Cigarette stacking device

A technology of cigarettes and equipment, which is applied in the field of cigarette sorting equipment, can solve the problems of high cost of manipulators, large strokes, and relatively large stacking efficiency limitations, and achieve the effects of improving stability, applicability, and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

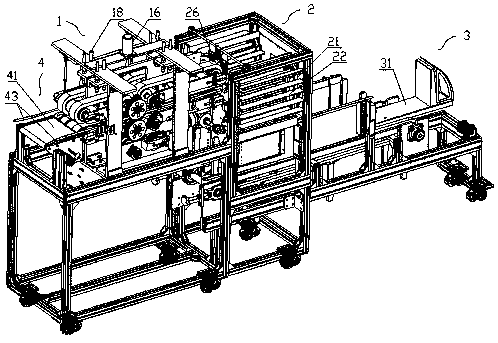

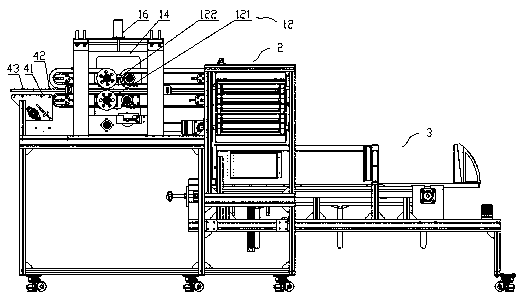

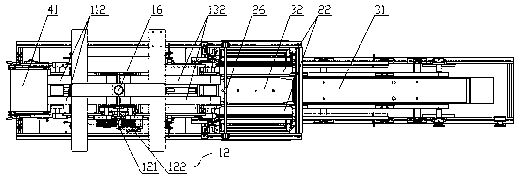

[0028] Example 1. A device for stacking cigarette sticks, consisting of Figure 1-Figure 9 As shown, it includes a sorting and counting device 1, the sorting and counting device 1 is connected to the palletizing device 2, and the palletizing device 2 is connected to the palletizing device 3; the sorting and counting device 1 includes a conveying mechanism I11, and the conveying mechanism I11 passes through The ferry mechanism 12 is connected with the conveying mechanism II13; the conveying mechanism I11 includes two conveyor belts IA111 and IB112 for clamping and transporting cigarettes; the conveying mechanism II13 includes two conveyor belts for clamping and transporting cigarettes The conveyor belt IIA131 and the conveyor belt IIB132, the conveying speed of the conveying mechanism I11 is less than the conveying speed of the conveying mechanism II13; the transition mechanism 12 includes a transition belt 121 connecting the gap between the conveyor belt IA111 and the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com