Turbine generator rotor assembly roundness measuring device

A technology for assembling hydro-generators and rotors, which is applied to mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of limited measuring accuracy, high manufacturing cost, and high cost, and achieves improved centering accuracy and reduced weight. , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

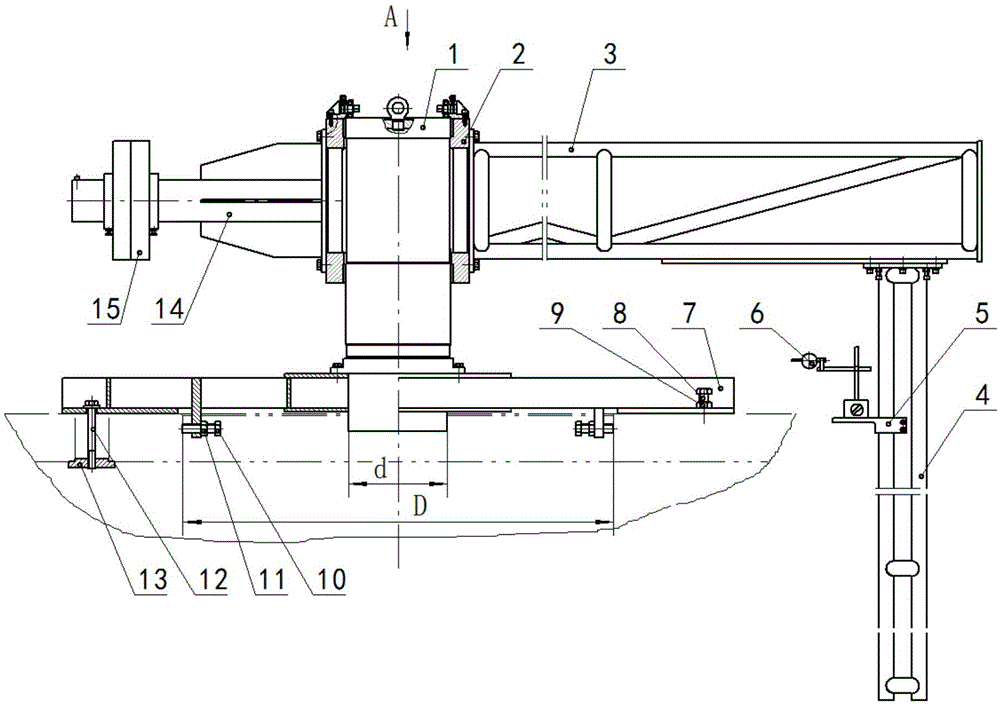

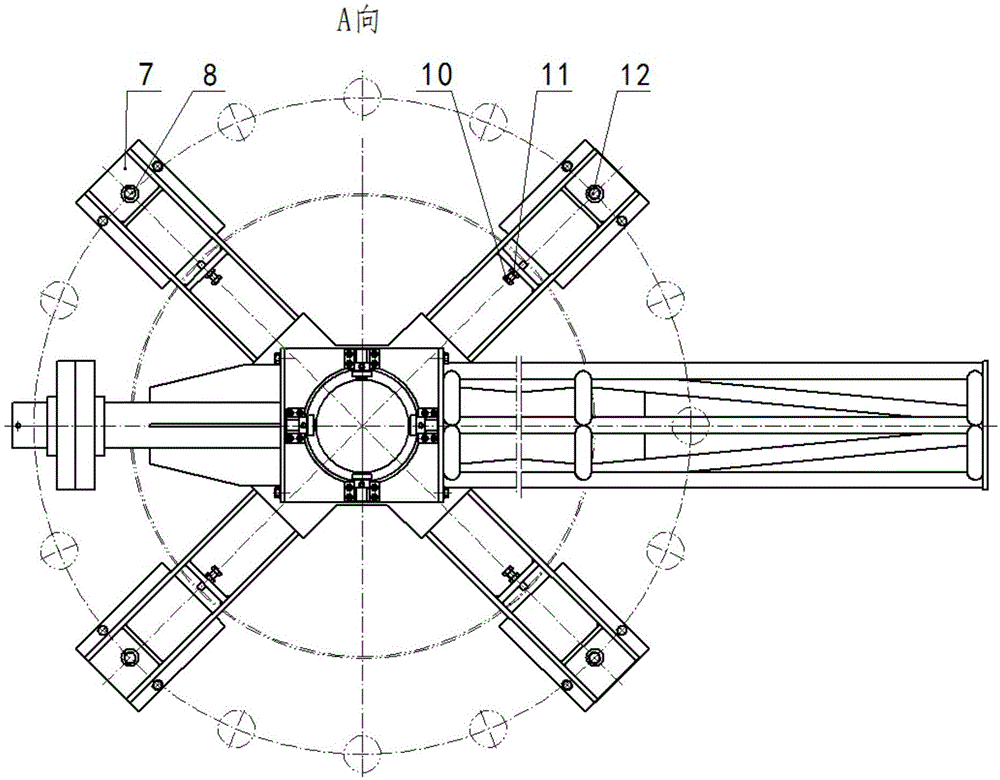

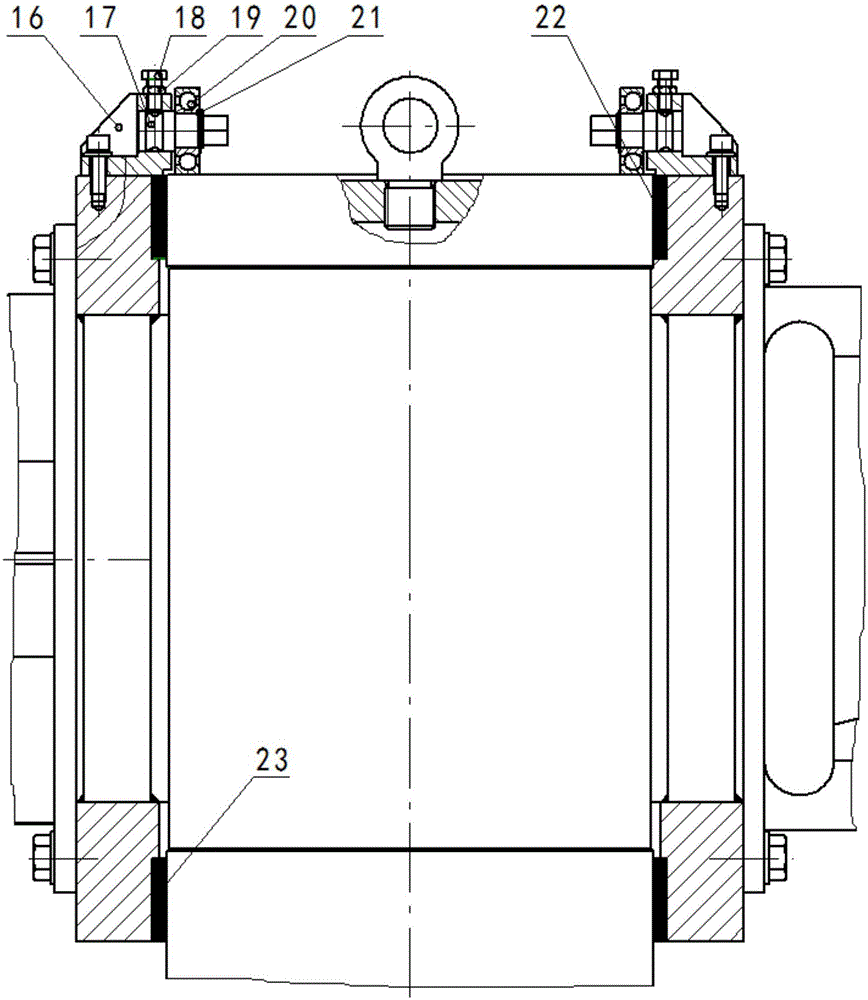

[0018] Such as figure 1 As shown, a hydroelectric generator rotor assembly circle measuring device, the column 1 is installed on the cross base 7, four supports 16 are evenly installed on the upper end surface of the central rotating body 2, and the eccentric shaft 17 is along the horizontal diameter of the column 1 circle. installed in the hole of the support 16, such as image 3 As shown, the third jacking wire 18 and the third lock nut 19 are installed on the upper end of the support 16, the bearing 20 and the stop ring 21 are installed on the eccentric shaft 17, and the upper radial sliding bearing 22 is installed in the upper end hole of the center rotating body 2 , the lower radial sliding bearing 23 is installed in the lower end hole of the central revolving body 2, the measuring arm 3 is installed horizontally on one side of the central revolving body 2, the balance arm 14 is installed horizontally on the other side of the central revolving body 2, and the measuring ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com