Hollow circular truncated cone spiral energy pile structure capable of improving heat transfer efficiency

A hollow circular platform and heat transfer efficiency technology, which is applied in the field of ground source heat pumps for building heating and cooling, and ground source heat pump systems. Small and other problems, to achieve the effect of reducing the amount of earthwork excavation, weakening the phenomenon of thermal short circuit, and increasing the heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

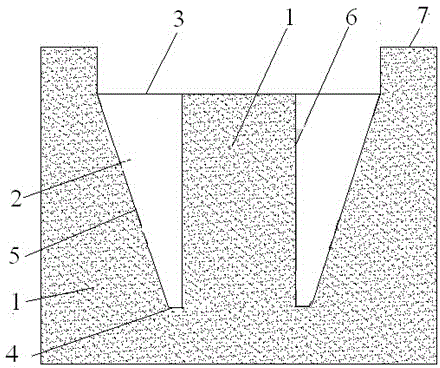

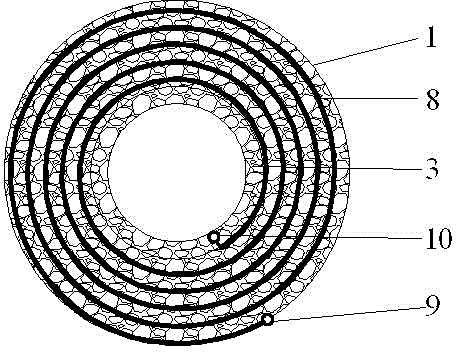

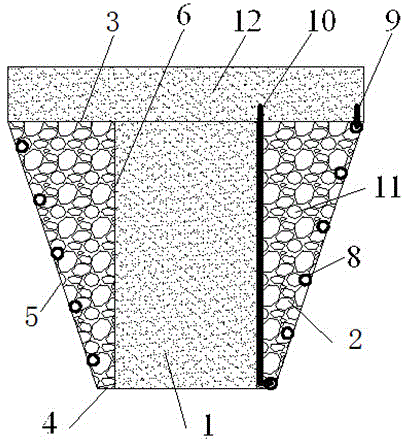

[0025] figure 1 As shown in the structure of the hollow circular platform energy pile well of the present invention, an energy pile well 2 is arranged in the soil layer 1, and the energy pile well 2 is in the shape of a truncated cone, an inverted conical shape; or a cylindrical truncated cone in the middle , the diameter of the upper bottom surface 3 of the energy pile is larger than the diameter of the lower bottom surface 4 of the energy pile; to ensure that the energy pile has a certain taper, thereby reducing the risk of the well wall collapse. The side curved surface 5 of the energy pile is a slope, and the inner wall surface 6 of the energy pile is vertical or inclined; the upper bottom surface 3 of the energy pile, the lower bottom surface 4 of the energy pile, the side curved surface 5 of the energy pile and the inner wall surface 6 of the energy pile constitute the middle part The cylindrical frustum-shaped energy pile well 2 has a trapezoidal cross-section, right-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com