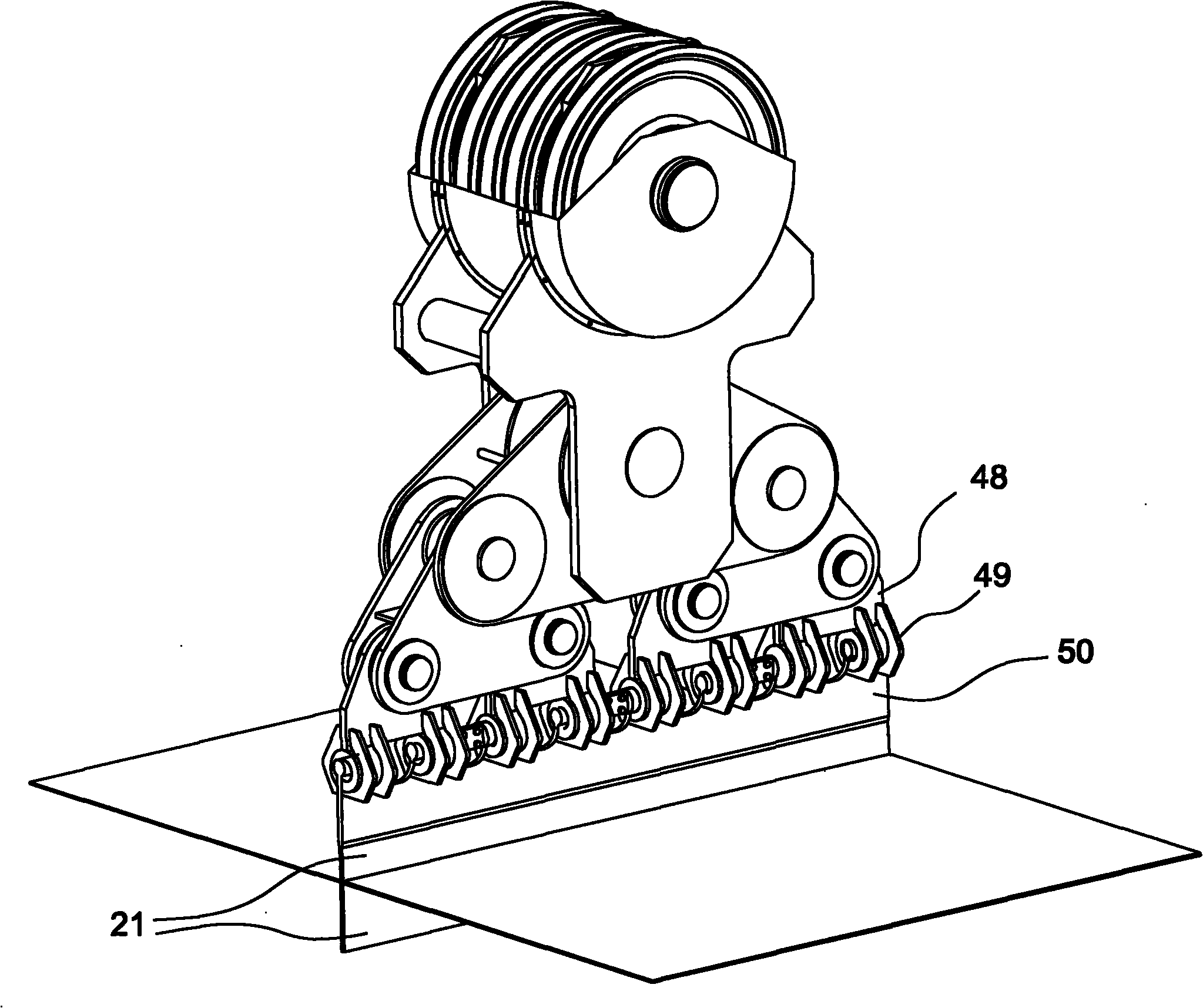

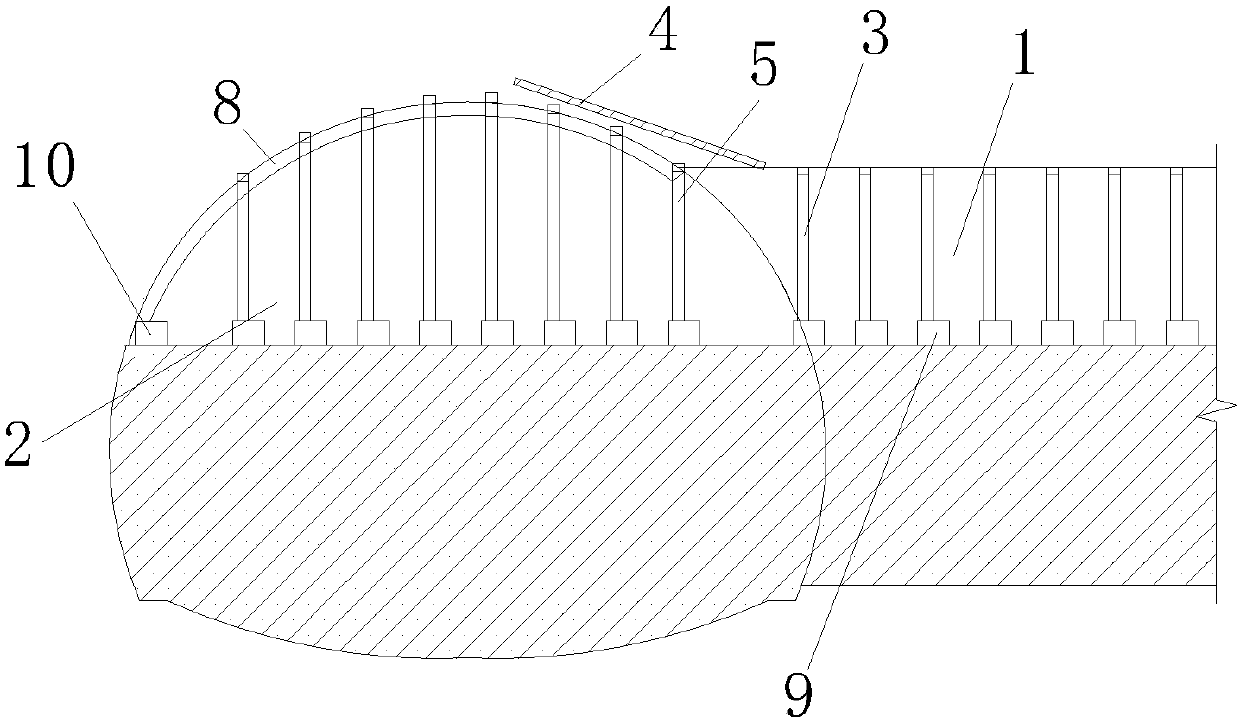

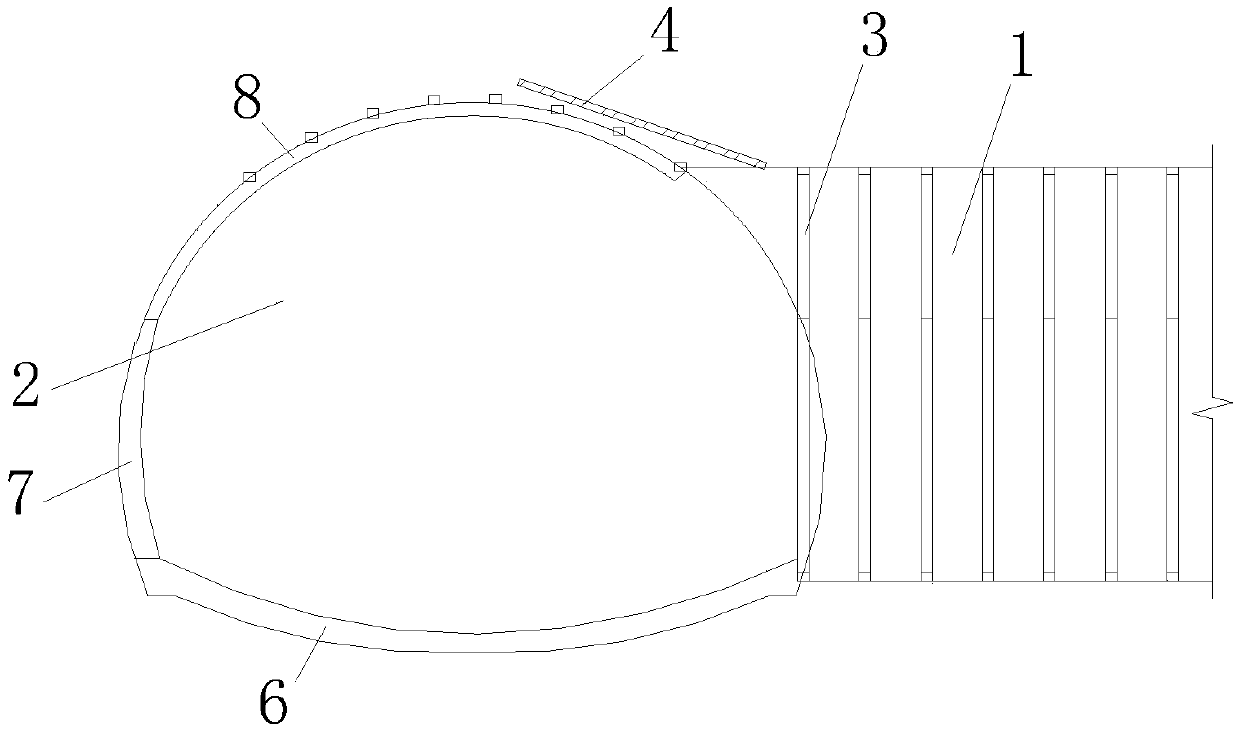

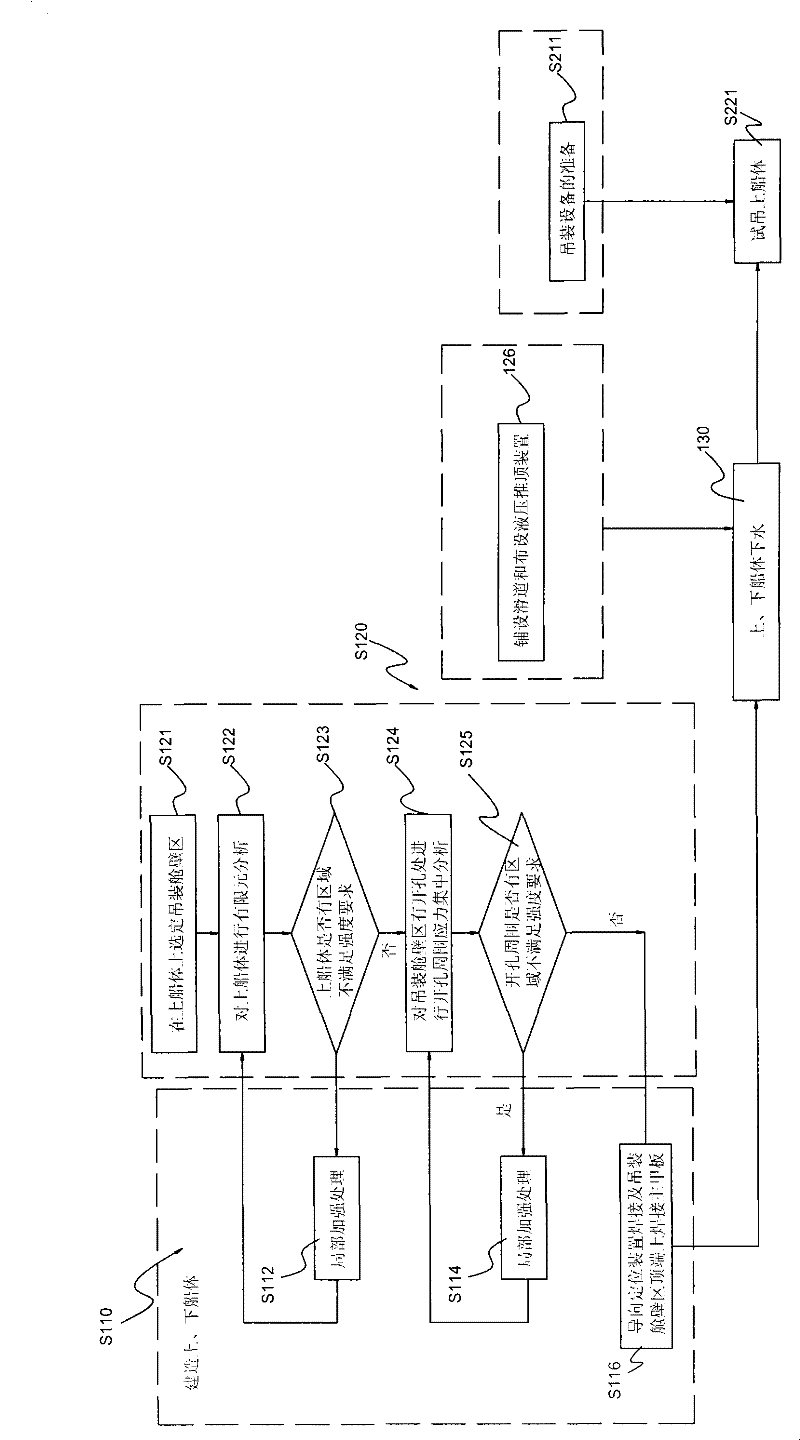

Method for integrally folding semi-submersible drilling platform

ActiveCN102145734AShorten the construction periodShort construction periodFloating buildingsOperabilityWelding process

