Bogie for railway wagon with integral low bearing surface and railway wagon

A railway freight car and bearing surface technology, which is applied to bogies, railway car body components, devices for lateral relative movement between the underframe and the bogie, etc. Vibration function, avoid the overall lifting, ensure the effect of running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

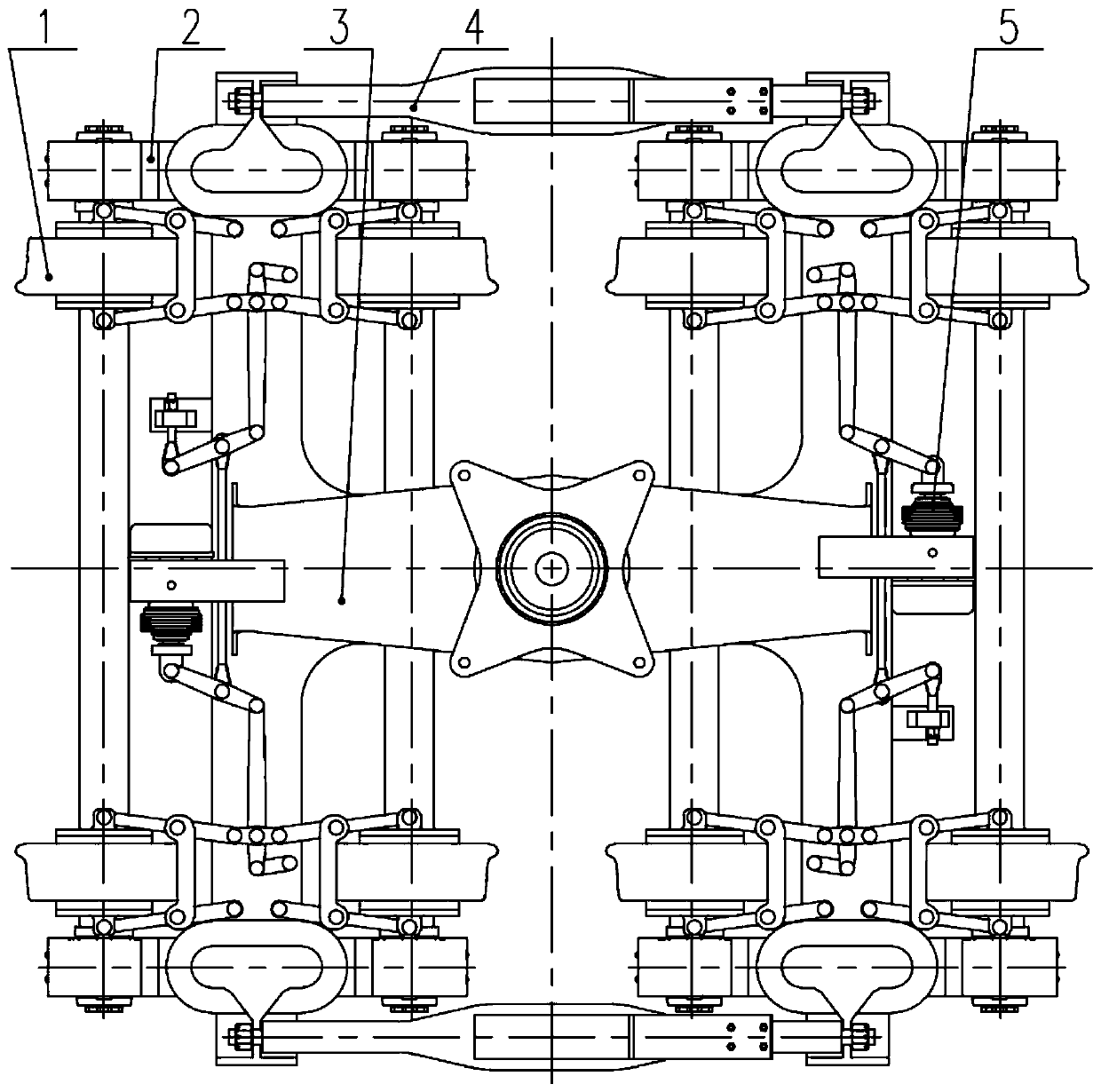

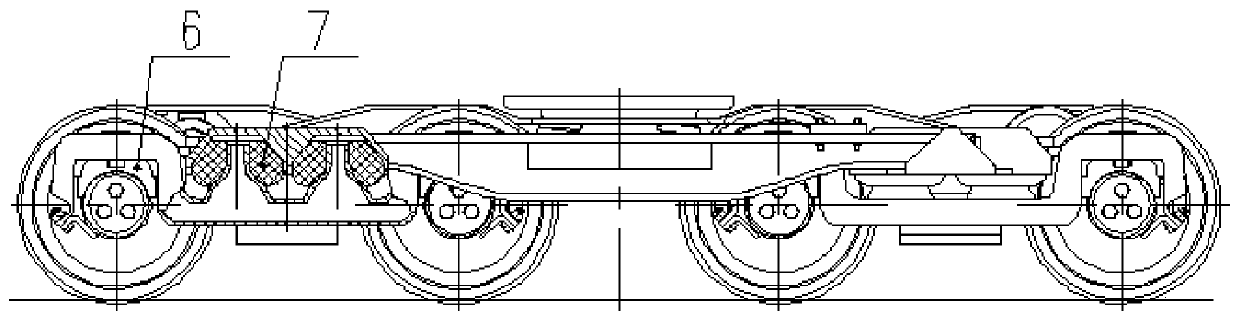

[0036] In a typical embodiment of the present invention, such as figure 1 , figure 2 shown. The present invention includes a wheel axle 1, a side beam 2, a frame 3, a side bearing 4, a braking device 5, a bearing saddle 6, and a suspension spring 7;

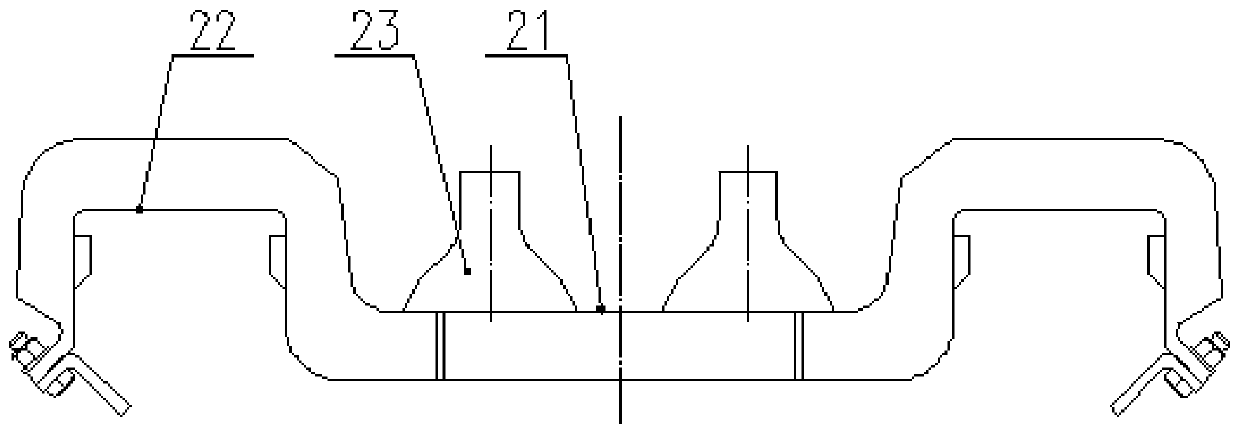

[0037] The frame 3 is composed of a longitudinal beam and two cross beams, the two cross beams are symmetrically installed on the longitudinal beam, the two cross beams are parallel to each other and perpendicular to the longitudinal beam; the middle part of the longitudinal beam is A concave structure, in which a center disk device is set; on both sides of each beam there is a wheel shaft 1 parallel to it, and the wheel shafts 1 on both sides of the beam are connected together by side beams 2; the side beams The beam 2 is a U-shaped structure with a concave middle part, with guide frames matched with the axle at both ends, and a spring seat in the middle; the frame 3 is loaded on the spring seats of the four side beams throug...

Embodiment 2

[0056] This embodiment discloses a railway freight car. The bogie part of the railway freight car adopts the same structure as that of Embodiment 1, and the structure adopts the existing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com