Squeezing weak surrounding rock tunnel prestressed anchor cable group support structure and construction technology

A prestressed anchor cable and weak surrounding rock technology, which is applied in the installation of anchor bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of delay in the construction period of reinforcing anchor cables, lack of systematic layout, etc., and reduce the risk of surrounding rock collapse risk, improving the internal force of surrounding rock, reducing the growth rate and the effect of deformation accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

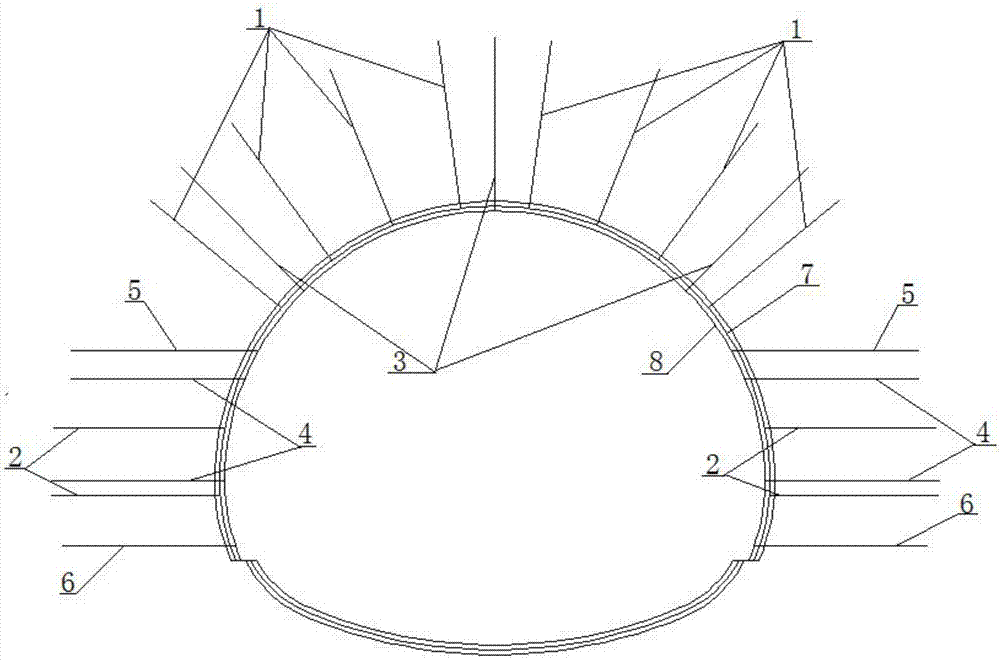

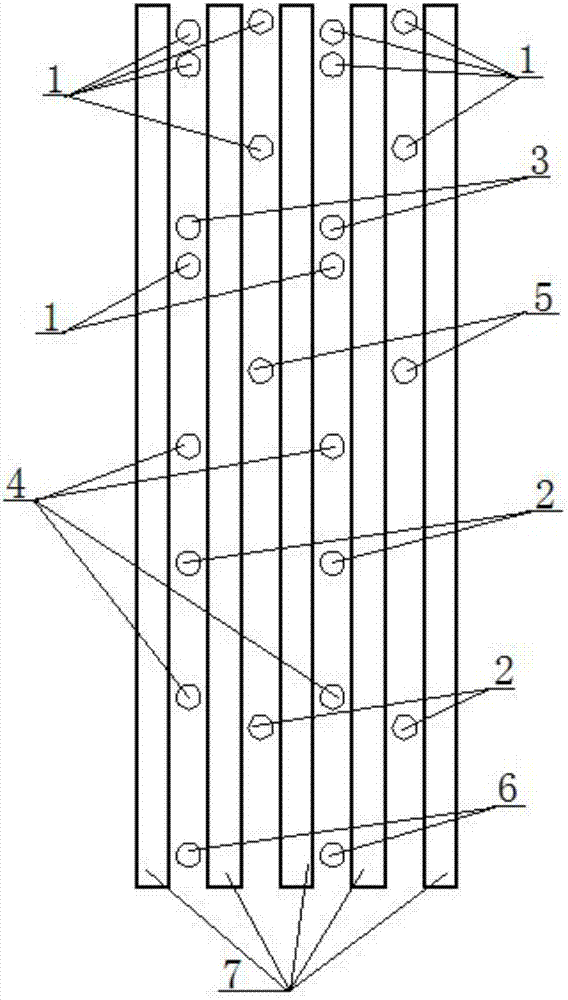

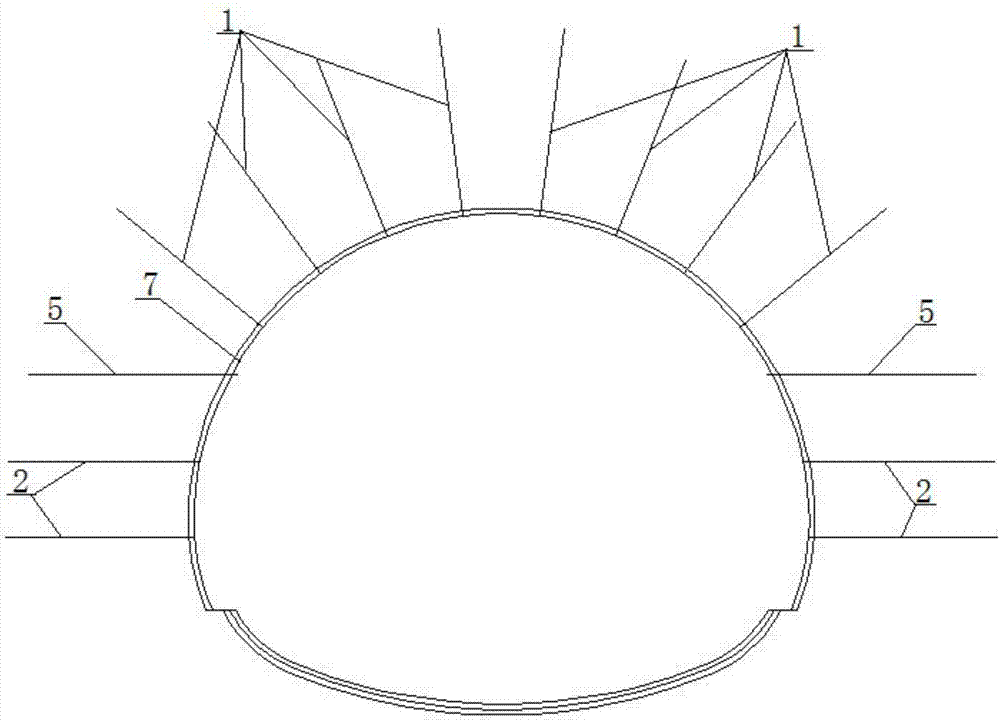

[0025] see Figure 1 to Figure 2 , an extrusion-type weak surrounding rock tunnel prestressed anchor cable group support structure, including the arch speed control anchor cable 1, the side wall speed control anchor cable 2, the arch limit anchor cable 3, the side wall limit anchor cable 4. Arch locking foot anchor cable 5, side wall locking foot anchor cable 6, primary support 7 of the first layer and primary support 8 of the second layer. The first layer of primary support 7 is a conventional primary support, and the first layer of primary support 7 includes a first layer of steel arches, and the first layer of steel arches is buried in spray concrete; The second layer of primary support 8 is a conventional primary support, and the second layer of primary support 8 includes a second layer of steel arches, and the second layer of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com