Construction method for opening off small-section underground chamber of coal mine rock roadway into large-section underground chamber

A construction method and small-section technology, applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of slow construction progress, unfavorable high-yield and high-efficiency mine construction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

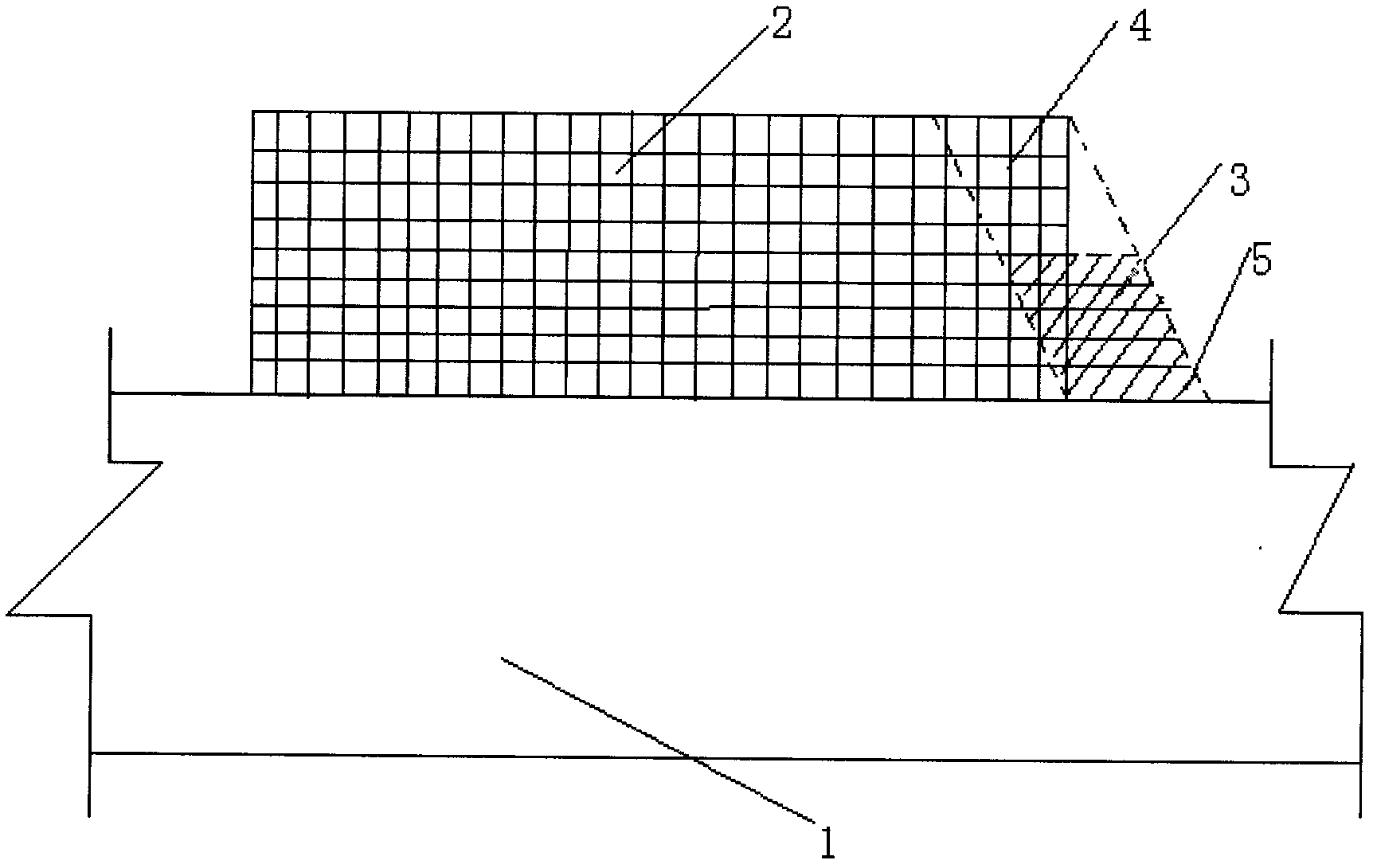

[0031] figure 1 Shown is the cross-sectional view of the chamber of the present invention, that is, the construction steps of the chamber top team 2, during construction, at the top of the rock roadway 1, 2 meters ahead of the design starting position of the chamber, according to the angle 5 with the longitudinal inclination 70°direction to drill and shoot. Then pick the roof in two layers, from the bottom to the top, first pick the first layer below, after the roof anchor net support, then pick the second layer, and then carry out the roof anchor net support, reach the predetermined position The design height of the overhang.

