Patents

Literature

207 results about "Neck structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

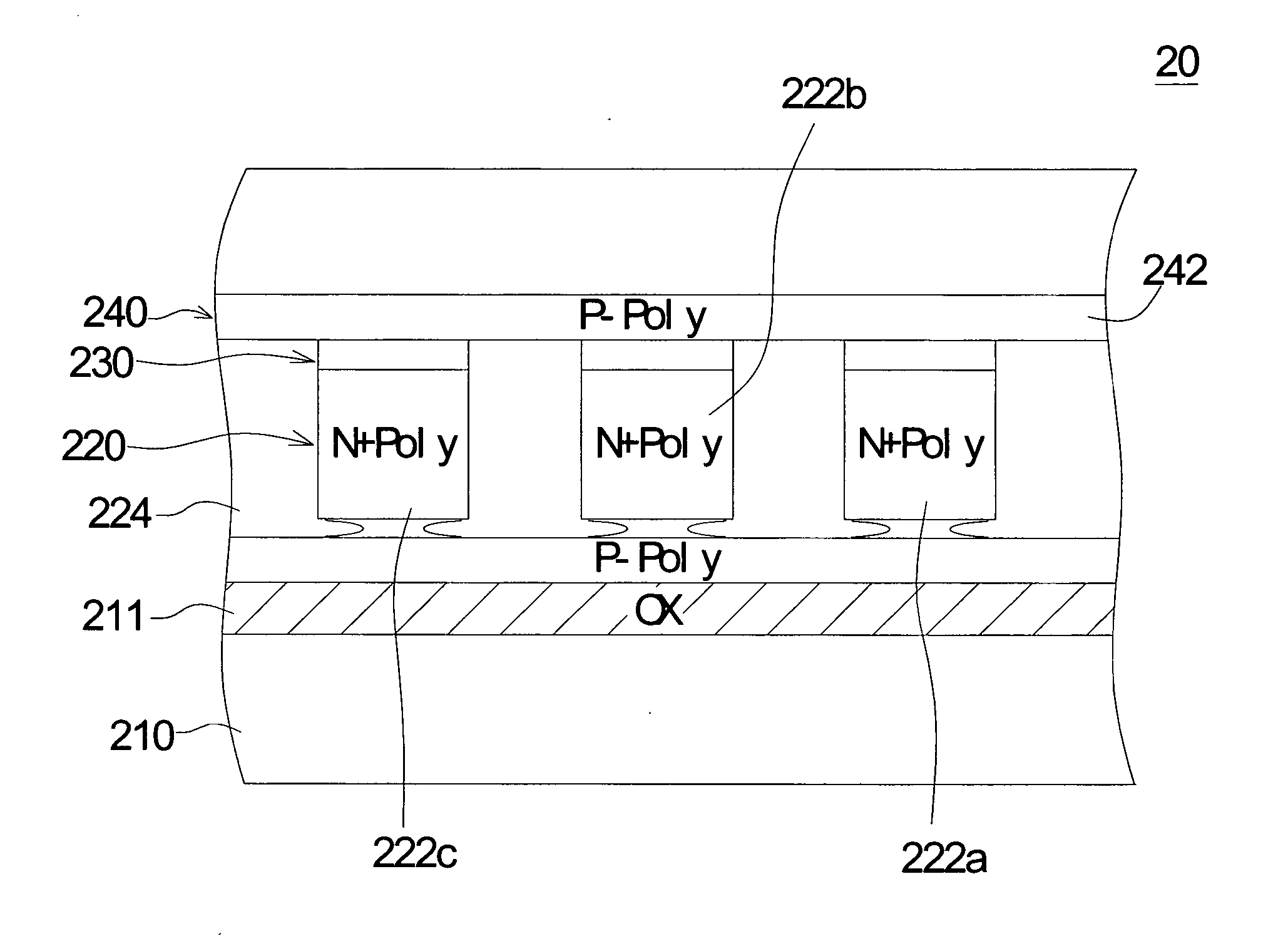

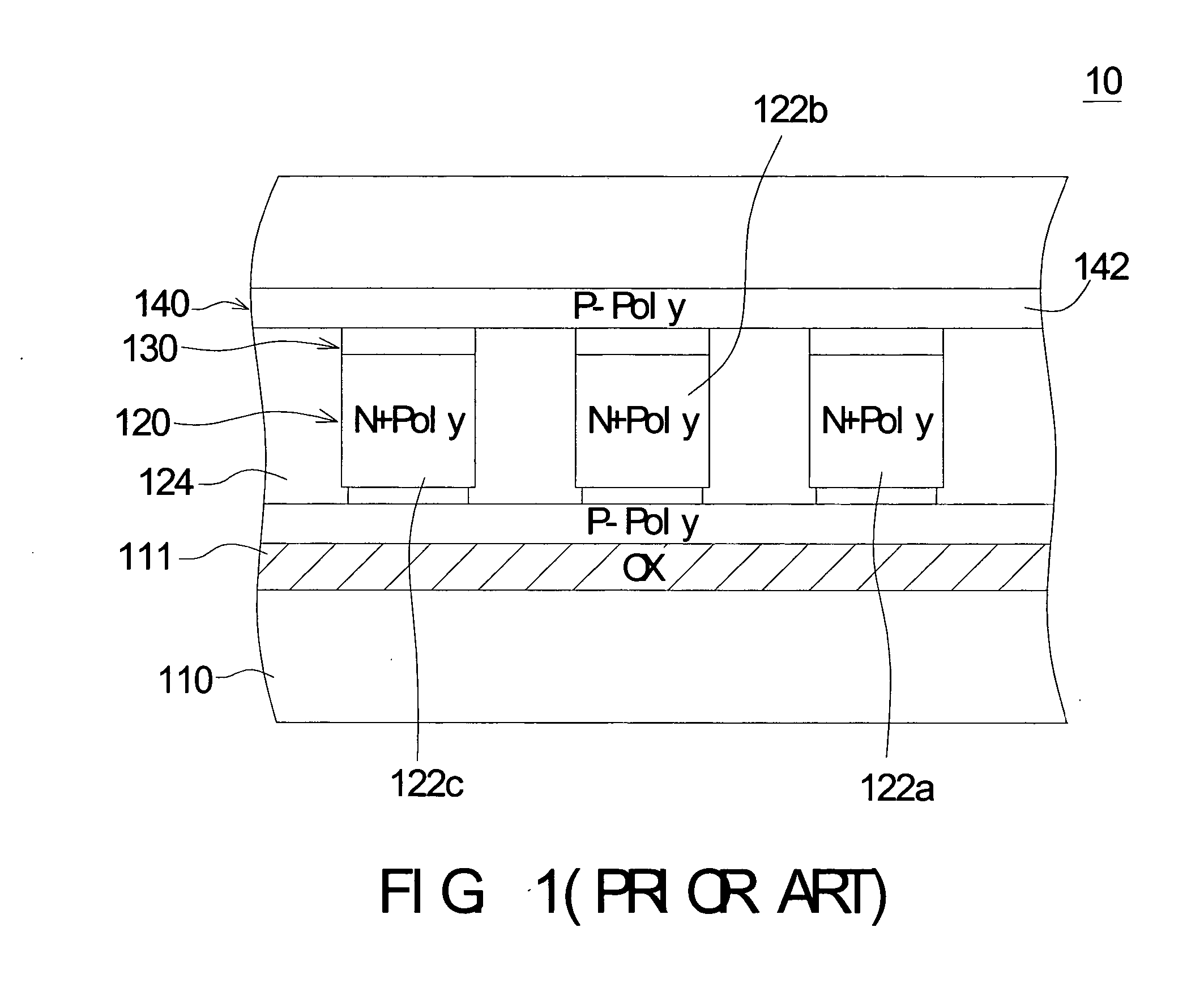

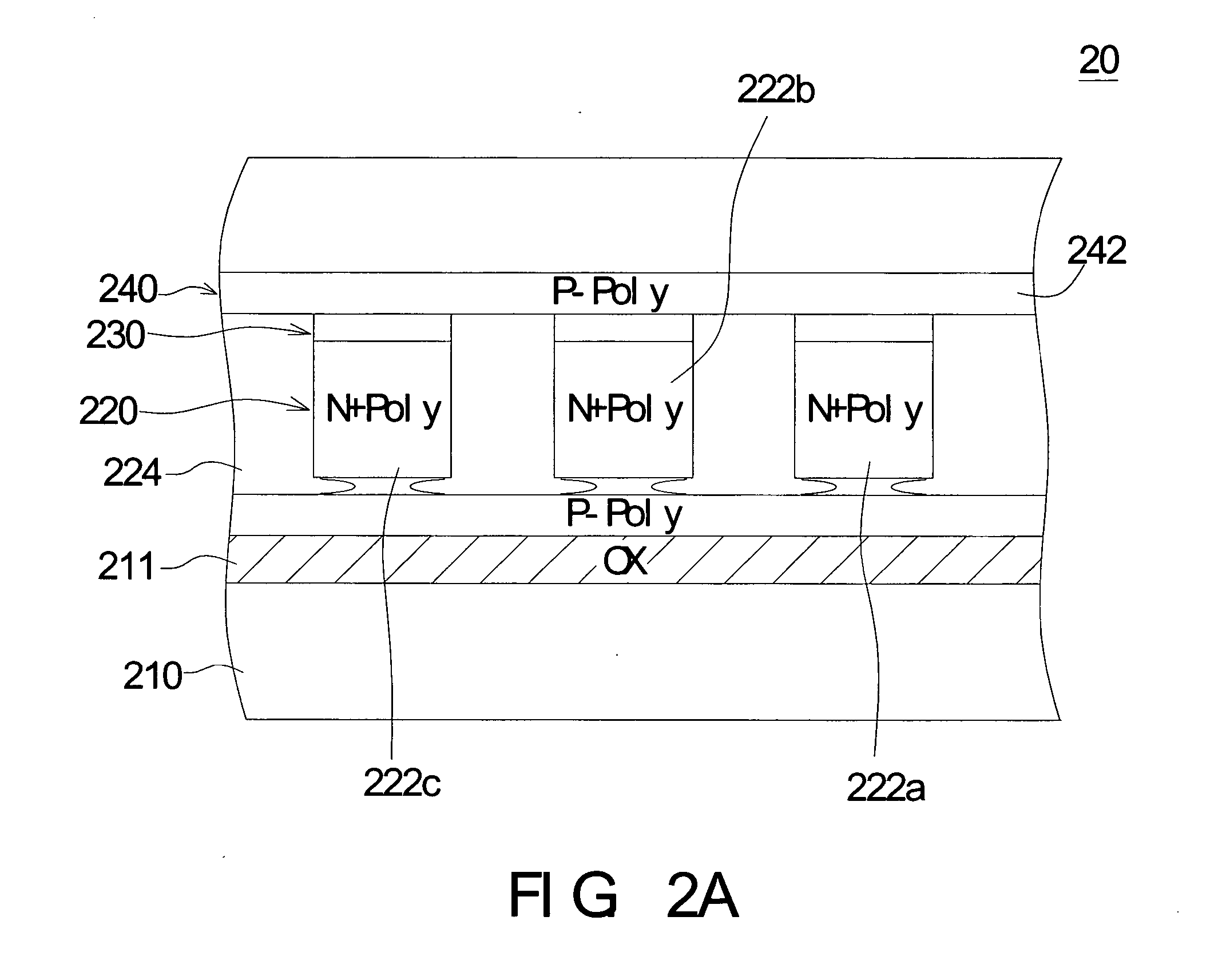

3D polysilicon ROM and method of fabrication thereof

ActiveUS20050124116A1Lower requirementYield in processing can be improvedTransistorSolid-state devicesHydrofluoric acidNeck structure

A 3D polysilicon read only memory at least including: a silicon substrate, an isolated silicon dioxide (SiO2) layer, a N-Type heavily doped (N+) polysilicon layer, a first oxide layer, a dielectric layer, a P-Type lightly doped (P−) polysilicon layer, at least a neck structure, and a second oxide layer. The isolated SiO2 layer is deposited on the silicon substrate, and the N+ polysilicon layer is deposited on the isolated SiO2 layer. The N+ polysilicon layer is further defined a plurality of parallel, separate word lines (WL), and the first oxide layer is filled in the space between the word lines. The dielectric layer is deposited on the word lines and the first oxide layer. The P-Type lightly doped (P−) polysilicon layer is deposited on the dielectric layer and is further defined a plurality of parallel, separate bit lines (BL). The bit lines overlap the word lines, from a top view, to form a shape approximately as a cross. There are at least a neck structure individually formed between the first polysilicon layer and the second polysilicon layer by isotropy wet etching the dielectric layer, with using dilute hydrofluoric acid (HF) as the example. The second oxide layer is filled in the space between the bit lines and is on the word lines and the first oxide layer.

Owner:MACRONIX INT CO LTD

Porous tantalum rod

ActiveCN102743218AEasy to fixIncrease success rateInternal osteosythesisFastenersNeck structureRight femoral head

The invention relates to a medical implant part for femoral head joint surface depression or I-stage or II-stage femoral head necrosis, namely a porous tantalum rod. One end of the implant part is provided with a connection fastening structure connected with a bone tissue, and a through hole is formed in the center of the tantalum rod; the porous tantalum rod is made of a porous tantalum material with a foam structure of pore three-dimensional communicated distribution, and is sintered by adopting a foam impregnation method; and tantalum powder particles have a sinter neck structure on a foam frame formed by accumulating the sintered pure tantalum powder. The through hole in the porous tantalum rod facilitates accurate positioning in an operation; and a related object can be picked out and injected conveniently through the through hole, so that the effect of constant pressure reduction can be achieved.

Owner:CHONGQING RUNZE PHARM CO LTD

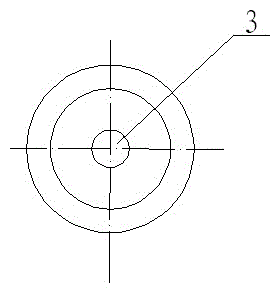

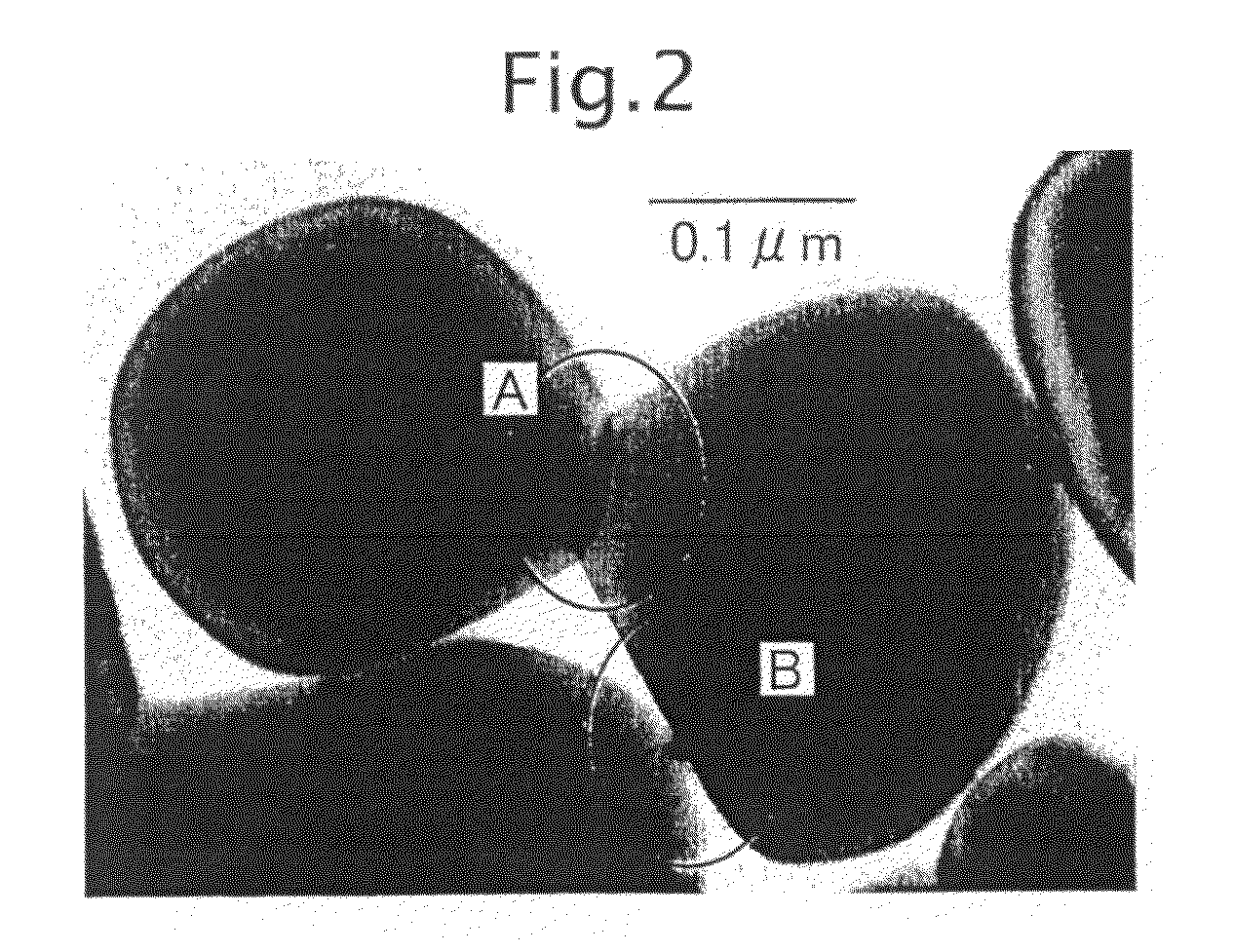

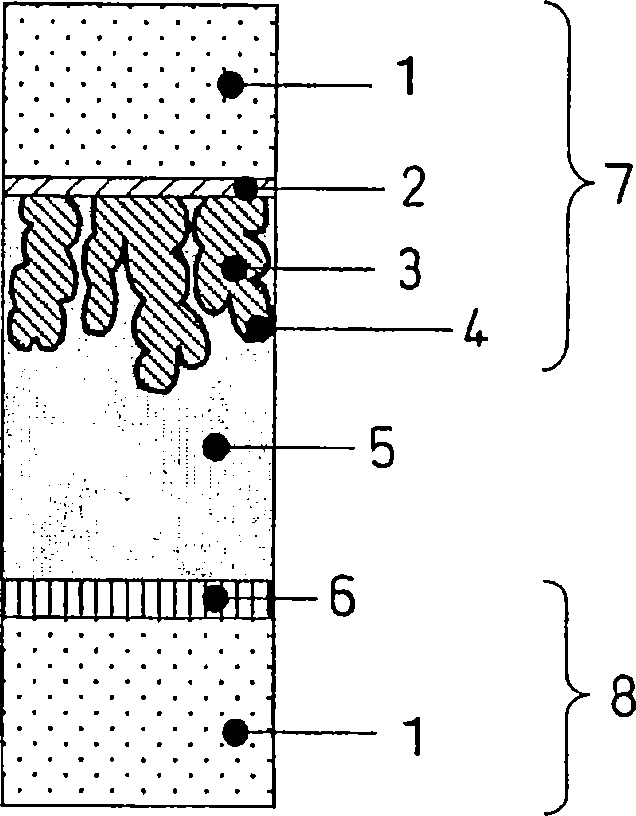

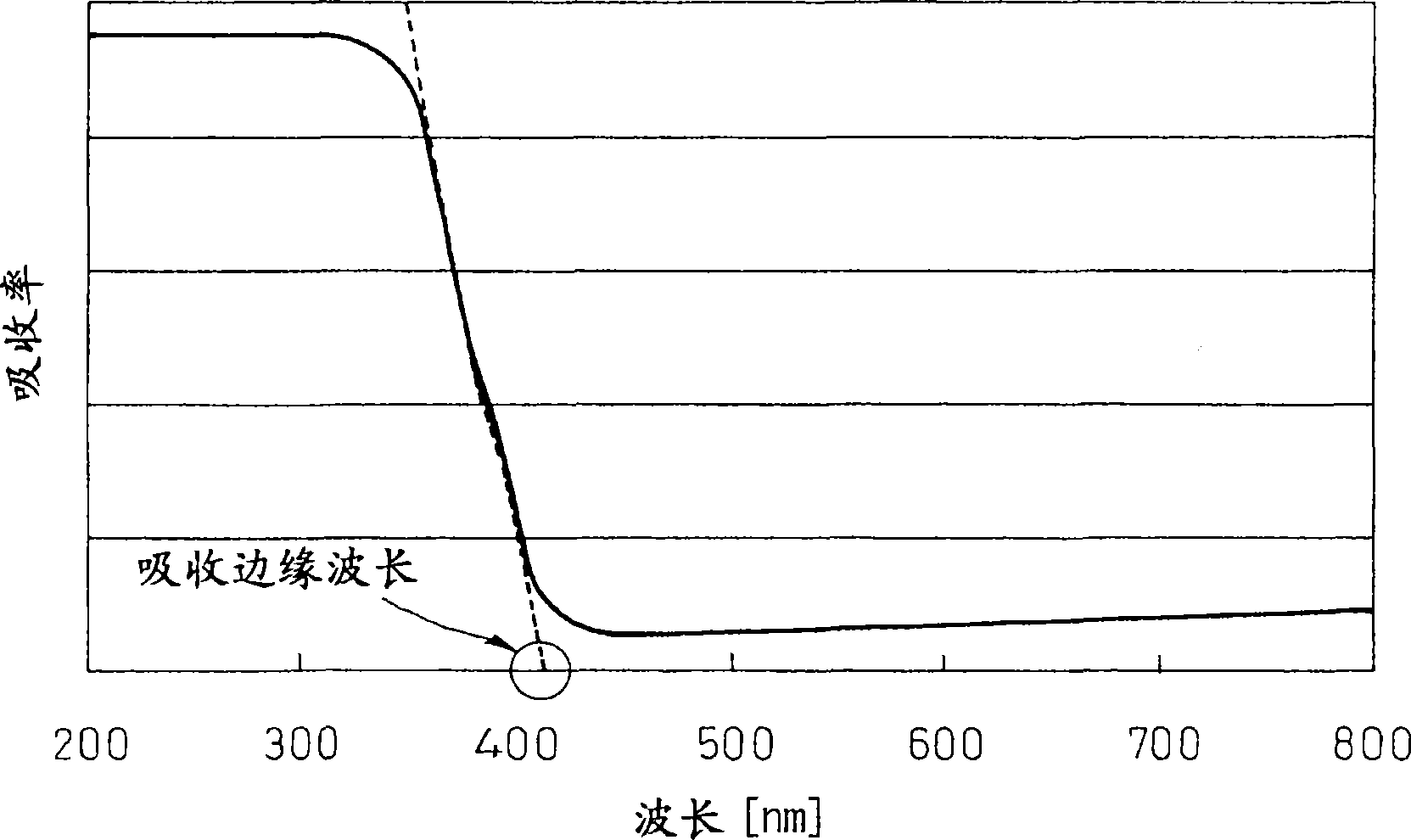

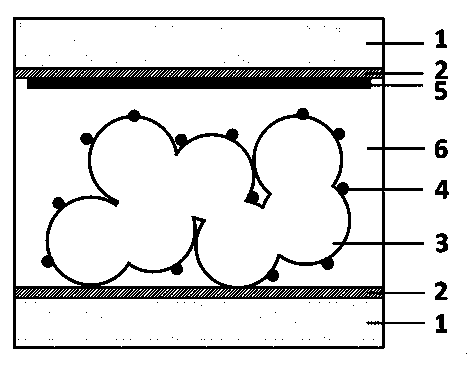

Metal Oxide Dispersion, Metal Oxide Electrode Film, and Dye Sensitized Solar Cell

InactiveUS20090014062A1Degraded cell performanceFacilitates electron transferElectrolysis componentsLight-sensitive devicesNeck structureIndium tin oxide

A metal oxide dispersion comprising metal oxide particles with a necking structure, and a solvent, wherein the liquid droplet contact angle of the metal oxide dispersion to an ITO film (Indium-Tin Oxide type film) formed is from 0 to 60°. A metal oxide dispersion for the production of a dye-sensitized solar cell electrode, comprising Metal Oxide Particle Group F having a necking structure formed by m connected particles, Metal Oxide Particle Group G having only 0.2 m or less connected particles, and a solvent, and being formable into a film at 200° C. or less. A metal oxide electrode comprising an electrically conducting substrate having thereon a metal oxide layer comprising metal oxide particles bound by a binder, wherein the binder content is from 0.005 to 5 mass % based on the metal oxide film and the metal oxide layer has a pencil scratch strength of H or more according to JIS5600.

