Patents

Literature

54results about How to "Eliminate Welding Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

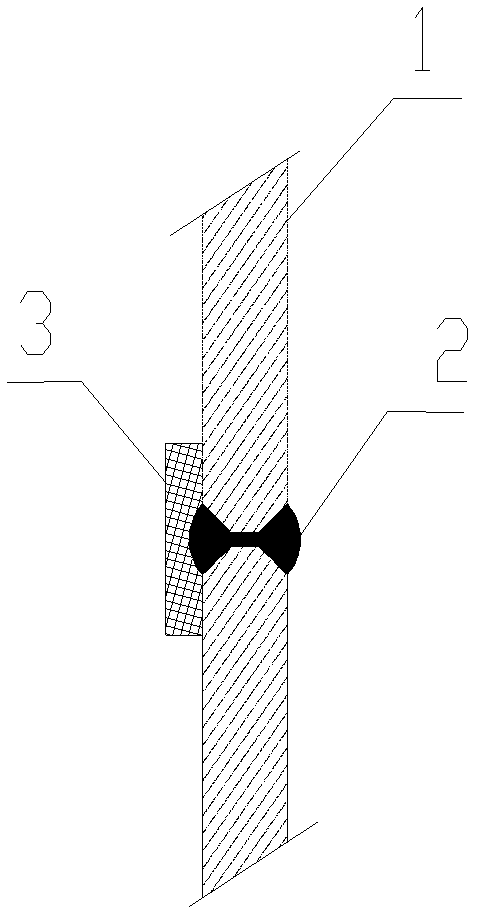

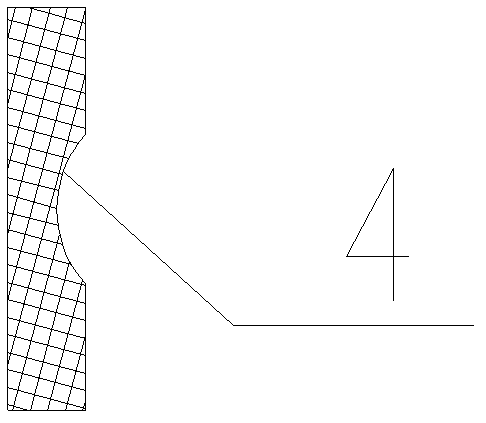

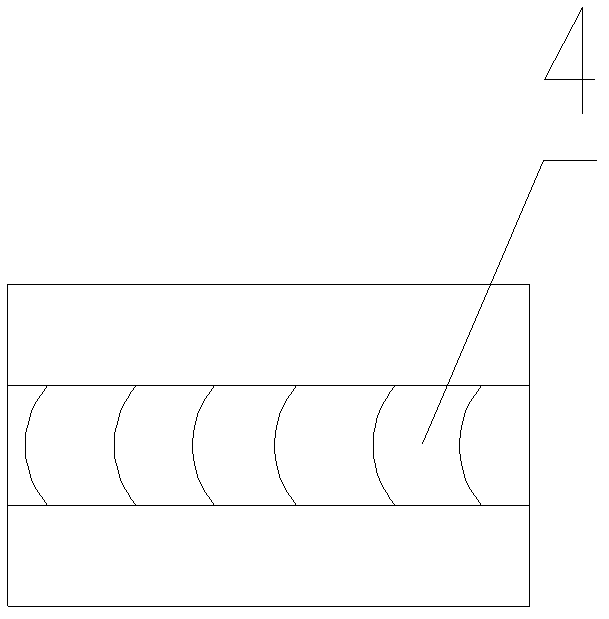

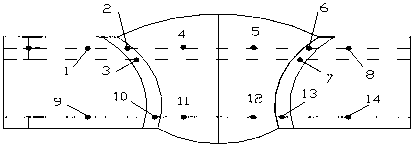

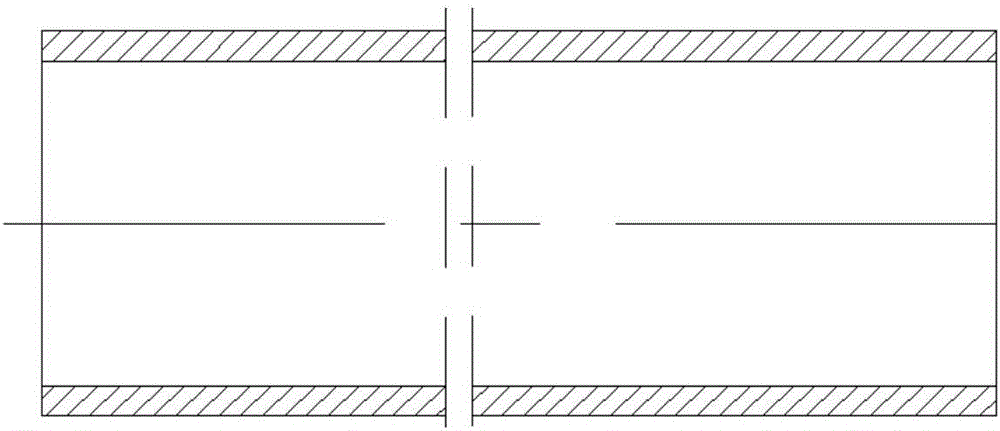

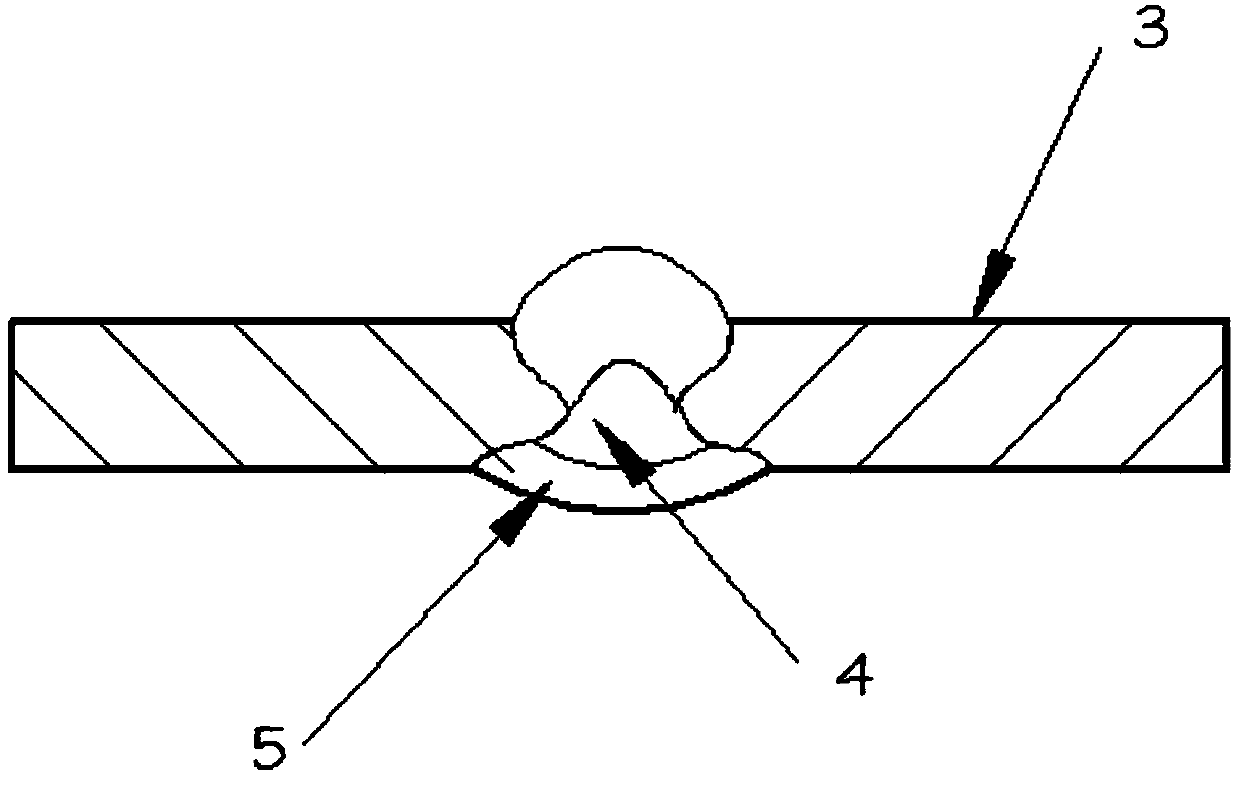

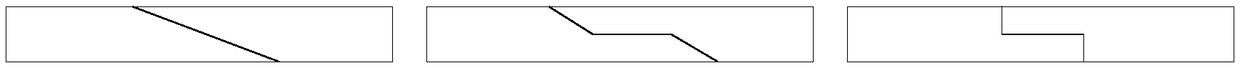

Large tank singe-face-weld double-face-forming method and weld joint forming pad

InactiveCN102489830AHigh technical levelReduce consumptionWelding accessoriesEngineeringWeld penetration

The invention provides a large tank singe-face-weld double-face-forming method, which comprises arranging a weld joint forming pad on the back face of a weld joint of a weld part, wherein the weld joint forming pad is provided with a weld joint forming groove with the shape matched with that of the weld joint; fixedly and tightly attaching the weld joint forming pad on the back face of the weld joint to enable the center of the weld joint to align at the center of the weld joint forming groove; welding the front face of the weld joint; using large weld current for weld penetration of a weld part at one step; and enabling a weld puddle to be cooled and solidified on the weld joint forming groove. Compared with a traditional double-face-weld method, the weld joint is formed by one step, weld quality is better, production efficiency is improved, and production cost is reduced.