The invention discloses a method for integrally folding a semi-submersible drilling platform. The method comprises the following steps of: preparing before folding, namely preparing hoisting equipment and an oriented positioning device; hoisting and folding on site, namely shipping a barge for a deck box into a dock, hoisting the deck box and positioning at a certain height position by using the hoisting equipment in the dock; shipping a lower hull into the dock and positioning below the deck box; dropping the deck box on the lower hull; positioning the deck box and the lower hull by using the oriented positioning device; sequentially welding the deck box and the lower hull which are positioned well; and unloading tensile force which is applied to a position corresponding to the deck box by the hoisting equipment one by one according to the welding process until all welding positions meet load bearing requirements. By the method, the folding operability is improved, and the cost of labor force is reduced; and the method is high in economical efficiency, is not limited by surging and has short folding time and high folding accuracy.

Owner:YANTAI RAFFLES SHIPYARD +2

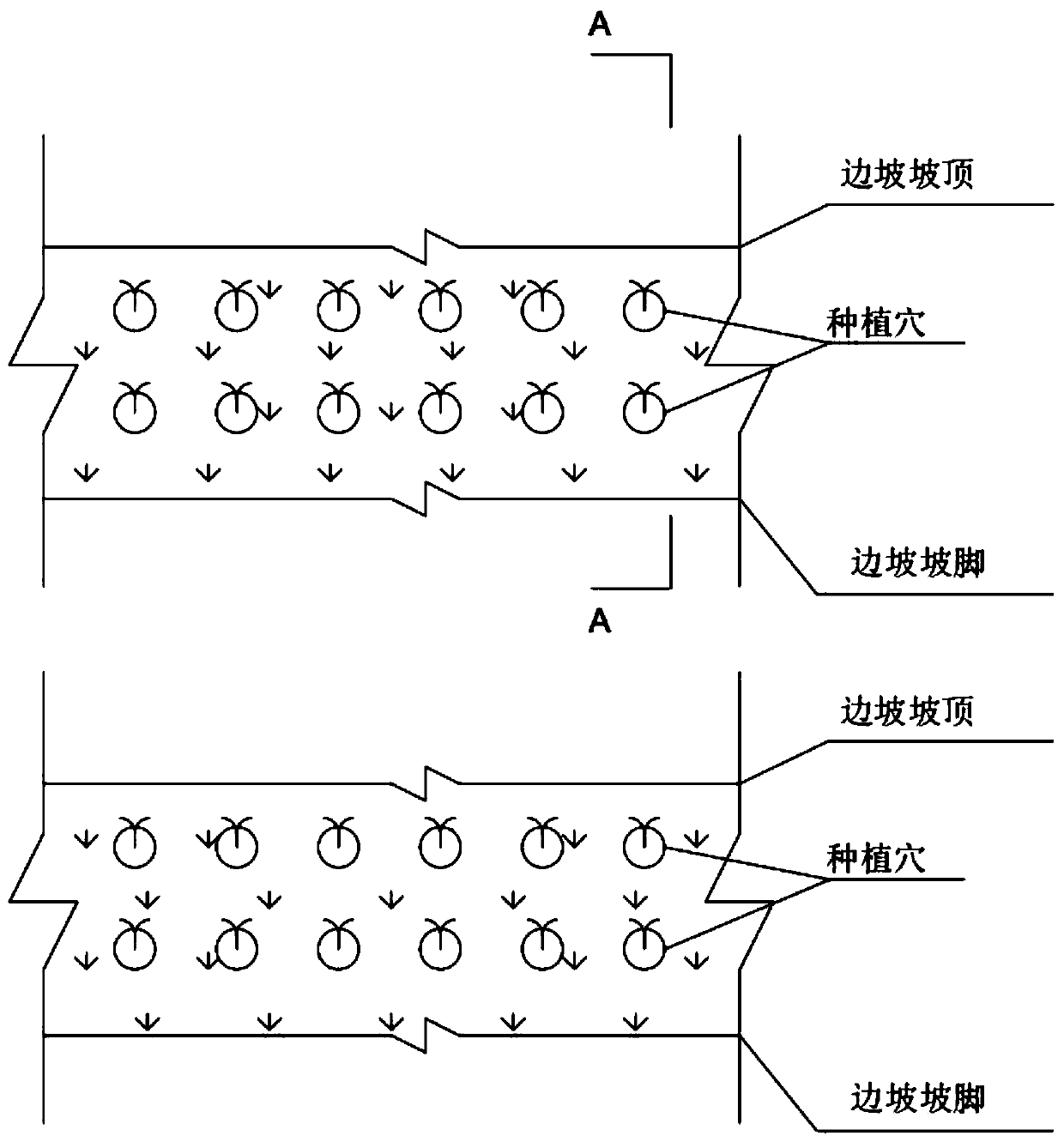

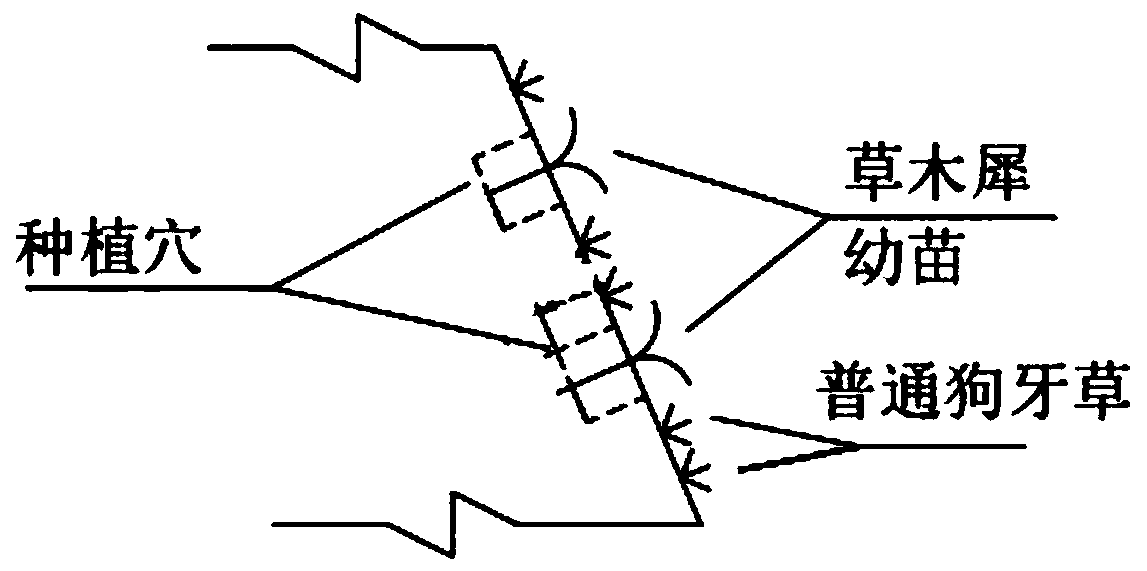

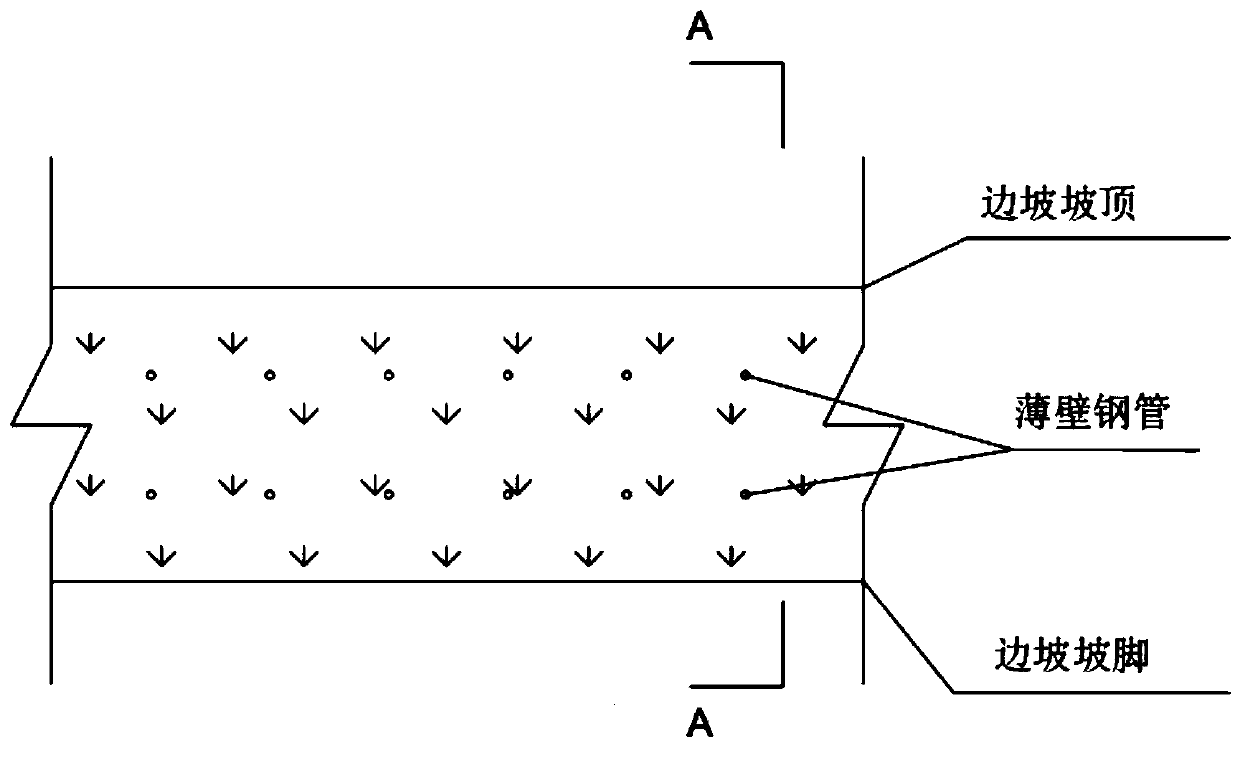

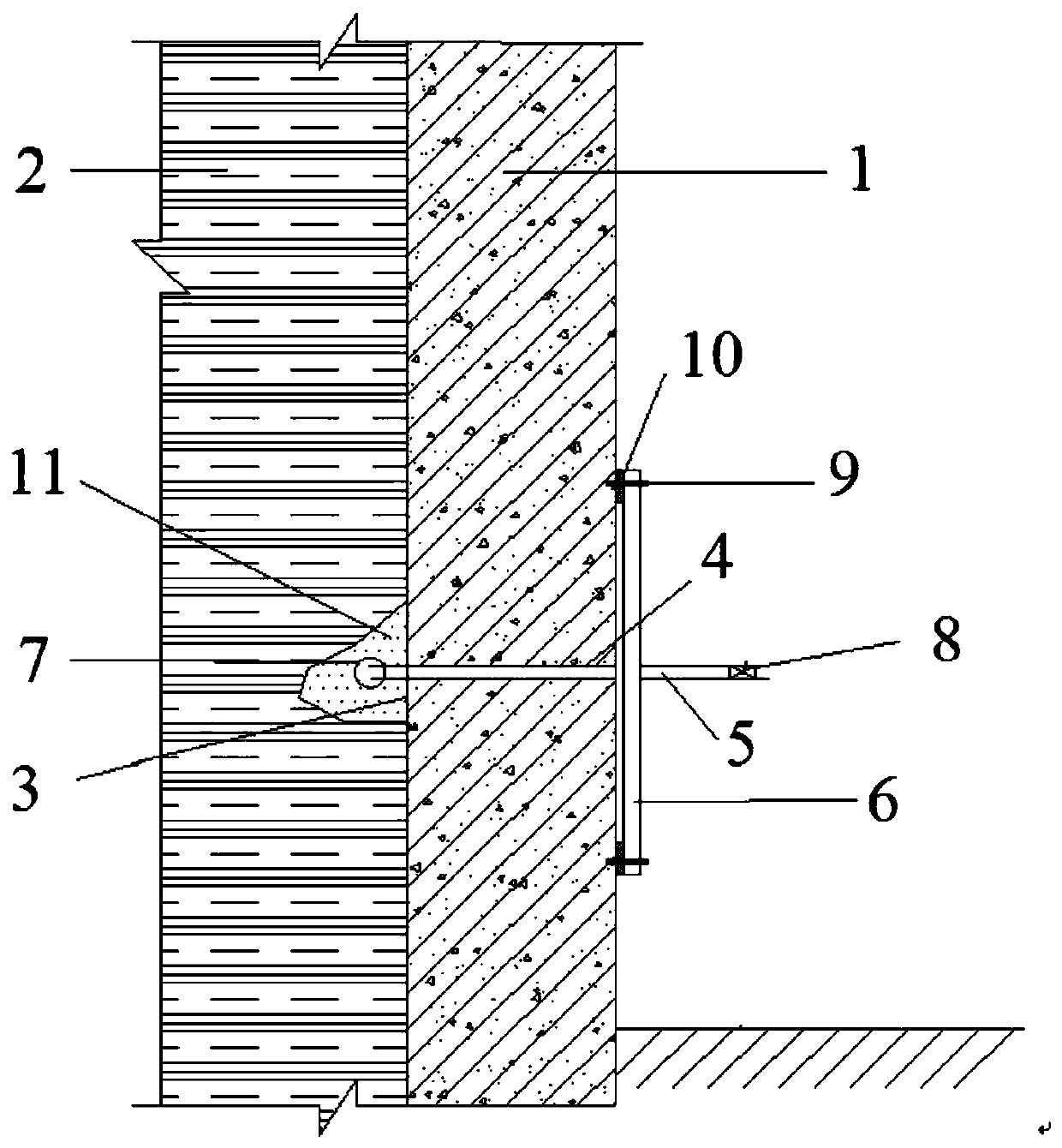

Side slope reinforcing construction method by combining vegetation with microorganisms and thin-walled steel tube for construction

InactiveCN110644508AShorten the growth cycleReduce exposure timeSoil lifting machinesFabaceae cultivationMicroorganismSoil science

The invention discloses a side slope reinforcing construction method by combining vegetation with microorganisms and a thin-walled steel tube for construction. The construction method protects a slopejointly by using clover and bermuda grass and injects bacillus pasteurii and a bonding liquid into soil, wherein the bacillus pasteurii and the bonding liquid are injected repeatedly every 6-8 days for 30-40 days. The clover and common bermuda grass are selected to protect the slope jointly, and meanwhile, and a product for microbial soil fixation is calcium carbonate which is good in integrationto a soil mass matrix, so that a formed bonding material is high in strength, and the shear strength of the soil mass of the side slope can be improved obviously. In a stage that the common bermuda grass does take roots, the side slope is reinforced, and meanwhile, the binding liquid contains a lot of urea to provide a lot of chemical fertilizer elements to the common bermuda grass, so that the growth period of the common bermuda grass can be shortened to 35 days, the side slope exposure time is further shortened, and the risk of collapse of the side slope is reduced. The invention also provides the thin-walled steel tube for construction, has the characteristics of being low in cost, easy to manufacture and convenient to construct, and brings convenience to quickly cure the soil mass inthe side slope.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for leaking stoppage of underground diaphragm wall surface

InactiveCN110080311AAvoid damageReduce chiselingArtificial islandsProtective foundationSlurry wallWater leakage

