Extrusion roller sleeve of roller press

A technology of extrusion rollers and roller presses, which is applied in the direction of grain processing, etc., can solve the problems of premature peeling off of wear-resistant surfacing materials and insufficient wear resistance, so as to improve the comprehensive performance of wear resistance and impact resistance and prolong the service life , The effect of prolonging the life of the roller body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

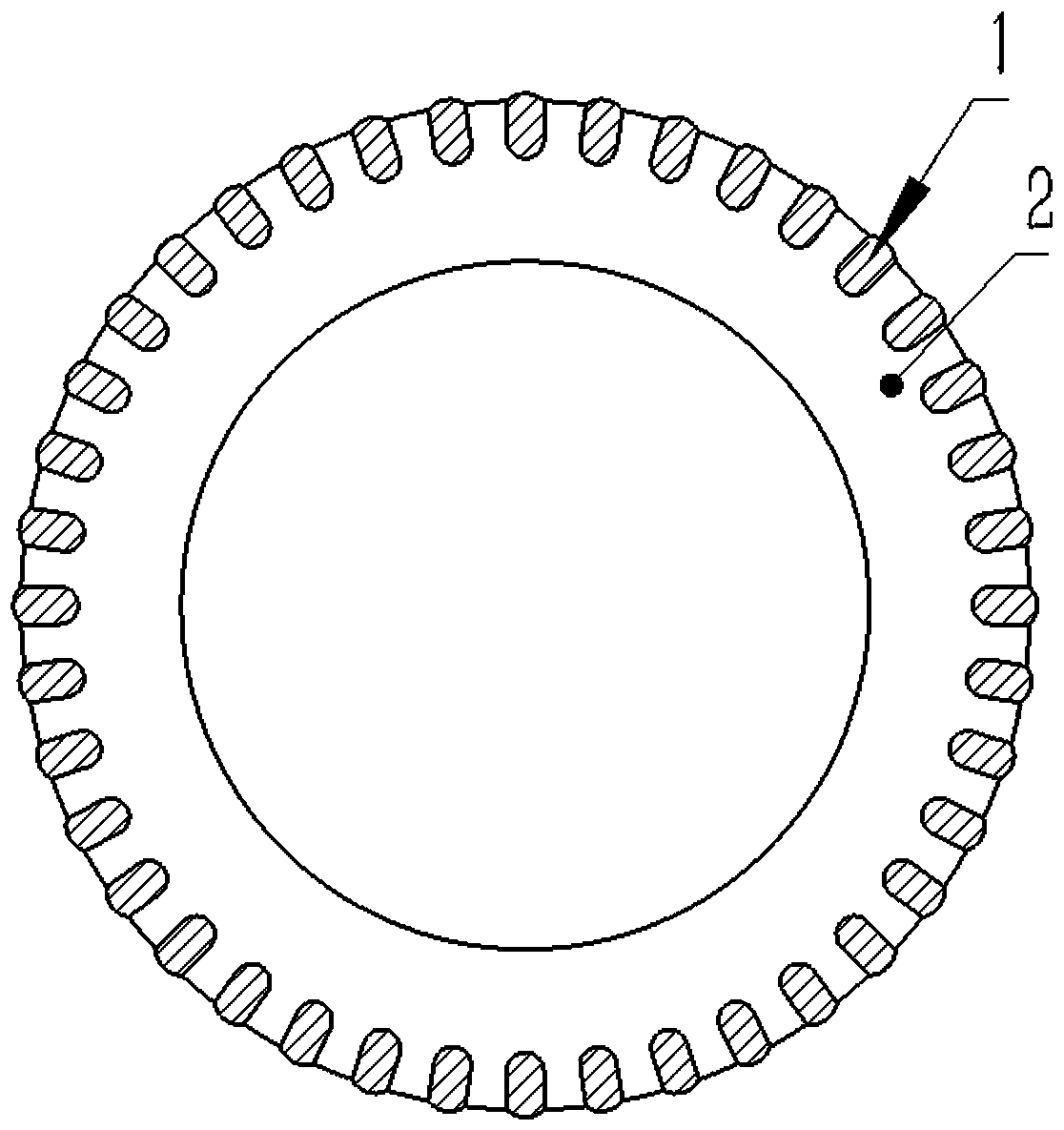

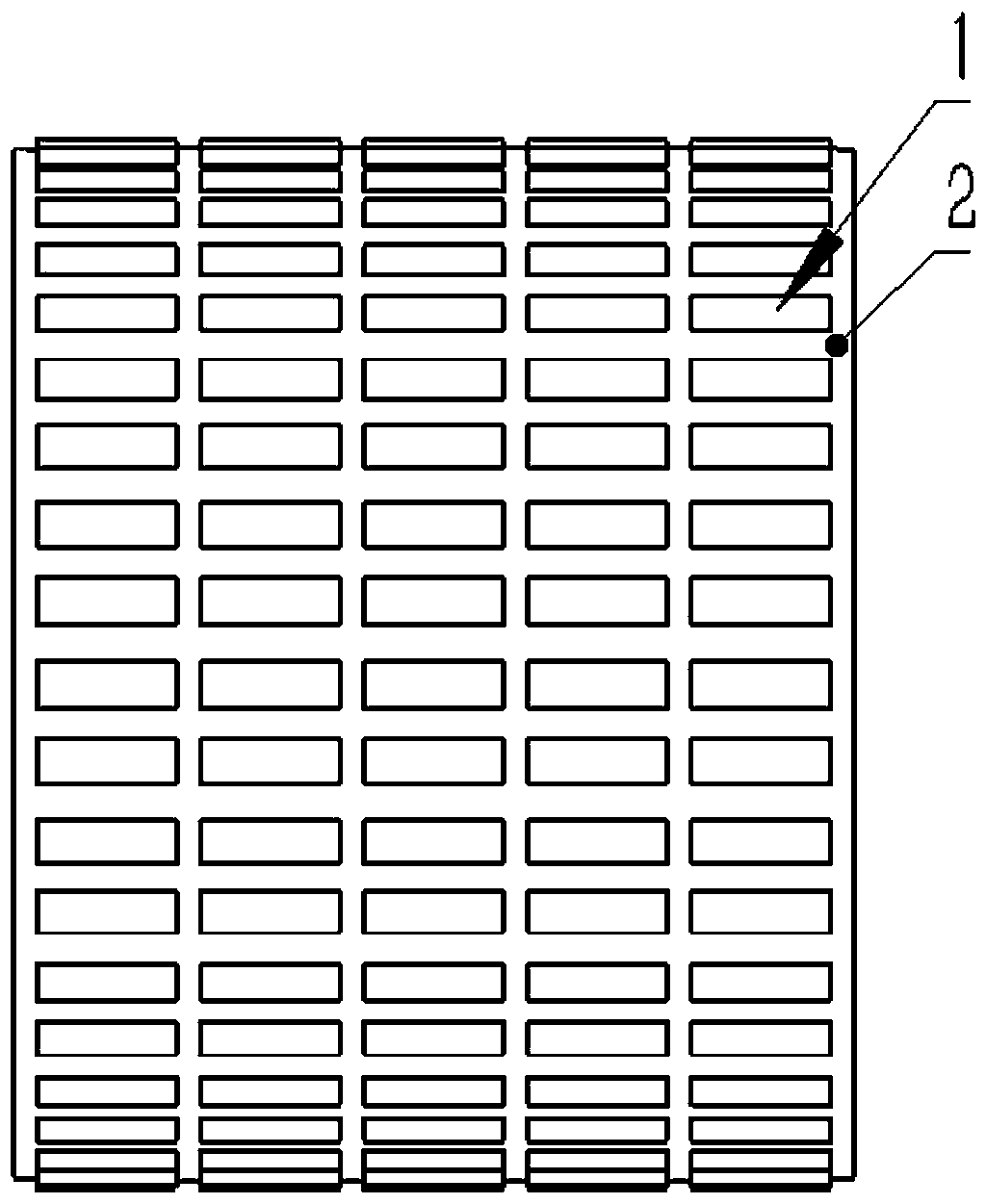

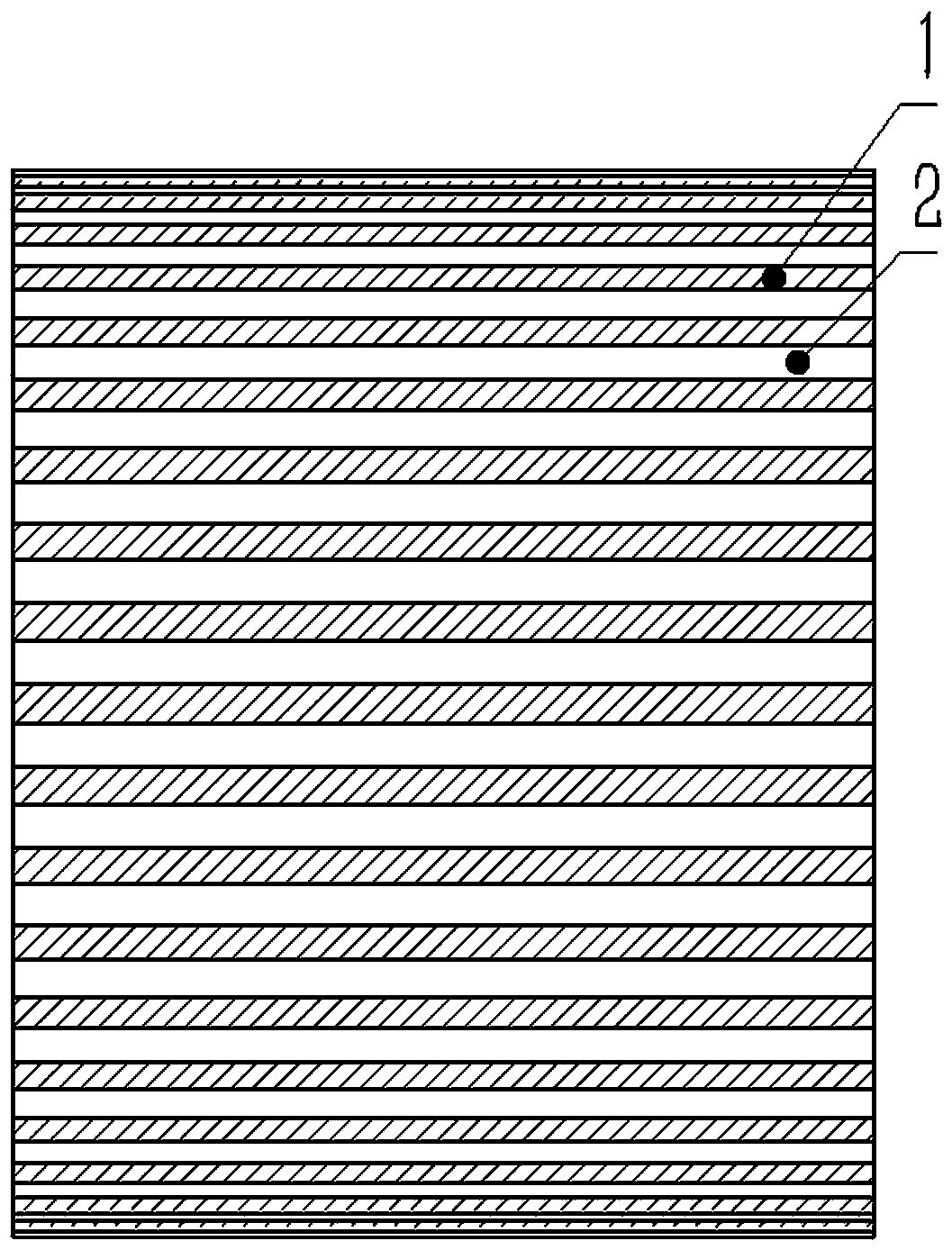

[0031] The squeeze roll sleeve of the rolling press of the present invention comprises a squeeze roll sleeve, and a plurality of grooves are uniformly distributed and processed on the outer surface of the squeeze roll sleeve. The wear-resistant material of 1-10mm on the surface of the roller body; the wear-resistant material can be commercially available such as: ZD310 or ZD903 wear-resistant flux-cored wire developed by Zhengzhou Machinery Research Institute Co., Ltd., and VAI Bole Welding Co., Ltd. SKC A43-O wear-resistant flux-cored welding wire or other surfacing welding materials with high wear resistance.

[0032] The cross-sectional shape of the groove in the present invention is any one of U-shaped, rectangular, V-shaped, trapezoidal or inverted trapezoidal structures.

[0033] The shape of the groove in the present invention can also be any suitable s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com