MOPU building method

A construction method and segmented construction technology, applied in ship construction, floating buildings, ship parts, etc., can solve the problems of long construction period and high construction cost of MOPU, avoid the use of large hoisting equipment, reduce labor costs, improve The effect of operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

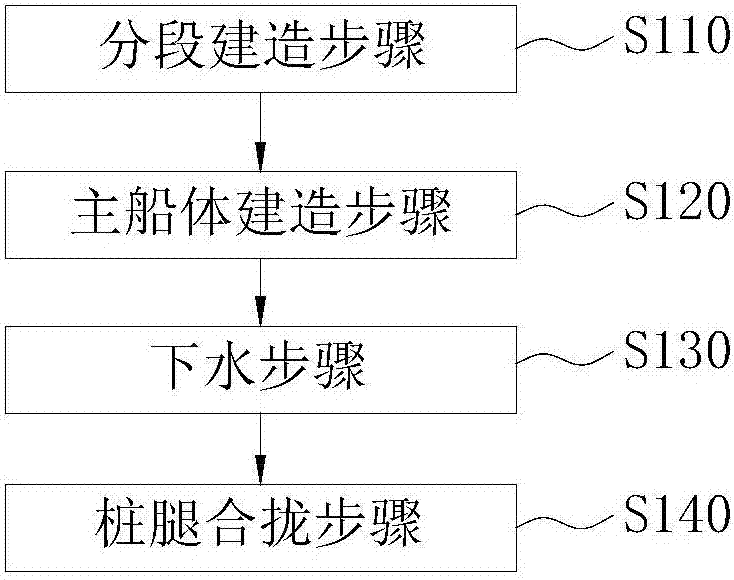

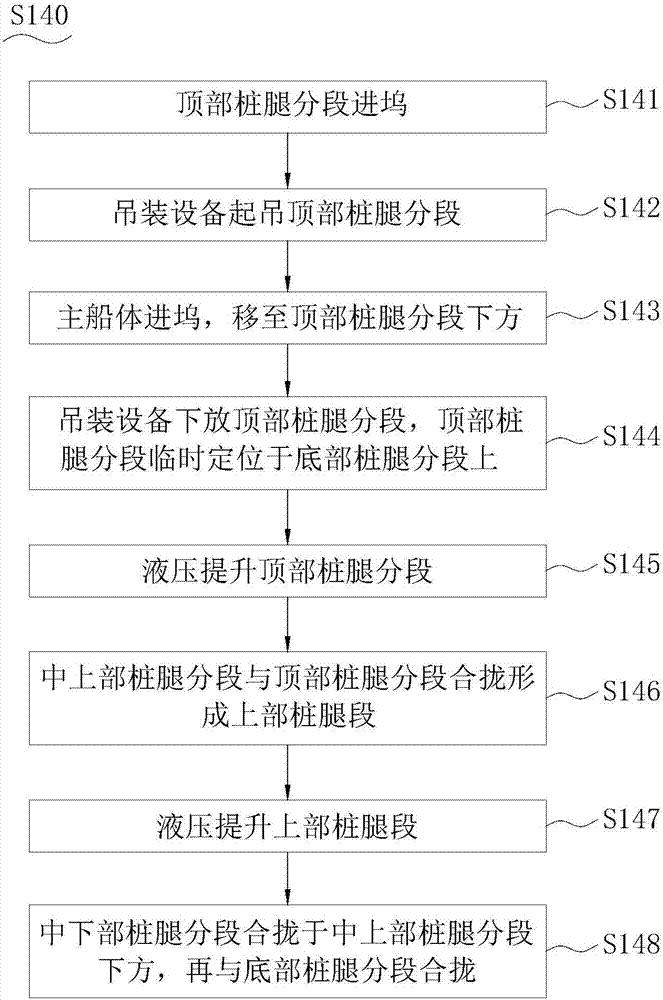

[0033] refer to figure 1 , the construction method of the MOPU provided by the preferred embodiment of the present invention includes:

[0034] S110. Segmented construction step: build sinker box segments, deck box segments, and leg segments respectively, wherein the leg segments include bottom leg segments, top leg segments, and multi-section middle leg segments part;

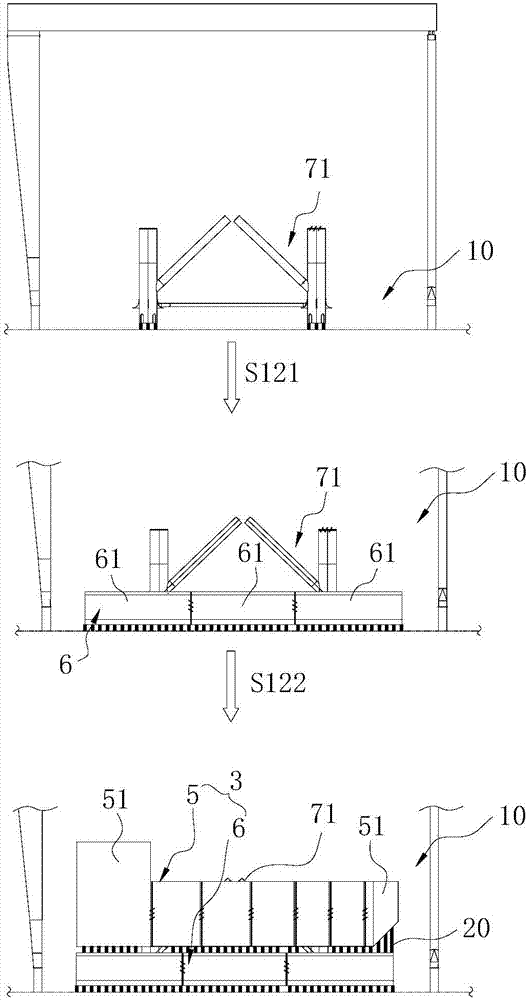

[0035] S120, the main hull construction step: based on the sectioned legs at the bottom, close up the sinkers in sections to form a sinker, close up the deck boxes on the sinker to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com