Owner:CHONGQING POLYCOMP INT

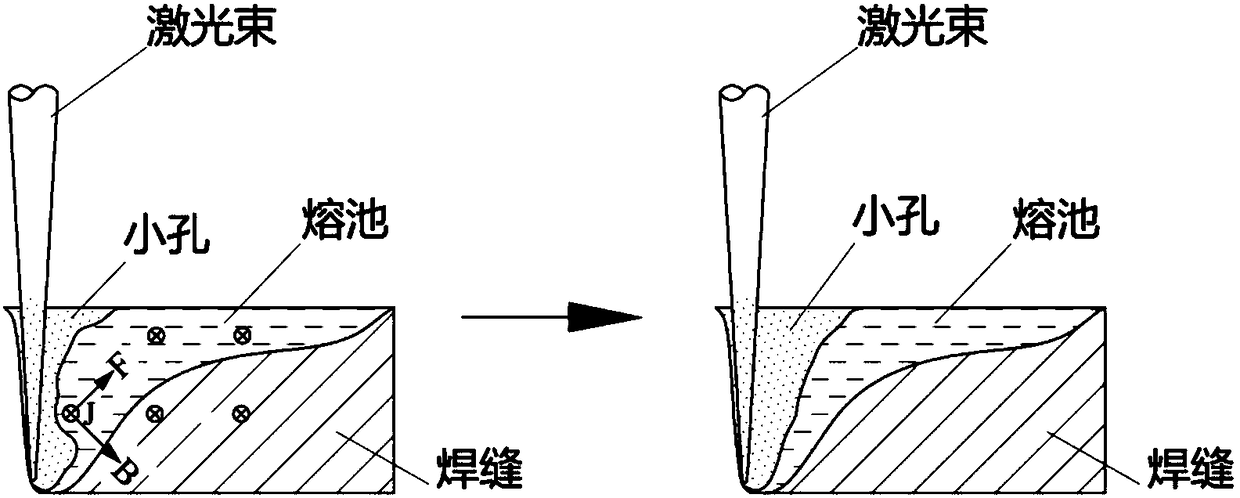

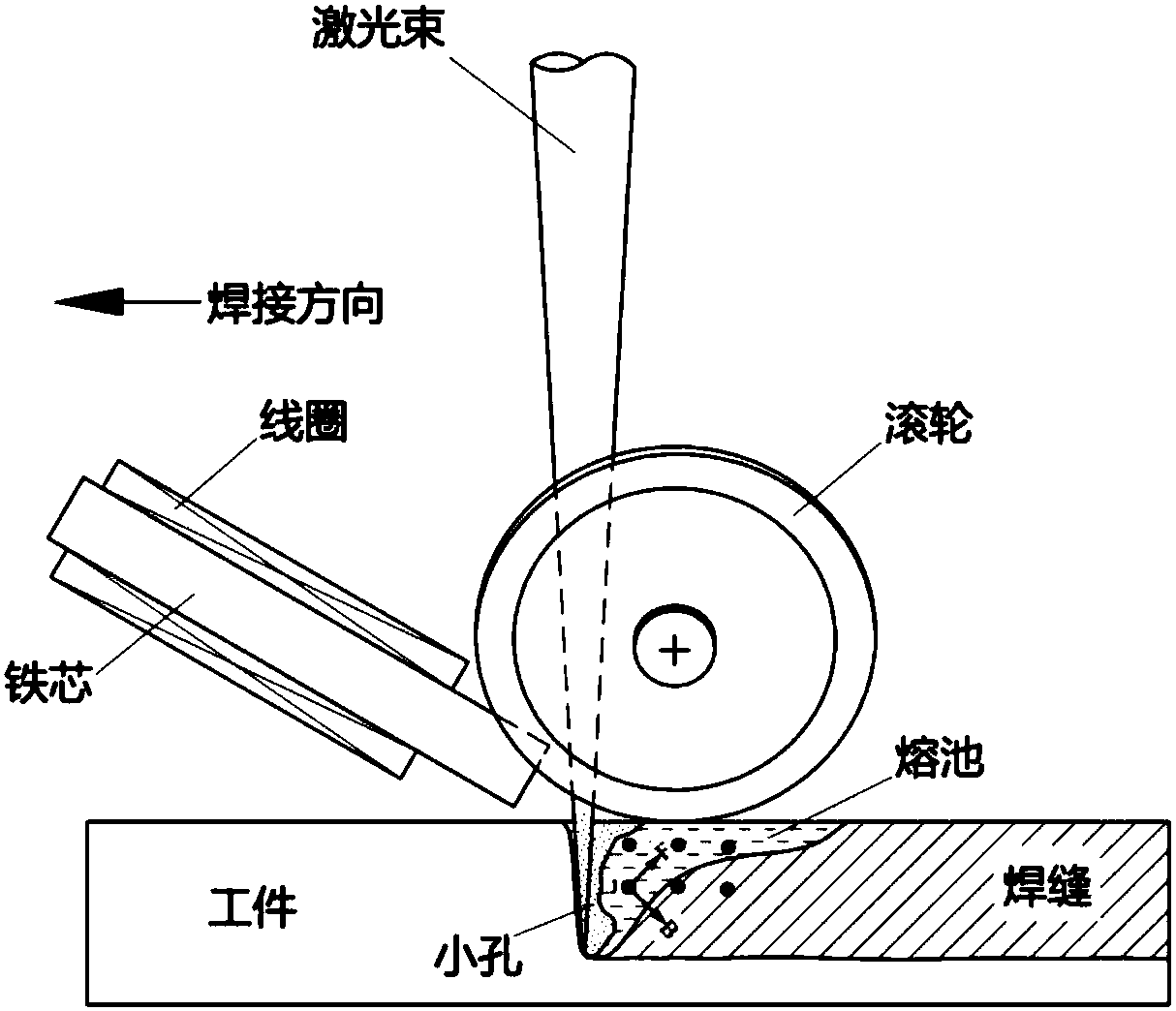

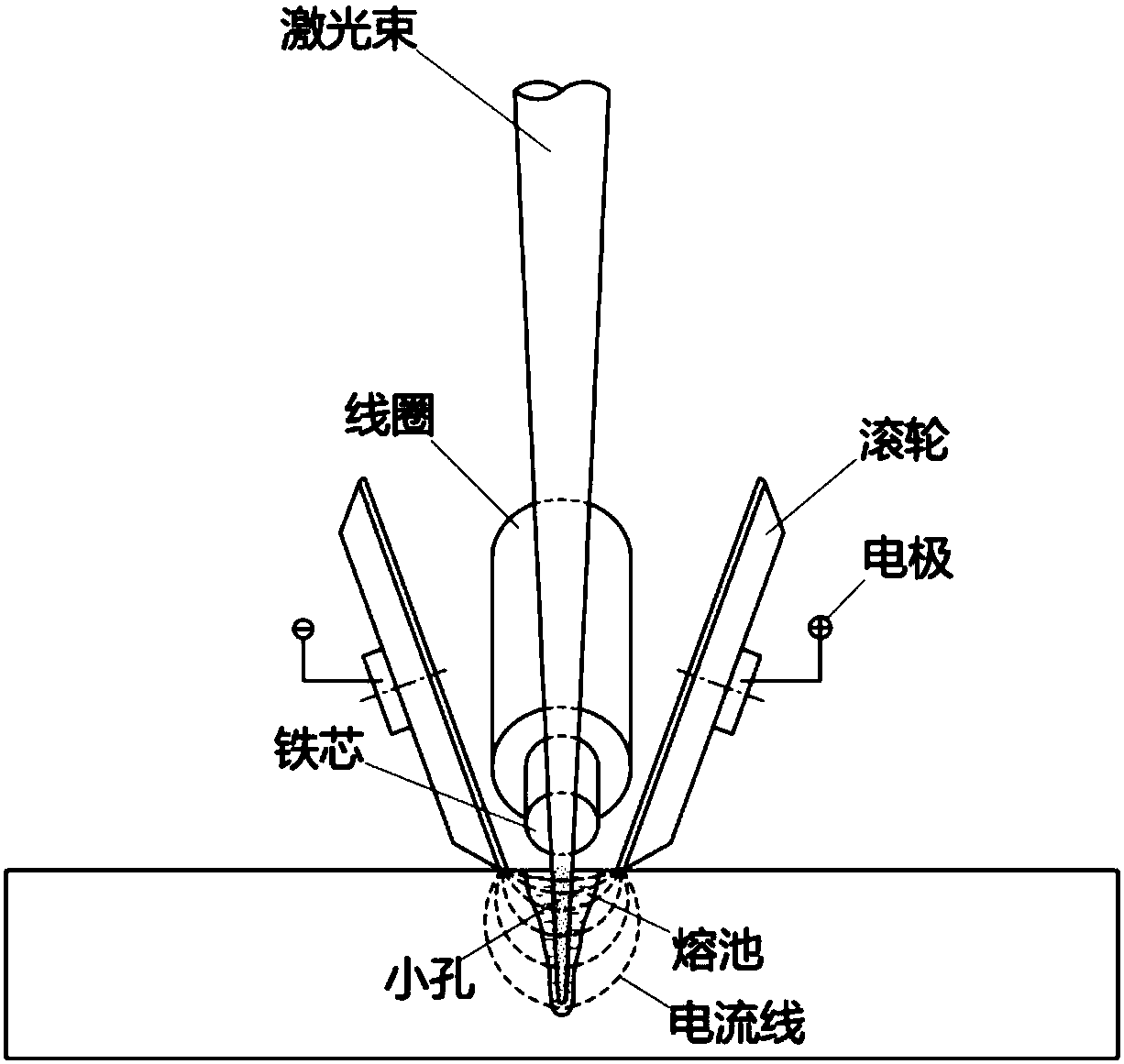

Lorentz-force-based laser welding pool control method

ActiveCN108247226AAffecting the physical laws of interactionImprove controllabilityLaser beam welding apparatusEngineeringStressed state

The invention provides a Lorentz-force-based laser welding pool control method and belongs to the technical field of laser processing. According to the method, current and a magnetic field which are perpendicular to each other are applied to a laser welding pool to generate Lorentz force following the ampere left-hand law in the welding pool; the stress state, the flow behavior and the solidification process of a melt are actively controlled through the Lorentz force. The backward Lorentz force is applied to the welding pool to make a welded tiny hole be deepened and stretched, so that metal vapor / plume in the tiny hole escape smoothly. A solution in the welding pool flows smoothly. The effects of increasing the weld penetration depth increase, improving the welding stability and optimizing welding formation are achieved. If AC or pulse wave modulation is conducted on parameters of the applied current and the applied magnetic field, the Lorentz force can have the effects of stirring, vibrating and directionally driving the solution in the welding pool. The adjustment functions of the weld microstructure and performance can be achieved while the welding defects such as pores, cracks, undercut and poor formation are controlled.

