Exhaust gas recirculation (EGR) cooler core body

A technology of EGR cooler and core body, which is applied to machines/engines, adding non-fuel substances to fuel, internal combustion piston engines, etc., which can solve the problem of not reaching the brazing assembly gap, unable to guarantee the brazing dimensional accuracy, EGR cooler Solve problems such as leakage at brazing joints, and achieve the effects of low production cost, easy maintenance, simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

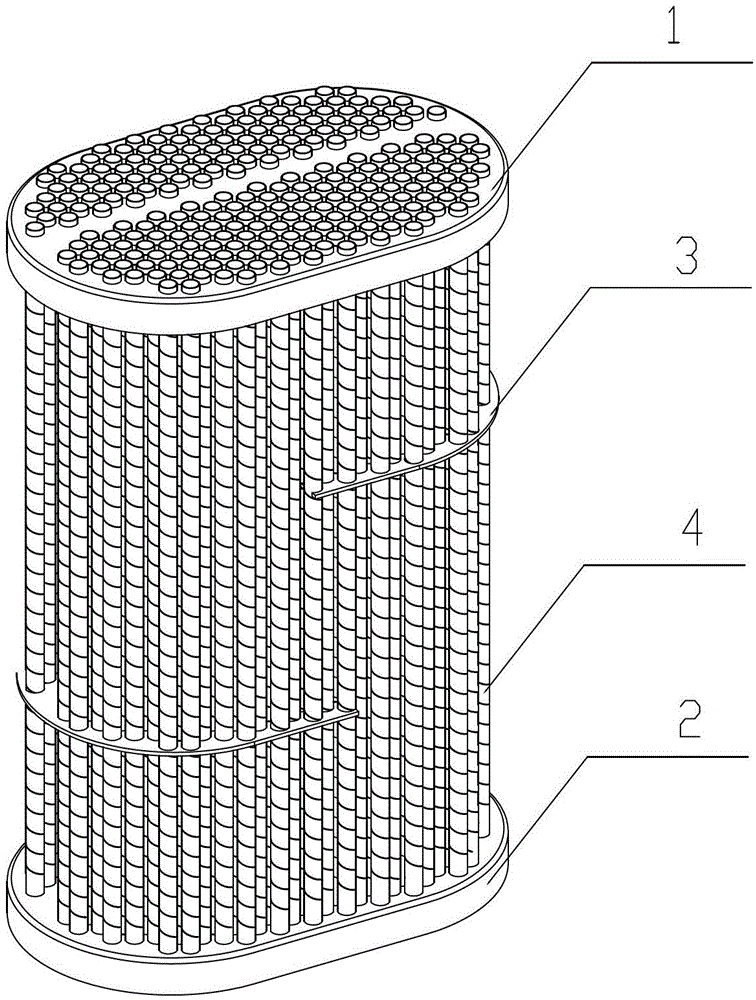

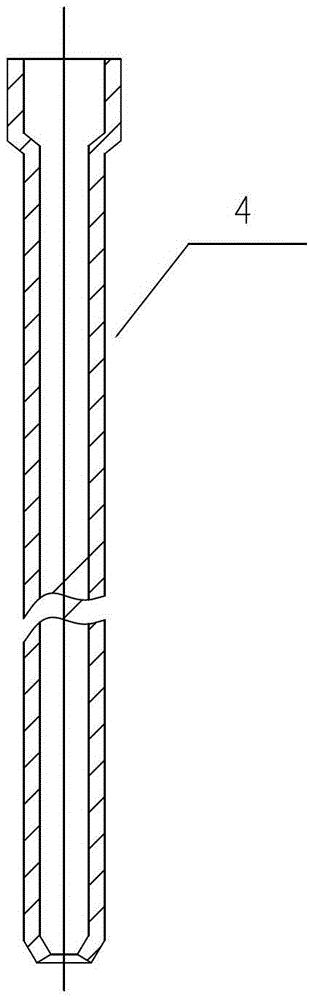

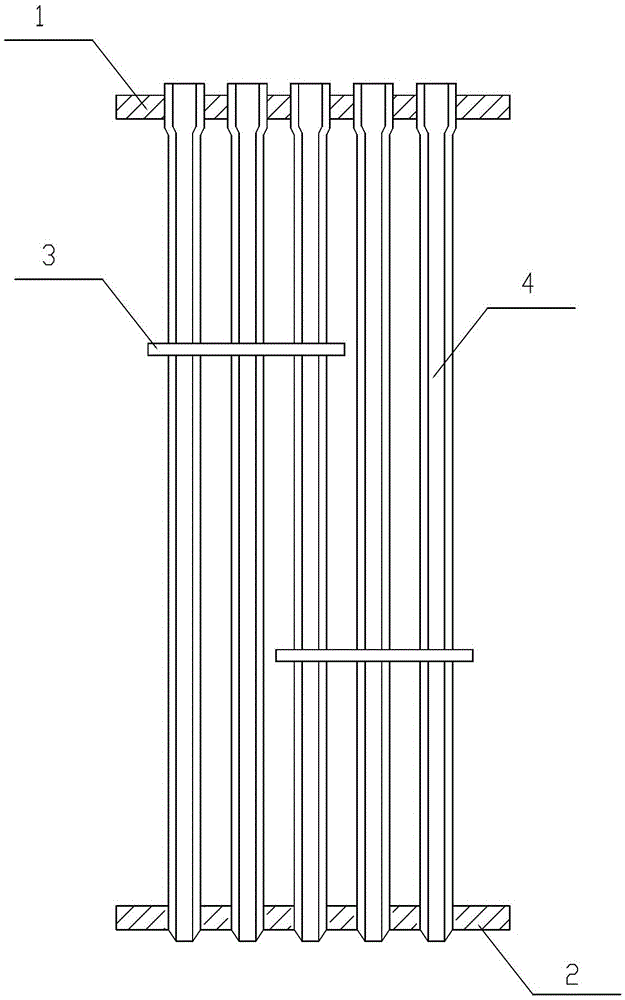

[0012] figure 1 , 2 , 3, including the upper fixed plate 1, the lower fixed plate 2, the deflector 3, the threaded pipe 4 and so on.

[0013] like figure 1 As shown, the present invention is a core body of an EGR cooler, comprising an upper fixing plate 1 and a lower fixing plate 2, the two ends of the threaded pipe 4 are respectively fixed in the through holes of the upper fixing plate 1 and the lower fixing plate 2, and the deflector 3 is fixed on the threaded pipe 4, the threaded pipe 4 is fixed on the upper fixing plate 1 and has a flared structure at one end, and one end fixed on the lower fixing plate 2 has a shrinking structure, and the diameter of the flared structure of the threaded pipe 4 is larger than that of the upper fixing plate 1 the diameter of the through hole, the diameter of the necking structure of the threaded pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com