Patents

Literature

84results about How to "Increased flexural rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

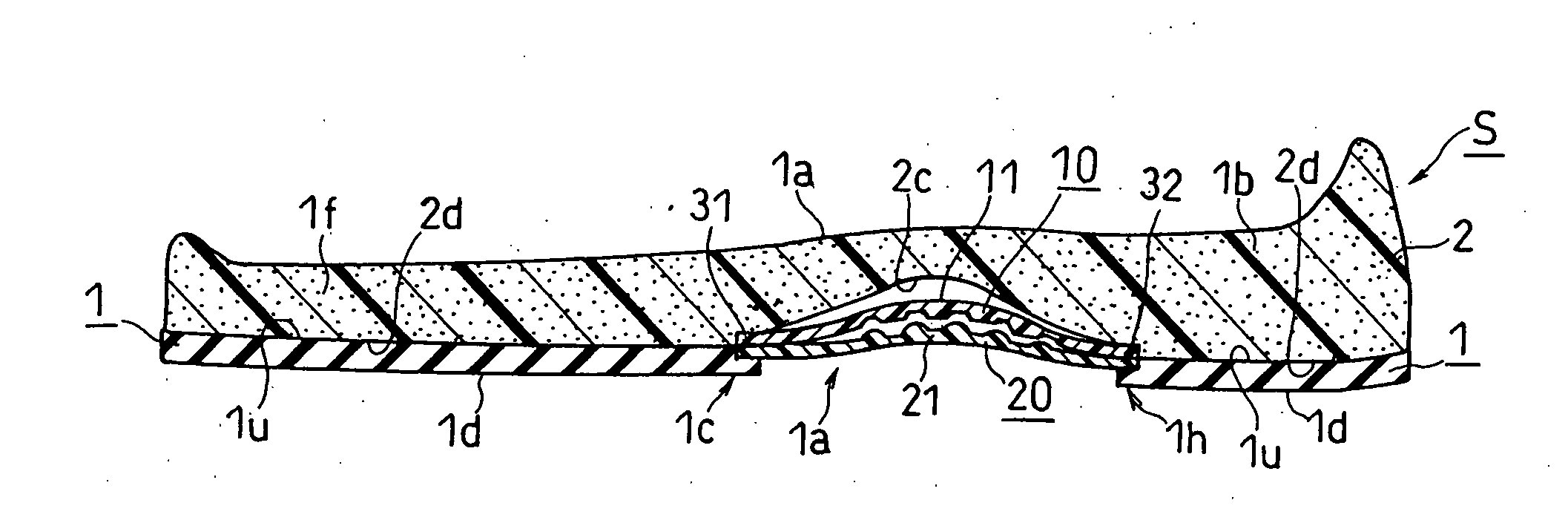

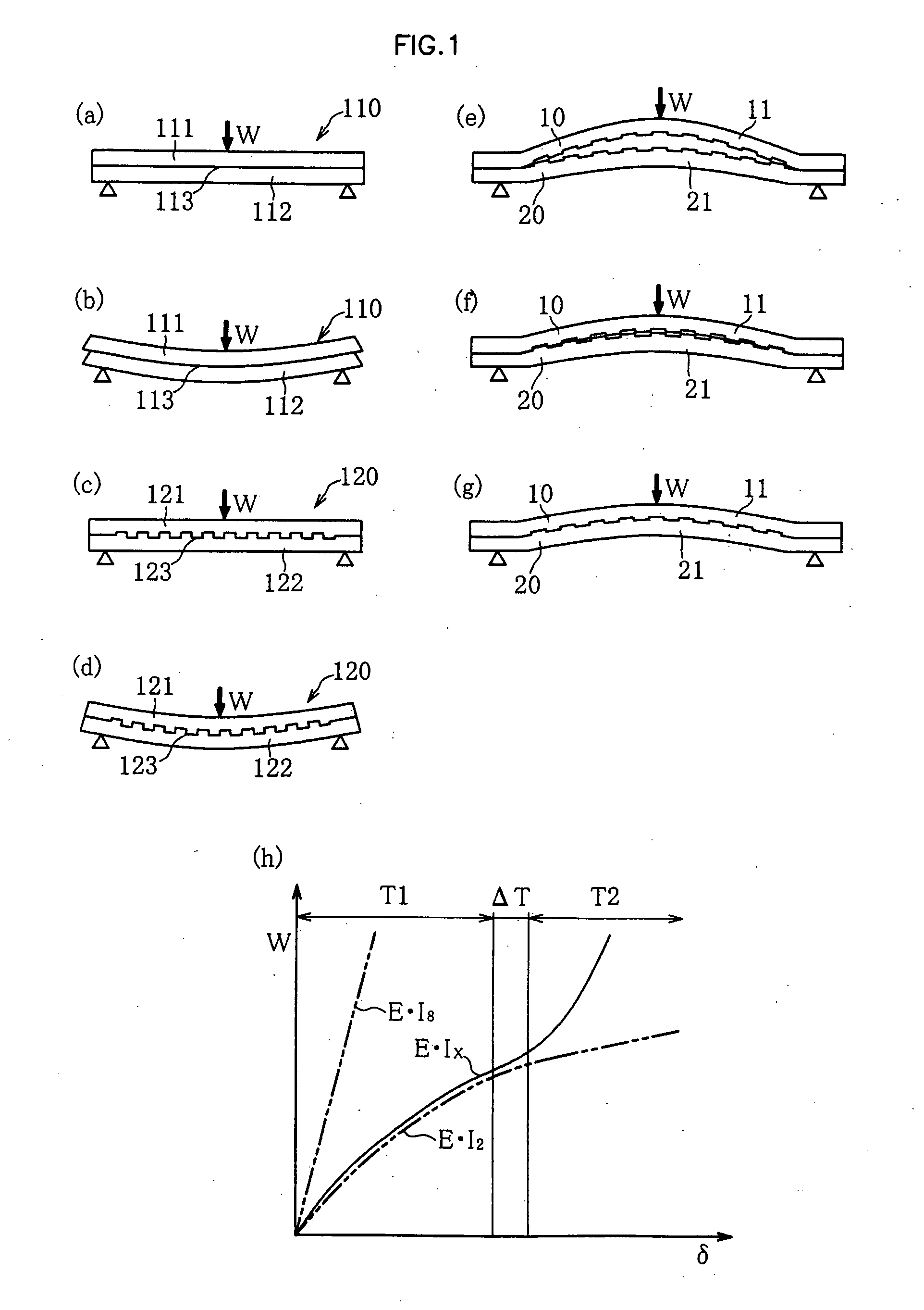

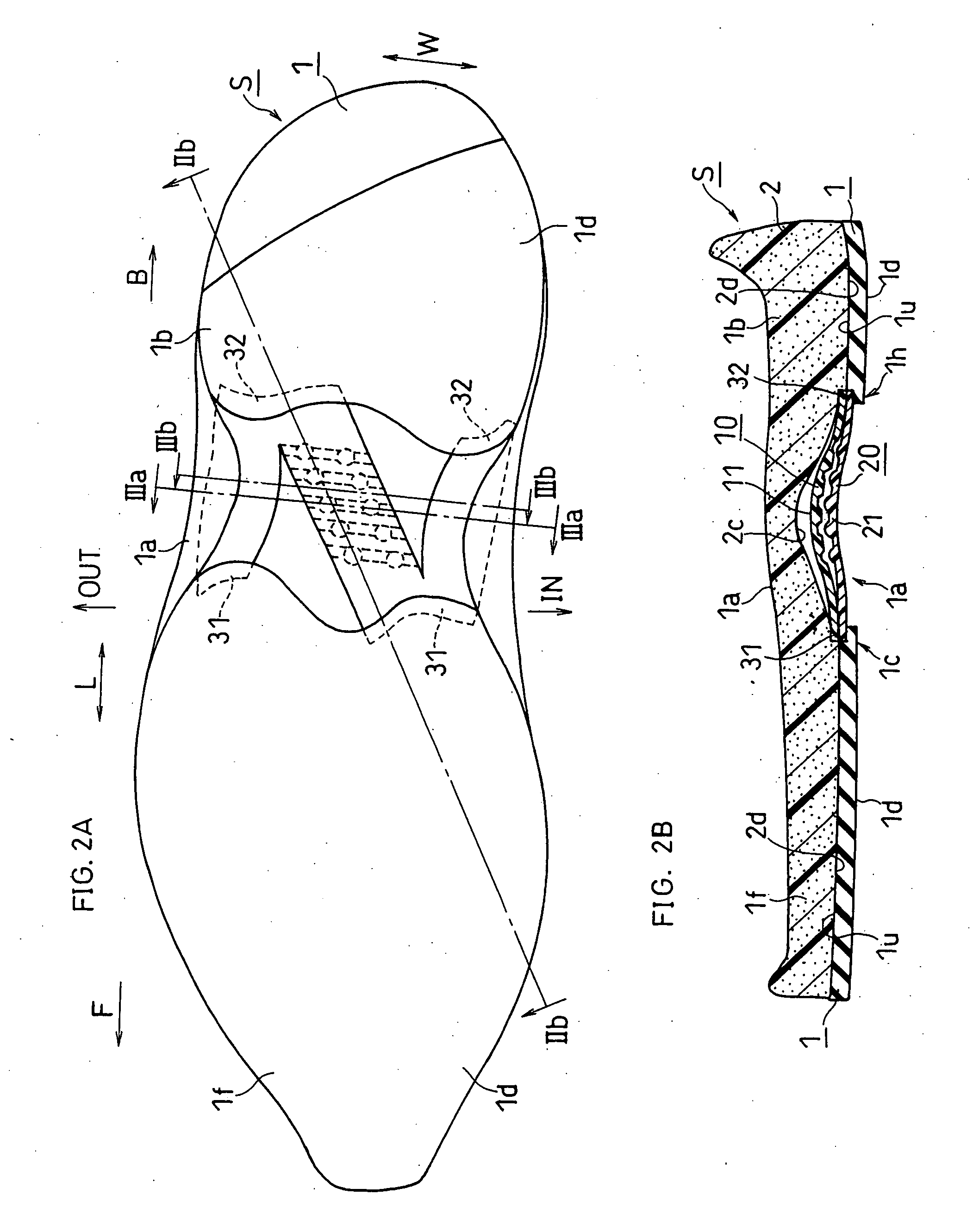

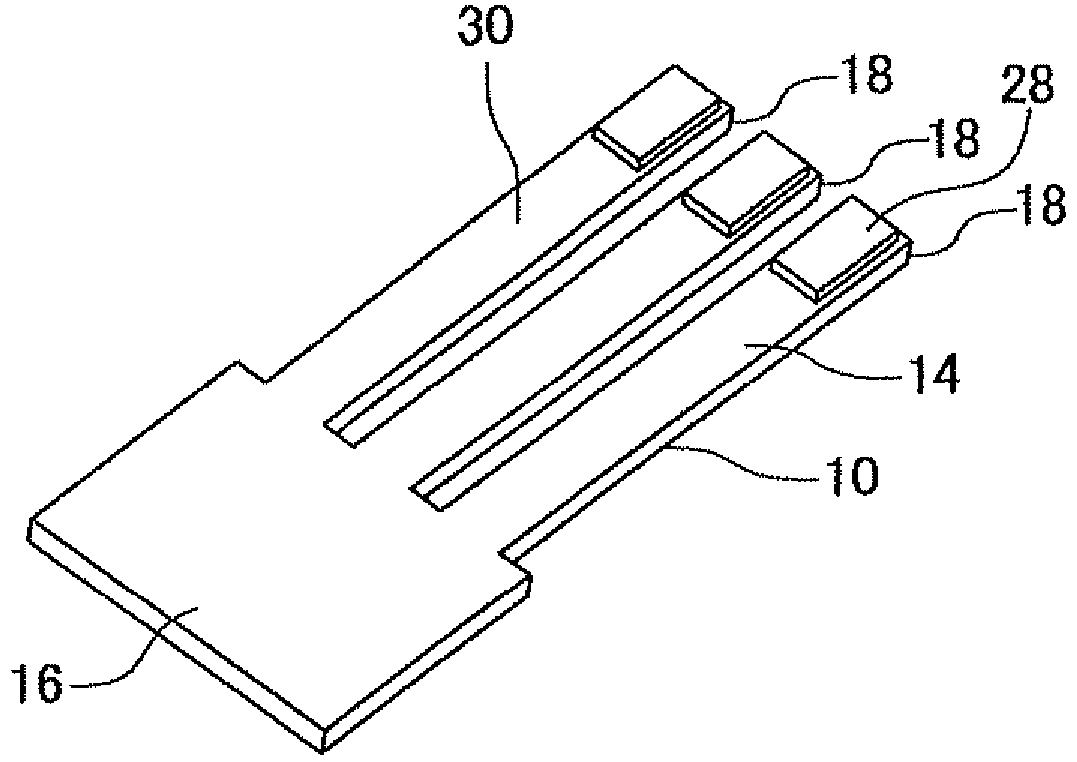

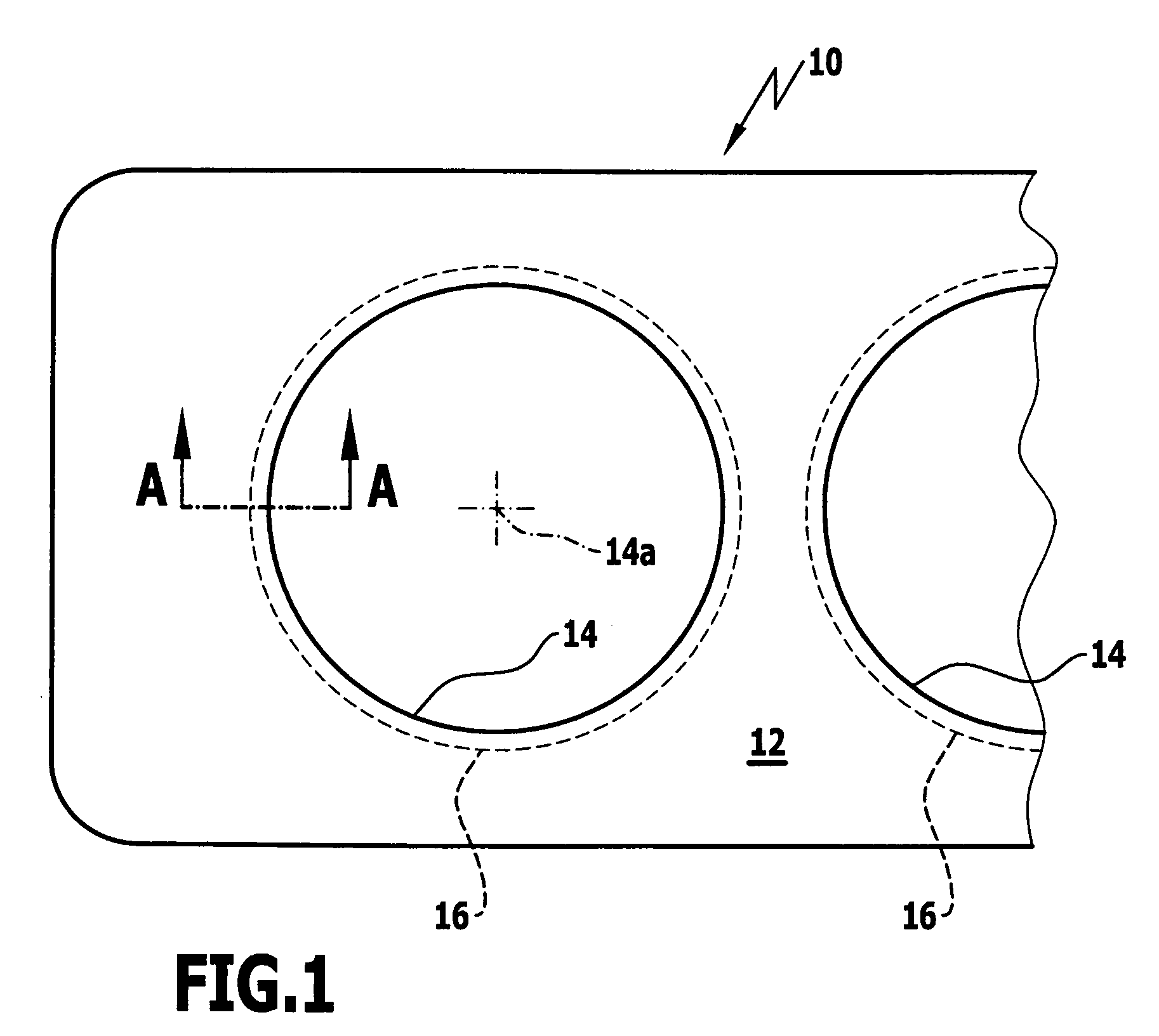

Shoe Sole with Reinforcement Structure

ActiveUS20100218397A1Small flexural rigidityPrevent functional degradationSolesEngineeringMechanical engineering

Owner:ASICS CORP

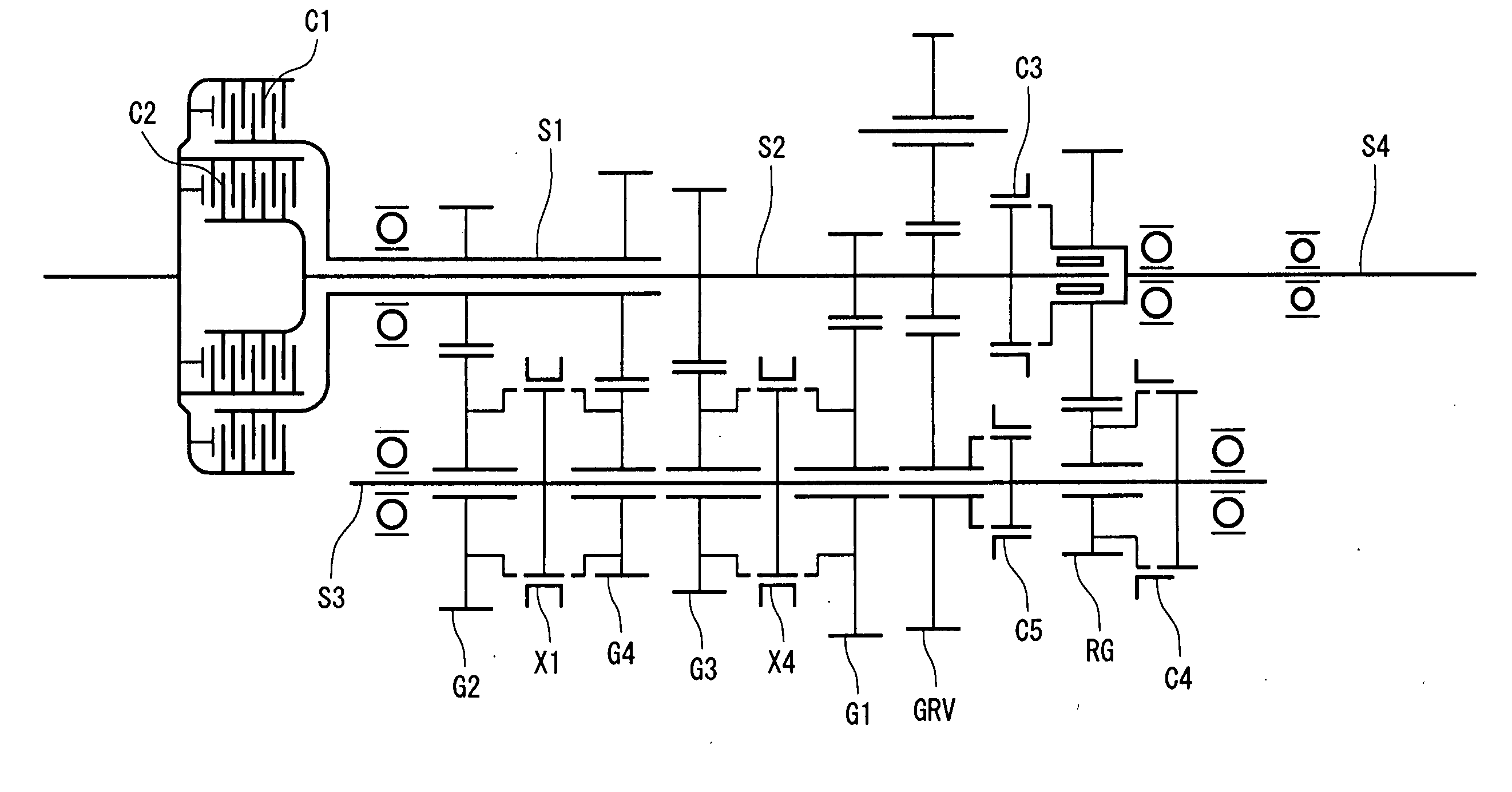

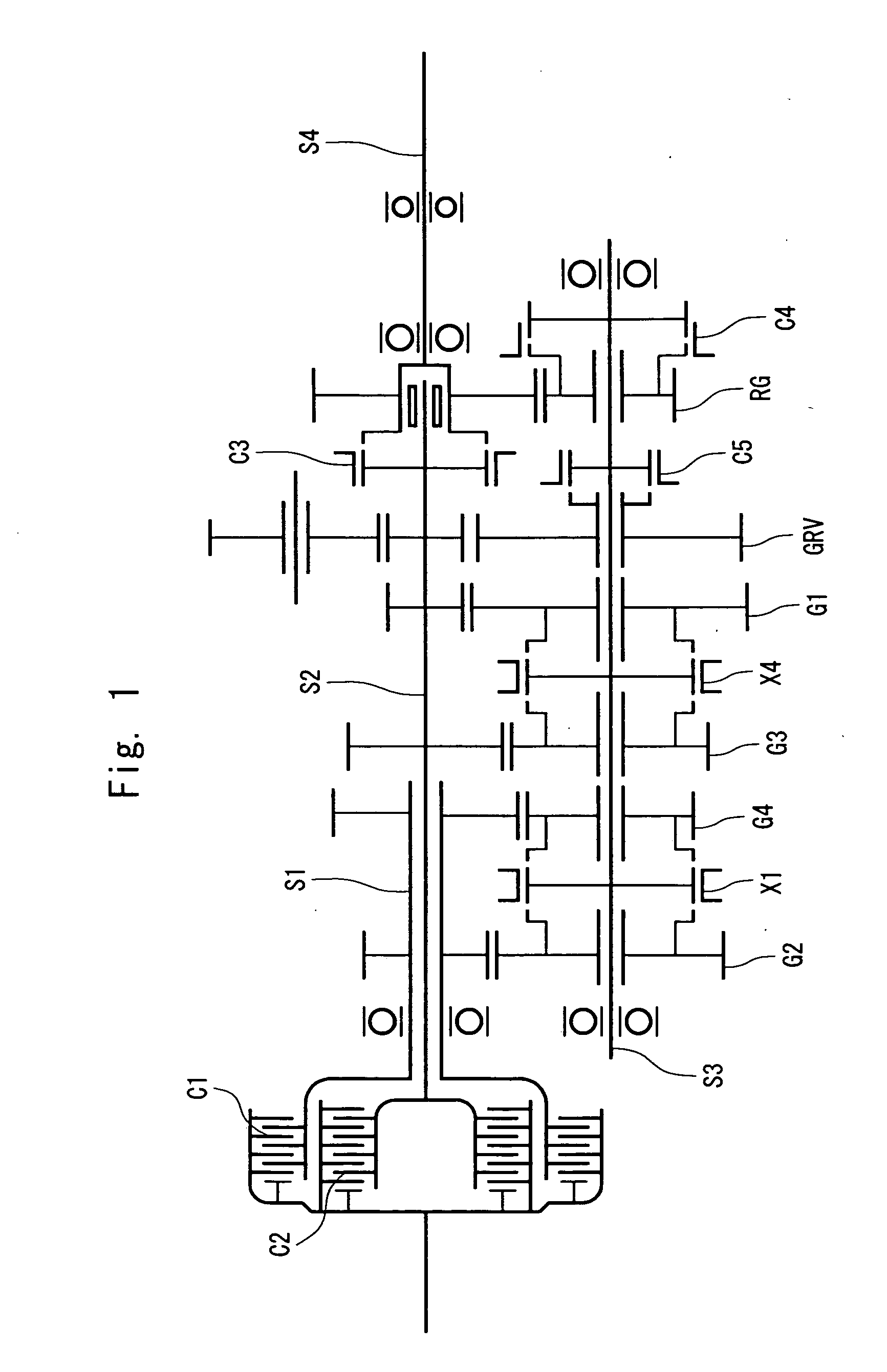

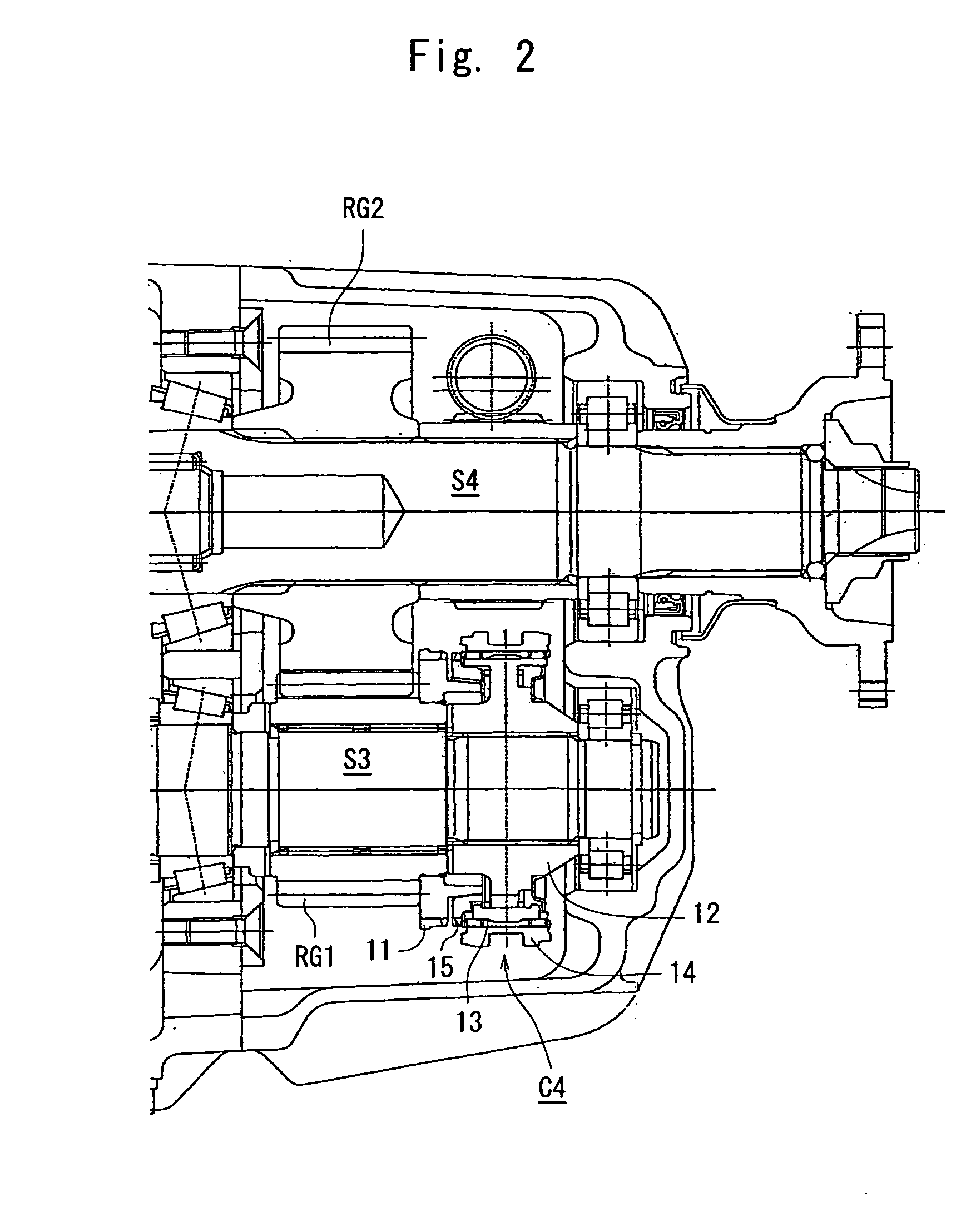

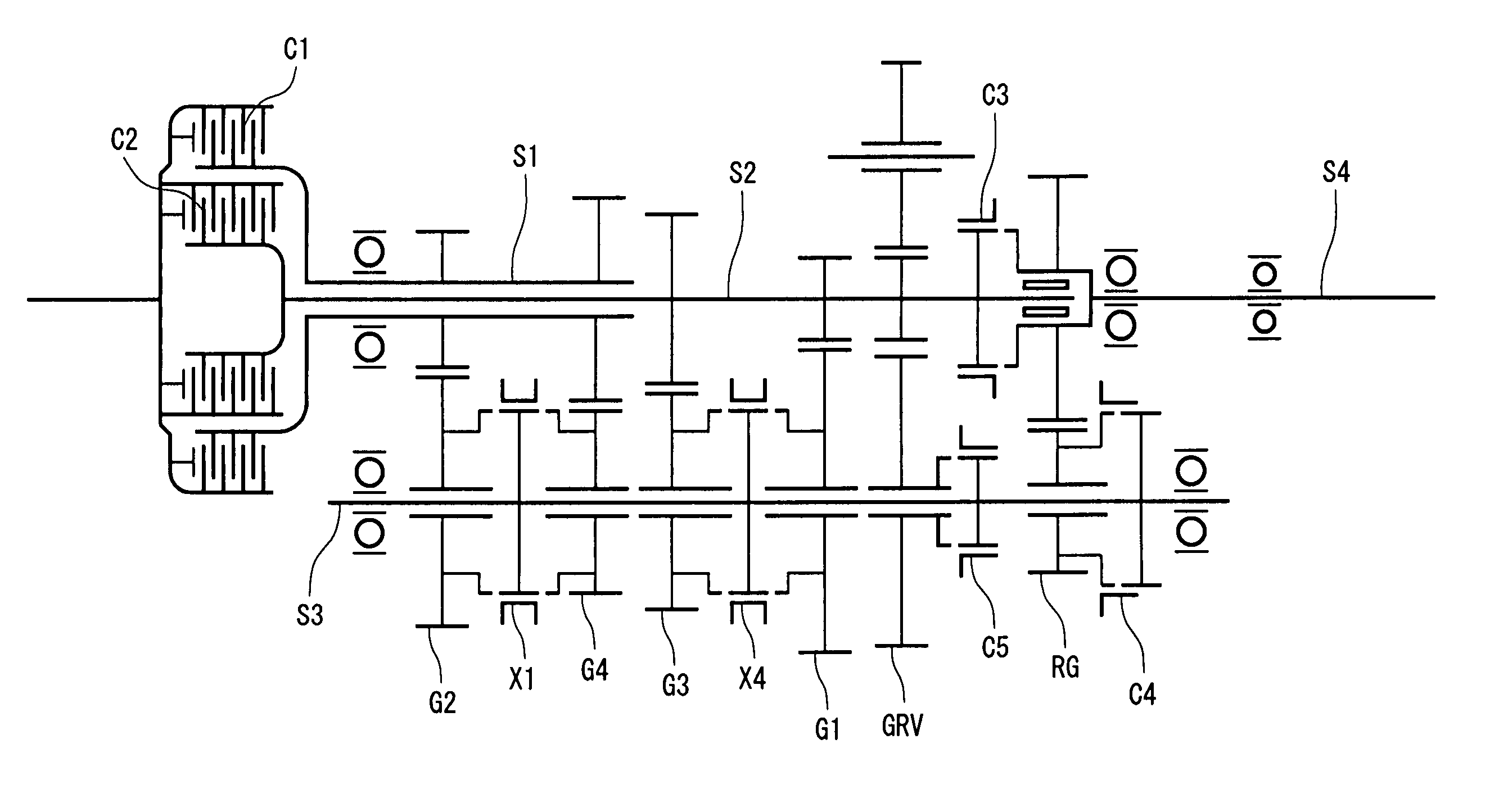

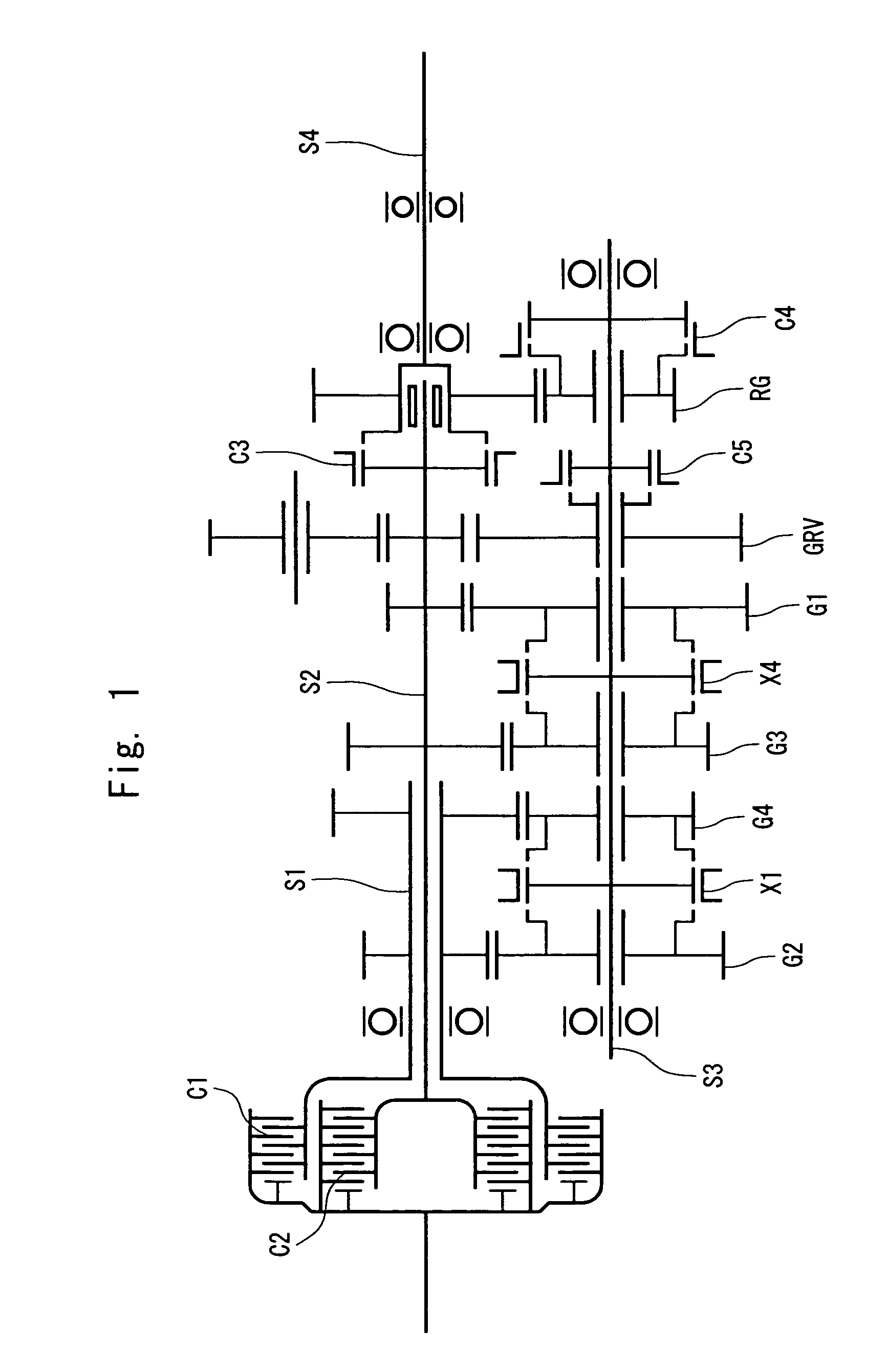

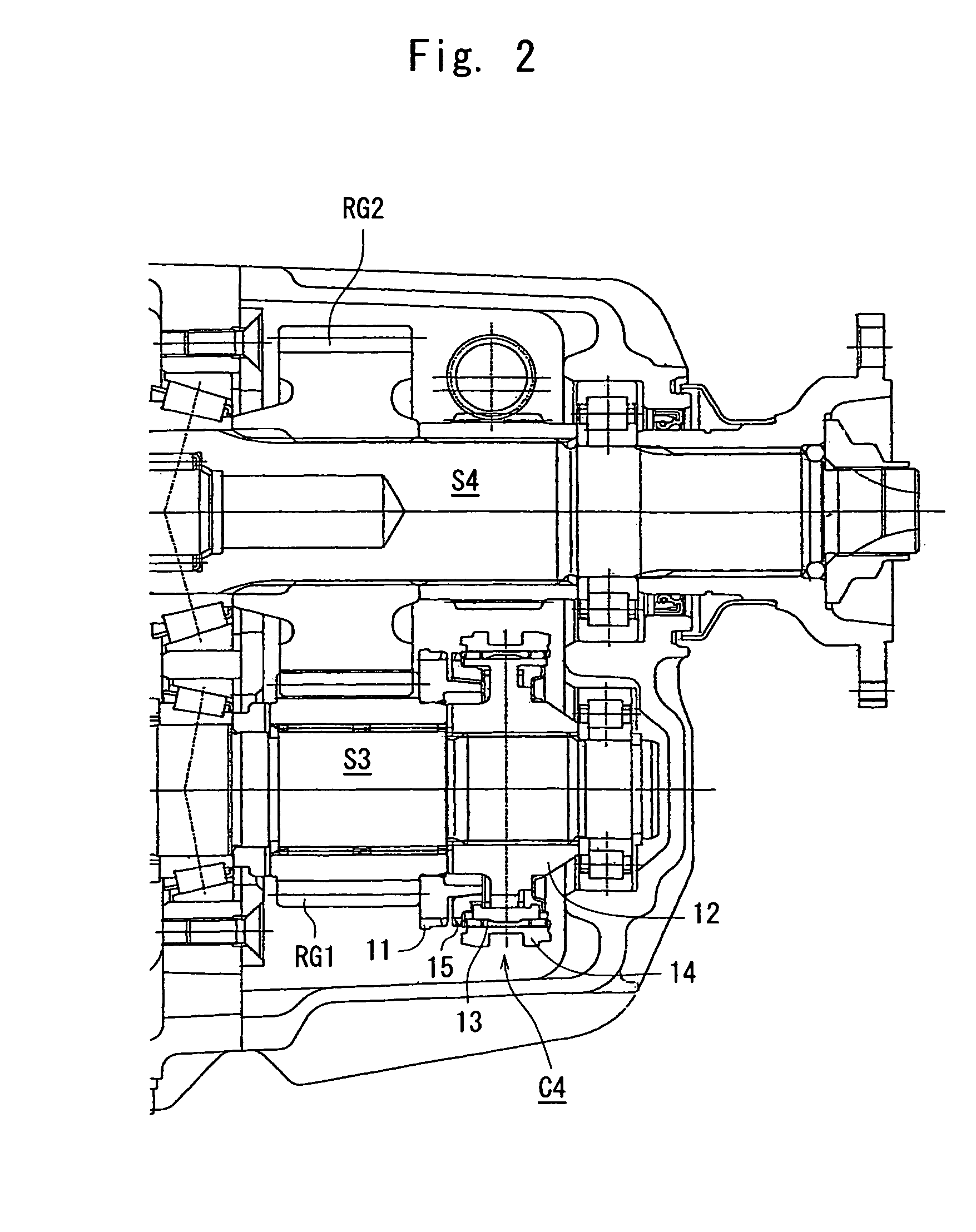

Output shaft reduction-type dual clutch transmission

ActiveUS20090320629A1Decrease in sizeIncrease in temperature increaseToothed gearingsTransmission elementsClutchVariator

A dual clutch transmission having two input shafts respectively connected to clutches, and an intermediate shaft, preventing the intermediate shaft from rotating idle when the vehicle is traveling at high speeds and avoiding excess stirring of lubricating oil in the transmission and increase in noise. In the dual clutch transmission, a direct connection clutch C3 is provided between one input shaft S2 and an output shaft S4, and an intermediate shaft connection clutch C4 for interrupting the transmission of power is provided between the intermediate shaft S3 and the output shaft S4. When the power is directly transmitted from the input shaft S2 to the output shaft S4 via the direct connection clutch C3, the intermediate shaft connection clutch C4 is disconnected to stop the rotation of the intermediate shaft S3 and to prevent the lubricating oil from being excessively stirred by the idle rotation of the intermediate shaft S3. Further, the intermediate shaft connection clutch C4 is disconnected, and a transmission step is constituted by utilizing the gear trains among the two input shafts and the intermediate shaft S3, making it possible to omit one gear train and, therefore, to shorten the length of the transmission.