Owner:SHOWA DENKO KK

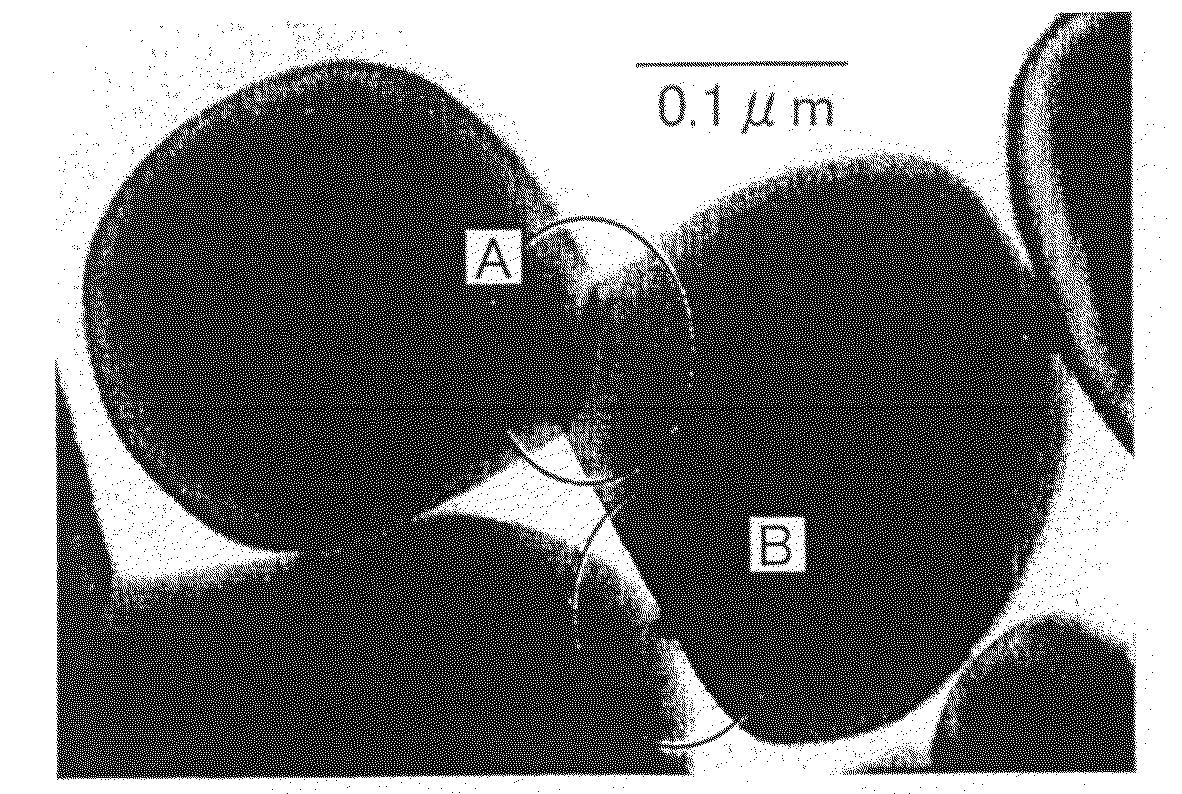

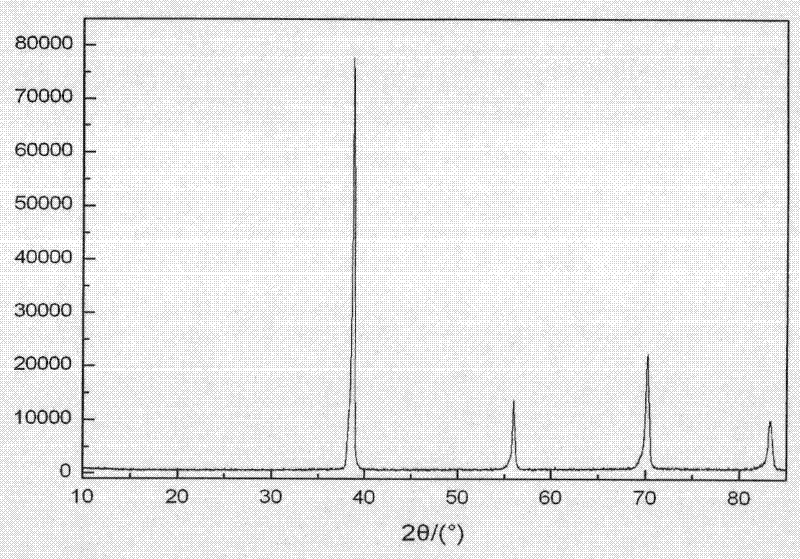

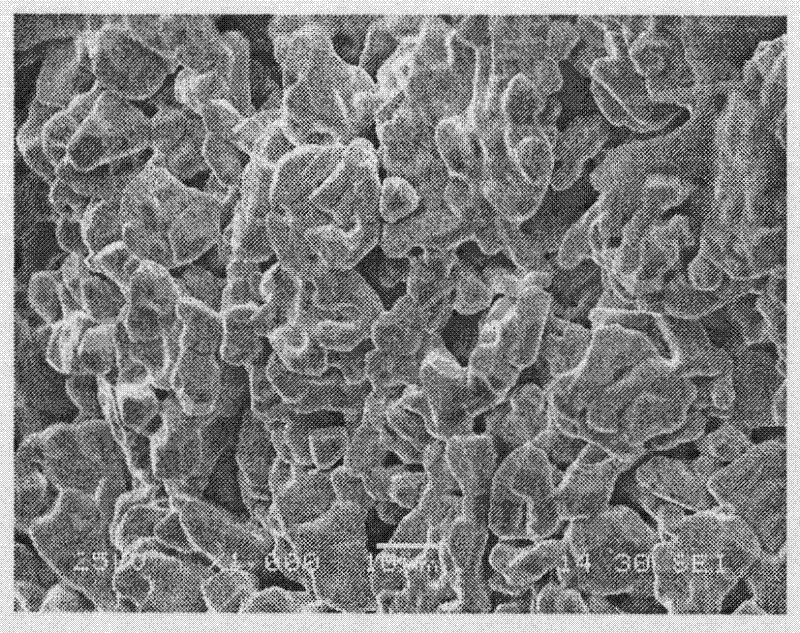

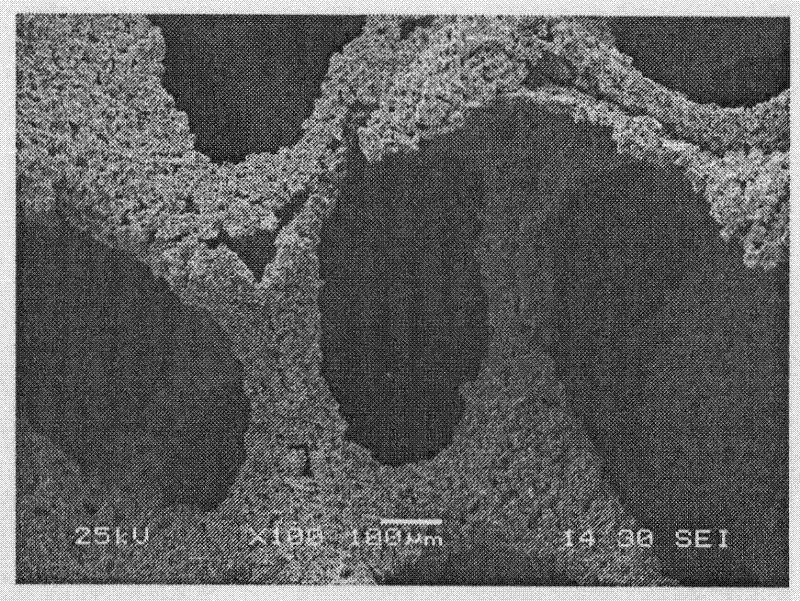

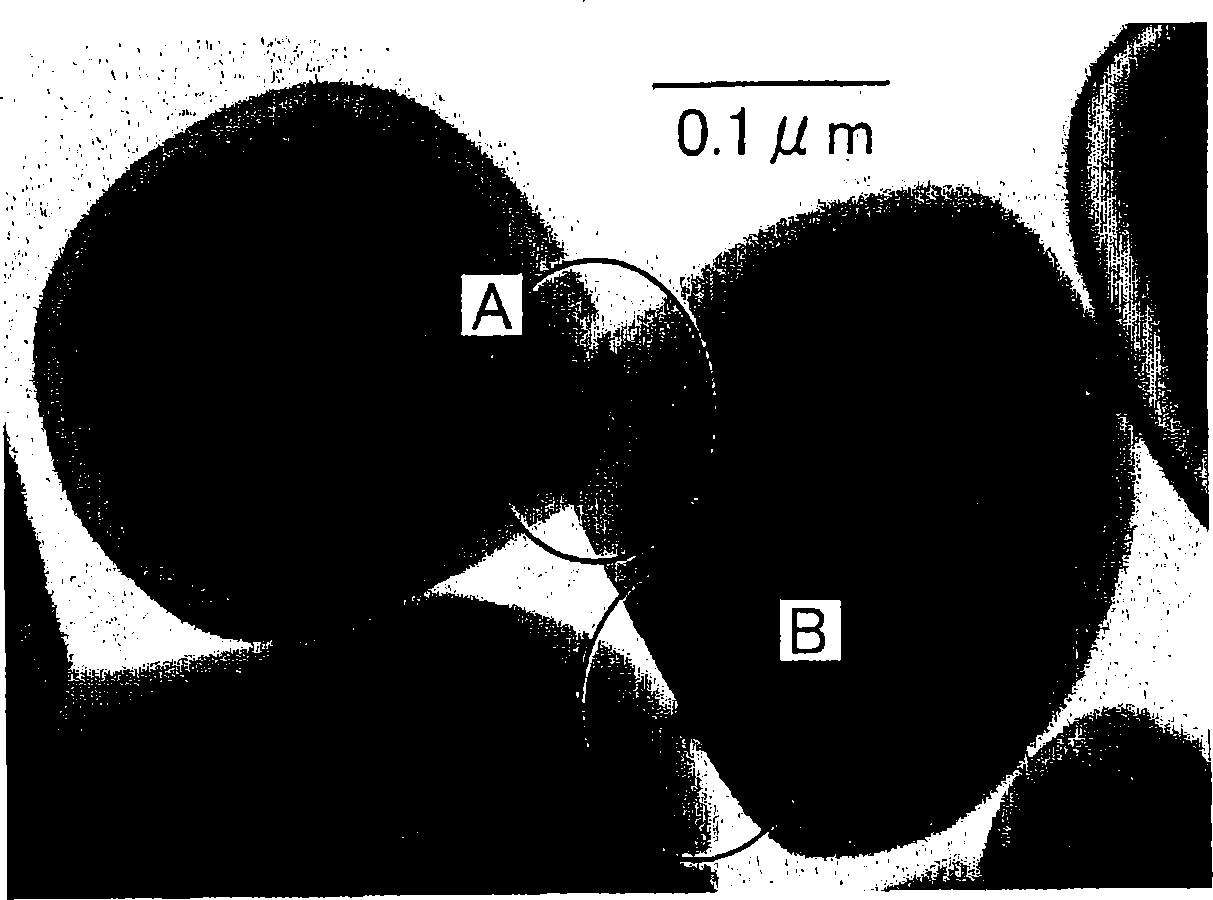

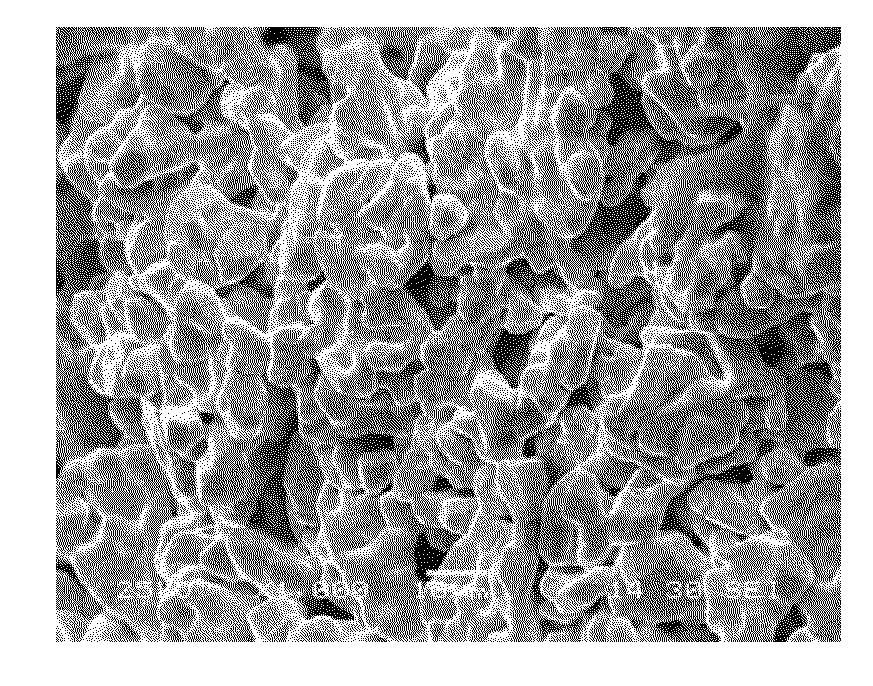

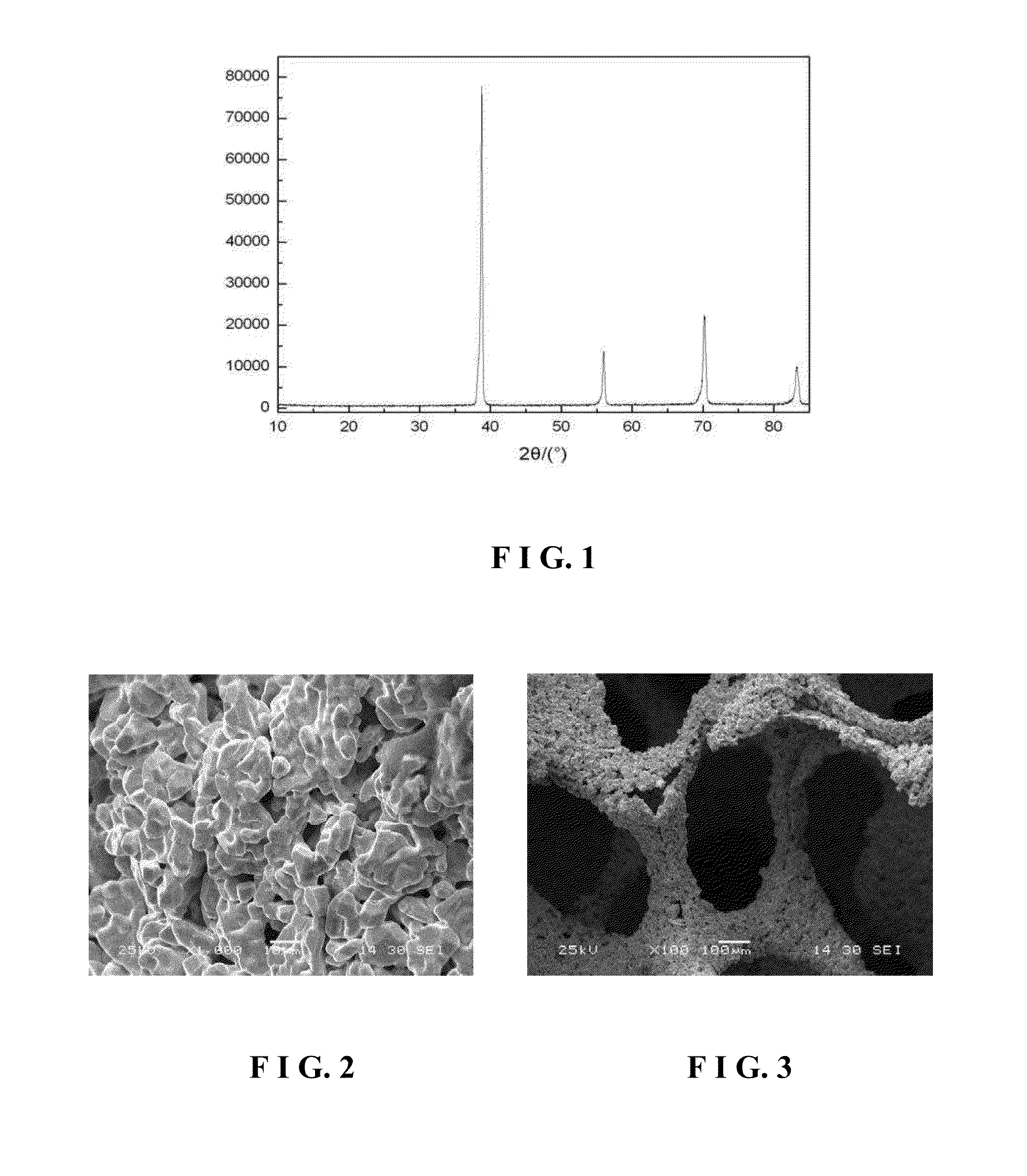

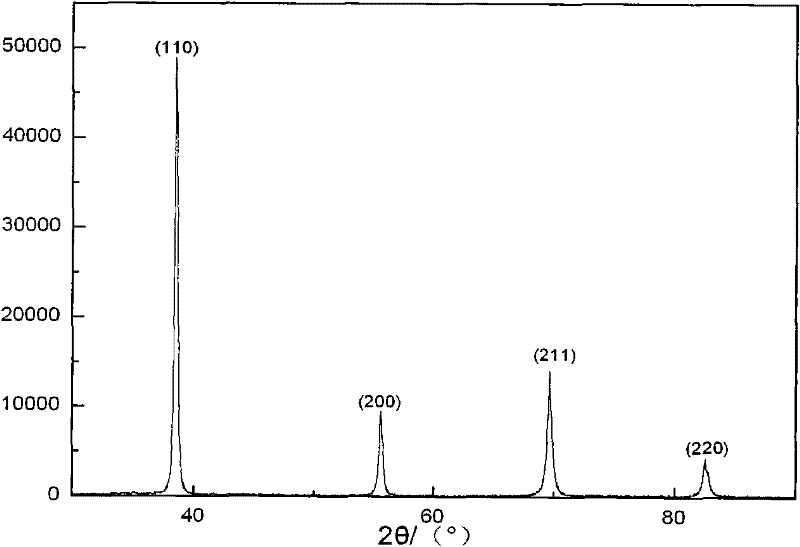

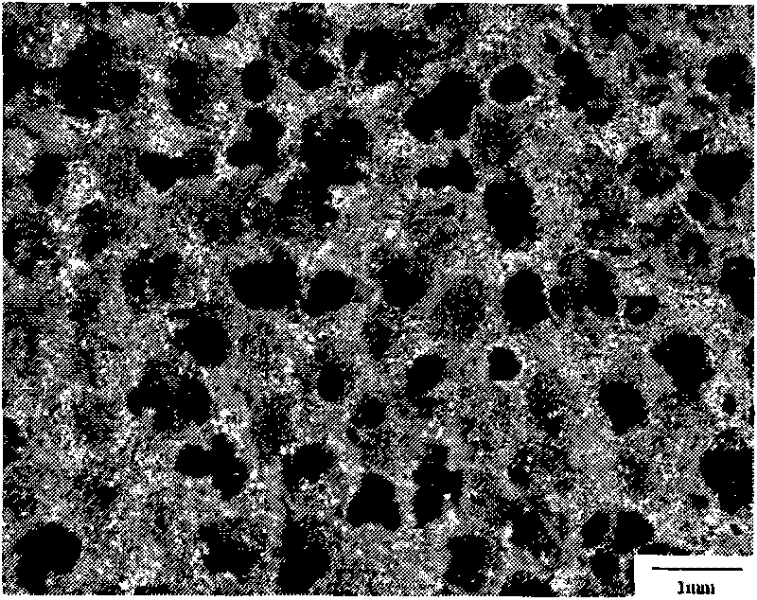

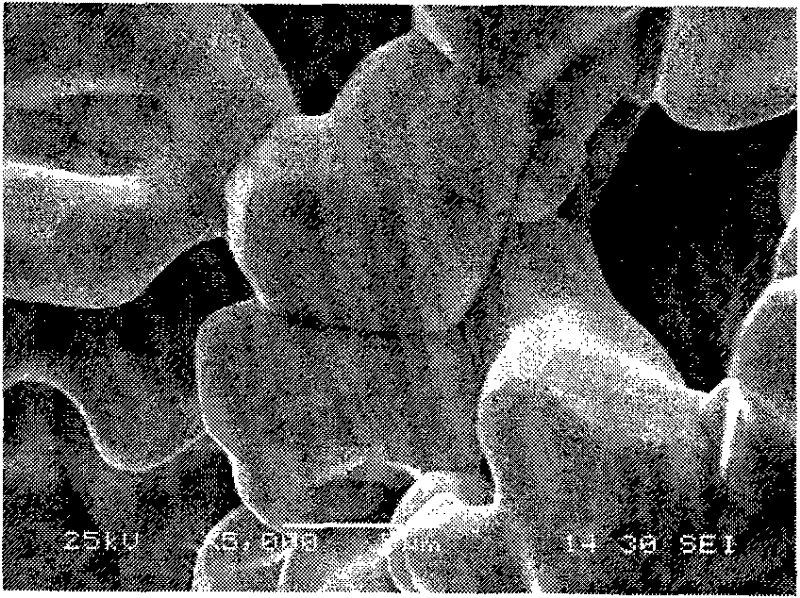

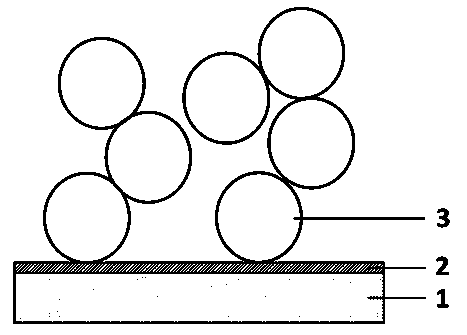

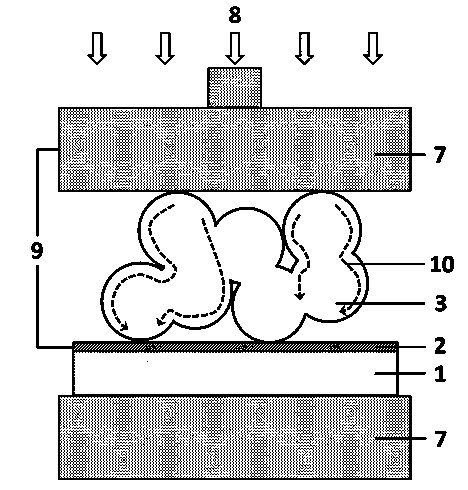

Porous tantalum serving as medical metal implanted material and preparation method thereof

ActiveCN102205144AReduce contentImprove mechanical propertiesMetal-working apparatusPharmaceutical delivery mechanismPorosityNeck structure

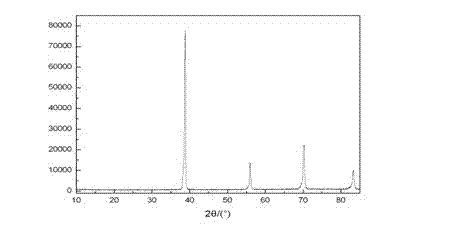

The invention relates to porous tantalum serving as a medical metal implanted material and a preparation method thereof. The porous tantalum has a pore three-dimensional communicating distribution foam structure, wherein a solution which is prepared from an organic adhesive and a dispersant and tantalum powder are adopted to prepare a tantalum powder slurry; the tantalum powder slurry is poured into an organic foam body and soaked until the tantalum powder slurry is filled in the pores of the organic foam body, drying is carried out so as to remove the dispersant in the organic foam body which is poured with the tantalum powder slurry, and ungreased treatment is carried out in the presence of inert gas so as to remove the organic adhesive and the organic foam body, and vacuum sintering is carried out so as to prepare the porous sintered body; on a foam framework which is formed by accumulated sintered pure tantalum powder, and a sintering neck structure exists among tantalum powder particles; and the tantalum powder is annealed in vacuum and subjected to conventional post-treatment. The porous tantalum has the advantages of high porosity, uniform and communicated porous distribution, uniform sintered microstructure particles, remarkable sintering neck, ensured excellent chemical performance and especially excellent ductibility.

Owner:CHONGQING RUNZE PHARM CO LTD

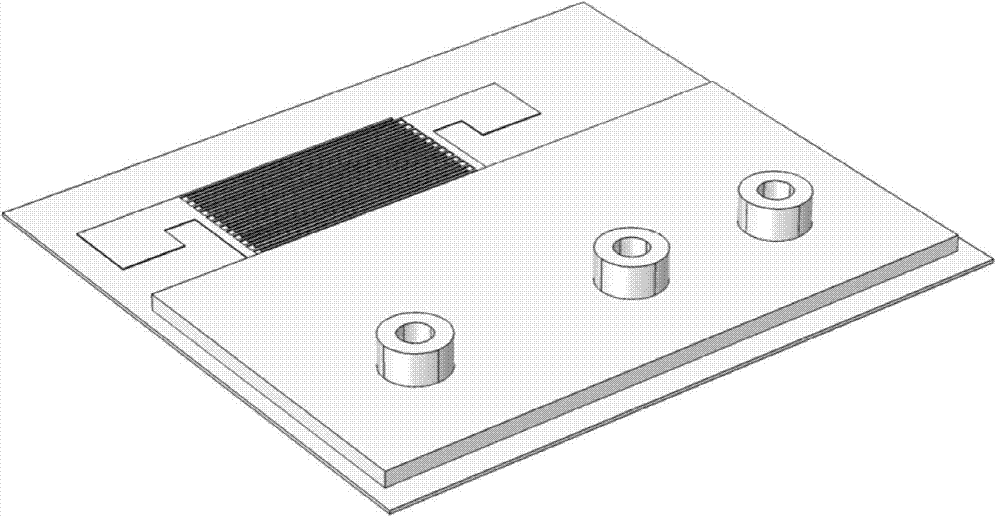

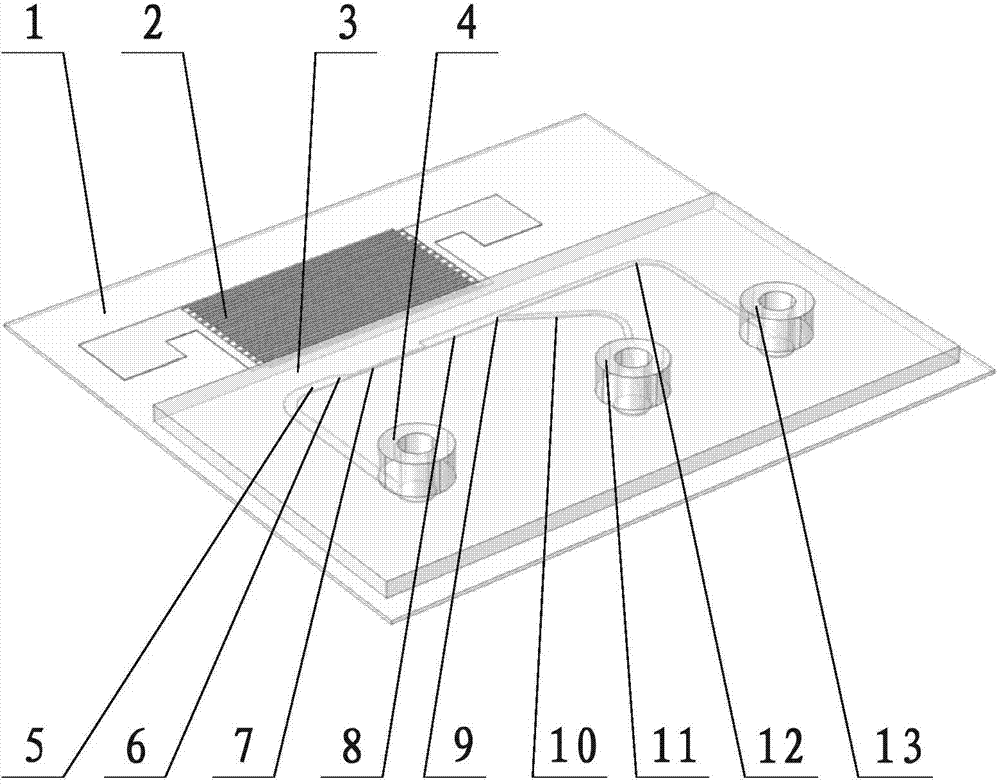

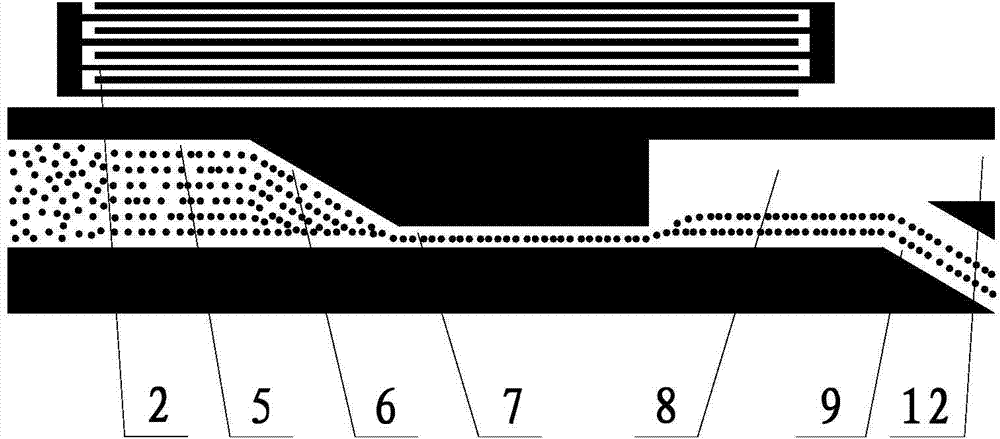

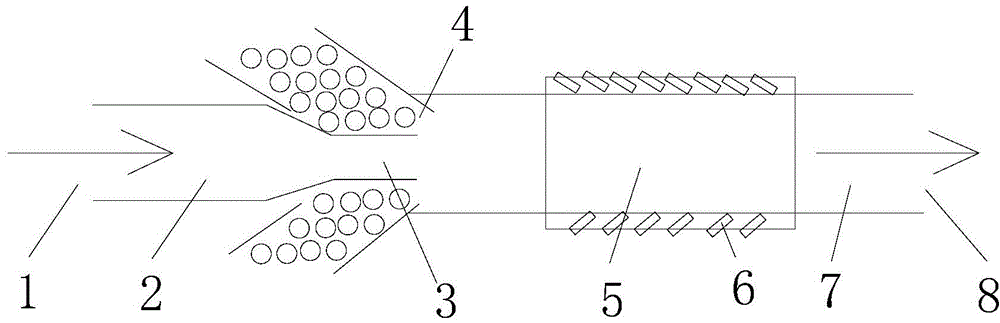

Acoustic surface wave based microfluidic plasma separating chip and method

ActiveCN104726331AReduce volumeReduce difficultyStress based microorganism growth stimulationHigh energySeparation technology

The invention discloses an acoustic surface wave based microfluidic plasma separating chip and method. The chip comprises a piezoelectric substrate, a set of interdigital transducer arranged on the piezoelectric substrate and a flow microchannel system which is arranged on the piezoelectric substrate in a bonding manner, located on one side of the interdigital transducer and has a necking structure. According to the chip, by use of width change of a microchannel, blood cells gradually shift to one side of a runner under the action of an acoustic radiation force, thus realizing the separation of plasma and blood cells. The chip takes such good advantages of the acoustic surface wave based microfluidic particle separation technology as high energy density and easy integration and manufacturing; in addition, only one set of interdigital transducer is arranged on the piezoelectric substrate and the distribution of an acoustic surface standing wave field is defined by a special geometrical shape of the PDMS flow microchannel; therefore, the defect that the existing acoustic surface wave based microfluidic particle separation technology requires two sets of interdigital transducer at the same time is overcome, the size of the separation chip is reduced further, and the requirement on alignment precision of the interdigital transducer and the microchannel system is reduced greatly.

Owner:XI AN JIAOTONG UNIV

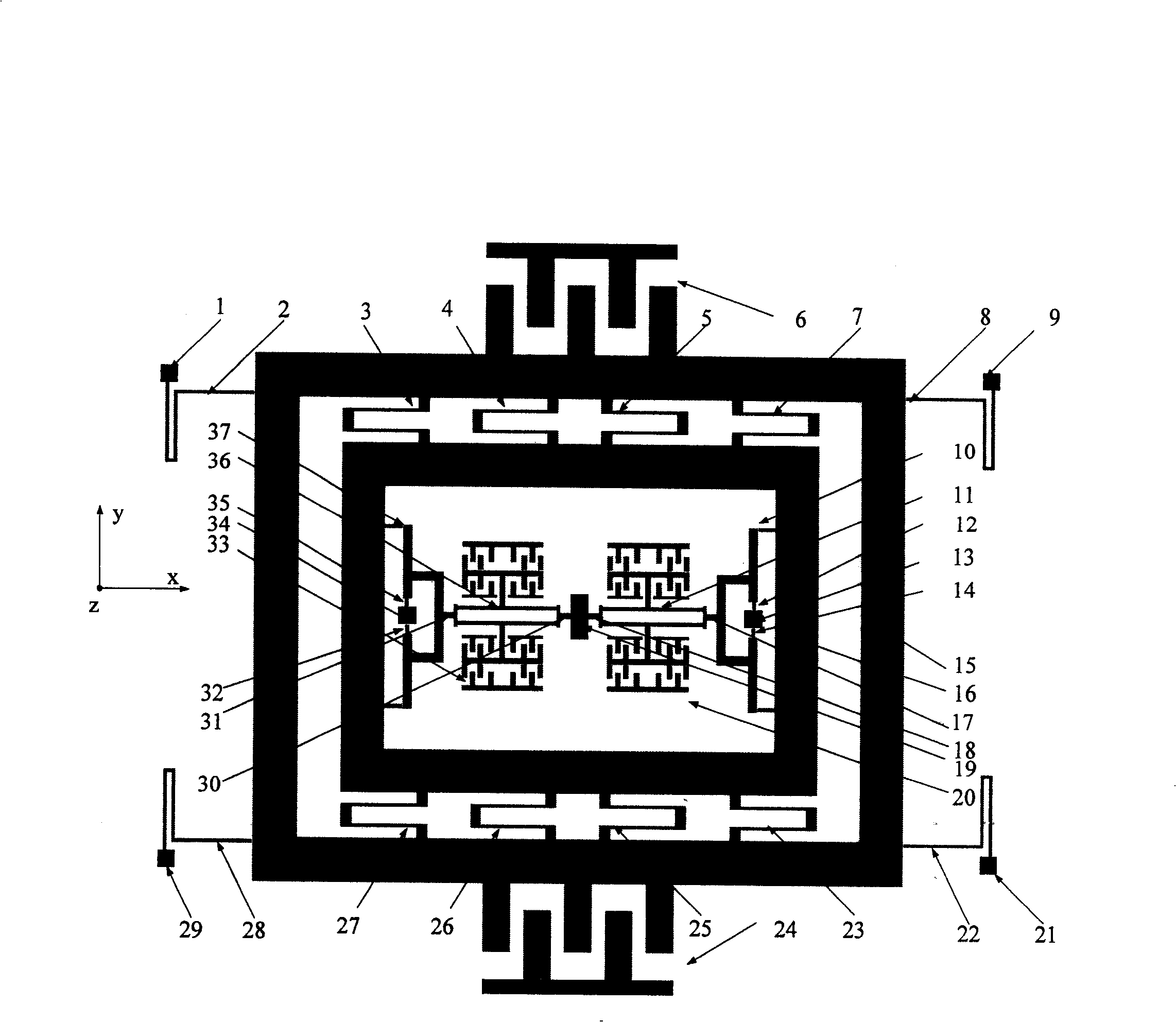

Self-decoupling high-sensitivity resonance silicon micro mechanical gyroscope

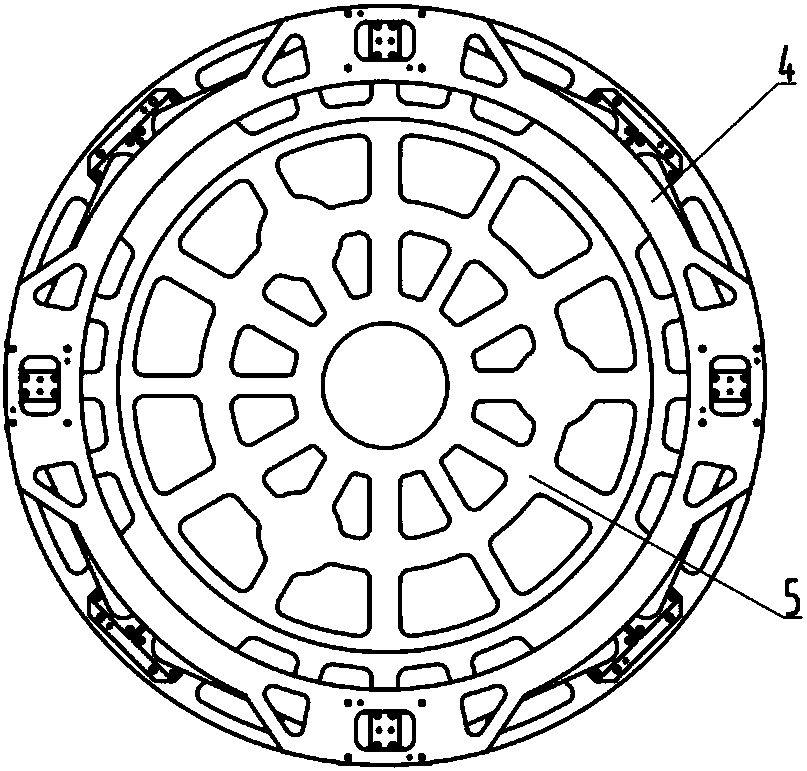

InactiveCN101303234AReduce couplingRealize structural decouplingSpeed measurement using gyroscopic effectsTurn-sensitive devicesAccelerometerGyroscope

A self-decoupling high-sensitivity resonant silicon micromechanical gyroscope mainly comprises an outer mass block, an inner mass block, a cantilever beam, a lever amplification mechanism, a DETF(double-ended tuning fork), a driving electrode, a detecting electrode, wherein the lever amplification mechanism, the fork, the driving electrode and the detecting electrode are arranged in the inner mass block. The structure of the micromechanical gyroscope is axially symmetric, and the inner and outer mass blocks are in Chinese character 'hui' shape, which is capable of making the component implement larger mass block in limited volume. The outer mass block and the inner mass block are separated by a folding beam for reducing effectively the coupling; a resonant beam is in the form of DETF, and both ends of the resonant beam are connected with the periphery through a fine neck structure, thereby reducing effectively the energy coupling of the resonant beam and the peripheral structure; two forks are arranged symmetrically for implementing difference output of resonant frequency, thereby reducing effectively the common-mode interference. The structural form of the invention improves sensitivity and resolution of the accelerometer, and reduces the coupling of the driving direction vibration to the detecting direction by using framework structure.

