Annular foam fire extinguishing system of oil storage tank

A foam fire extinguishing and oil storage tank technology, applied in fire rescue and other fields, can solve problems such as disasters, backflow, fire extinguishing foam bursting, etc., and achieve the effects of light weight, low fire extinguishing efficiency and fast fire extinguishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

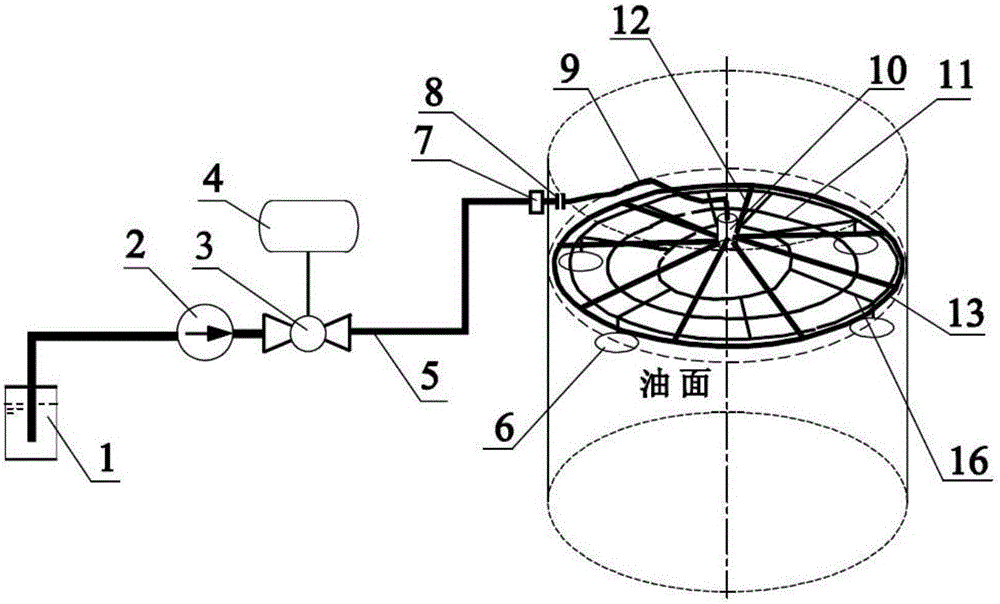

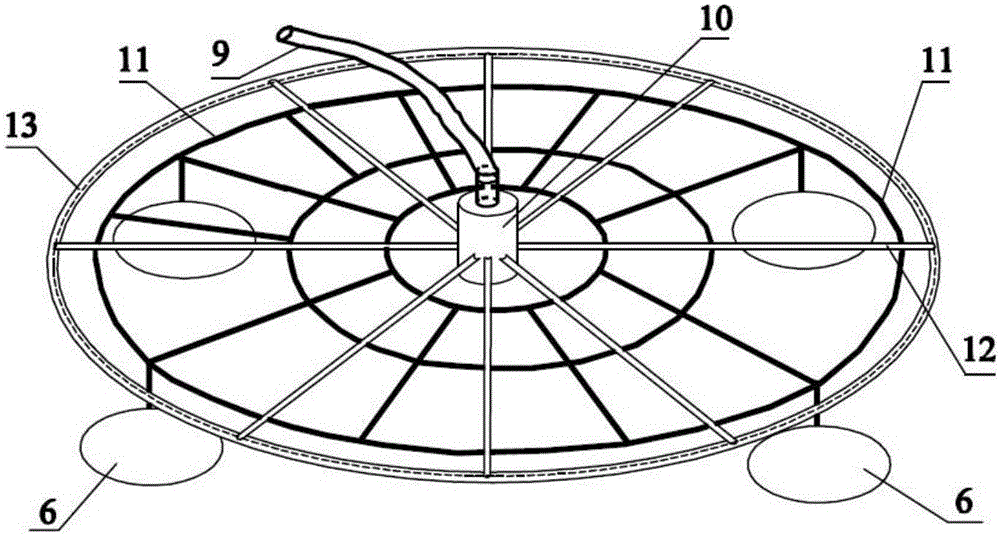

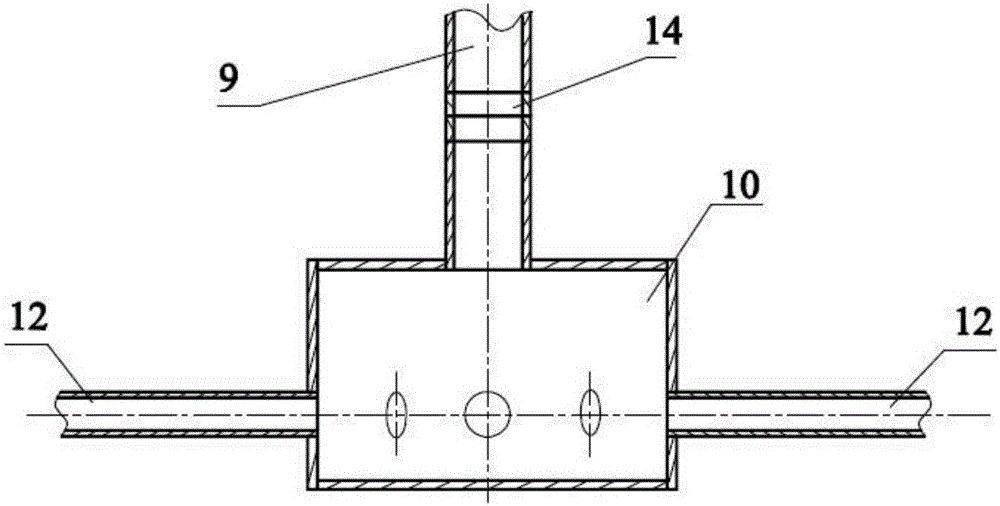

[0026] Embodiment: Referring to the accompanying drawings, the annular foam fire extinguishing system of the oil storage tank of the present embodiment is provided with a buoyancy support 11 suspended on the oil surface in the oil storage tank, and a fire extinguishing foam injection device is fixedly arranged on the buoyancy support 11, The fire extinguishing foam injection device communicates with the fire extinguishing foam supply device outside the oil storage tank through a pipeline;

[0027] Wherein, the buoyancy support 11 is made of 2-3 aluminum alloy rings forming a concentric circle structure and reinforcing ribs 16 connected between the aluminum alloy rings, and a supporting floating ball 6 is provided at the bottom of the aluminum alloy rings / ribs for use For suspending the entire buoyancy support 11 and the fire extinguishing foam injection device, in the specific setting, the reinforcing ribs 16 are set to eight, and the eight reinforcing ribs are radially and equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com