Method for integrally folding semi-submersible drilling platform

A drilling platform and semi-submersible technology, applied in the direction of floating buildings, etc., can solve the problems of high water depth and sea surface calmness, barge size limitation, and long time in the dock, so as to reduce the number of high-altitude hoisting operations and alignment Precise, time-saving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

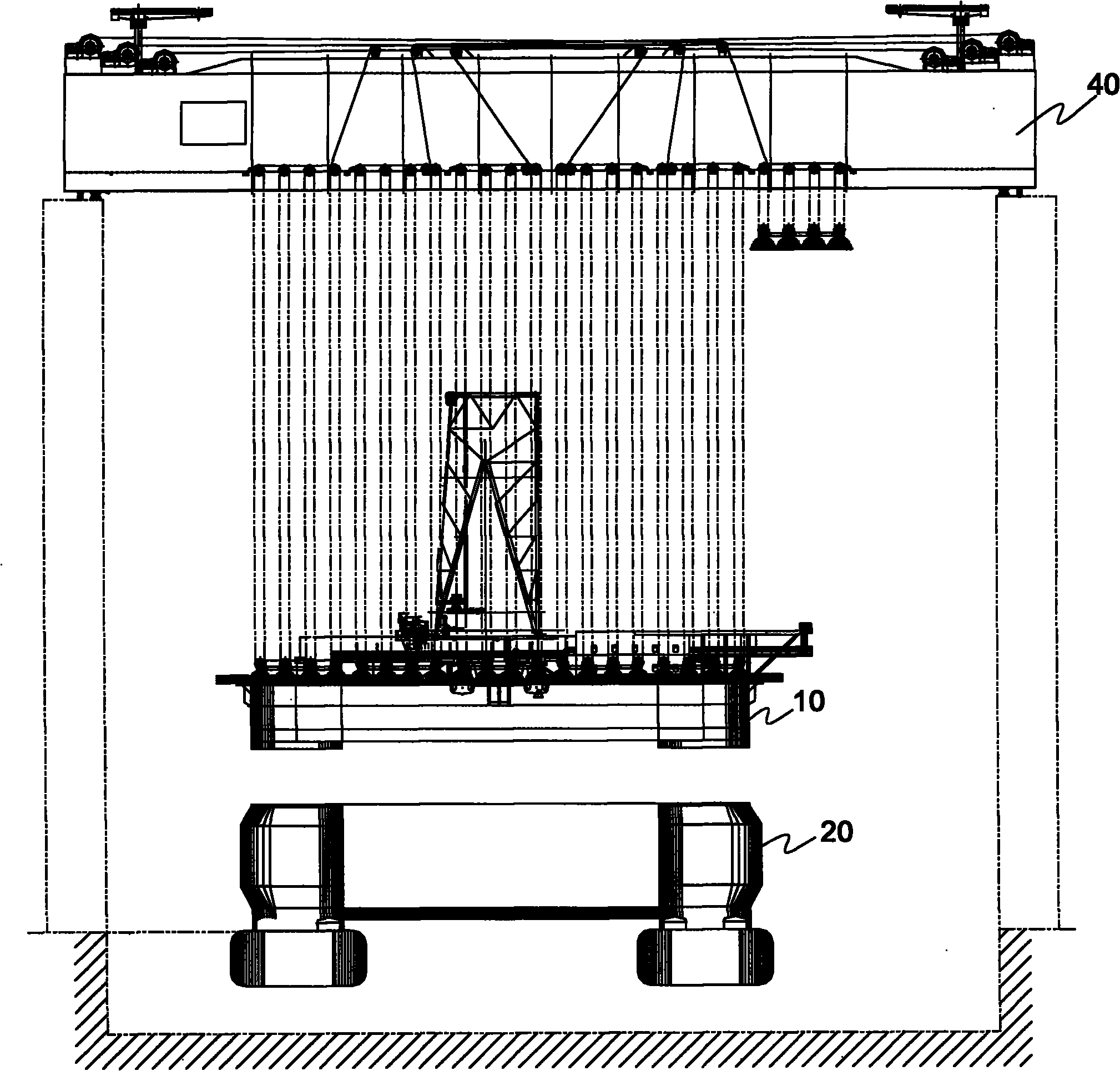

[0058]The overall closing method of the semi-submersible drilling platform of the present invention is used to close the built upper hull and lower hull into a whole ship. It should be noted that the upper and lower hulls here can be constructed at the same time respectively, so as to shorten the platform construction period .

