Novel hole-pattern heavy-duty goods shelf stand column and manufacturing method thereof

A technology for shelf columns and manufacturing methods, which is applied in the field of new-hole heavy-duty shelf columns and its manufacturing, can solve the problems of complex production process, insufficient strength, and impact on the load-bearing capacity of shelves, so as to improve utilization rate and safety, prevent structural Deformation, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

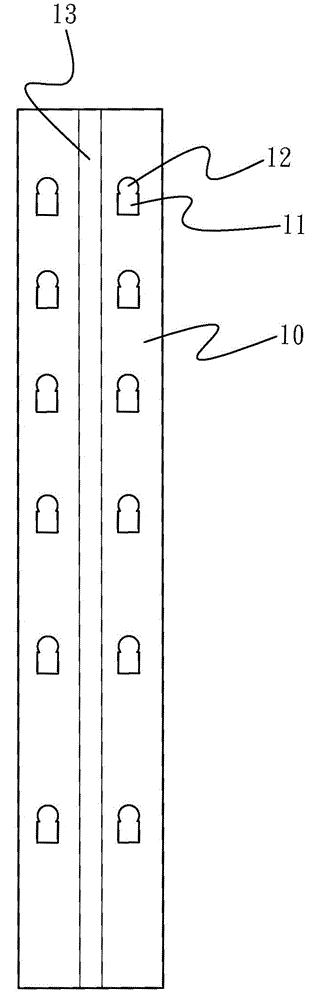

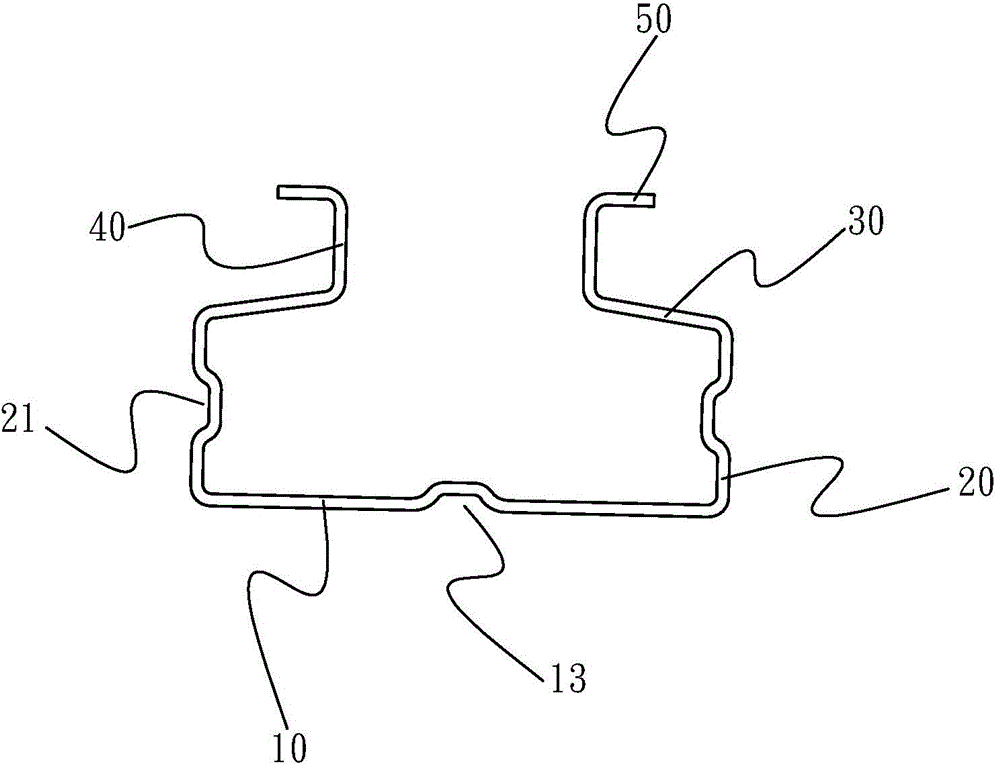

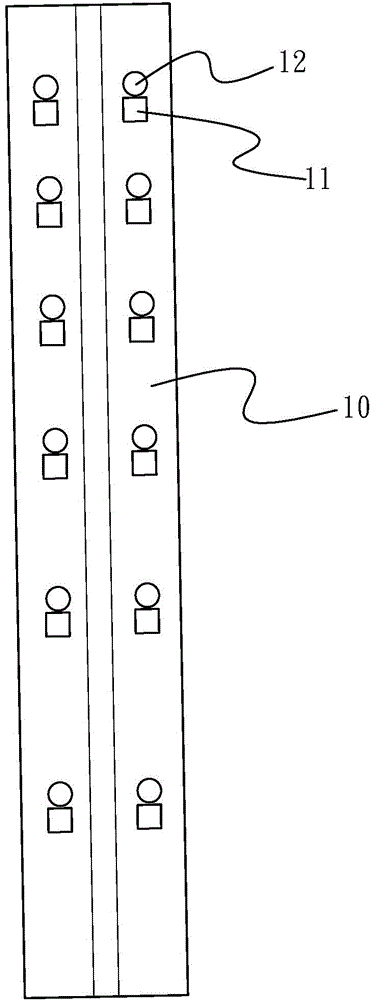

[0028] see figure 1 and figure 2 In the present invention, a new hole-type heavy-duty shelf column has a vertically extending column body 10, two opposite first connecting parts 20 formed by extending in the same direction from the two side edges of the column body 10, and respectively formed by the first The two second connecting portions 30 extending from the side of the connecting portion 20 away from the main body of the column close to each other, and the two clamping portions 40 respectively extending from the sides of the second connecting portion 30 away from the main body of the column in the same direction. The column of the new hole type heavy-duty shelf is applied on the shelf, and the shelf also includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com