Owner:ISUZU MOTORS LTD

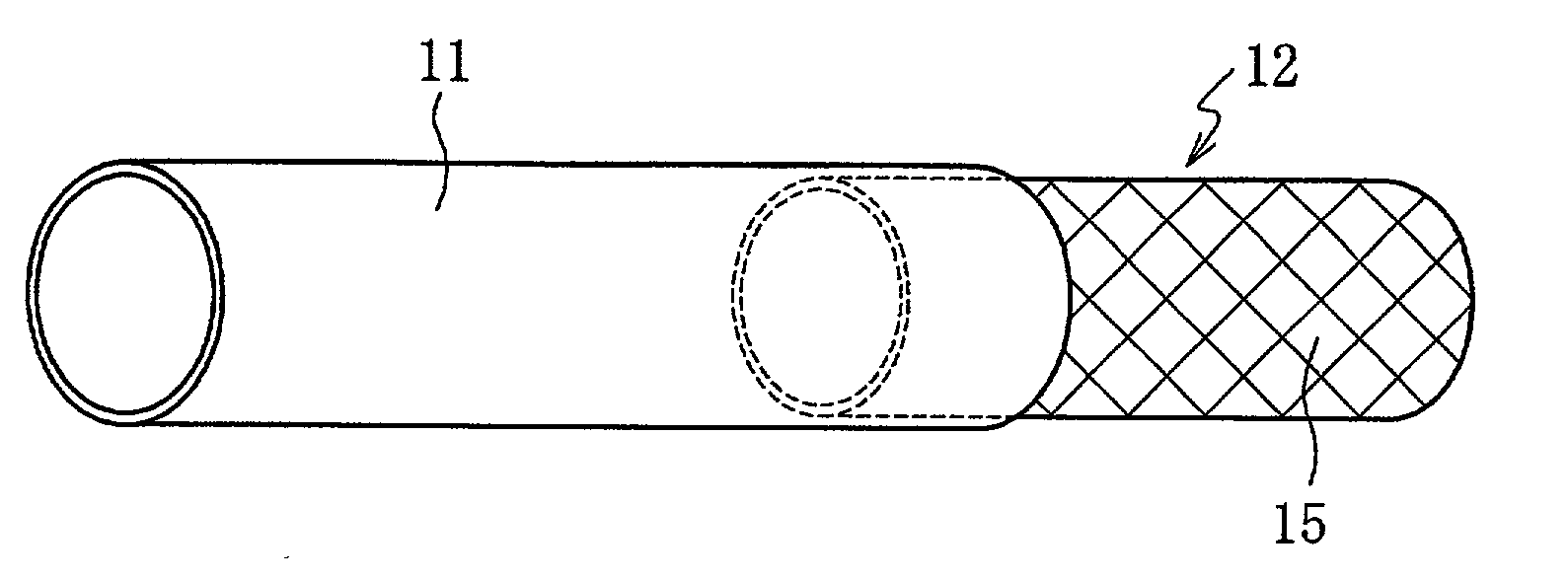

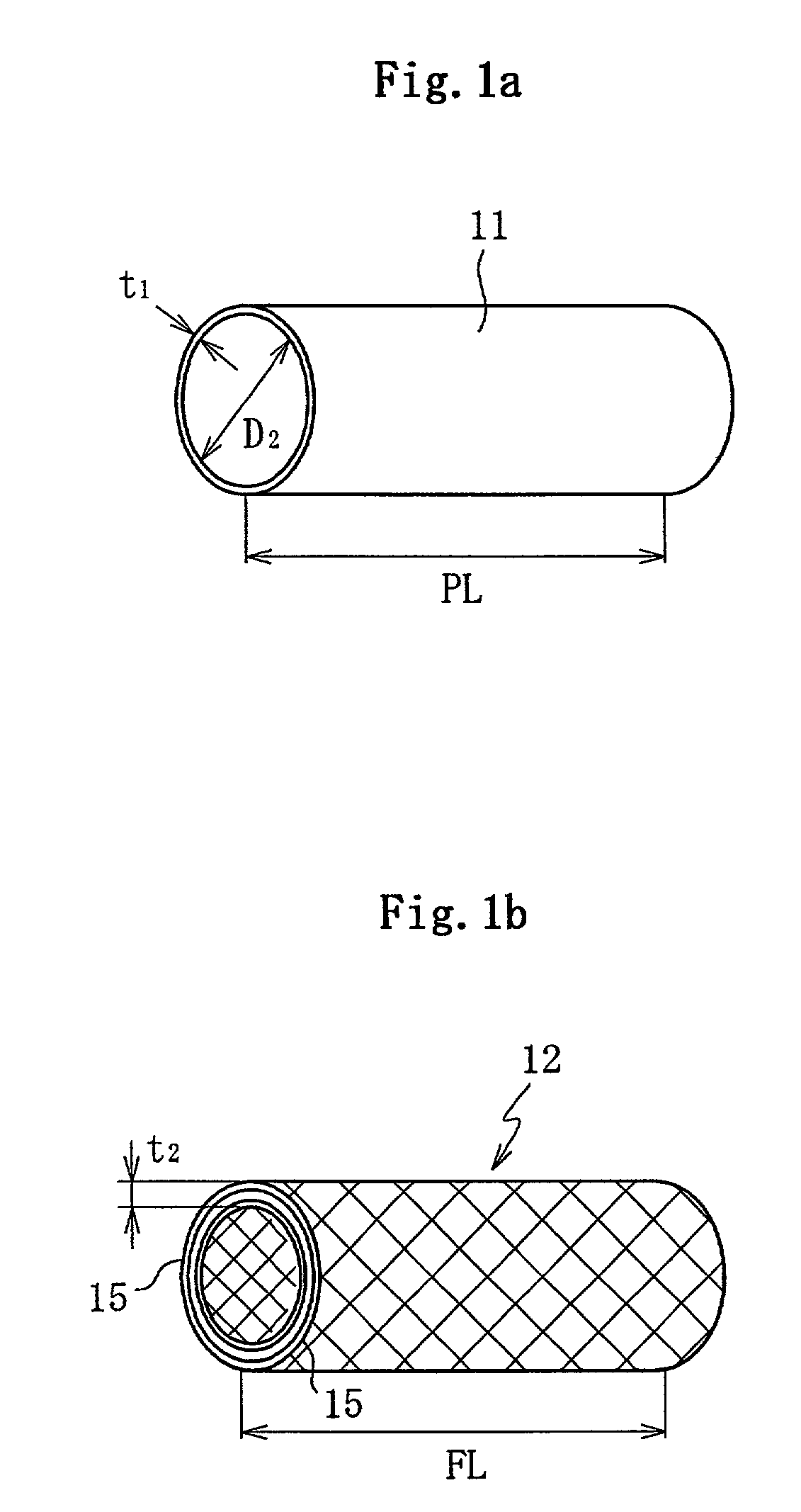

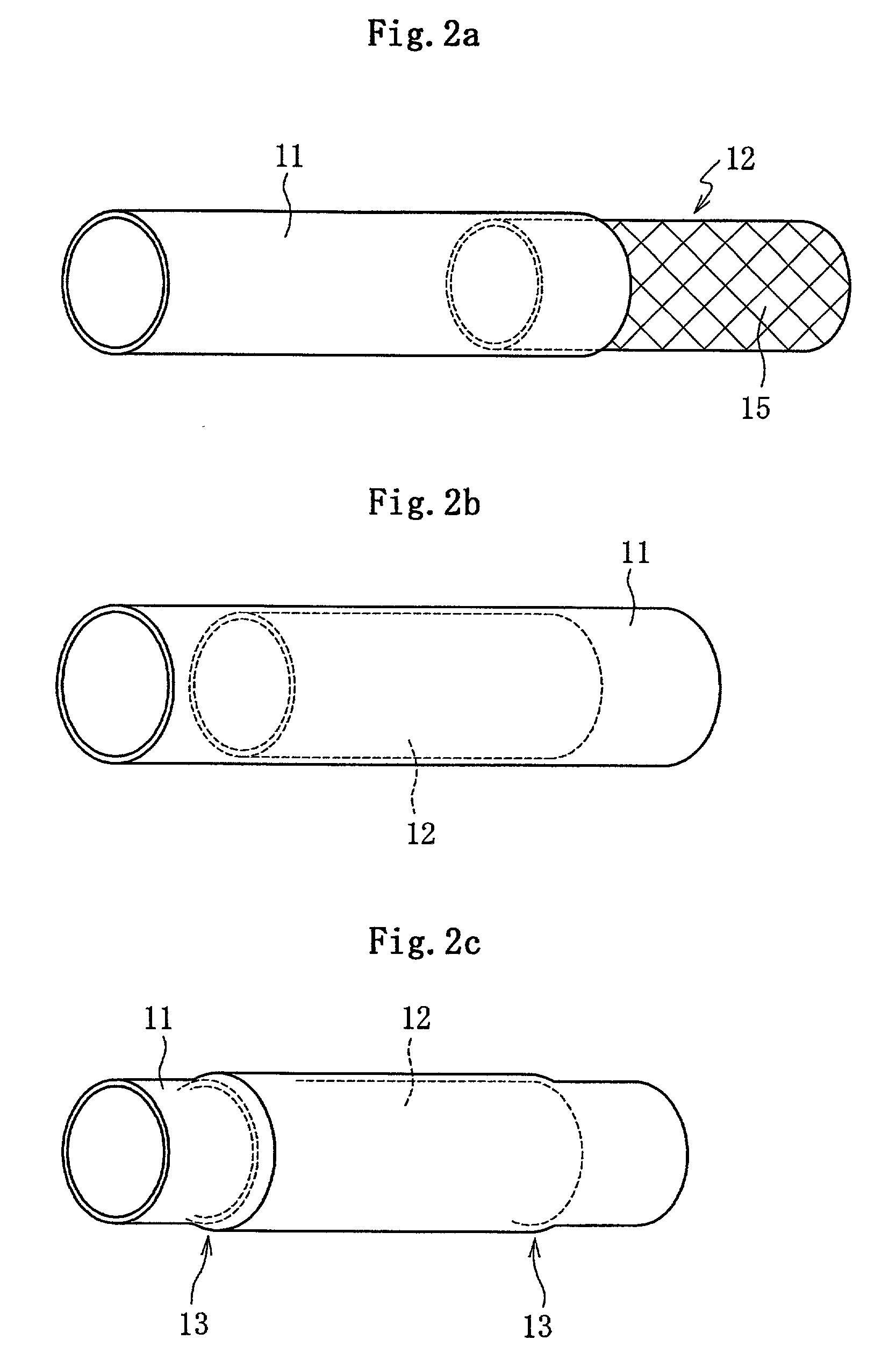

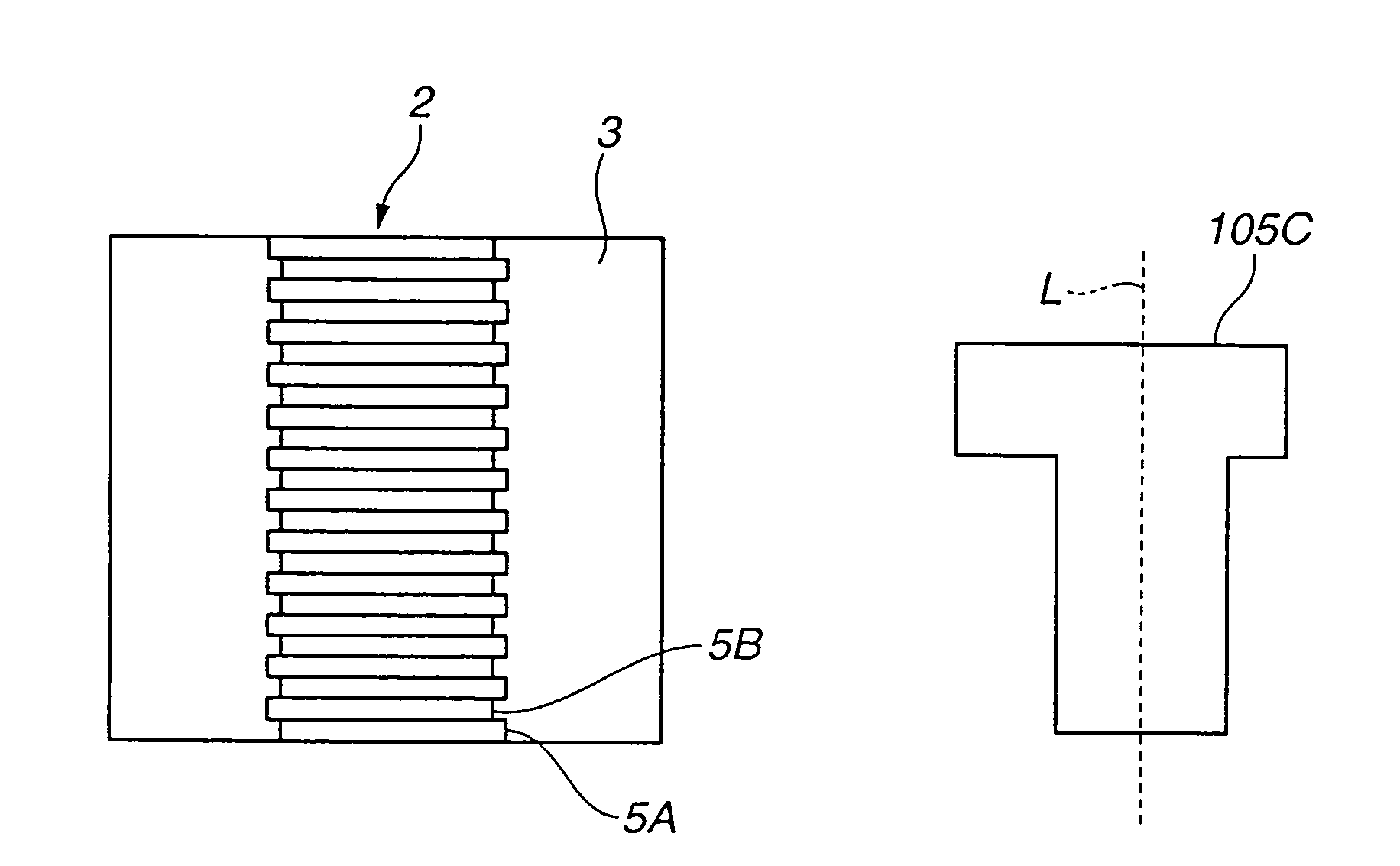

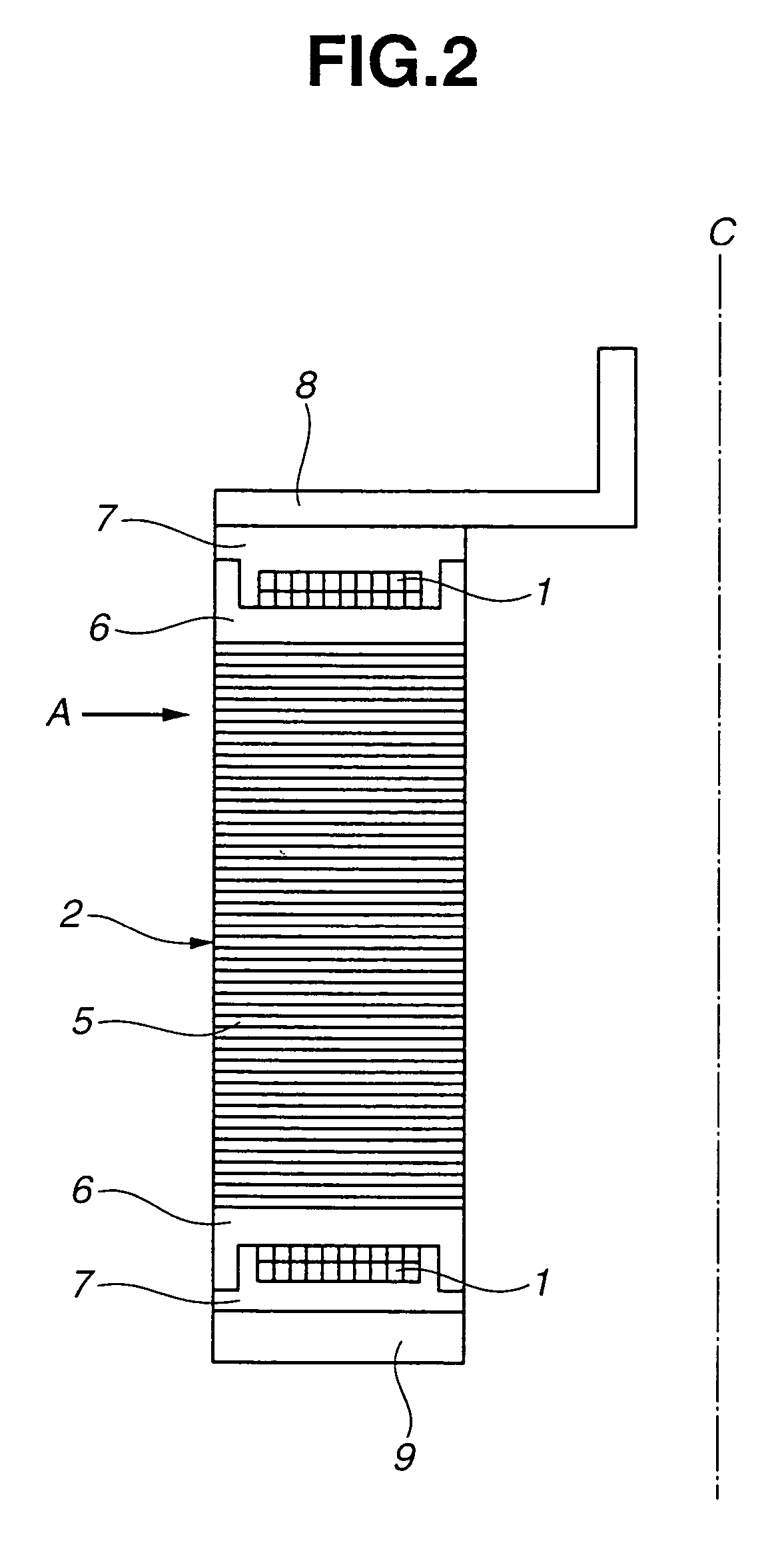

Fiber reinforced plastic pipe and power transmission shaft employing the same

ActiveUS20020117228A1Reduce thicknessIncrease the diameterShaftsFlexible pipesSurface layerFiber bundle

A fiber reinforced plastic pipe is provided to prevent it from being damaged and make full use of its practical performance when the fiber reinforced plastic pipe, reduced in thickness and increased in diameter by pultrusion process, is reduced in the circumferential direction and inserted into a metal pipe. The fiber reinforced plastic pipe, reduced in thickness and increased in diameter by pultrusion process, includes a fiber bundle spun and aligned in the longitudinal direction, and circumferential reinforced fiber sheet provided at least on one of the outer and inner surface layers. The circumferential reinforced fiber sheet is inserted into the metal pipe to form a power transmission shaft such as an intermediate shaft for use with a propeller shaft or a drive shaft.

Owner:NTN CORP +2

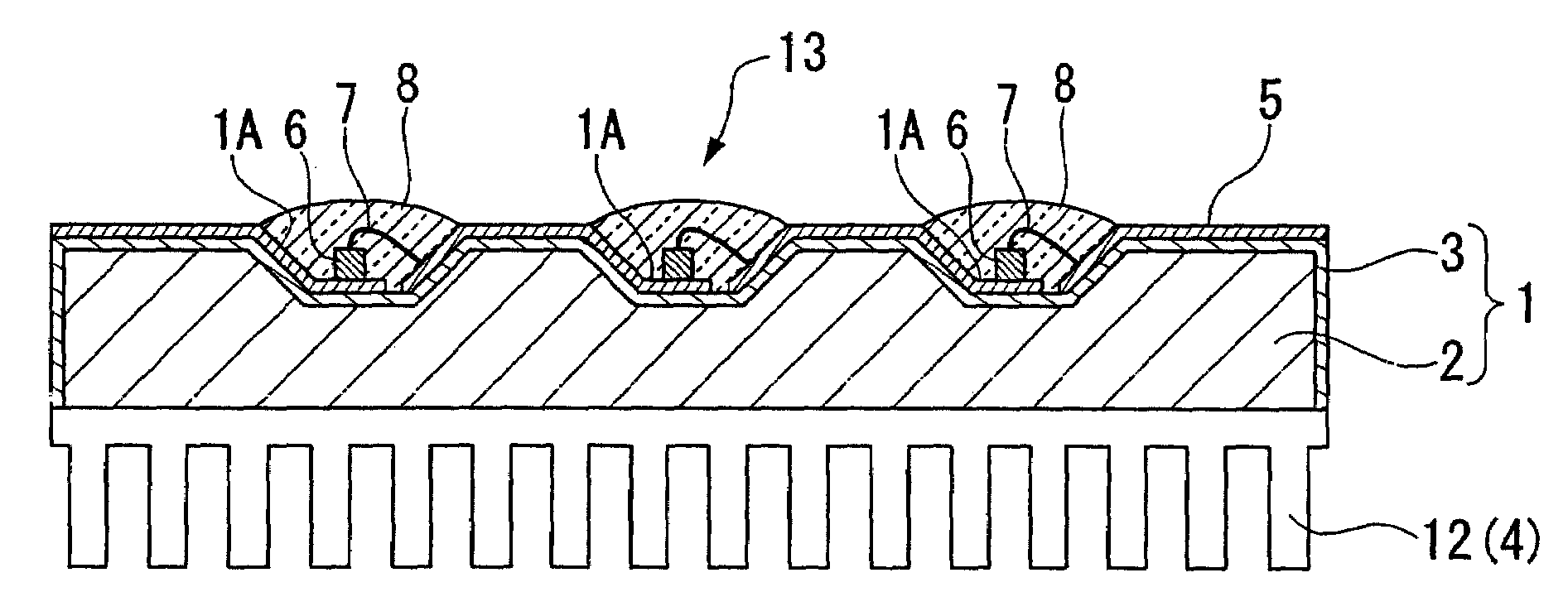

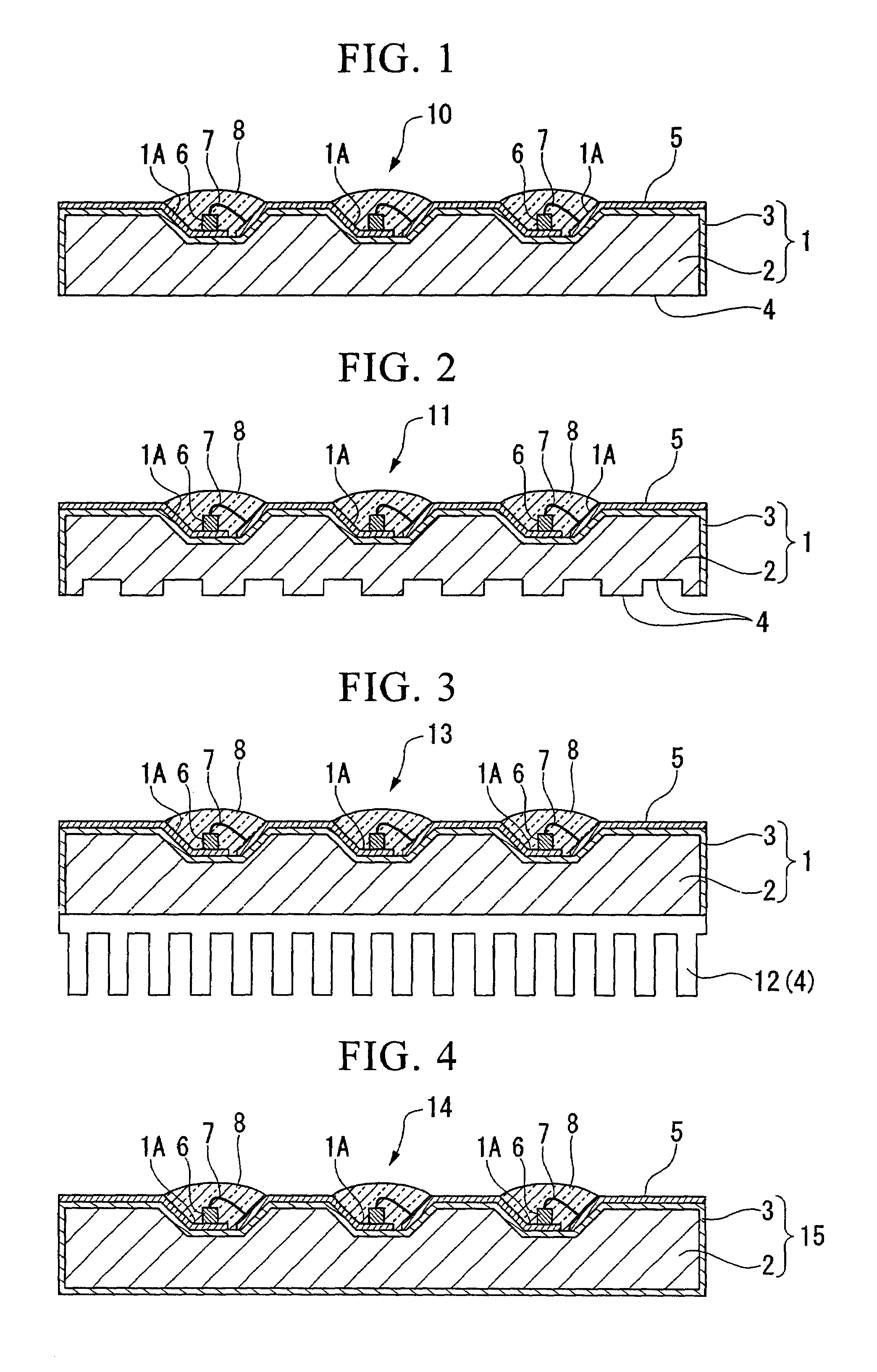

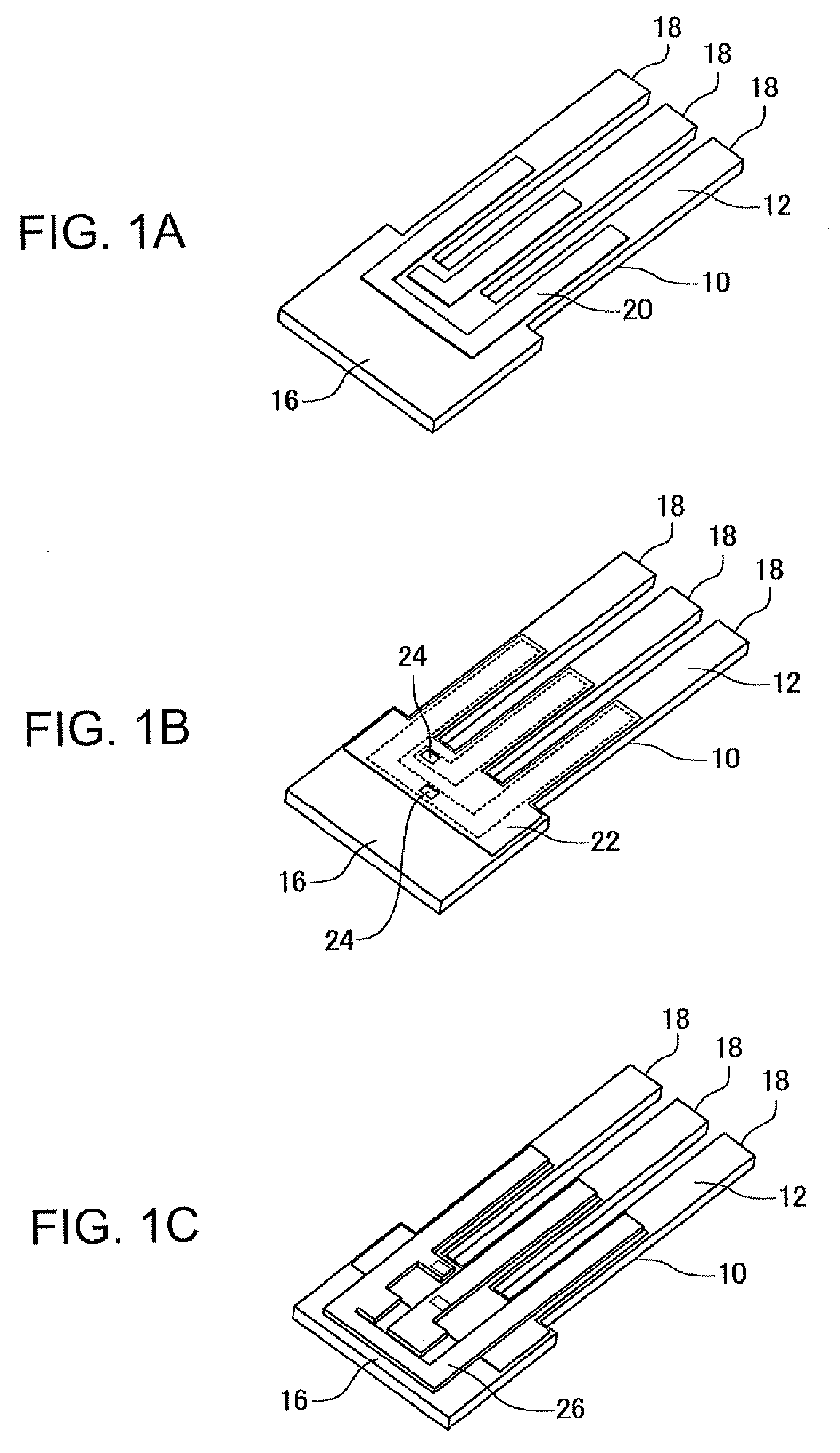

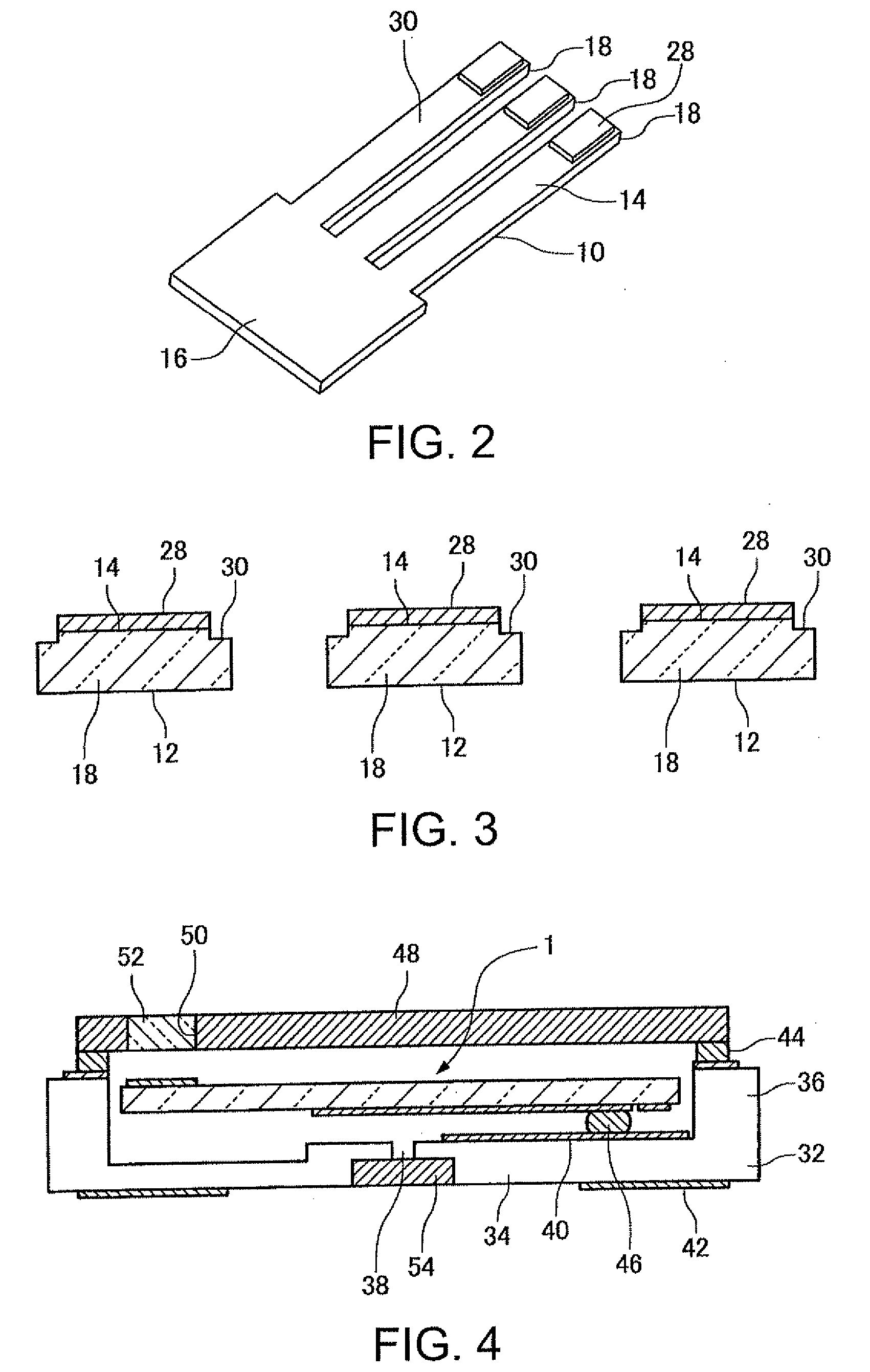

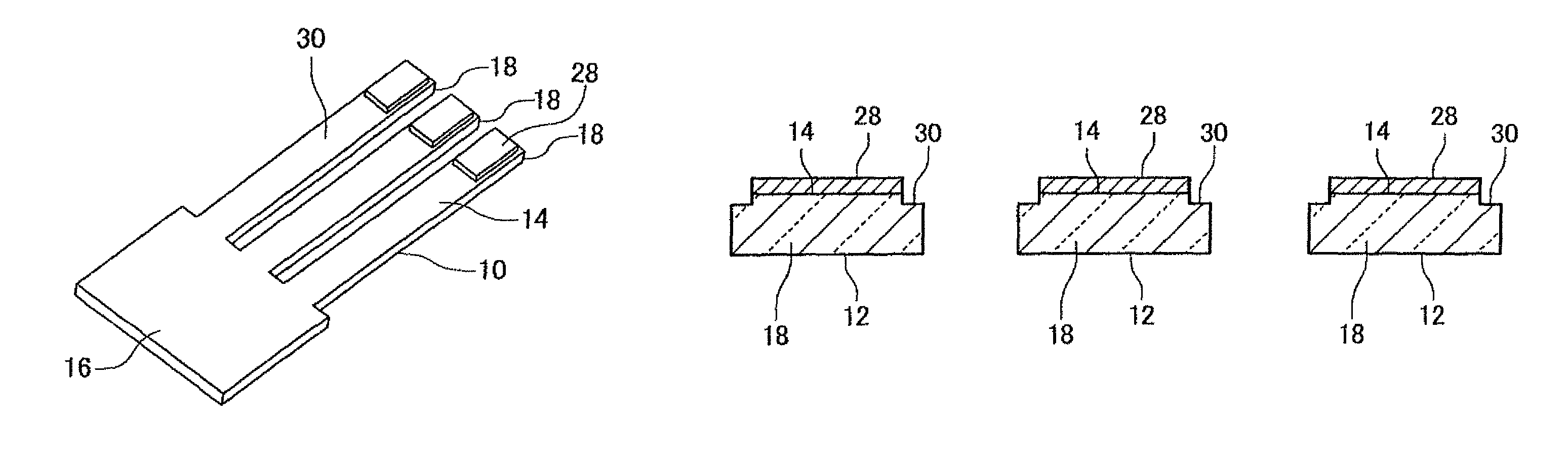

Light-emitting element mounting board, light-emitting element module, lighting device, display device, and traffic signal equipment

InactiveUS7699500B2Light emission efficiency of the light-emitting elements can be maintained at a high levelIncrease heat radiationLighting heating/cooling arrangementsPrinted circuit aspectsTraffic signalDisplay device

In accordance with the present invention, a light-emitting element mounting board is provided including an enamel layer which covers the surface of a core metal, wherein reflective cup portions for mounting light-emitting elements are provided on one face of the board, and wherein a heat radiating part is formed by at least partially removing the enamel layer on the other face of the board, and exposing the core metal. Further, a light-emitting element module including light-emitting elements mounted thereon, a lighting device including the light-emitting element, a display device, and traffic signal equipment are provided.

