Treatment method for upper corner suspension roof of heavy pitch fully mechanized mining coalface

A technology of fully mechanized mining face and coal mining face, which is applied in the direction of drilling equipment and methods, ground mining, mining equipment, etc., and can solve problems such as roof not collapsing, gas exceeding the limit, roof accidents, etc., to solve safety threats , reduce the possibility, the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

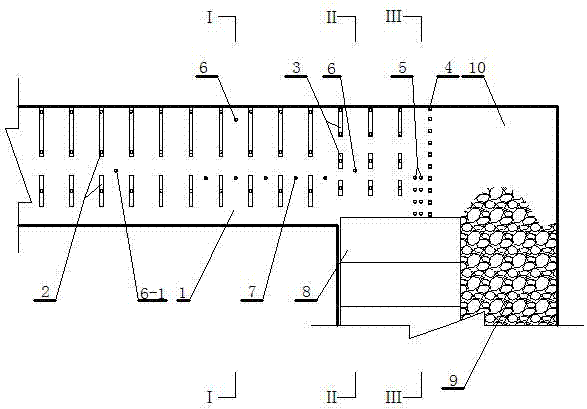

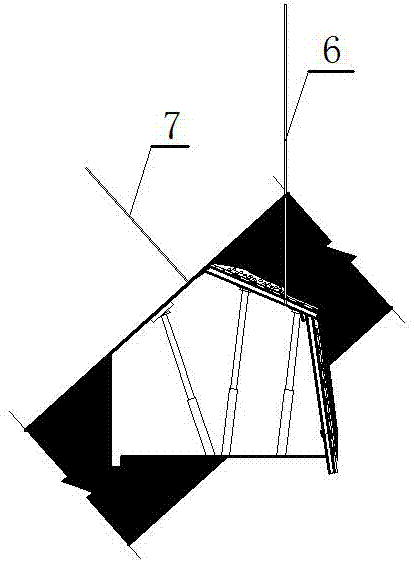

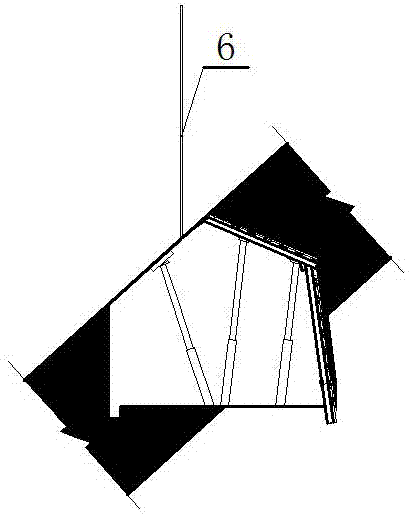

[0018] see figure 1 , figure 2 , image 3 , Figure 4 , a method for controlling the suspended roof at the corner of a steeply inclined fully mechanized mining face is mainly composed of forced caving drilling (5), hydraulic fracturing drilling (6), and advanced pre-splitting blasting drilling (7). Dense roof cutting support (4) in the coal working face arranges two rows of forced caving holes (5) along the inclination, and arranges a row of advanced pre-cracking in the wind tunnel (1) of the coal mining face (2) along the strike direction The blasting drill hole (7), the hydraulic fracturing drill hole (6) is arranged between the end support (3) of the coal mining face and the advance support (2) of the wind tunnel (1).

[0019] In this embodiment, the forced caving holes (5) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com