The invention discloses a method for leaking stoppage of an underground diaphragm wall surface, and the underground diaphragm wall surface is arranged close to a soil body. The method comprises the following steps: (1) finding a water seepage point of the underground diaphragm wall; (2) digging a guide hole in the center of the water seepage point, the guide hole penetrating through the underground diaphragm wall, then a guide tube with a valve penetrating through the guide hole, the front end of the guide tube extending to the water seepage point of the soil body on the inner side of the underground diaphragm wall, arranging a filter screen at the front end of the guide tube, the rear end of the guide tube extending to the outer side of the underground diaphragm wall, and the rear end ofthe guide tube penetrating through a plugging board, and fixedly arranging the plugging board on the underground diaphragm wall; (3) injecting an edge sealing material into a gap where the plugging board is in contact with the underground diaphragm wall; (4) opening the valve on the flow guide tube, draining water at the water seepage point through the flow guide tube, and then performing pressurized grouting plugging on the water seepage point through the flow guide tube until the whole water leakage position and the flow guide tube are filled with water; and (5) closing the valve. Accordingto the method, damage to the underground diaphragm wall is small, and the wall surface of the water seepage position can be quickly and effectively blocked.

Owner:GUANGXI UNIV +1

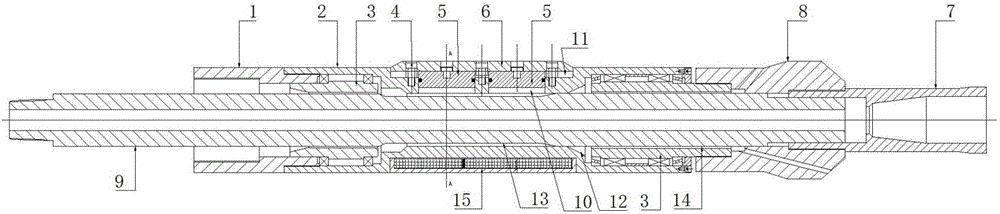

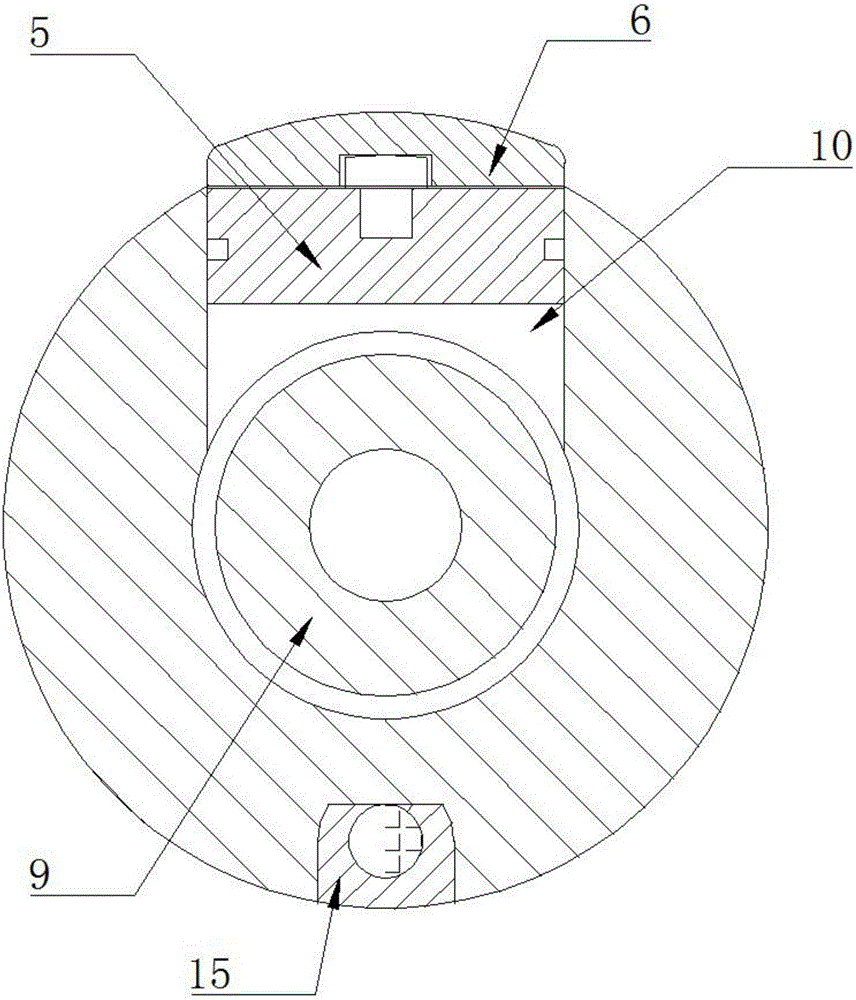

Double drill push-the-bit type guide section

ActiveCN106522826ASmall hole diameterReduced risk of collapseDrilling rodsConstructionsPistonPlunger

The invention discloses a double drill push-the-bit type guide section which includes an oil cylinder outer wrap, an oil cylinder, an internal drill pole and a support plate. The internal drill pole is arranged in the oil cylinder outer wrap and moves along the direction of the axle of the oil cylinder outer wrap. An accommodating cavity is arranged on the outer wall of the oil cylinder outer wrap. A decompression hole is formed in the bottom of the accommodating cavity. The oil cylinder is arranged in the decompression hole. The hole wall of the oil cylinder and the decompression hole slides correspondingly. A seal ring is used for sealing between the hole wall and the oil cylinder. The plunger of the oil cylinder is fixedly connected with the support plate. The oil cylinder outer wrap includes a drilling end and a dynamic end. A convex plate is arranged along the circumference of the inner wall of the oil cylinder outer wrap which is between the accommodating cavity and the dynamic end. The internal drill hole includes a drill pole neck and a drill pole body. The outer diameter of the drill pole body is greater than the outer diameter of the drill pole neck. When the drill pole neck of the internal drill pole moves to correspond to the convex plate, the place between the drill pole neck and the convex plate is provided with an annulus. When the drill pole body of the internal drill pole moves to correspond to the convex plate, the drill pole body is matched with the gap of the convex plate. The double drill push-the-bit type guide section adjusts the extension length of the support plate by adjusting the pressure of the drilling fluid and thus the rate of deviation change of the drilling tools is adjusted.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

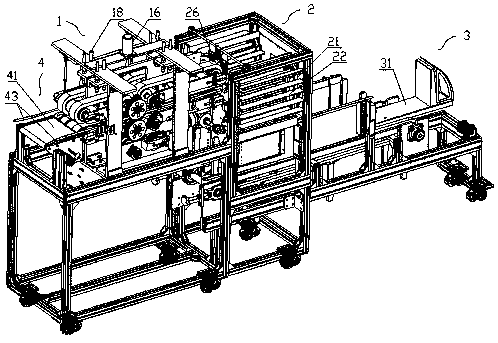

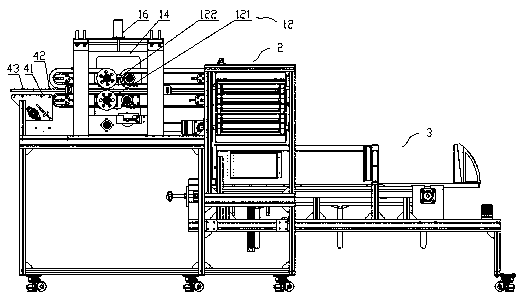

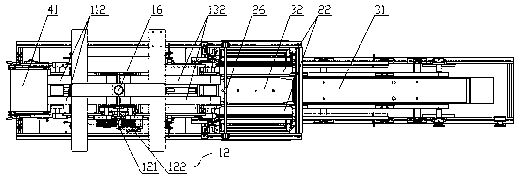

Cigarette stacking device

InactiveCN110104376AGood for sorting and palletizingImprove stabilityConveyorsCounting objects on conveyorsEngineeringMechanical engineering