Owner:BEIJING UNIV OF TECH

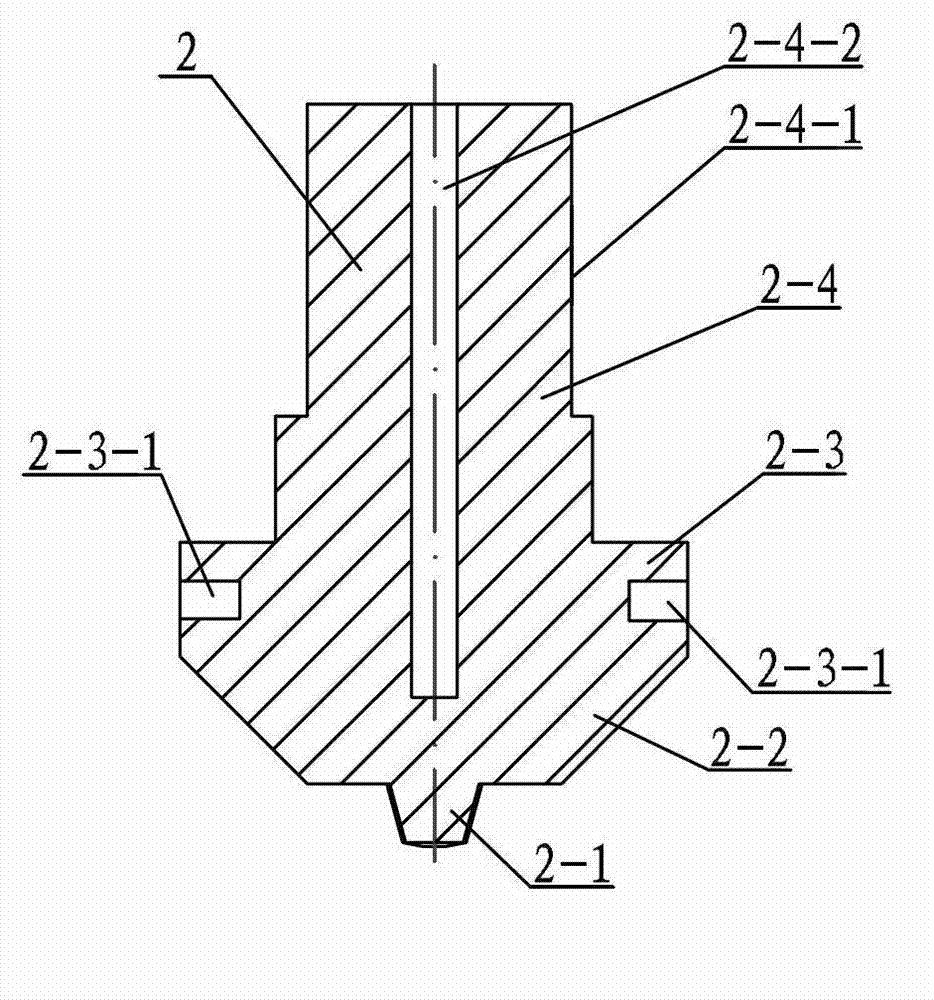

Welding tool and method for electromagnetic plastic friction stir welding

InactiveCN103028838AReduce distortionImprove plasticityNon-electric welding apparatusEngineeringFriction stir welding

The invention discloses a welding tool and method for electromagnetic plastic friction stir welding, which relates to the welding tool and method for friction stir welding and solves the problems of residual stress, hole defect and poorer welding performance in an existing friction stir welding head. The welding tool is characterized in that 2-8 bar magnets are respectively arranged in 2-8 bar magnet grooves, and gaps are arranged between a connecting body and a clamping hole. The method comprises the following steps of 1, packaging insulation paper on the connecting body, arranging the connecting body in the clamping hole, arranging a strong magnet in a strong magnet groove, and arranging the bar magnets in the bar magnet grooves; 2, respectively adhering one conducting plate at the end surface positions at two ends of an abutting part of a to-be-welded workpiece, and respectively connecting an anode and a cathode of an additional power supply to the conducting plates which are arranged at the two ends; 3, enabling the current size to meet the requirement that the density of the current passing the workpiece to be larger than a critical value (106A / m<2>) of electroplasticity, and controlling the resistance thermal power of the workpiece to be under 100W; and 4, carrying out the electromagnetic plastic friction stir welding. The welding tool and the method, disclosed by the invention, are used for the friction stir welding of aluminum alloy, magnesium alloy, copper alloy and dissimilar materials.

Owner:HARBIN INST OF TECH

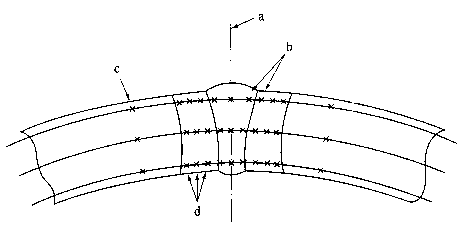

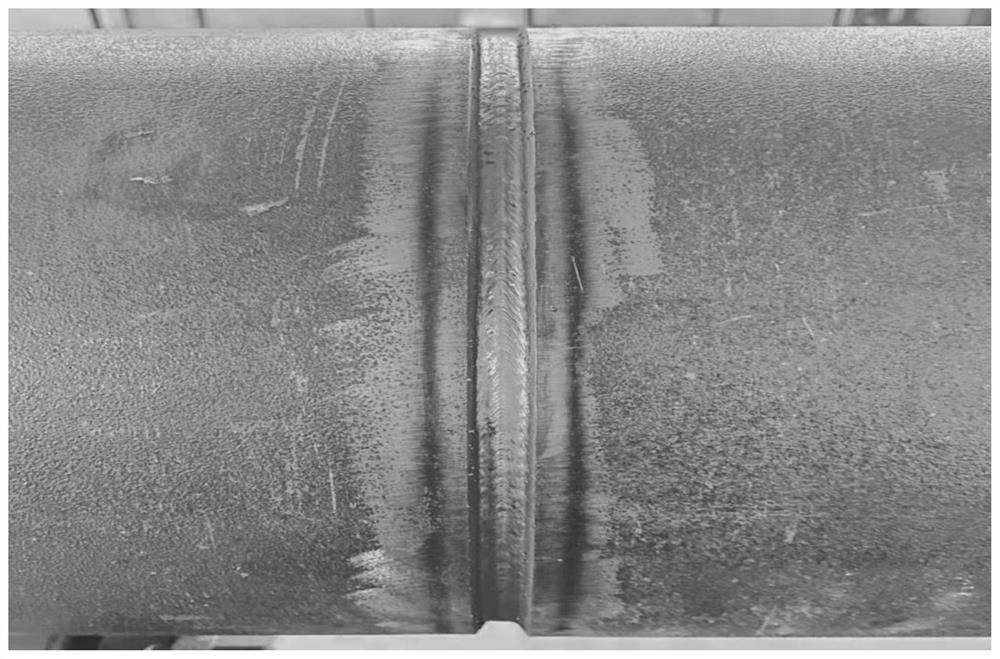

Spiral seam submerged-arc welded pipe butt joint process

ActiveCN103008999ASimple designIncrease automatic submerged arc weldingArc welding apparatusSlag (welding)Butt joint

