Power transmission electric pole and manufacture method thereof

A manufacturing method and pole technology, applied to building types, buildings, towers, etc., can solve the problems of increasing the cost of power transmission, aggravating the damage process, and skewing the power transmission pole, so as to reduce the overall quality, improve stability, and increase strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

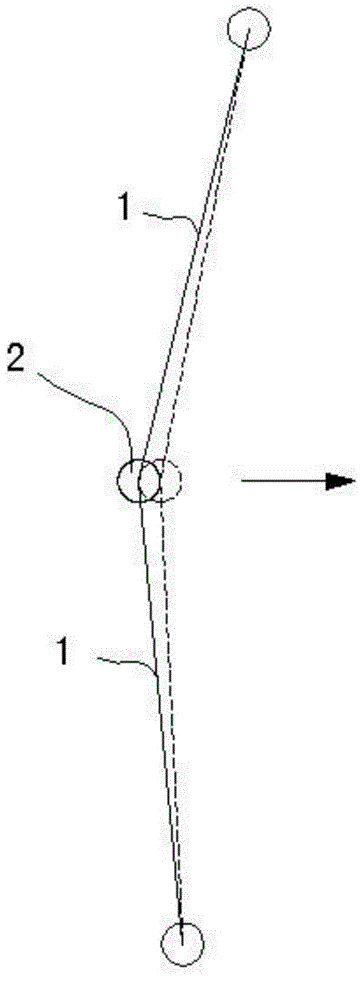

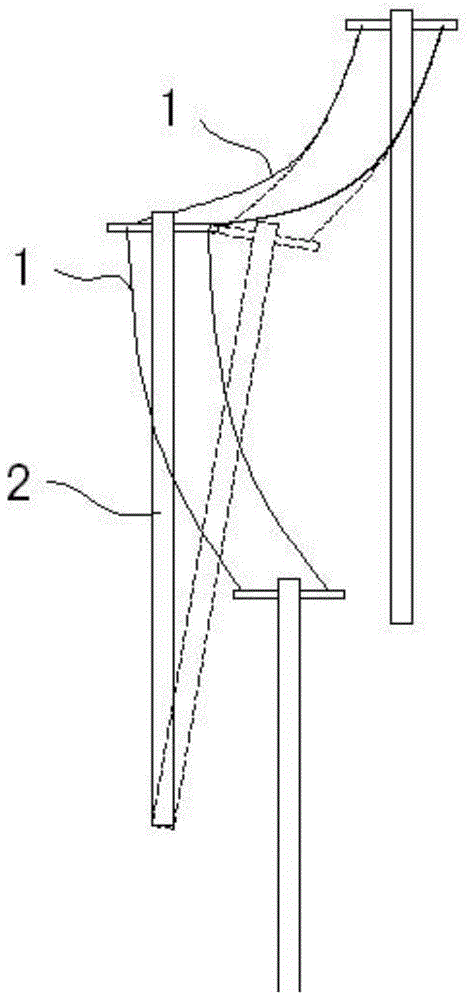

[0037] The present invention also provides the preparation method of the above-mentioned transmission pole, and its preparation process is as follows: Figure 8 As shown, polyurethane and fiber are used as raw materials in the preparation process, and the rod-making mold is used as the mold. The two ends of the rod-making mold are fixed and rotated around the fixed point as the axis. During the rotation of the rod-making mold, the Polyurethane and fibers are covered on the mold together until the raw materials cover the mold, then stop covering the mold, remove the mold and the raw materials covered on it, and bake at a temperature of 100°C to 140°C. The raw materials on the grill are slightly softened, and then the raw materials at both ends of the mold are cut, and the hair edges at both ends are cut off, and finally the mold is pulled out to obtain the transmission pole.

[0038] In the preparation process of the above-mentioned transmission poles, since the length of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com