Owner:FUJIKURA LTD

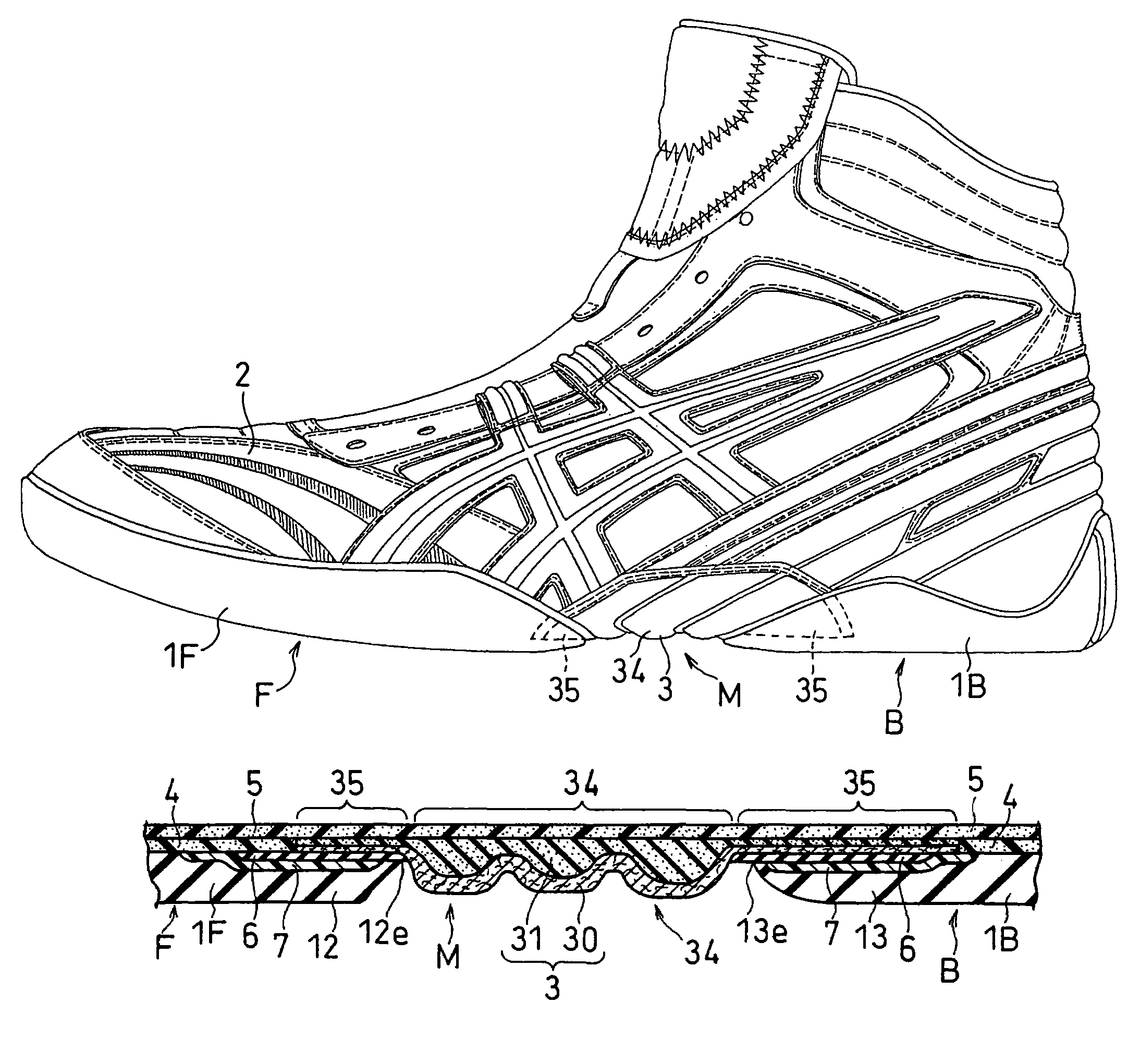

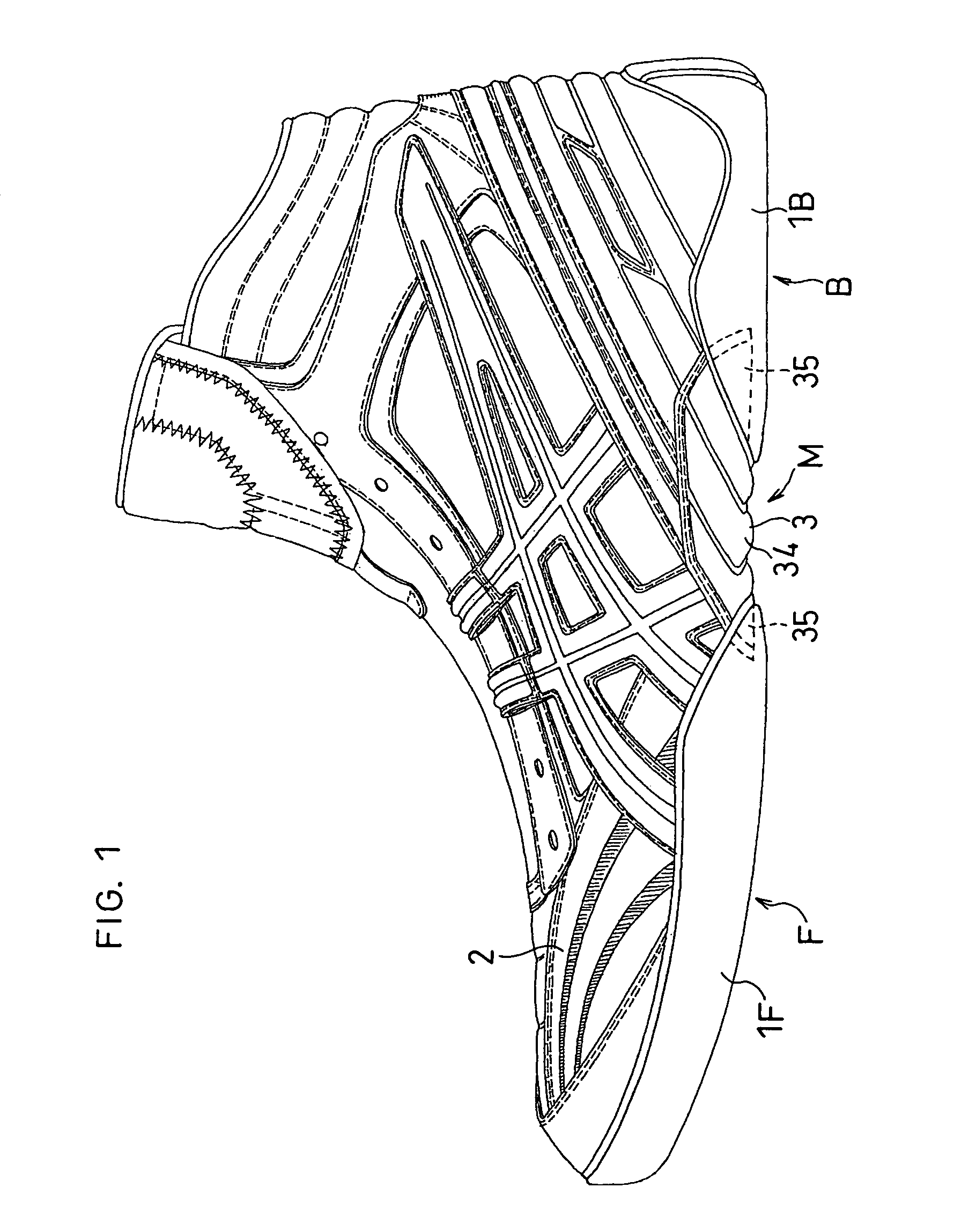

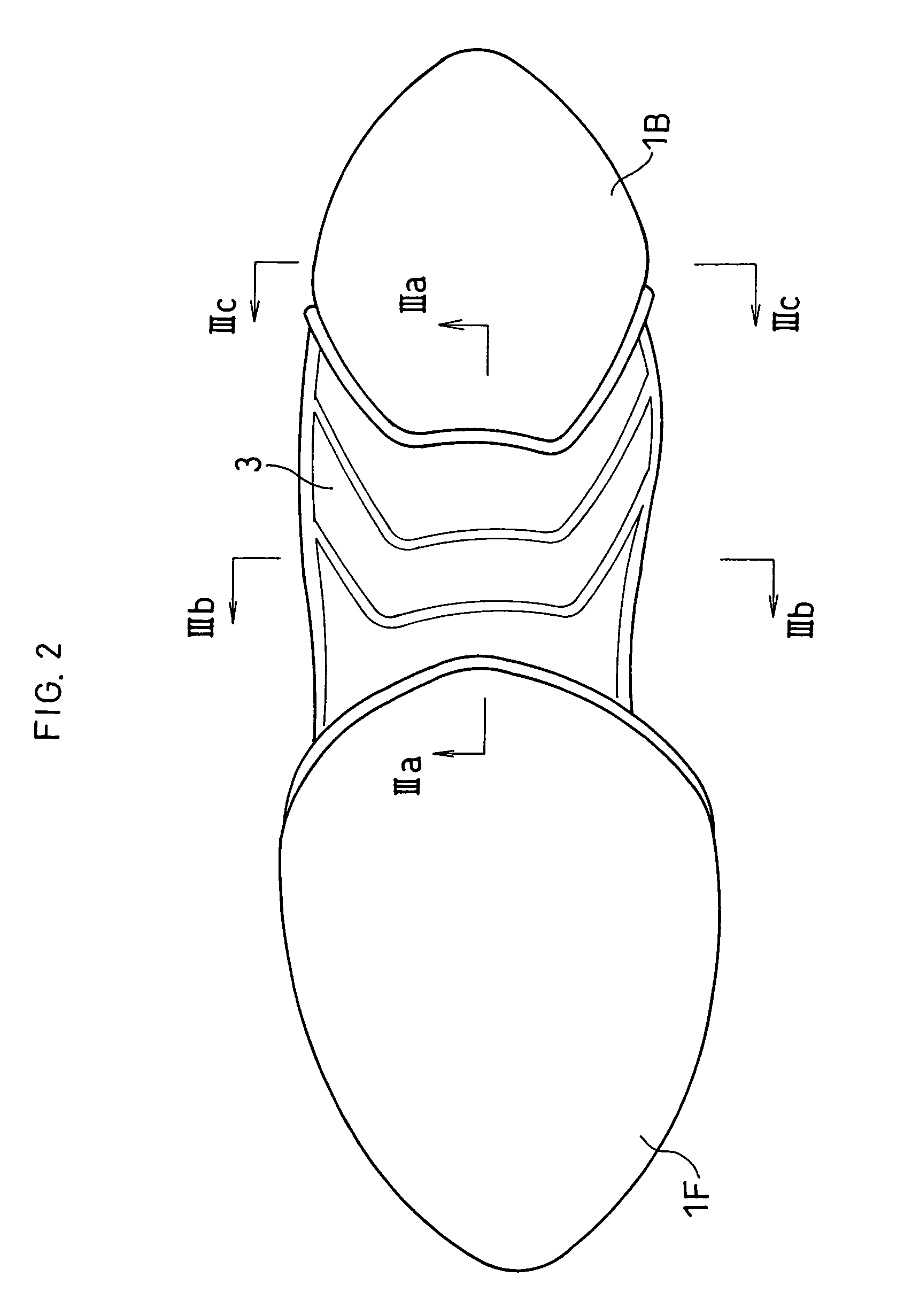

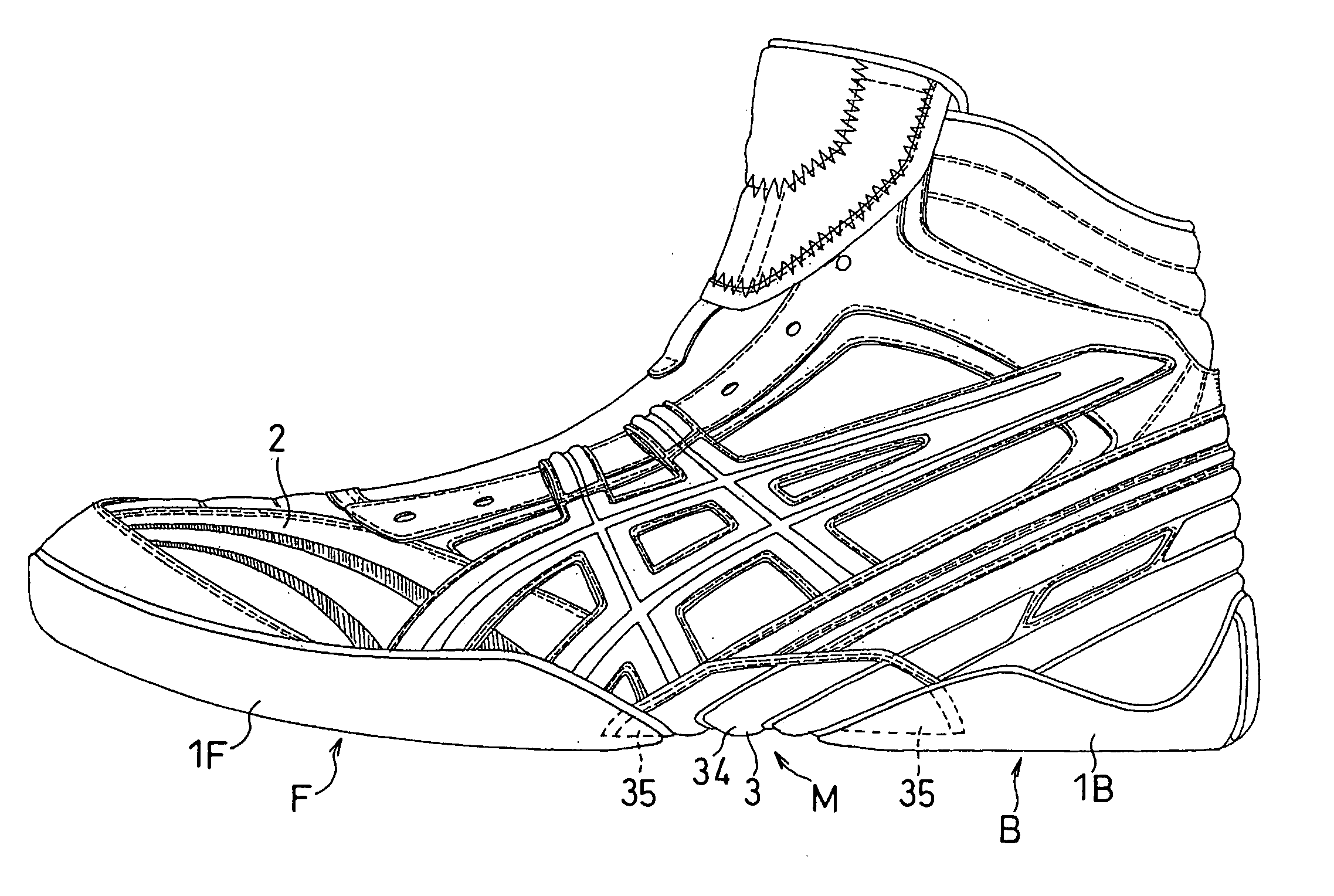

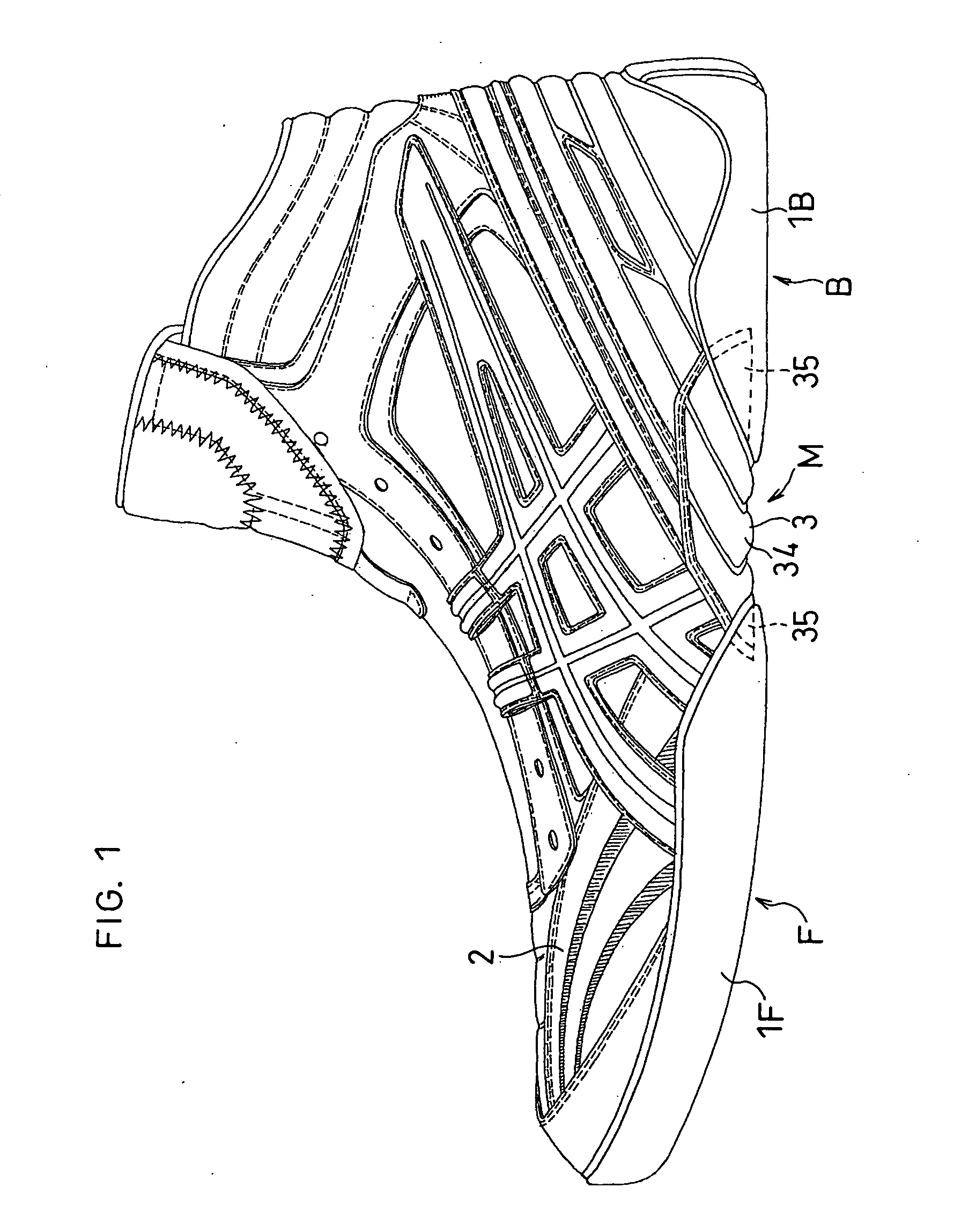

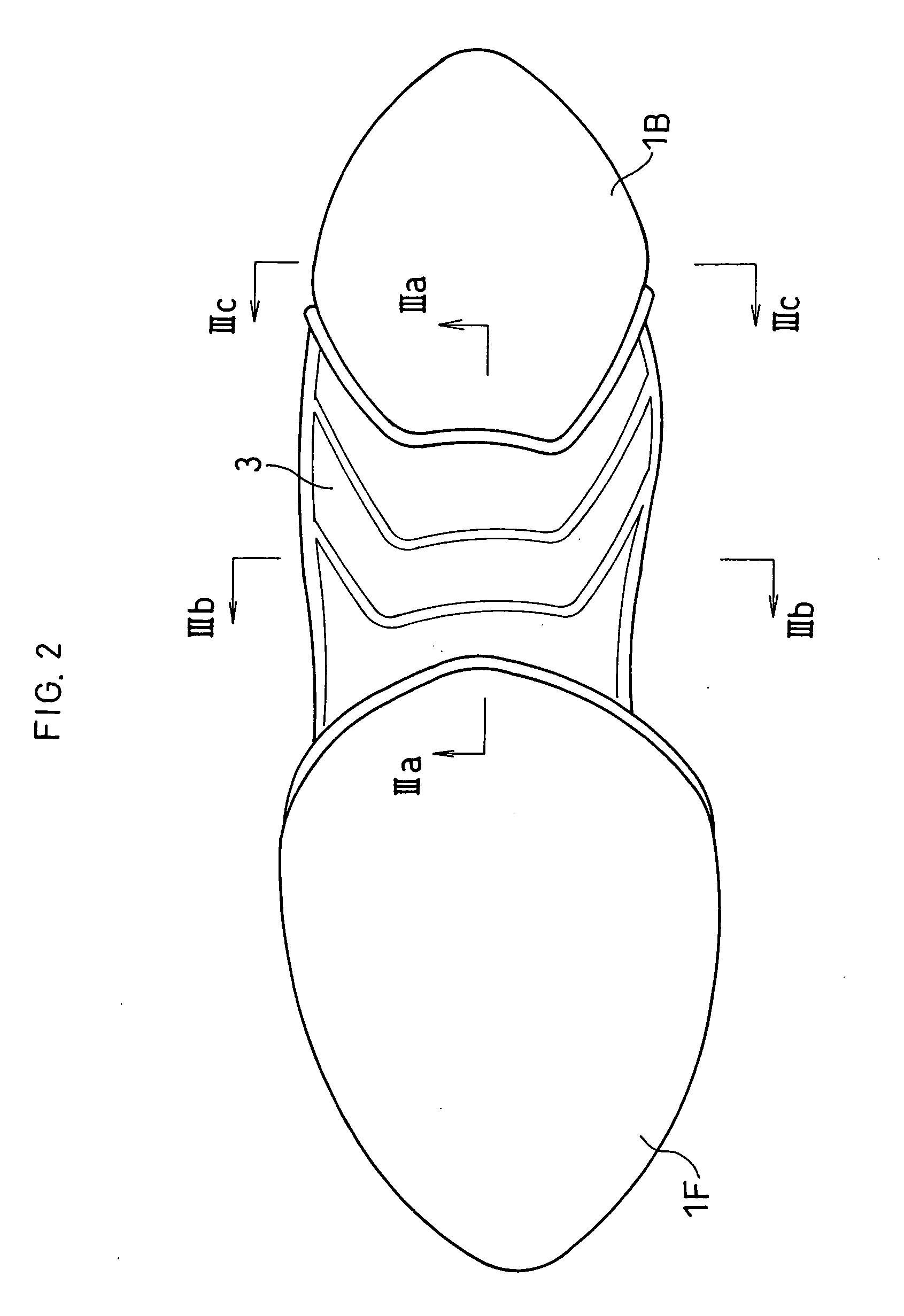

Wrestling shoe with separated outer soles

ActiveUS7325336B2Excellent fitting property and support and shock-absorbing propertyComplete flexibilitySolesUpperSurface layerBiomedical engineering

The wrestling shoe according to the present invention comprises outer soles 1F and 1B separated forward and rearward on the side of a grounding surface of the shoe. The fore and rear outer soles 1F and 1B essentially protrude downward further than an outer skin 3, thereby to support the foot in a fore foot part and a rear foot part, respectively, when landing on the ground. The fore and rear outer soles 1F and 1B are made of an outer sole material of rubber and / or resin. The outer skin 3 is formed of a laminated body where an outer surface layer 30 and a cushion layer 31 are laminated. The outer surface layer 30 is exposed in a mid foot part M and made of substantially flexible sheet-like material, and the cushion layer 31 is laminated on the inner side of the outer surface layer 30 and made of substantially flexible rubber foam or resin foam. The outer skin 3 is formed so that a bottom portion 32 and medial and lateral roll-up portions 33 that roll up from the bottom portion 32 along an upper 2 are integrally formed.

Owner:ASICS CORP

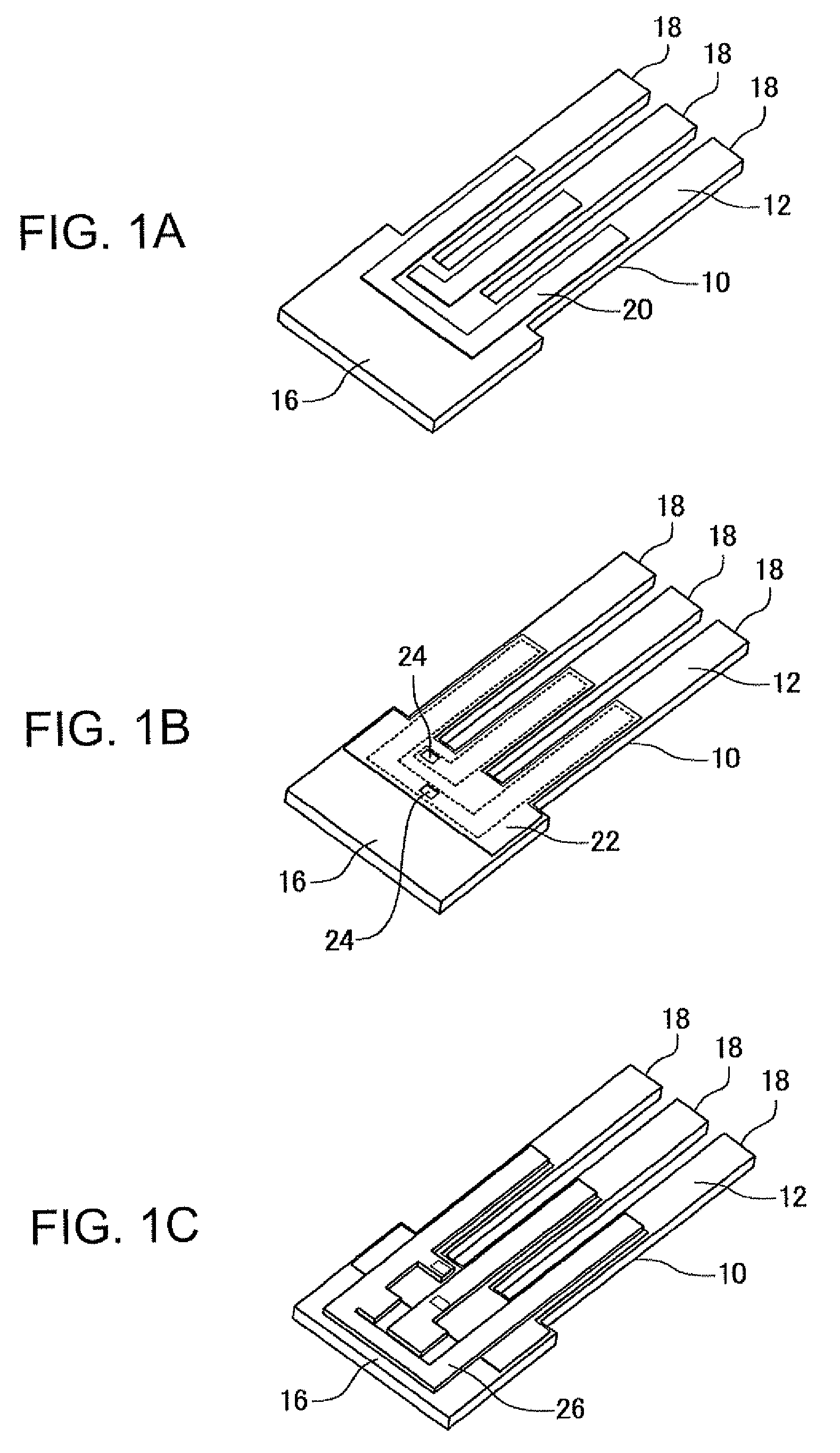

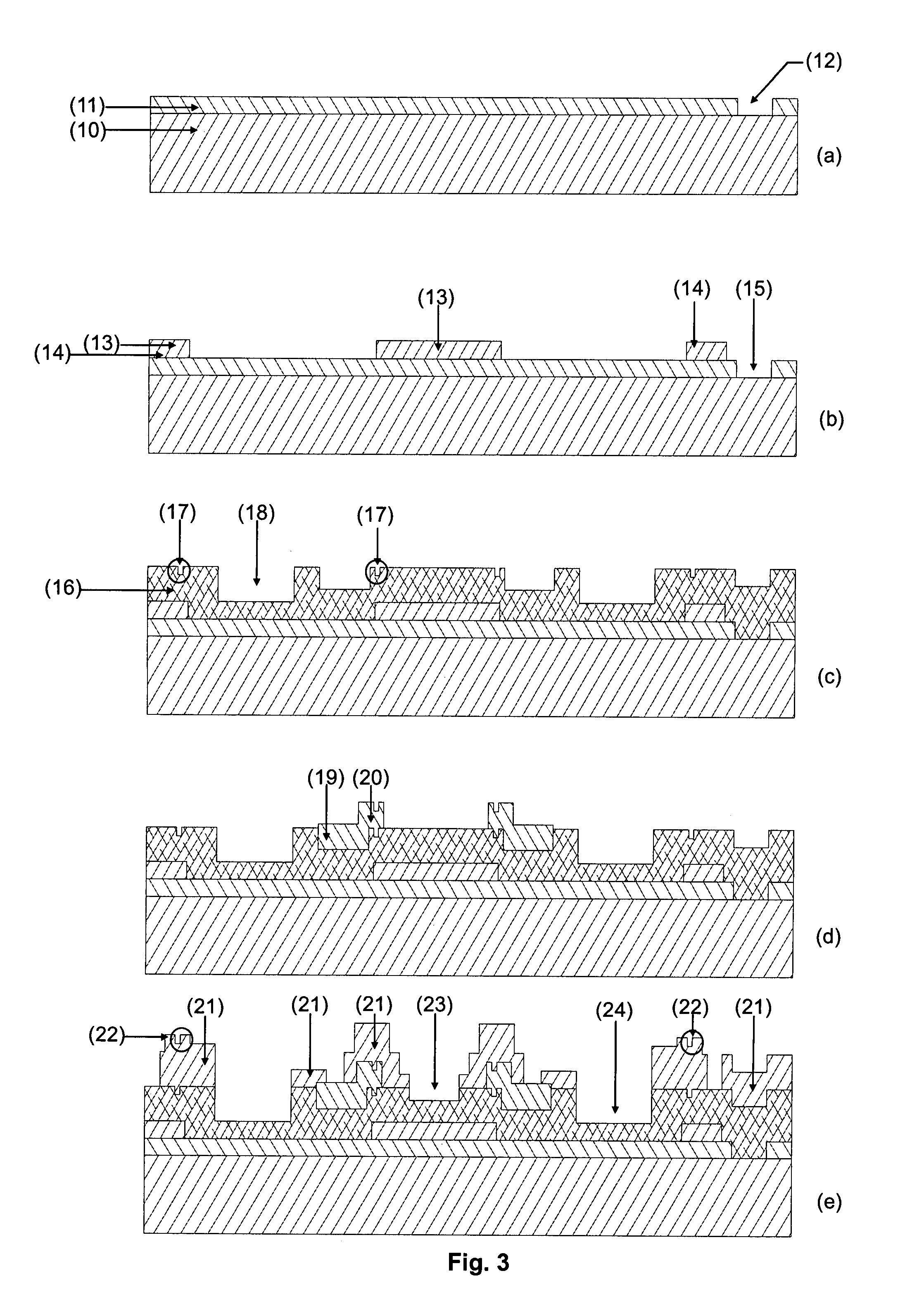

Vibrating piece manufacturing method and vibrator manufacturing method

InactiveUS20090178260A1Extend the scope of controlReduce thicknessPiezoelectric/electrostrictive device manufacture/assemblyRecord carriersEngineeringFlexural rigidity

A vibrating piece manufacturing method includes: (a) preparing a supporting body having first and second surfaces, the first and second surfaces defining a thickness while being directed toward opposite directions, the supporting body including a base and a plurality of arms, the arms extending side-by-side in a direction orthogonal to a direction of the thickness from the base, a lower electrode film being disposed on the first surface of each of the arms, a piezoelectric film being disposed on the lower electrode films, at least one upper electrode film being disposed on the piezoelectric film, at least a part of the second surface of each of the arms being an exposed area; and (b) etching the exposed area of the second surface so as to reduce the thickness to reduce flexural rigidity of the arms with respect to the thickness direction.

Owner:SEIKO EPSON CORP

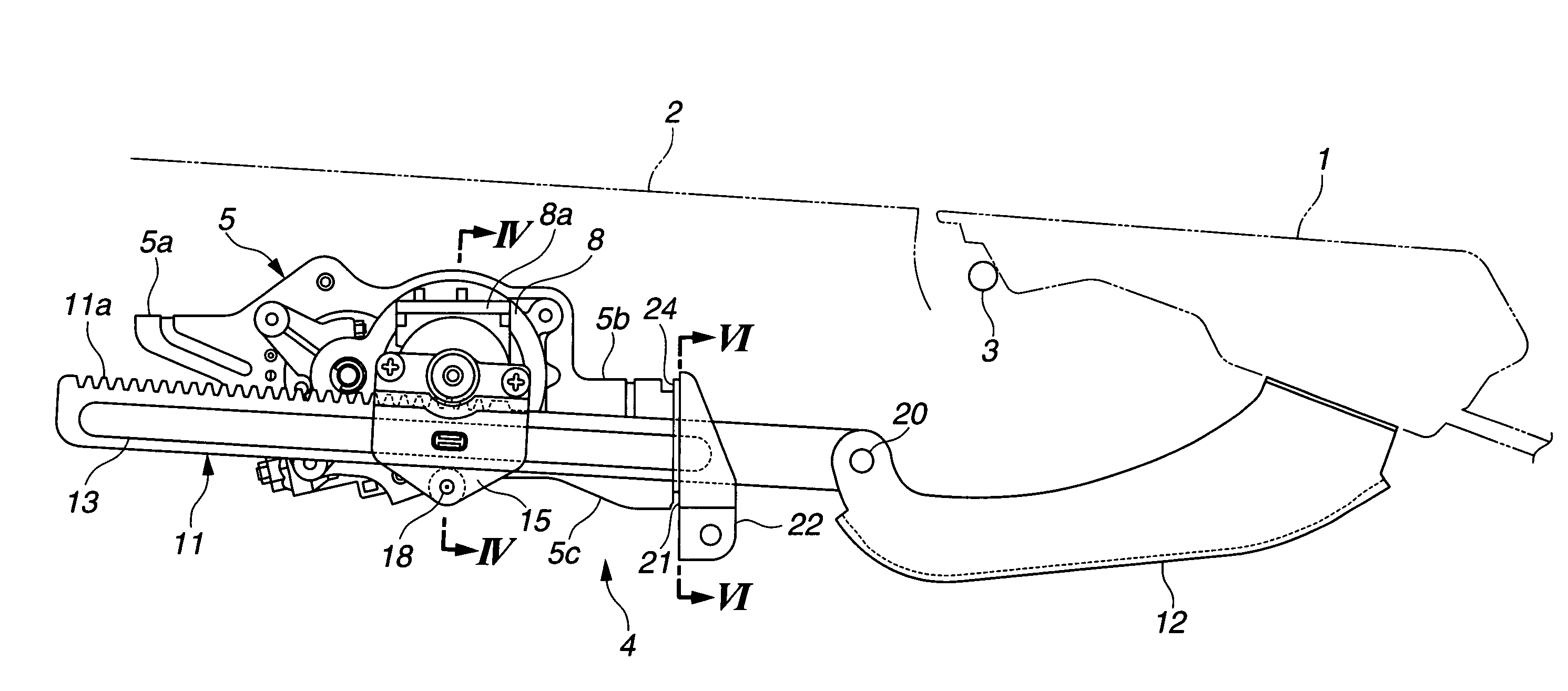

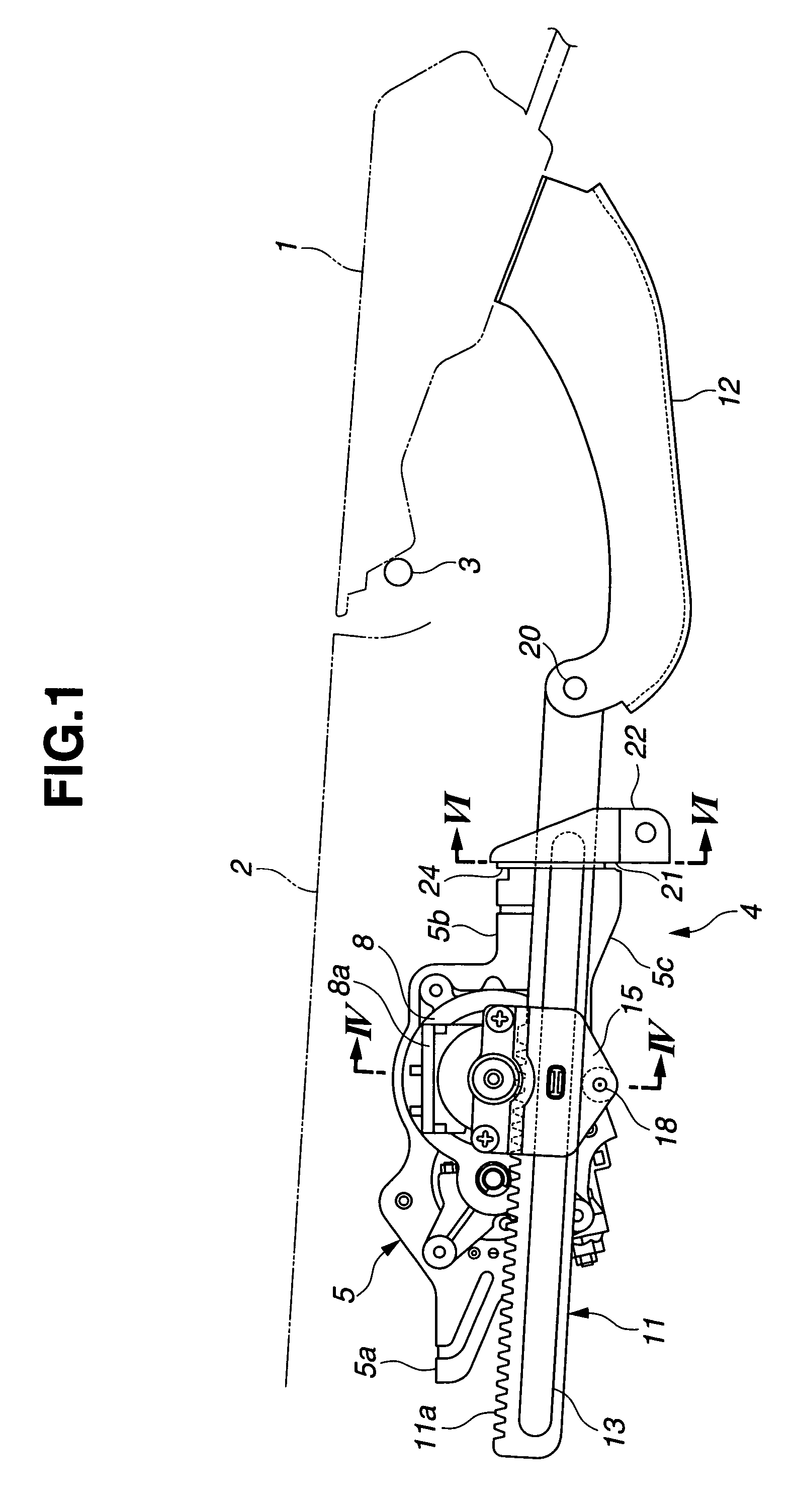

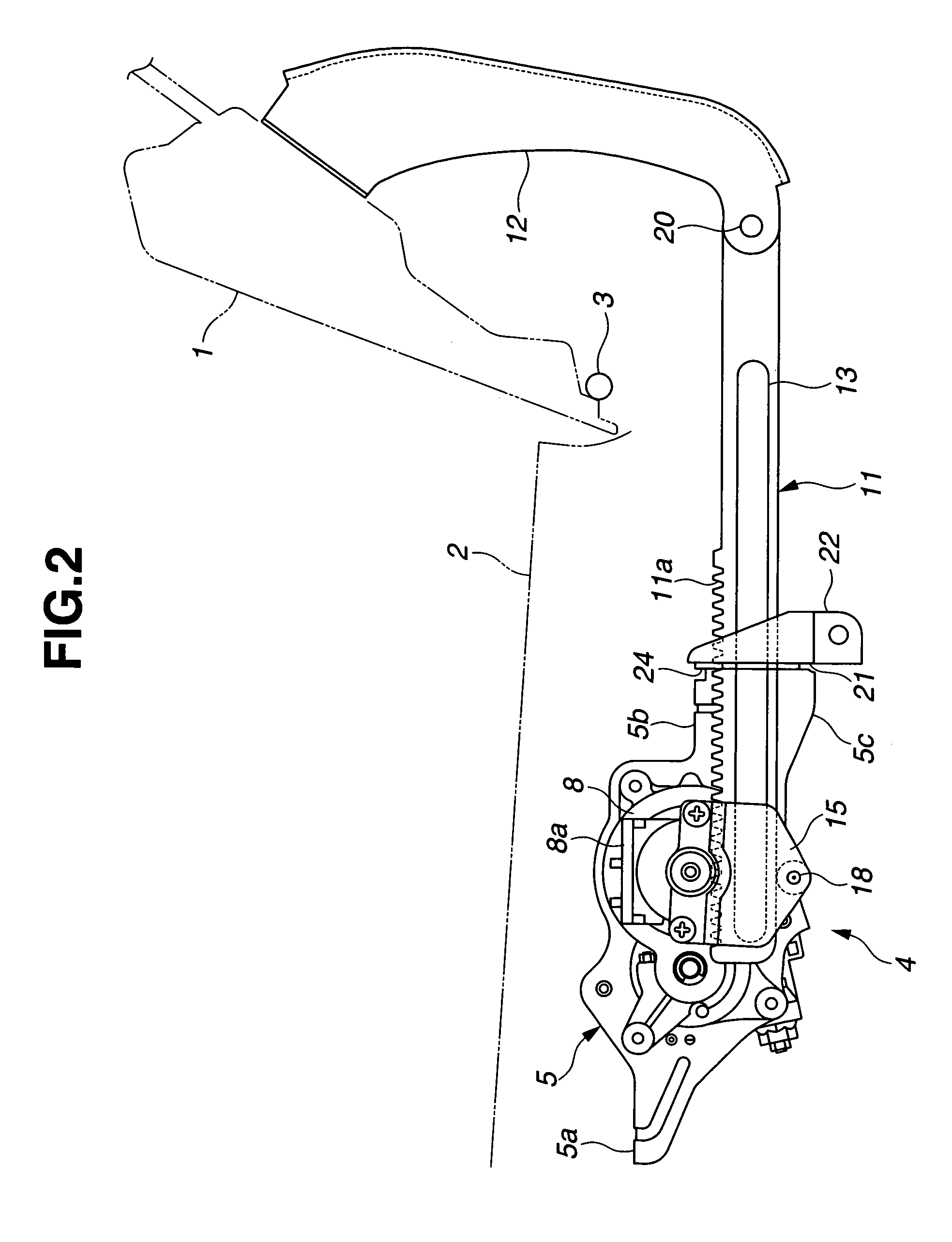

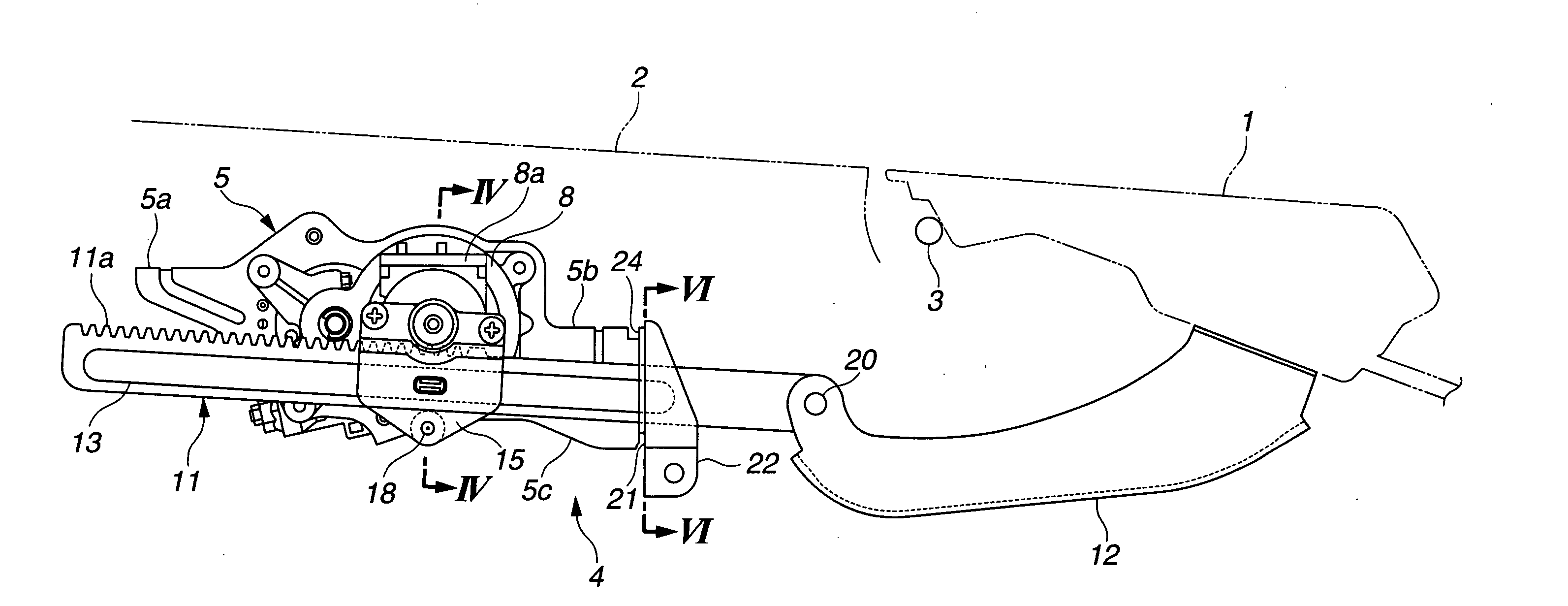

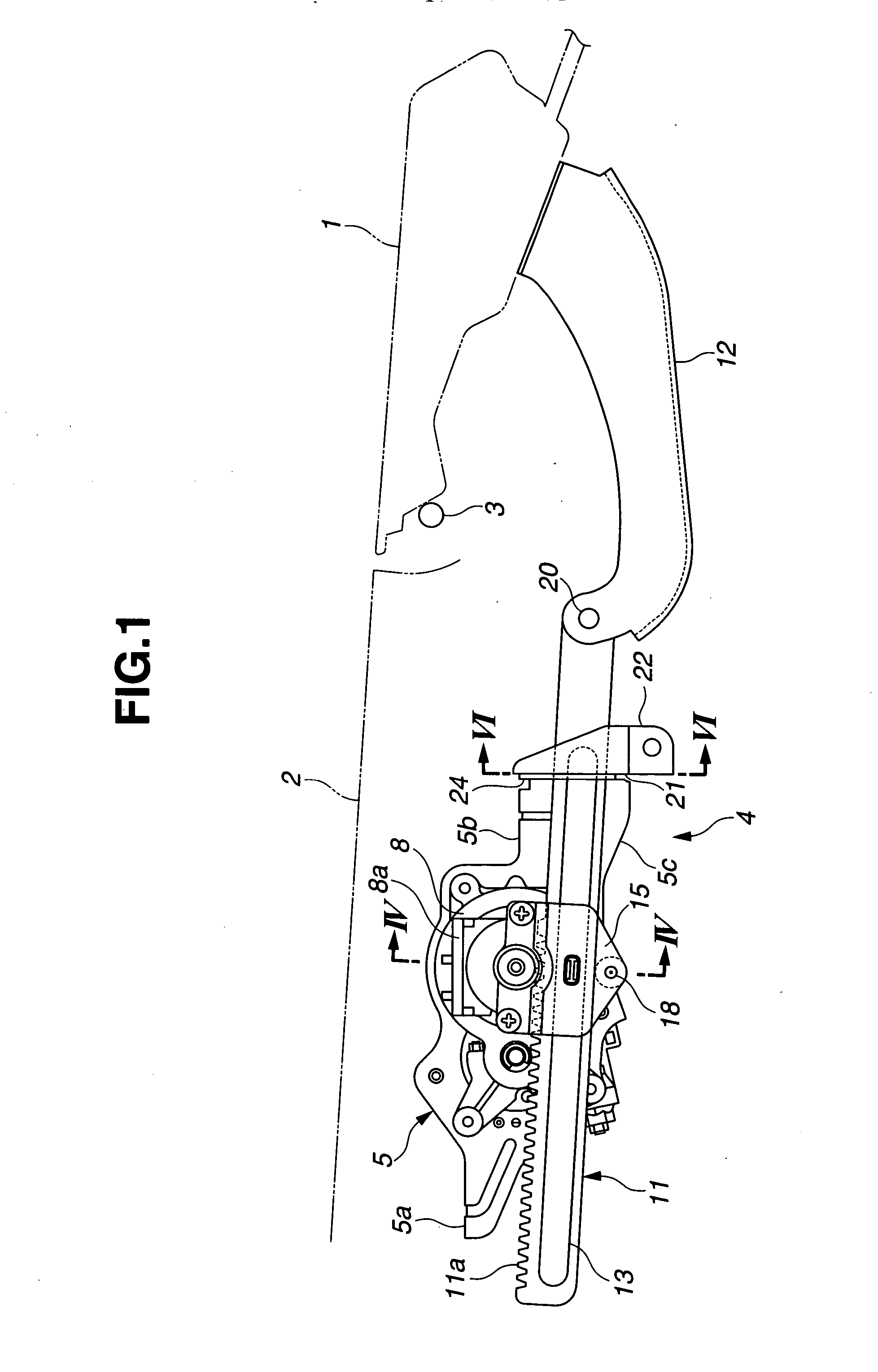

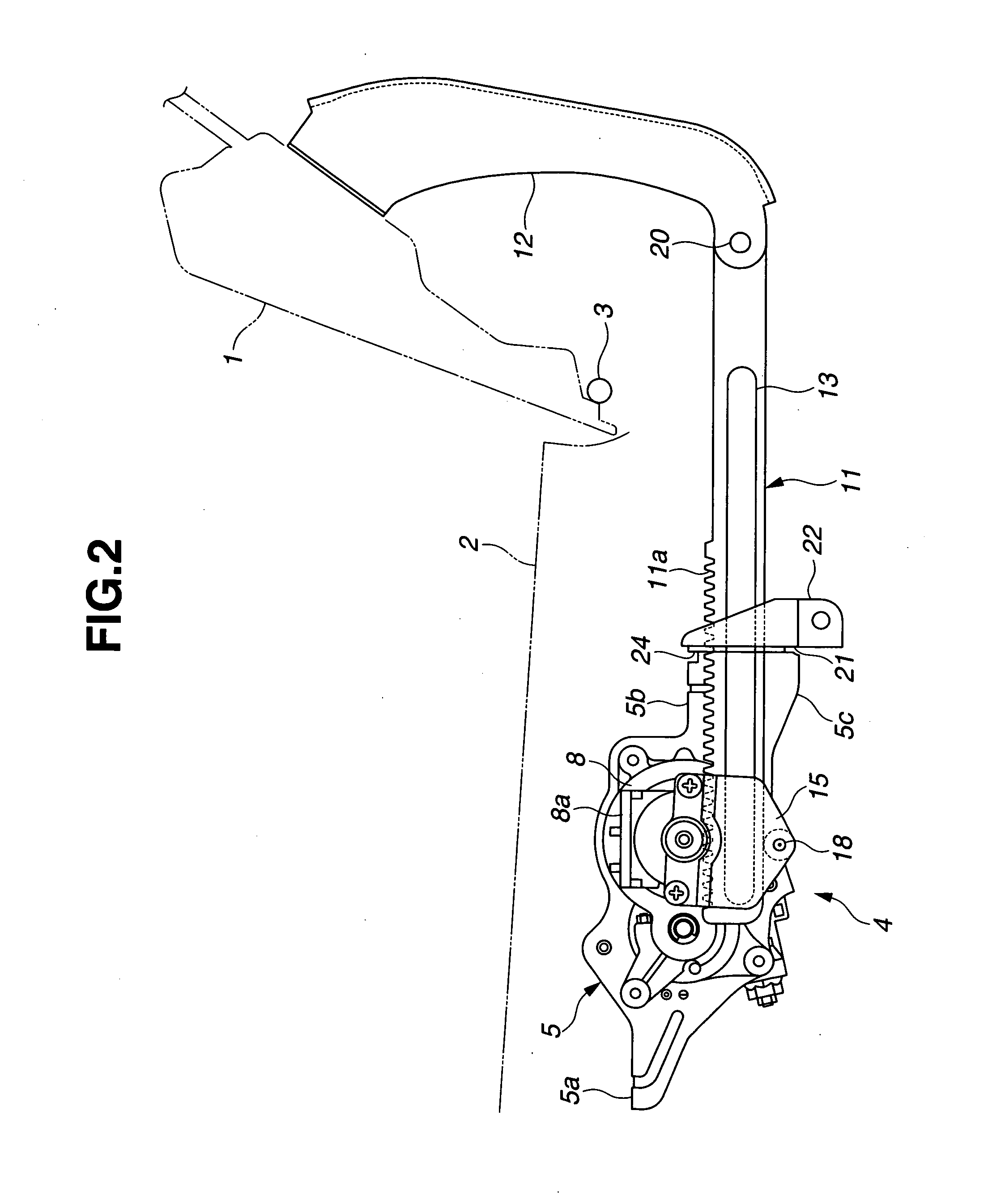

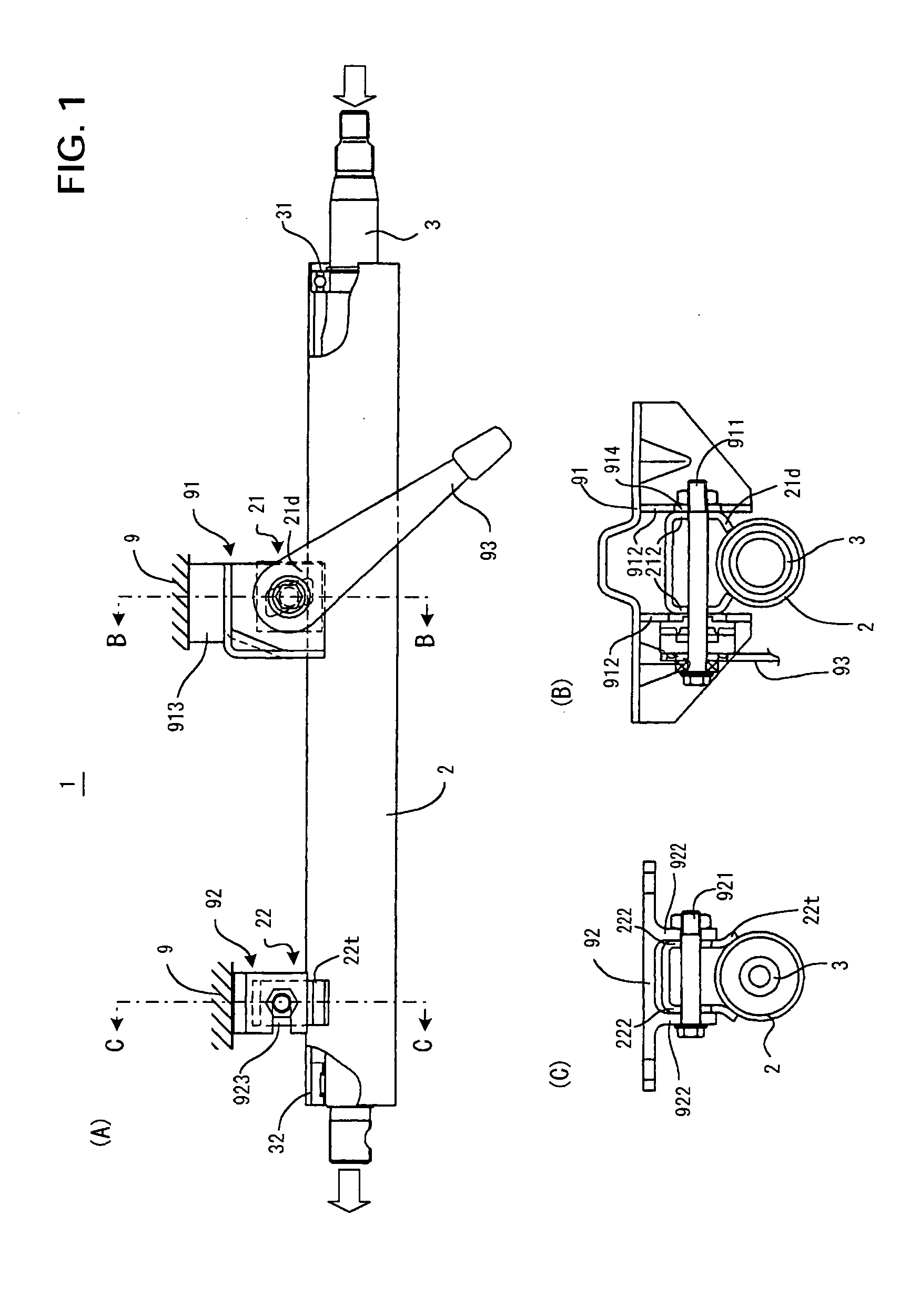

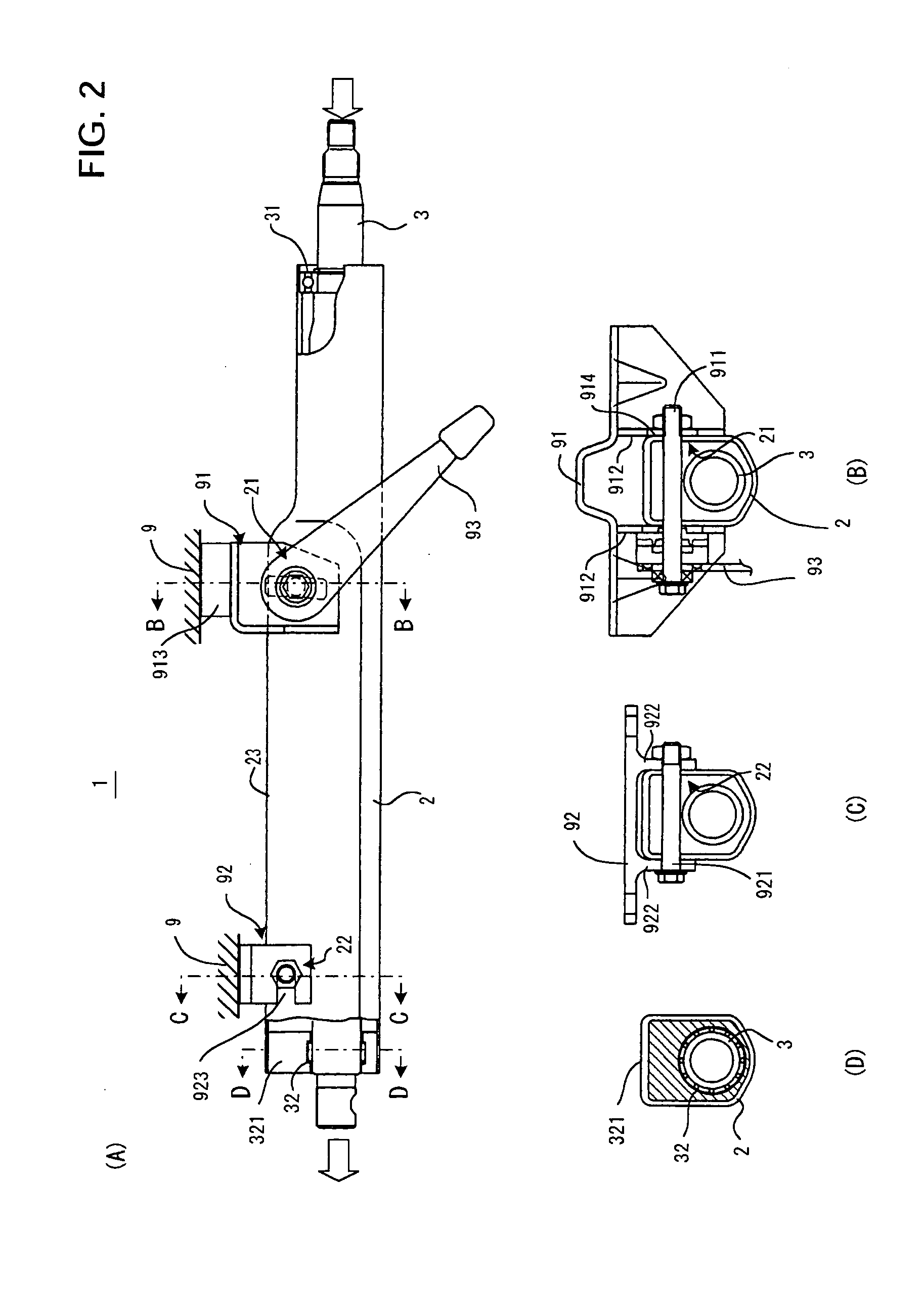

Opening and closing apparatus for opening and closing body of vehicle

InactiveUS7243976B2Increased flexural rigidityIncreasing the thicknessMan-operated mechanismPower-operated mechanismReciprocating motionEngineering

