Construction method for ocean platform

A construction method and technology for offshore platforms, applied in the field of construction of offshore platforms, can solve the problems of high water depth and sea surface calmness, long time in the dock, high cost, etc., and achieve the goals of shortening the platform construction period, good economy, and saving time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

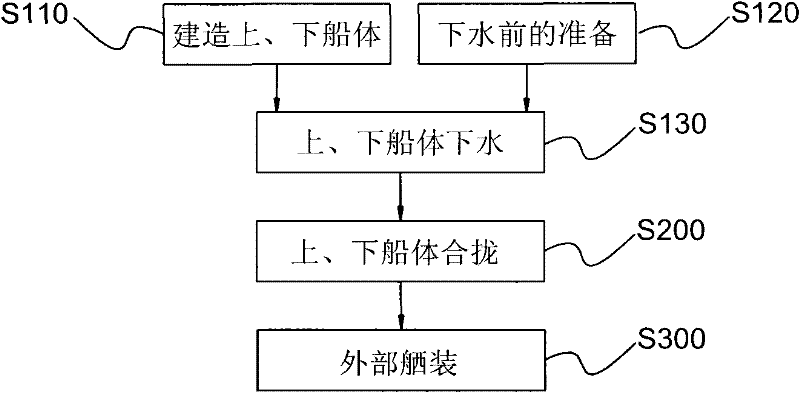

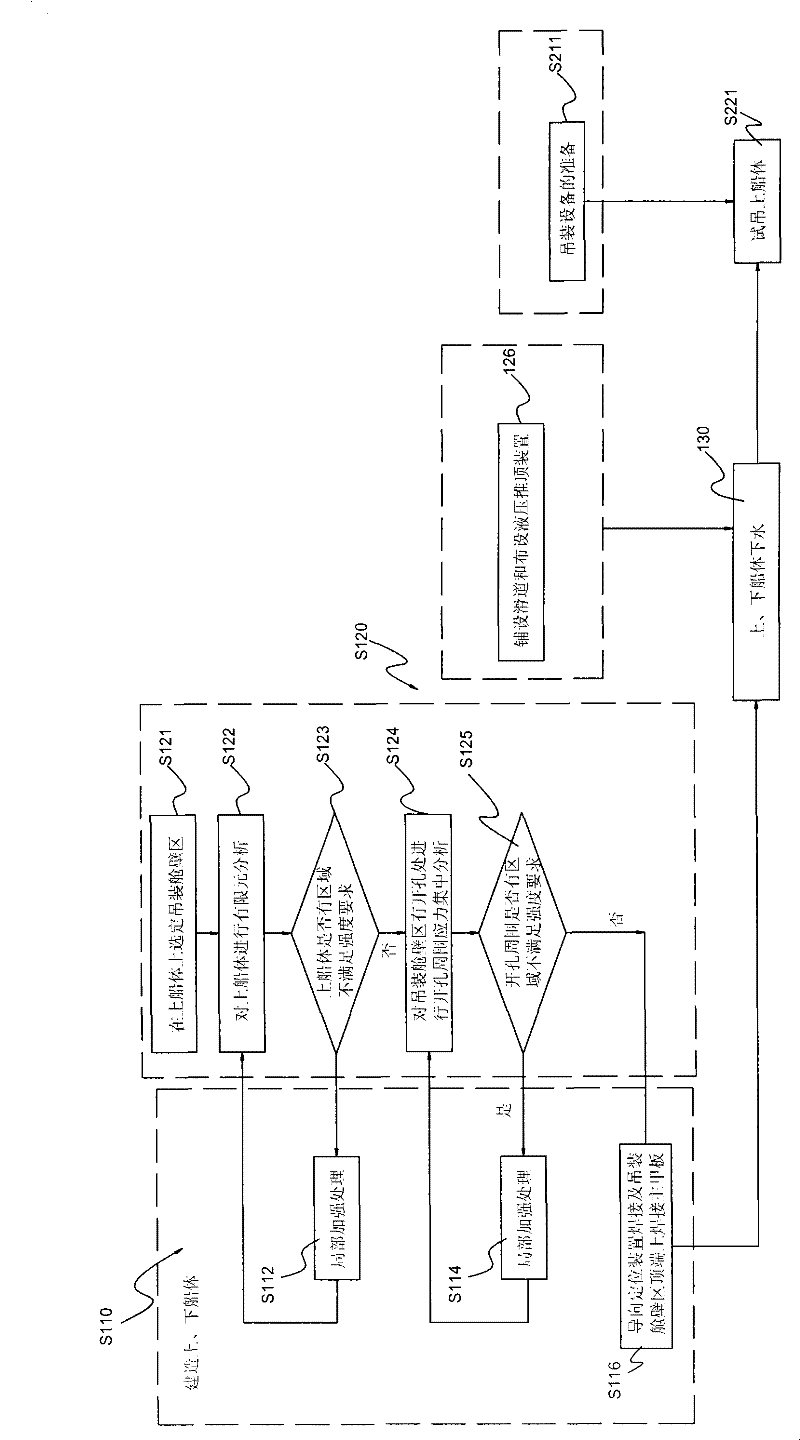

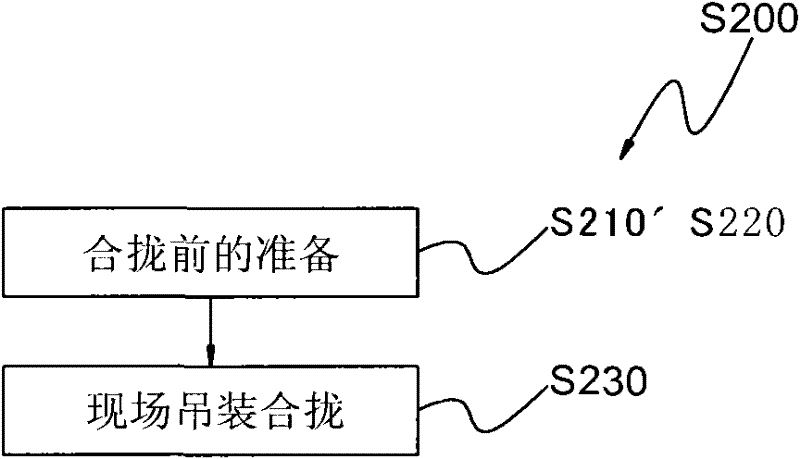

[0093] Such as figure 1 As shown, the offshore platform construction method of the present invention includes the step S110 of building the upper and lower hulls, the preparation step S120 before launching, the step 130 of launching the upper and lower hulls, the step S200 of closing the upper and lower hulls, and the step S300 of external outfitting. It should be noted that, in the process of implementing the step S200 of closing the upper and lower hulls, it is necessary to adopt the guiding and positioning device 300 and the hoisting arrangement 40 described later (see Figure 11 and Figure 13 ).

[0094] In order to shorten the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com