Owner:BEIHANG UNIV

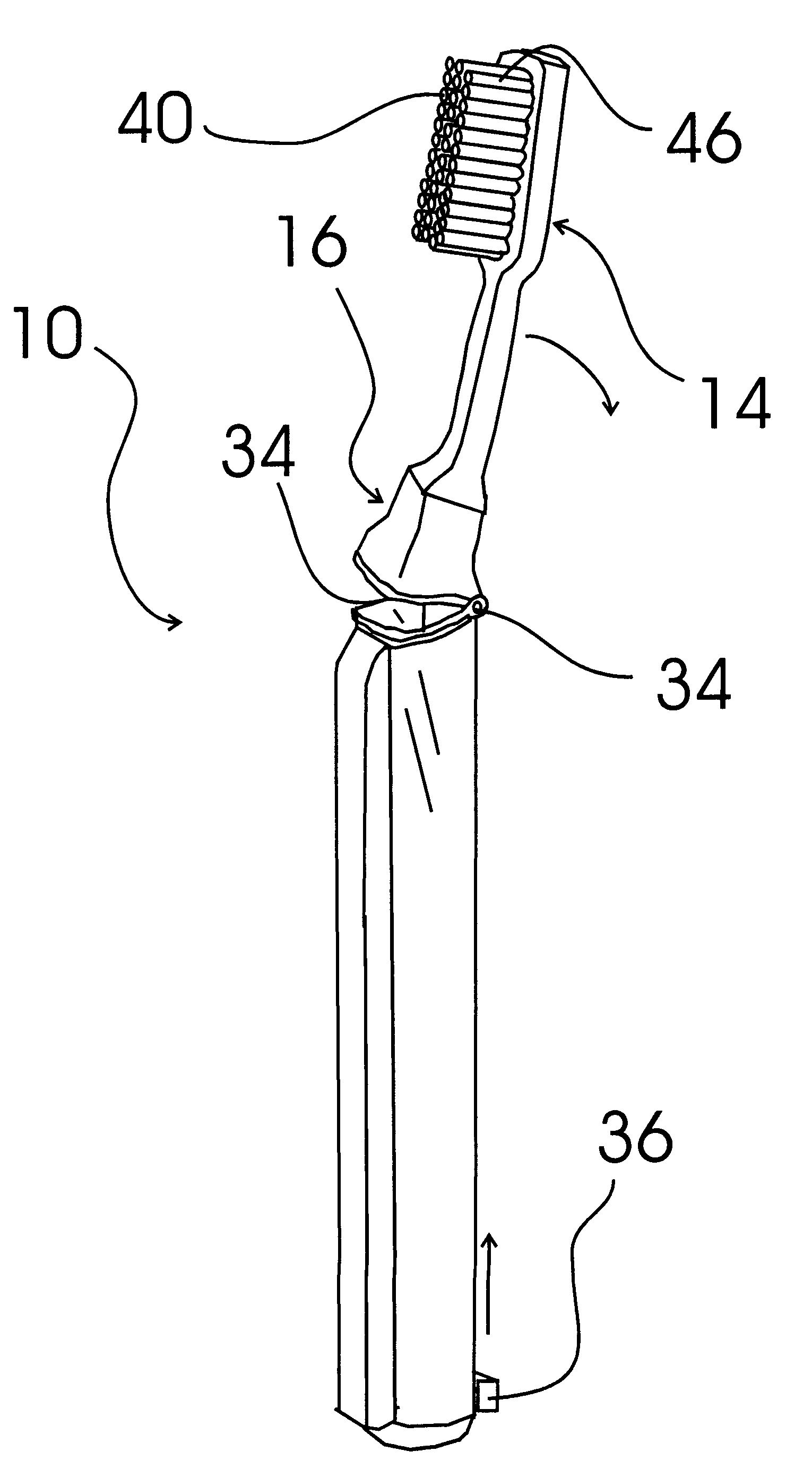

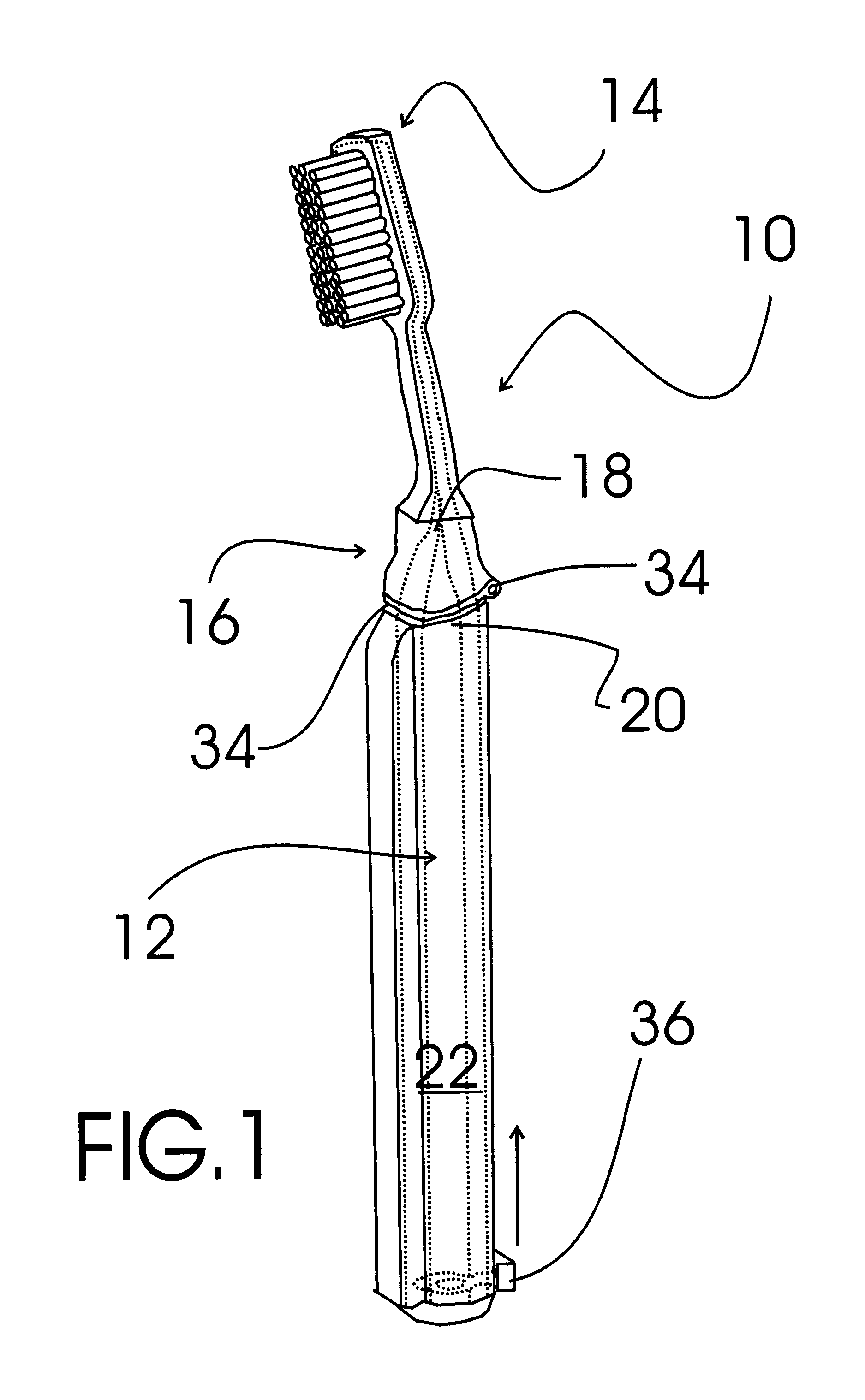

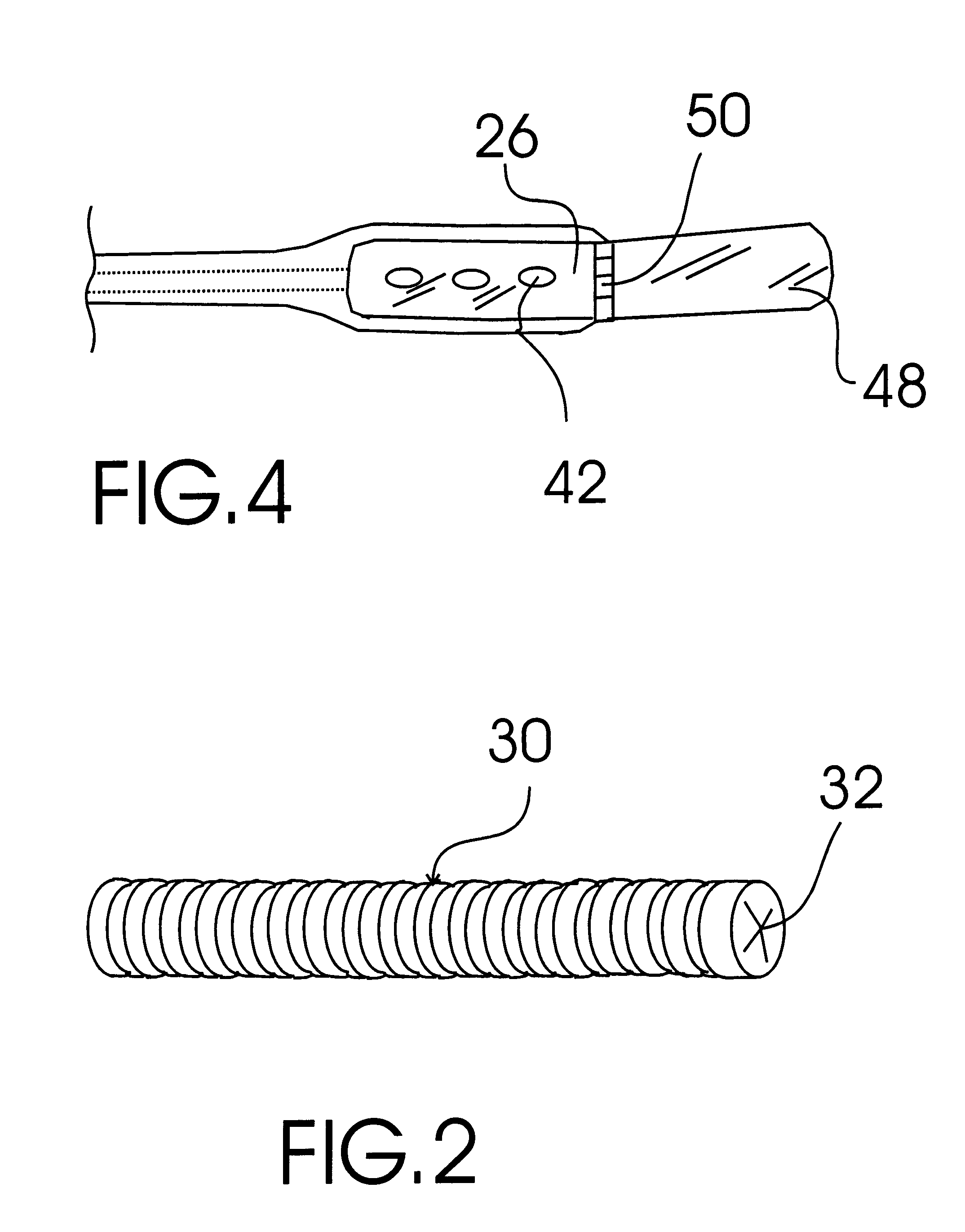

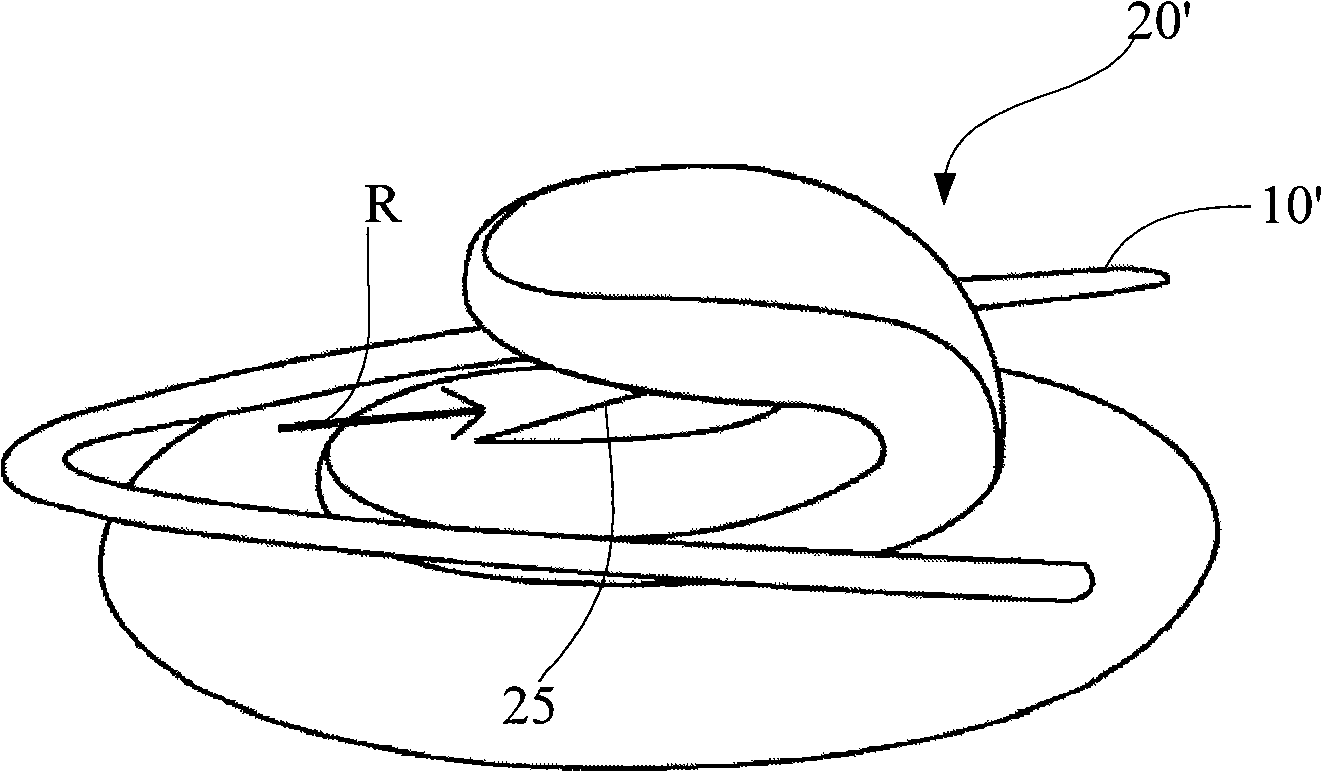

Toothbrush with toothpaste feed system

A toothbrush with a toothpaste feed system that includes a toothpaste cartridge feed handle, a hollow brush head, a resilient hinge openable neck structure connected between the toothpaste cartridge feed handle and the hollow brush head and providing a neck toothpaste passageway between a toothpaste feed end of a toothpaste cartridge cavity within toothpaste cartridge feed handle and a brush head toothpaste passageway formed within hollow brush head, and an accordion fold toothpaste filled cartridge with a rupturable perforated foil end that is sized to fit into the toothpaste cartridge cavity with the rupturable perforated foil end positioned within toothpaste feed end of toothpaste cartridge cavity. The back of the hollow brush head is provided with a flip open back cap that is in connection with the brush head toothpaste passageway and which is moveable into an open position to allow for cleaning of the brush head toothpaste passageway between uses.

Owner:TRYON TRACI L

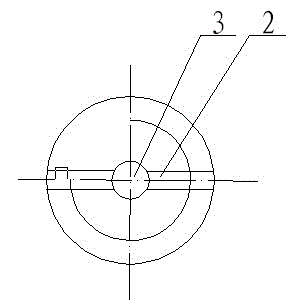

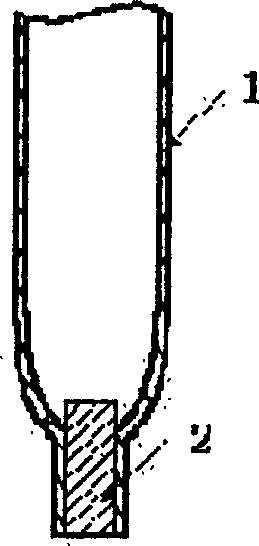

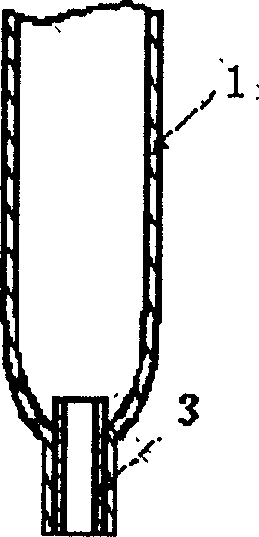

Method for suppressing stray crystal forming and growing at seed crystal starting end, and casting case construction thereof

InactiveCN1570224AIncrease success rateGuaranteed OrientationLiquid-phase epitaxial-layer growthNeck structureCrystal orientation

The invention relates to a technology for preparing a single crystal high-temperature alloy and especially provides a method for inhibiting stray crystal formation and growth in seed crystal initiating terminal and the shuttering structure. The preparing method based on seed crystal method comprises: preplacing the seed crystal in the shuttering, arranging a necking structure in the initiating terminal, forming stray crystal in the initiating terminal of inhibiting the seed crystal growth, and growing into the single crystal from the alloy melt on the unmelted interface of the seed crystal in the form of the epitaxial growth. The shuttering structure in the invention is the shuttering structure for preplacing the seed crystal, a necking structure is arranged on the bottom of the shuttering over the initiating terminal of seed crystal growth. The invention combines the seed crystal method initiating terminal design with the necking crystal-selecting device for inhibiting and removing the stray crystal in the process of the single crystal growth, controlling the crystal orientation, and improving the single crystal yield.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Metal oxide dispersion, metal oxide electrode film, and dye sensitized solar cell

A metal oxide dispersion comprising metal oxide particles with a necking structure, and a solvent, wherein the liquid droplet contact angle of the metal oxide dispersion to an ITO film (Indium-Tin Oxide type film) formed is from 0 to 60 DEG . A metal oxide dispersion for the production of a dye-sensitized solar cell electrode, comprising Metal Oxide Particle Group F having a necking structure formed by m connected particles, Metal Oxide Particle Group G having only 0.2m or less connected particles, and a solvent, and being formable into a film at 200 DEG C or less. A metal oxide electrode comprising an electrically conducting substrate having thereon a metal oxide layer comprising metal oxide particles bound by a binder, wherein the binder content is from 0.005 to 5 mass% based on the metal oxide film and the metal oxide layer has a pencil scratch strength of H or more according to JIS5600.

Owner:SHOWA DENKO KK

Porous tantalum used for medical implantation and method for preparing the same

InactiveUS20130011691A1Reduce the presence of impuritiesImprove mechanical propertiesLayered productsMetal-working apparatusNeck structurePorous tantalum

A porous tantalum used for medical implantation is provided, which includes a foam structure with three-dimensional interconnecting pores and produced by: mixing a solution made by organic binder and dispersant and tantalum powder to form tantalum slurry, casting the tantalum slurry into a organic foam body through impregnation until the pores of the organic foam body are filled, drying the impregnated organic foam body with the tantalum slurry to remove the dispersant, degreasing the dried organic foam body to separate the organic binder and the organic foam body from the dried tantalum slurry in a protective environment of inert gas, vacuum sintering the dried tantalum slurry to obtain a porous sintered body, and vacuum annealing then treating the porous sintered body with normal post-treatments to obtain the porous tantalum. Accordingly, the porous tantalum has well-distributed interconnecting pores and sintering neck structures resulting in good mechanical properties, and especially good ductility.

