Enhanced heat transfer fin and production process thereof

A technology to strengthen heat transfer and fins, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of low production efficiency of fins, the uniformity of process structure parameters is not easy to be guaranteed, etc. High production efficiency, lower drag coefficient, and enhanced heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

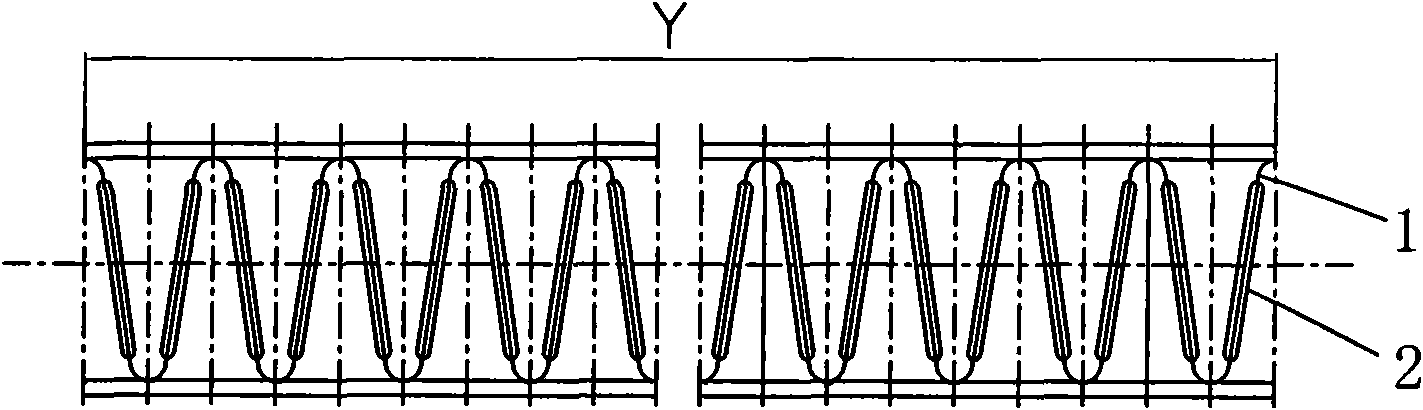

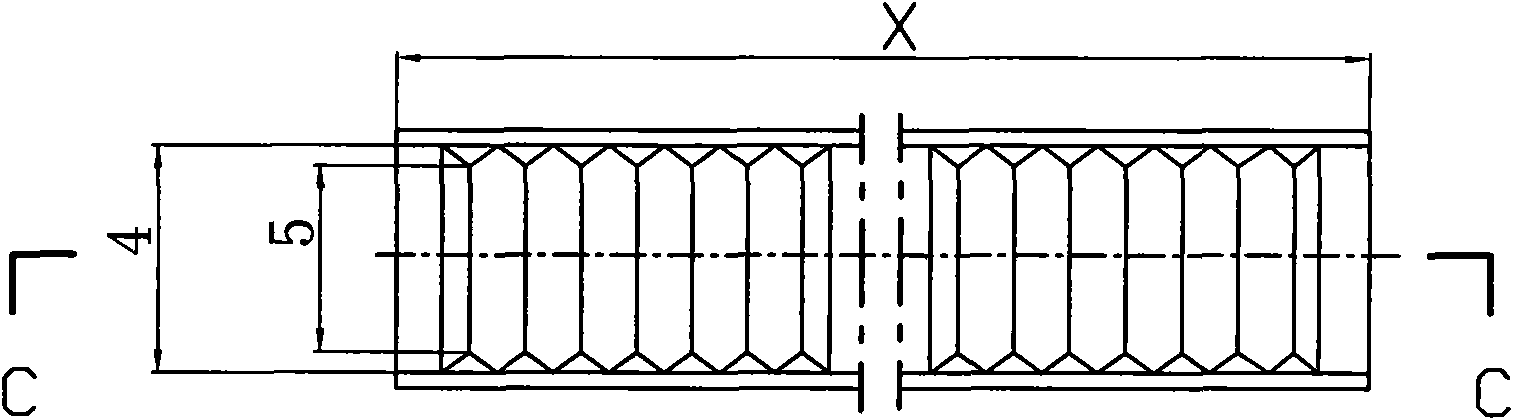

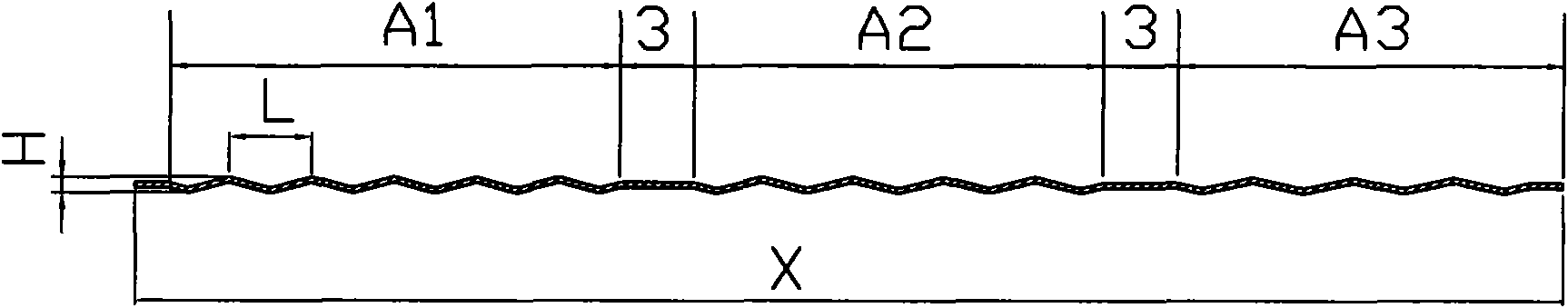

[0027] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-4 :

[0028] Enhanced heat transfer fins, including a flat substrate 1, formed on the flat substrate with corrugated fins 2 that protrude from the straight substrate 1 and form a certain angle with the flat substrate 1, and several corrugated fins 2 is provided with a reversing area 3, and the reversing area 3 divides the corrugated fins into several groups of corrugated fin areas A1, A2, A3 with different numbers of corrugations, and the wavelength L and amplitude H of each corrugated fin in each group The number of corrugated fins 2 in different groups and the wavelength L are not equal. The number of corrugated fins in the areas A1, A2, and A3 of each group of corrugated fins decreases in turn within the entire fin length X, and the wavelength L in turn Increase.

[0029] The unequal number of corrugated fins in the areas A1, A2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com