Owner:MITSUI KINZOKU ACT

Wrestling shoe with separated outer soles

ActiveUS20050108901A1Excellent fitting property propertyStable supportSolesUpperForefootBiomedical engineering

The wrestling shoe according to the present invention comprises outer soles 1F and 1B separated forward and rearward on the side of a grounding surface of the shoe. The fore and rear outer soles 1F and 1B essentially protrude downward further than an outer skin 3, thereby to support the foot in a fore foot part and a rear foot part, respectively, when landing on the ground. The fore and rear outer soles 1F and 1B are made of an outer sole material of rubber and / or resin. The outer skin 3 is formed of a laminated body where an outer surface layer 30 and a cushion layer 31 are laminated. The outer surface layer 30 is exposed in a mid foot part M and made of substantially flexible sheet-like material, and the cushion layer 31 is laminated on the inner side of the outer surface layer 30 and made of substantially flexible rubber foam or resin foam. The outer skin 3 is formed so that a bottom portion 32 and medial and lateral roll-up portions 33 that roll up from the bottom portion 32 along an upper 2 are integrally formed.

Owner:ASICS CORP

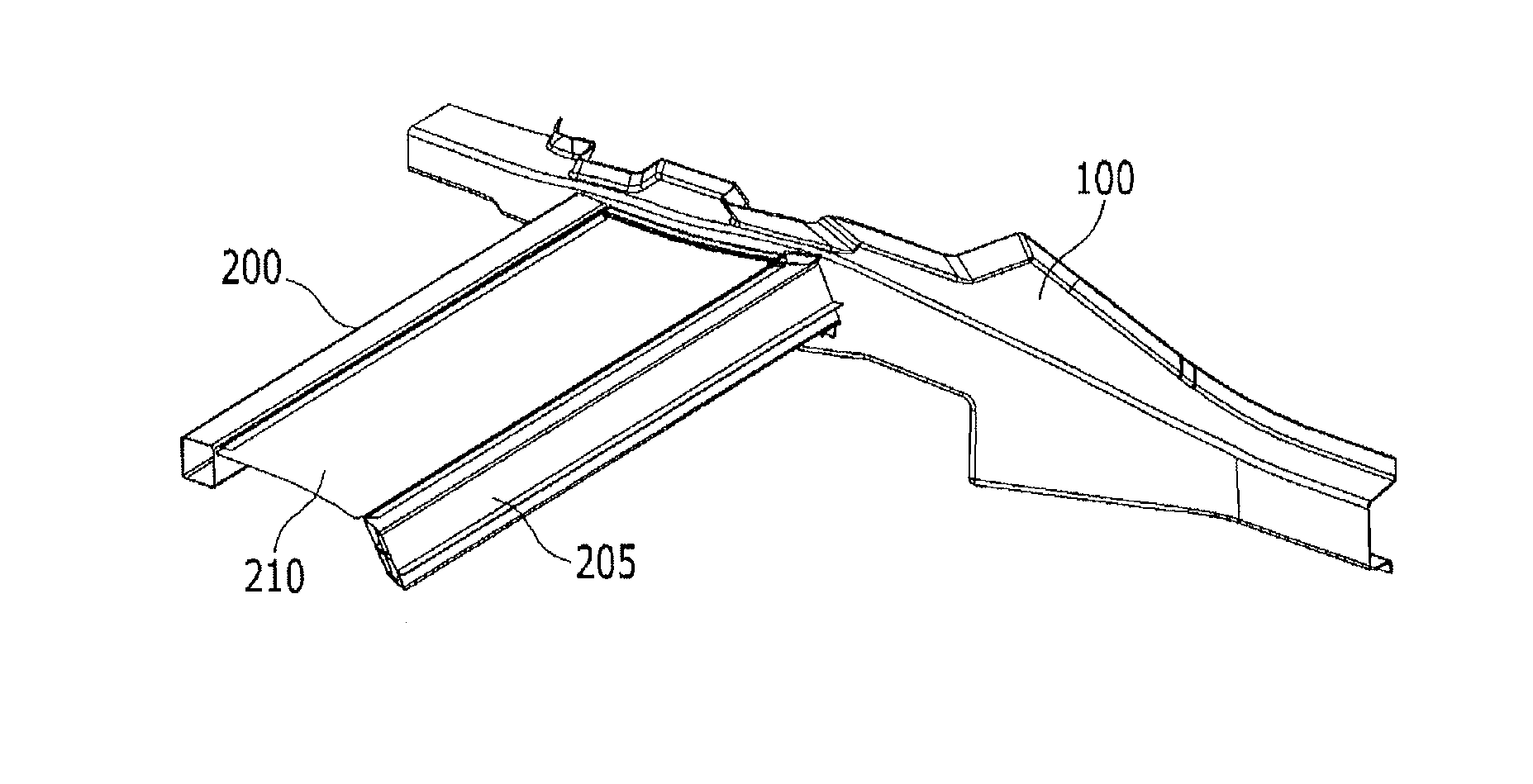

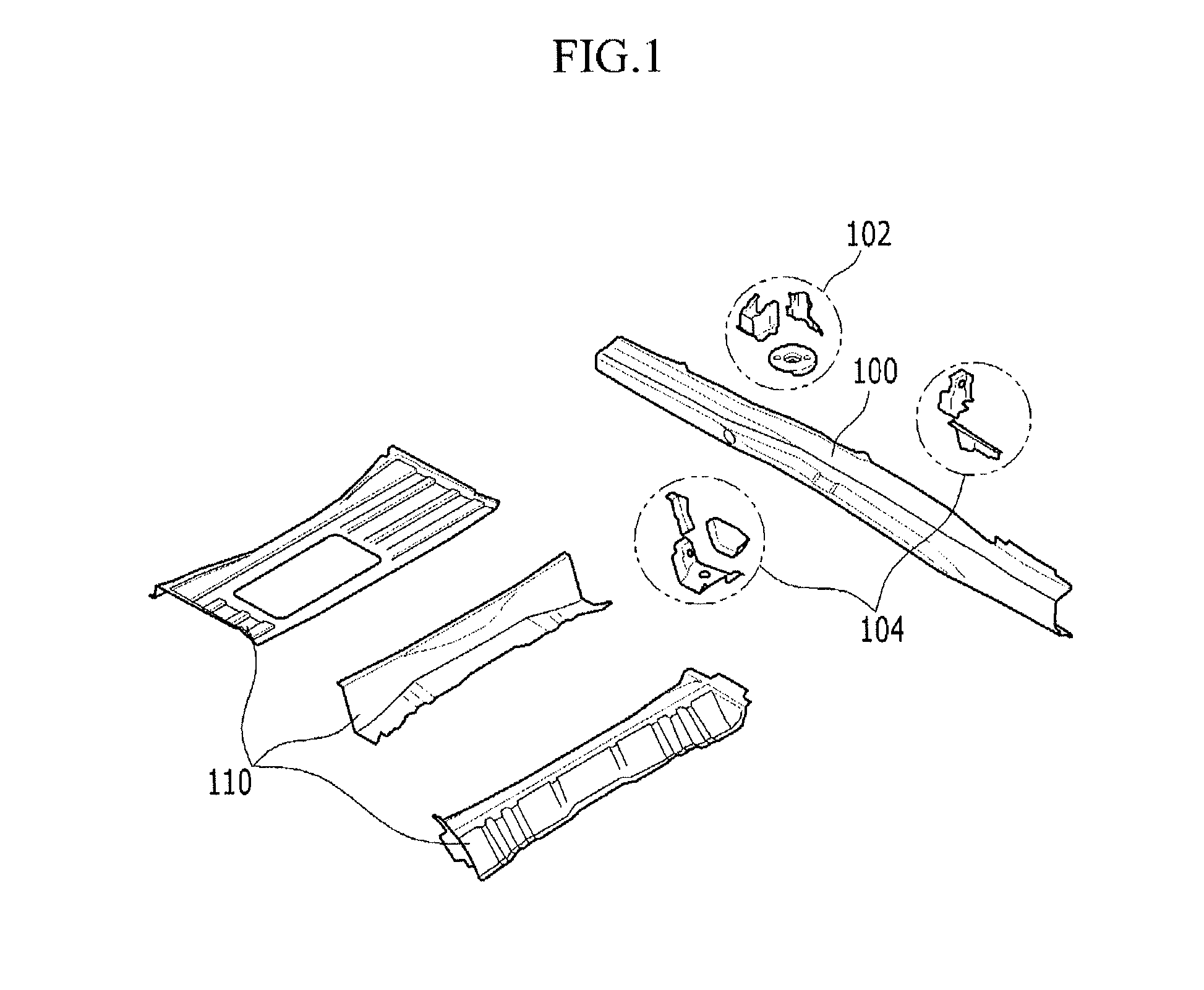

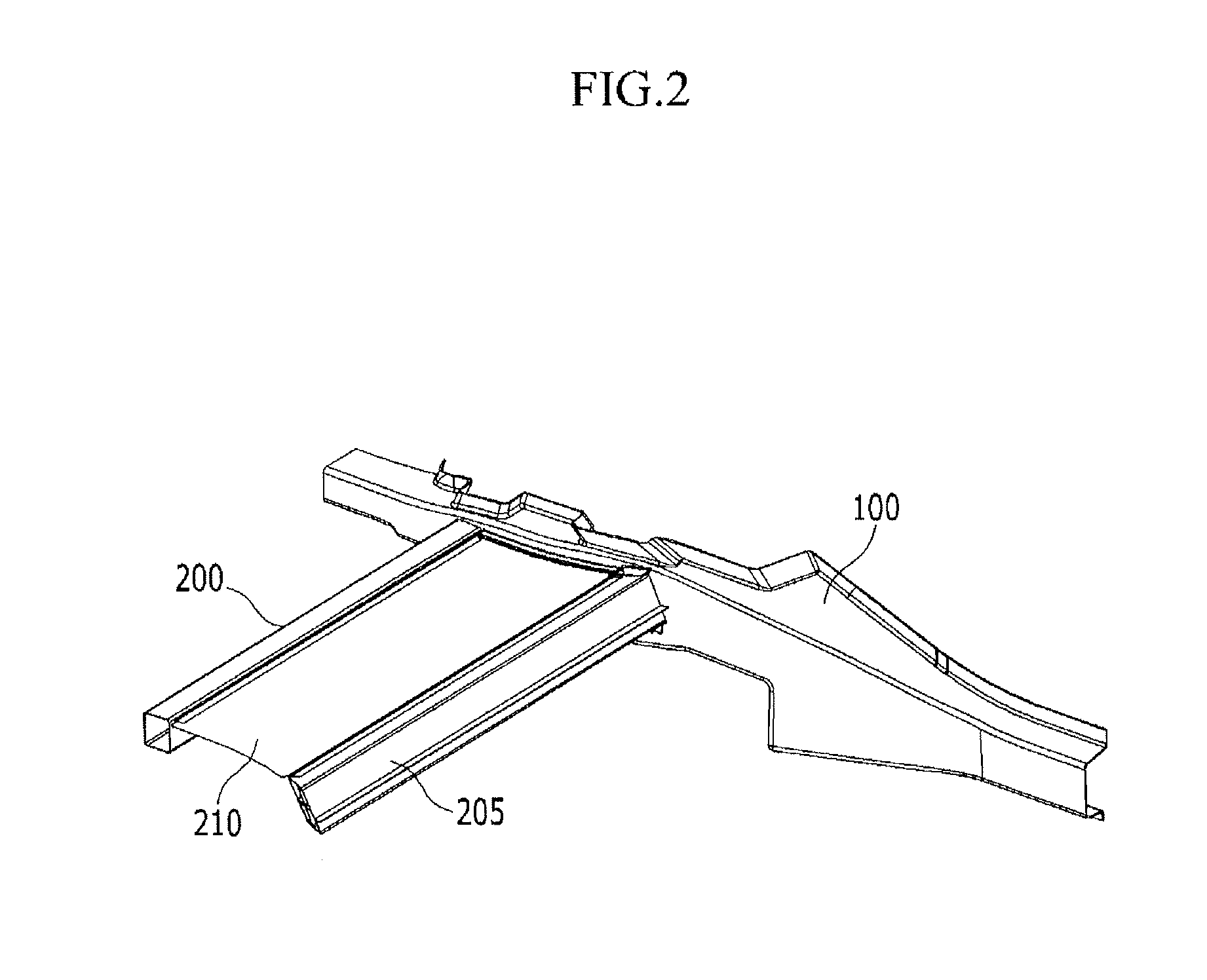

Vehicle body having rear side member

ActiveUS20150042129A1Increased flexural rigidityIncreased torsional rigidityVehicle seatsUnderstructuresEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD

