Electron beam welding method applicable to small-diameter flange plates on thin-wall top cover

An electron beam welding, small-diameter technology, applied in the direction of electron beam welding equipment, welding equipment, workpiece edge, etc., can solve the problem of low weight, achieve the effect of ensuring assembly accuracy and welding quality, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] An electron beam welding method suitable for small-diameter flanges with thin-walled roofs, such as image 3 As shown, the surface of the top cover is a rotating ellipsoidal surface, the opening of the top cover is the normal direction of the ellipsoidal surface, N flanges are distributed at different positions from the center of the ellipsoidal surface axis, N≥4, N The distance between the center of a flange and the axis center of the ellipsoidal surface is 480mm and 500mm;

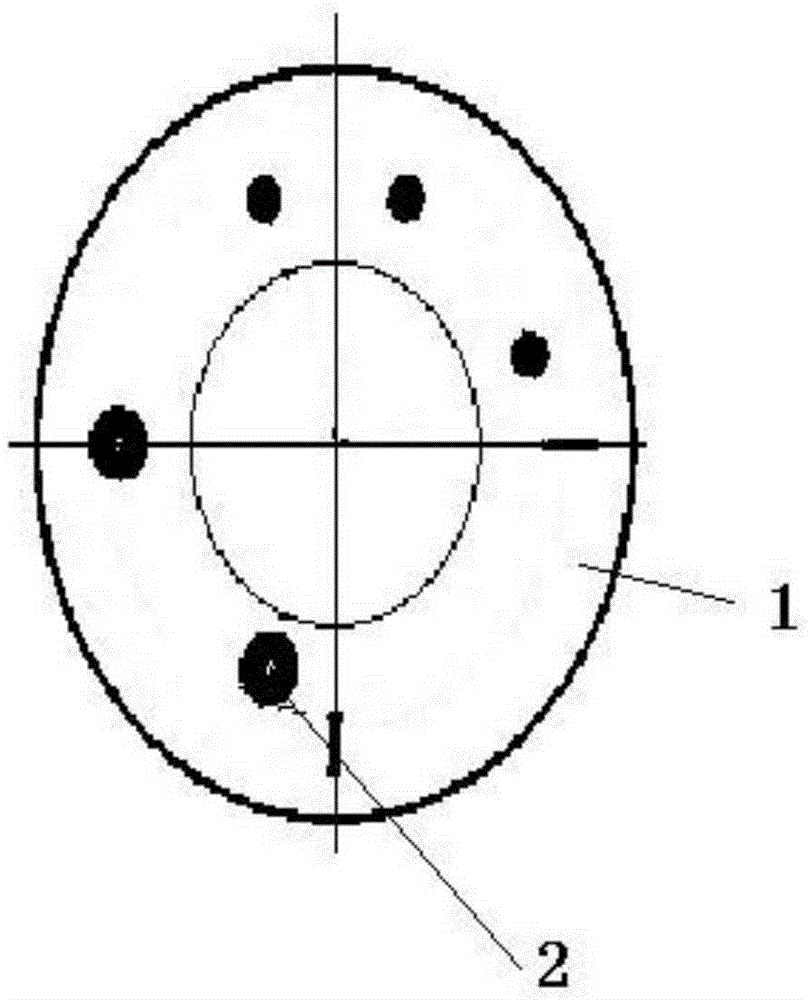

[0053] The theoretical surface of the top cover is an ellipsoidal surface, such as Figure 7 As shown, let the bus equation be Draw an ellipse according to the busbar equation; set point O as the center point of the ellipse, point P as the tangent point of the center of the flange on the ellipse of the top cover, is the tang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com