Owner:GUIZHOU INST OF TECH

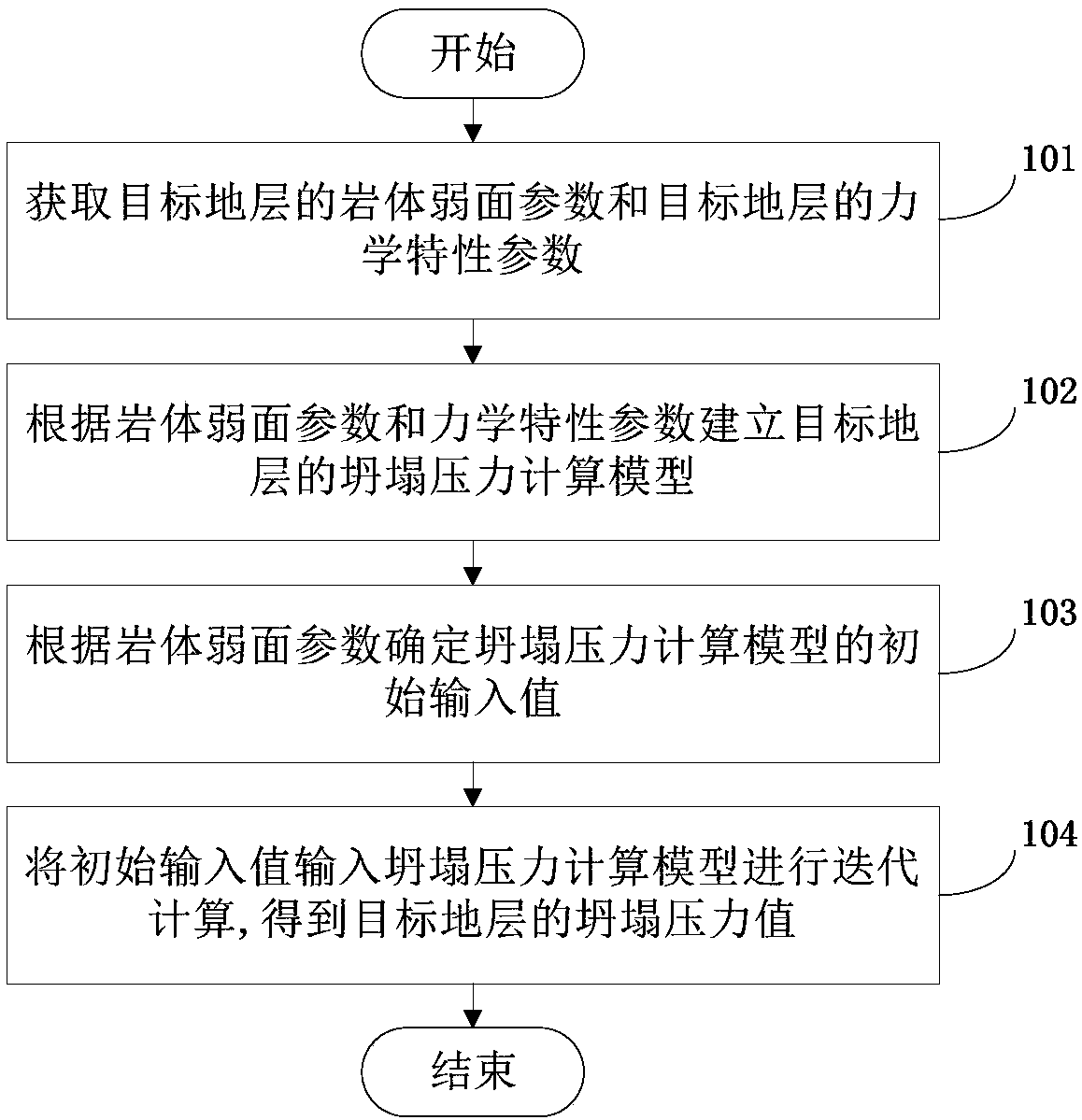

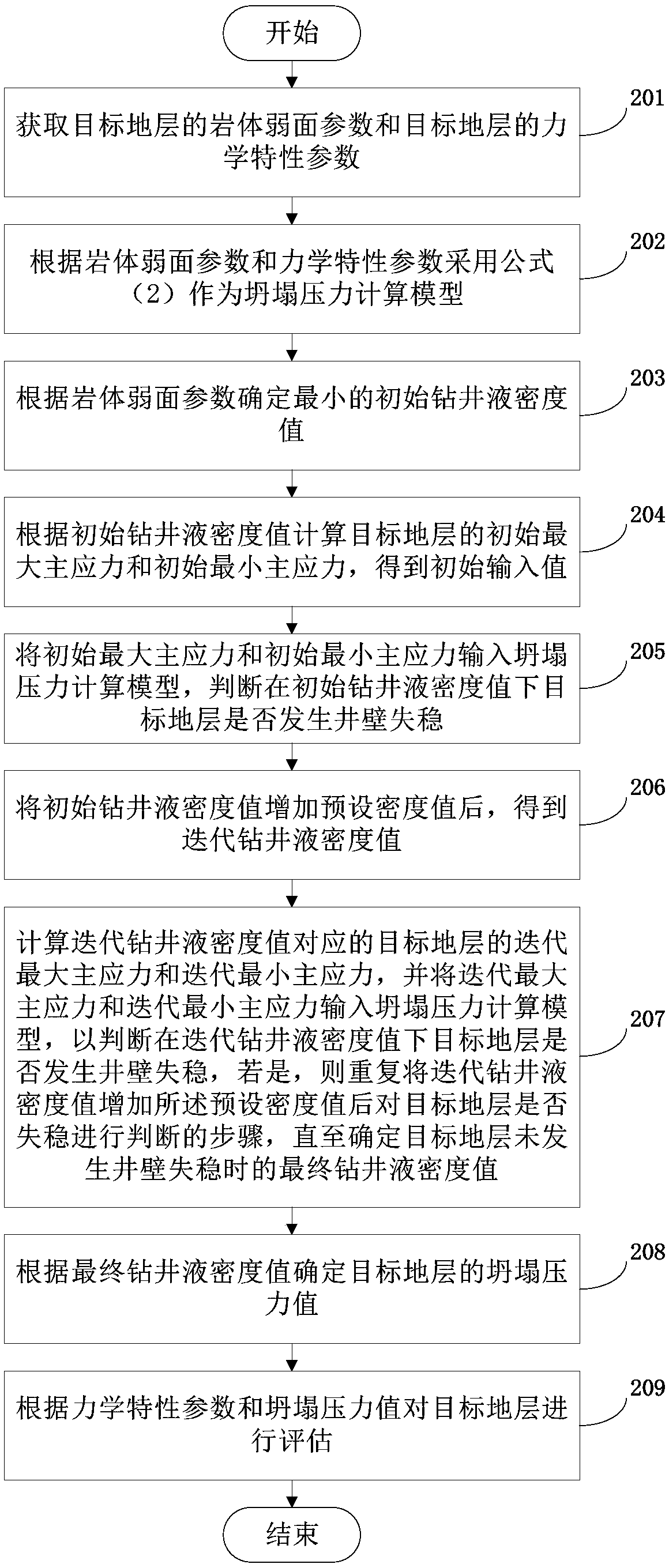

Method and device for determining formation collapse pressure

InactiveCN109555515AReduce risk of collapseThe law of destruction is accurateBorehole/well accessoriesEnvironmental geologyDrilling fluid

The invention provides a method and device for determining formation collapse pressure. The method comprises the steps that rock mass weak plane parameters of a target formation and mechanical property parameters of the target formation are obtained; according to the rock mass weak plane parameters and the mechanical property parameters, a collapse pressure calculation model of the target formation is established; an initial input value of the collapse pressure calculation model is determined according to the rock mass weak plane parameters; and the initial input value is input into the collapse pressure calculation model for iterative calculation to obtain a collapse pressure value of the target formation. The method and device fully consider the influence of a rock mass weak plane structure of the target formation on the failure law of a rock mass, can obtain the relatively accurate collapse pressure value, can truly reflect the failure law of rocks with the weak plane structure, areconducive to accurate adjustment of the density of drilling fluid in the drilling process, and reduce the risk of collapse of a lower-layer well wall.

Owner:CNOOC TIANJIN BRANCH +1

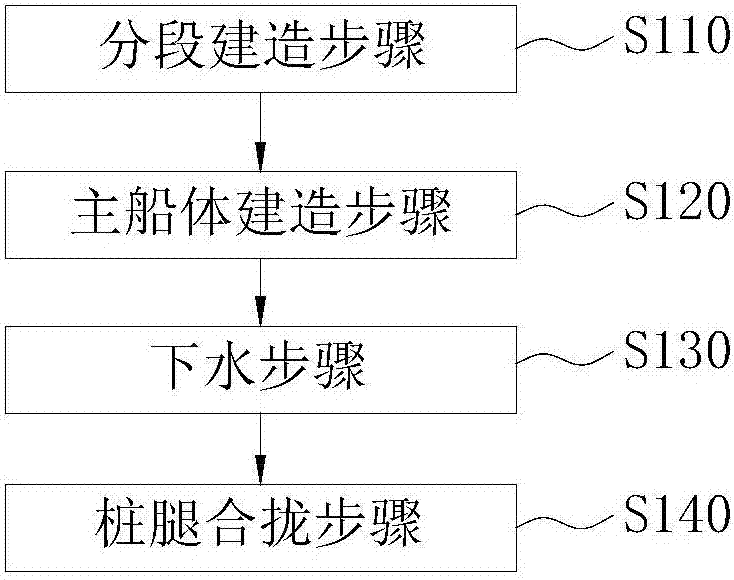

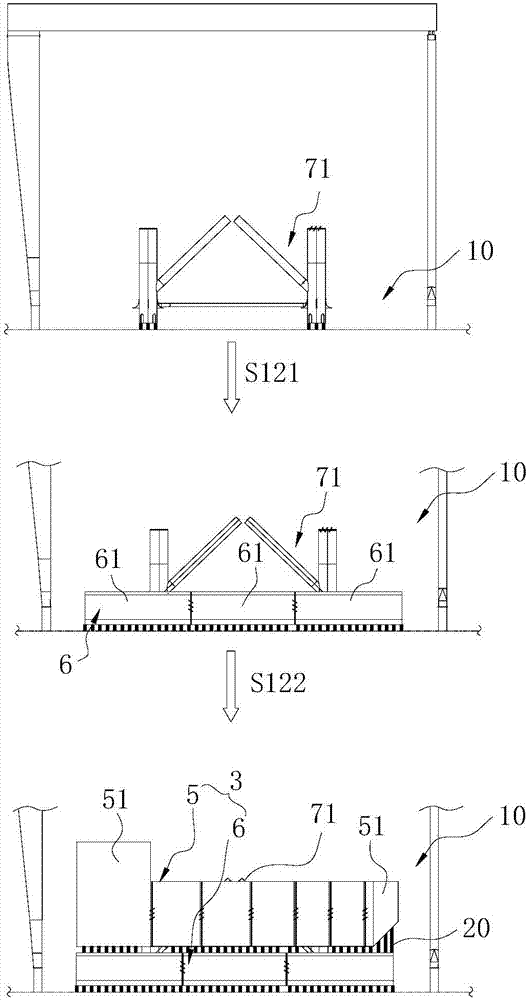

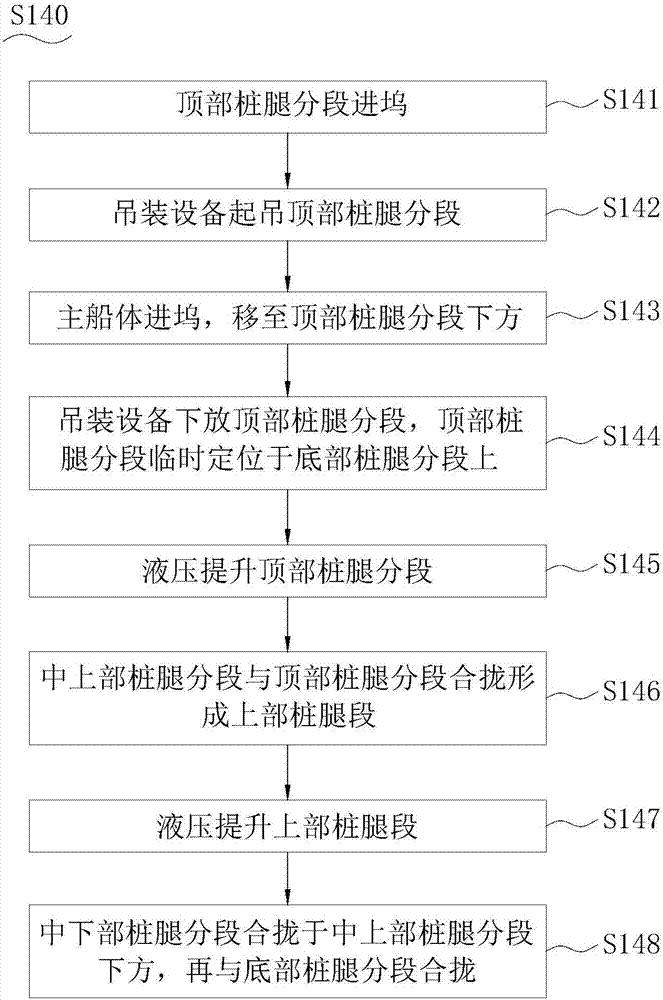

MOPU building method

ActiveCN107399412AReduce usageImprove securityVessel designingFloating buildingsOperabilityBuilding construction