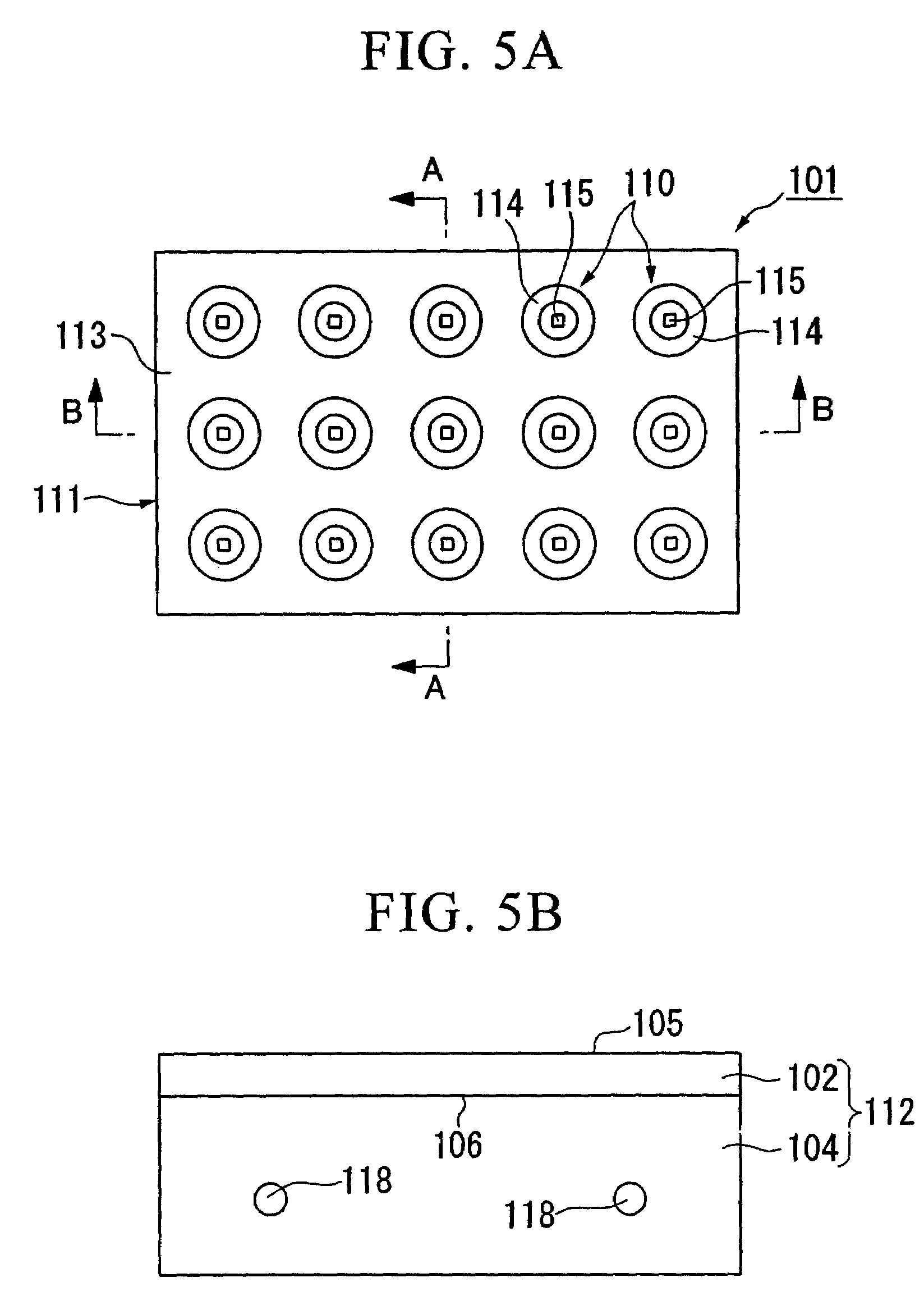

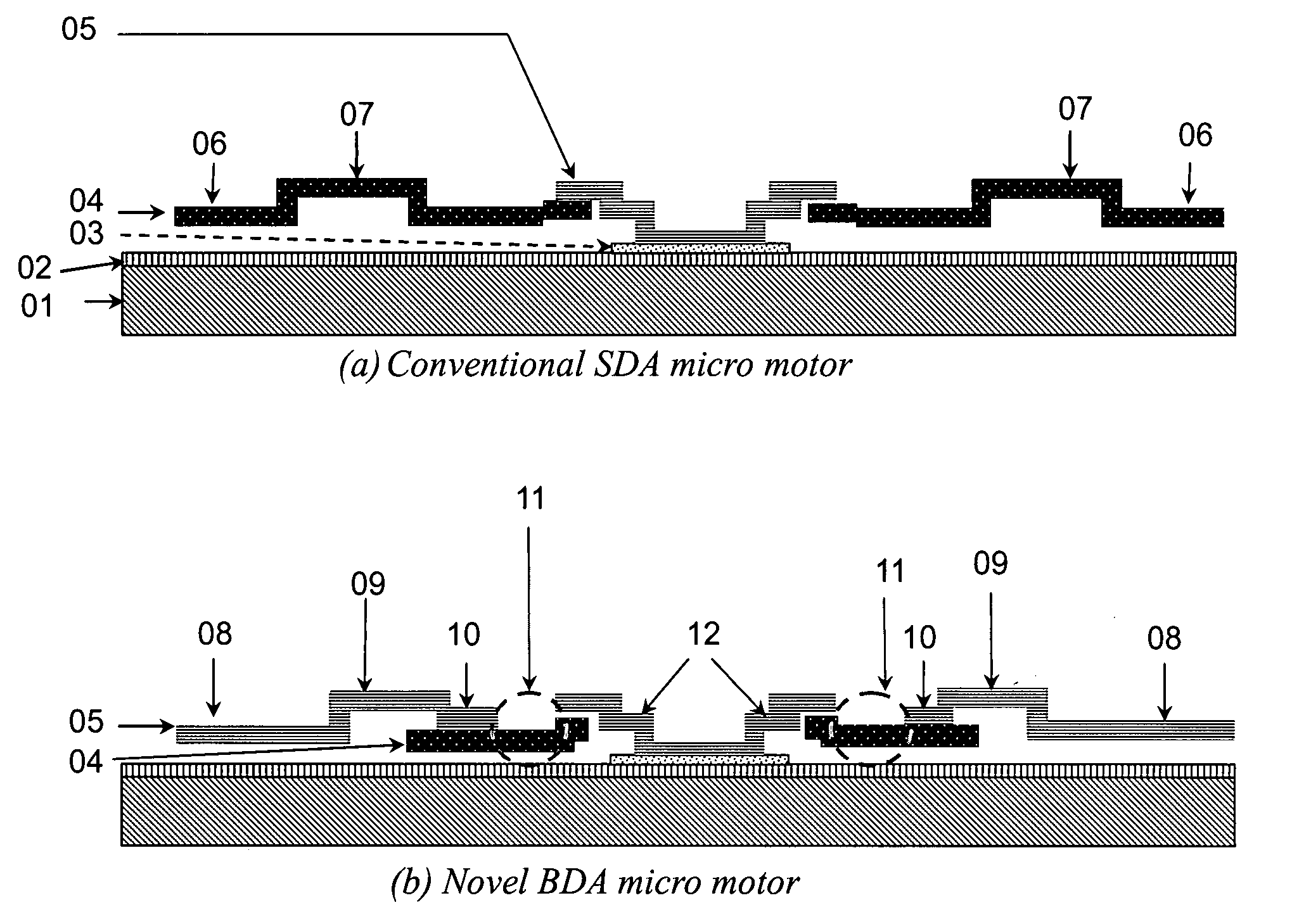

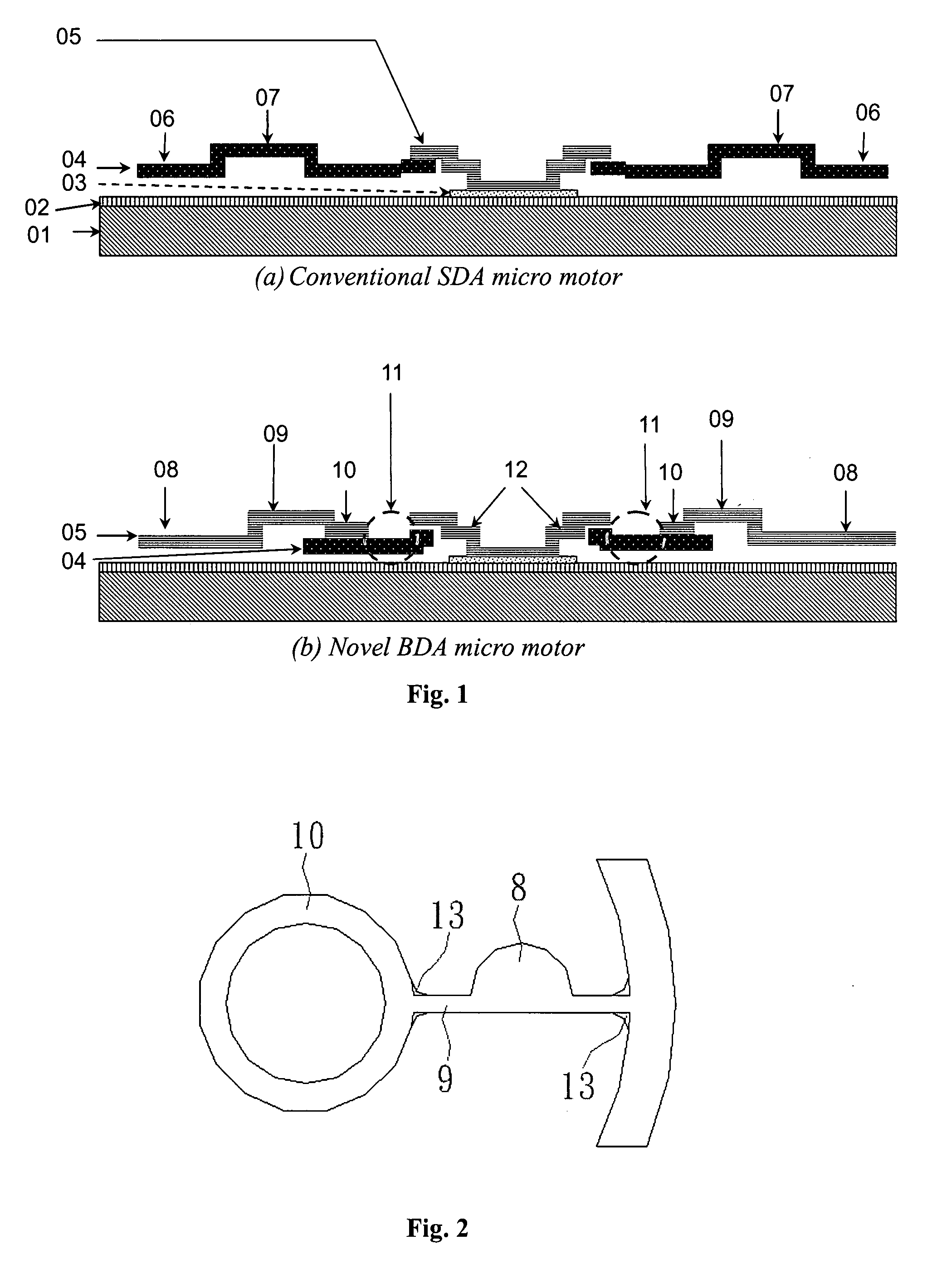

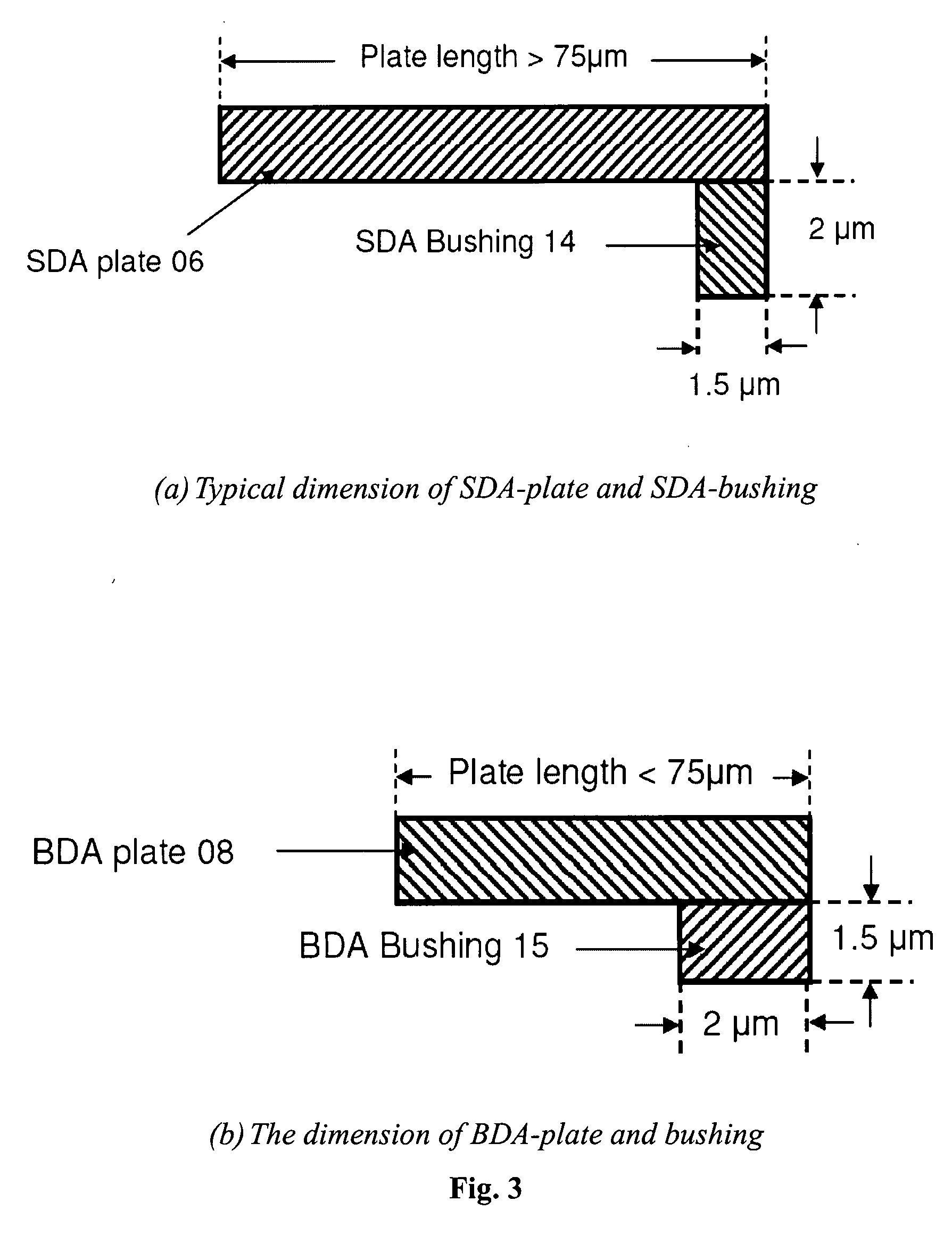

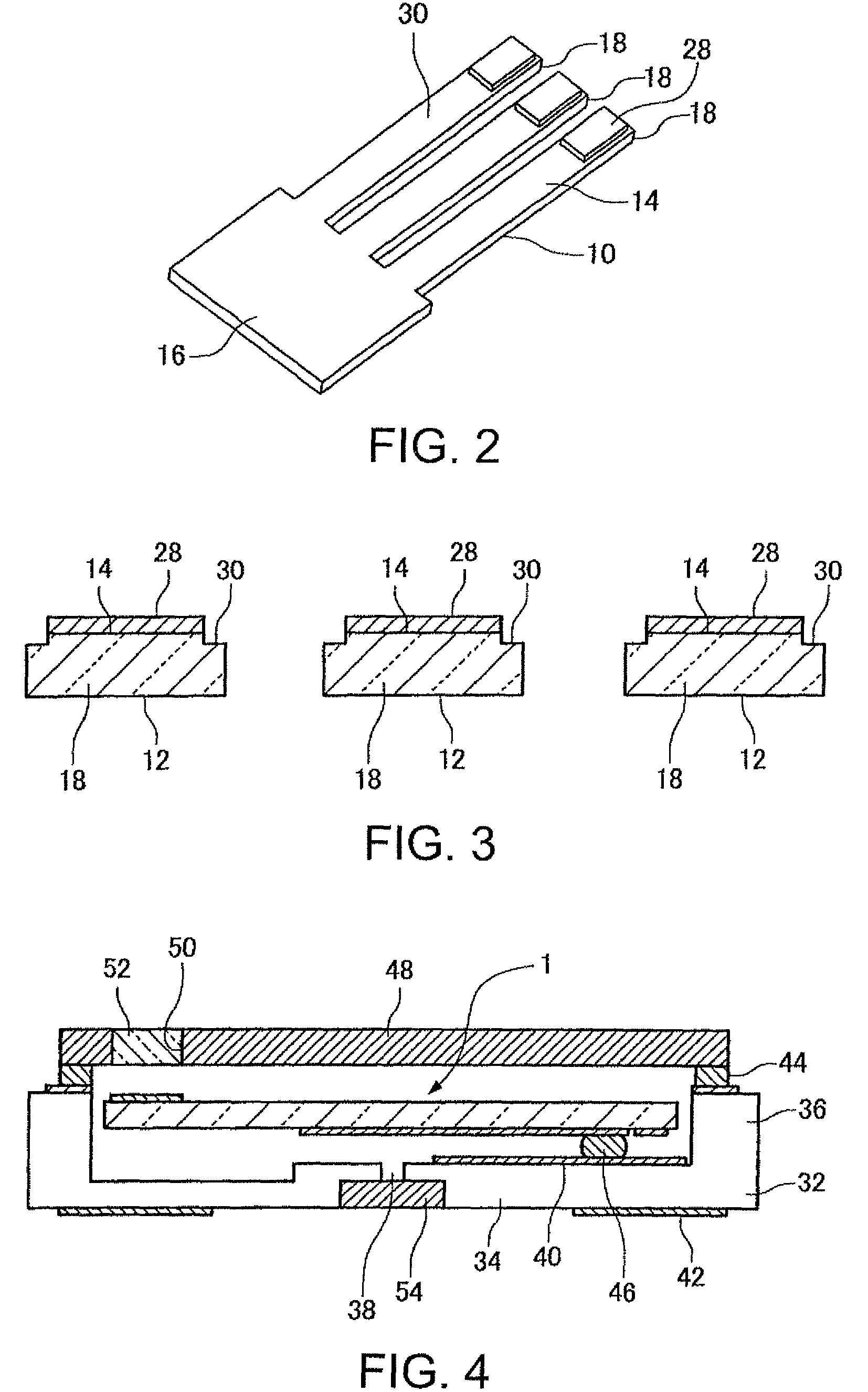

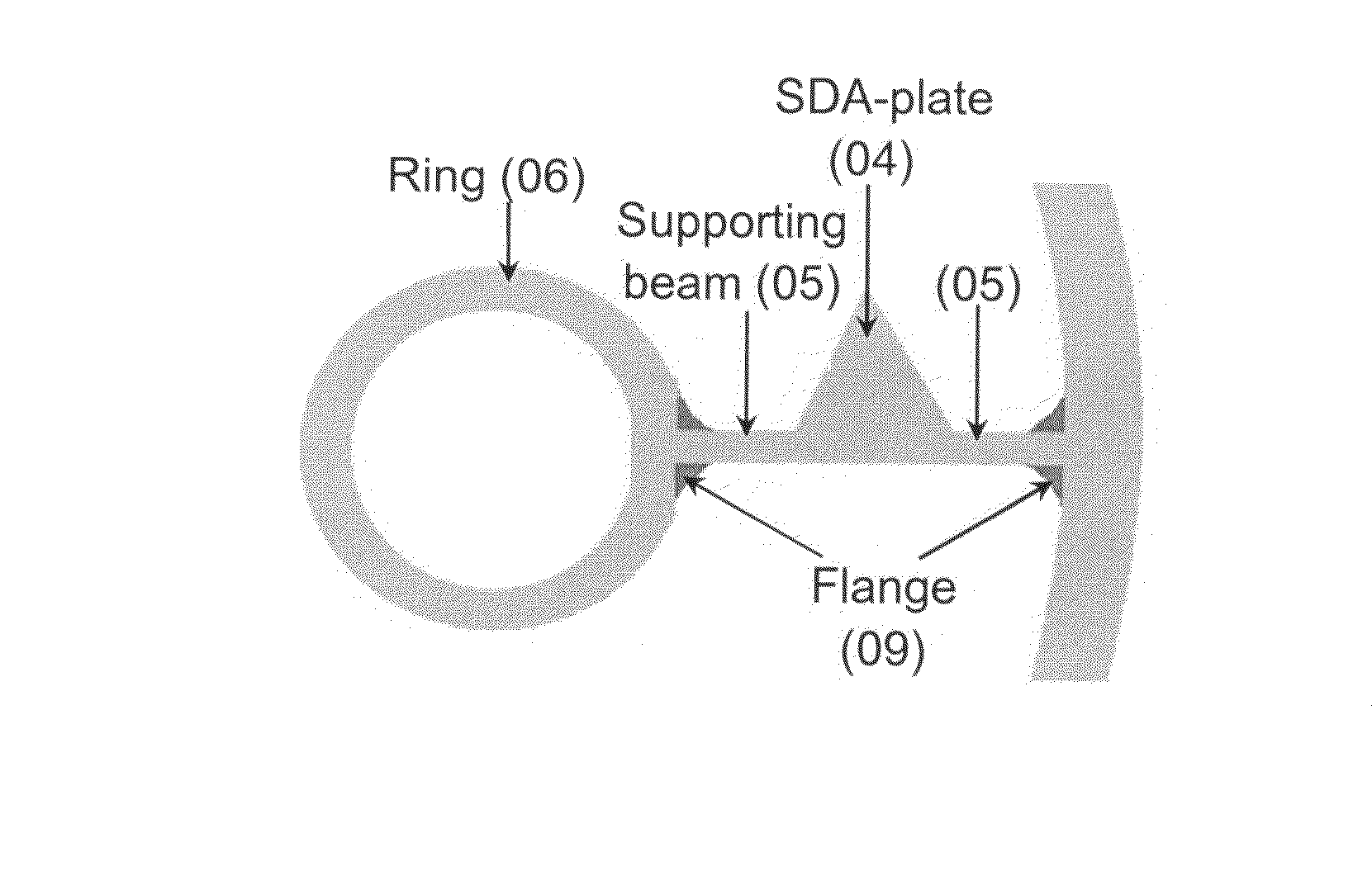

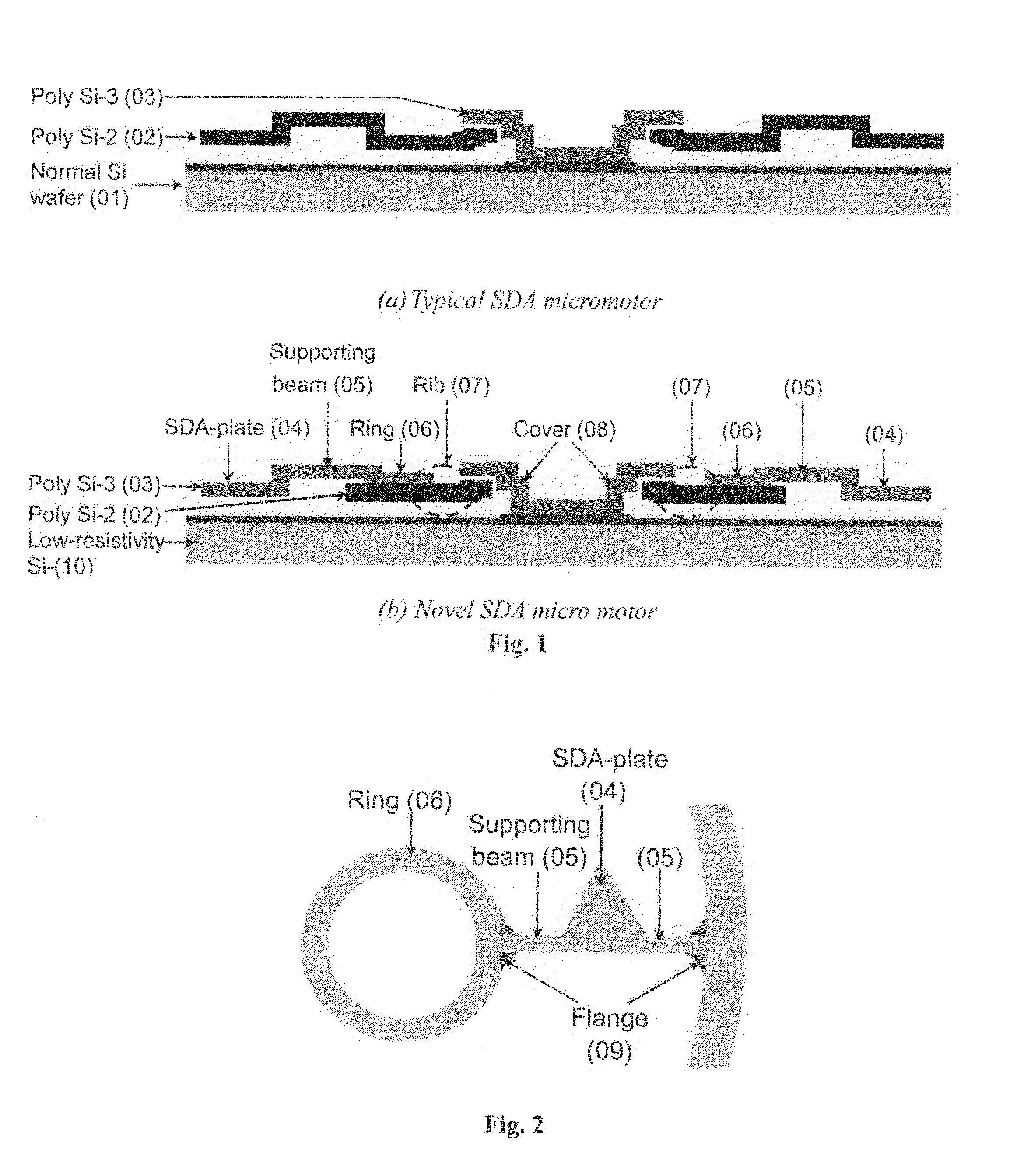

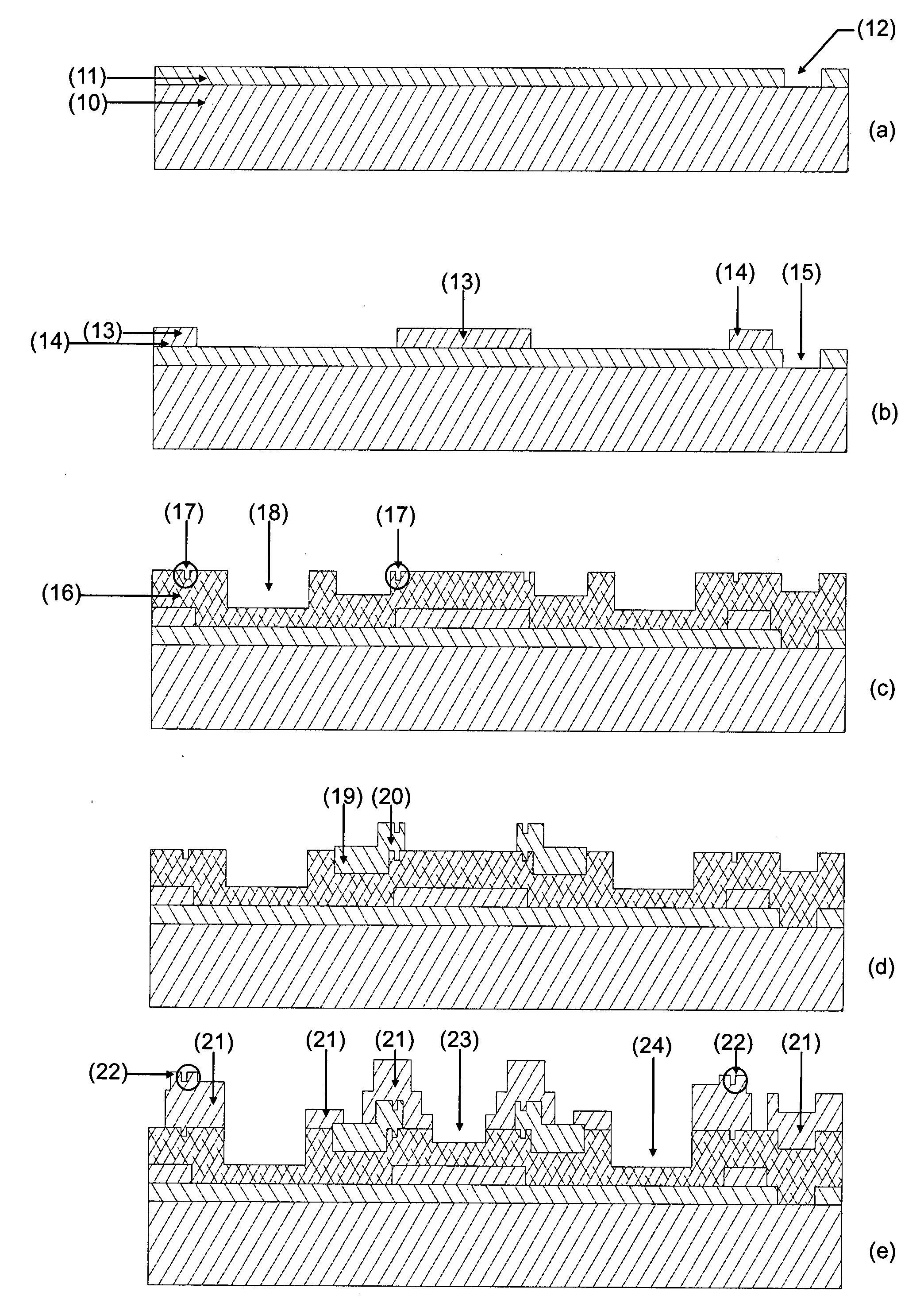

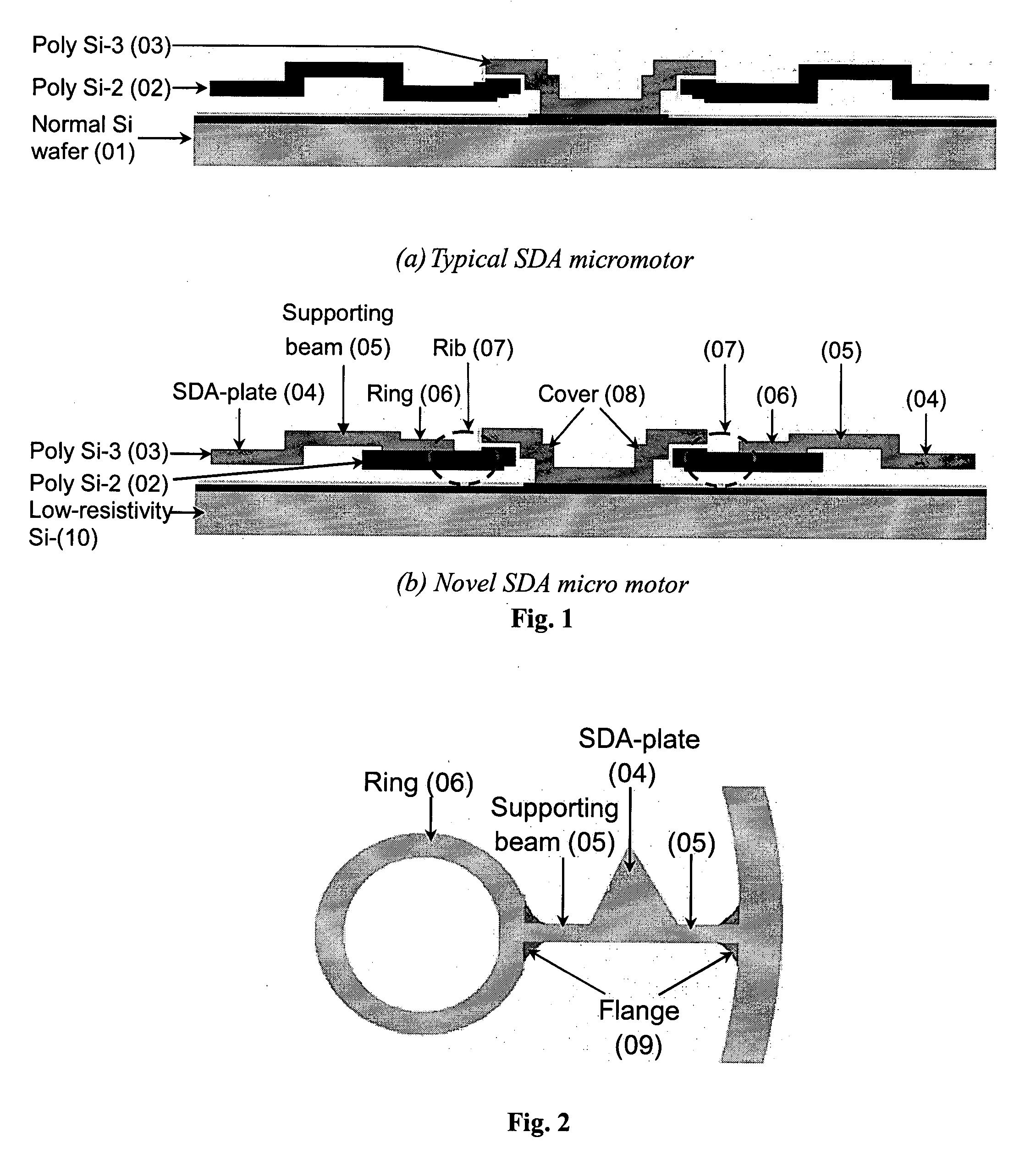

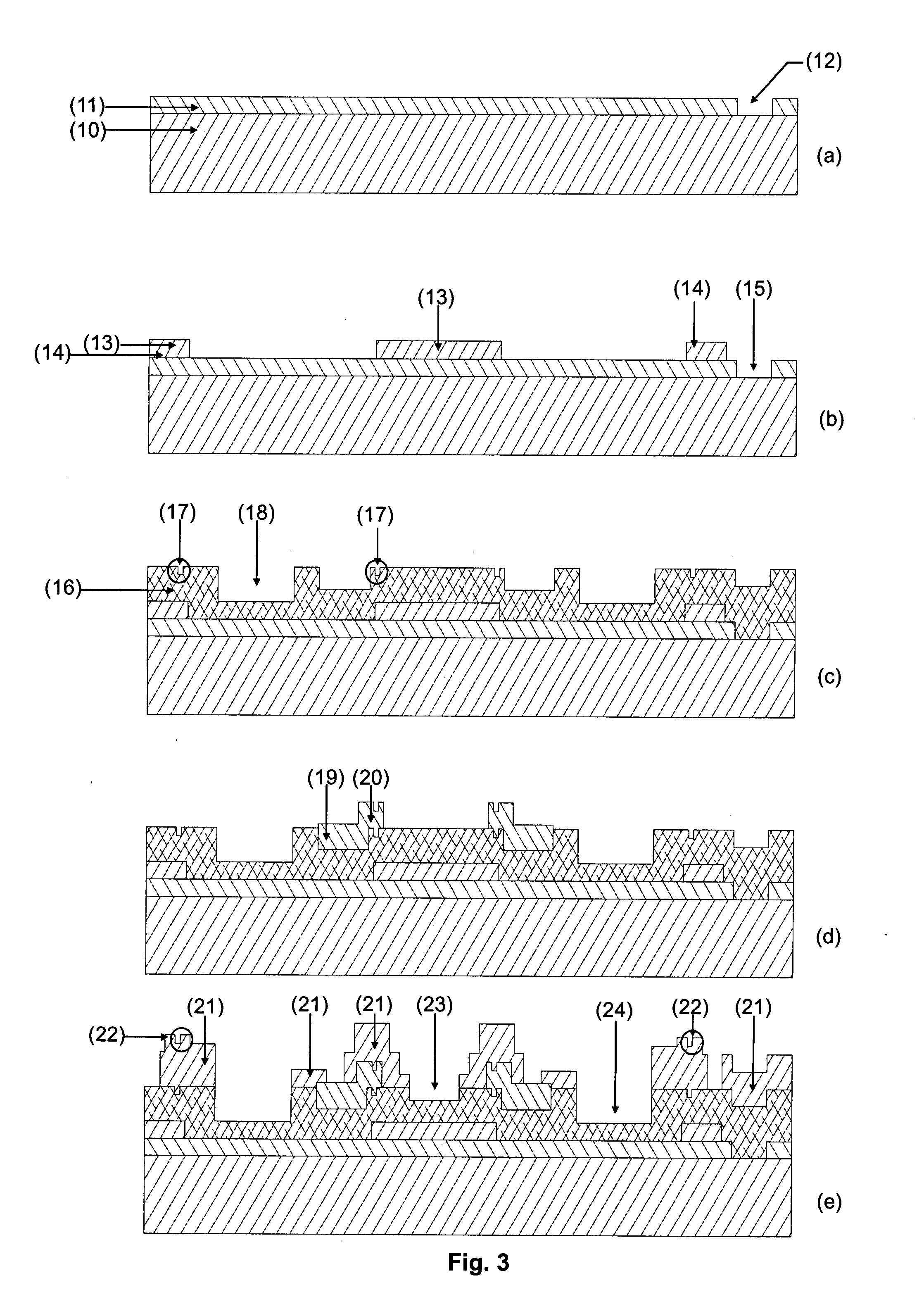

Bounce drive actuator and micromotor

InactiveUS20080280231A1Increased flexural rigidityReduce exposureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusActuatorScratch drive actuator

Provided is the design and fabrication of the novel bounce drive actuator (BDA) for the development of a new-type micro rotary motor. Although the scratch drive actuator (SDA) micro motor has been developed more than one decade, such device has limited commercial applications due to its shorter lifetime, high power consumption and sudden reverse rotation. In contrast, present invention proposes an innovative BDA micro rotary motor with different actuating mechanism and improved performance. Several significant investigations shown in this research present that the length of the SDA-plate is longer than 75 μm and the plate length of the BDA is less than 75 μm. Under the same driving power and frequency with SDA-based micro motor, the BDA-based micro rotary motor exhibited a consistent “reverse” rotation and a higher speed. BDA has higher flexural rigidity due to its shorter length of plate; thus, the contact area of the bending BDA-plate and the insulator substrate will substantially be reduced even under the same applied voltage as the priming value of SDA-plate. Furthermore, a novel rib and flange structure design for the improvement of lifetime (>100 hrs) and rotational speed (>30 rpm) of BDA micro motor was also demonstrated in this invention.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

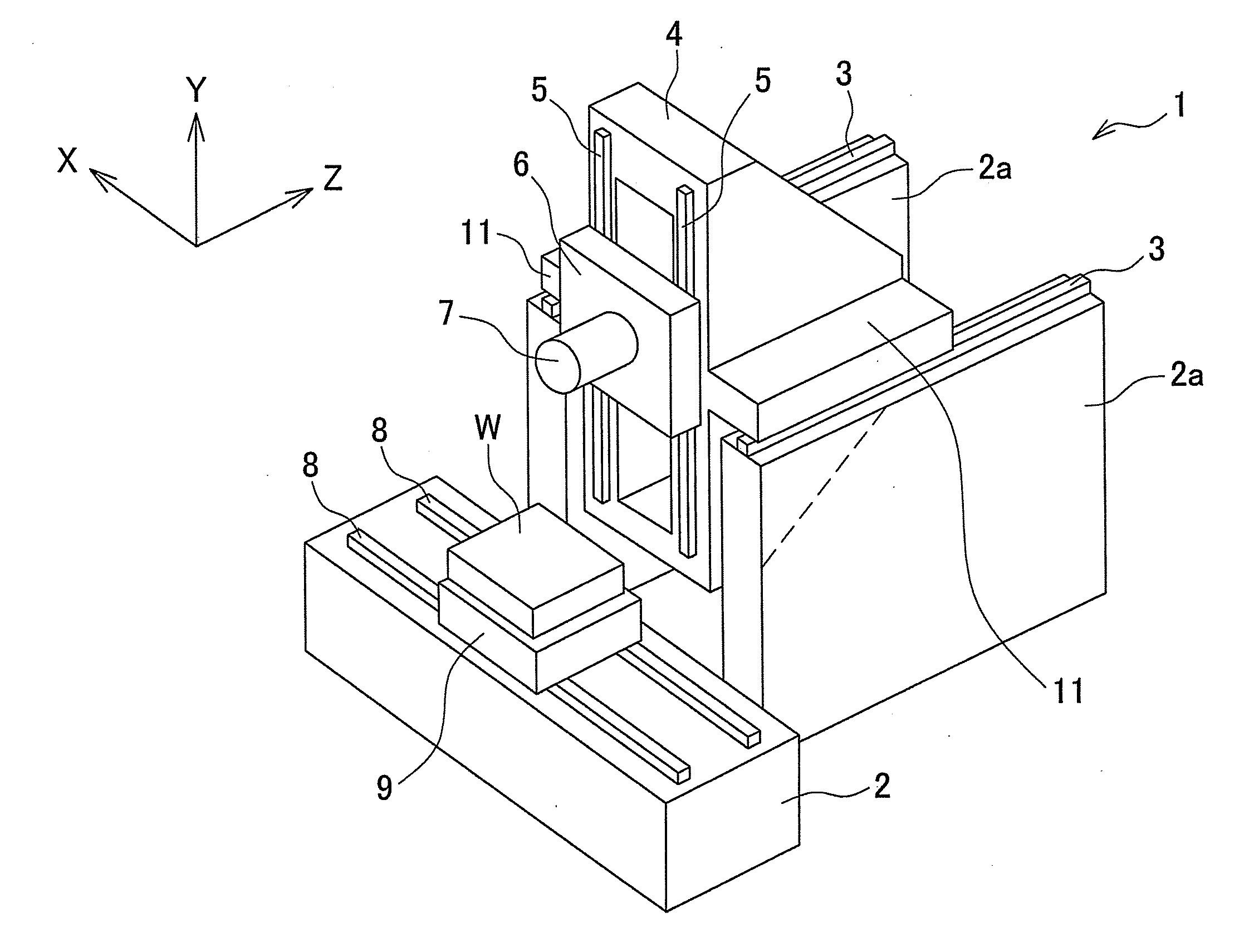

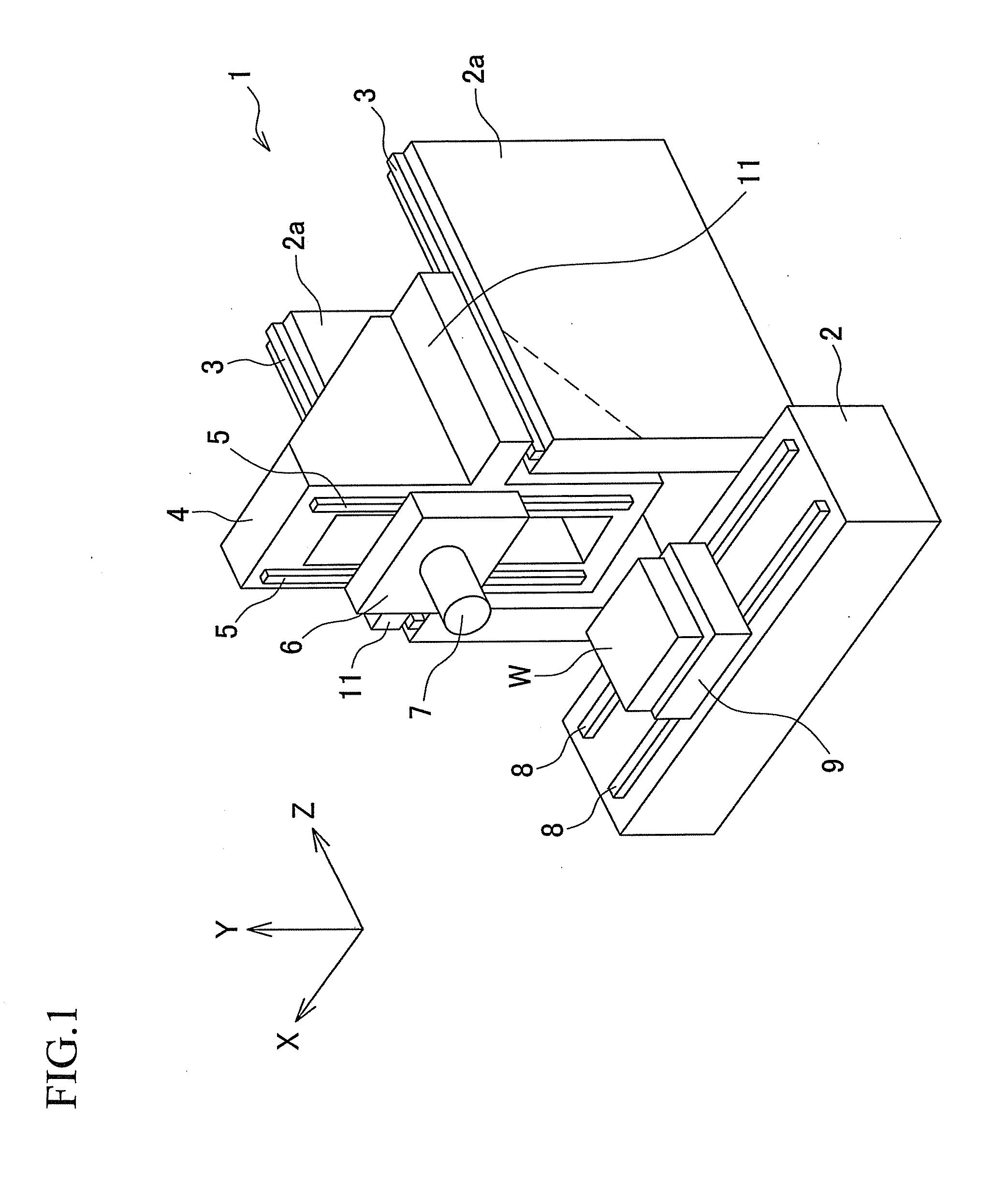

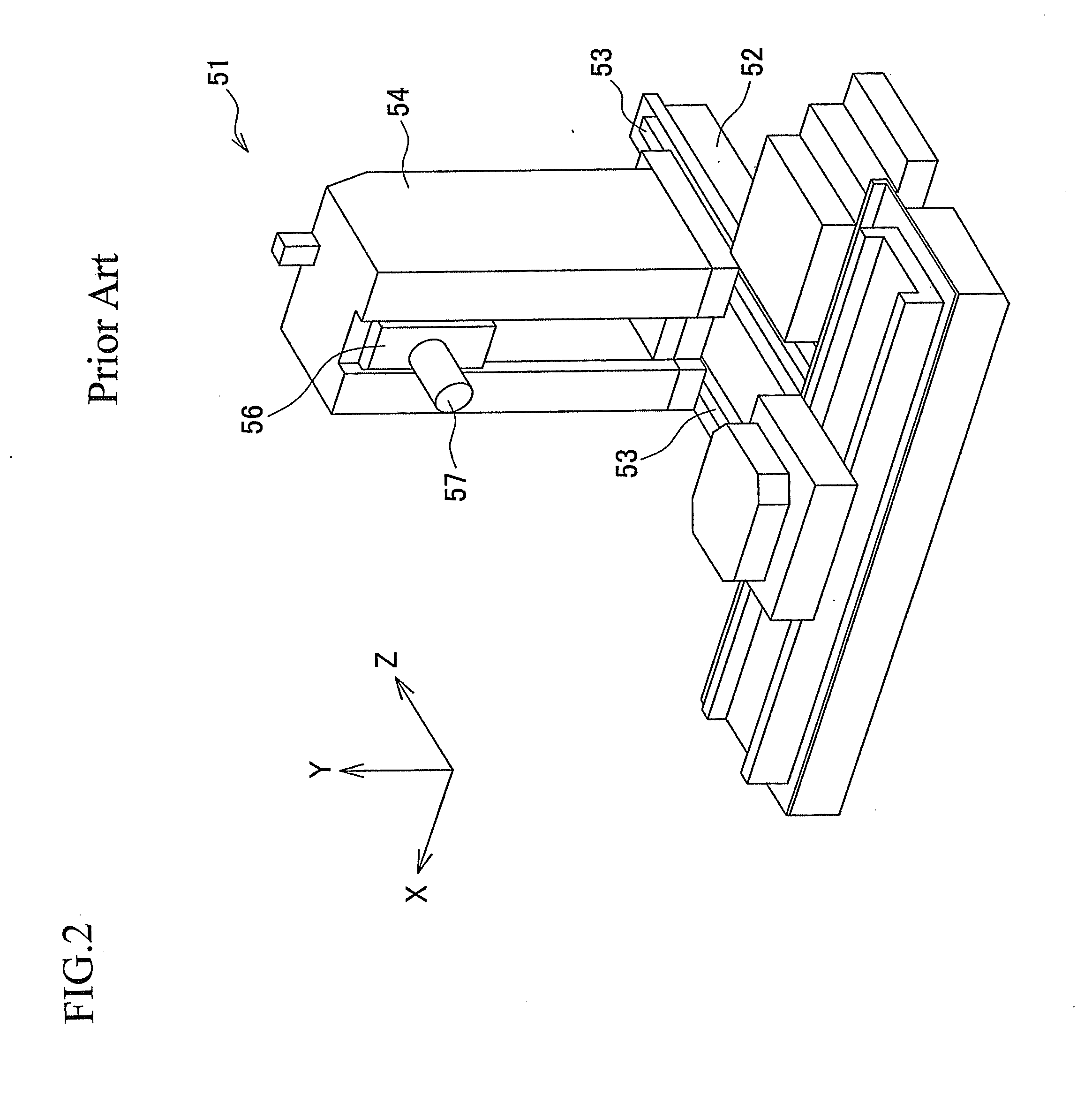

Machine tool

In a machine tool, a support member to which a headstock is mounted movably in an upward-downward direction is movable so as to change a position thereof in a horizontal direction relative to that of a bed. A guide member is provided on the bed and configured to guide the support member. An engageable portion at which the support member is supported by the guide member is located in the support member at a level within a range of upward-downward movement of the headstock along the support member.

Owner:OKUMA CORP

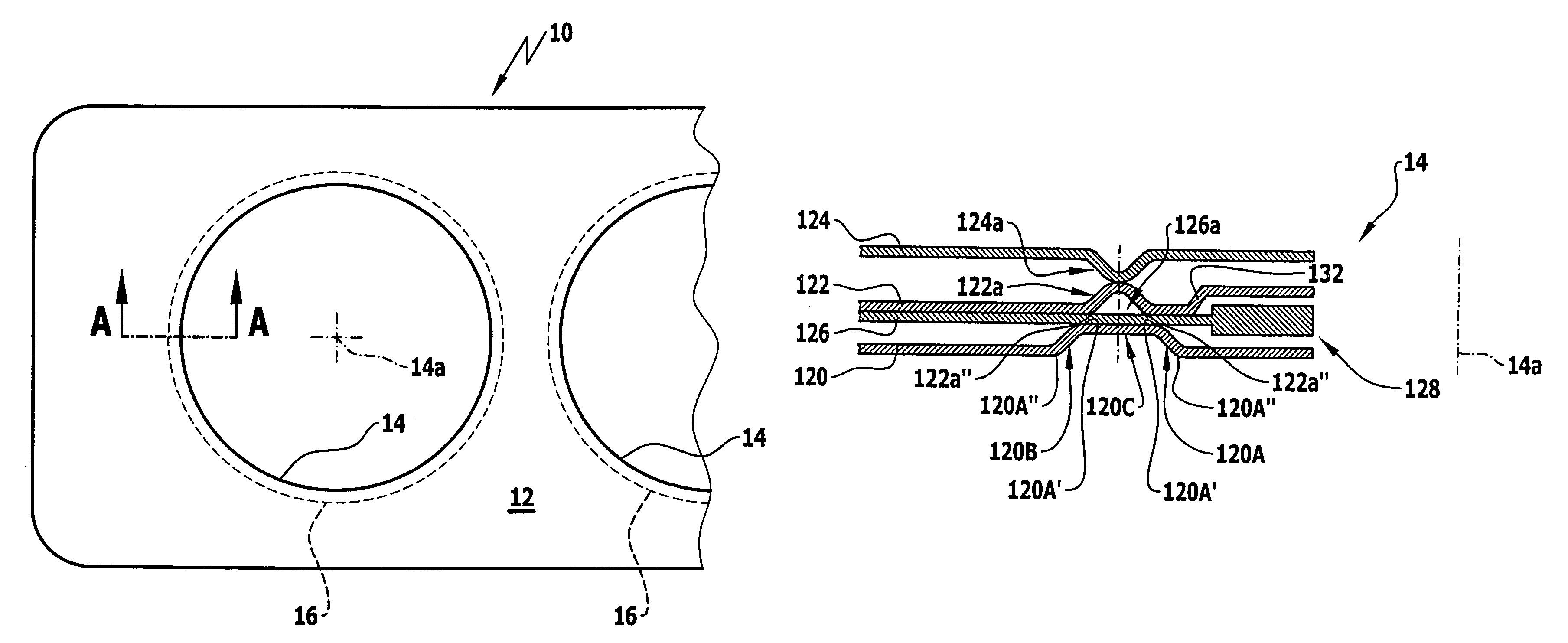

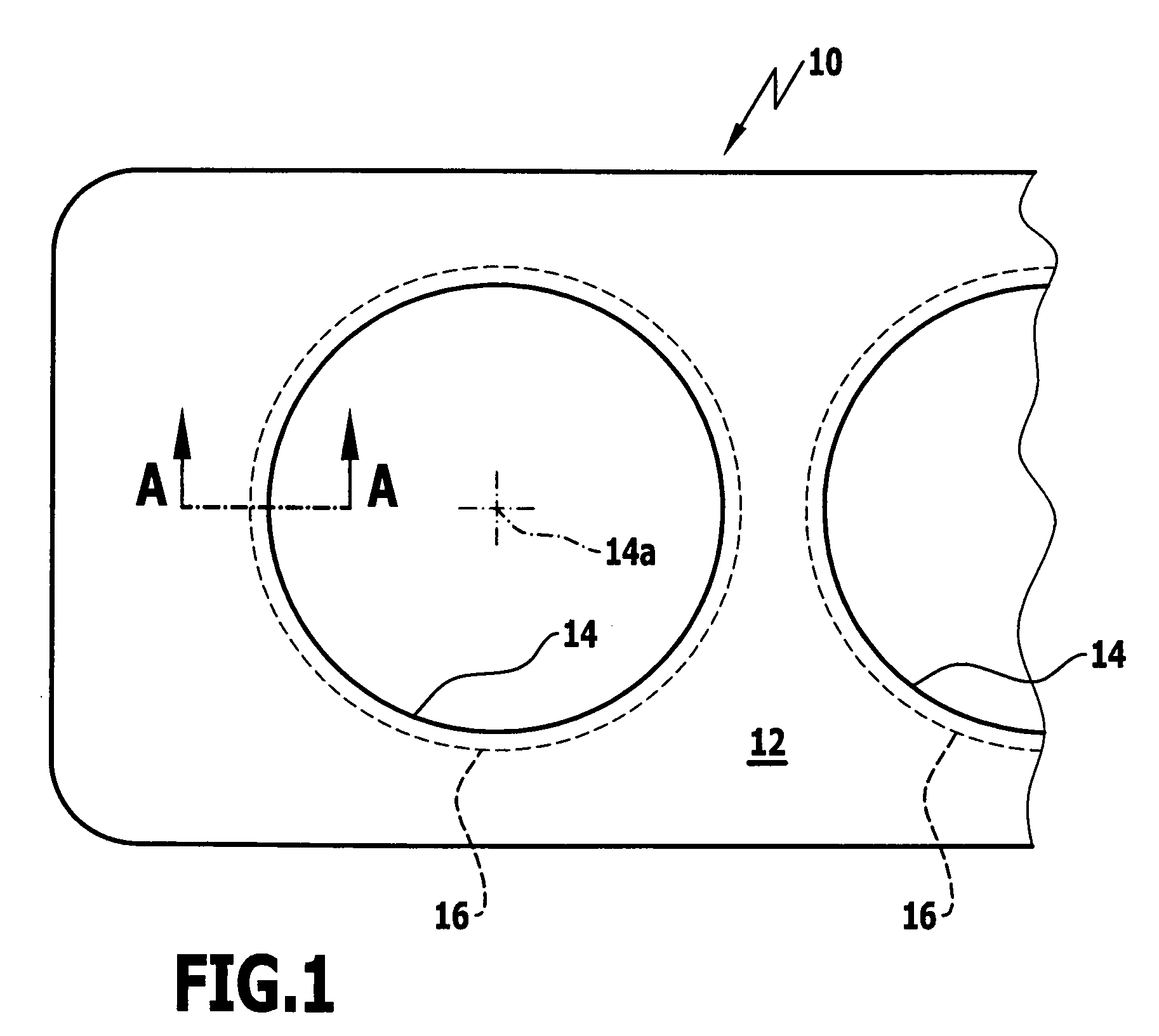

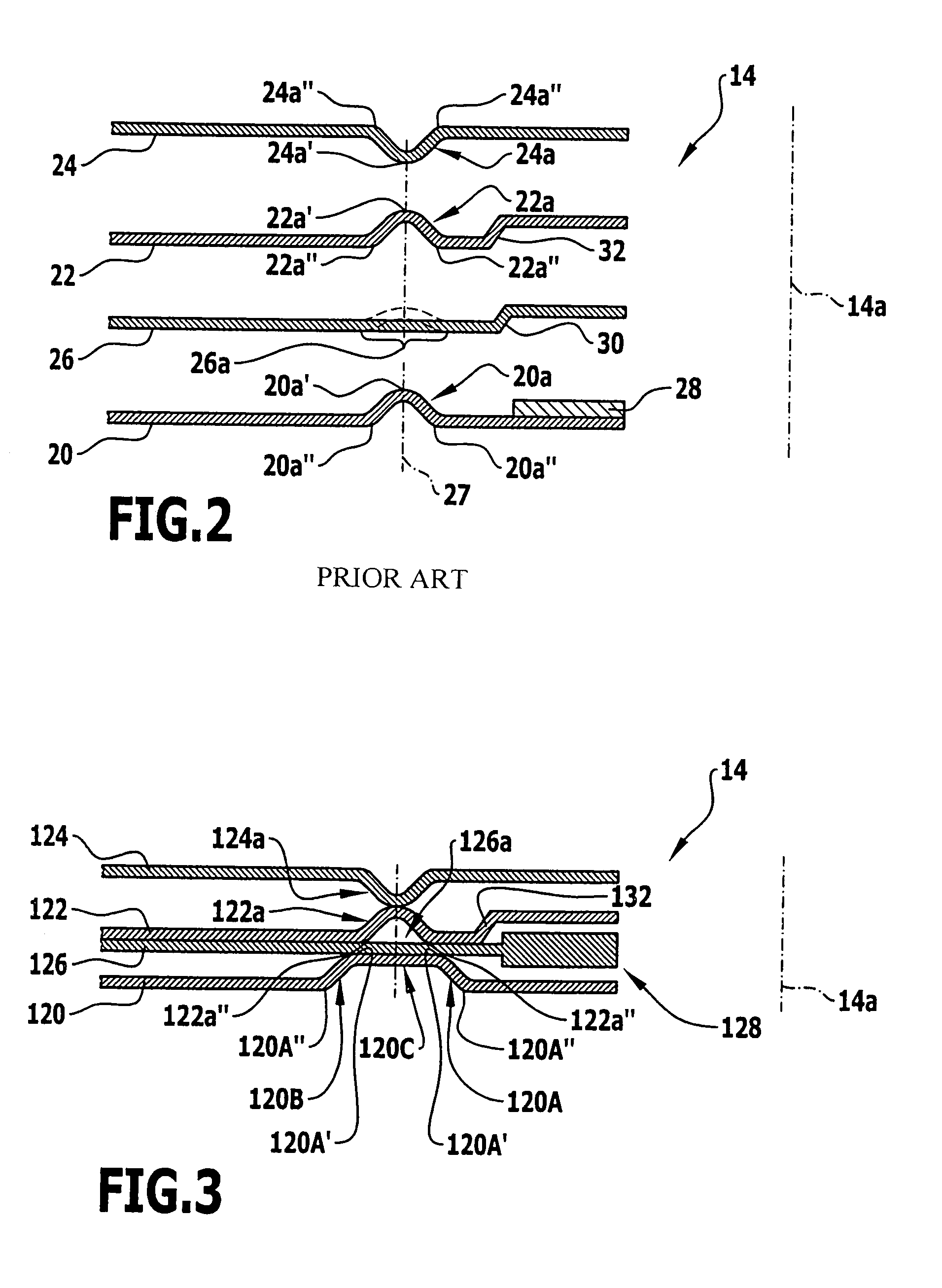

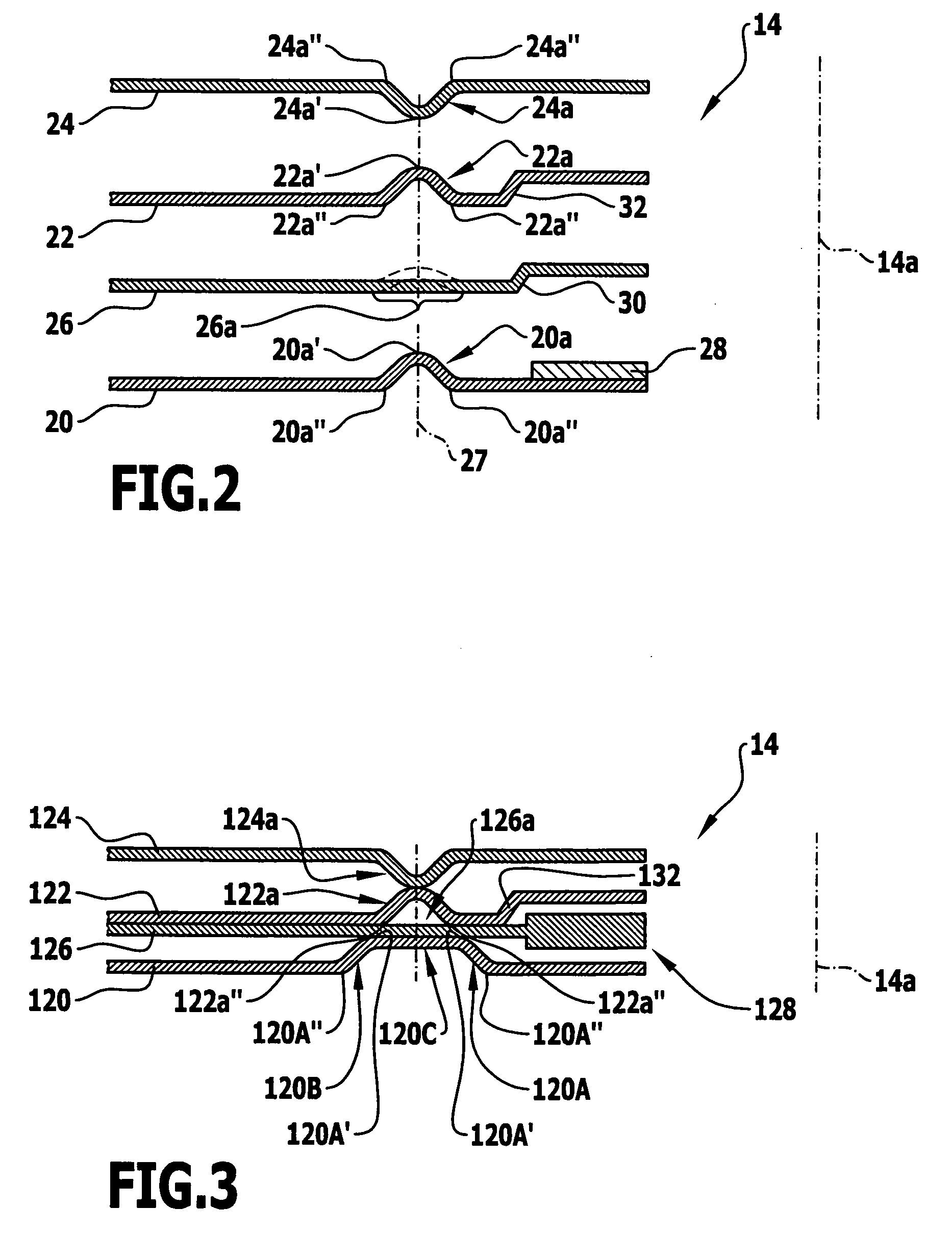

Cylinder head gasket

InactiveUS8267407B2Increased flexural rigidityRisk of in minimizedEngine sealsSealing arrangements for enginesEngineeringHead gasket

Cylinder head gasket with a gasket plate comprising a plurality of sheet metal layers and at least one combustion chamber opening, an inner layer being arranged in the gasket plate directly between two functional layers having sealing beads arranged one over the other, which enclose the combustion chamber opening and have bead feet lying in the planes of the functional layers and bead crests with which sealing beads of the two functional layers all project over the functional layers in a first direction extending perpendicularly to the gasket plane, at least one ring zone of the inner layer being clamped between the bead feet of the one functional layer and at least one bead crest of the other functional layer when the gasket is pressed; to minimize arching of this ring zone, it is stiffened and / or those ring zone regions against which at least one bead crest of one functional layer lies when the gasket is pressed are supported by bead feet of the other functional layer.