Owner:CHONGQING RUNZE PHARM CO LTD

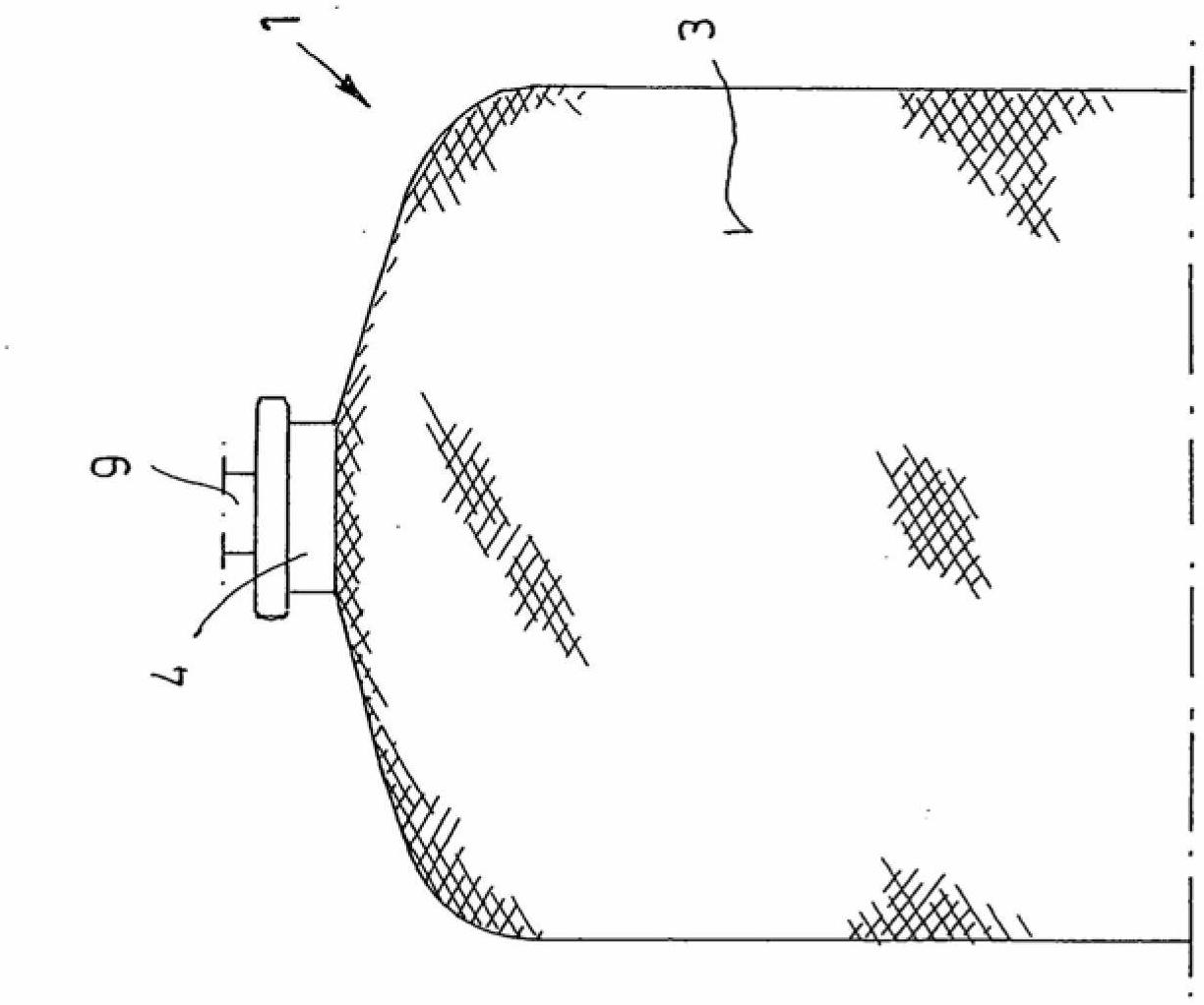

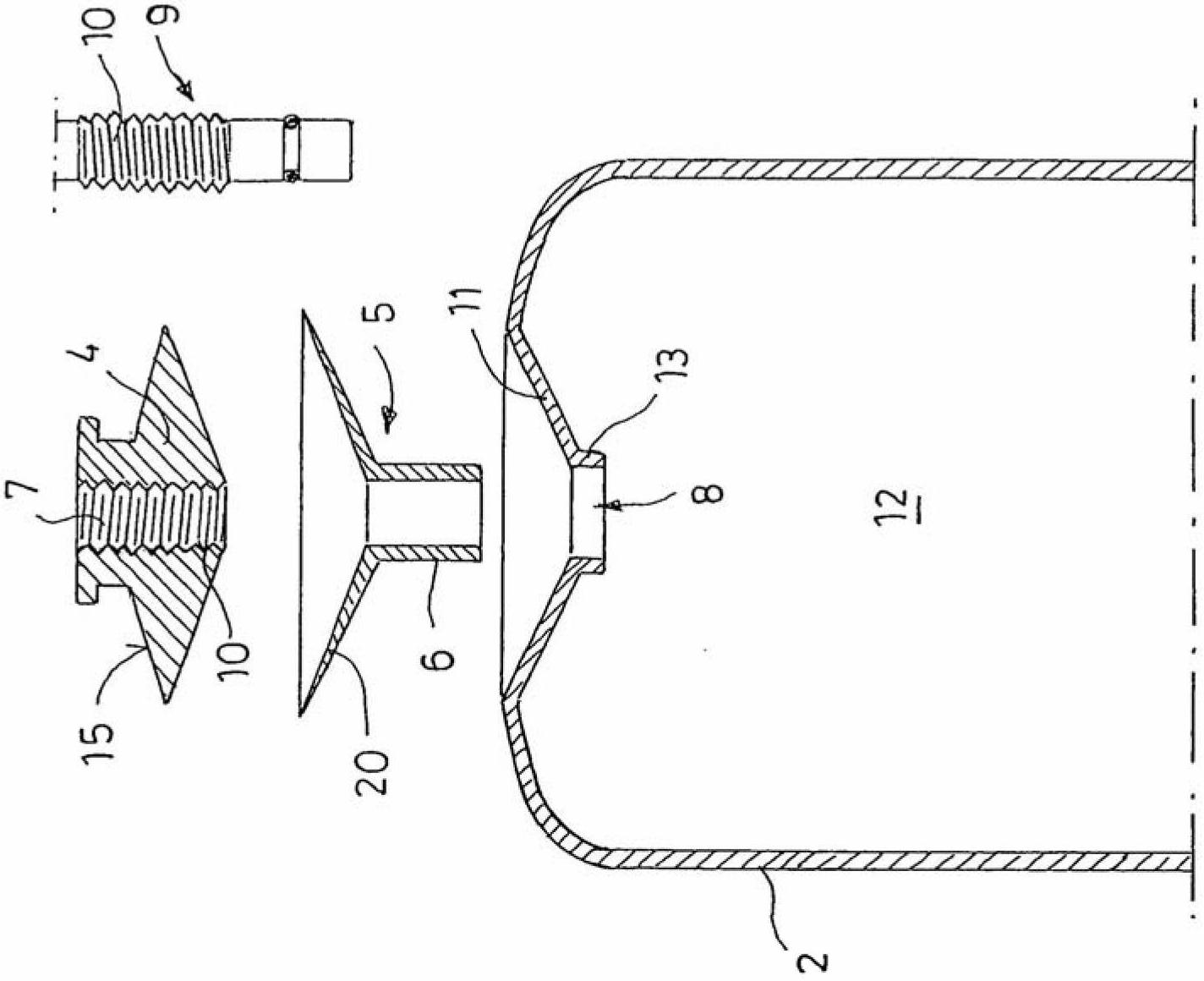

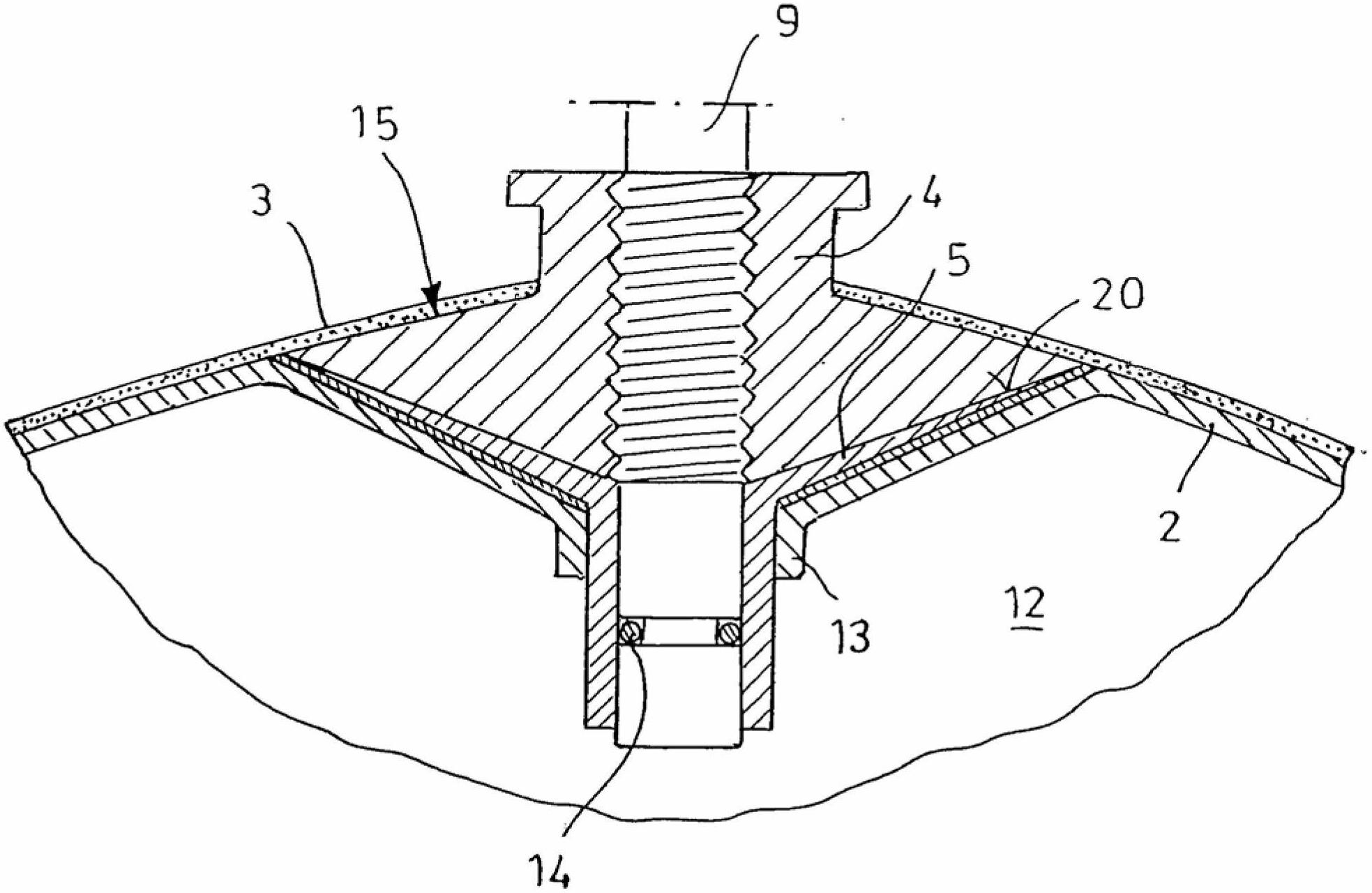

Vessel neck construction of a pressure vessel

The invention relates to a pressure vessel for storing liquid or gaseous media. The pressure vessel (1) comprises a plastic inner vessel (2), at least one neck piece (4) connected thereto as a separate piece, said neck piece being arranged on the vessel neck in the area of the vessel opening (8), and a support casing (3) that at least partially encloses the plastic inner vessel (2) and the neck piece (4). The neck piece (4) is provided with means for accommodating a connection fitting (9). The pressure vessel according to the invention is characterized by an insert (5), which forms at least part of the vessel neck and which forms a sealing seat for the fitting (9) to be inserted into the neck piece (4).

Owner:考特斯机械科技(佛山)有限公司

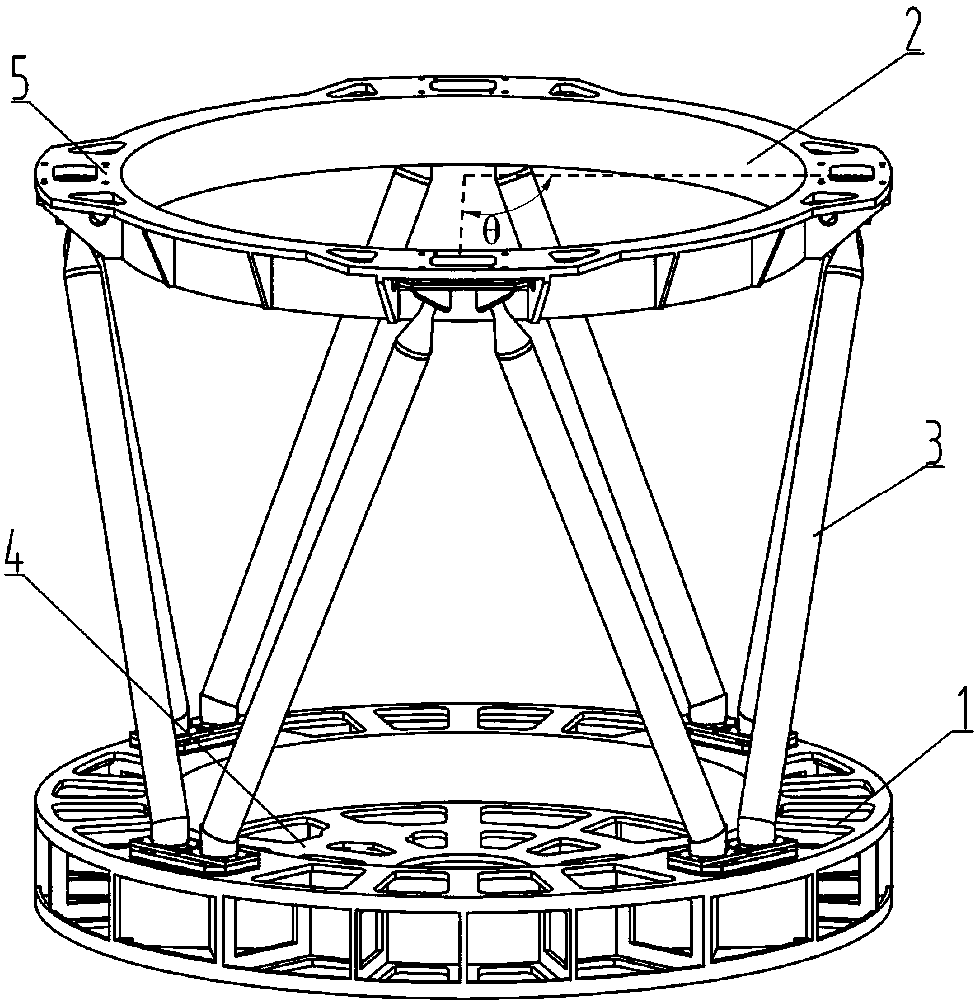

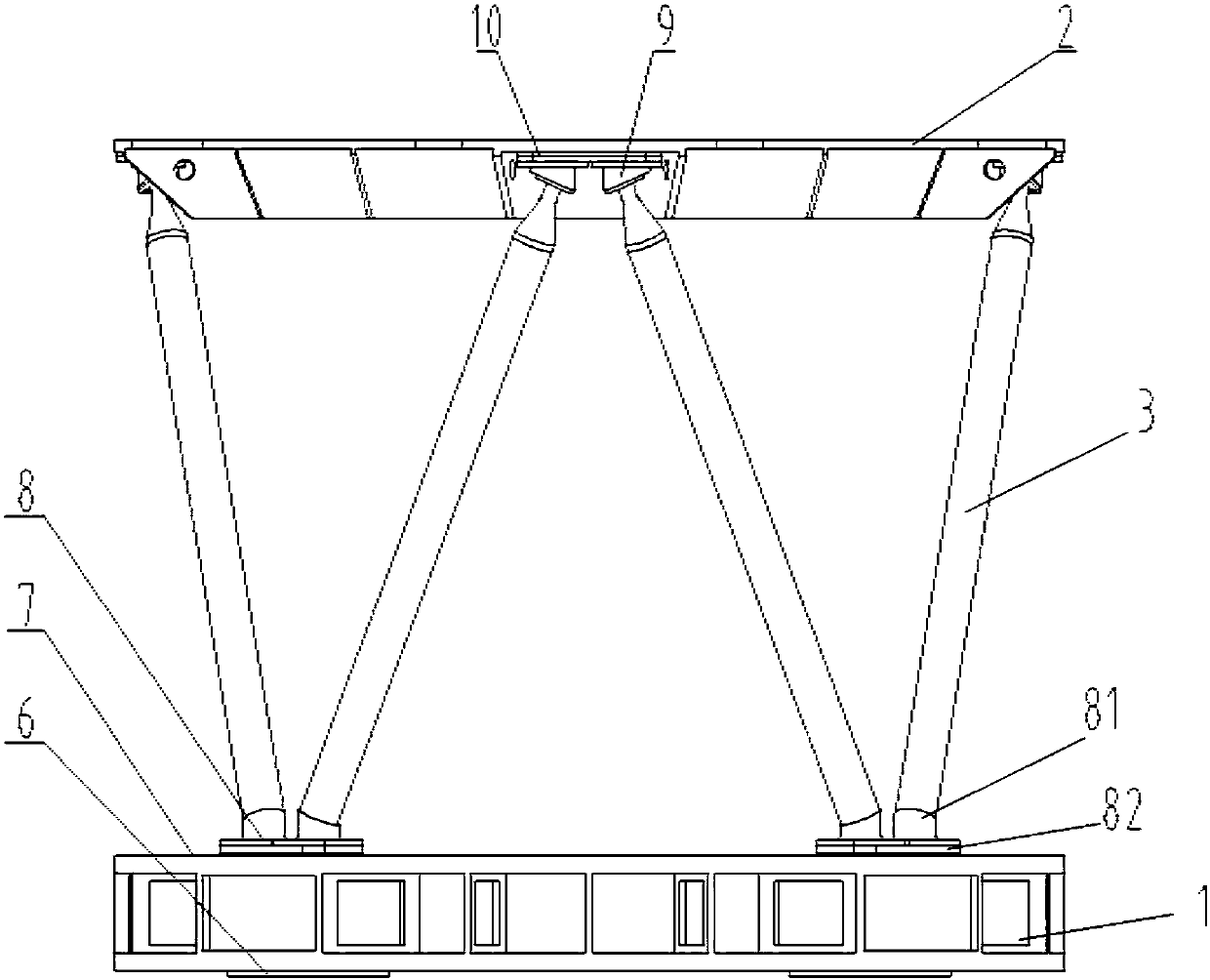

Quasi-zero-expansion space optical remote sensor supporting structure and method thereof

PendingCN108594396AAchieving a quasi-zero expansion designSimple structureMountingsNeck structureBending moment

The invention belongs to the technical field of space optical remote sensing, and relates to a quasi-zero-expansion space optical remote sensor supporting structure and a method thereof. By combininga geometrical configuration of a truss, and based on the characteristic that the distance between a main reflector and a minor reflector changes due to radial deformation of a support frame, a relation between linear expansion coefficients of a top support frame and truss rods is established. When the support structure is temperature loaded, deformations, along an optical axis direction (the lineconnection direction of the main reflector and the minor reflector), of the top support frame and the truss rods can compensate for each other, and an effect of axial quasi-zero-expansion of an integrated truss structure is realized. To release bending moments, at joint positions, of adjacent support truss rods when the top support frame deforms radially, thin-neck structures are adopted for partsof top joints, so that thermal stress and other assembling stress can be released effectively. The quasi-zero-expansion space optical remote sensor supporting structure and the method thereof solve the problems of high cost and implementation difficulty, caused by only reducing linear expansion of materials on transfer paths or improving on-track stability through precise temperature control, ofexisting optical sensors.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

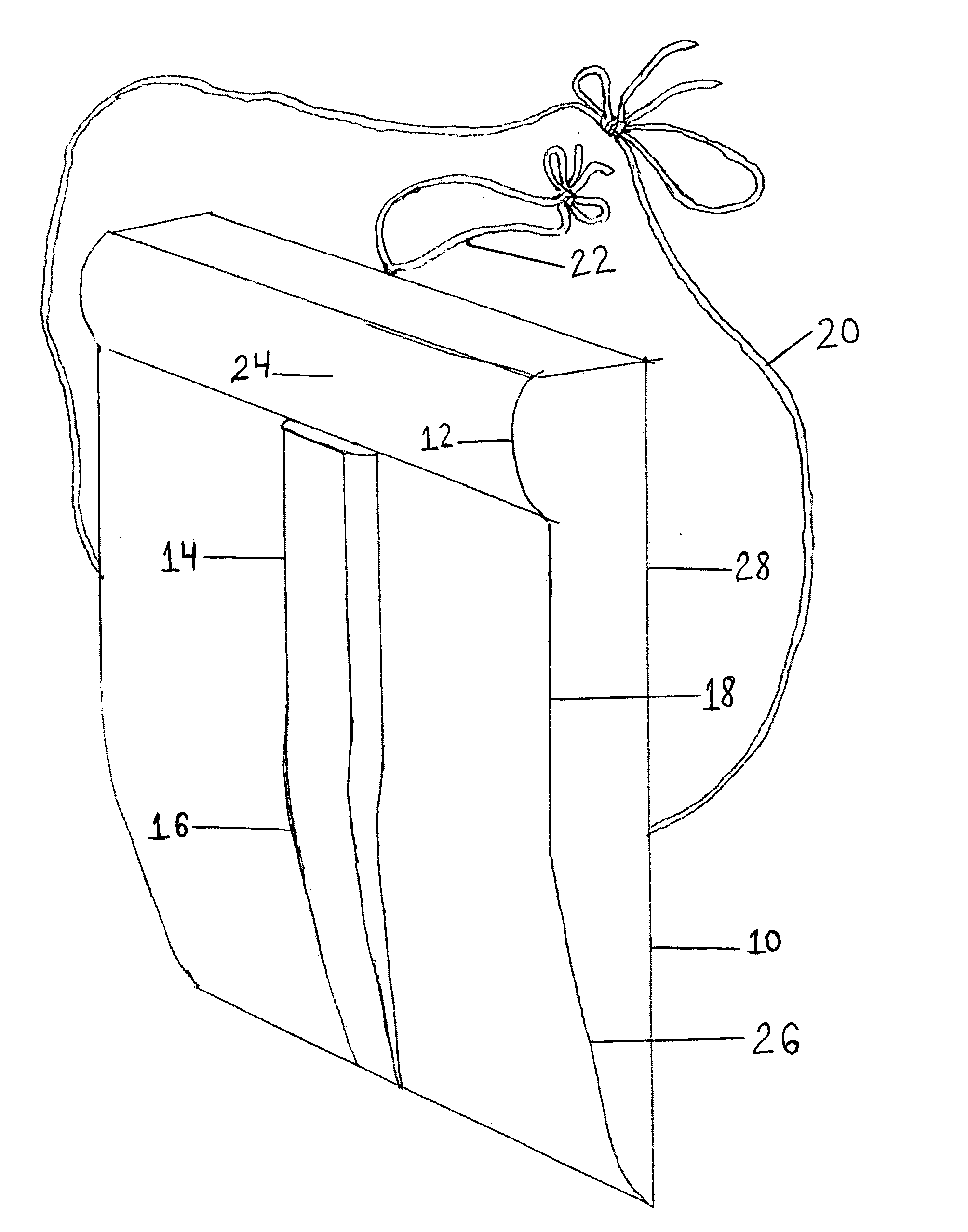

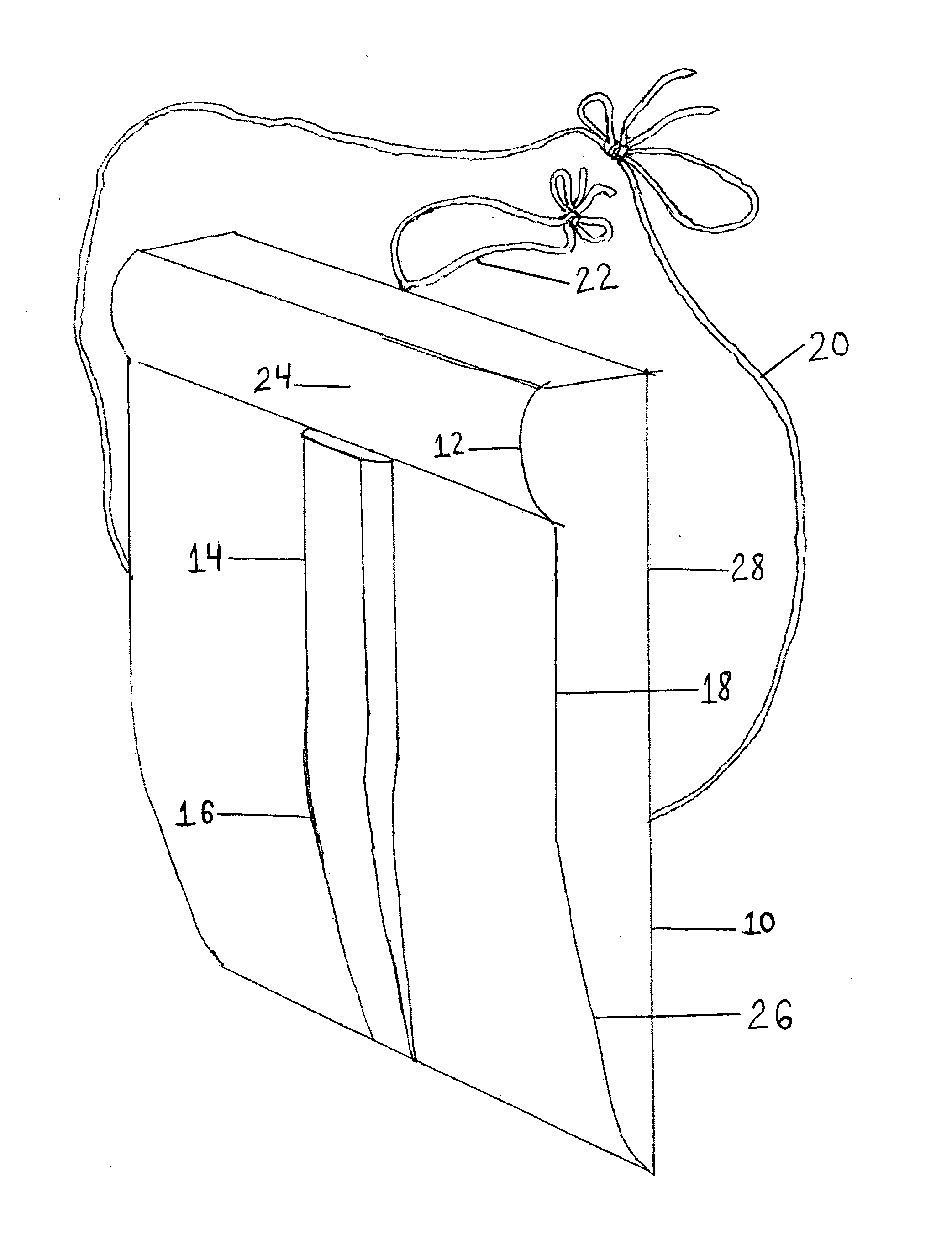

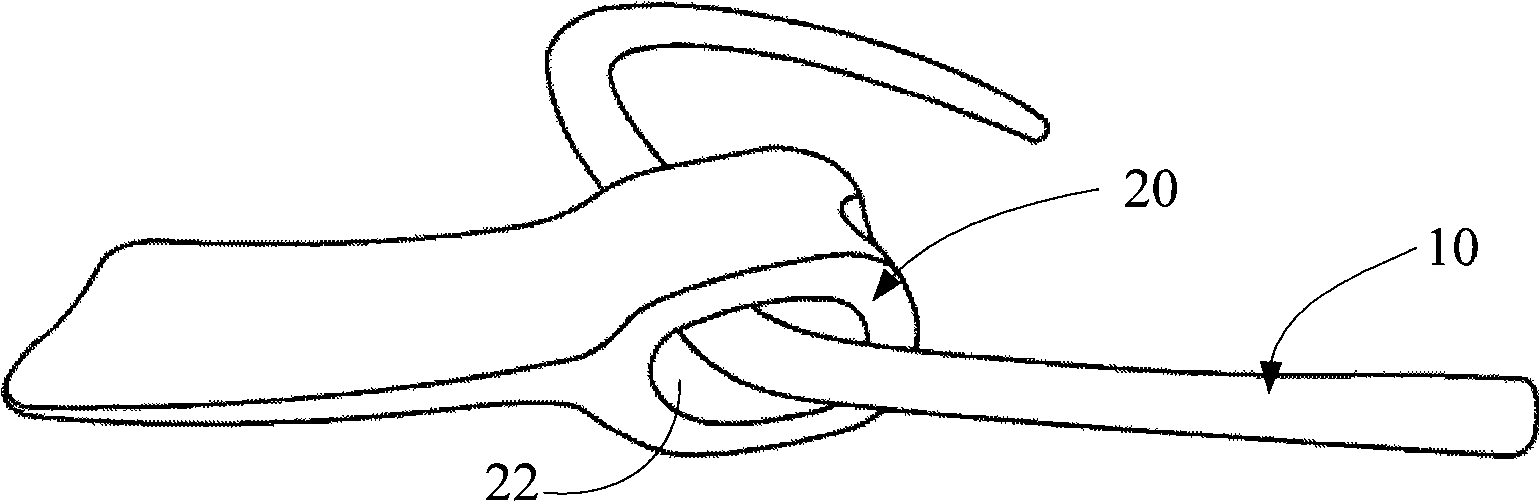

Accessory car seat cushion

A portable back support cushion (10) having two securing tie strings (22), and (20). The upper cushion portion (12) has a convex cervical support (24) that adequately supports neck structures. The middle cushion portion (18) has a flat surface with a longitudinal elevated thoracic support (14) that adequately supports mid-section dorsal structures. The lower cushion portion (26) has a flat surface with a longitudinal elevated lumbar support (16) that adequately supports lower dorsal structures.