The invention provides a building method of a MOPU which comprises section construction steps, main hull construction steps, launching into water steps and pile legs closure steps. Section construction steps: sub-merged container sections, deck box sections and pile leg sections are built respectively, wherein the pile leg sections comprise bottom pile leg sections, top pile leg sections and a plurality of middle pile leg sections. Main hull construction steps: the sub-merged container sections are closed together to form a sub-merged container and further fixed with the bottom pile leg sections, with the bottom pile leg sections as benchmarks, and the deck box sections are closed together to form a deck box, the sub-merged container and the deck box constitute the main hull. Launching into water steps: the main hull section, the top file leg sections and the middle pile leg sections are launched into water respectively. Pile legs closure steps: the middle pile leg sections and the top file leg sections are closed above the bottom pile leg sections. The MOPU building method has the advantages that the sub-merged container sections, the deck box sections and the pile leg sections are built respectively and simultaneously, the use of large hoisting equipment is avoided in the closure process, the closure risk is reduced effectively, the closure operability is improved, labor costs are reduced and further good economy is provided.

Owner:YANTAI RAFFLES SHIPYARD +2

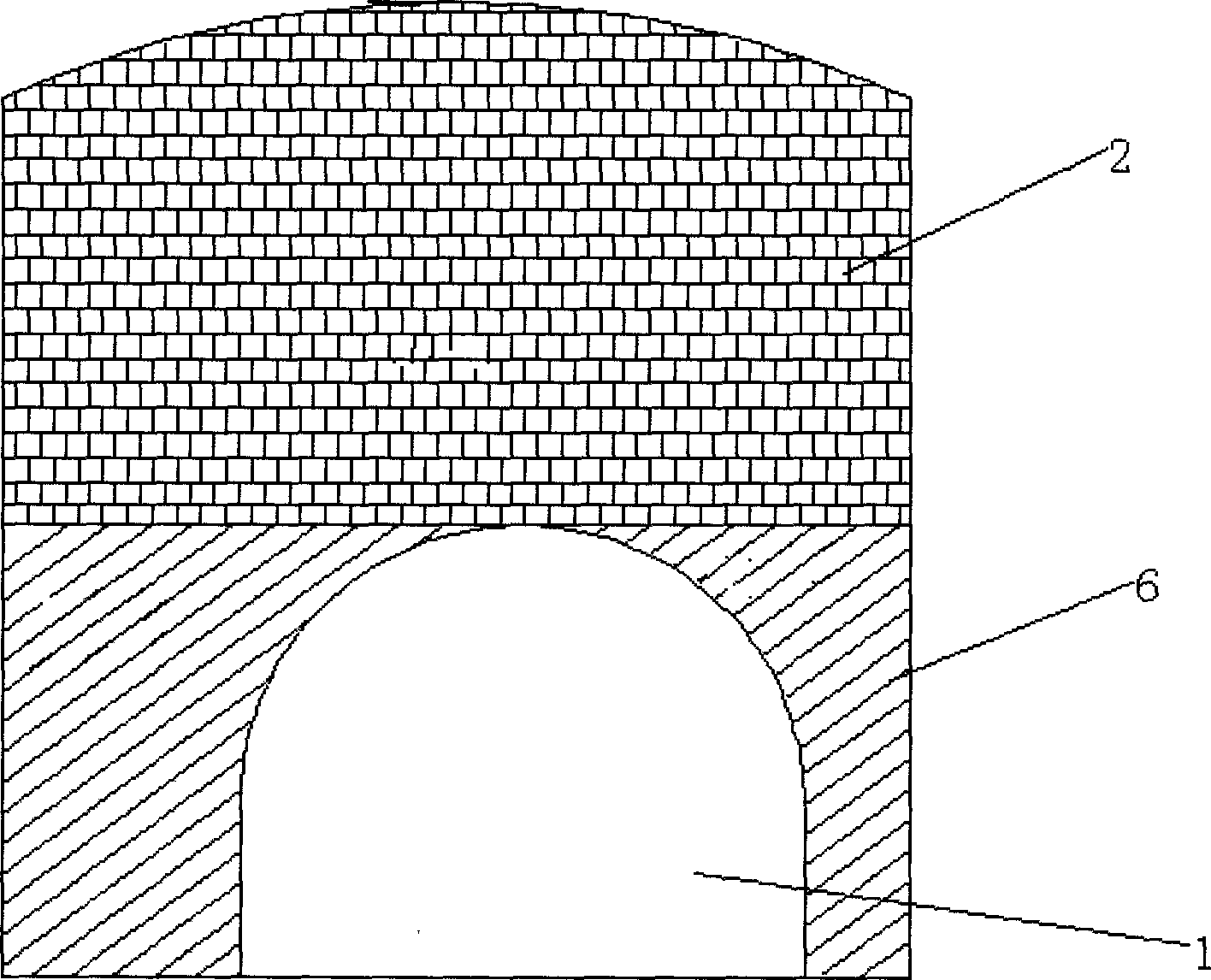

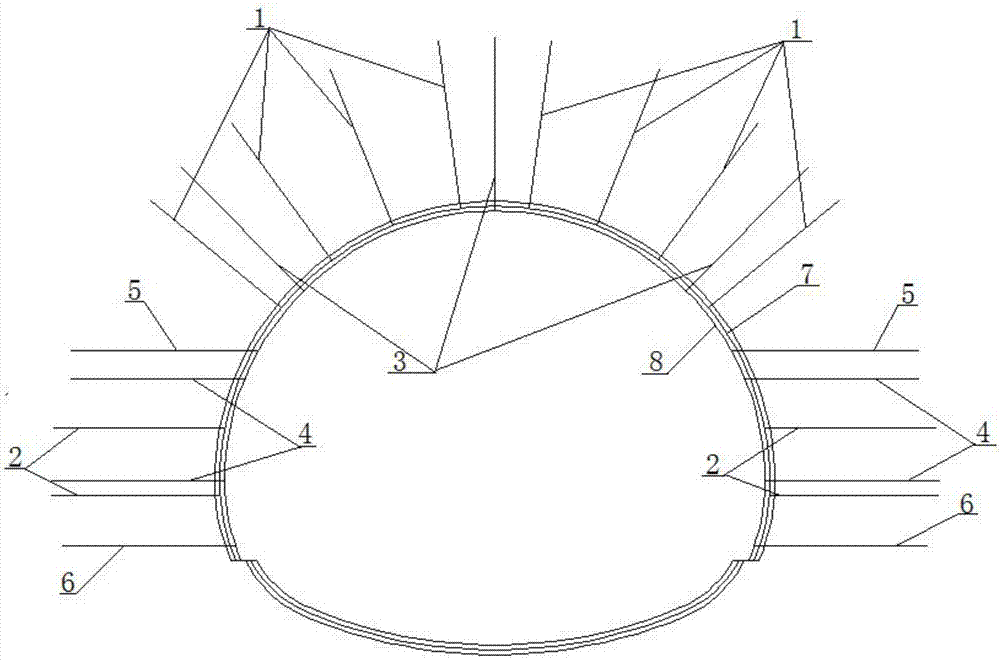

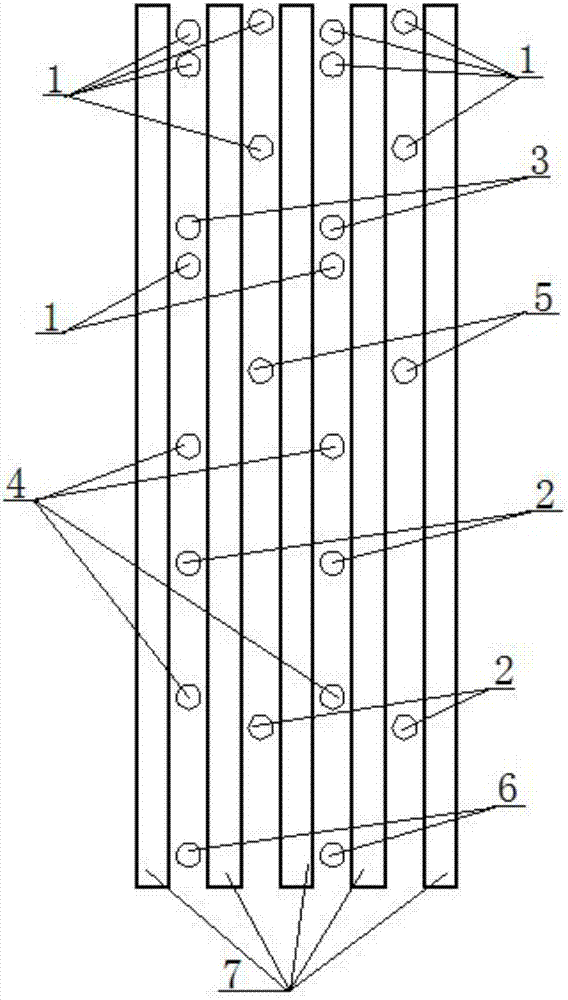

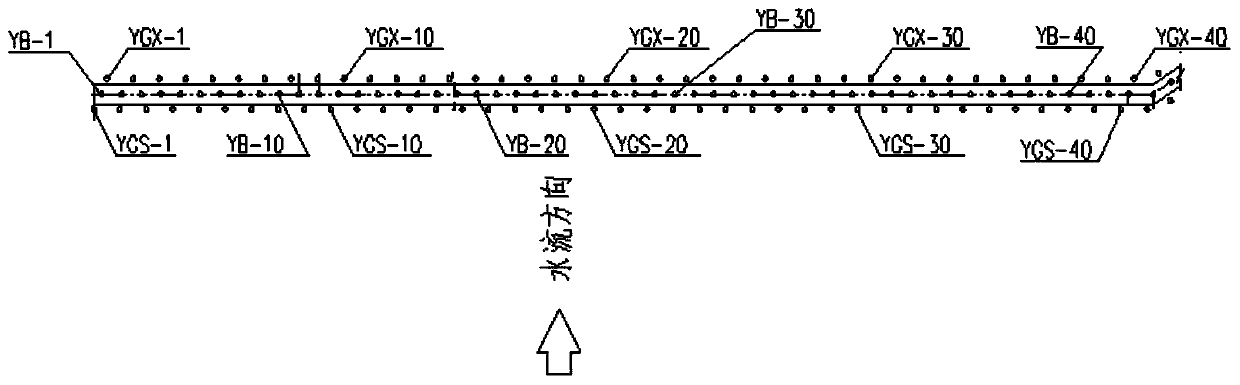

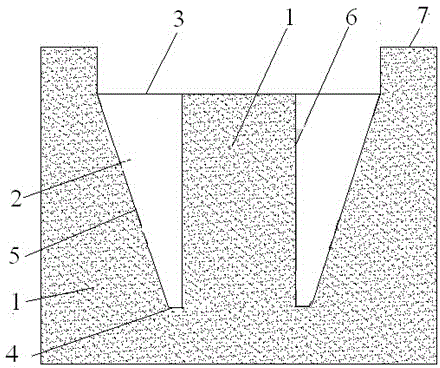

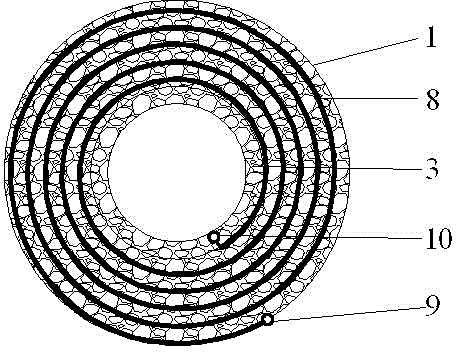

Squeezing weak surrounding rock tunnel prestressed anchor cable group support structure and construction technology