Owner:ELRINGKLINGER AG

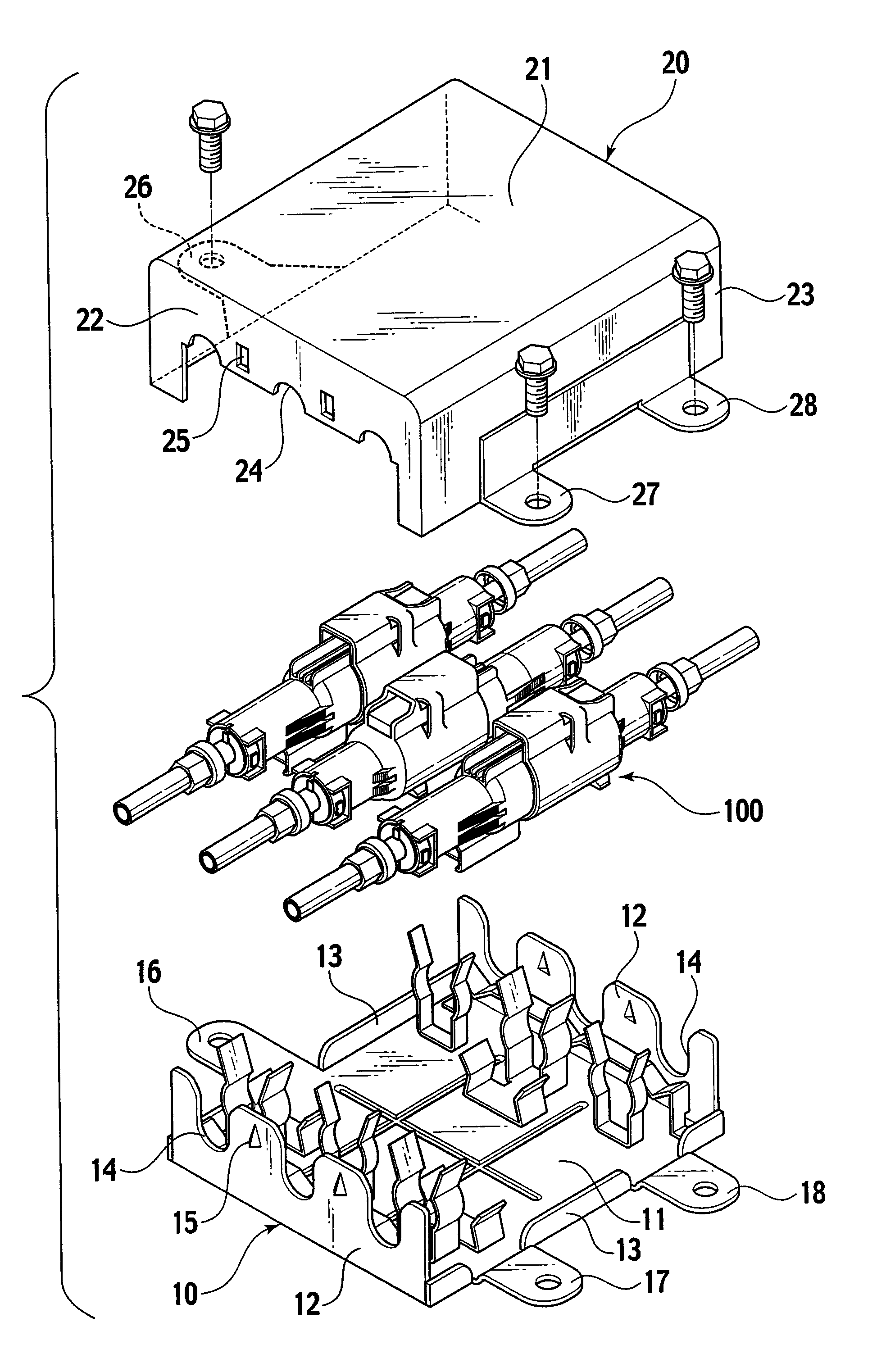

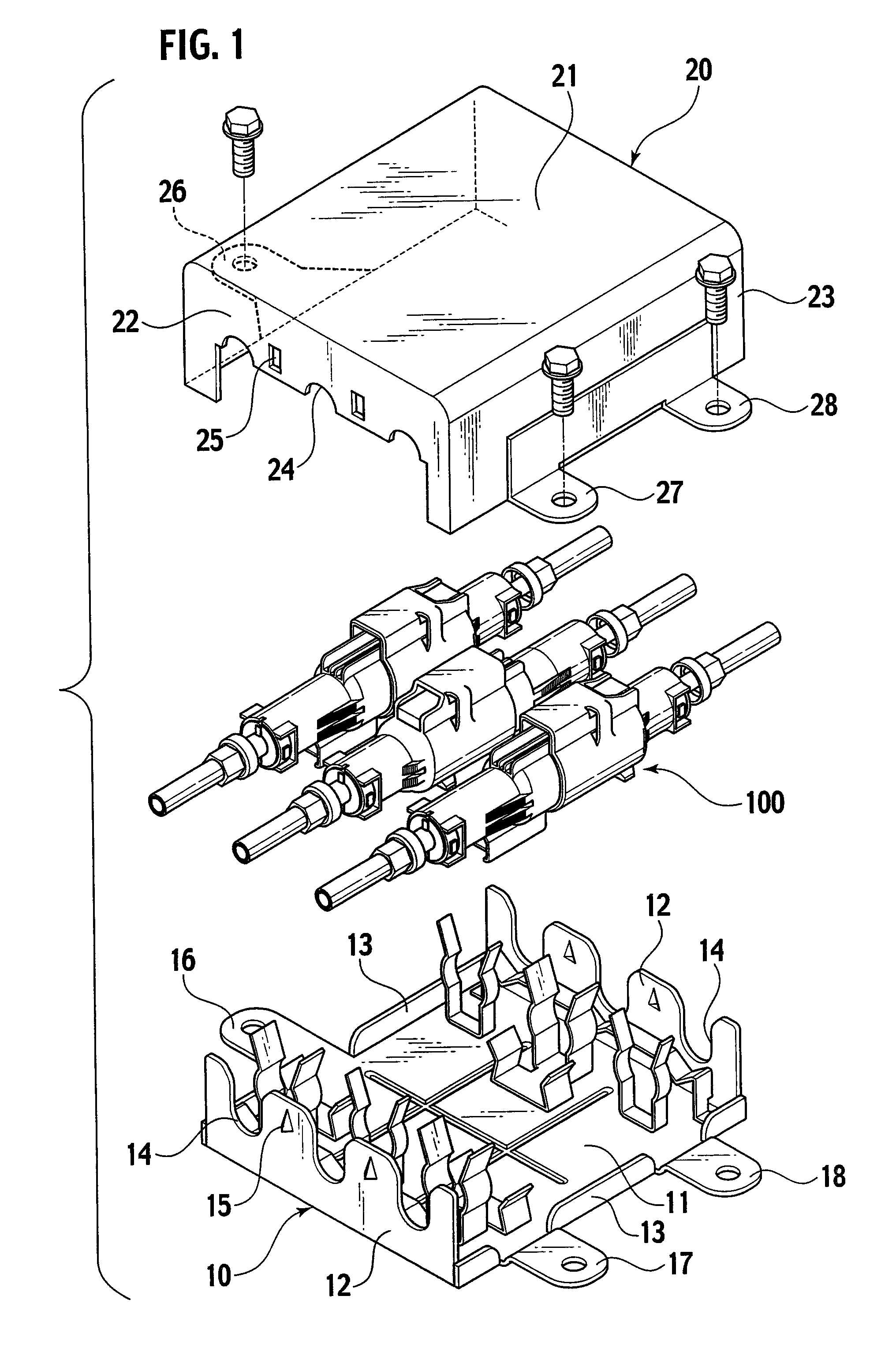

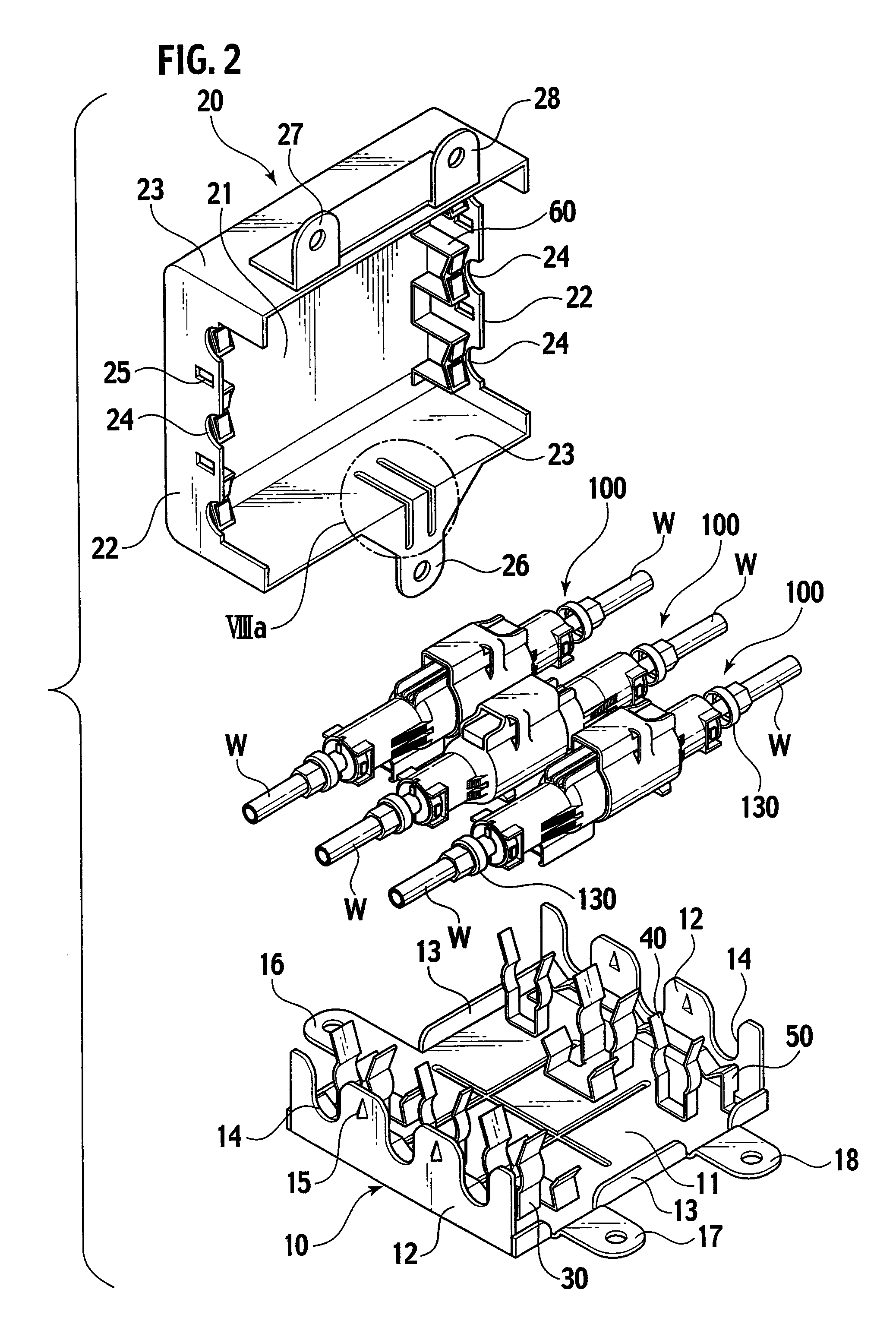

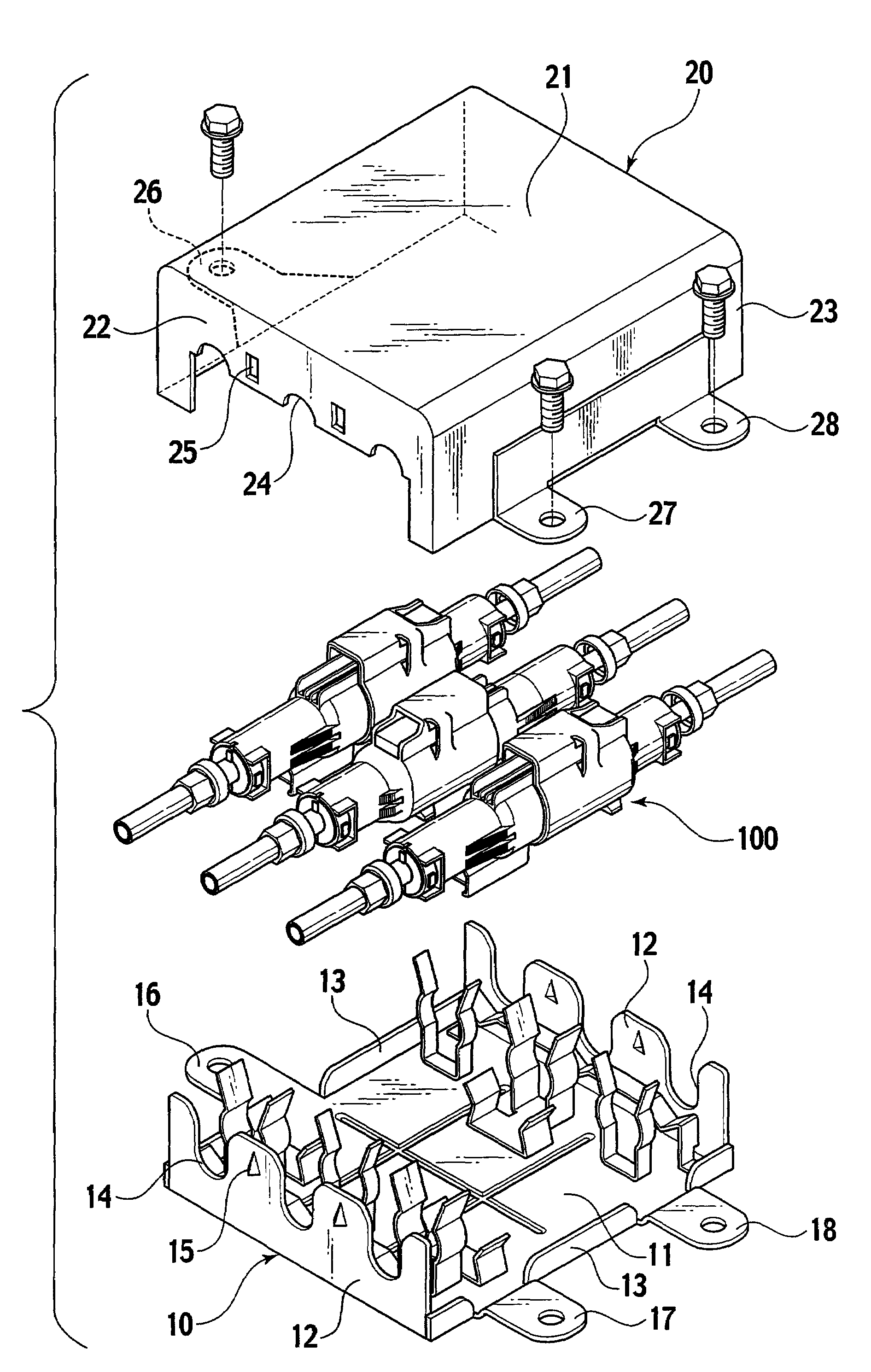

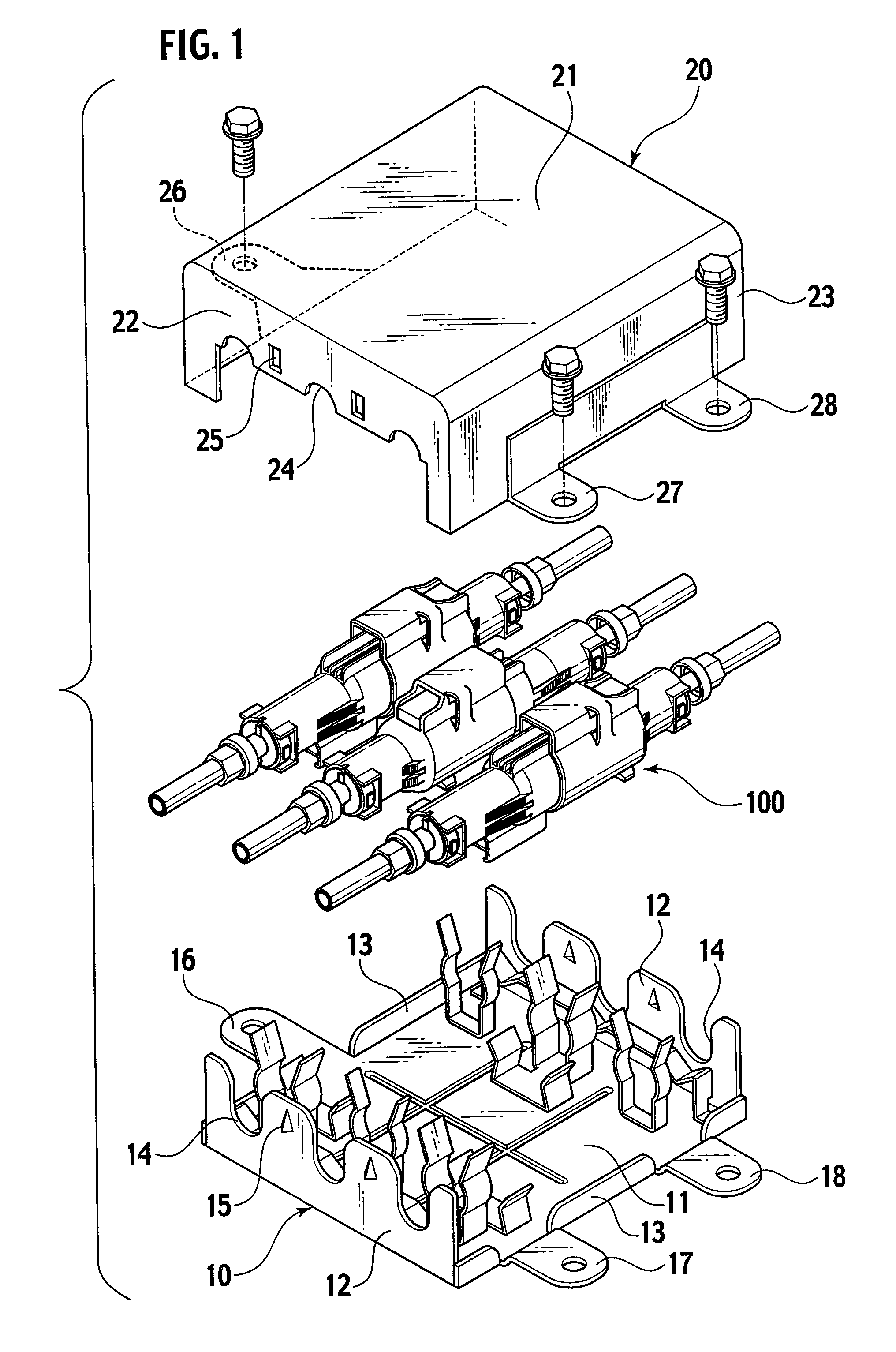

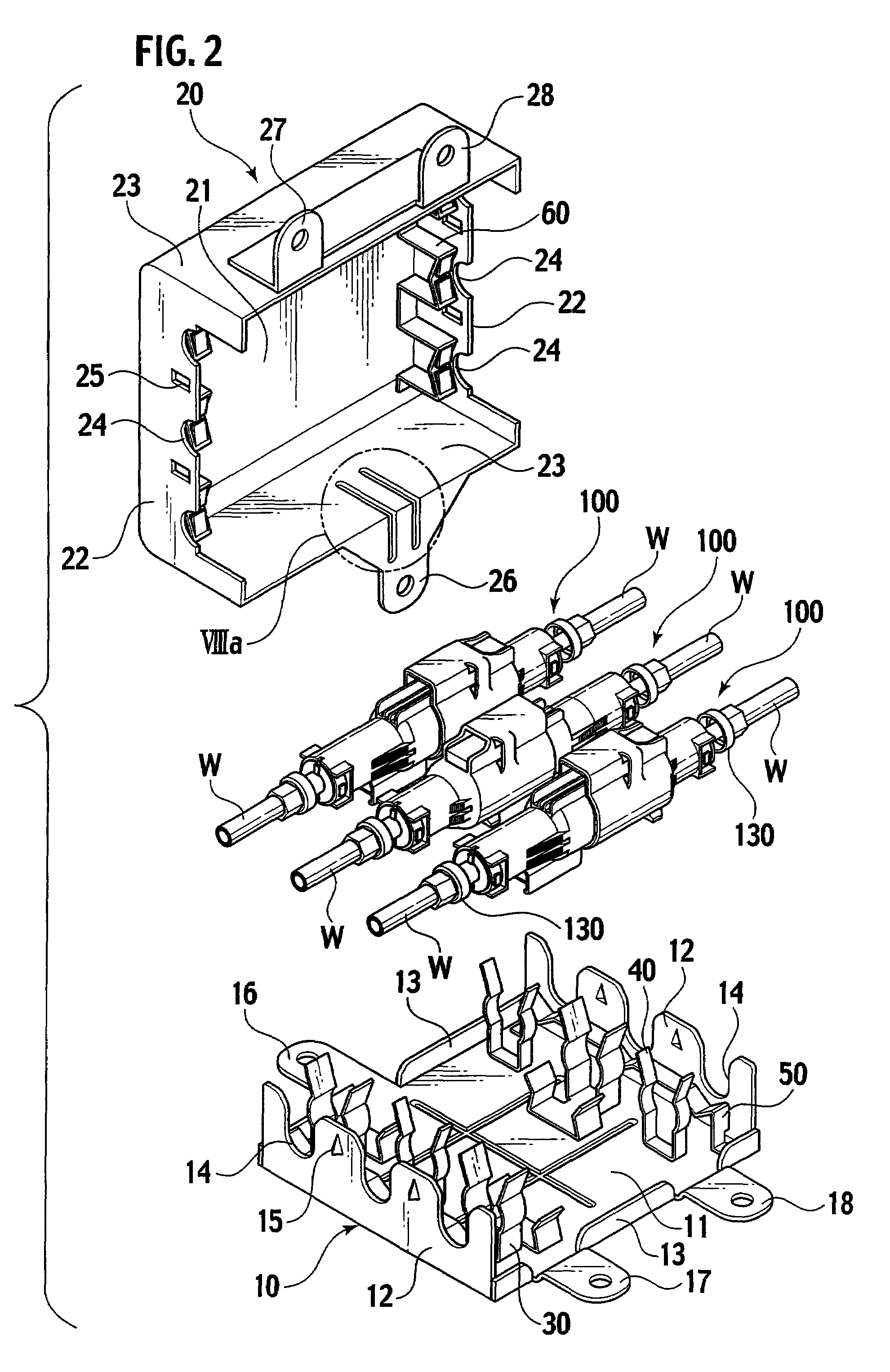

Shield Box

InactiveUS20090025974A1Improve reliabilityPrevent jumpingElectrically conductive connectionsMagnetic/electric field screeningElectrical conductorElectromagnetic shielding

A shield box is composed of metal-made upper box and lower box, which are combined with each other. The shield box houses therein a plurality of shield connectors interconnecting shield wires, and thereby electromagnetically shields entirety of the shield connectors and the shield wires. On an upper surface of a lower surface plate of the lower box, clamp fittings capable of restraining the respective shield connectors in axial, axial rotation, left-and-right and up-and-down directions thereof are provided. On opposite surfaces of the upper and lower boxes, press fittings are provided to sandwich shield terminal portions from upper and lower sides and conduct the shield terminal portions to the upper and lower boxes when the upper and lower boxes are matched with each other. The shield terminal portions, which are electrically connected to shield conductors of respective shield wires and are exposed to both ends of the respective shield connectors, are grounded.

Owner:YAZAKI CORP

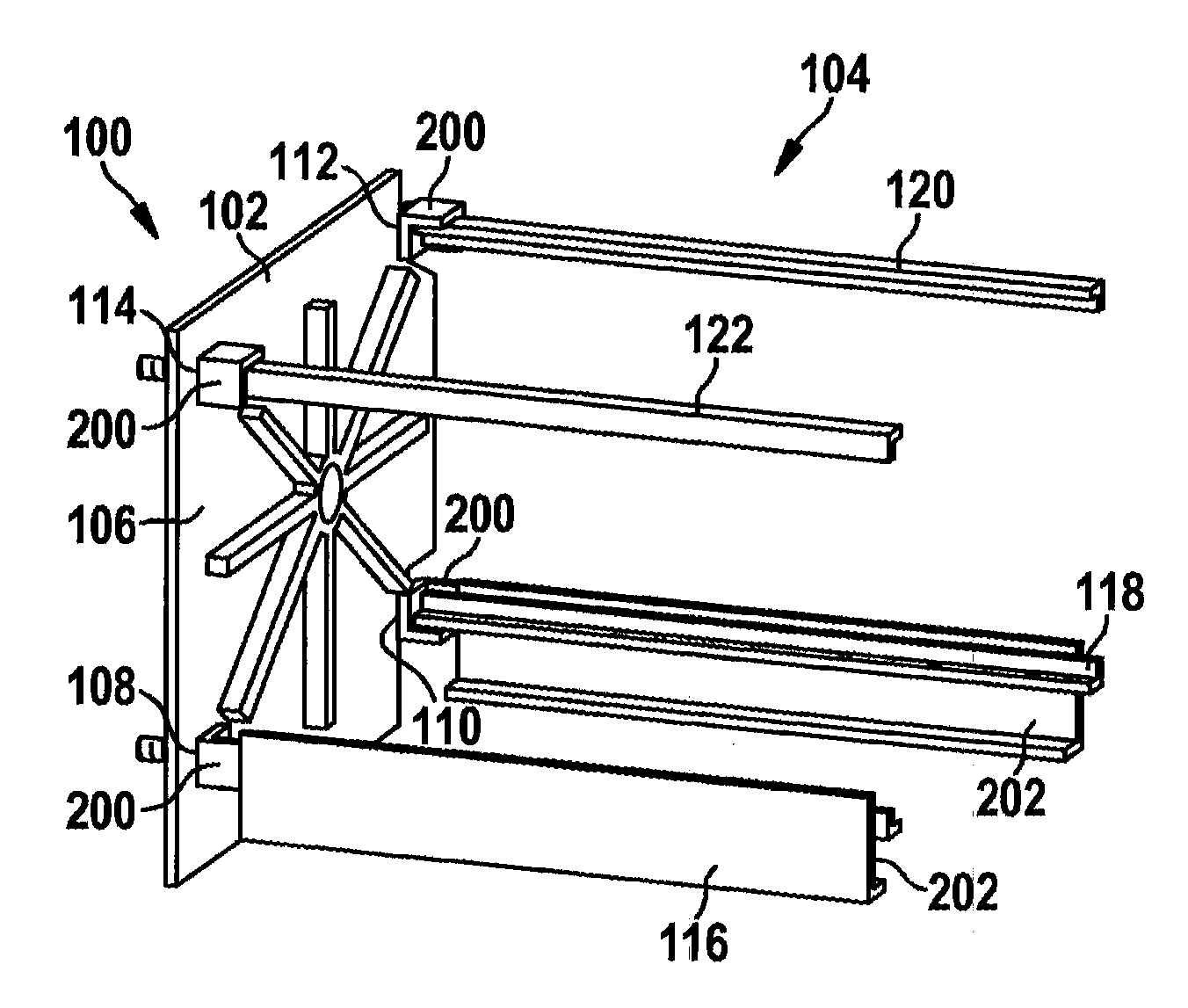

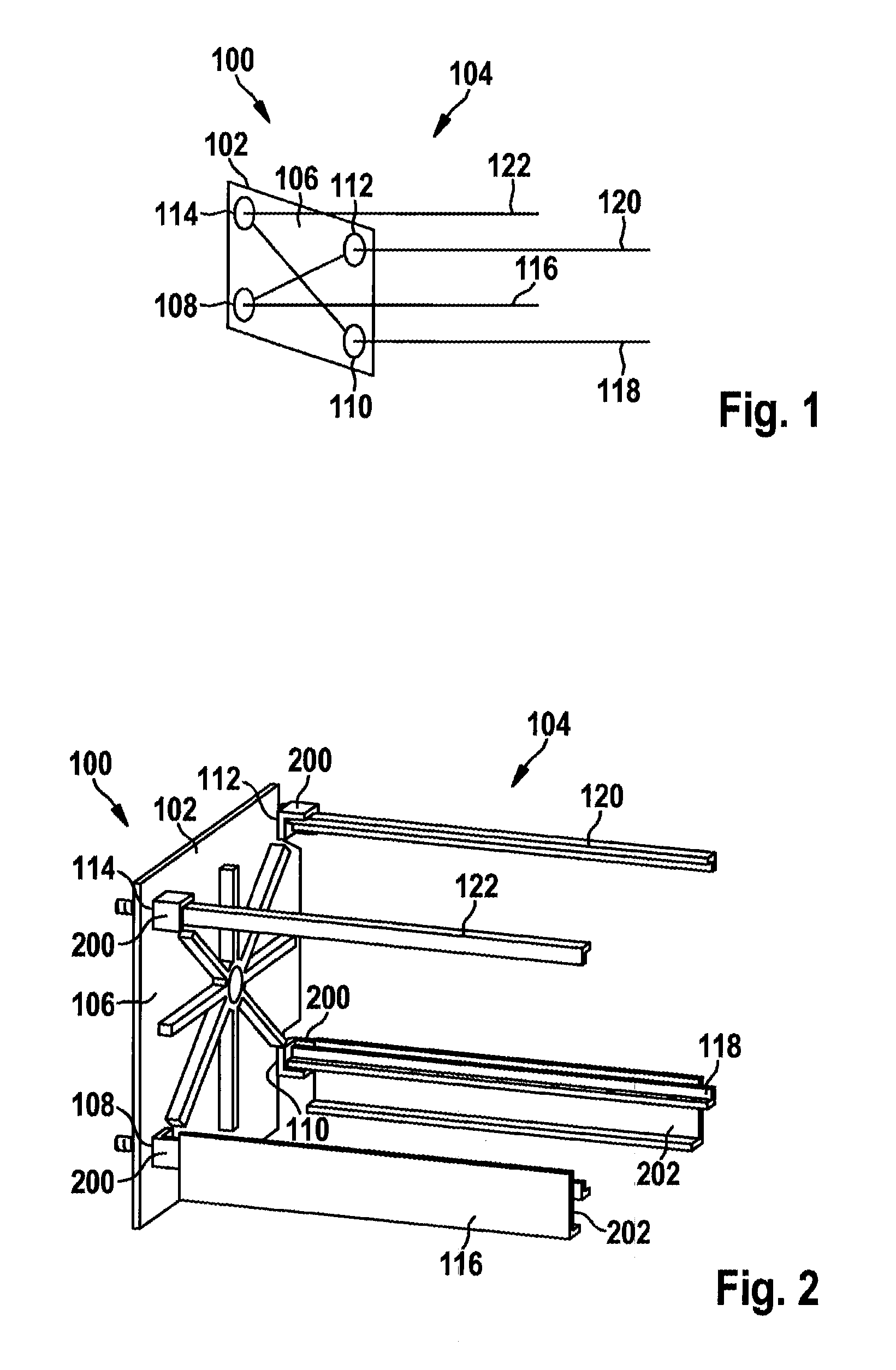

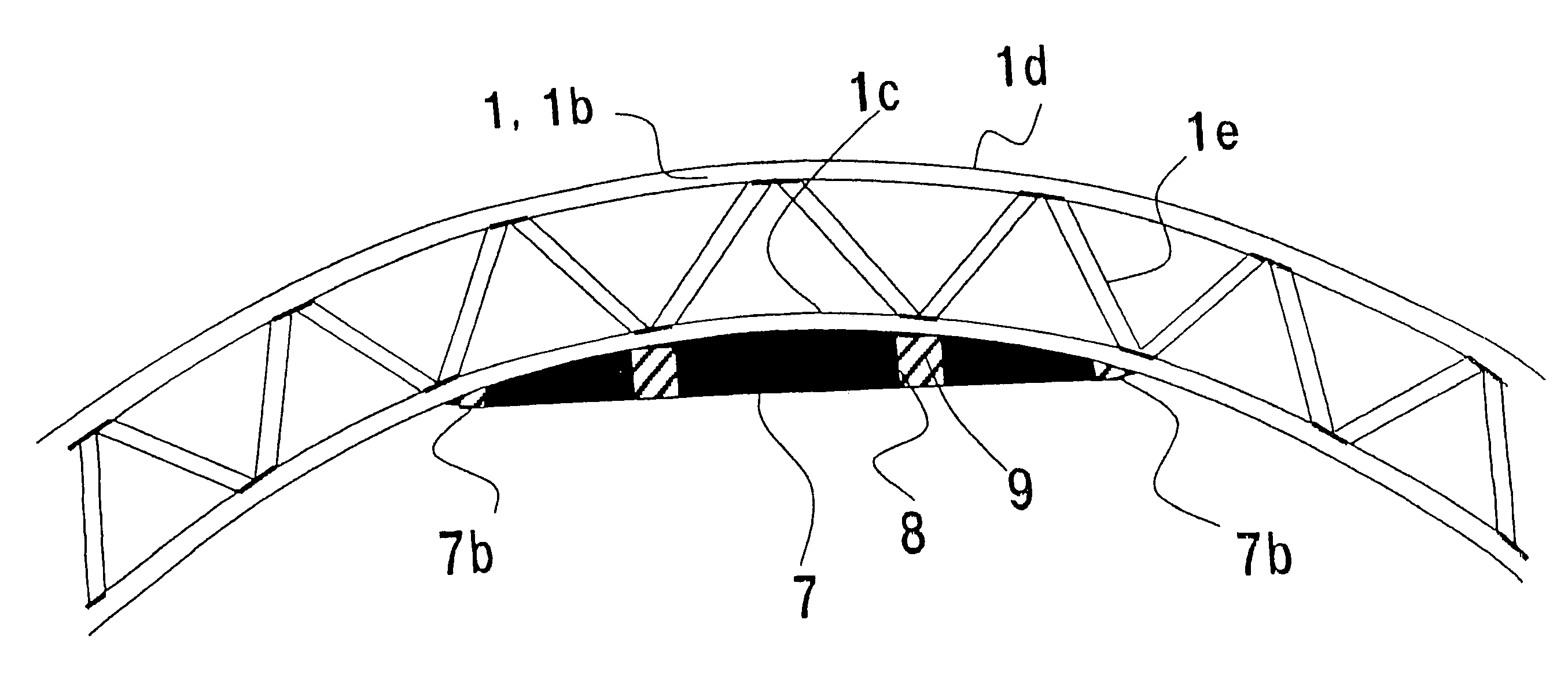

Supporting pillar for an aircraft's structural component manufactured by a selective laser melting process

InactiveUS20110253878A1Possible to produceIncreased flexural rigidityFuselage framesMetal-working apparatusSelective laser meltingHigh intensity

The invention relates to an elongated supporting pillar for a high-strength structural component, wherein the supporting pillar is designed to absorb bending forces that act transversely to a longitudinal direction of extension of the supporting pillar. The supporting pillar comprises a wall which at least partially encloses an elongated cavity of the supporting pillar. A reinforcement structure is arranged within the cavity and transversely to the direction of longitudinal extension in such a manner that the reinforcement structure can absorb at least some of the bending forces. The reinforcement structure is designed integrally with the wall, wherein both the wall and the reinforcement structure comprise a meltable material.

Owner:AIRBUS OPERATIONS GMBH

Opening and closing apparatus for opening and closing body of vehicle

InactiveUS20070063536A1Increased flexural rigidityIncreasing the thicknessMan-operated mechanismPower-operated mechanismReciprocating motionEngineering

Owner:MITSUI KINZOKU ACT

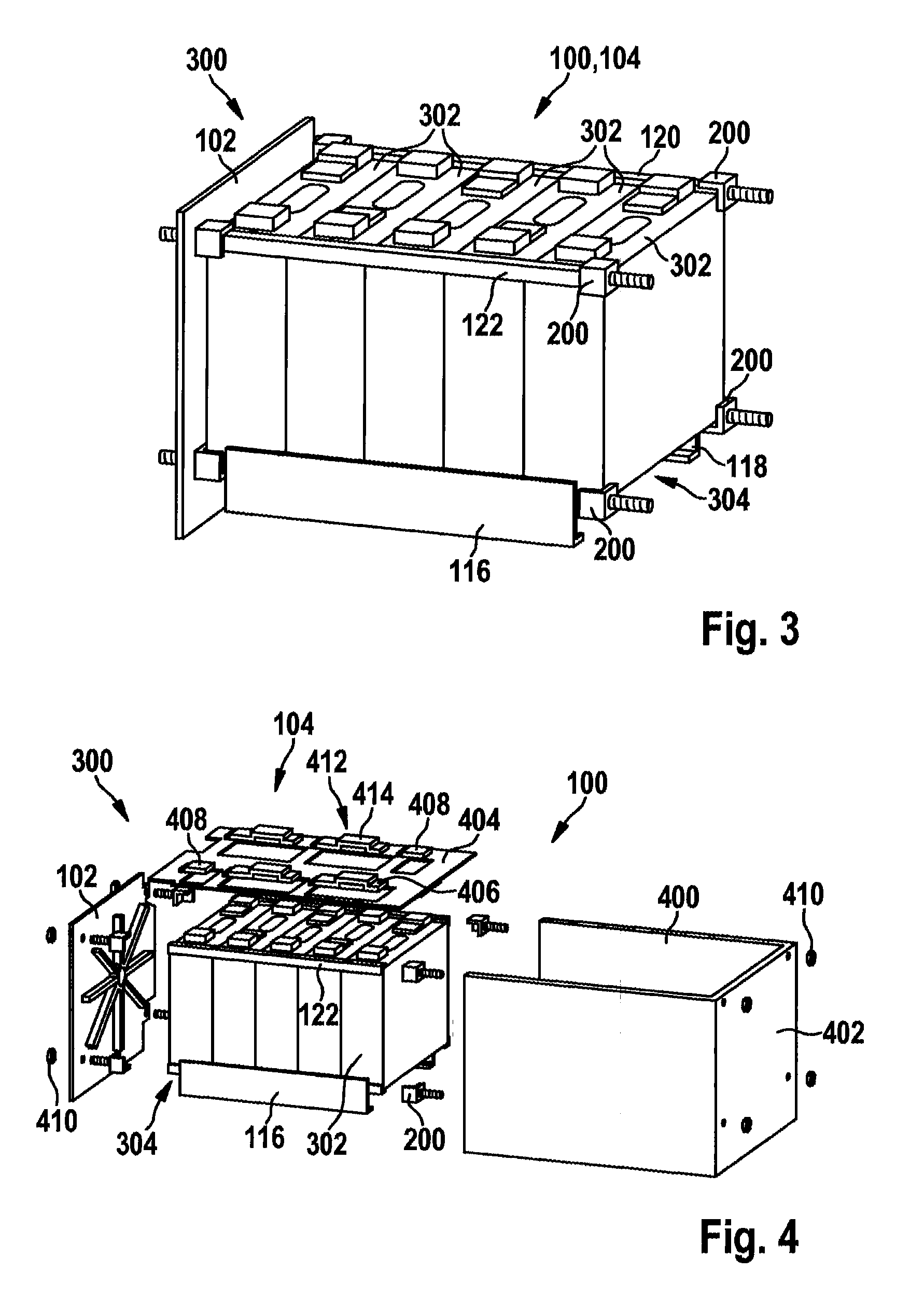

Housing composed of a metal frame structure and a plastic component for accommodating a cell stack

ActiveUS20160043365A1Quality improvementSafe and controlled operationFinal product manufacturePrimary cellsEngineeringMechanical engineering