The invention discloses a spiral seam submerged-arc welded pipe butt joint process and relates to the technical field of a spiral seam submerged-arc welded pipe. The process comprises the processing procedures of pipe end rounding, pipe end chamfering, steel pipe butt joint, prewelding, inner welding, outer welding, repair welding and circular seam nondestructive inspection. Compared with the traditional manual welding single-side welding double-sided forming process, the spiral seam submerged-arc welded pipe butt joint process has the advantages that the problems of welding quality stability influence and the like caused by great probability generation of defects such as air holes, slag clamping and cracks in the welding seam of the manual welding are solved, the butt joint quality and the efficiency of a steel pipe are greatly improved, the material consumption and the production cost can be greatly reduced, the field construction operation is convenient, and the batch production capability for producing butt joint pipes meeting API5L and relevant standard requirements is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

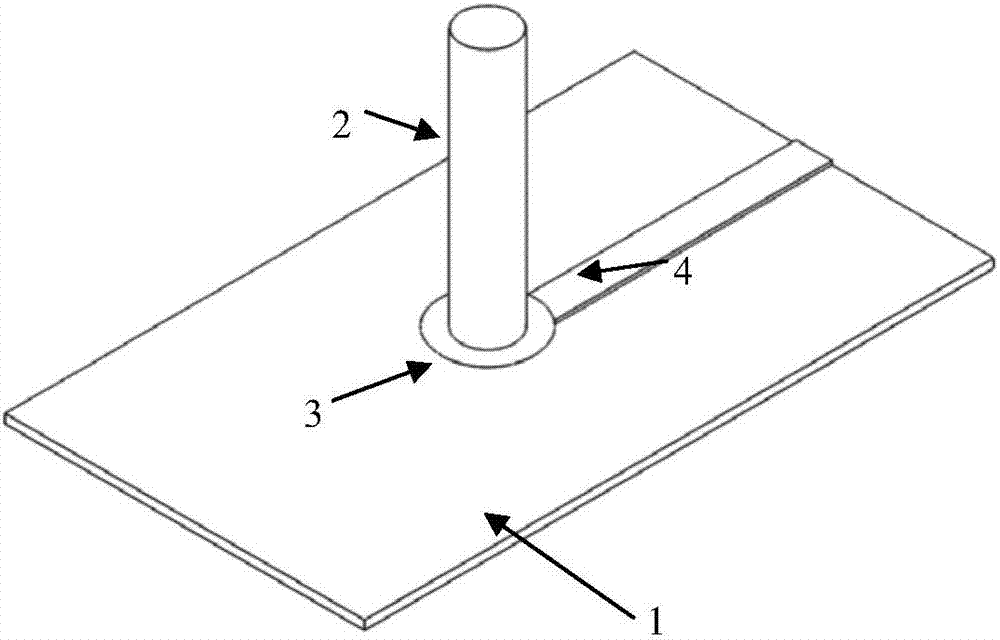

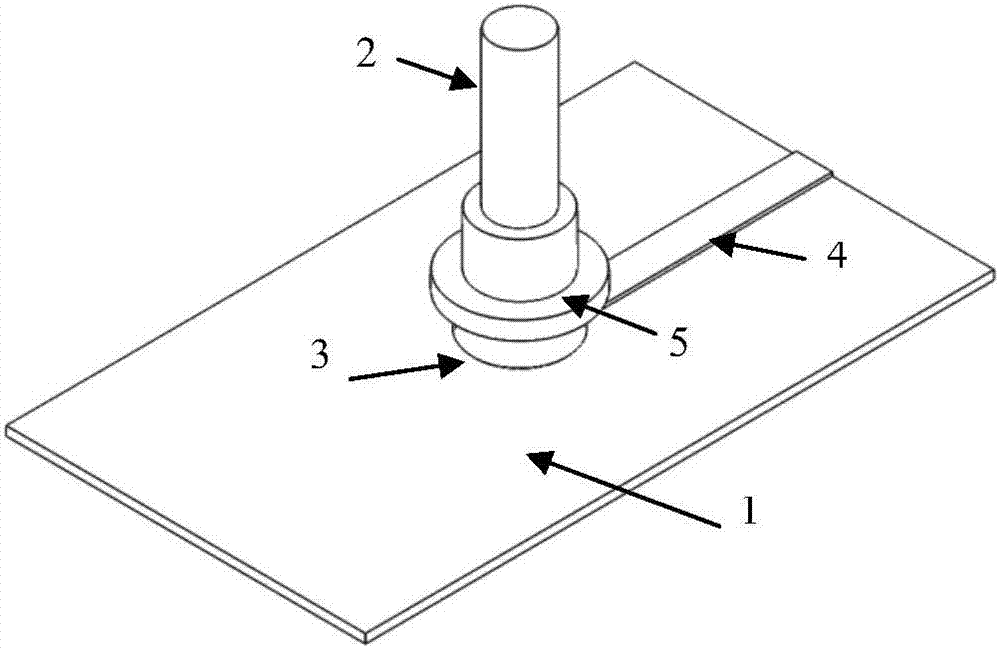

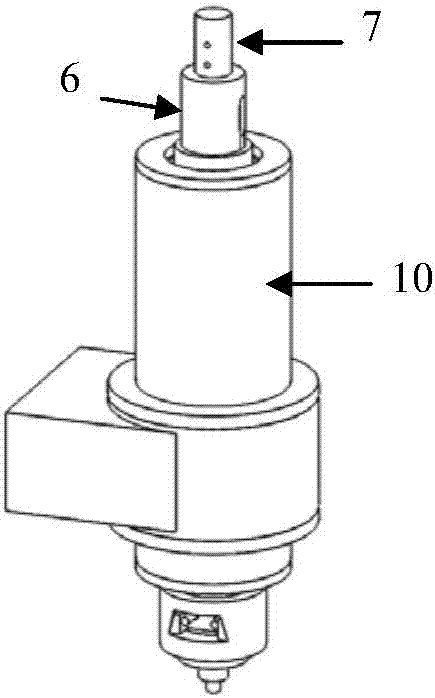

Spindle system for realizing friction surfacing with shaft shoulder

ActiveCN107052560AGeneration of restrictionsIncrease profitNon-electric welding apparatusSurface layerSelf locking

The invention discloses a spindle system for realizing friction surfacing with a shaft shoulder. The spindle system comprises a round bar consumable, a cylindrical shell, a hollow spindle, a shaft sleeve, a self-locking clamping mechanism and a rigid shaft sleeve, wherein the hollow spindle is coaxial with the cylindrical shell and is arranged in the cylindrical shell, and the shaft sleeve slides up and down along an inner hole of the hollow spindle; and the self-locking clamping mechanism is fixed to the lower end of the hollow spindle. The upper end of the round bar consumable is fixed to the shaft sleeve, and the lower end of the round bar consumable contacts with the surface of a workpiece through the self-locking clamping mechanism and the rigid shaft sleeve. When the hollow spindle rotates at high speed, the round bar consumable and the rigid shaft sleeve are driven by the shaft sleeve and the self-locking clamping mechanism at the lower end to rotate at high speed, and the shaft sleeve moves down along the hollow spindle at the same time, so that the round bar consumable rotates at high speed while can move down along the axial direction. The rigid shaft sleeve plays a role of friction and extrusion without consuming the shaft shoulder, and therefore the friction surfacing process with the shaft shoulder is realized. The spindle system can improve the use ratio of the round bar consumable and effectively eliminates the weak connection defect of the edge of a traditional friction surfacing layer, and thereby obtaining the friction surfacing layer with a good mechanical property.