The invention relates to a squeezing weak surrounding rock tunnel prestressed anchor cable group support structure and a construction technology. The support structure comprises arch speed control anchor cables (1), side wall speed control anchor cables (2), arch limiting anchor cables (3), side wall limiting anchor cables (4), arch locking anchor cables (5), side wall locking anchor cables (6), a first layer primary support (7) and a second layer primary support (8); all anchor cables in the construction technology adopt drilling and grouting simultaneously, however, reserved tensioning is conducted according to times, batches and parts. Controlling release on surrounding rock stress is achieved, the surrounding rock deformation growth rate and deformation accumulation amount are lowered, large deformation is effectively controlled, steel arch centering replacement caused by too large deformation is avoided, and the surrounding rock collapse hazard is lowered; in addition, the work efficiency is improved, constructors can conduct drilling conveniently, and it is guaranteed that the anchor cable positions are accurate, and tensioning can be conducted in time.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

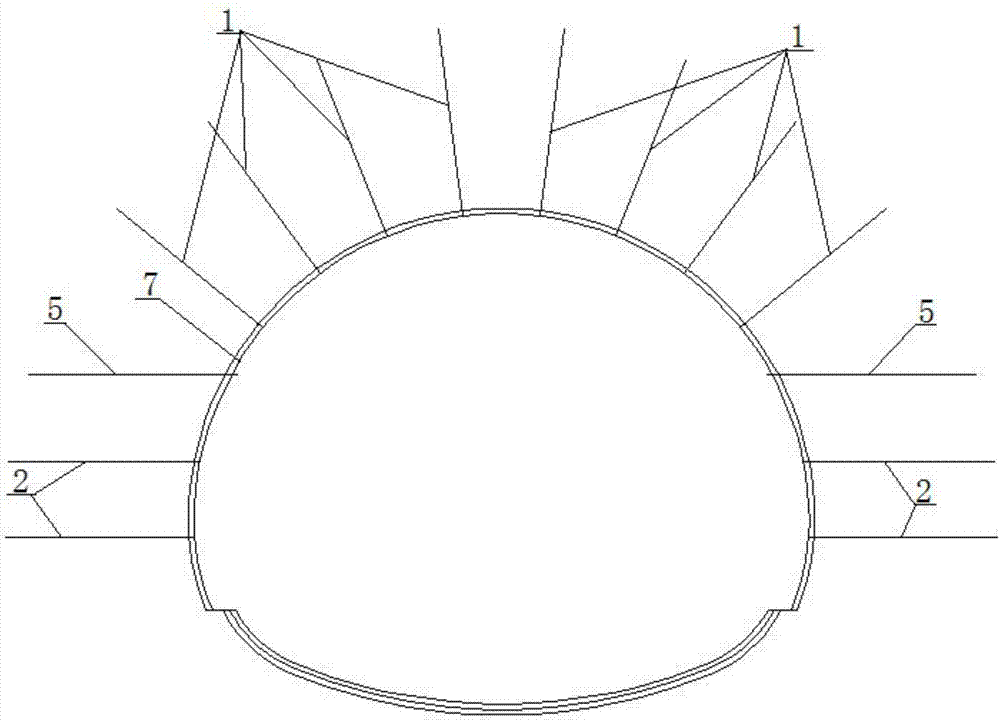

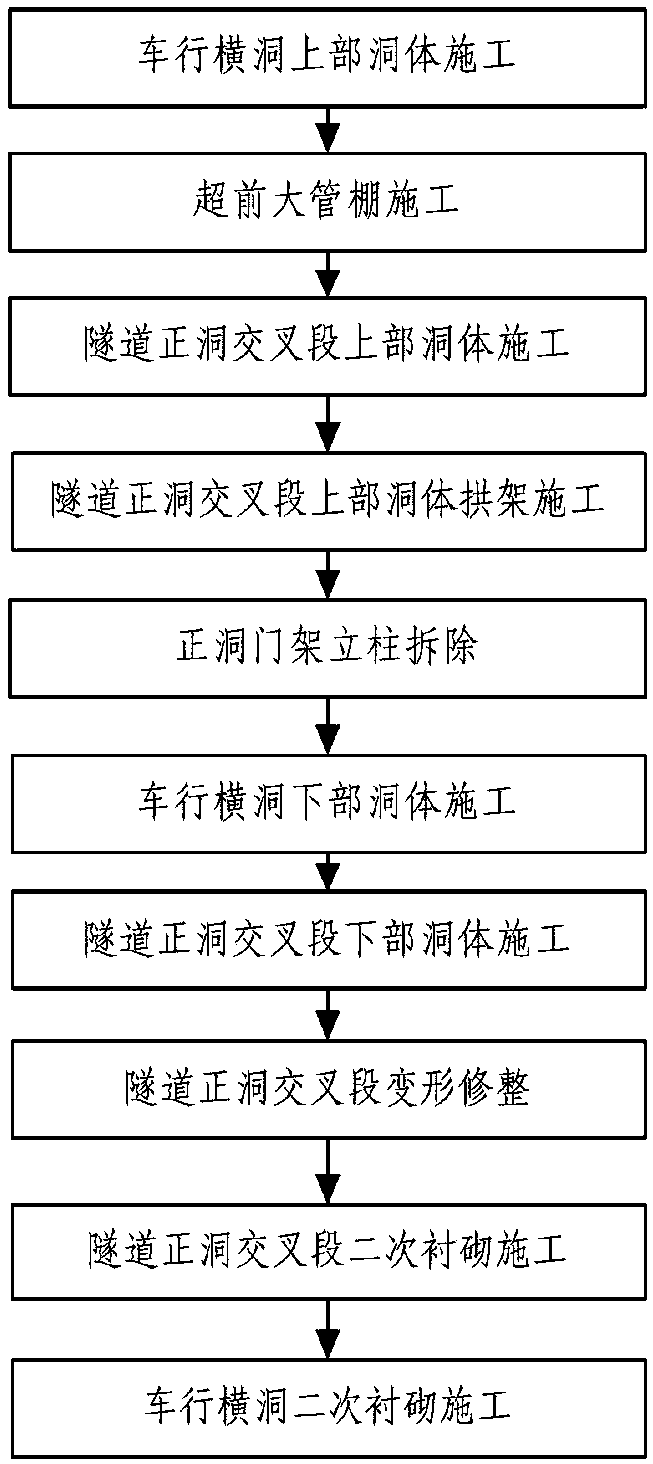

Construction method for cross position of vehicle-traveling transverse cave and tunnel main cave based on temporary support system

ActiveCN107762529AReduced risk of vault collapseAchieve a solid supportUnderground chambersTunnel liningCaveSupport system

The invention discloses a construction method for the cross position of a vehicle-traveling transverse cave and a tunnel main cave based on a temporary support system. The designed position of the vehicle-traveling transverse cave is located on one side of the designed position of the tunnel main cave, the designed axis of the vehicle-traveling transverse cave and the designed axis of the tunnel main cave cross, and the designed cross section of the vehicle-traveling transverse cave is rectangular. In specific construction, the construction method comprises the following steps that firstly, anupper cave body of the vehicle-traveling transverse cave is constructed; secondly, an advanced large pipe shed is constructed; thirdly, an upper cave body at the tunnel main cave crossing section isconstructed; fourthly, arch frames of the upper cave body at the tunnel main cave crossing section is constructed; fifthly, vertical columns of main cave gantries are detached; sixthly, a lower cave body of the vehicle-traveling transverse cave is constructed; seventhly, a lower cave body at the tunnel main cave crossing section is constructed; eighthly, deformation finishing of the tunnel main cave crossing section is conducted; ninthly, a secondary lining of the tunnel main cave crossing section is constructed; and tenthly a secondary lining of the vehicle-traveling transverse cave is constructed. The construction requirements of the cross position of the vehicle-traveling transverse cave and the tunnel main cave in broken surrounding rock can be met.

Owner:中铁二十局集团第二工程有限公司

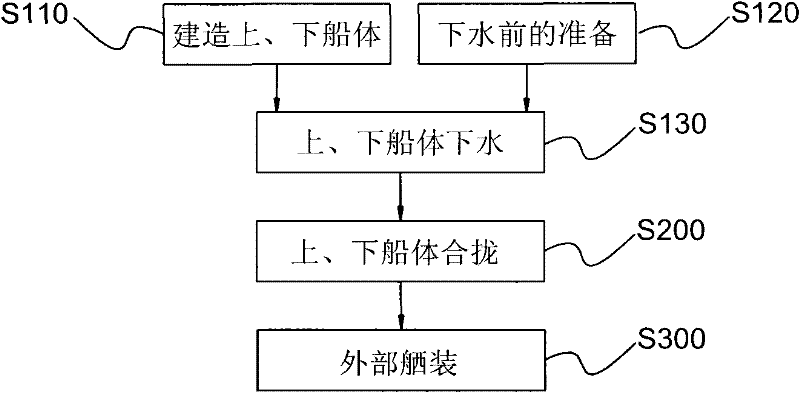

Construction method for ocean platform

ActiveCN102190065AShorten the construction periodGood collapsibilitySlipwaysVessel partsMarine engineeringButt joint

The invention discloses a construction method for an ocean platform. The method comprises the following steps of: constructing an upper ship body and a lower ship body; launching the upper ship body and the lower ship body; folding the upper ship body and the lower ship body; and performing outside fitting-out. The upper and lower ship body folding process comprises the following steps of: dragging launched upper and lower ship bodies to a dockyard specified position; hoisting the upper ship body to a certain height position; positioning the lower ship body below the upper ship body; and folding the upper ship body and the lower ship body into a whole in a butt joint mode. By the method, the construction period of the ocean platform can be shortened, and labor cost can be saved; and the method is not limited by surges, and is short in folding time and high in folding accuracy.

Owner:YANTAI RAFFLES SHIPYARD +2

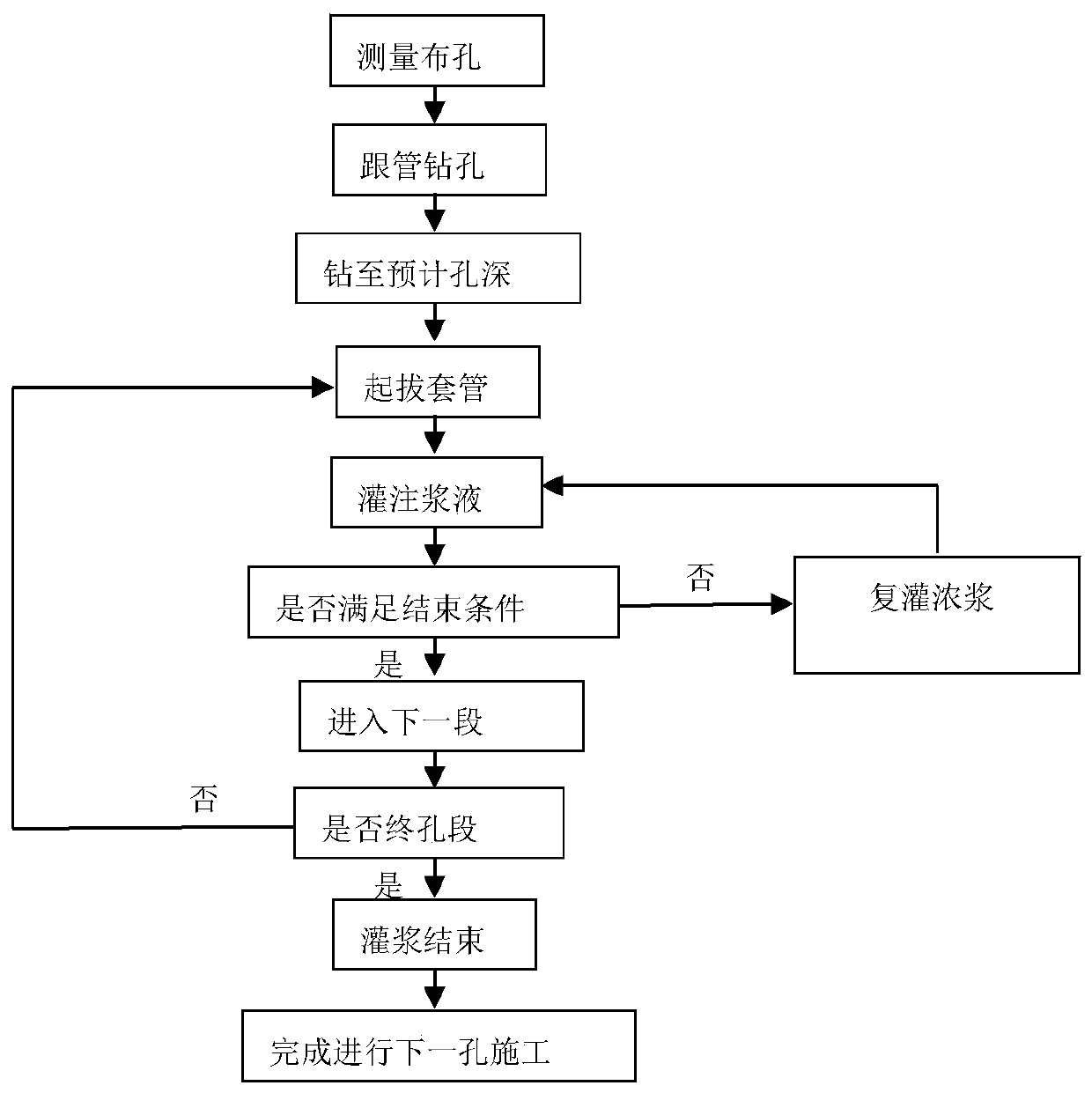

In-stratum stepped-heaped-weir-type safe grouting construction process for blocking large water gushing from sidewall of deep foundation pit

