Thrust rod ball joint and assembling method thereof

An assembly method and technology of thrust rods, applied in the direction of shafts and bearings, mechanical equipment, pivots, etc., can solve problems such as short service life and failure to meet vibration reduction requirements, so as to improve service life, not easy to wrinkle and unglue, and increase The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples. It should be understood that one or more method steps mentioned in the present invention do not exclude that there are other method steps before and after the combined steps or other method steps can be inserted between these explicitly mentioned steps; it should also be understood that these The examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

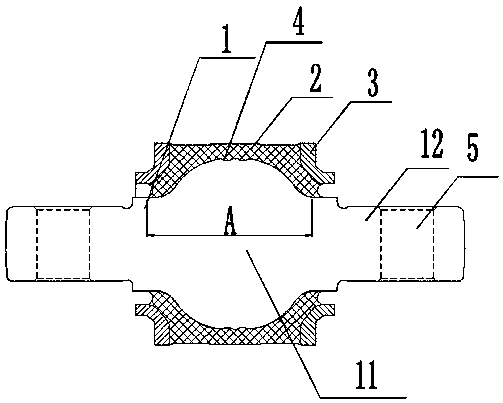

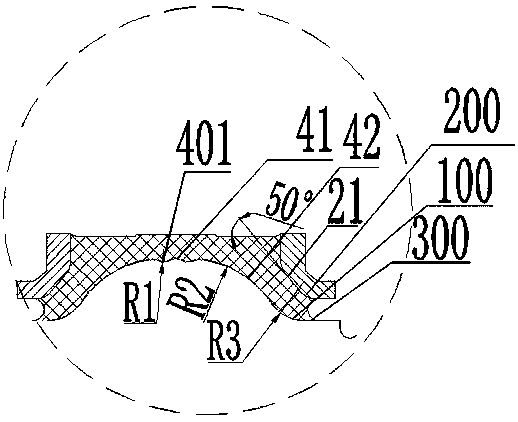

[0033] Such as Figure 1~2 as shown, figure 1 A thrust rod ball joint is provided for the present invention. The rubber ball joint includes a metal mandrel 1, a rubber layer 2 and a metal end cap 3 sequentially from the inside to the outside. The metal end cap 3 is vulcanized and bonded to both ends of the rubber layer 2. To prevent the extrusion of both ends of the rubber layer 2; the rubber layer 2 is vulcanized and bonded on the metal mandrel 1, and the bonde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com