Fire protection heptafluoropropane steel cylinder and manufacturing method thereof

A heptafluoropropane and fire-fighting technology, which is applied to container filling methods, container discharge methods, pressure vessels, etc., can solve problems such as incomplete penetration, air holes, and uneven gaps, and achieve good welding quality, simplified process, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

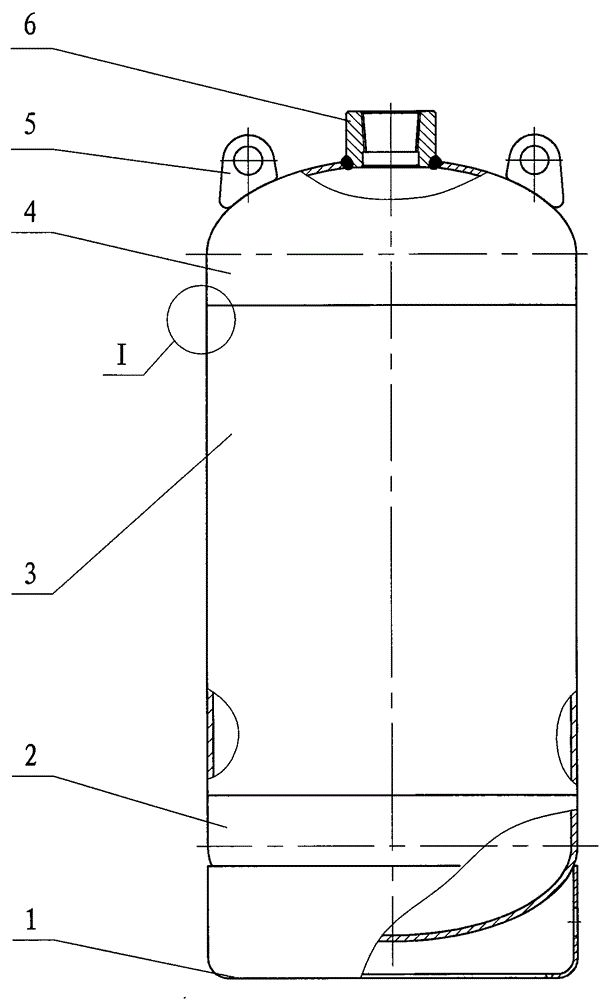

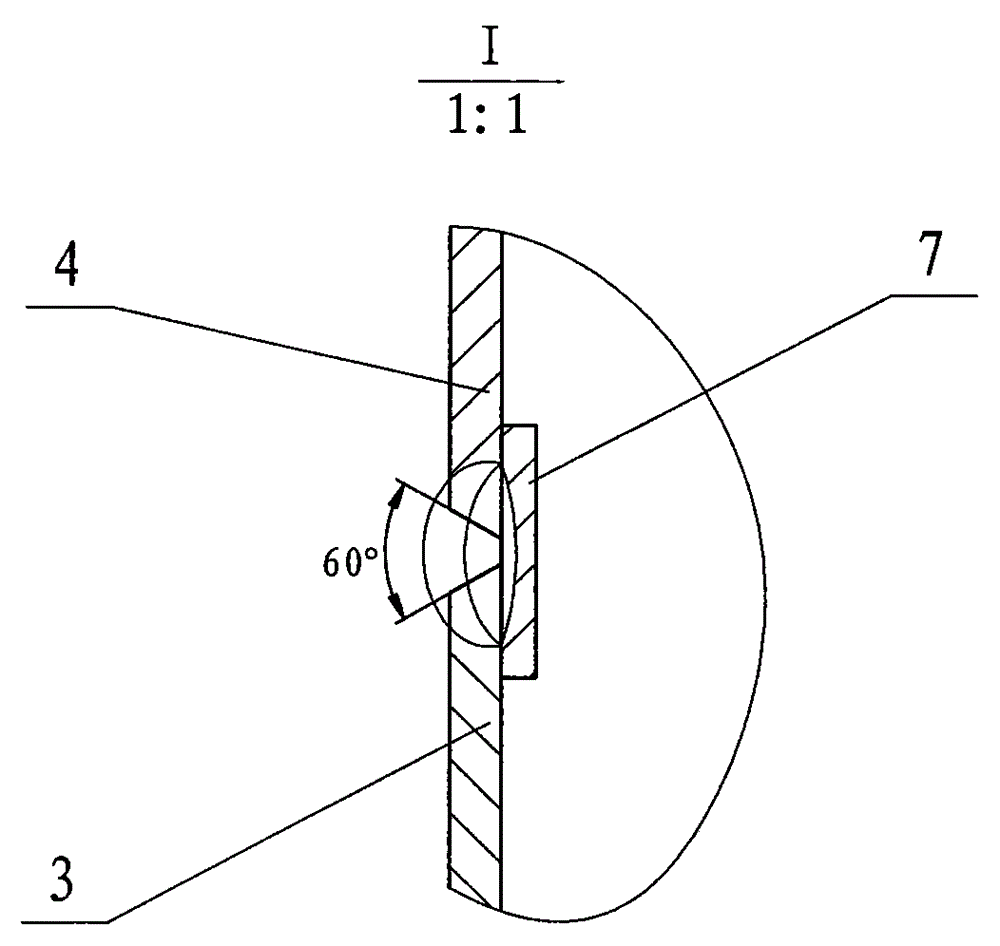

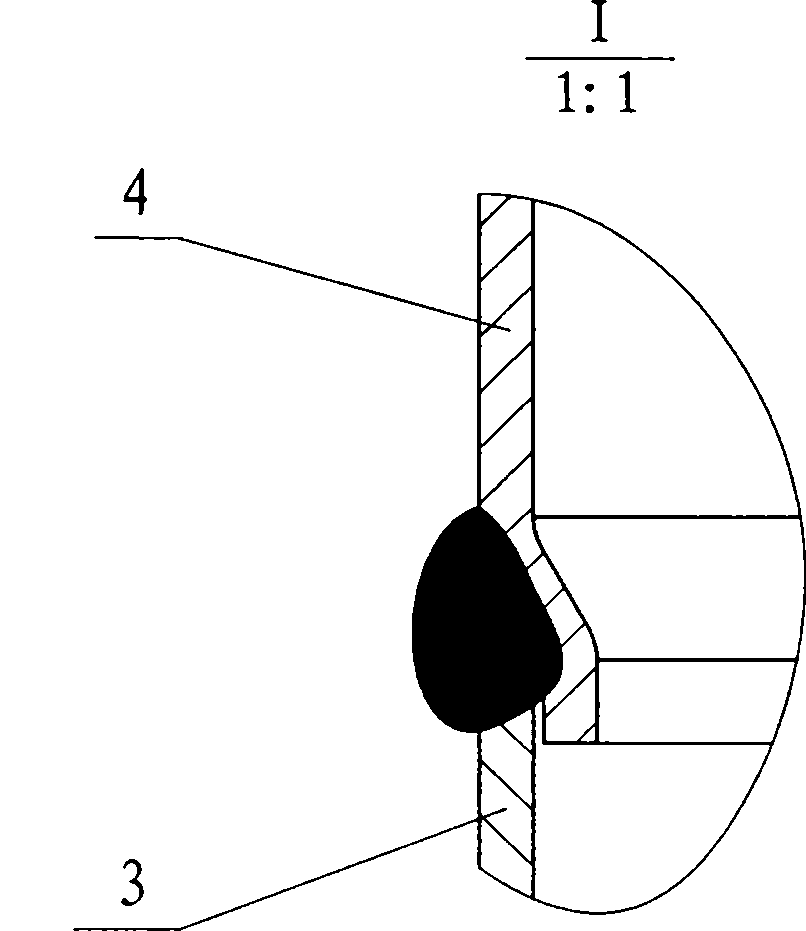

[0021] Such as figure 1 Shown, be the structural appearance schematic diagram of heptafluoropropane steel cylinder, among the figure I is the joint of the upper head 4 of steel cylinder and barrel body 3. Such as figure 2 It is a schematic diagram of the internal structure of the connection point I between the upper head 4 and the barrel body 3 with the original process backing plate ring 7, the upper head 4 and the barrel body 3 at a V of 60° Groove pairs are welded. Such as image 3 Shown is the schematic diagram of the internal structure of I in the embodiment, after the upper head 4 is improved to shrink, the structure of the connection between the upper head 4 and the cylinder body 3, from image 3 It can be seen that the upper head 4 has a necking, and the upper head 4 is welded together after the necking and the cylinder body 3 cooperate.

[0022] The manufacturing process of embodiment is:

[0023] a. Processing cylinder body 3: the cylinder body is rounded, weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com