Owner:BRISCOE BETTY JANE

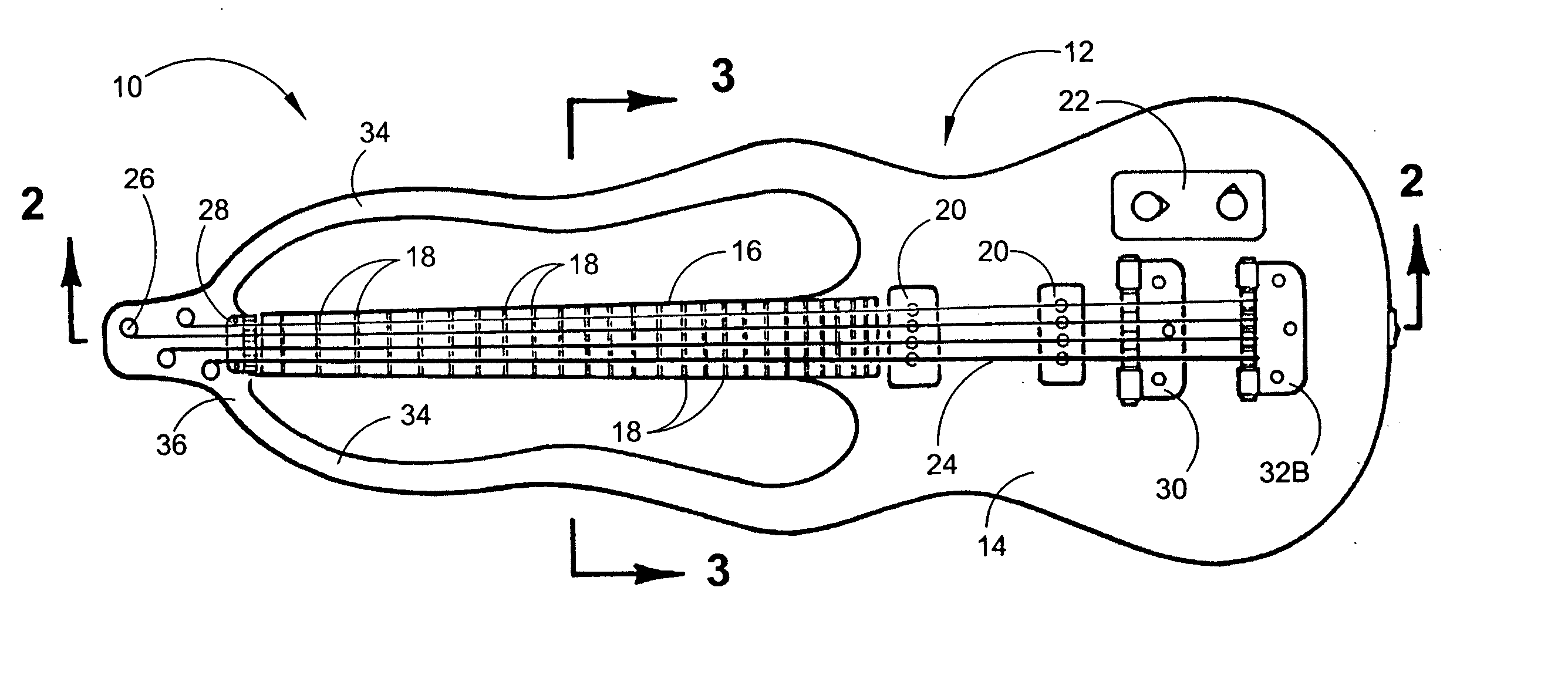

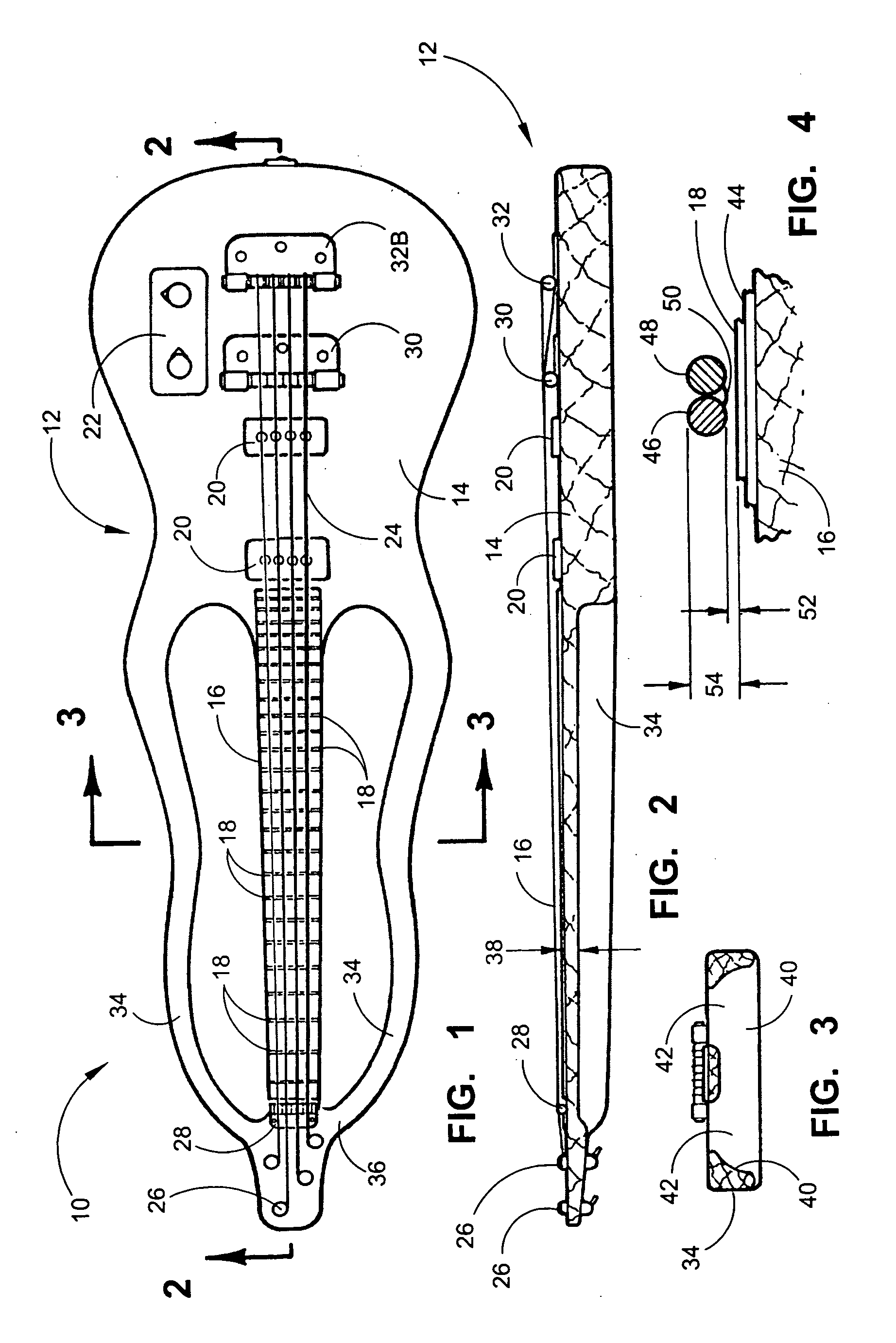

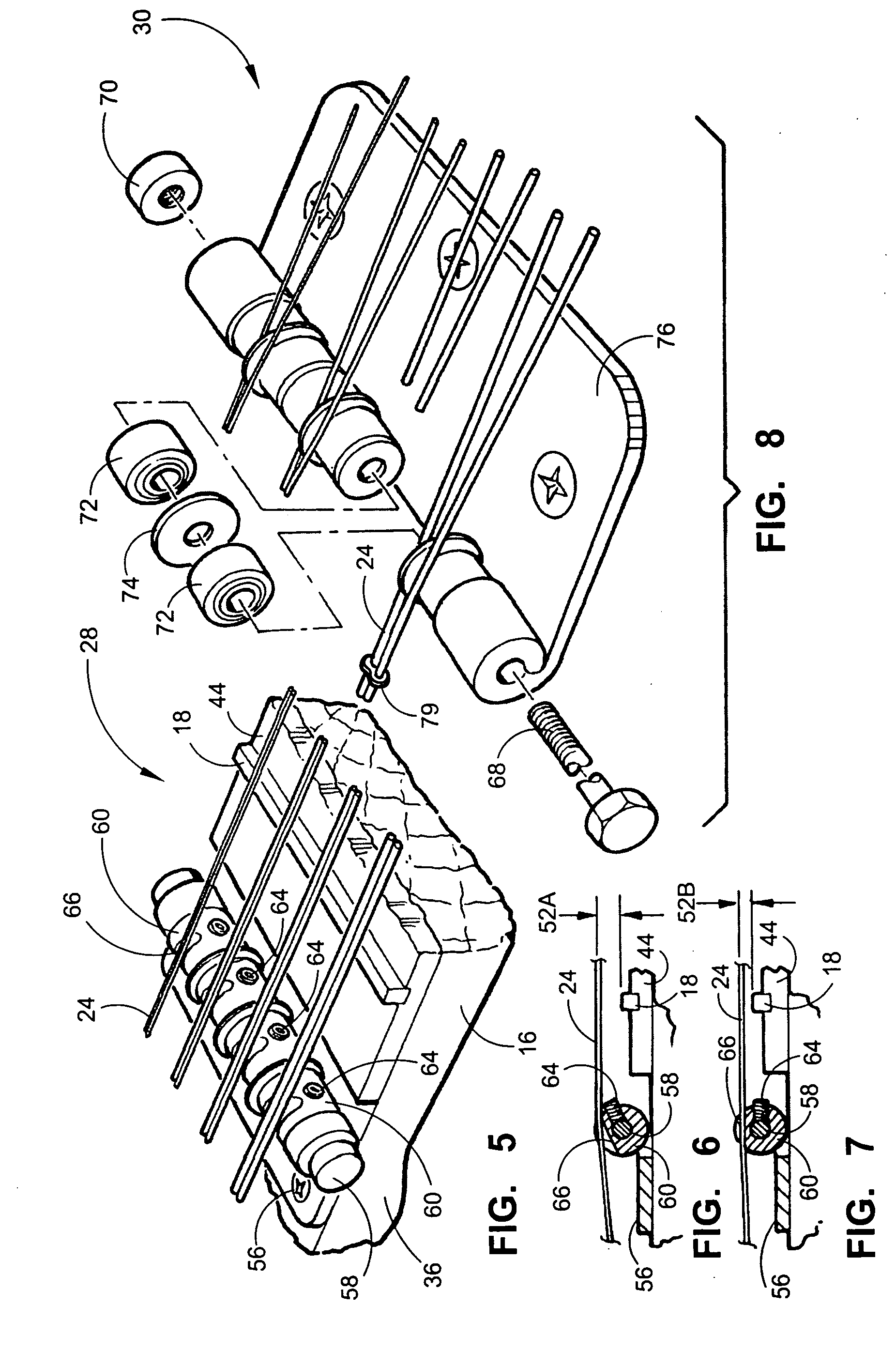

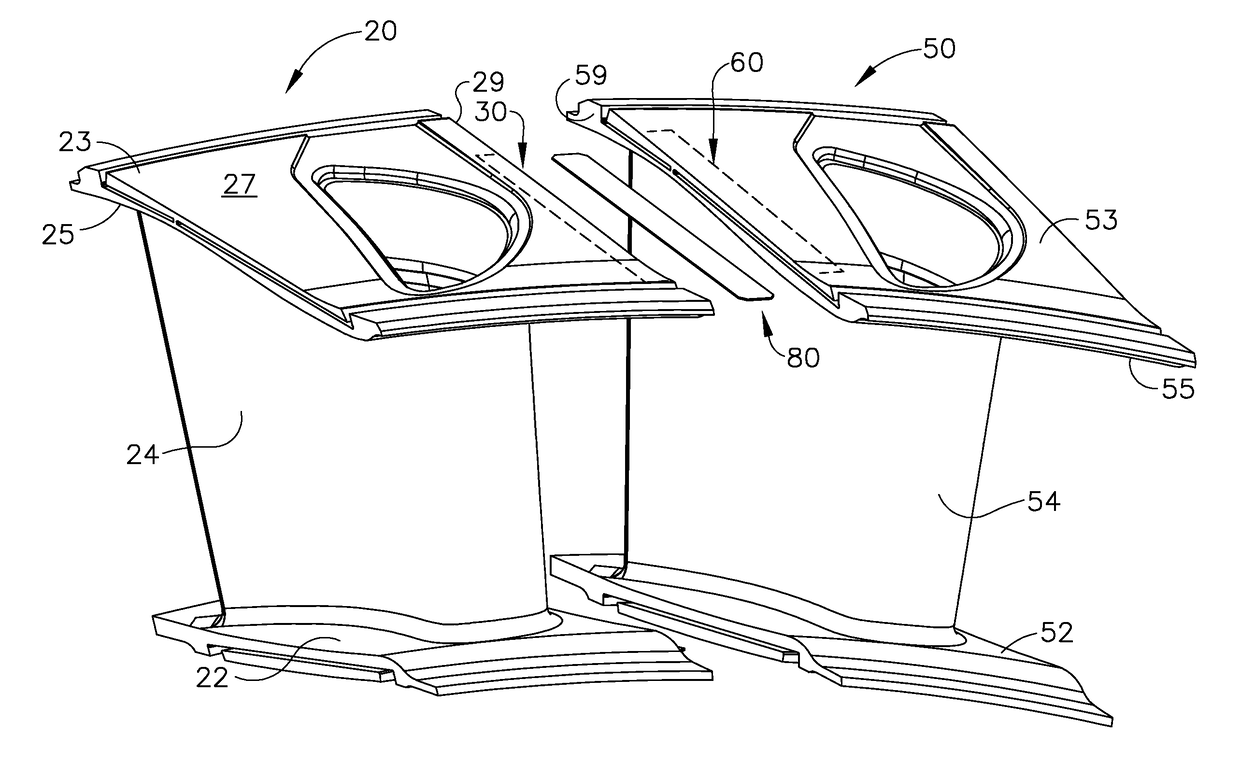

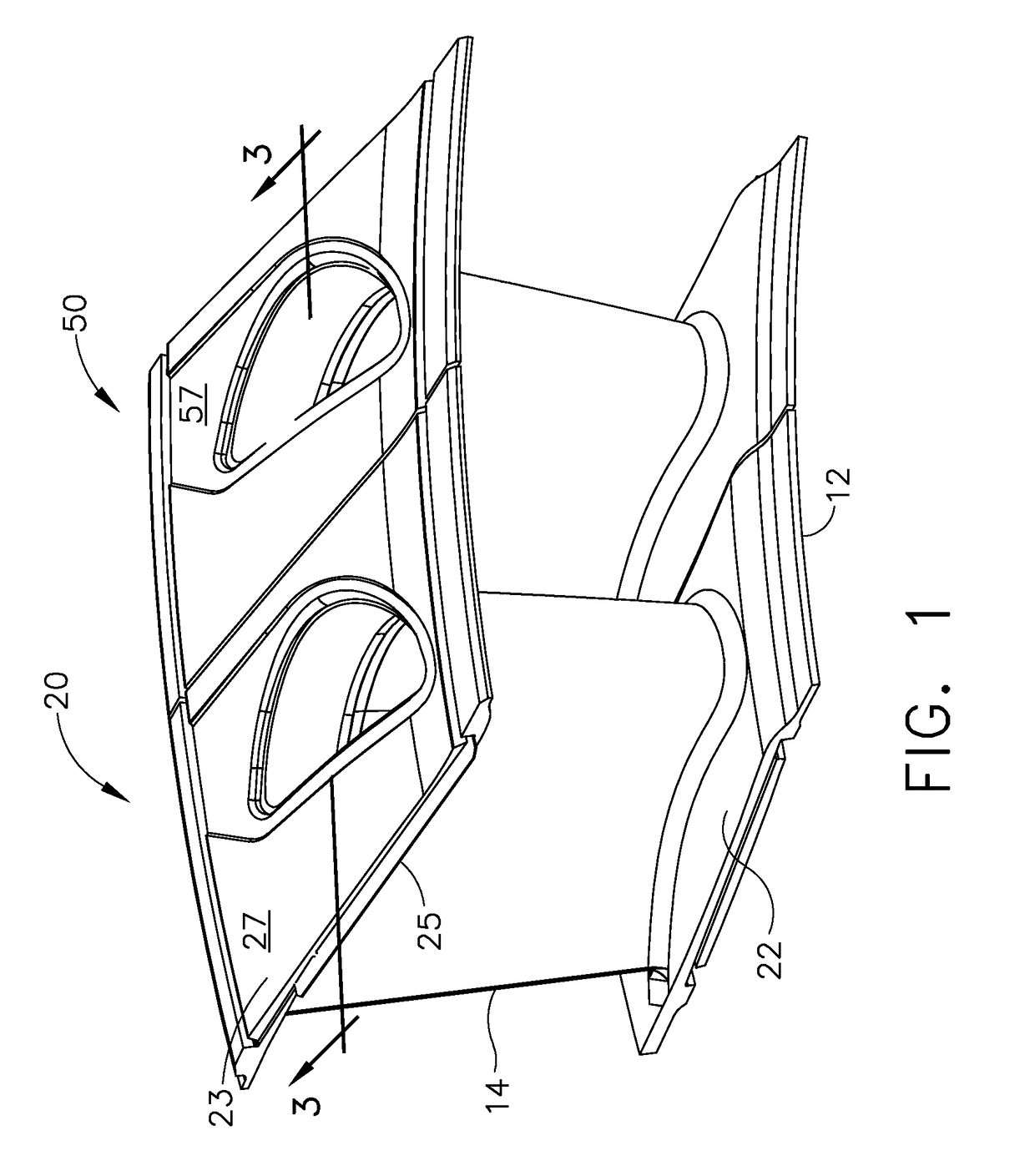

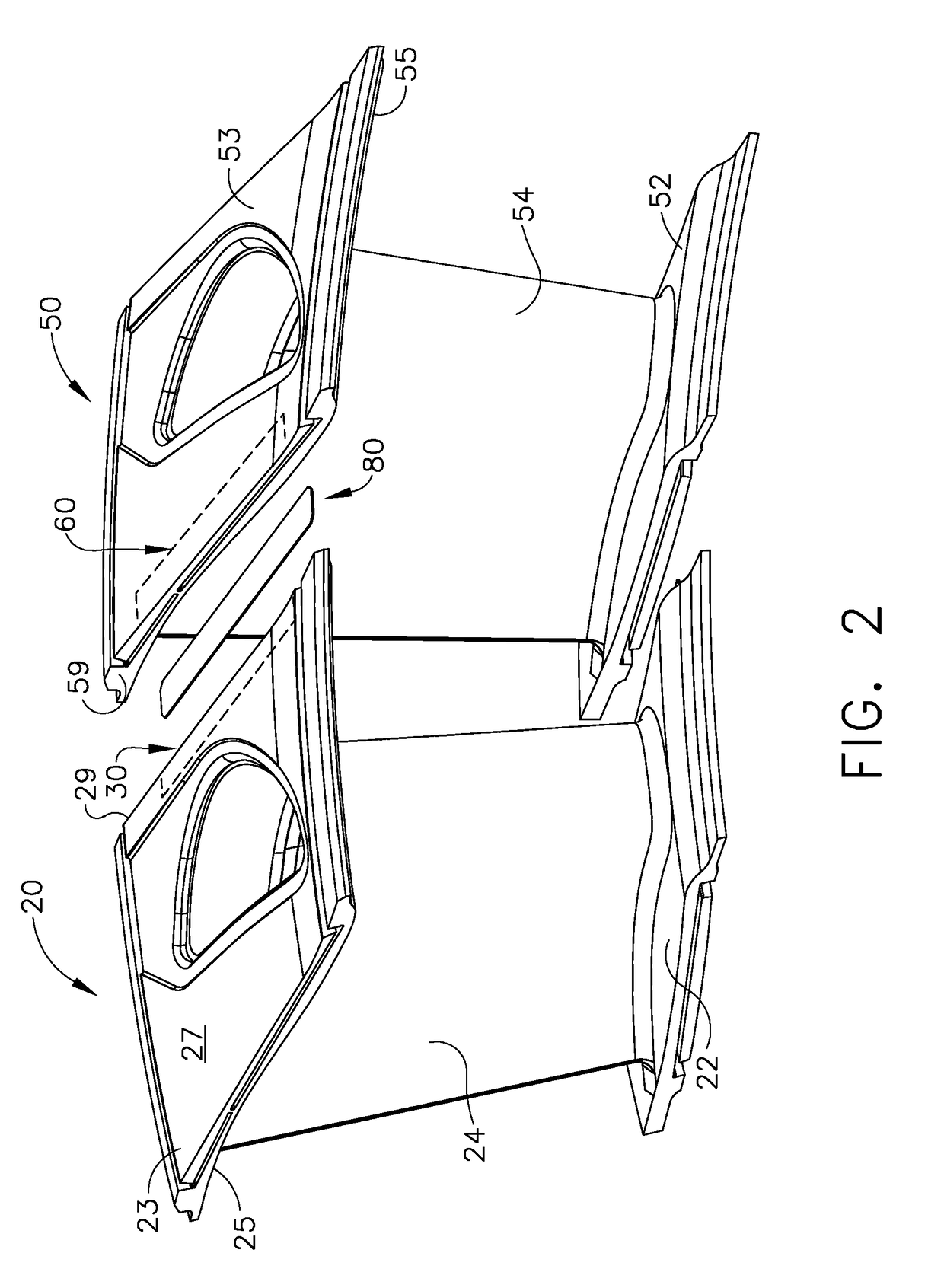

Compound musical instrument string configuration and support system

InactiveUS20050155480A1Support added stressGood neckStringed musical instrumentsSupporting systemNeck structure

An apparatus for doubling of the length of each string of a stringed instrument using two legs of an extended string. The effective longer string length allows for the production of a lower tone range without lengthening the neck of the instrument, or the same tone range while shortening the neck of the instrument. If required to prevent bowing of the neck, a reinforcing structure may be included to the neck structure or in a second preferred embodiment a buttress support to the neck of the instrument may be provided. The height of the paired strings above the fret board may also be adjusted.

Owner:JOSEPH PATTERSON MARTIN

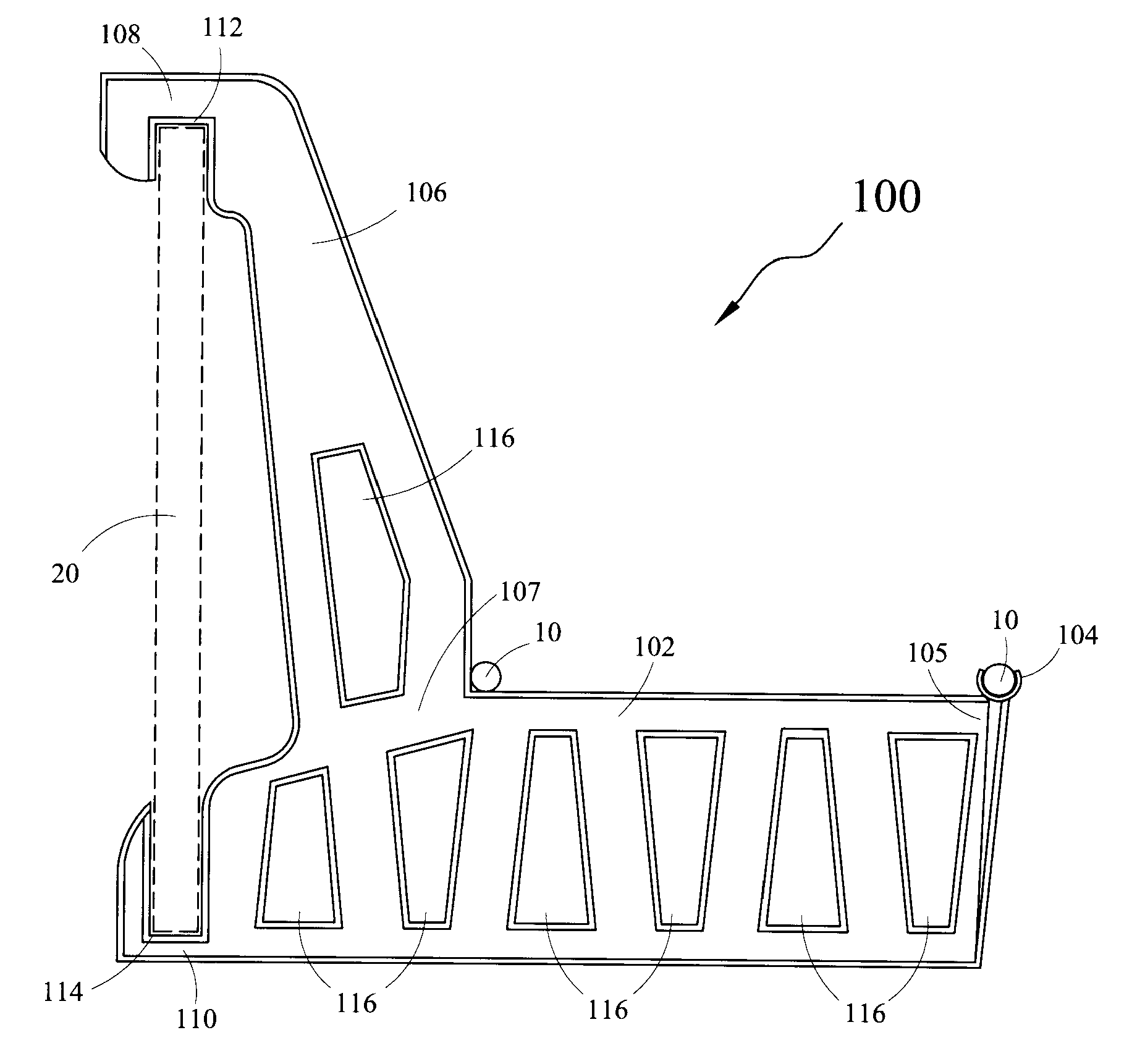

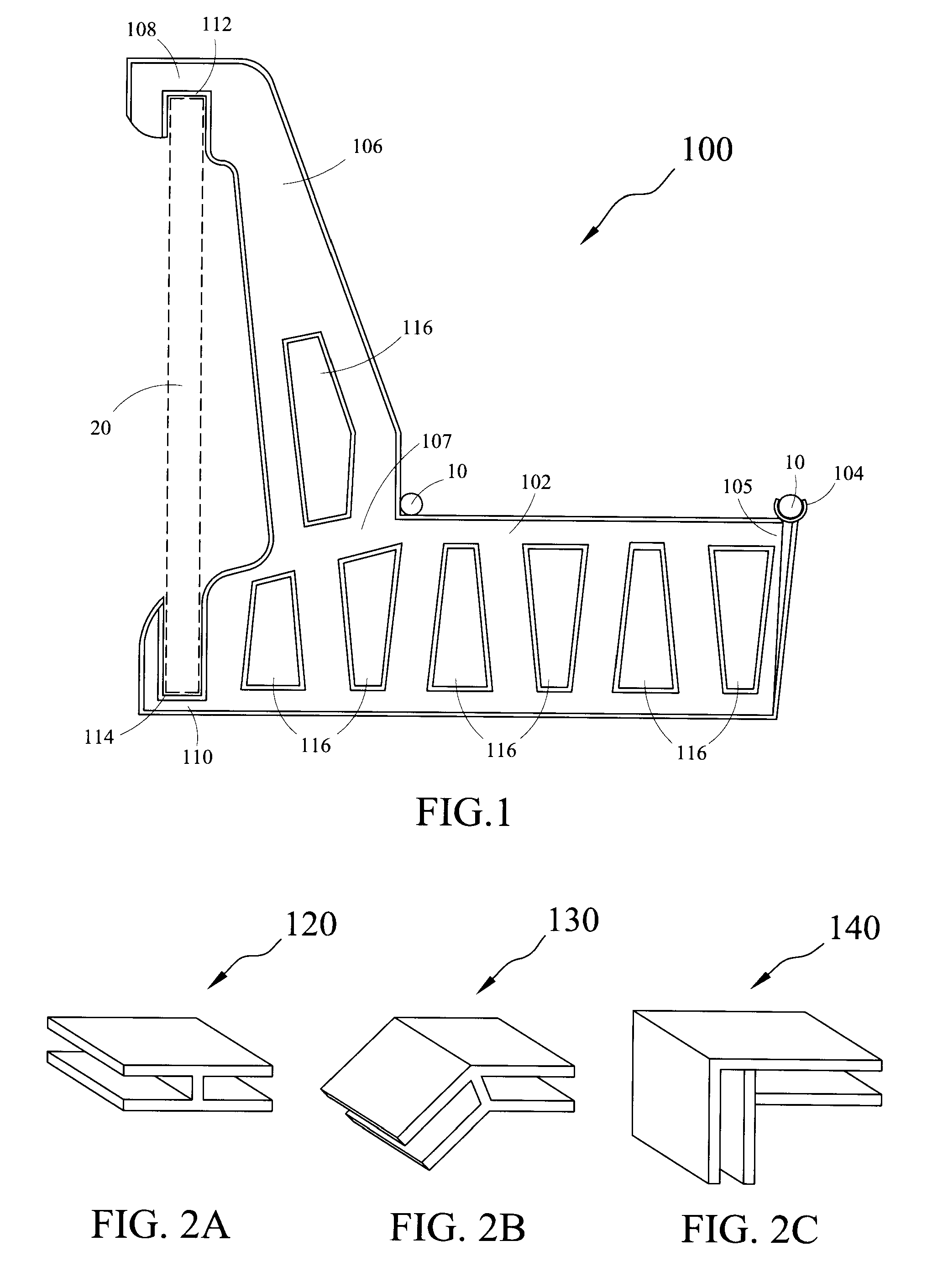

Building construction system for stem wall foundations

InactiveUS20090260306A1Overcomes drawbackQuick and easy and effective and economicalBuilding repairsFoundation engineeringNeck structureElongated neck

A building construction system for setting up and casting a stem wall foundation. The system comprises a plurality of forms, a plurality of code clips configured to fix the forms; and a plurality of code spacers having a body, a partially encircling clasp protruding from a first end portion of the body, and an elongated neck structure at a second end portion of the body and having a top receiving channel and a bottom receiving channel snapping the form in a vertical position. One of the code spacers is snapped onto a reinforcement bar and another of the spacers is distanced adjacently such that the elongated neck structure of code spacers facing opposite to each other, and the reinforcement bar is accommodated on the clasps of both the code spacers laterally and perpendicularly and two reinforcement bars accommodated at a junction of the body and the elongated neck structures.

Owner:EBANKS DESMOND A

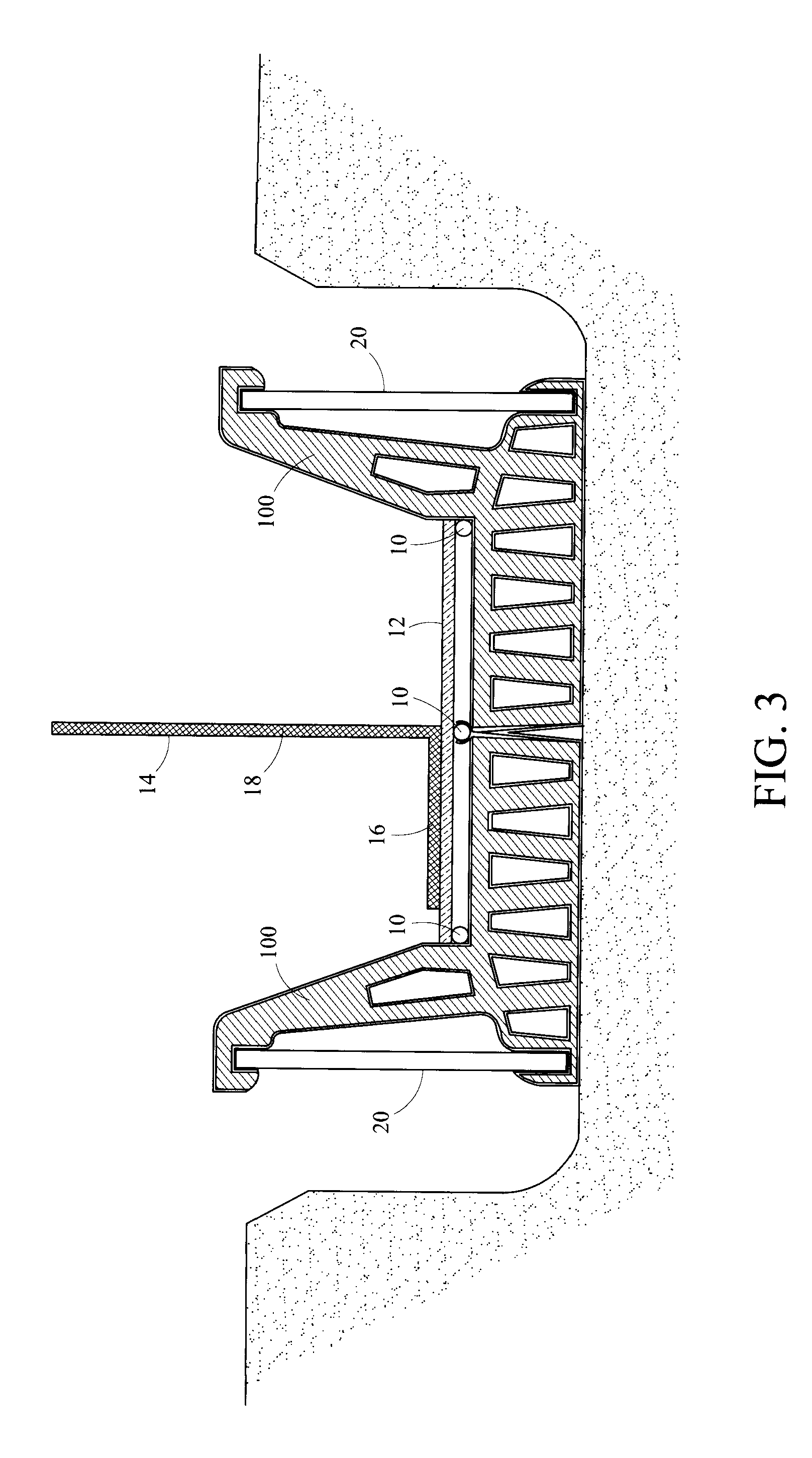

Turbine component having a seal slot and additive manufacturing process for making same

A method of forming a structure in a turbine component having a seal slot, the slot including walls defining an opening therebetween, the method includes the step of using an additive manufacturing process to form a neck structure on a wall so as to reduce a size of the opening.

Owner:GENERAL ELECTRIC CO

Medical metal implant material porous niobium and preparation method thereof

A porous niobium used as medical implant material is of a foam structure with three dimensional interconnecting pores. There is a sintering neck structure between the niobium particles. The method for preparing the porous niobium comprises the steps of using the niobium powder and the solution prepared by mixing an organic binder and a dispersant to obtain the niobium slurry, casting the niobium slurry into an organic foam body to immerse until the pores of the organic foam body are full of the niobium slurry, drying to remove the dispersant in the organic foam body in which the niobium slurry is cast, degreasing to remove the organic binder and the organic foam body in the protective environment of inert gas, and then vacuum sintering to obtain the porous sintered body. The porous niobium is of high porosity and good ductility.