The invention discloses an in-stratum stepped-heaped-weir-type safe grouting construction process for blocking large water gushing from a sidewall of a deep foundation pit. The safe grouting construction process comprises the following steps: the amounts of gushed water and silt from the sidewall at the deep part of the foundation pit are observed and calculated; a water drain pipe is arranged ina water gushing point to drain water; backpressure bodies are arranged around the water gushing point to form backpressure on the sidewall, of the foundation pit, around the water gushing point; holesare drilled in the surface of the sidewall where the water gushing point is positioned, the holes are divided into at least two rows, the depths of the first row of holes and the second row of holesare arranged in a vertically-stepped form, the first row of holes is near a supporting protective body of the sidewall, and the depths of the drilled holes decrease sequentially from inward to outward; and grouting is performed for blocking. Vertical drilling is carried out quickly in the surface on the outer side of the sidewall, where the water gushing point in the the deep part of the foundation pit is positioned; aggregate and anti-dispersion high-early-strength rapid-hardening grout are injected into a water guide channel or a formed cavity through the drilled holes to rapidly form a water-blocking curtain in a stratum where water gushes out, so as to block an underground water gushing channel and achieve the purposes of quickly controlling water gushing and by grouting, reinforcing the stratum damaged by water gushing.

Owner:SHANDONG UNIV

Extrusion roller sleeve of roller press

PendingCN109865554AReduce the risk of collapseExtend your lifeGrain treatmentsWear resistantHigh wear resistance

The invention provides an extrusion roller sleeve of a roller press. The extrusion roller sleeve comprises an extrusion roller sleeve and is characterized in that a plurality of grooves are formed inthe outer surface of the extrusion roller sleeve in a uniform distribution mode, and wear-resistant materials which are higher 1-10mm than the surface of a roller body are welded in the grooves, suchas ZD310 or ZD903 wear-resistant flux-cored wires developed by Zhengzhou Research Institute of Mechanical Engineering Co., Ltd, and SKC A43-O wear-resistant flux-cored wires or other surfacing materials with high wear resistance developed by Voestalpine Bohler Welding Co., Ltd. The extrusion roller with the structure combines the advantages of the surfacing extrusion roller and an insert pin typeextrusion roller, so that the risk that a pattern layer is broken away from a roller body is reduced, and the problem that column nails are separated from the roller body is solved. Meanwhile, a basemetal between weld joints forms a trend of delaying downward abrasion of a material cushion after being worn to a certain degree, and the service life of the roller body is effectively prolonged.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

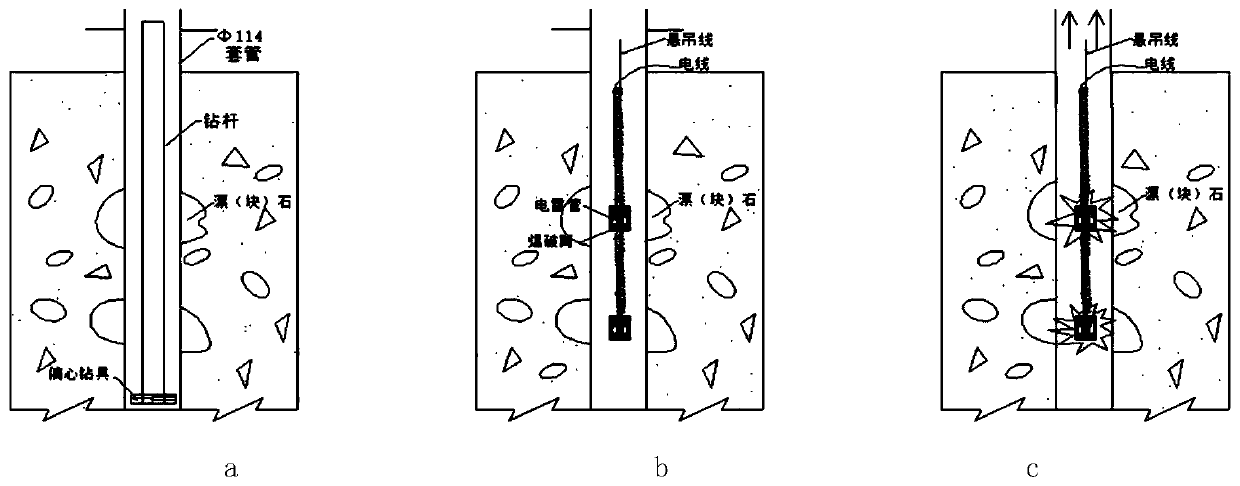

Construction method of diaphragm wall of barrier body

ActiveCN110541425AGet rid of the harm as soon as possibleReduce the risk of collapseExcavationsStructural engineeringPre treatment

The invention discloses a construction method of a diaphragm wall of a barrier body. The method comprises the following steps: pretreating a stratum with the boulder content higher than 50% and serious overhead of the diaphragm wall of the barrier bod to form a homogenized stratum which is favorable for subsequent diaphragm wall grooving on the stratum; after forming a homogenized stratum, drilling the homogenized stratum by taking the axis of the barrier body impervious wall as a reference to form a slotted hole; after the slotted hole is formed, hanging embedded pipes layer by layer througha cross beam so as to arrange in the slotted hole layer by layer; when each layer of embedded pipes is arranged below, positioning a plurality of embedded pipes in the layer of the embedded pipes simultaneously through an embedded pipe truss which is arranged in the slotted hole together with the layer of embedded pipes; then arranging a pouring guide pipe in the slotted hole; and after the pouring guide pipe is arranged below the slotted hole, pouring concrete into the groove hole through the pouring guide pipe so that the diaphragm wall can be quickly formed in the slotted hole. With the adoption of the method, the diaphragm wall of the barrier body can be quickly and safely build under the geological conditions of a weir plug body which has more boulders, large particle size, serious overhead phenomenon and un-deposited and cemented stratum.

Owner:SINOHYDRO FOUND ENG

Coalbed methane horizontal well underbalance drilling system and method thereof

ActiveCN111878041APlay the role of anti-blowoutOvercoming structural complexityFluid removalWell/borehole valve arrangementsDrilling systemGeotechnical engineering

The invention discloses a coalbed methane horizontal well underbalance drilling system and a method thereof. The coalbed methane horizontal well underbalance drilling system comprises a casing pipe, adrill rod, a fluid director, a top drive, degassing valves, a water-gas mixing supply unit and a three-phase separator. According to stable underbalance drilling, the displacement and the pressure ofcompressed air are adjusted according to the displacement and the pressure of drilling fluid, a certain proportion of compressed air is injected into the drill rod, and the compressed air is separated from a coal seam borehole far away from the position of a drill bit through the set of degassing valves installed on the drill rod and rapidly expands. Expanded air bubbles ascend and continuously expand, the expanded air bubbles can replace or discharge drilling fluid with the same volume, and the density of the compressed air bubbles is far smaller than that of the drilling fluid, so that thedensity of a fluid in an annulus channel is reduced, and the pressure of an annulus liquid column acting on the coal seam borehole is reduced; and in this way, an underbalance or near-balanced drilling state that the pressure of the annulus liquid column acting on the coal seam borehole is smaller than or approximately equal to the coal seam gap pressure is formed.