Owner:TIANJIN UNIV

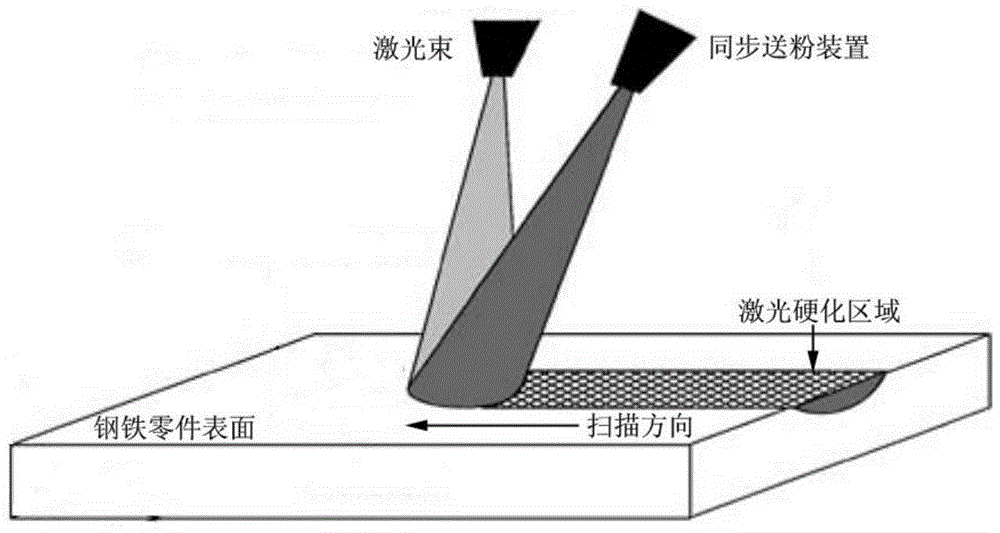

Manufacturing method of strengthened valve tappet

ActiveCN104862694AImprove surface strengthImprove surface wear resistanceMetallic material coating processesLaser quenchingHardness

The invention provides a manufacturing method of a strengthened valve tappet. The method comprises the following steps that the bottom face of the valve tappet is cleaned, and phosphating is carried out on the cleaned bottom face of the valve tappet; laser heat treatment is carried out on the phosphated bottom face of the valve tappet to obtain the strengthened valve tappet; and the laser heat treatment is laser quenching treatment or laser remelting treatment or laser fusion covering treatment. The laser surface modification technology that is the laser quenching method or the laser remelting method or the laser fusion covering method is adopted to strengthen the bottom working face of the valve tappet, and parameter adjustment in the laser surface modification technology is adjusted, so that the hardness and the wear resistance of the treated valve tappet are greatly improved.