Owner:ROBERT BOSCH GMBH

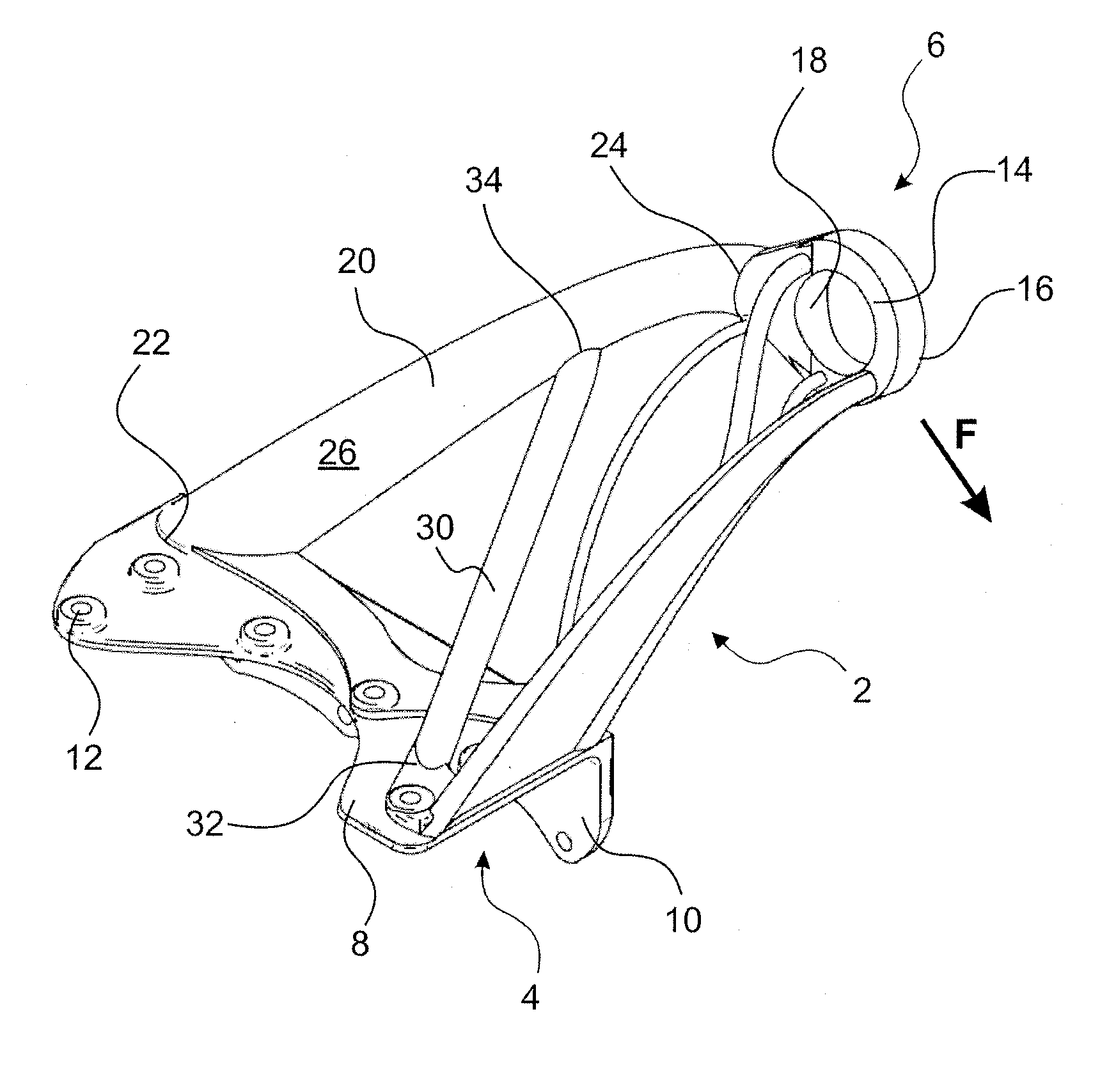

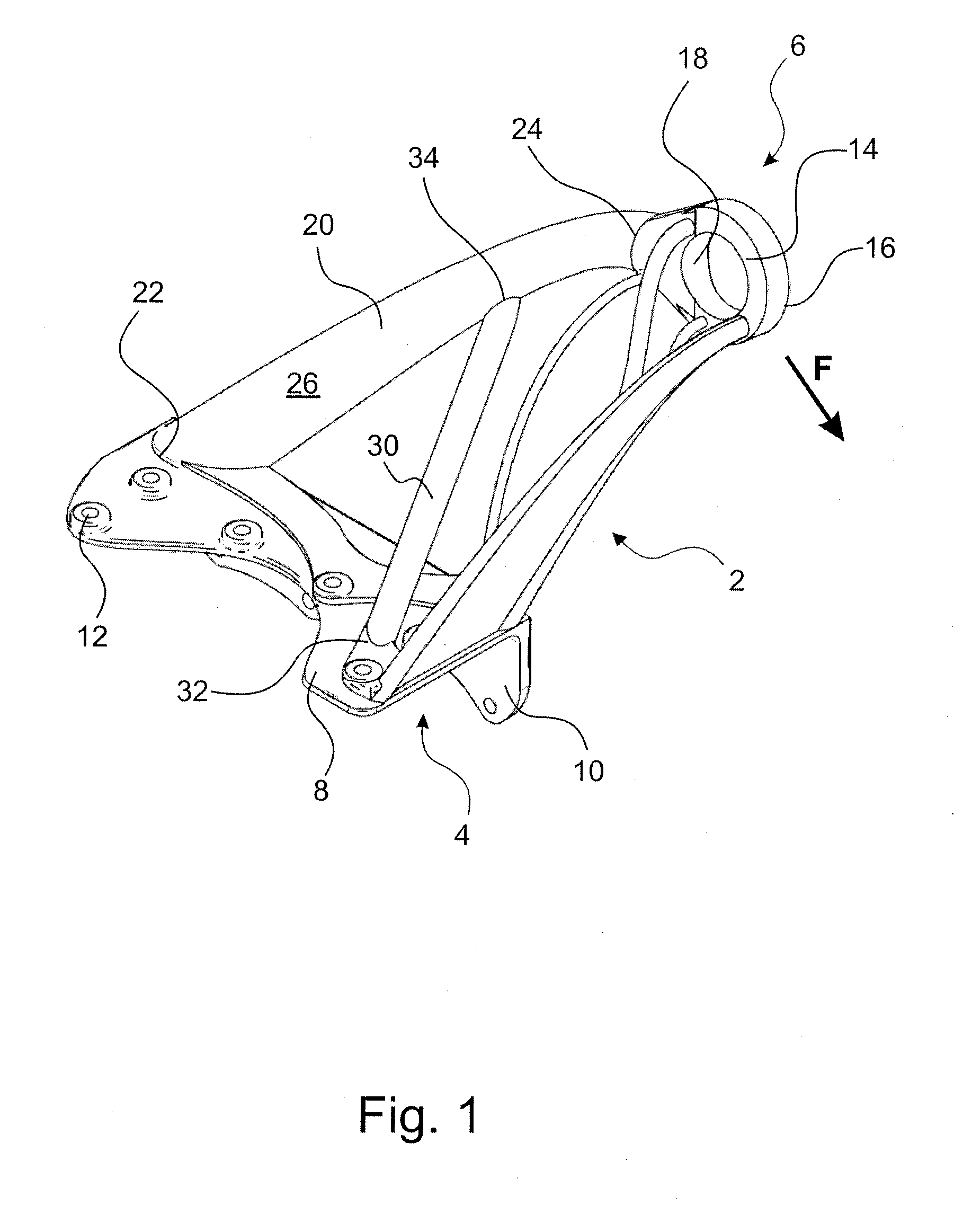

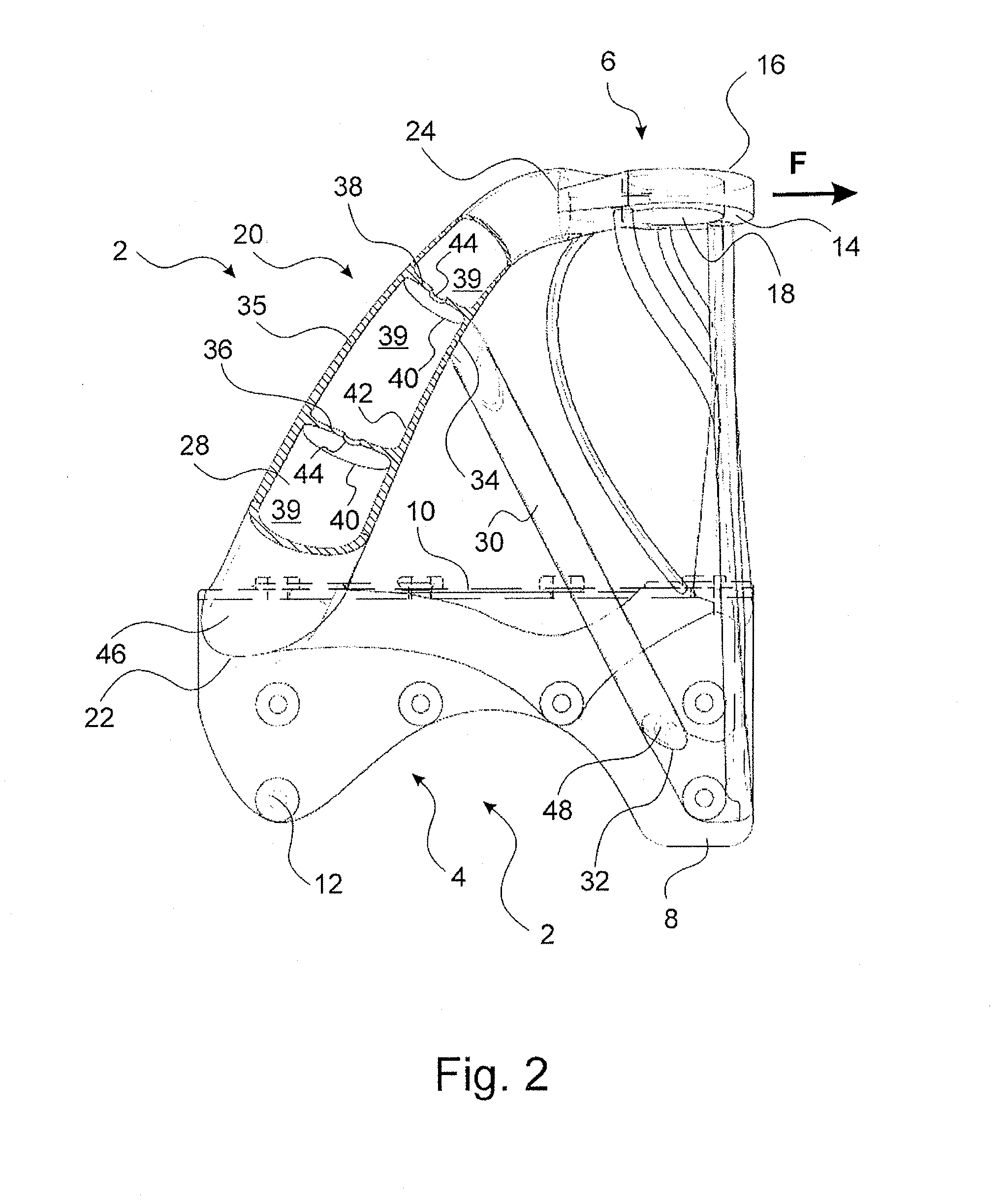

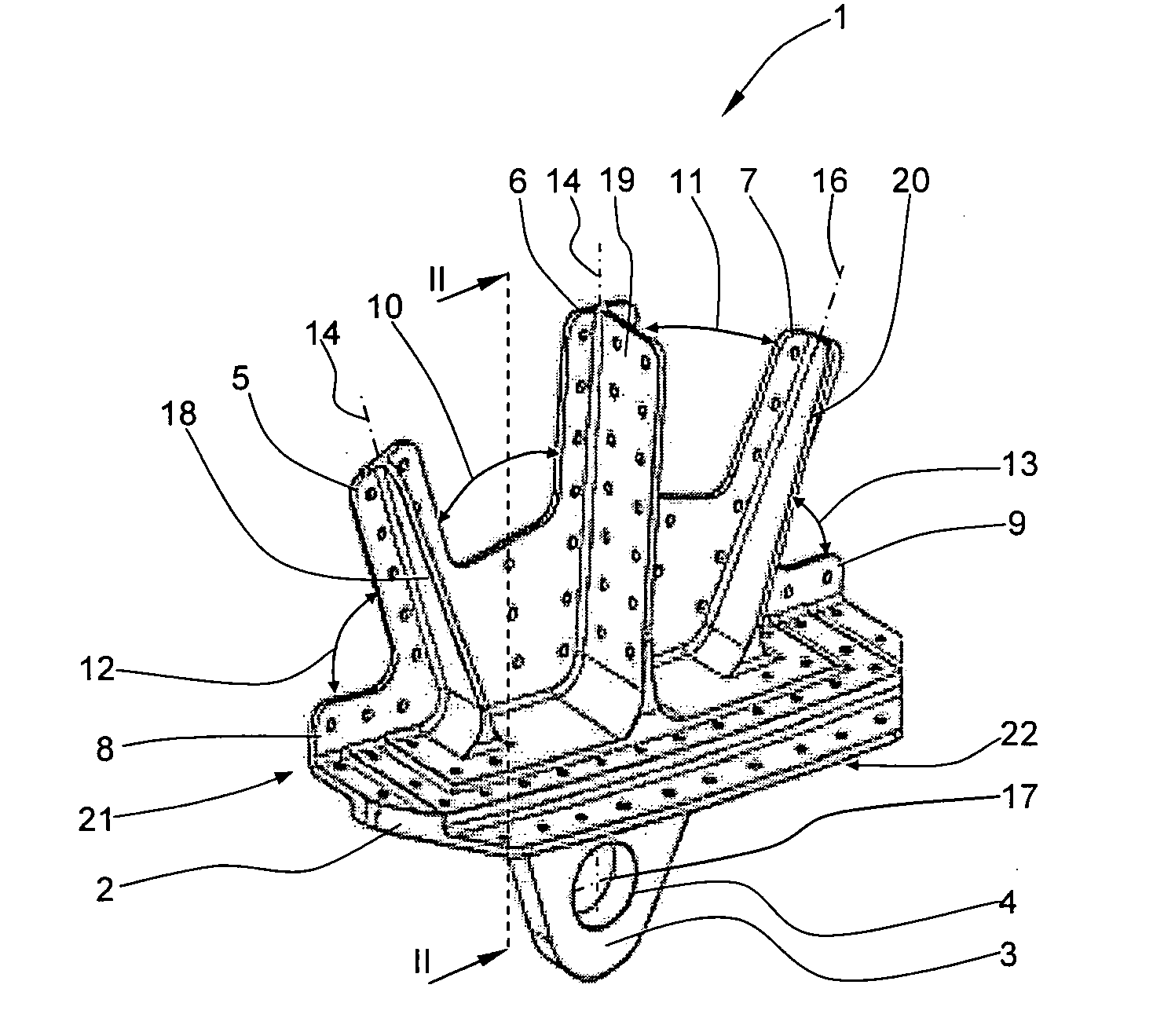

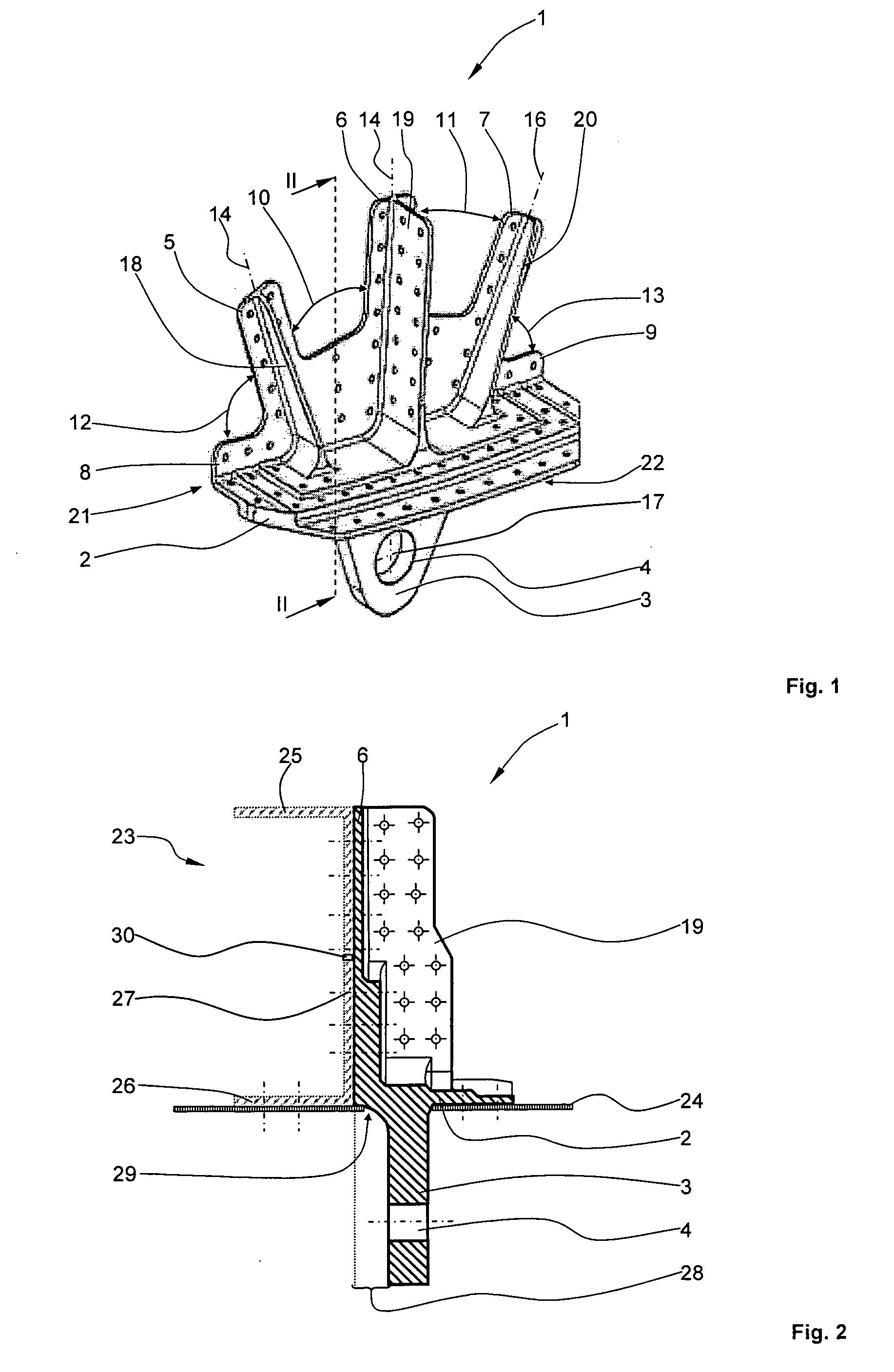

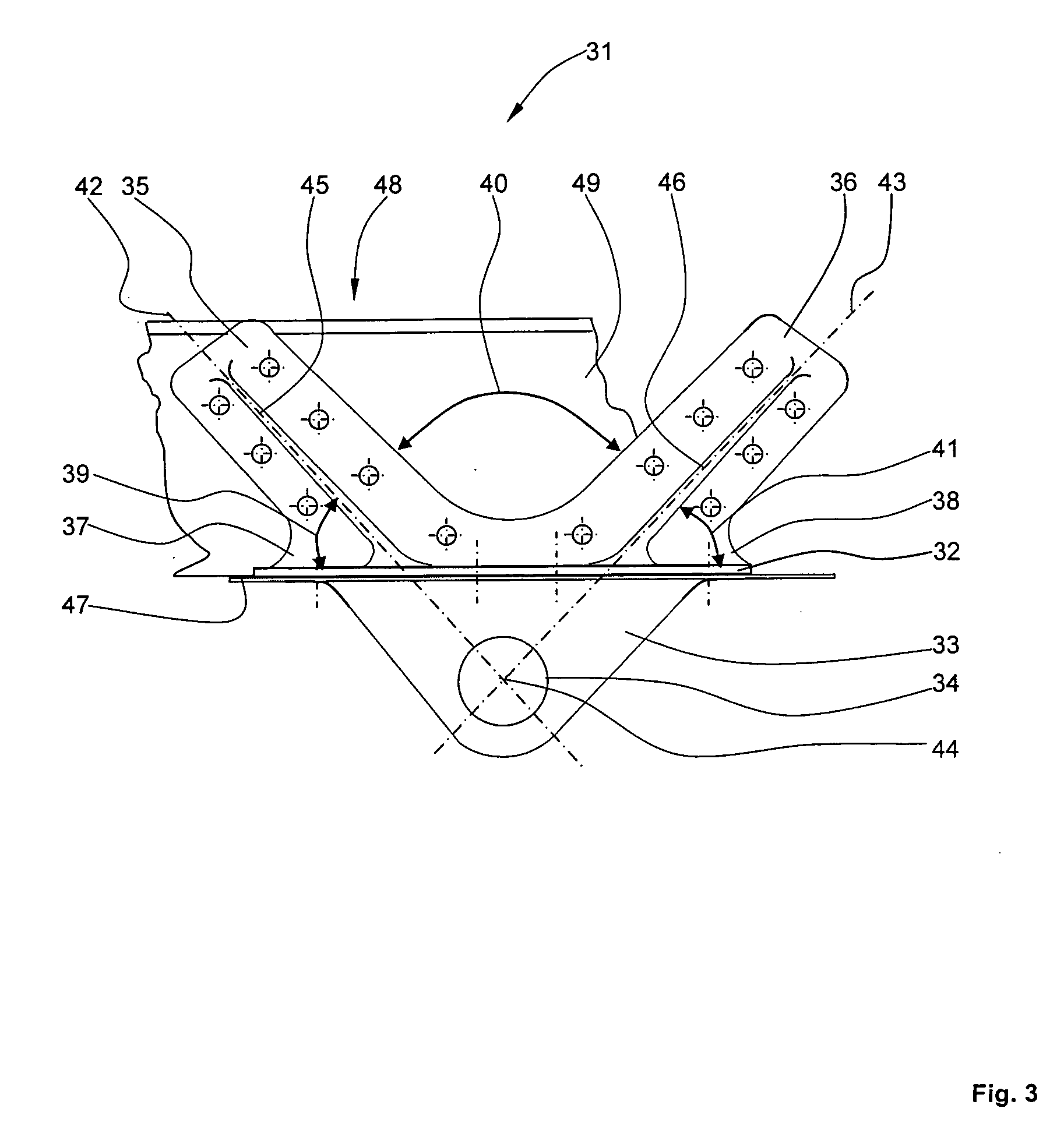

Fitting for introducing high forces into a fuselage cell of an aircraft

ActiveUS20080173761A1Improve force transmission performanceAvoid disadvantagesFuselage framesFuselage bulkheadsAirplaneEngineering

Disclosed is a fitting for introducing great loads into a fuselage cell of an aircraft, in particular those which emanate from undercarriage components or are introduced into them. The fitting has a shoulder plate for bearing against the inside of the skin of the fuselage cell for example over its full surface area. Arranged underneath the shoulder plate is a vertical lug shackle with a lug for introducing the loads, wherein the lug shackle is led to the outside through a clearance in the skin of the fuselage cell. At least one approximately upright fastening shackle is provided on the upper side of the shoulder plate for connecting the fitting to a frame web. According to the invention, the loads occurring are introduced into the frame, substantially “moment-free” in the region of a neutral fiber, so that the said frame is not exposed to any appreciable flexural stresses and can be of a more lightweight design. The frame becomes the load introducing instrument and distributes the loads uniformly into the skin of the fuselage cell. Radially acting loads are transferred from the shoulder plate directly into the skin of the fuselage cell by way of shearing.

Owner:AIRBUS OPERATIONS GMBH

Vibrating piece manufacturing method and vibrator manufacturing method

InactiveUS8191216B2Reduce thicknessReduce rigidityPiezoelectric/electrostrictive device manufacture/assemblyRecord carriersEngineeringFlexural rigidity

A vibrating piece manufacturing method includes: (a) preparing a supporting body having first and second surfaces, the first and second surfaces defining a thickness while being directed toward opposite directions, the supporting body including a base and a plurality of arms, the arms extending side-by-side in a direction orthogonal to a direction of the thickness from the base, a lower electrode film being disposed on the first surface of each of the arms, a piezoelectric film being disposed on the lower electrode films, at least one upper electrode film being disposed on the piezoelectric film, at least a part of the second surface of each of the arms being an exposed area; and (b) etching the exposed area of the second surface so as to reduce the thickness to reduce flexural rigidity of the arms with respect to the thickness direction.

Owner:SEIKO EPSON CORP

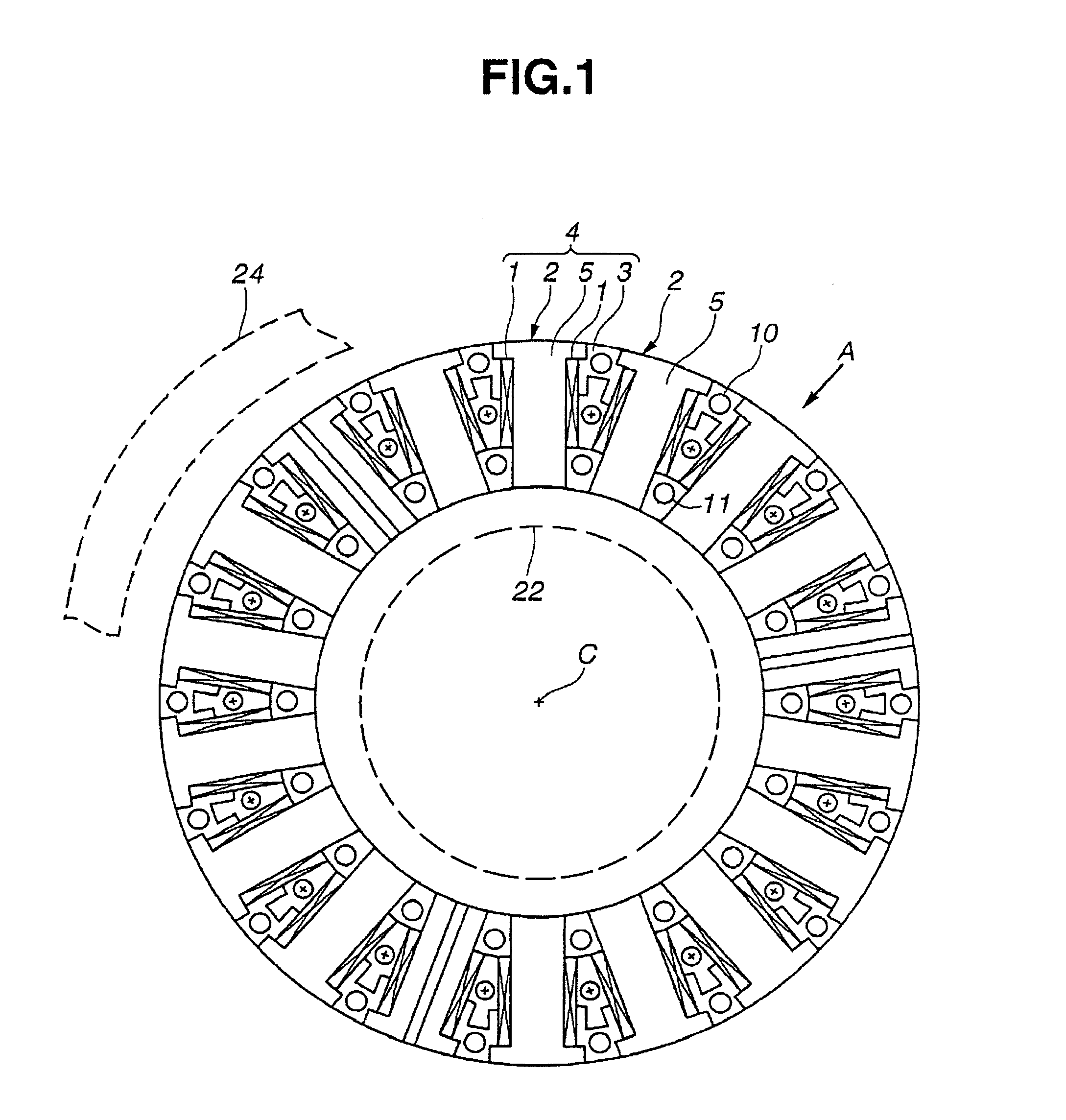

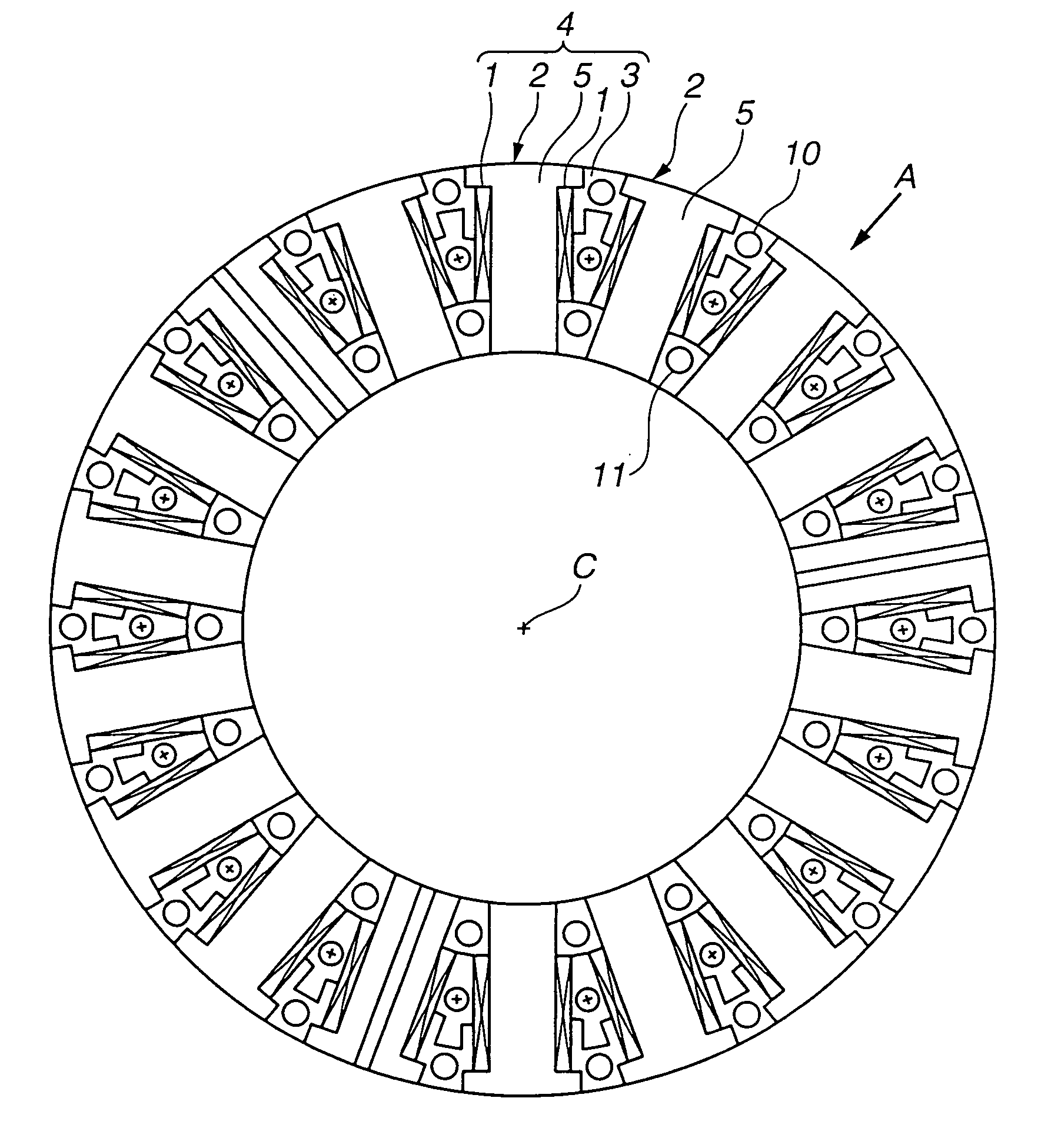

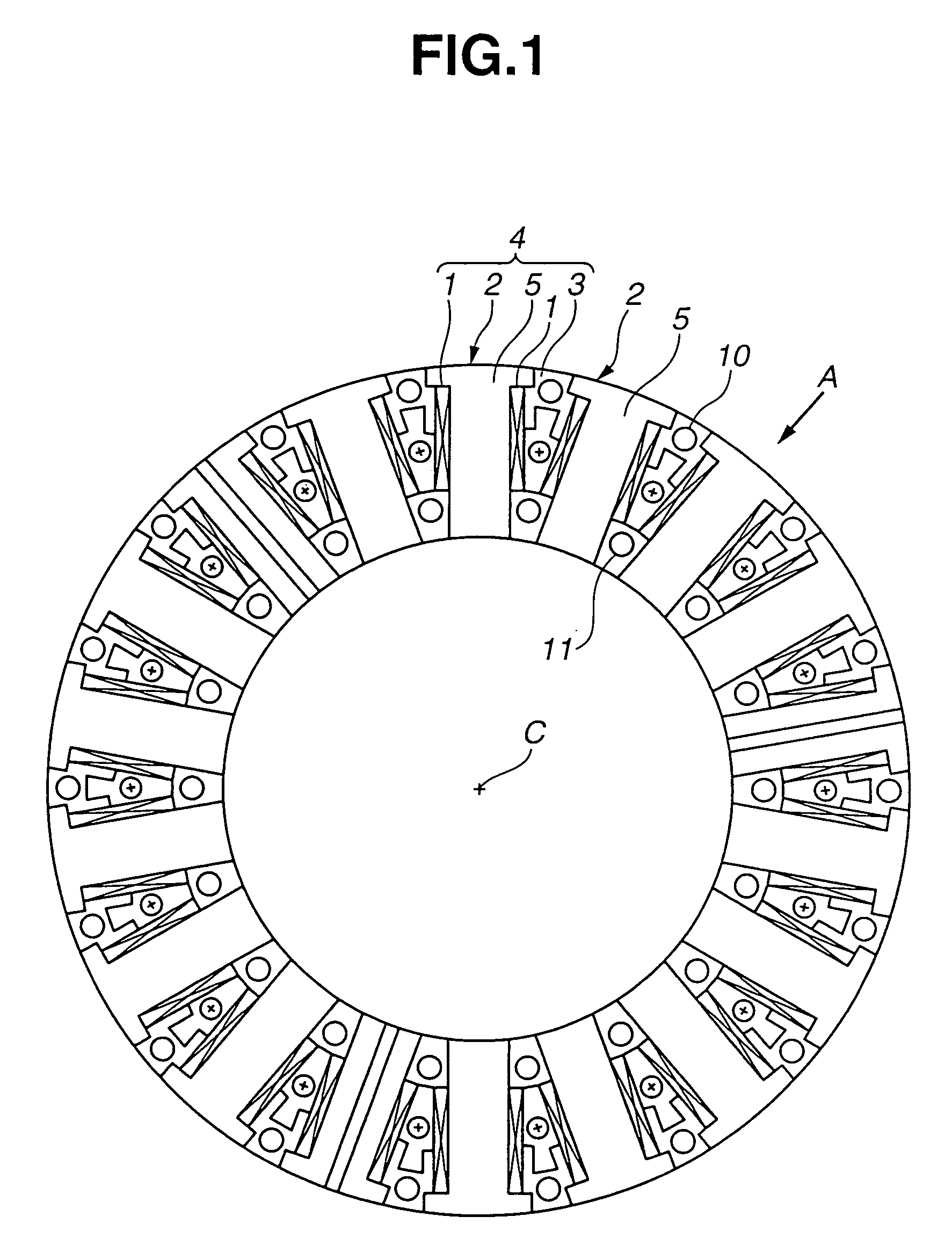

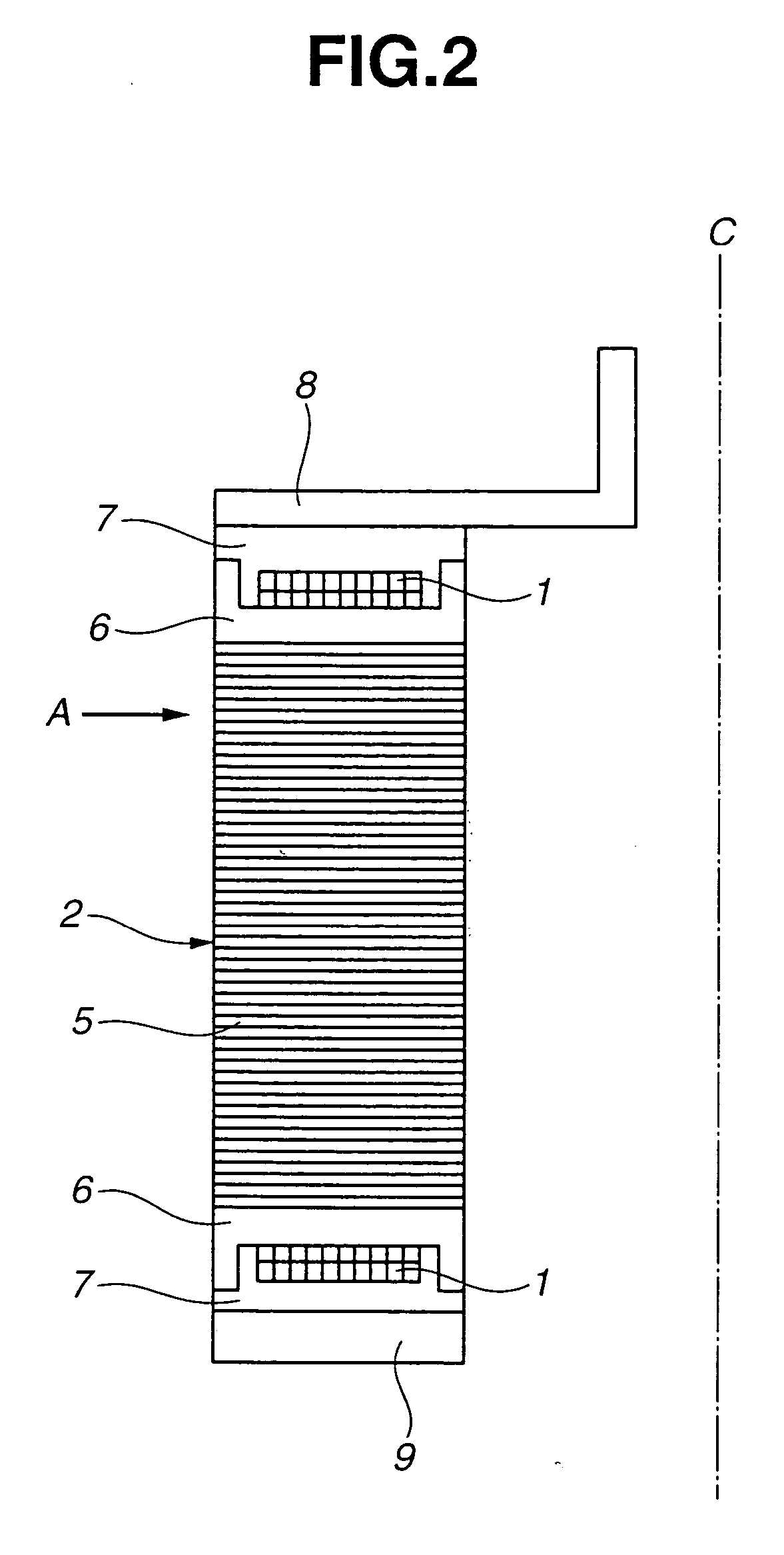

Stator for rotary electric machine

InactiveUS7608969B2Increased flexural rigidityPrevent movementWindingsMagnetic circuit rotating partsElectric machineElectrical and Electronics engineering

A stator for a rotary electric machine, including a plurality of stator cores arranged in a circumferentially spaced relation about a central axis of the stator, and a molded resin filled between the adjacent stator cores. Each of the stator cores includes a meshing portion which is meshed with the molded resin and formed on circumferentially opposed side surfaces of the stator core. The stator core includes a plurality of stator segments laminated along a direction of the central axis so as to form the meshing portion.

Owner:NISSAN MOTOR CO LTD

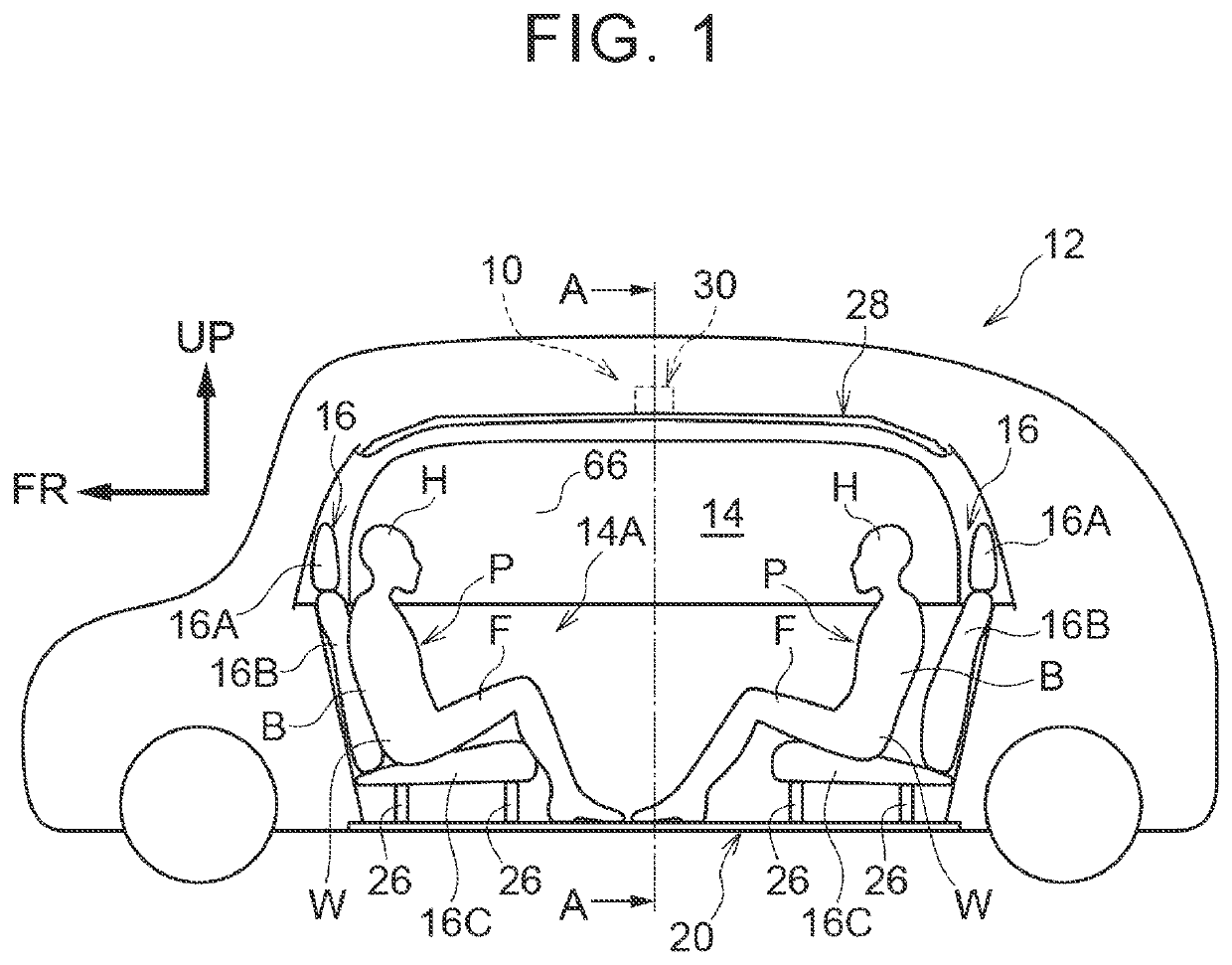

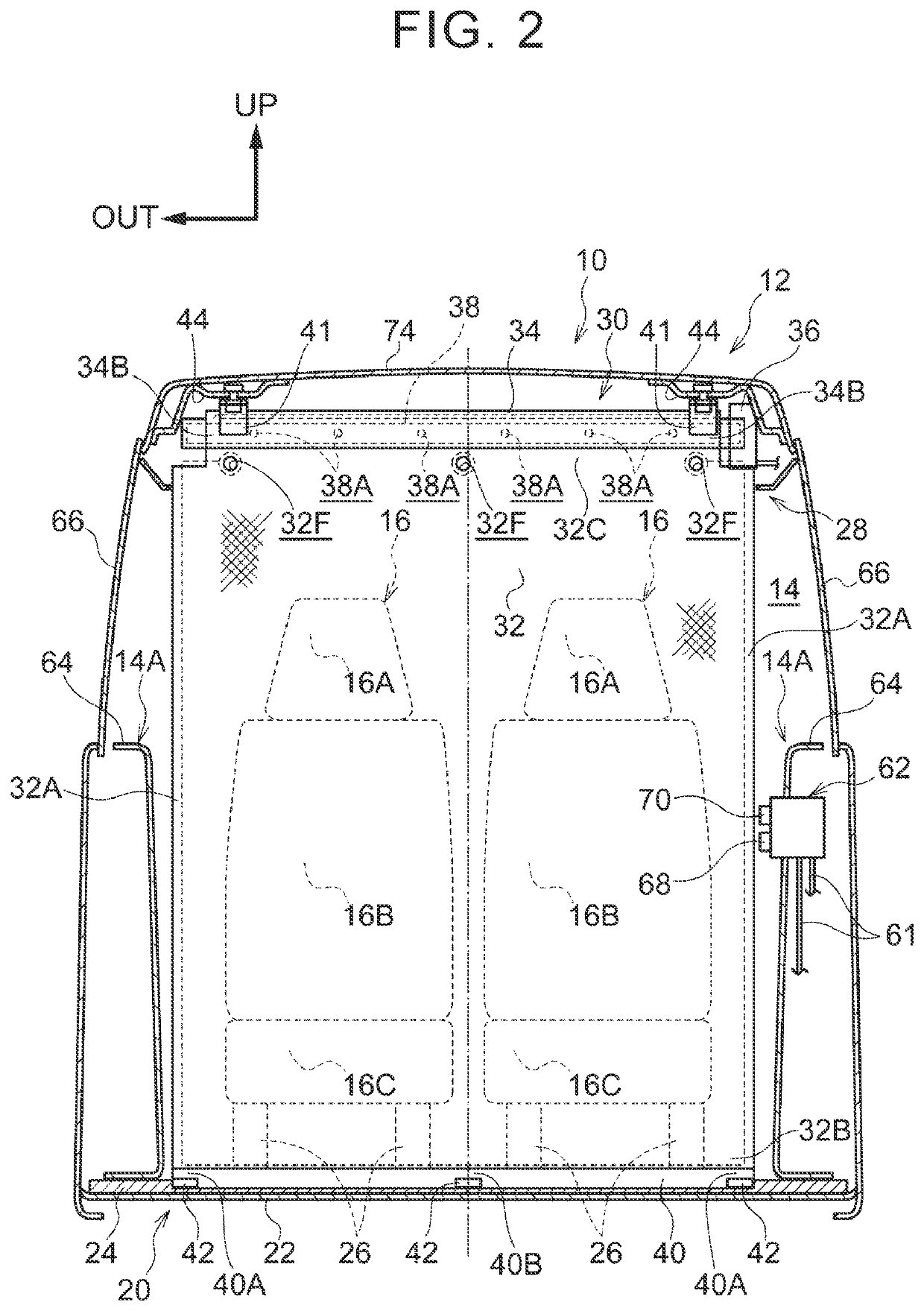

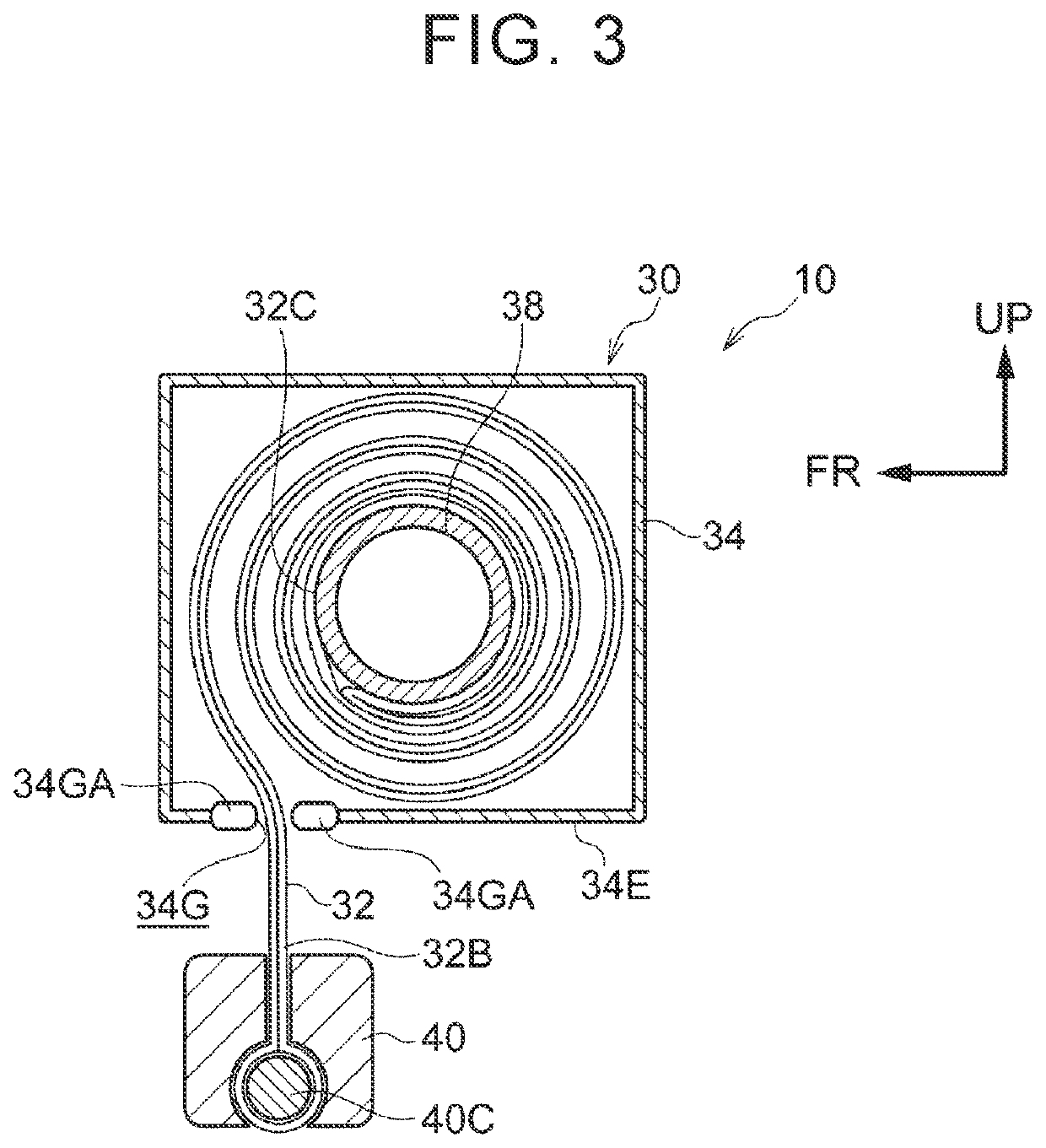

Occupant protective apparatus

ActiveUS20200384940A1Improve exterior designImproved occupant restraint performancePedestrian/occupant safety arrangementControl theoryGas supply

In a shielding state, a partition extends from an upper portion to a lower portion of a cabin in such a manner as to partition a space between a pair of opposing vehicle seats. In the case where the partition is in the shielding state during a collision of a vehicle, the partition is inflated in a vehicle longitudinal direction by gas supplied from an inflator that is actuated when a collision detection sensor detects the collision of the vehicle. That is, since the partition is inflated in the space between the pair of the vehicle seats without interfering with the vehicle seats, the partition can reliably restrain an occupant who receives a collision load and is thereby displaced in the vehicle longitudinal direction from the vehicle seat. In this way, it is possible to easily secure a private space in the cabin and to improve occupant restraint performance.