Owner:CHONGQING RUNZE PHARM CO LTD

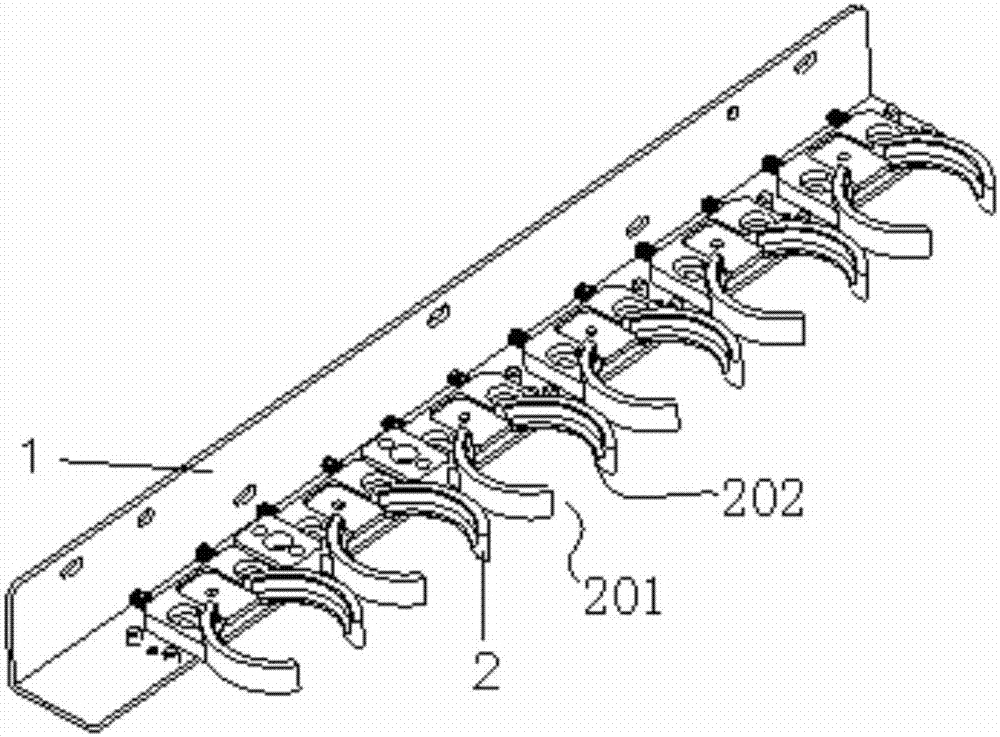

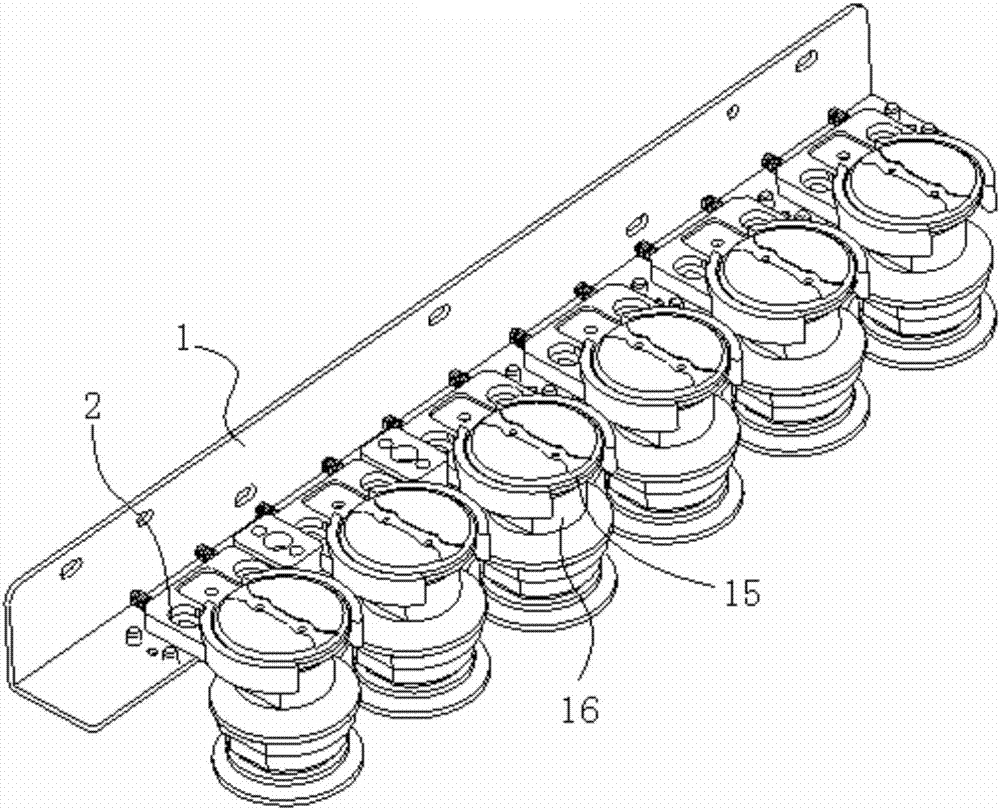

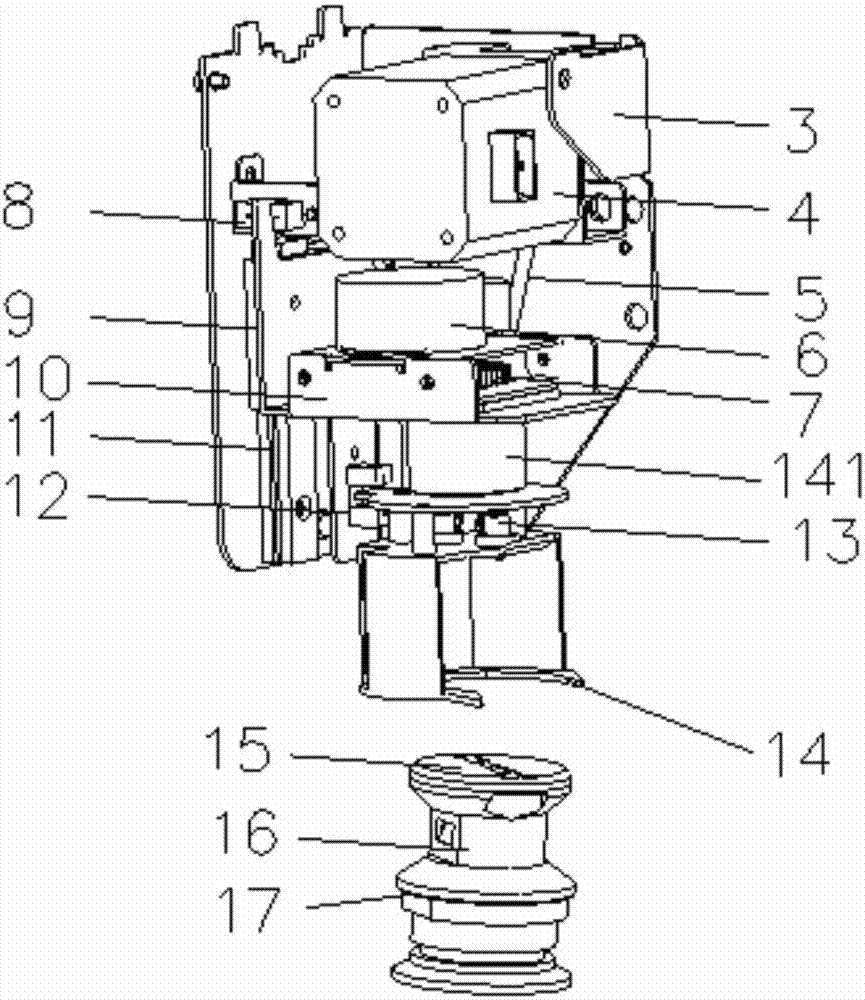

Buckled type automatic stamp taking-out and putting-in device

The invention discloses a buckled type automatic stamp taking-out and putting-in device which comprises a stamp storage room and a stamp taking-out mechanism. The stamp storage room comprises a plurality of stamp clamping bases used for locating stamps, and each stamp clamping base is of an annular component corresponding to the neck structure of the corresponding stamp and is provided with a clamping opening allowing the corresponding stamp neck to pass through. The stamp taking-out mechanism comprises a stamp taking-out claw connected with a three-coordinate linear moving system, the stamp taking-out claw is provided with a clamping opening opposite to the stamp clamping bases, and the clamping opening corresponds to stamp taking-out steps arranged on the stamps. A synchronous belt is driven by a lifting motor to drive the stamp taking-out claws to move up and down, a rotary motor drives the stamp taking-out claws to achieve the function of stamping in a stamp horizontal plane by any angle, and when stamp heads are moved to the clamping openings of the stamp clamping bases through stamp claws, the stamp taking-out claws can disengage from the stamp taking-out steps of the stamps; when the stamps are lifted by the stamp claws and the stamp necks are moved by the stamp claws to the clamping openings of the stamp clamping bases, the stamps can be easily taken out by the stamp taking-out claws, and the automatic stamp taking-out and putting-in functions are achieved.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

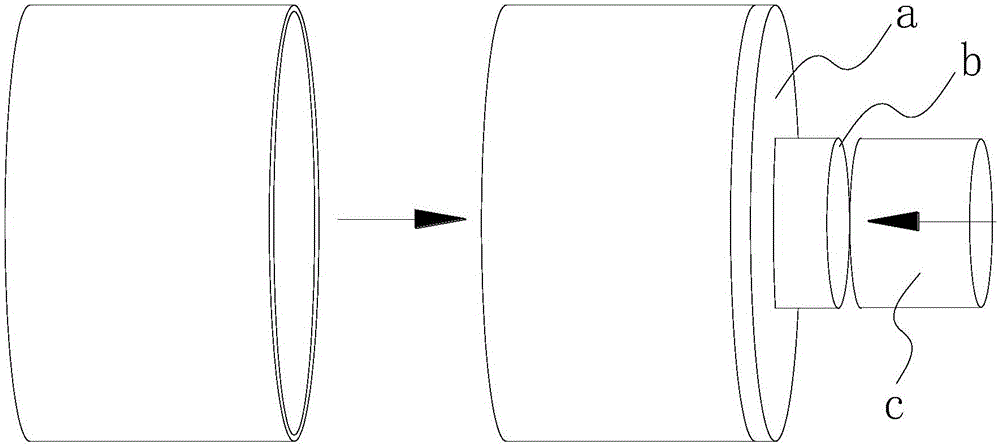

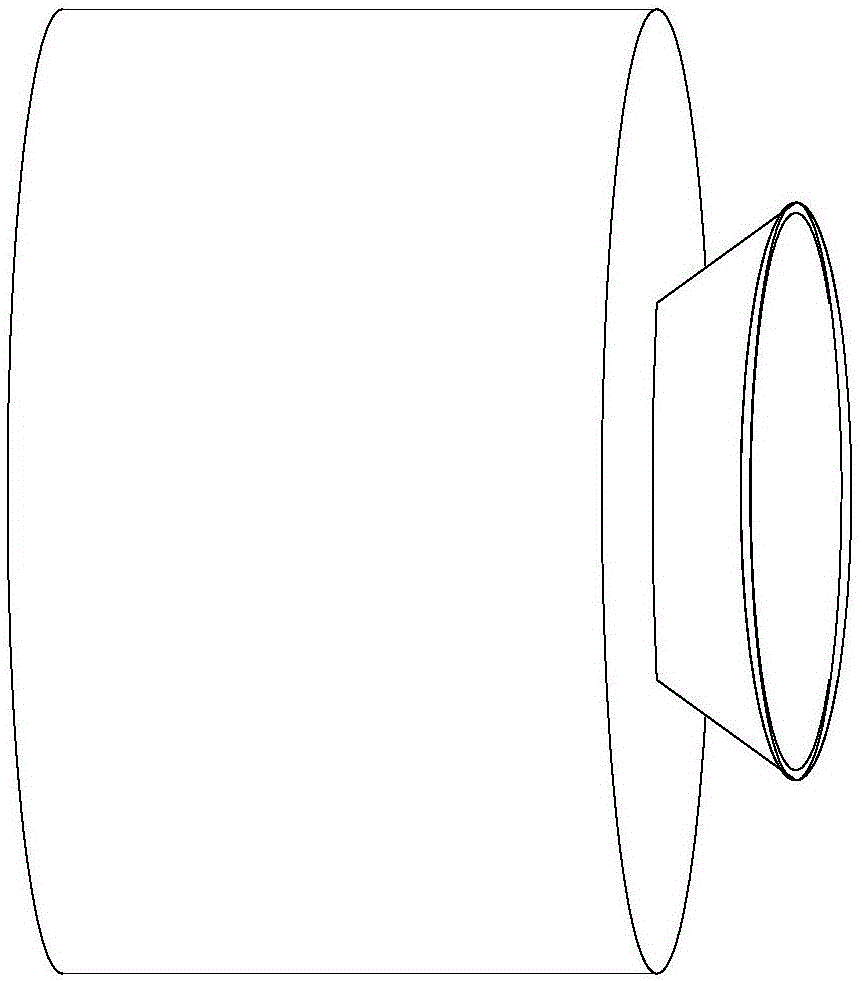

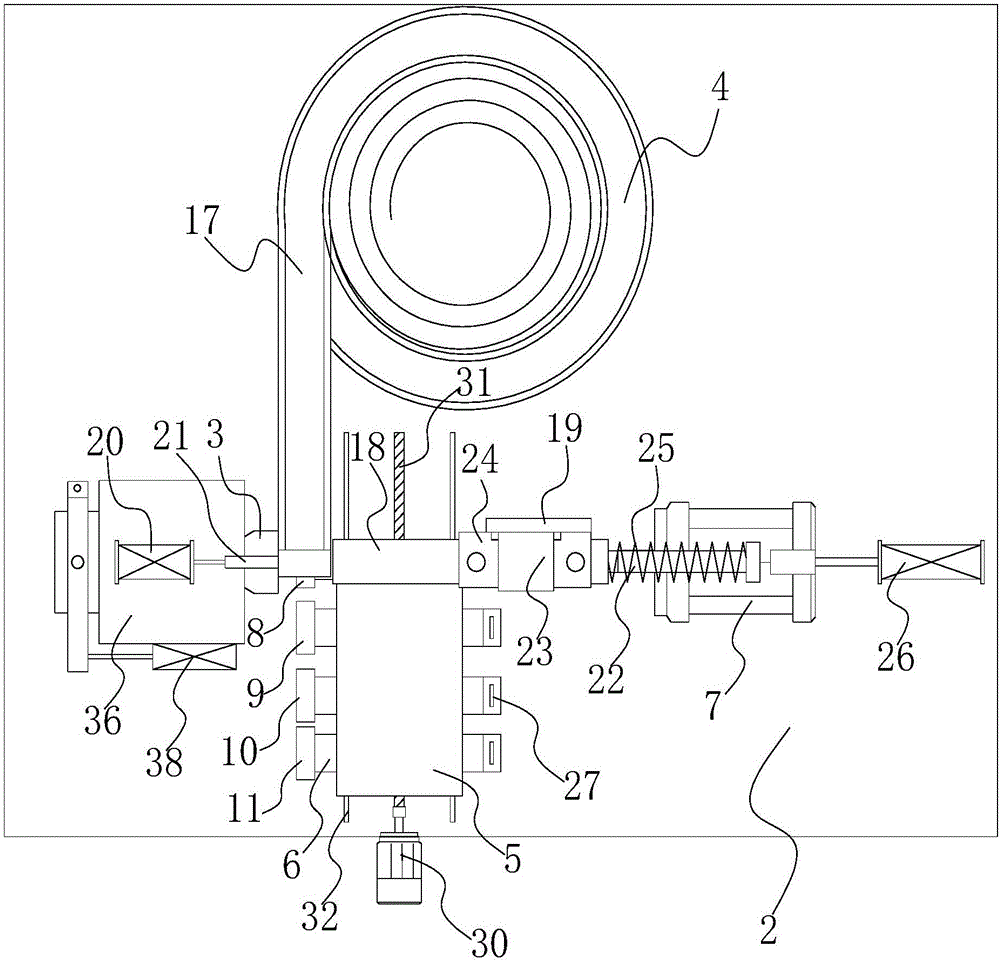

Continuous machining device for necking and flaring connecting parts of automotive air conditioner metal fittings

ActiveCN106270280AEasy to installAchieve continuous processingMetal-working feeding devicesVehicle componentsNeck structurePunching

The invention discloses a continuous machining device for necking and flaring connecting parts of automotive air conditioner metal fittings. The continuous machining device comprises a rack, a working table located on the rack, a fixture fixed to the working table and used for fixing the automotive air conditioner metal fittings to be machined and a vibration feed table used for conveying the automotive air conditioner metal fittings to be machined. A feeding mechanism located on one side of the fixture is arranged on the working table. Compared with the prior art, the continuous machining device shrinks the ends of the barrel-shaped automotive air conditioner metal fittings into necking structures through the cold pressing method and conducts direct punching on the necking parts into flared connecting parts. The traditional welding forming method is changed. The machining process is shortened. The flared connecting parts facilitate mounting of branch pipes. Meanwhile, the branch pipes can be fixed by necking the connecting part. The product quality and machining efficiency are improved. Continuous machining can be realized.

Owner:ZHEJIANG FANGHONG AIR CONDITIONING EQUIP

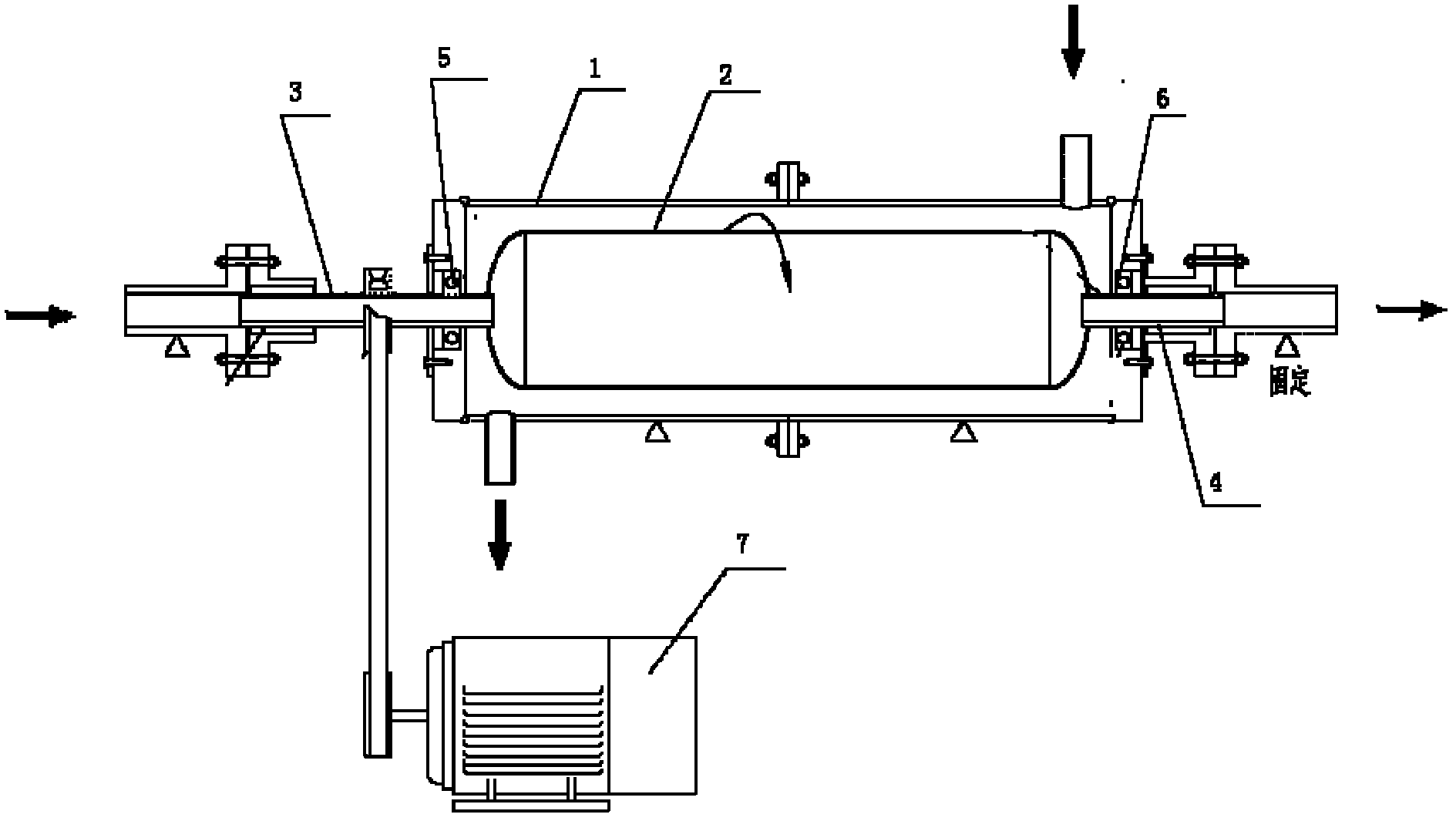

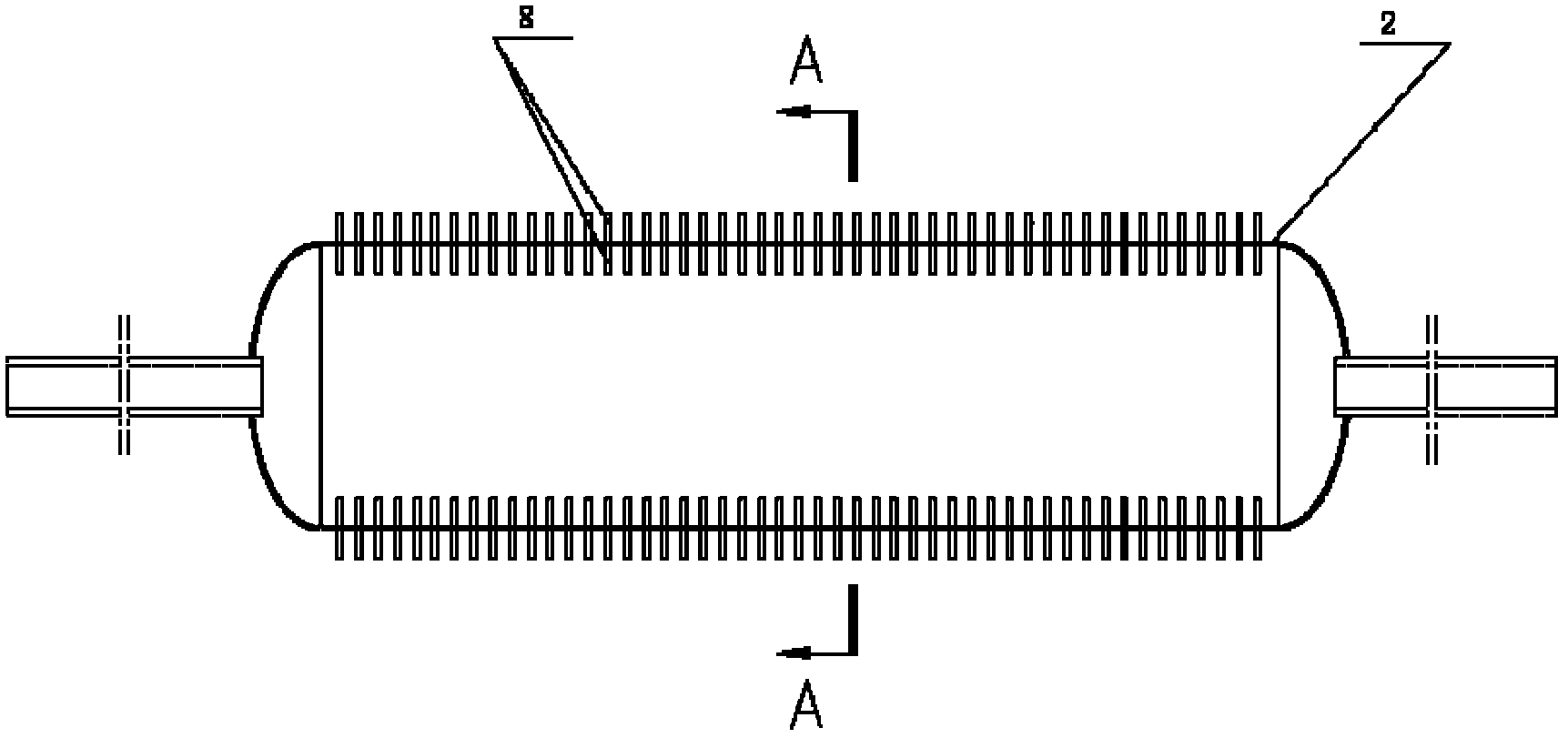

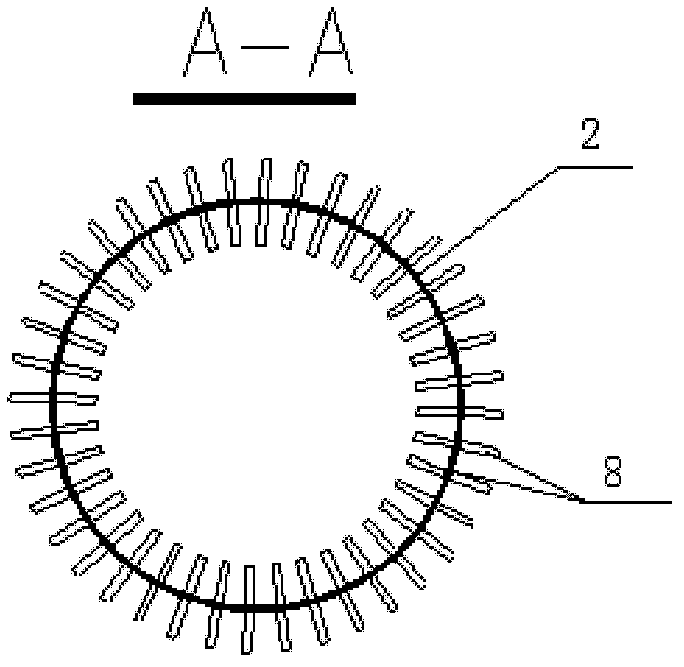

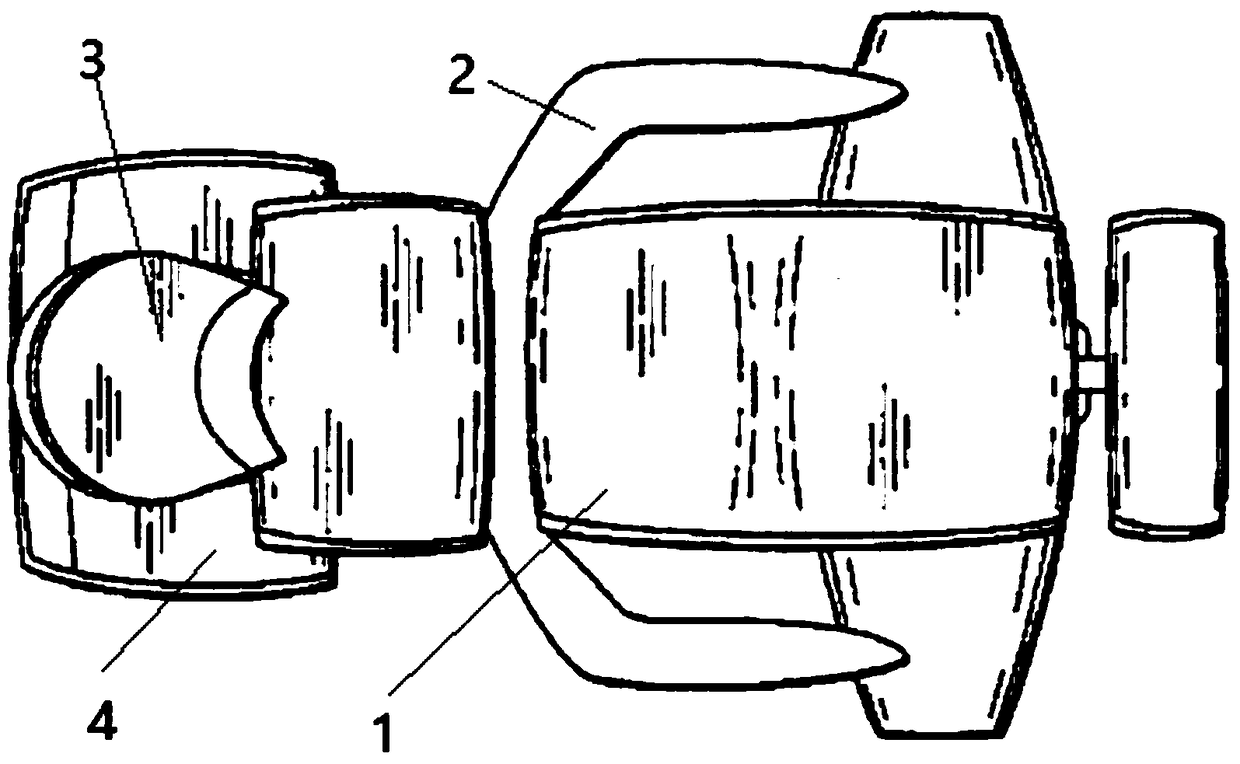

Heat exchanger with heat exchange surface capable of rotating so as to strengthen heat exchange

InactiveCN102519282AAvoid mutual leakageIncrease the heat exchange areaMoving conduit heat exchangersNeck structurePlate heat exchanger

The invention relates to a heat exchanger, in particular to a heat exchanger for viscous fluid with poor liquidity. The heat exchanger can be used for the fields of chemical engineering, petrochemical industry, food, medicine, papermaking, ships and the like and comprises a shell, an inner barrel, a motor, a heat exchange medium a, a heat exchange medium b, a bearing a and a bearing b; a fluid inlet and an outlet are arranged at the upper end and the lower end of the shell and are located at two ends of the shell; through holes are arranged at the left end and the right end of the shell, and annular grooves are arranged on the through holes; two ends of the inner barrel are necking structures; the heat exchange surface is capable of rotating, so that heat exchange area is increased, disturbance is improved so as to strengthen heat exchange, and the heat exchange medium a and the heat exchange medium b do not permeate to each other; and as hermetic connection between a rotating pipeline and an outer barrel is in non-elastic contact dynamic sealing, mutual permeation of the two heat exchange media can be prevented.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