Embodiment 2

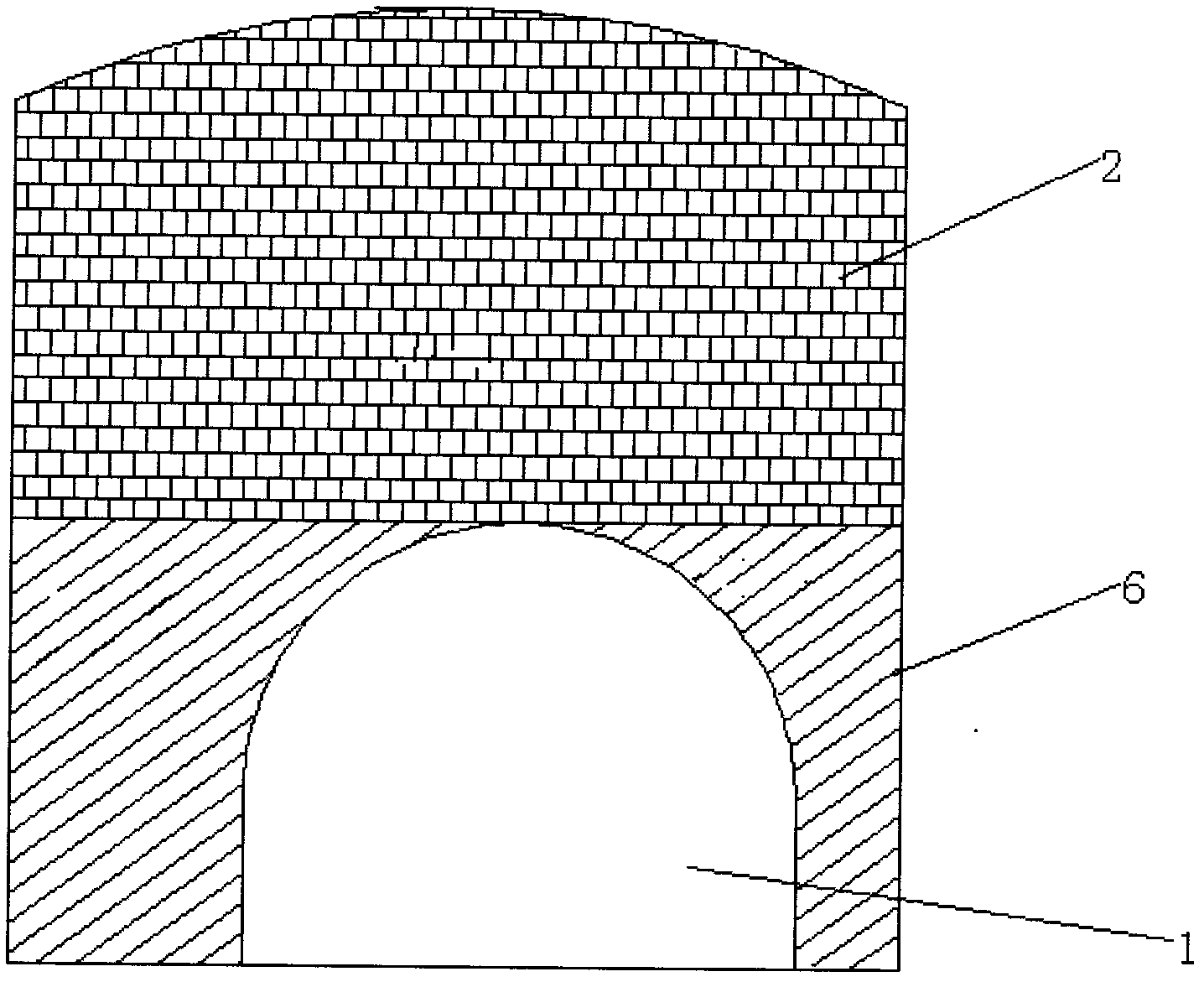

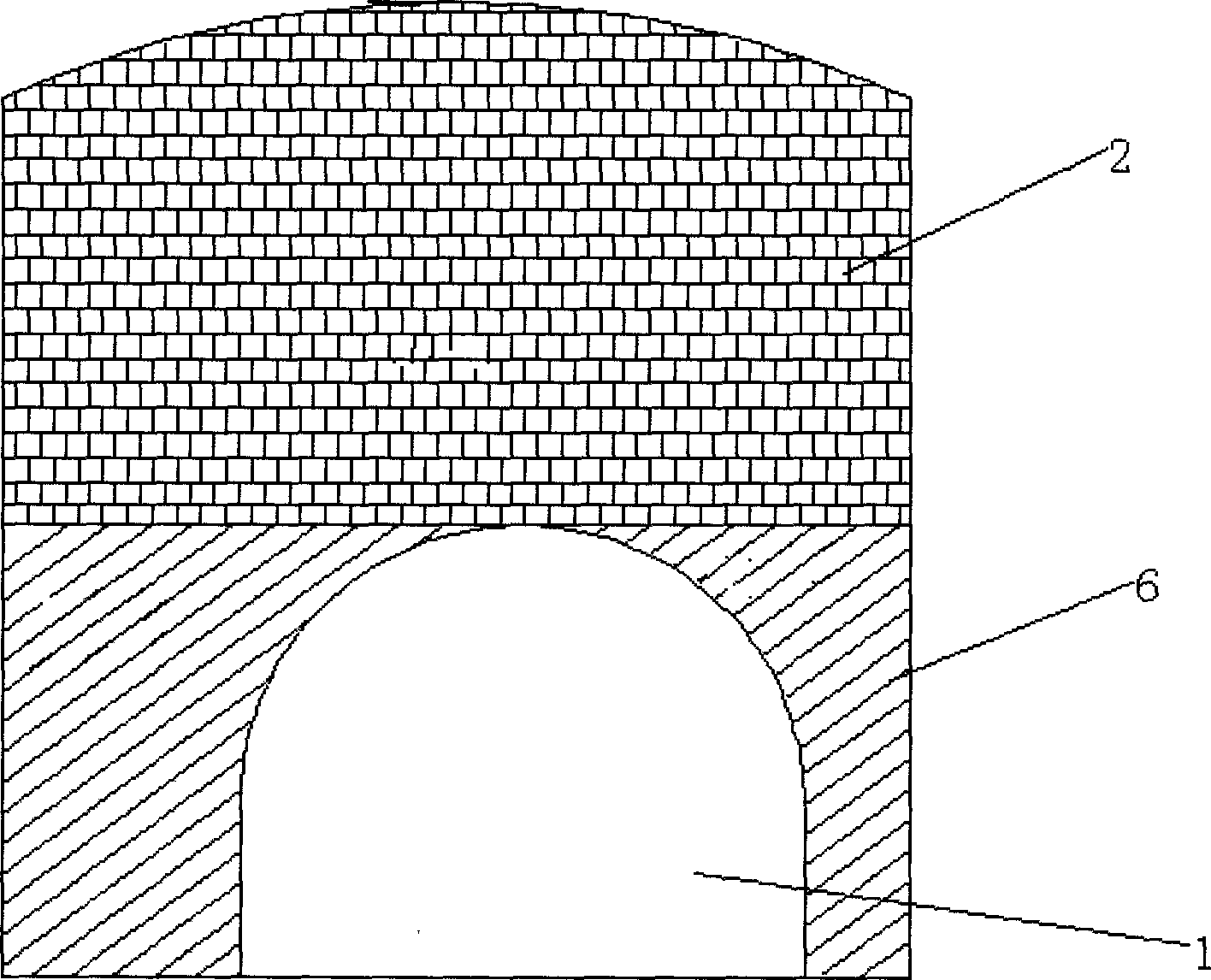

[0033] figure 2 It is the front view of the chamber, that is, the shape of the chamber after construction, and the shaded part in the figure is the part to be constructed.

[0034] On the basis of the existing rock roadway 1, it is expanded into a large-section chamber. Firstly, the top 2 of the chamber is drilled and blasted, then the roof is layered, and finally sprayed for support; In the direction of the chamber, the sides are brushed and sprayed for support in sequence, and finally the designed large-section chamber is formed.

Embodiment 3

[0036] Taking Qianying Coal Mine 3211 Wind Lane as the basis to expand into a large section chamber as an example, to solve the need to install the hoisting fully mechanized mining support on the 3211 working face of Qianying Coal Mine, an assembly chamber was constructed in the chamber of the 3211 Wind Lane Union Lane. The gross cross-section of the designed chamber reaches: width 7.6m, height 8.093m, cross-sectional area 61.5m 2 ; The net section is 7.4m wide, 7.993m high, and 59.15m sectional area 2 , The construction length is 30m.

[0037] The construction method of expanding the small section of the rock lane into a large section chamber is realized by the following construction methods:

[0038] (1) At the top of the rock roadway and 2 meters in front of the design starting position of the chamber, drill holes and shoot in a direction inclined 70° to the longitudinal direction, and carry out anchor net support after the shooting;

[0039] (2) Continue the above steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com