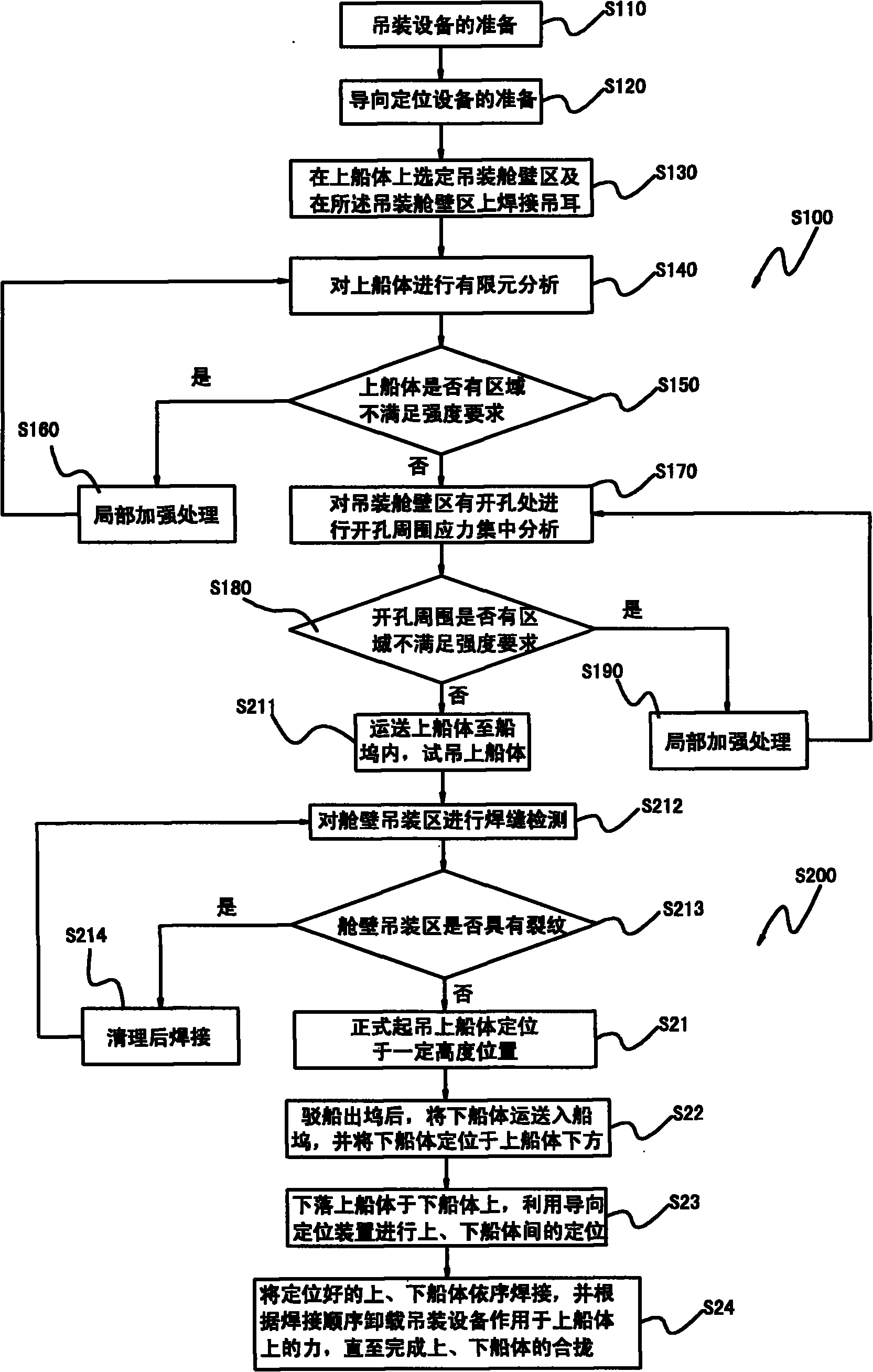

[0059] refer to figure 1 and combine figure 2 , The overall closing method of the semi-submersible drilling platform of the present invention includes two steps: the preparation step S100 before closing and the on-site hoisting and closing step S200.