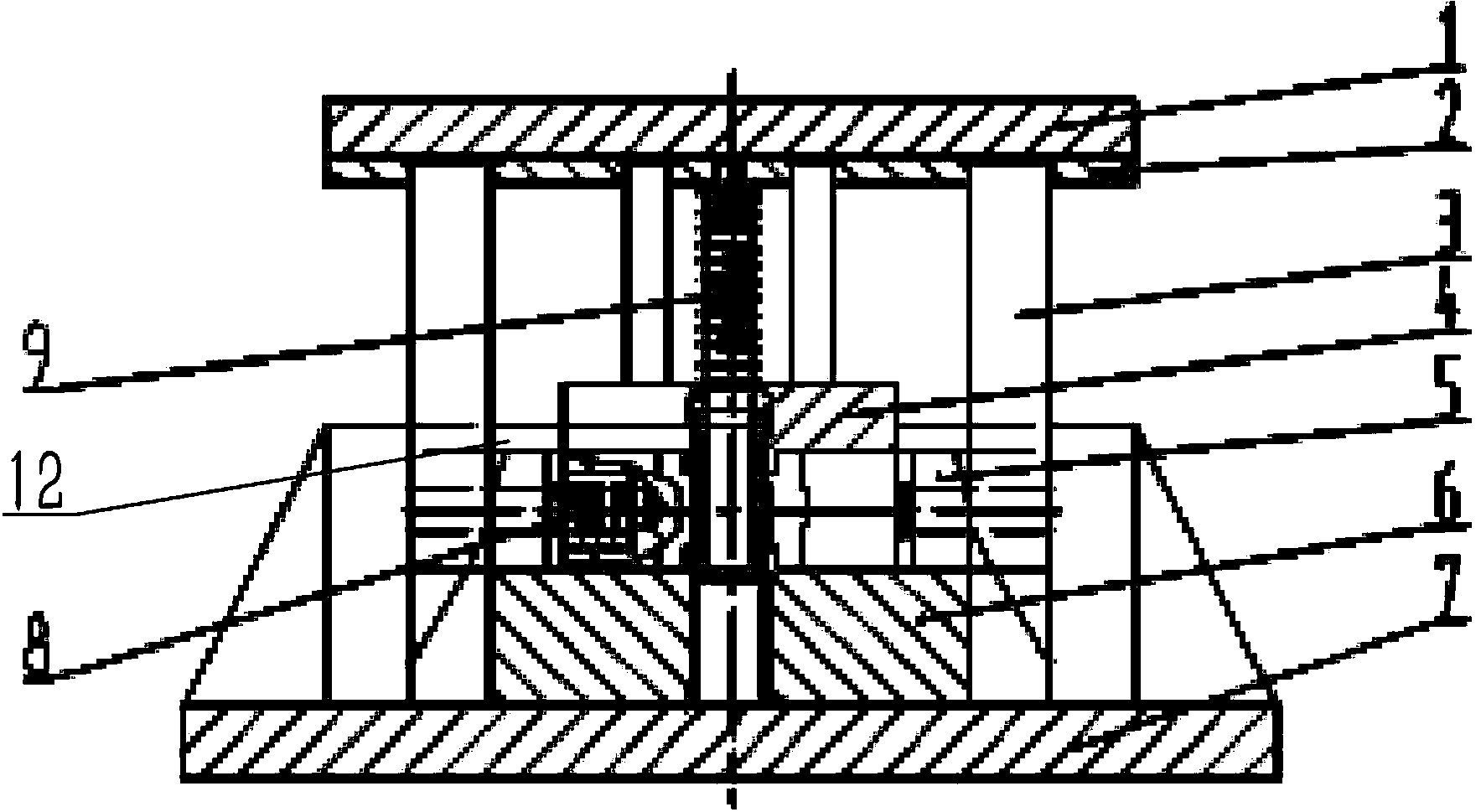

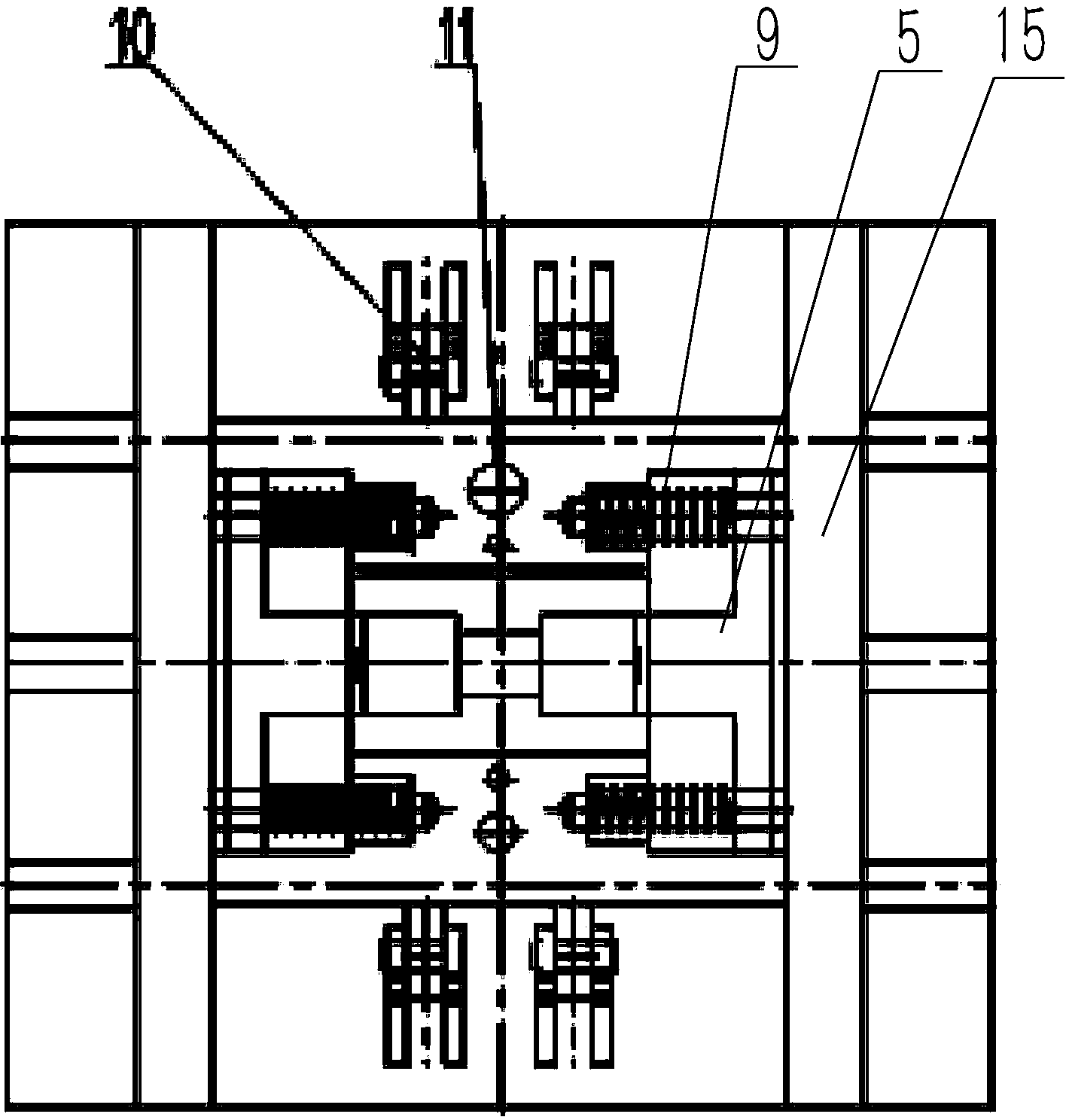

Forging mould and forming die of forging mould

InactiveCN104325058AImprove processing efficiencyImprove machining accuracyForging/hammering/pressing machinesNeck structureNeck parts

The invention discloses a forging mould and a forming die of the forging mould. A die cavity of the forming die is a necking cavity which is wide in two ends and narrow in middle, wherein die cores are assembled on two ends of the die cavity by guiding and moving in opposite directions; opposite ends of the two die cores are forming ends; the reverse ends of the two die cores are force transmission ends which are matched with a wedge-shaped surface of a wedge-shaped part and are pressed into the inner end of a guide hole. When the forming die is used, along with lamination of a pressing die to a main die body, the wedge-shaped part is matched with the wedge-shaped surface, so that the forming ends of the two die cores are oppositely pressed, and thus the whole die cores oppositely move in the die cavity; the forming ends of the die cores are used for oppositely extruding and thickening two ends of a bar in the die cavity; the forging and forming can be implemented by extruding the end of the bar by the forming ends of the die cores, namely two ends of the bar are simultaneously thickened and a necking part is processed in the middle of the bar, so that the processing efficiency of the bar for forging and processing thin-neck structures; the processing accuracy is improved.

Owner:HENAN PINGGAO ELECTRIC +2

Gas-liquid-solid three-phase fluid mixing apparatus

ActiveCN104906731AImprove spray distanceMeet the needs of firefightingFire rescueNeck structureInjection port

The present invention discloses a gas-liquid-solid three-phase fluid mixing apparatus, which comprises a mixing cylinder, wherein the mixing cylinder comprises a liquid-phase injection section, a solid-liquid mixing section, a gas-liquid-solid three-phase mixing section, and a three-phase jet flow output section, the liquid-phase injection section, the solid-liquid mixing section, the gas-liquid-solid three-phase mixing section and the three-phase jet flow output section are sequentially communicated, the liquid-phase injection section is provided with a liquid-phase injection port, the solid-liquid mixing section is provided with a solid-phase injection port, the gas-liquid-solid three-phase mixing section is provided with a gas-phase injection port, the three-phase jet flow output section is provided with a three-phase jet flow output port, the liquid-phase injection port of the liquid-phase injection section is provided with a necking structure, the solid-phase injection port and the gas-phase injection port are annular injection ports, the included angle of the solid-phase injection port and the flowing direction of the fluid in the mixing cylinder is 45-60 DEG C, and the included angle of the gas-phase injection port and the flowing direction of the fluid in the mixing cylinder is 45-60 DEG C. According to the present invention, the internal structure of the existing mixing apparatus is changed and the gas phase mixing is arranged so as to fundamentally change the characteristic of the flow field, and with the solid particle stirring effect, the liquid phase and air mixing effect is strengthened so as to achieve the large flow spraying of the positive pressure type foam generator, improve the foam foaming performance, and increase the fire extinguishing efficiency.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

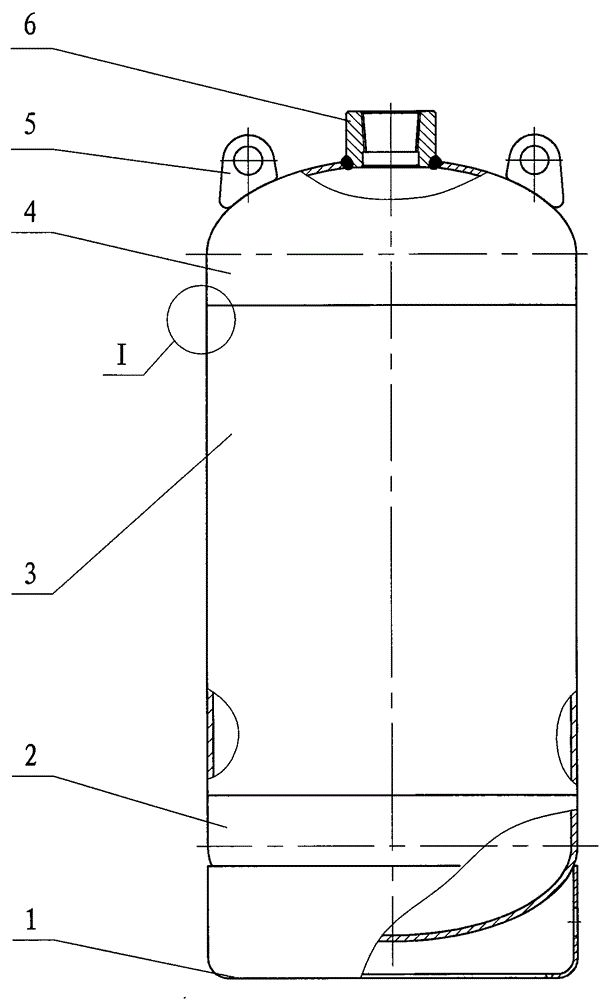

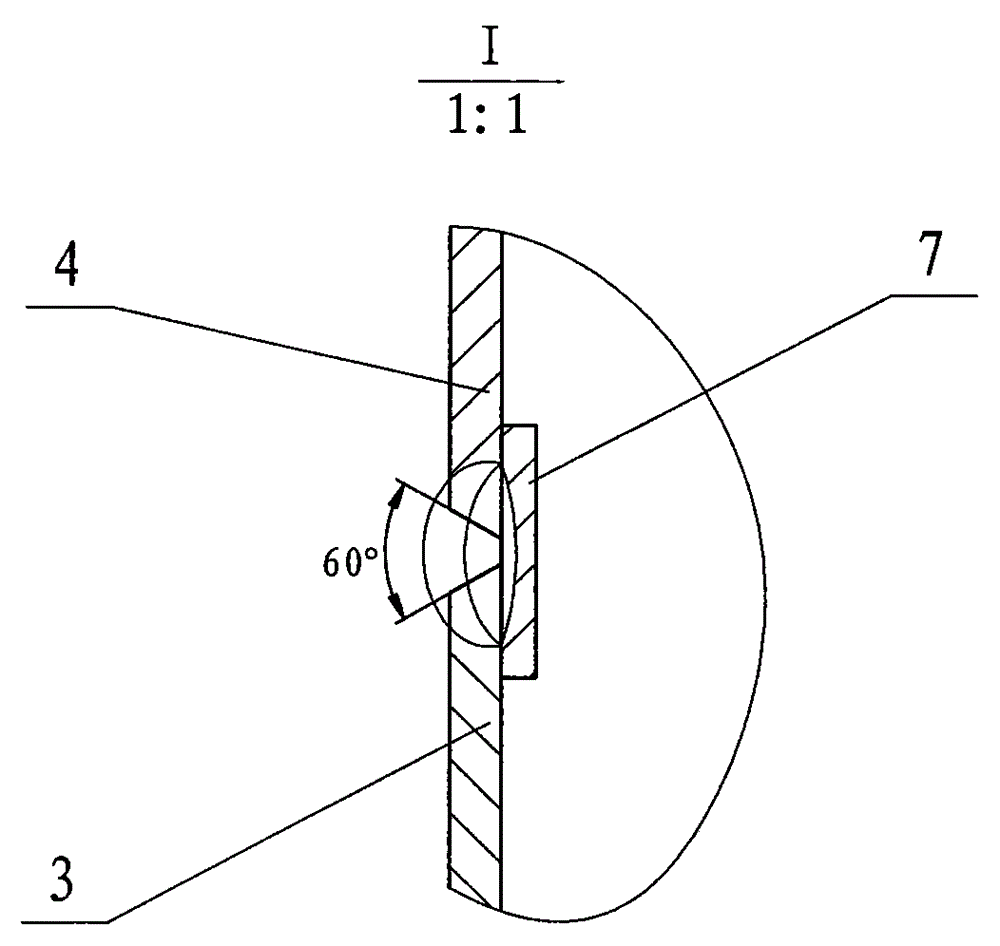

Fire protection heptafluoropropane steel cylinder and manufacturing method thereof

InactiveCN104154412AGuaranteed roundnessImprove welding qualityContainer filling methodsPressure vesselsNeck structureFire protection

The invention relates to a fire protection heptafluoropropane steel cylinder and a manufacturing method thereof and aims at providing a fire protection heptafluoropropane steel cylinder which is free of process pad ring and simple in machining process and a manufacturing method of the fire protection heptafluoropropane steel cylinder; no clearance is reserved between a cylinder body and sealing heads after the steel cylinder body is paired with the sealing heads, so that the roundness of the cylinder body can be guaranteed, the quality of the machining process can be improved, and the welding defect can be eliminated. According to the technical scheme, the fire protection heptafluoropropane steel cylinder comprises an upper sealing head, a lower sealing head, the cylinder body, a base, a valve seat and a lifting lug; the fire protection heptafluoropropane steel cylinder is characterized in that necking structures are designed on the upper sealing head and the lower sealing head.

Owner:汪佳泉

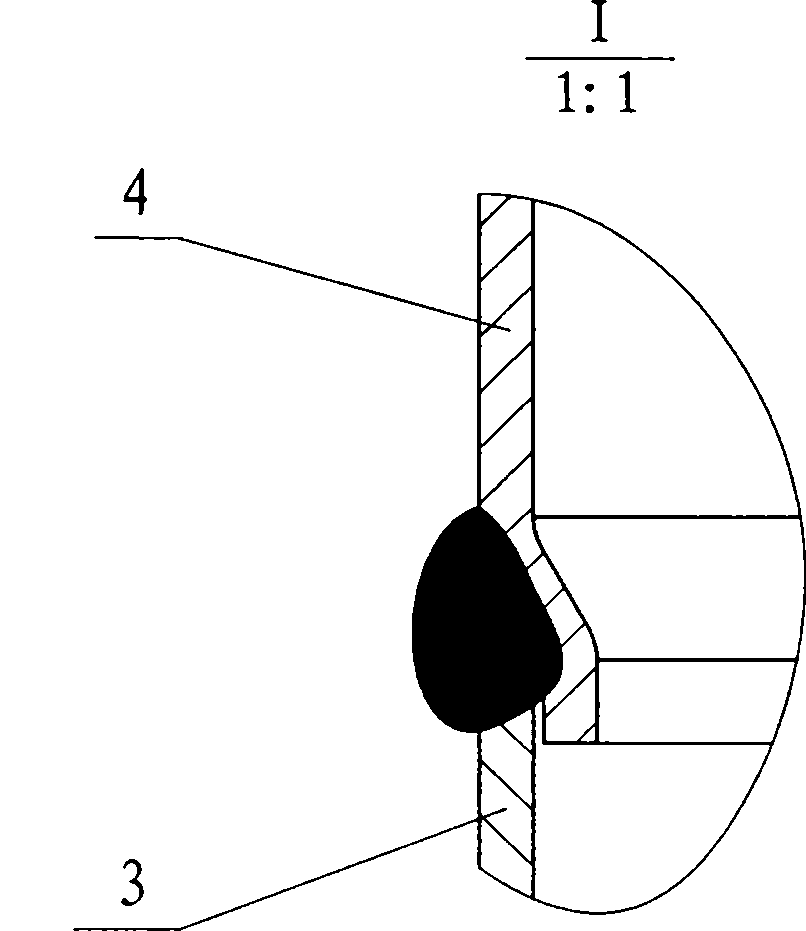

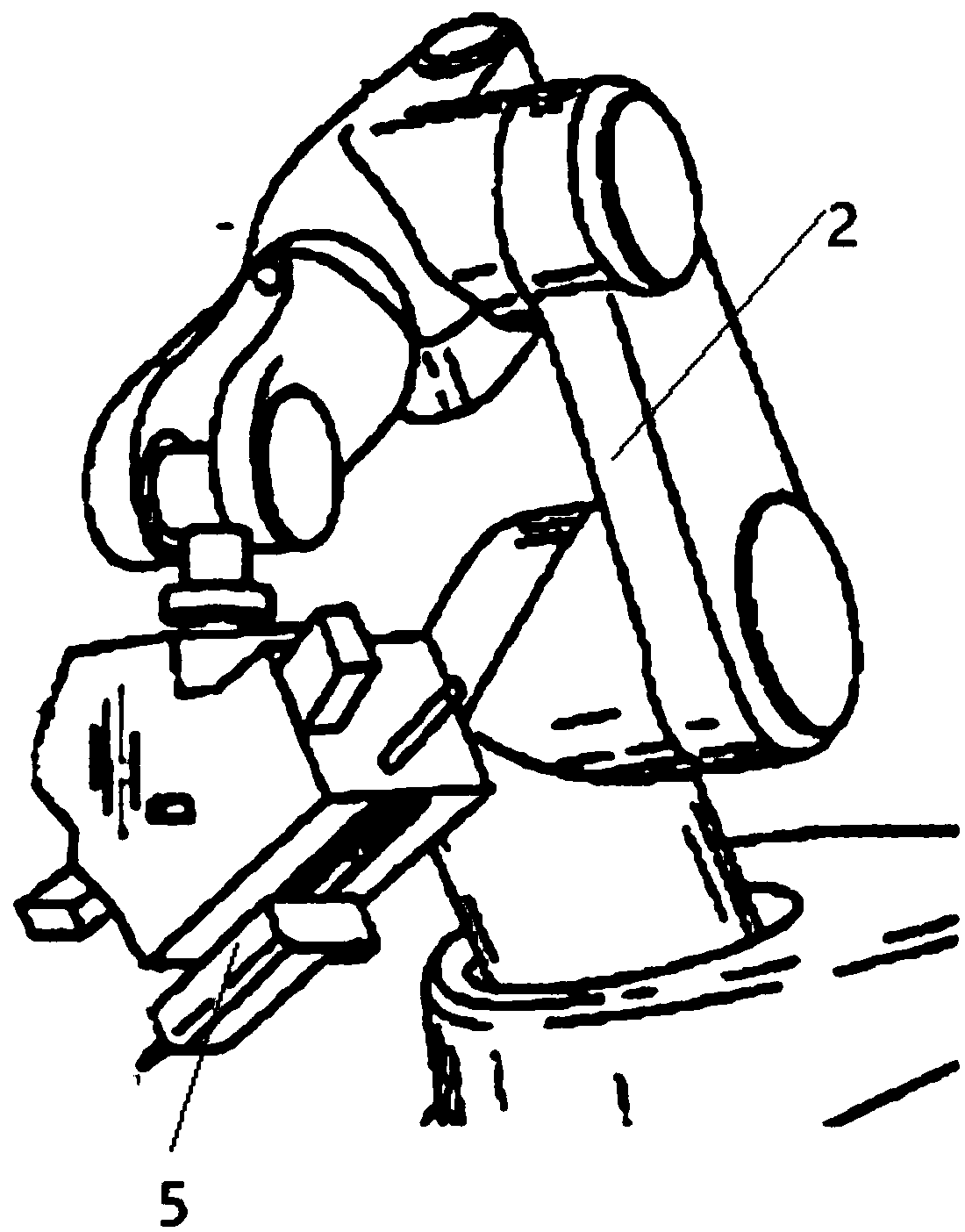

Hair transplantation robot

ActiveCN109044424APowerfulEasy and flexible operationSkin implantsSurgical robotsNeck structureGraft transplant

A hair transplantation robot comprises a robot body (1), robot limb structures (2), a robot neck structure (3) and a robot head structure (4). The robot limb structures (2) can be hinged to the robotbody (1), the robot neck structure (3) is connected to the upper portion of the robot body (1), and the robot head structure (4) can be hinged to the robot neck structure (3); each robot limb structure (2) is provided with an operation end (5) arranged at the front end, the robot neck structure (3) serves as a fixing device for fixing the patient's head in hair transplantation, and the robot headstructure (4) serves as a control and image acquisition terminal in hair transplantation. The hair transplantation robot integrates various functions such as hair transfer, hair transplantation, hairfollicle detection and diagnosis, and is powerful in function, flexible and easy to operate and capable of meeting various demands of hair transplantation patients.

Owner:南京新生医疗科技发展有限公司

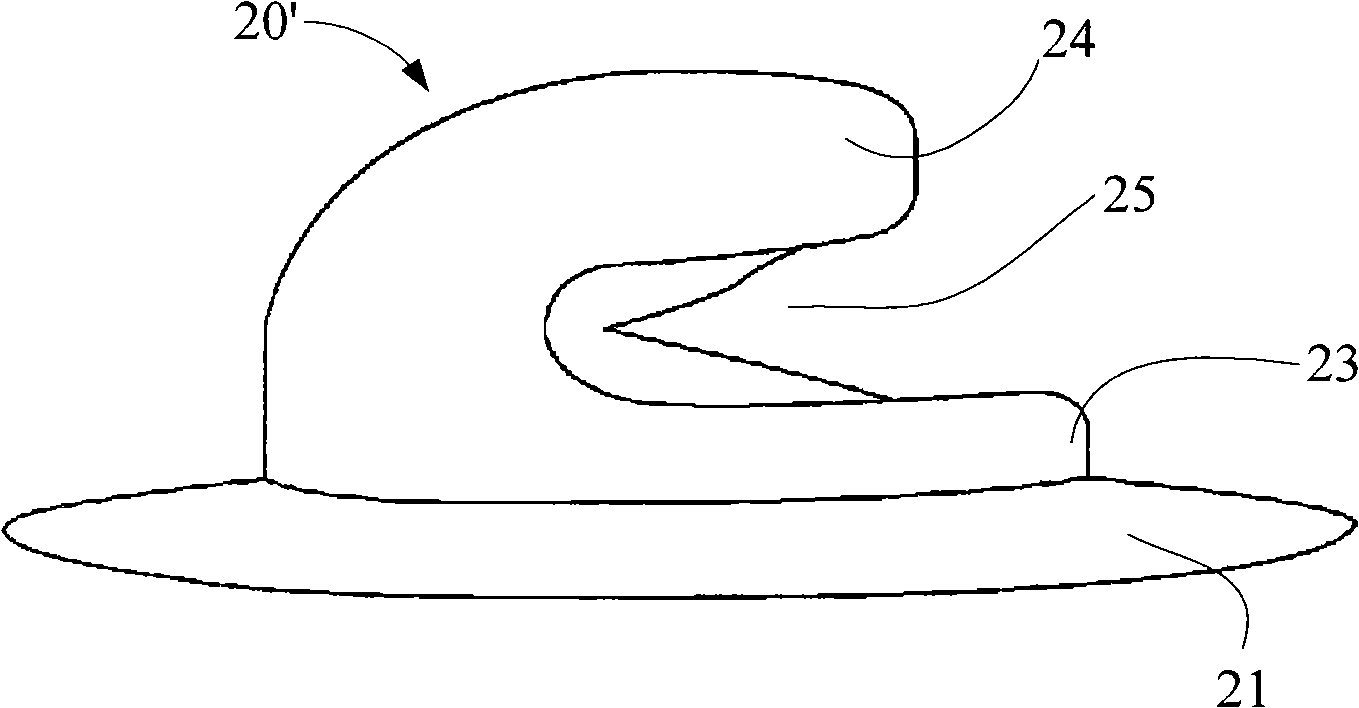

Shoelace buckle and shoes

The invention discloses a shoelace buckle used in shoes, which comprises a bottom, a neck which is cut across the surface on the bottom from one end of the bottom and is protruded and an arm extending transversely from the neck to the other end of the bottom. The arm, the neck and the bottom jointly define an accommodating hole used for accommodating a shoelace; the end of the arm protrudes a stop part towards the bottom; an opening, which is communicated with the accommodating hole and has the height lower than the accommodating hole, is defined between the stop part and the bottom; the height of the opening is set to elastically extrude the shoelace so as to place the extruded shoelace in the accommodating hole through the opening. The opening and the accommodating hole are formed into a necking structure, and the shoelace can be elastically stuck in the necking structure or taken out from the necking structure by elastically extruding the shoelace by the shoelace buckle, so that the shoelace conveniently is stuck on the shoelace buckle; moreover, the shoelace can slide freely inside the necking structure. In addition, the invention discloses shoes with the shoelace buckle and shoes provided with the shoelace buckle, the shoelace and a shoelace tightness control device at the same time.

Owner:刘兴棋

High-efficiency flexible dye-sensitized solar cell and preparation method thereof

InactiveCN103531362AImprove efficiencyIncrease photocurrentLight-sensitive devicesPhotovoltaic energy generationNeck structureSolar cell

The invention discloses a high-efficiency flexible dye-sensitized solar cell comprising a photoanode, a counter electrode and an electrolyte filling the space between the two electrodes. Moreover, the dye-sensitized solar cell is characterized in the photoanode includes a conductive substrate, a porous metallic oxide film, and dyes absorbed on the porous metallic oxide film; the counter electrode includes a conductive substrate and a catalyst film deposited on the conductive substrate. Besides, neck structure are formed between metallic oxide particles in the porous metallic oxide film by bridging. In addition, the invention also discloses a method for preparing the high-efficiency flexible dye-sensitized solar cell. According to the invention, the light current of the cell is enhanced; the cell efficiency is improved; the production energy consumption during the preparation process is reduced; and the production efficiency is improved.

