Drill bit and construction method for constructing one-time forming high-pressure rotary spraying soil anchor rod

A high-pressure rotary jet and drill bit technology, used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of long construction period, affecting the adhesion between cement slurry and soil, hindering the diffusion and penetration of cement slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

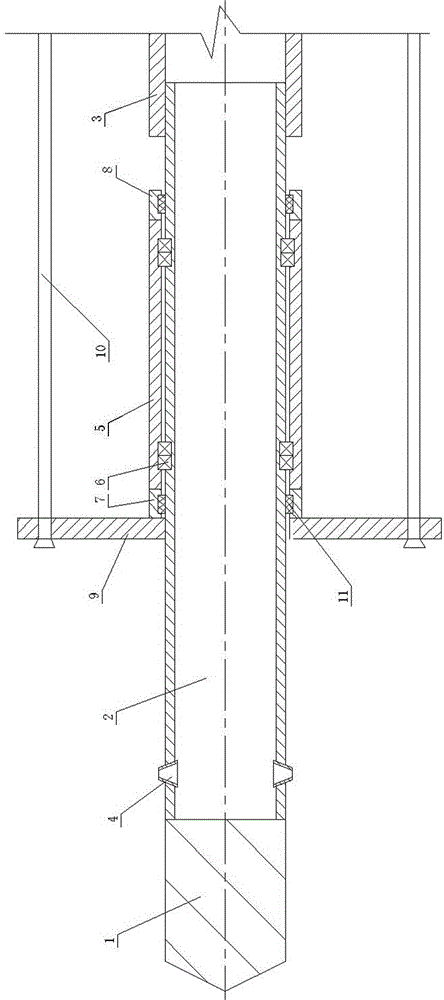

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] like figure 1 Shown, the present invention is used for the drill bit of the high-pressure rotary-spraying type soil bolt of construction once molding, and it comprises drill bit tip 1 and the drill bit pipe 2 with center hole. The drill tip 1 is welded and fixed to the front end of the drill pipe 2 . The drill pipe 2 is provided with an external thread for screwing with the drill pipe 3. Specifically, the rear section of the drill pipe 2 is provided with an external thread, the front section of the center hole of the drill pipe 3 is provided with an internal thread, and the rear section of the drill pipe 2 is provided with an external thread. It is screwed and fixed with the front section of the drill pipe 3 center hole. The rear end of the drilling rod 3 is connected with the hydraulic drilling rig. The drill pipe 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com