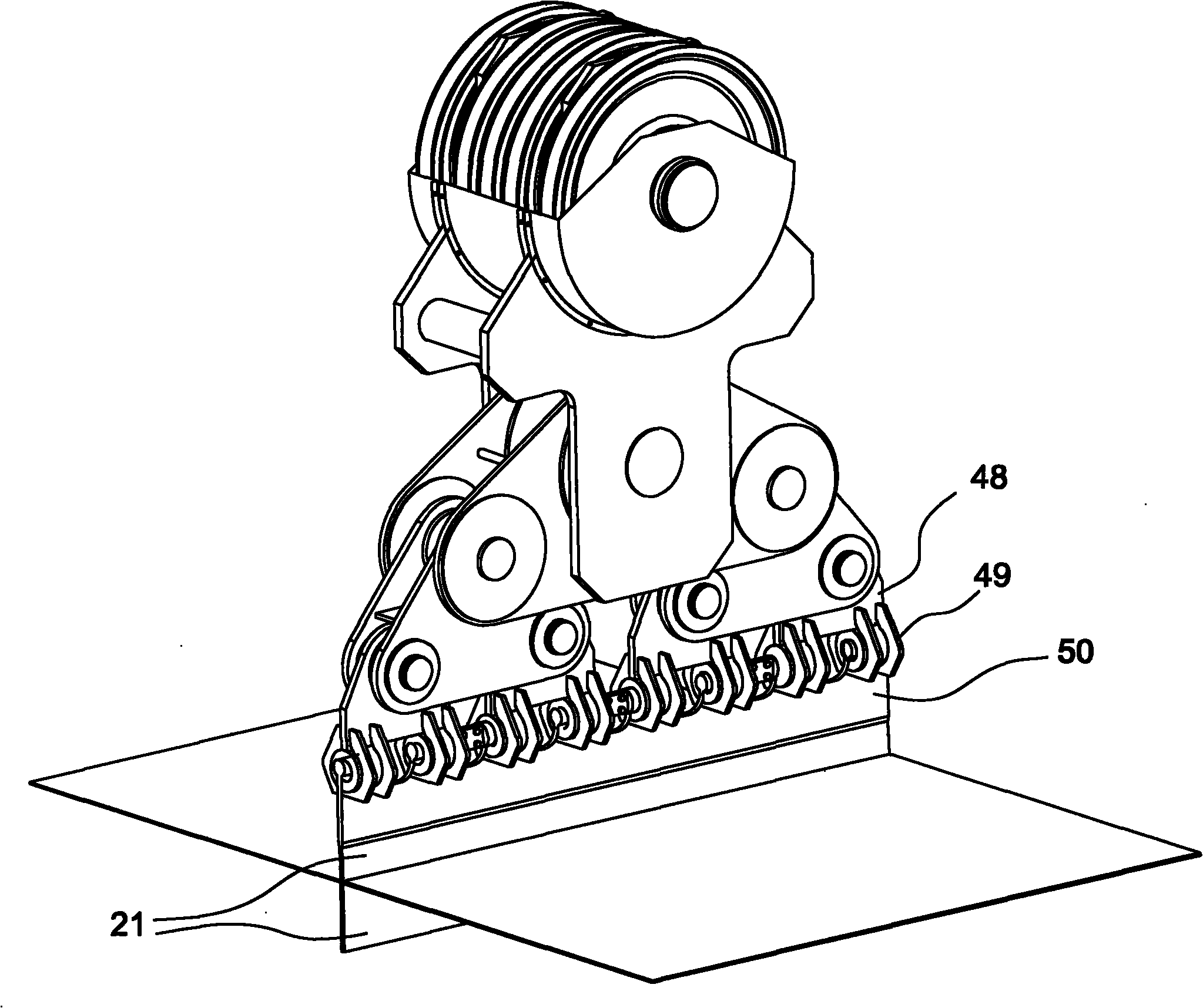

[0060] Specifically, the preparatory step S100 before fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com