Owner:TOYOTA JIDOSHA KK

Bulkhead door for a vessel

InactiveUS7213528B1Good chemical resistanceEasy to disassembleHull bulkheadsWatertight door arrangementsAdhesiveStandard distance

A bulkhead door for watertight closing of a bulkhead opening of a naval vessel, comprising a composite outer shell and inner shell, a chamber therebetween, and a channel along the door margin for retaining a gasket without adhesive. The chamber may be filled with a material such as a rigid foam to increase door strength and rigidity. The outer shell includes hinge blades spaced apart by a standard distance and spaced equally from ends of the door, so that each door may be used for either a right-hand or left-hand bulkhead hinge pin orientation. Metal strikers are bonded to the outer surface of the door for engaging closure dogs in use. A door may be provided without any strikers, and the strikers then bonded to the door at appropriate locations during installation of a door to a specific bulkhead opening location.

Owner:PERFORMANCE BY DESIGN INT

Cylinder head gasket

InactiveUS20090267308A1Increased flexural rigidityRisk of in minimizedEngine sealsSealing arrangements for enginesEngineeringHead gasket

Cylinder head gasket with a gasket plate comprising a plurality of sheet metal layers and at least one combustion chamber opening, an inner layer being arranged in the gasket plate directly between two functional layers having sealing beads arranged one over the other, which enclose the combustion chamber opening and have bead feet lying in the planes of the functional layers and bead crests with which sealing beads of the two functional layers all project over the functional layers in a first direction extending perpendicularly to the gasket plane, at least one ring zone of the inner layer being clamped between the bead feet of the one functional layer and at least one bead crest of the other functional layer when the gasket is pressed; to minimize arching of this ring zone, it is stiffened and / or those ring zone regions against which at least one bead crest of one functional layer lies when the gasket is pressed are supported by bead feet of the other functional layer.

Owner:ELRINGKLINGER AG

Stator for rotary electric machine

InactiveUS20060061229A1Prevent movementIncreased flexural rigidityWindingsMagnetic circuit rotating partsElectric machineElectrical and Electronics engineering

A stator for a rotary electric machine, including a plurality of stator cores arranged in a circumferentially spaced relation about a central axis of the stator, and a molded resin filled between the adjacent stator cores. Each of the stator cores includes a meshing portion which is meshed with the molded resin and formed on circumferentially opposed side surfaces of the stator core. The stator core includes a plurality of stator segments laminated along a direction of the central axis so as to form the meshing portion.

Owner:NISSAN MOTOR CO LTD

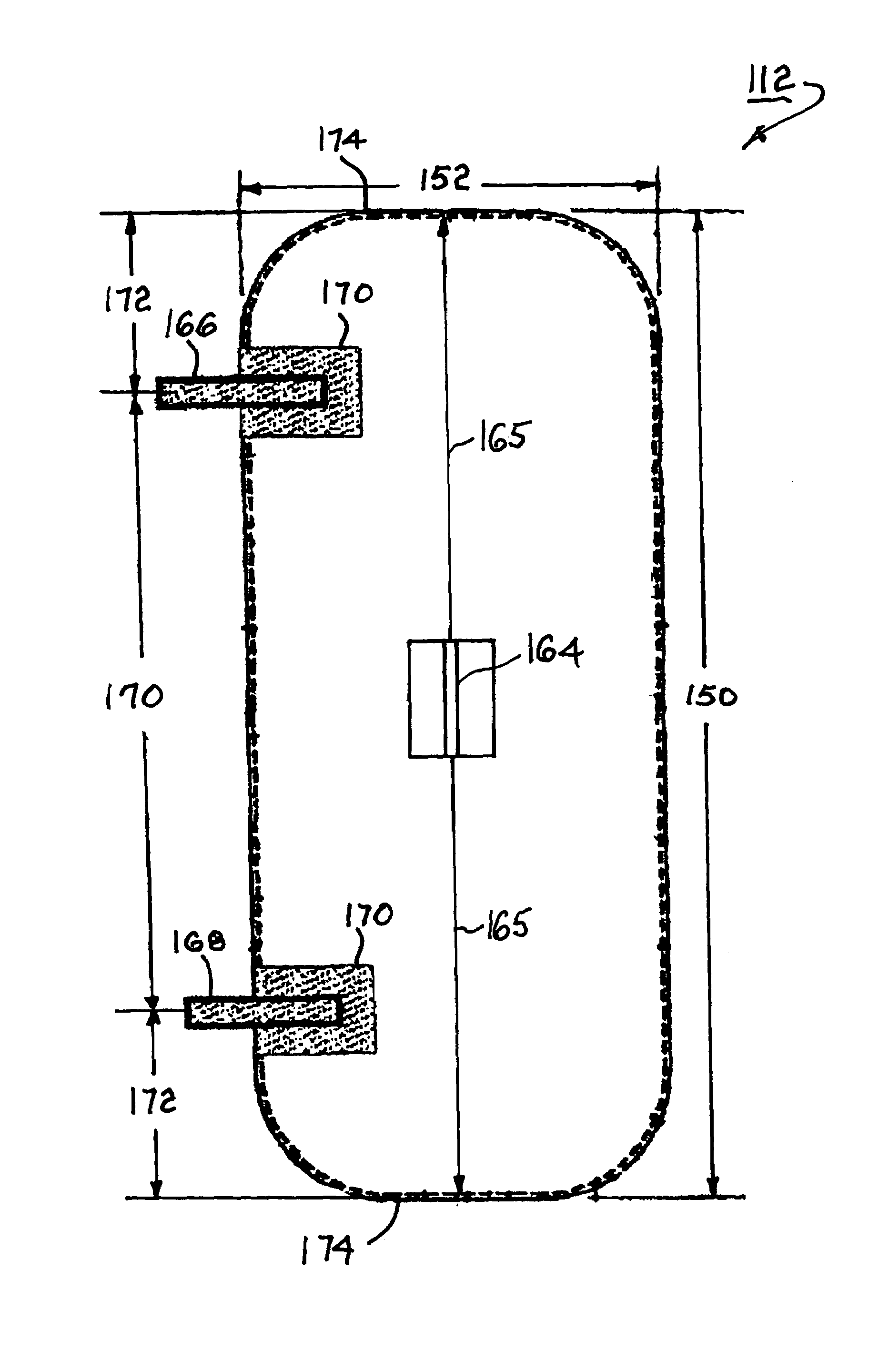

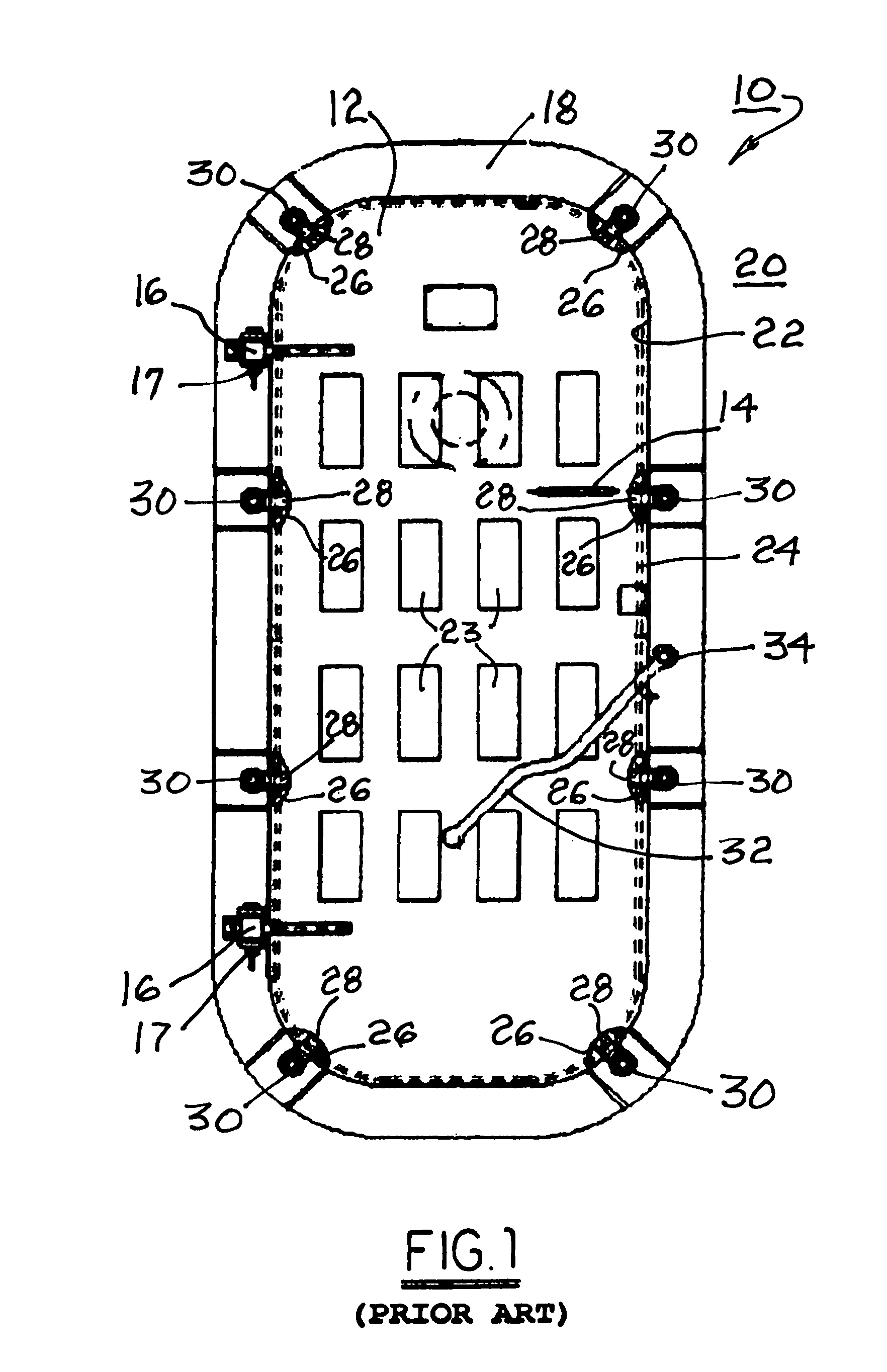

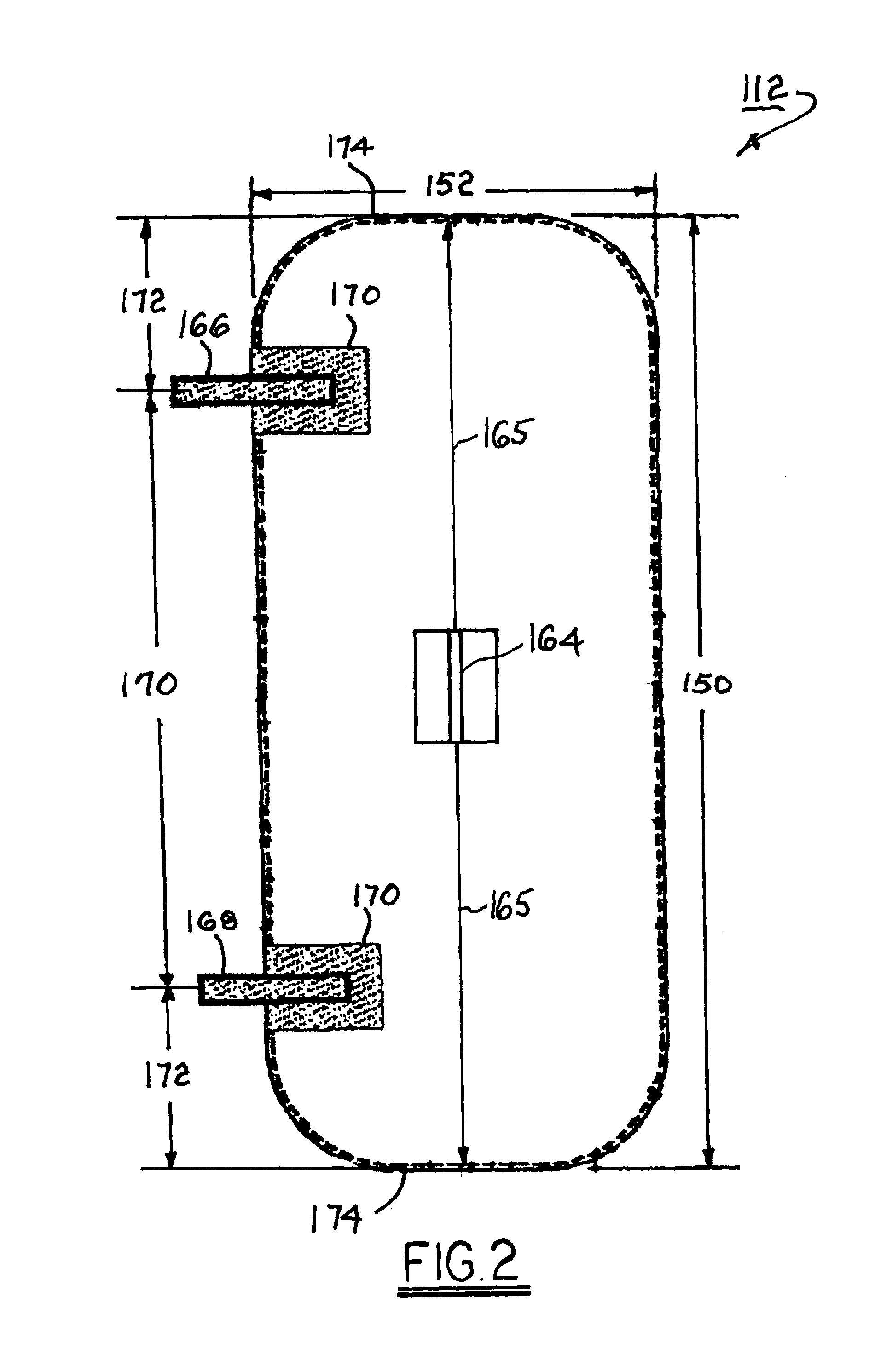

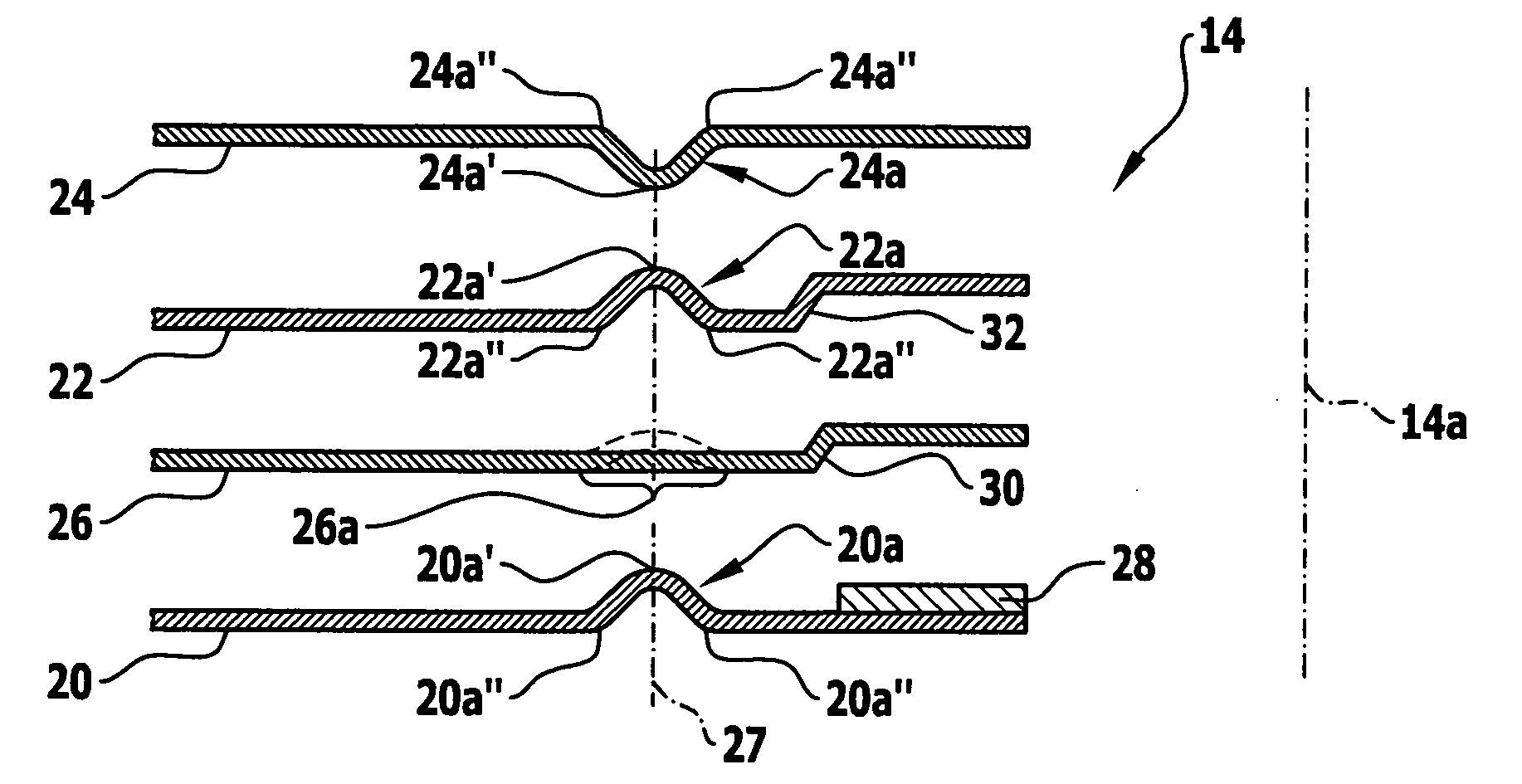

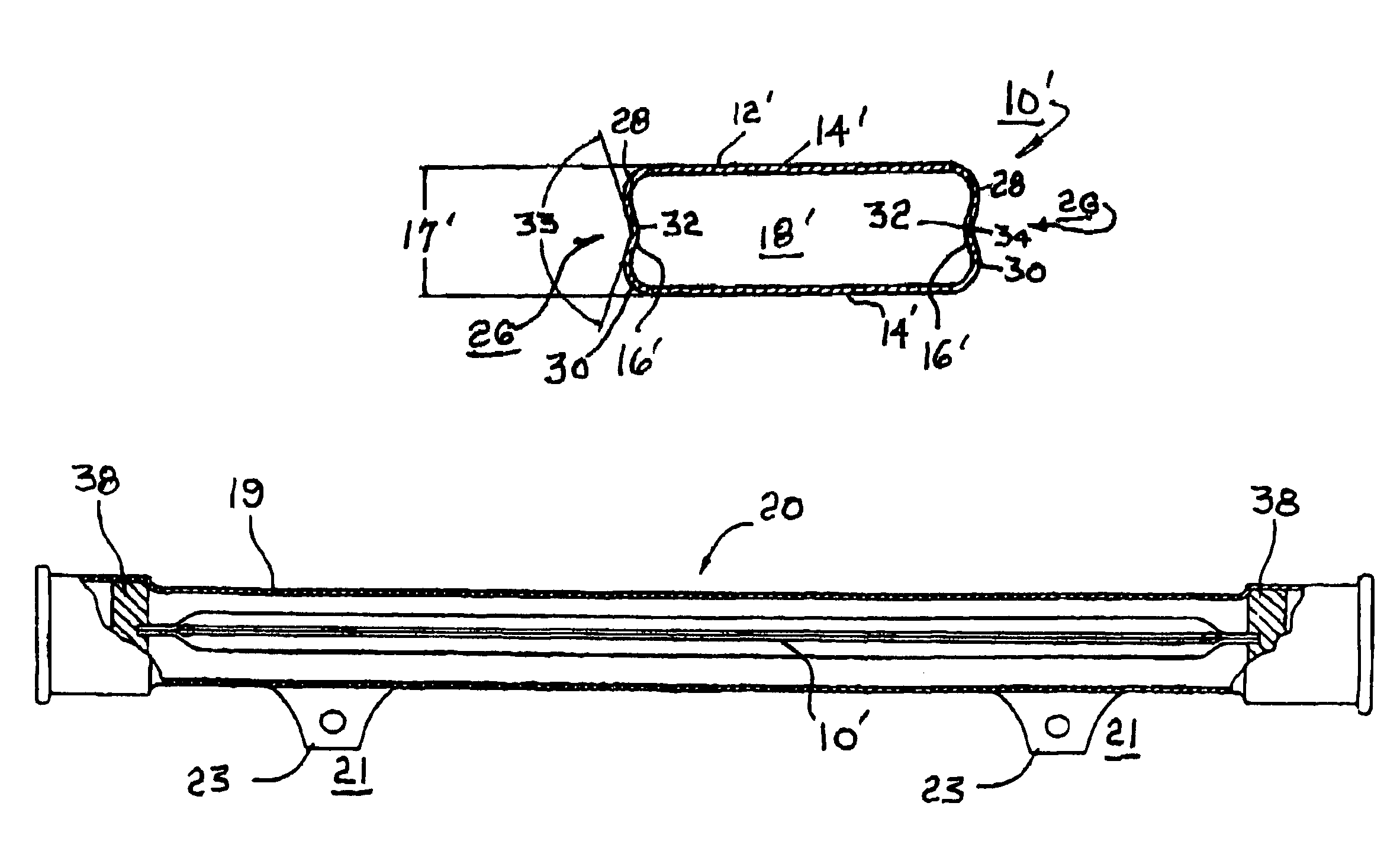

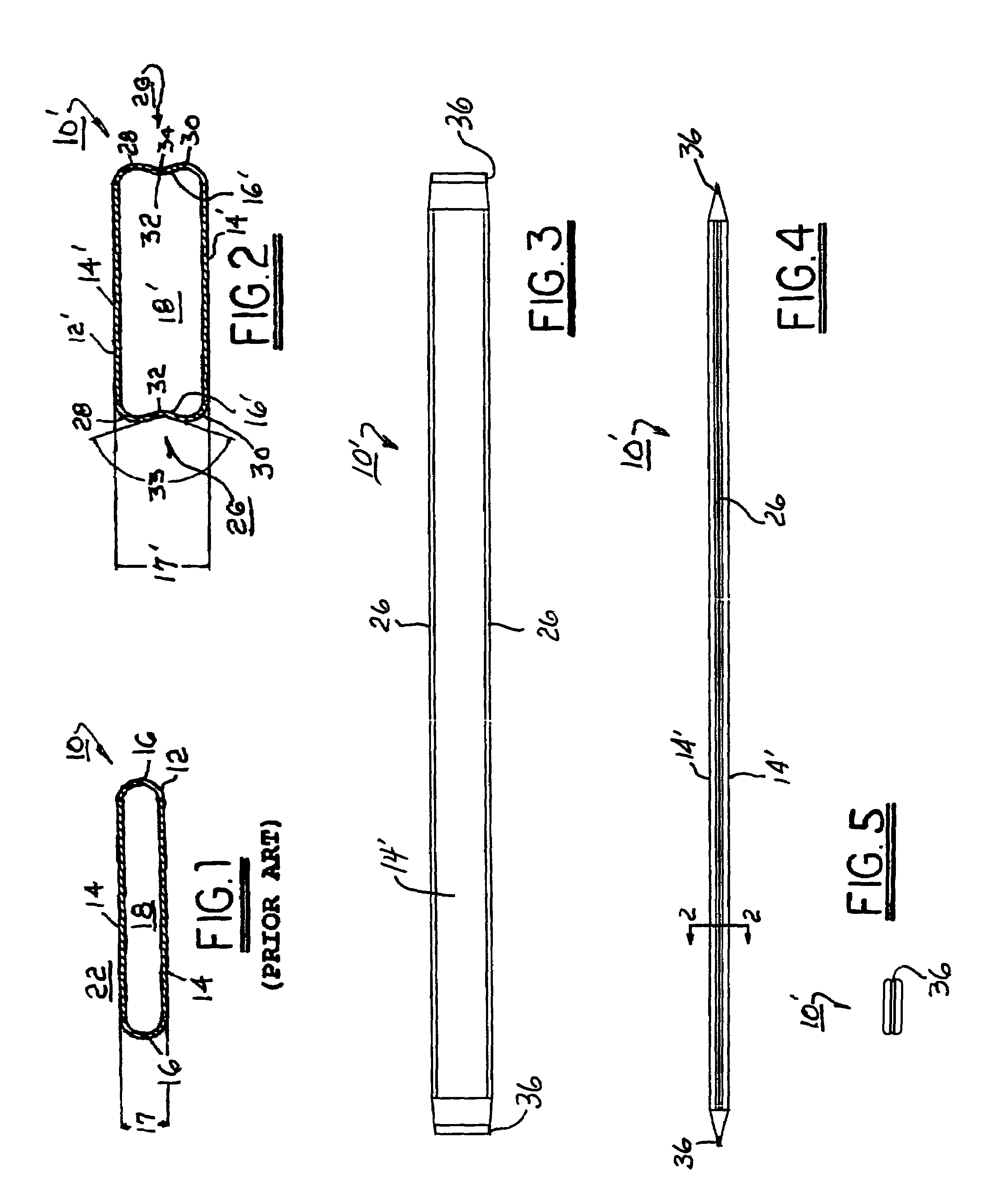

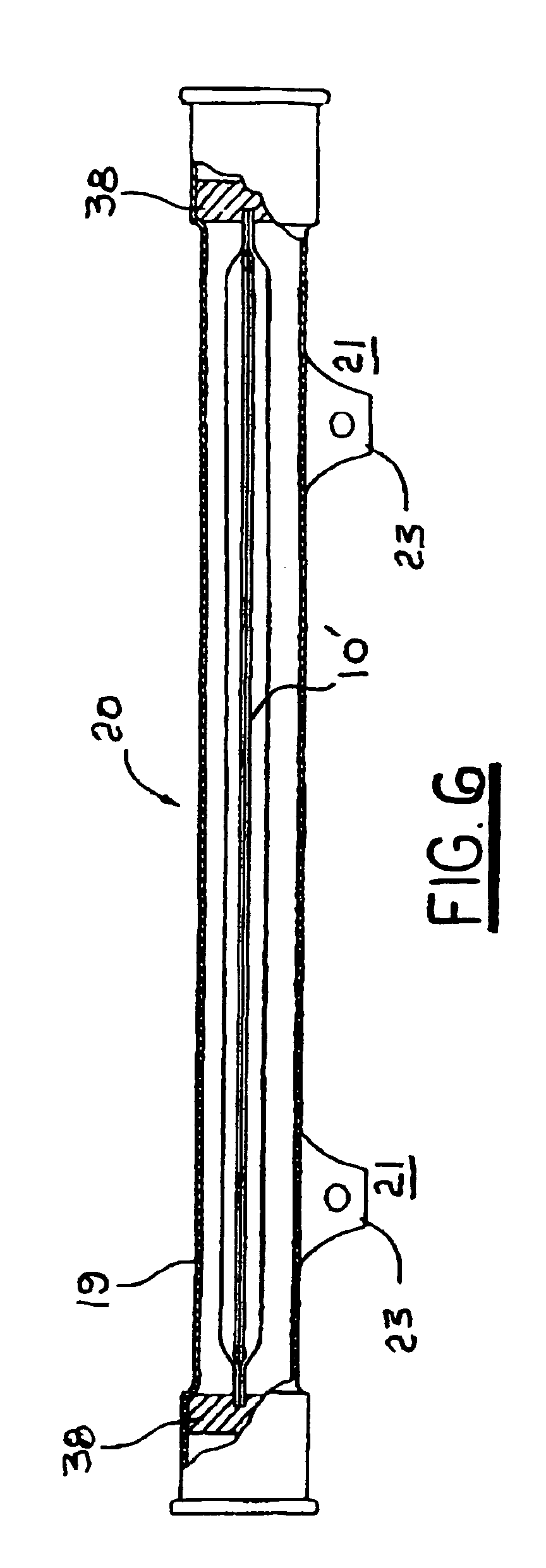

Fuel rail pulse damper with integral strengthening rib

InactiveUS7036487B2Increase rangeHigh sensitivityLow-pressure fuel injectionPipe elementsAir volumeEngineering

An internal pulse damper for a fuel rail. The damper has an increased captive air volume and consequent improved damping and stress characteristics. The improved damper is a pillow having a modified flat oval cross-sectional profile, with two long diaphragm sides and rigid short sides connecting the two long sides. At least one of the short sides, and preferably both, is strengthened by being provided with a longitudinal reverse bend or inwardly-extending longitudinal rib generally parallel with the long sides. Preferably, the short sides are somewhat higher than the comparable short sides of similar prior art dampers, to increase the captive air volume, yet are not high enough to preclude installation of the improved damper within an existing fuel rail configuration.

Owner:DELPHI TECH INC

Output shaft reduction-type dual clutch transmission

ActiveUS8201469B2Increase in temperature increaseIncrease in increase in transmissionToothed gearingsTransmission elementsGear trainClutch

A dual clutch transmission having two input shafts respectively connected to clutches, and an intermediate shaft, preventing the intermediate shaft from rotating idle when the vehicle is traveling at high speeds and avoiding excess stirring of lubricating oil in the transmission and increase in noise. In the dual clutch transmission, a direct connection clutch C3 is provided between one input shaft S2 and an output shaft S4, and an intermediate shaft connection clutch C4 for interrupting the transmission of power is provided between the intermediate shaft S3 and the output shaft S4. When the power is directly transmitted from the input shaft S2 to the output shaft S4 via the direct connection clutch C3, the intermediate shaft connection clutch C4 is disconnected to stop the rotation of the intermediate shaft S3 and to prevent the lubricating oil from being excessively stirred by the idle rotation of the intermediate shaft S3. Further, the intermediate shaft connection clutch C4 is disconnected, and a transmission step is constituted by utilizing the gear trains among the two input shafts and the intermediate shaft S3, making it possible to omit one gear train and, therefore, to shorten the length of the transmission.

Owner:ISUZU MOTORS LTD

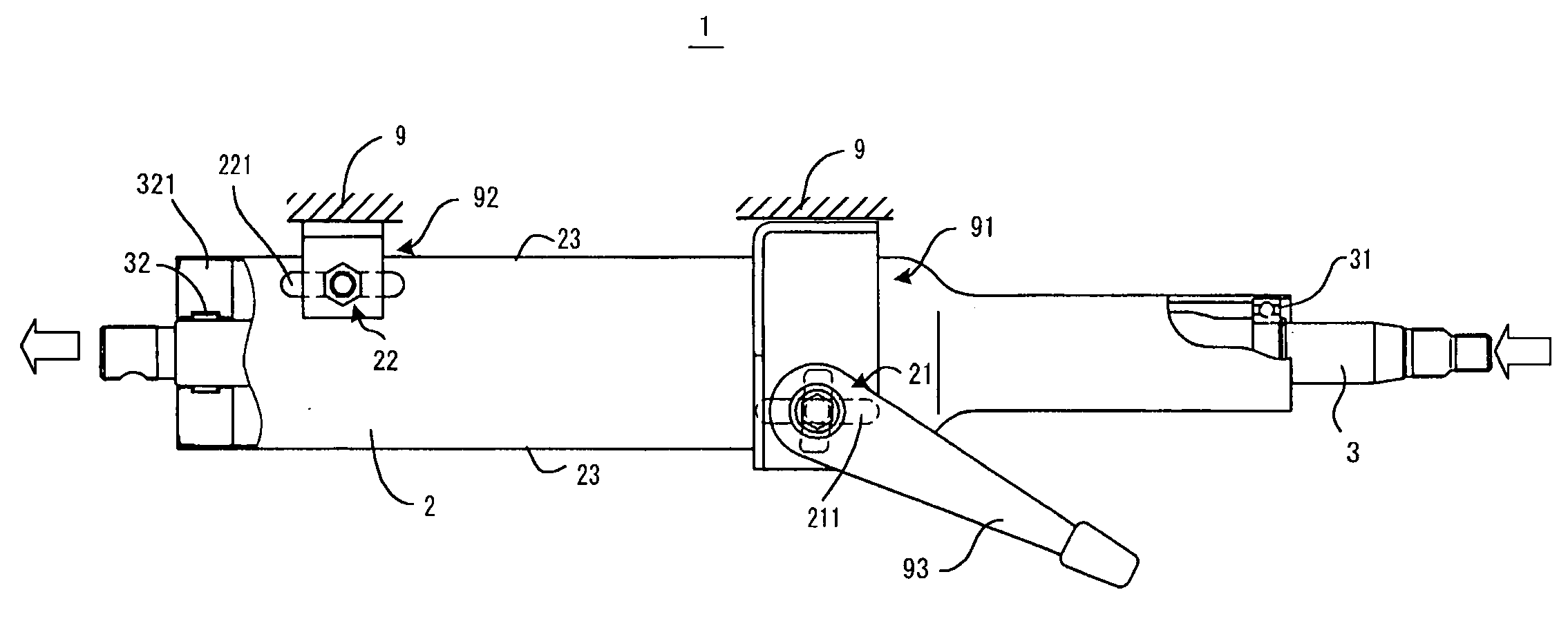

Steering column device

InactiveUS20060053935A1Increased flexural rigidityImproving resistance to vibration propertySteering columnsSteering columnEngineering

A steering column device (1), comprising a column body (2) having a swelled shell part (23) in deformed section swelled in the side direction of a steering shaft (3) beyond the portion of thereof where an upper bearing (31) is installed and having opposed walls parallel with each other, wherein a lower body mounting part (22) and an upper body mounting part (21) are formed in the swelled shell part (23), whereby a distance bracket and a lower bracket must not be prepared and fixedly positioned on the column body.

Owner:NSK LTD

Layout design and fabrication of SDA micro motor for low driving voltage and high lifetime application

InactiveUS7504275B2Reduce the driving voltageExtend your lifeSemiconductor/solid-state device manufacturingElectrostatic motorsGeometric designMicro motor

Provided is a new design and fabrication of scratch drive actuator (SDA) micro rotary motor with low driving voltage and high lifetime characteristics. To substantially reduce the driving voltage from 30˜150 Vo-p to 12˜30 Vo-p ac amplitude, a silicon wafer with very low resistivity (<0.004 Ω-cm) was firstly adopted as the substrate of SDA micro motor. Furthermore, a novel SDA structure and geometric design for the improvement of lifetime (>75 hrs) and rotational speed (˜30 rpm) of SDA micro motor was also demonstrated in this patent.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Shield box

InactiveUS7663065B2Reliable shieldingIncreased flexural rigidityElectrically conductive connectionsMagnetic/electric field screeningElectrical conductorEngineering

A shield box is composed of metal-made upper box and lower box, which are combined with each other. The shield box houses therein a plurality of shield connectors interconnecting shield wires, and thereby electromagnetically shields entirety of the shield connectors and the shield wires. On an upper surface of a lower surface plate of the lower box, clamp fittings capable of restraining the respective shield connectors in axial, axial rotation, left-and-right and up-and-down directions thereof are provided. On opposite surfaces of the upper and lower boxes, press fittings are provided to sandwich shield terminal portions from upper and lower sides and conduct the shield terminal portions to the upper and lower boxes when the upper and lower boxes are matched with each other. The shield terminal portions, which are electrically connected to shield conductors of respective shield wires and are exposed to both ends of the respective shield connectors, are grounded.

Owner:YAZAKI CORP

Layout design and fabrication of SDA micro motor for low driving voltage and high lifetime application

InactiveUS20080280387A1Low costImprove compatibilitySemiconductor/solid-state device manufacturingElectrostatic motorsGeometric designMicro motor

Provided is a new design and fabrication of scratch drive actuator (SDA) micro rotary motor with low driving voltage and high lifetime characteristics. To substantially reduce the driving voltage from 30˜150 Vo-p to 12˜30 Vo-p ac amplitude, a silicon wafer with very low resistivity (<0.004 Ω-cm) was firstly adopted as the substrate of SDA micro motor. Furthermore, a novel SDA structure and geometric design for the improvement of lifetime (>75 hrs) and rotational speed (˜30 rpm) of SDA micro motor was also demonstrated in this patent.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

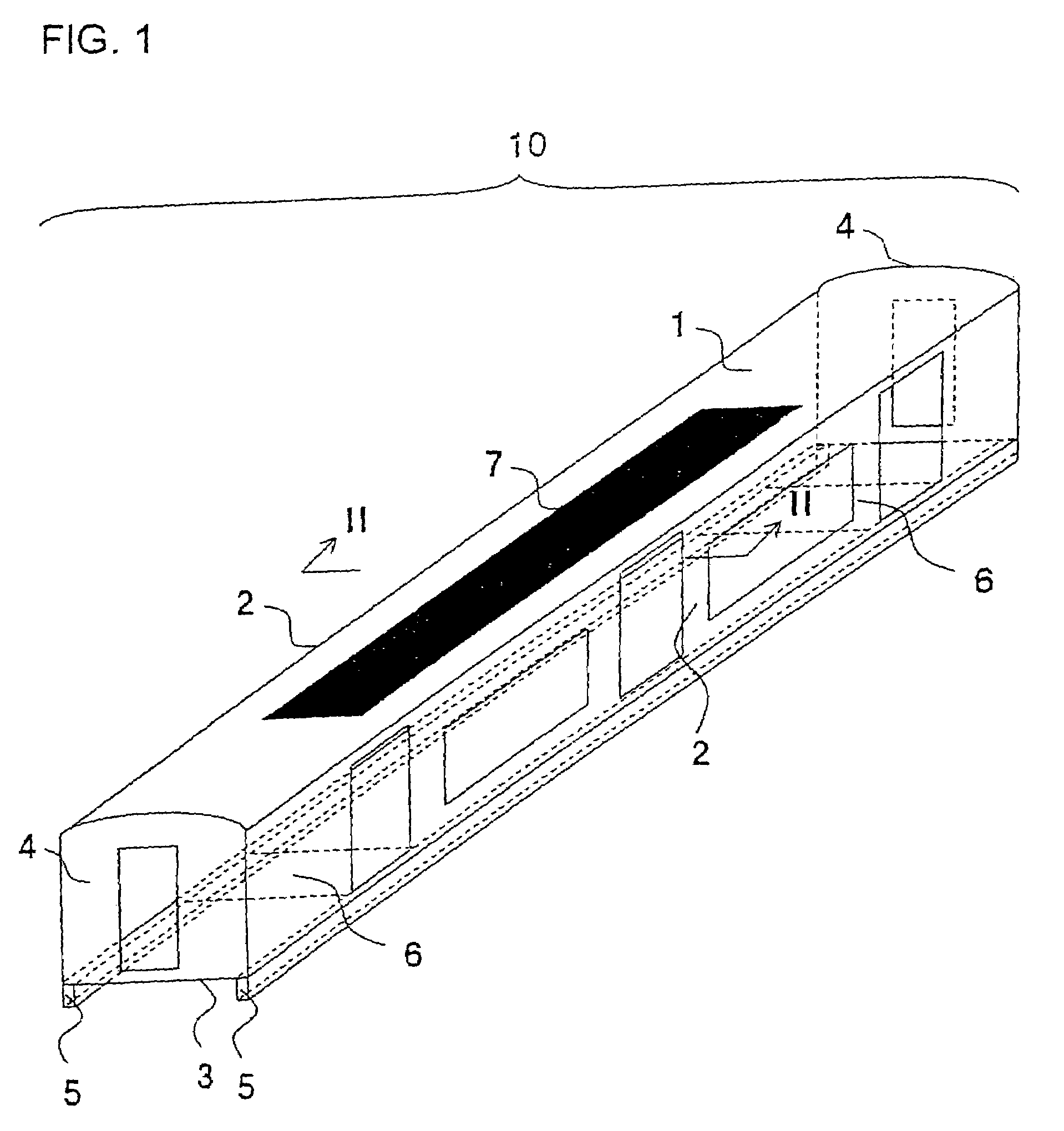

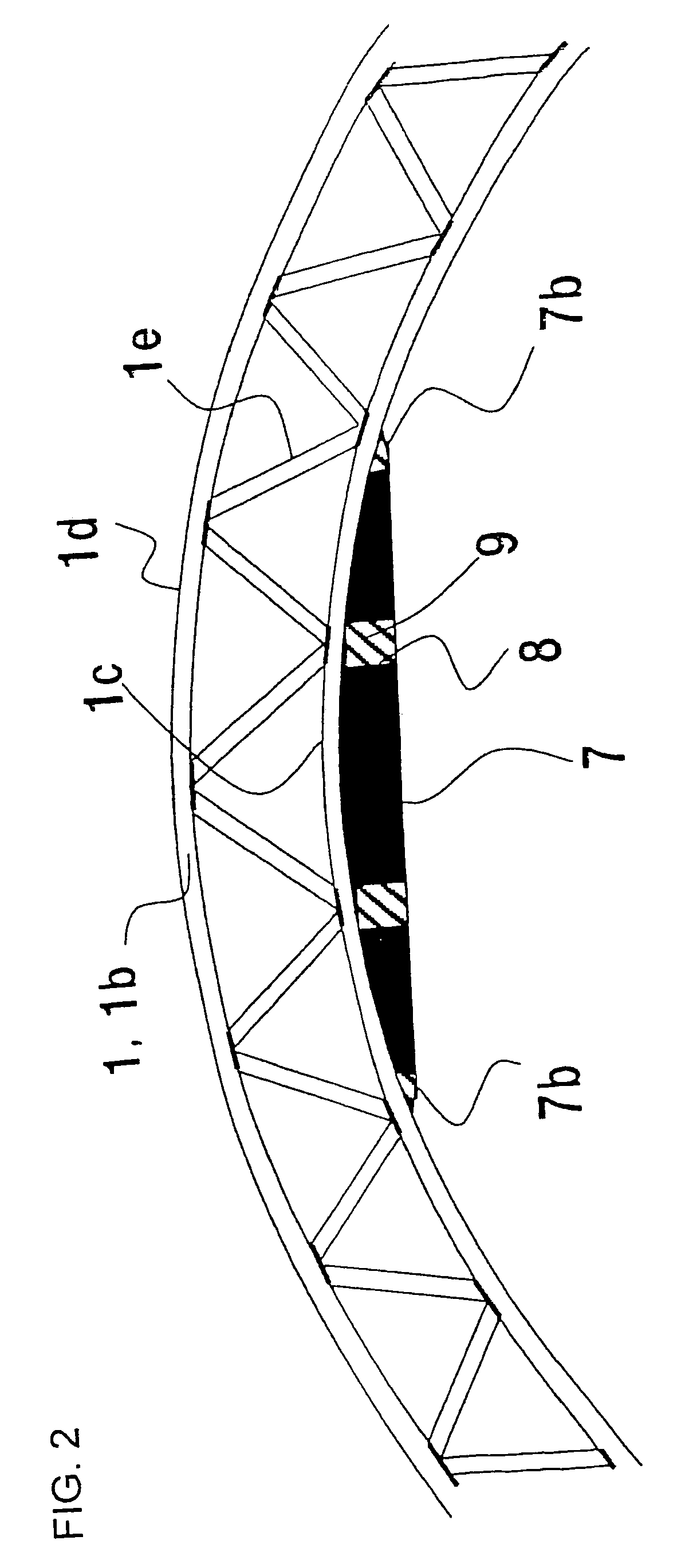

Car body structure

InactiveUS7438001B2Quality improvementSuppressing bending vibrationRailway roofsAxle-box lubricationFlexural rigidityBending vibration

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com