Owner:EAST CHINA NORMAL UNIV +1

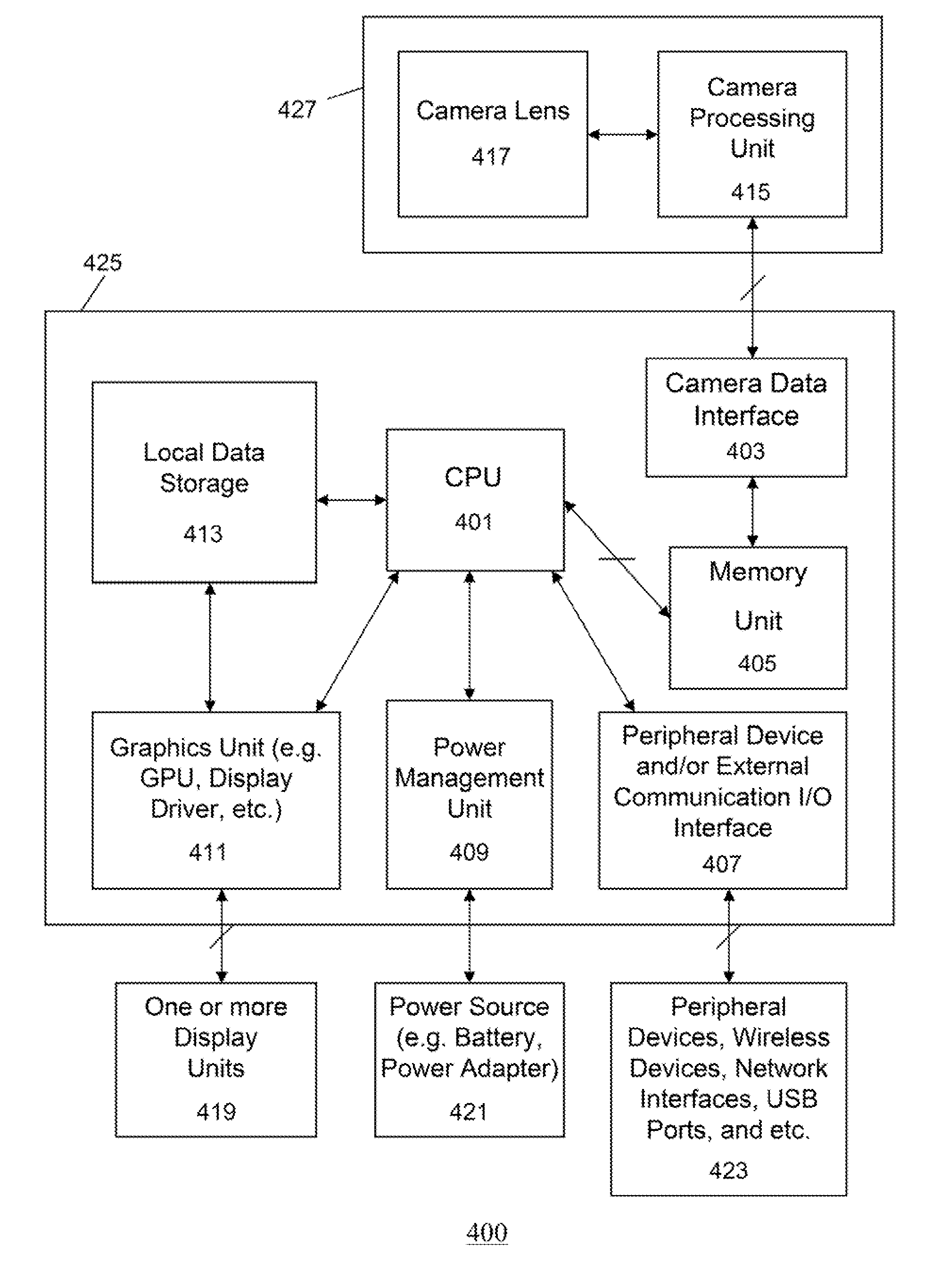

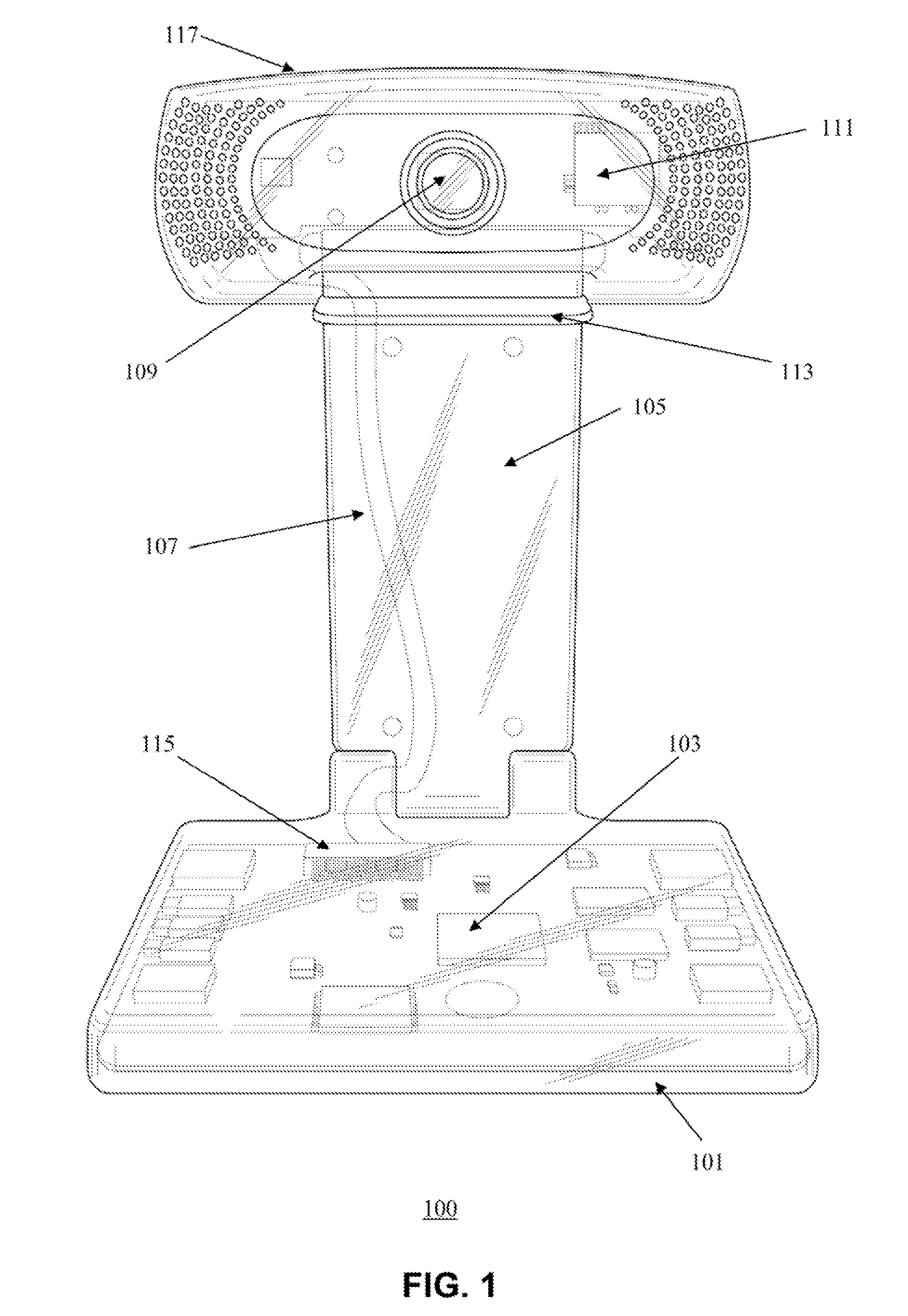

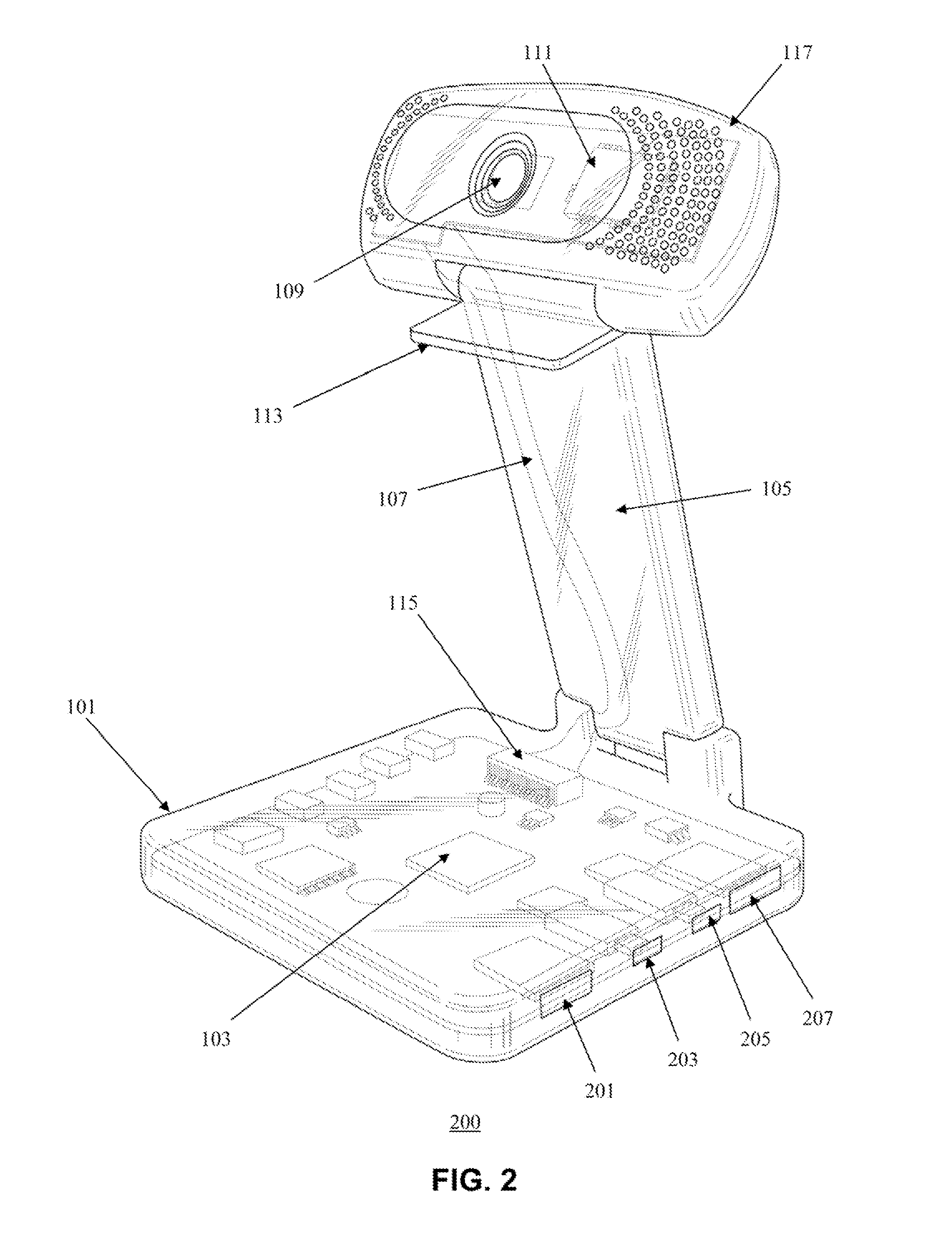

Smart Webcam Device in Distributed Circuit Casings and Cable-Encapsulating Neck Structure

Various embodiments of a novel smart webcam device in distributed circuit casings and cable-encapsulating neck structure are disclosed. In one embodiment, the novel smart webcam device has a bottom housing that contains a network communication-capable computing circuitry, a top housing that contains a webcam-specific circuitry (e.g. a camera lens and a camera processing unit), and a cable-encapsulating neck structure interposed between the bottom housing and the top housing that uniquely encapsulates a data communication and power cable, which connects a camera data interface in the bottom housing and a webcam unit interface in the top housing. Preferably, the top housing and the bottom housing are swivel-capable around the cable-encapsulating neck structure. The novel smart webcam device is internally capable of transforming raw multimedia data captured from the webcam-specific circuitry into processed multimedia data in standardized formats, and can also transmit the processed multimedia data over a data network.

Owner:HUANG JEFFREY

Preparation method for medical metal implant material porous niobium

The invention provides a preparation method for a medical metal implant material porous niobium. According to the invention, a solution prepared from ethyl cellulose which is used as an organic binder and anhydrous ethanol which is used as a dispersant and mixed powder prepared from starch and niobium powder which has an average particle size of less than 43 mu m and oxygen content of less than 0.1% are used to prepare niobium powder slurry which is casted and dipped into an organic foam; the organic foam is dried and then is subjected to degreasing under the protection of an inert gas atmosphere and to sintering in vacuum so as to prepare a porous sintered body, sintered niobium powder particles mutually have a sintering neck structure, and after annealing in vacuum and normal post-treatment, porous niobium is prepared; wherein, the content of starch in the mixed powder of metallic niobium powder and starch is 5 to 10%. The medical metal implant material porous niobium prepared in the invention has excellent bio-compatibility and bio-safety; meanwhile, the porous niobium has a sintering neck structure, which enables mechanical properties of the porous niobium like ductility, etc., to be improved; the invention provides a good method for convenient and effective application of porous niobium in the field of medical metal implantation.

Owner:CHONGQING RUNZE PHARM CO LTD

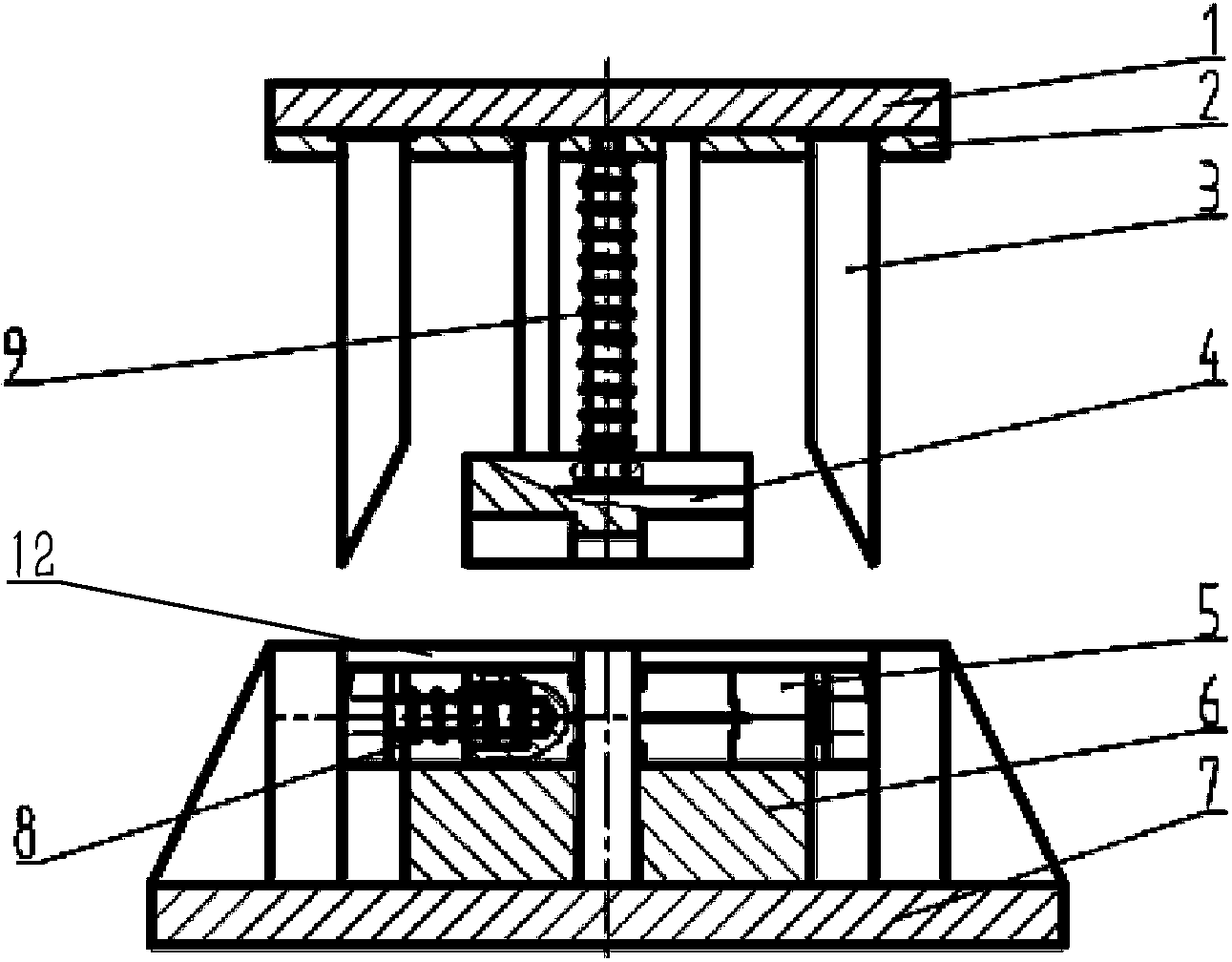

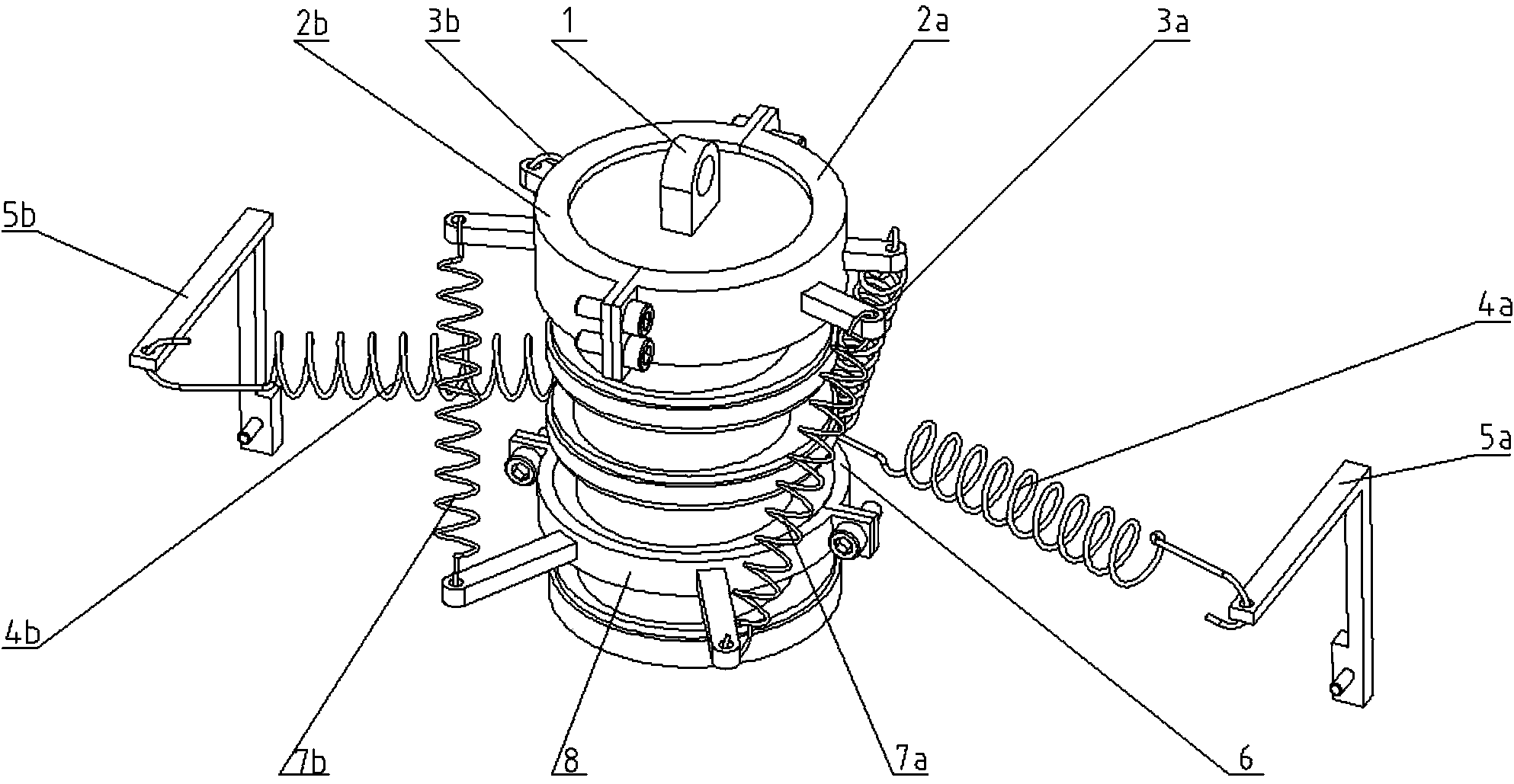

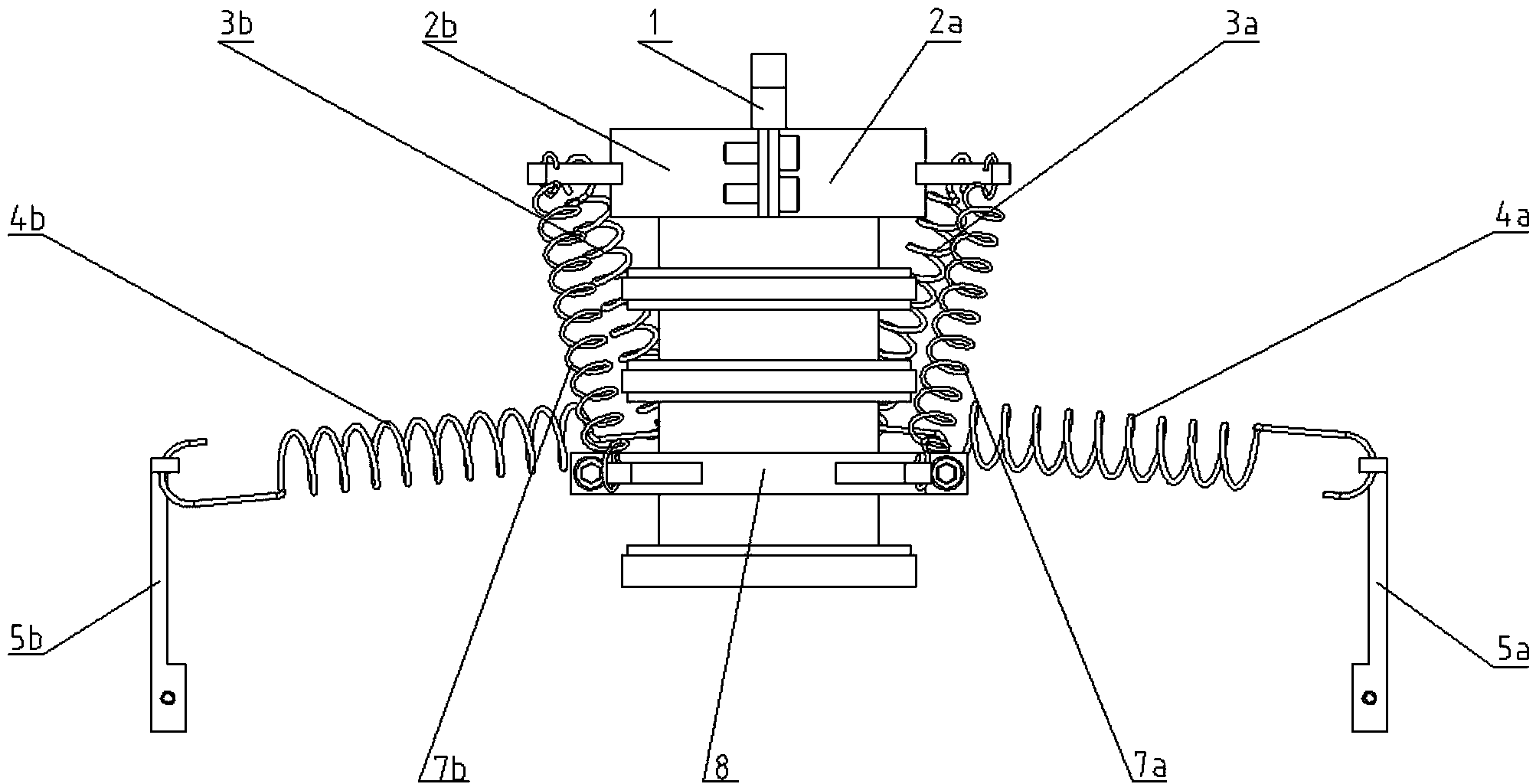

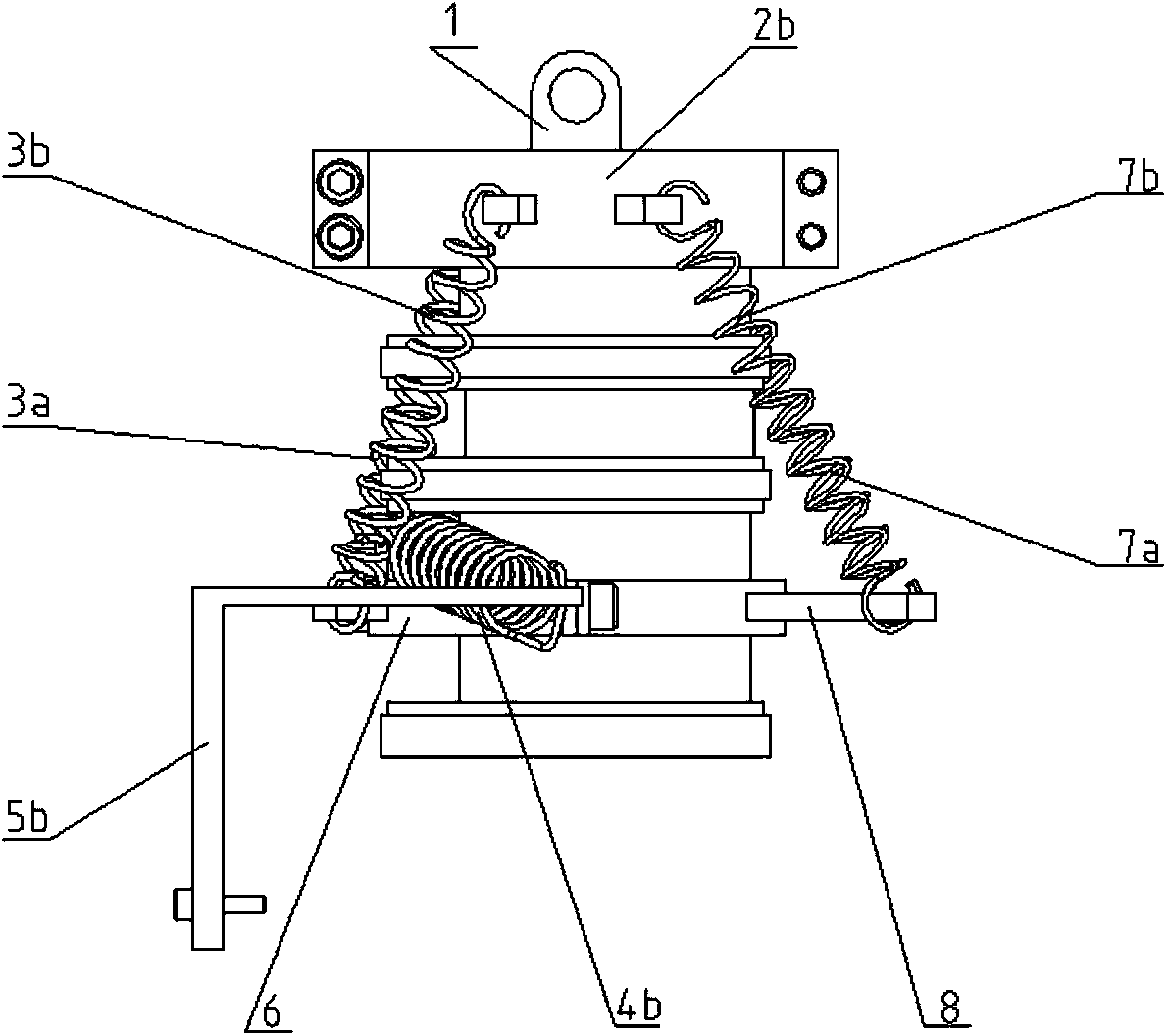

Collision dummy neck structure reflecting human neck mechanical properties and design method thereof

ActiveCN103926046AReal starting pointAccurate starting and ending pointsShock testingNeck structurePhysical medicine and rehabilitation

The invention discloses a collision dummy neck structure reflecting human neck mechanical properties. The collision dummy neck structure is composed of a muscle fixing module and a muscle module. The muscle fixing module is composed of an upper neck ring, a lower neck ring and shoulder rings. The upper neck ring is connected with an upper fundamental dummy neck portion, the lower neck ring is connected with a lower fundamental dummy neck portion, and the shoulder rings are connected with fundamental dummy shoulder portions. The muscle module is composed of springs with different elastic coefficients and comprises two sternocleidomastoid springs, two splenius capitis springs and two trapezius springs, wherein the two ends of each sternocleidomastoid spring are connected with the upper neck ring and the lower neck ring respectively, the two ends of each splenius capitis spring are connected with the upper neck ring and the lower neck ring respectively, and the two ends of each trapezius spring are connected with the corresponding shoulder ring and the lower neck ring. The collision dummy neck structure is applied to the neck portion of a collision dummy, the action of neck muscles on the head and the neck can be effectively achieved, and a higher biosimulation degree is obtained; The invention further discloses a design method of the collision dummy neck structure reflecting the human neck mechanical properties.

Owner:北京威禾知识产权代理有限公司

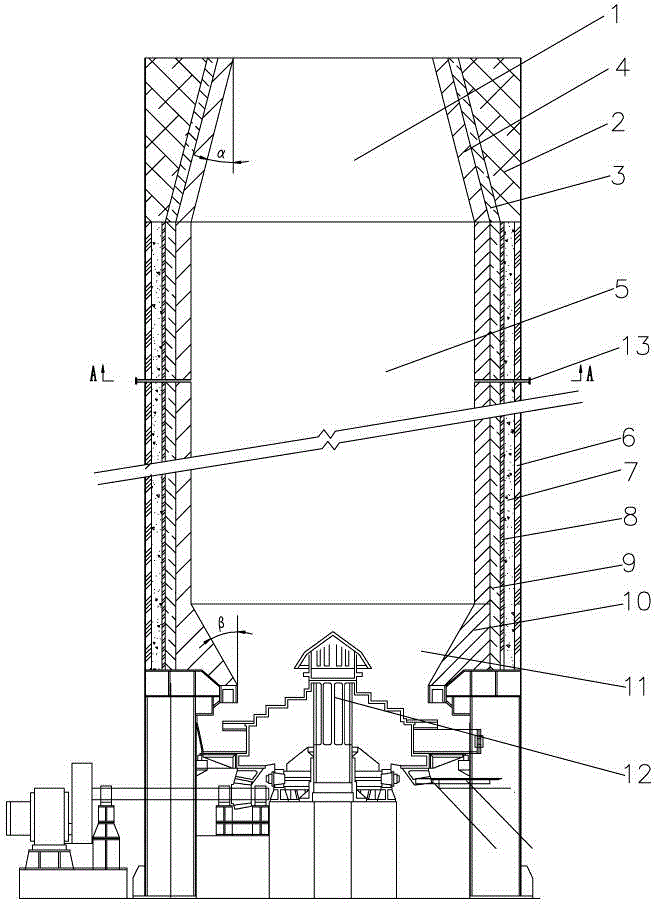

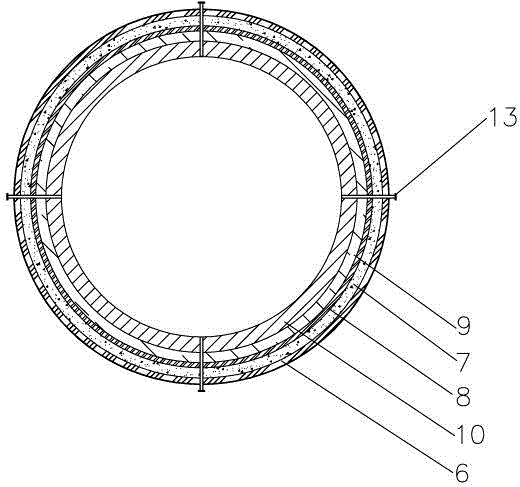

Energy-saving automatic material overturning lime calcining kiln

The invention relates to the technical field of industrial furnaces, and particularly relates to an energy-saving automatic material overturning lime calcining kiln which comprises a kiln body, and a discharge device installed at the bottom of the kiln body. The lime calcining kiln is characterized in that the kiln body has three sections, wherein the upper section is a waste gas outlet section, the middle section is a sintering section, and the lower section is a discharge section; the sintering section also comprises a preheating zone, a burning zone and a cooling zone; the inner wall of the waste gas outlet section has a cone-shaped necking structure, the included angle alpha between the conical surface of the cone-shaped necking structure and the center line is 15 degrees + / -1 degree; the diameter difference between the large opening and the small opening of the waste gas outlet section is 1000+ / -200mm; the sintering section is of a cylindrical structure; the inner wall of the discharge section is of an inverted cone-shaped necking structure, the included angle beta between the conical surface of the inverted cone-shaped necking structure and the center line is 30 degrees + / -2 degrees, the diameter difference between the large opening and the small opening of the discharge section is 1600mm+ / -400mm, and the diameters of the large opening ends at the inner walls of the waste gas outlet section and the discharge section are equal to the inner diameter of the sintering section. By adopting the energy-saving automatic material overturning lime calcining kiln, such problems of traditional shaft kilns as high heat consumption and high investment, short service life of the kiln lining, and poor quality of the finished product lime are solved, and the kiln is mainly used for lime production.

Owner:HUANGSHI LANTIAN ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com