Owner:WEICHAI POWER CO LTD

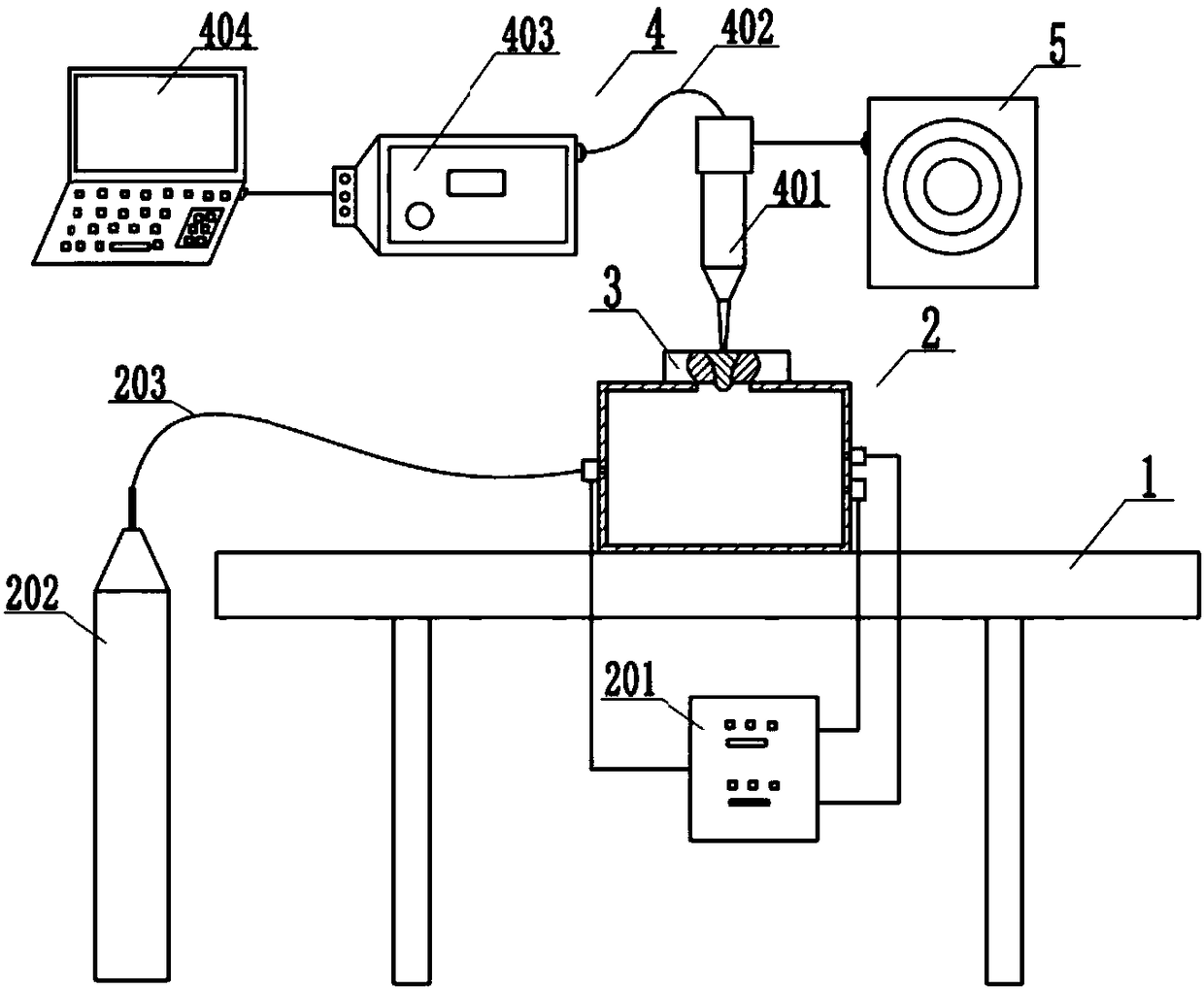

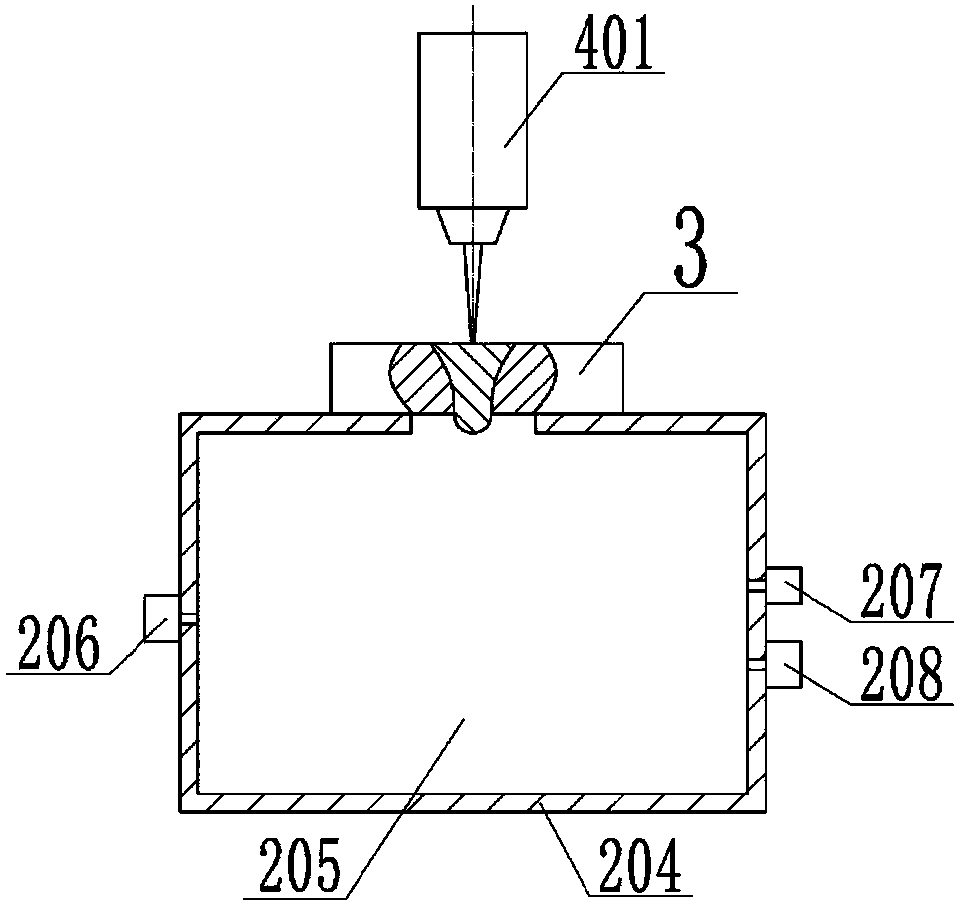

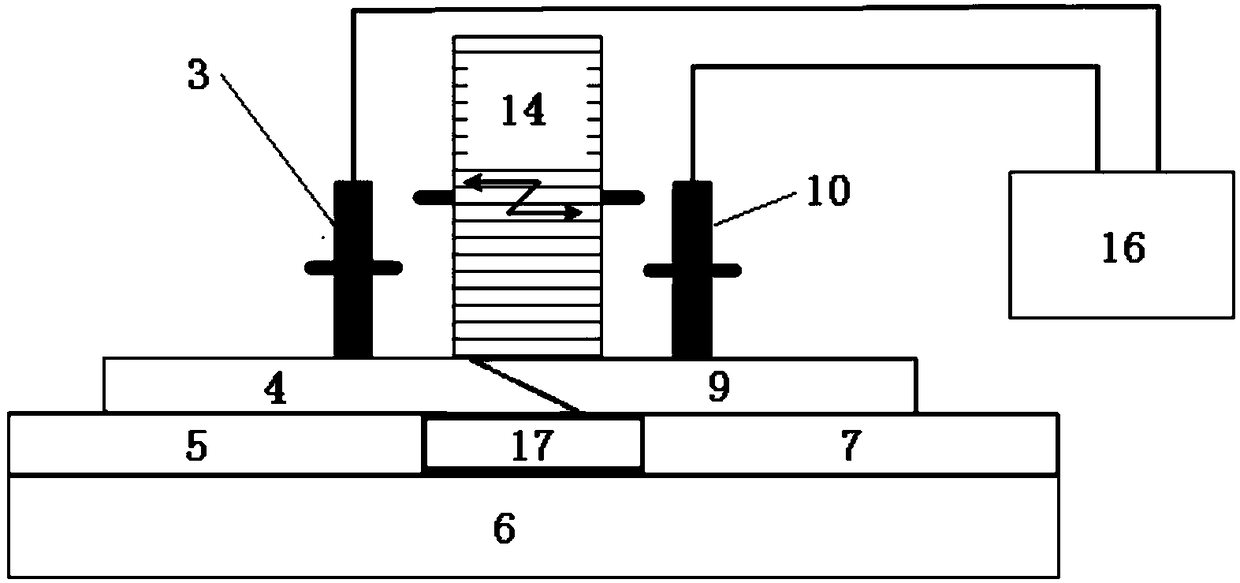