Owner:北京方圆天地油气技术有限责任公司

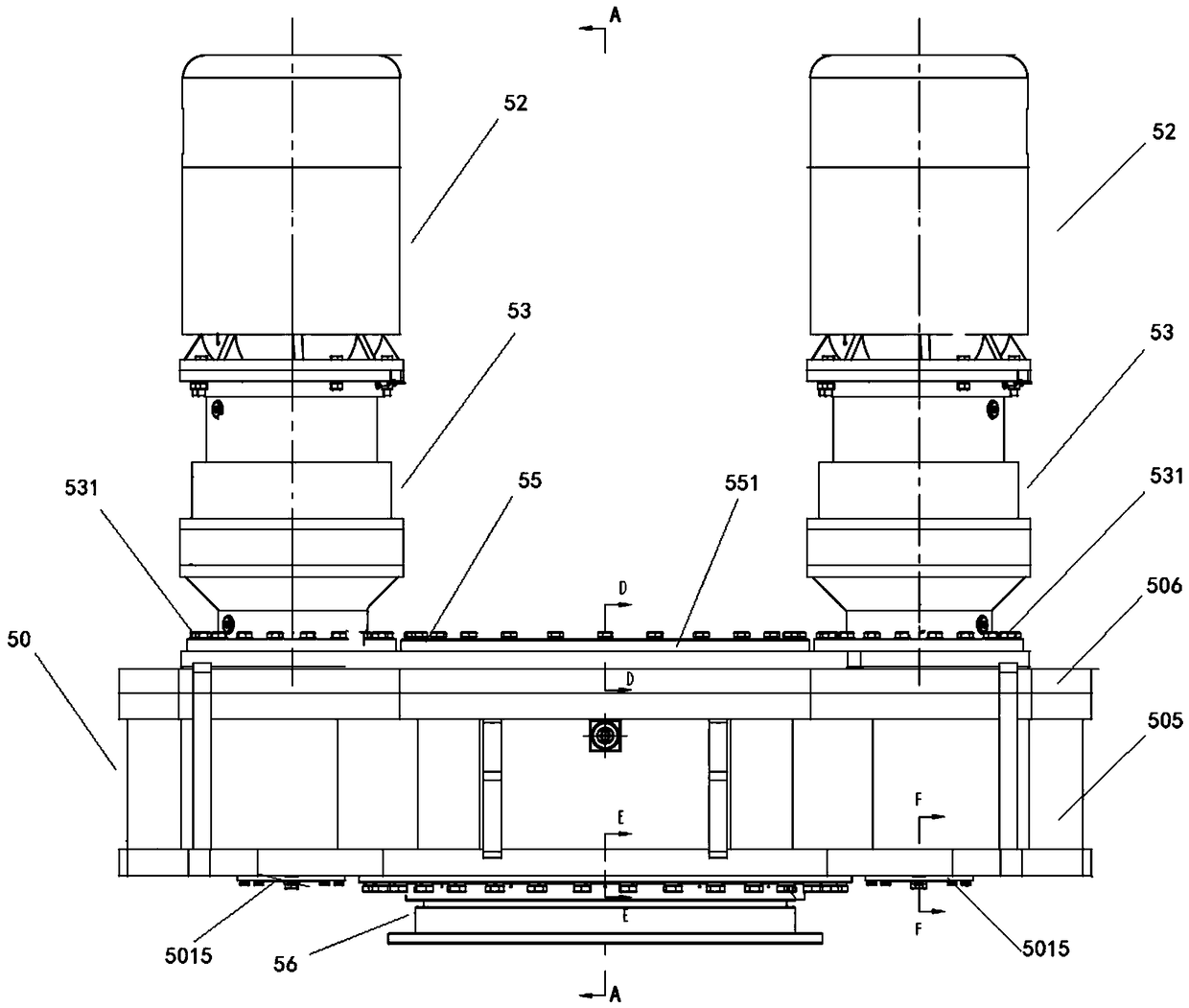

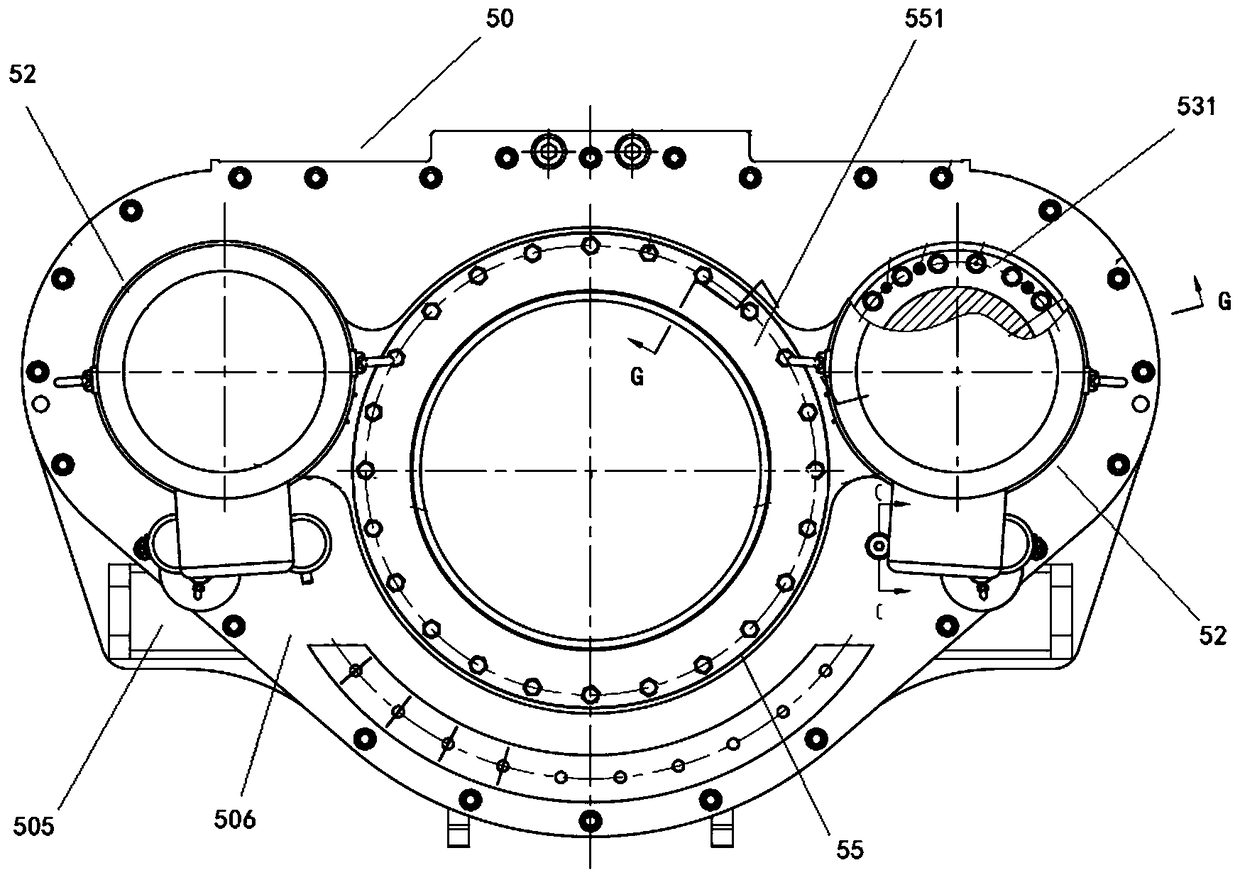

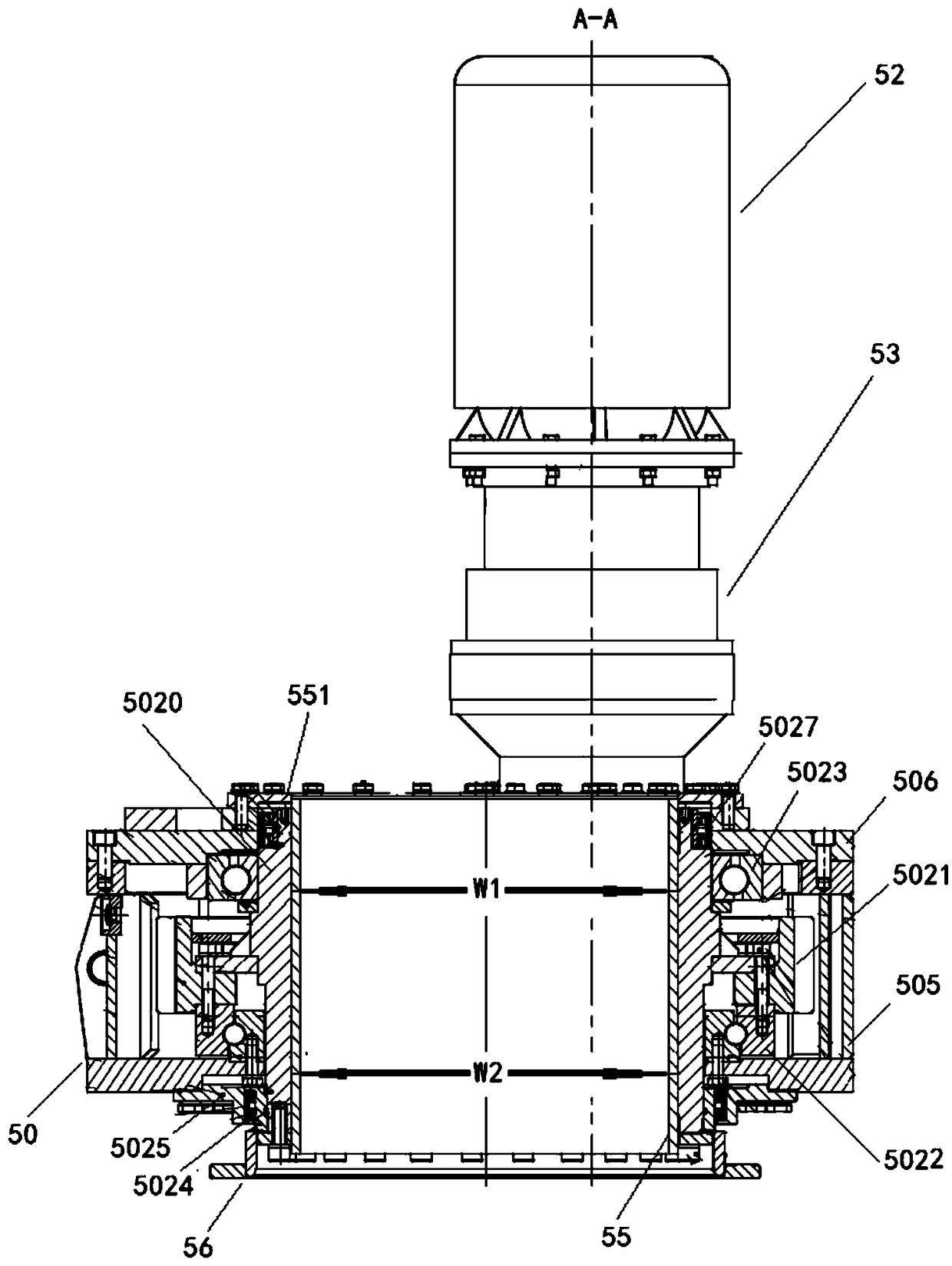

Lower driving head of dual-power drilling machine

PendingCN109356528AGuaranteed uptimeReduce risk of collapseBorehole drivesDrilling machines and methodsGear wheelTorque transmission

The invention discloses a lower driving head of a dual-power drilling machine. The lower driving head of the dual-power drilling machine comprises a gear box, planetary reducers, two sets of verticaltype motors, an inner retainer and a lower flange, wherein the gear box includes an output sleeve assembly. The output sleeve assembly penetrates through the gear box perpendicularly through a sleevebody of the output sleeve assembly. The planetary reducers are arranged on the left and right sides of the output sleeve assembly. Pinion gears on output shafts mesh with big gear wheels on the outputsleeve assembly separately. The inner retainer penetrates through the sleeve body and is fixedly installed on the upper end surface of the sleeve body through an end flange of the inner retainer. Thelower flange is fixedly installed at the lowermost end of the inner retainer. The fit clearance between the inner diameter W1 of the sleeve body and the outer diameter W2 of the inner retainer is 0.20-0.5 mm. The lower driving head drives a lower sleeve drilling tool to rotate reversely to follow up wall protection and drilling, the verticality of a drilling hole is improved, the risk of collapseof a hole wall is reduced, the loads of a drill pipe and the drilling tool are reduced, torque transmission of the sleeve body and the drilling safety are ensured, stable operation of the lower driving head is ensured, the work efficiency is high, and the requirements of low carbon emission and energy conservation and environmental protection for pile foundation construction are met.

Owner:上海工程机械厂有限公司

Power transmission electric pole and manufacture method thereof

The invention relates to the field of power transmission devices, and more specifically, relates to a power transmission electric pole and a manufacture method thereof. The manufacture method comprises following steps: a bended pole can be used to produce the power transmission electric pole, polyurethane and fiber are adopted as raw materials, and a pole production mold is adopted as the mold; two ends of the pole production mold are fixed and the mold is made to rotate; the polyurethane and the glass fiber are made to cover the surface of the pole production mold during rotation until the raw materials uniformly cover the pole production mold; then the pole production mold and the raw materials are baked; then the pole production mold and the raw materials are taken out and the method is finished. The provided bended power transmission electric pole can be used in corners of electric transmission lines. Furthermore, electric poles with different degrees of bending can be manufactured according to different angles of different corners. By use of the power transmission electric pole with certain curvature, a resultant force of pulling forces at two sides of the electric pole around a corner is offset so that pulling lines of traditional power transmission electric poles can be saved, and as a result the cost of wiring is saved.

Owner:胡广生

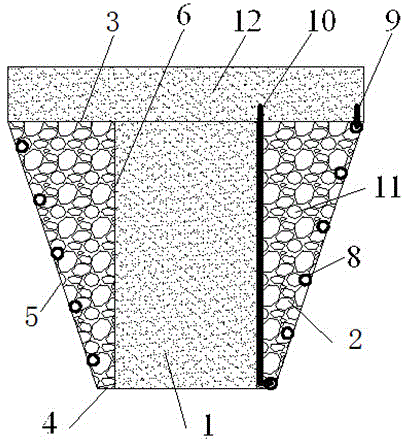

Hollow circular truncated cone spiral energy pile structure capable of improving heat transfer efficiency

InactiveCN104912068AImprove heat transfer efficiencyReduce initial investmentHeat pumpsGeothermal energy generationCircular coneTemperature difference

The invention discloses a hollow circular truncated cone spiral energy pile structure capable of improving heat transfer efficiency. An energy pile well is arranged in solum, and is in a circular truncated cone shape, and the diameter of the energy pile upper bottom face is larger than that of the energy pile lower bottom face. A heat exchange pipe is arranged in the energy pile well and fixed, and the heat exchange pipe is composed of a heat exchange pipe inlet pipe section, a spiral heat exchange pipe section and a heat exchange pipe outlet pipe section which are sequentially connected. The energy pile well is backfilled through energy pile backfill materials. The spiral heat exchange pipe section is arranged at certain taper, spiral pipes are staggered in the radial direction, the heat disturbance intensity of the adjacent spiral pipes in the axial direction is weakened, and the heat transfer capacity of the spiral pipes in the axial direction is improved. Heat exchange fluid flows in from the upper bottom face of a circular truncated cone with the large radius, the heat exchange temperature difference between soil and the fluid is large, the heat short-circuit phenomenon of the backfill region at the energy pile upper portion is weakened to a certain degree, and the heat transfer efficiency of an energy pile is improved. Corrosion resistance is remarkably improved, and service life is greatly prolonged.

Owner:黄光勤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com