Improved method for disc face of vertical disc filtering machine

A vertical disc filter and filter technology, applied in the filter field, can solve the problems of equipment jumping and stopping, short service life of filter cloth, bending and twisting of fan plates, etc., so as to prolong the service life of spare parts, reduce labor intensity of workers, Improve the effect of adjusting the neutral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Partial improvement processing.

[0022] (1) Using the original spare parts, install double throats at the connecting parts; the filter cloth joints are sewn with thread.

[0023] (2) Push the central shaft to the position with a jack, and tighten the round nut of the tapered bushing.

[0024] (3) Change the width of the hoop connection plate to be the same as the width of the hoop, even if the disk surface is skewed to a certain extent.

[0025] 2. Reinforcement and transformation of the disk surface.

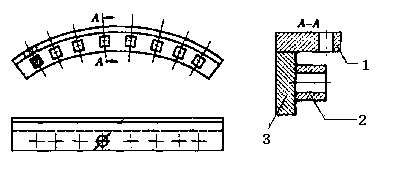

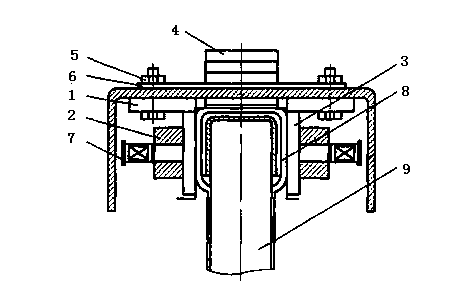

[0026] (1) The fixed plate (1) and the adjusting plate (3) are both processed from steel plates with a thickness of 10mm. The arc length is 60mm less than that of the hoop. During processing, the arc must be R2716mm, which is consistent with the inner surface of the hoop. Same, weld the fixing plate (1), adjusting bolt seat (2) and adjusting plate (3) together vertically, as figure 1 As shown, the outer side of the contact should be smooth without edges and corne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com