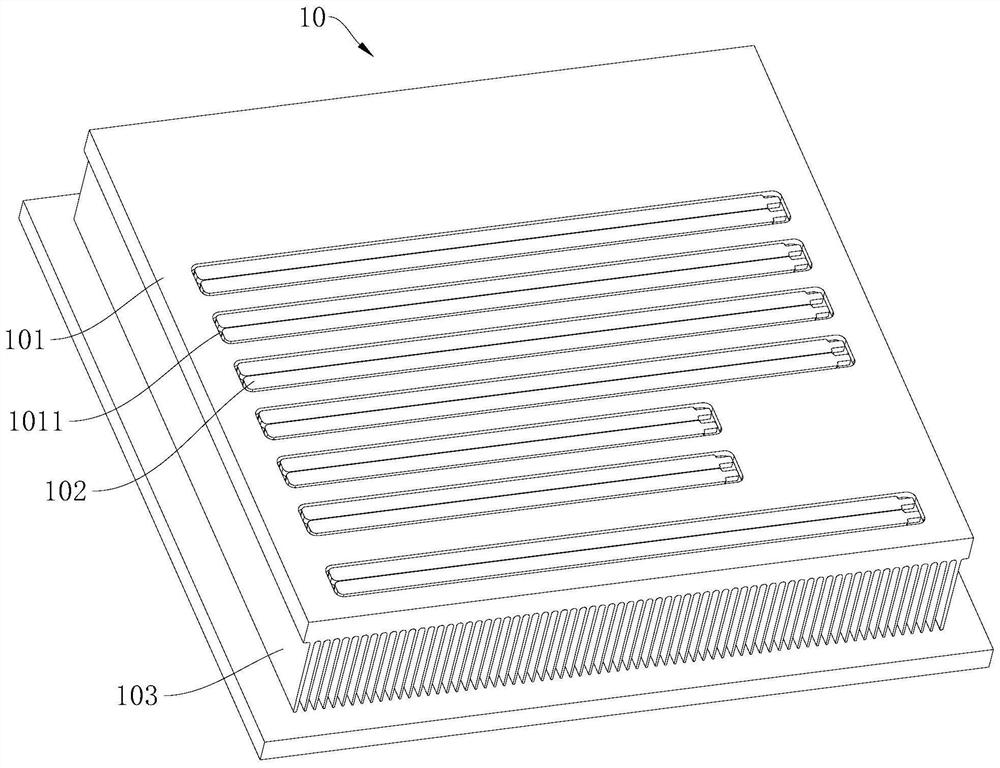

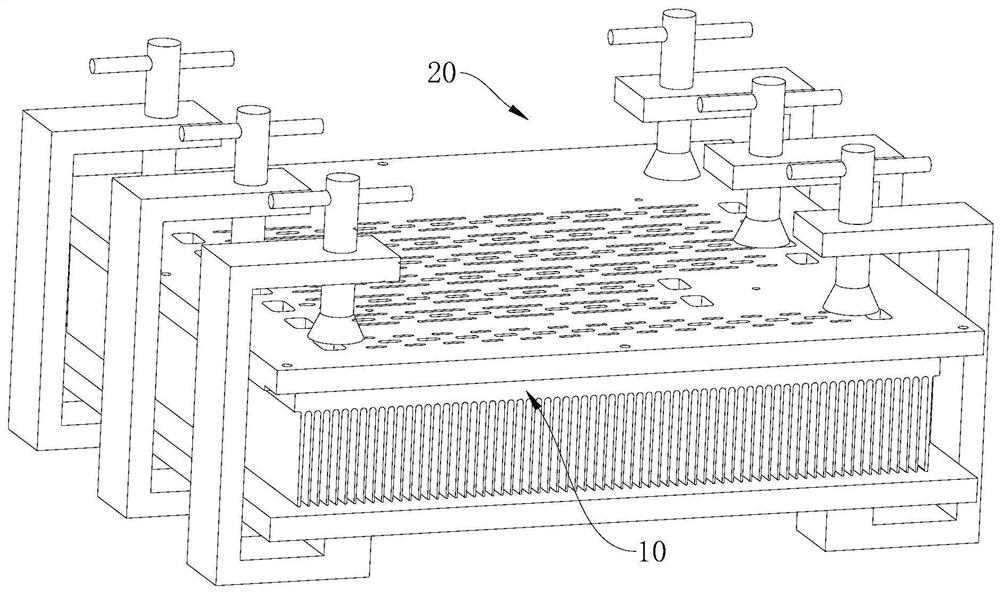

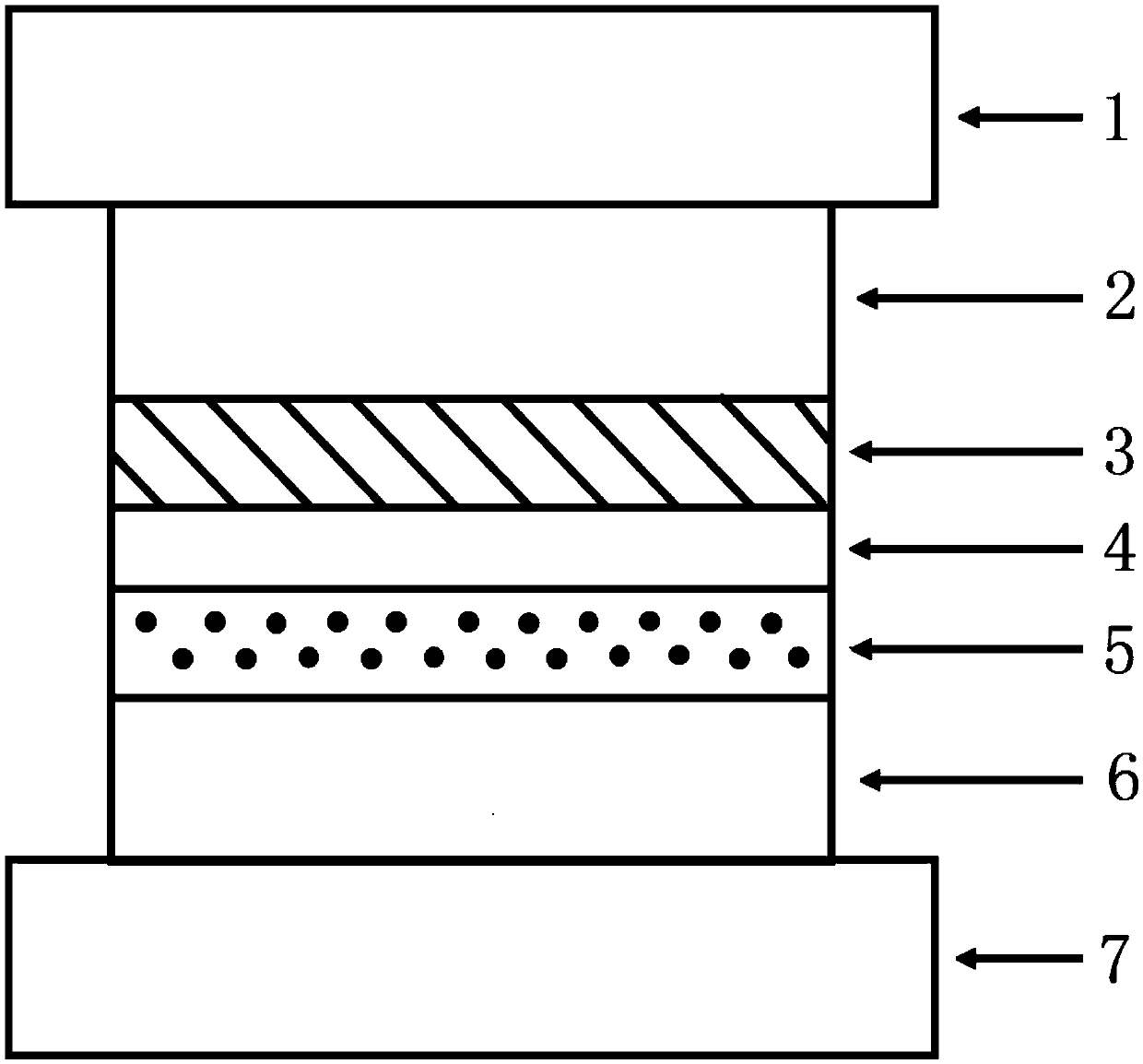

Gas buoyancy auxiliary welding device and welding method utilizing same

ActiveCN108406145AIncrease weldable thicknessEliminate Welding DefectsLaser beam welding apparatusSolenoid valveEngineering

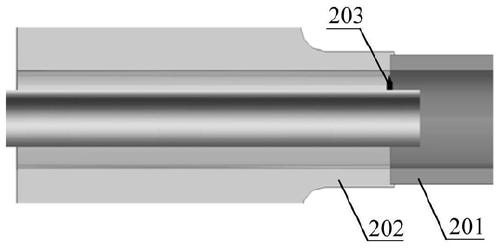

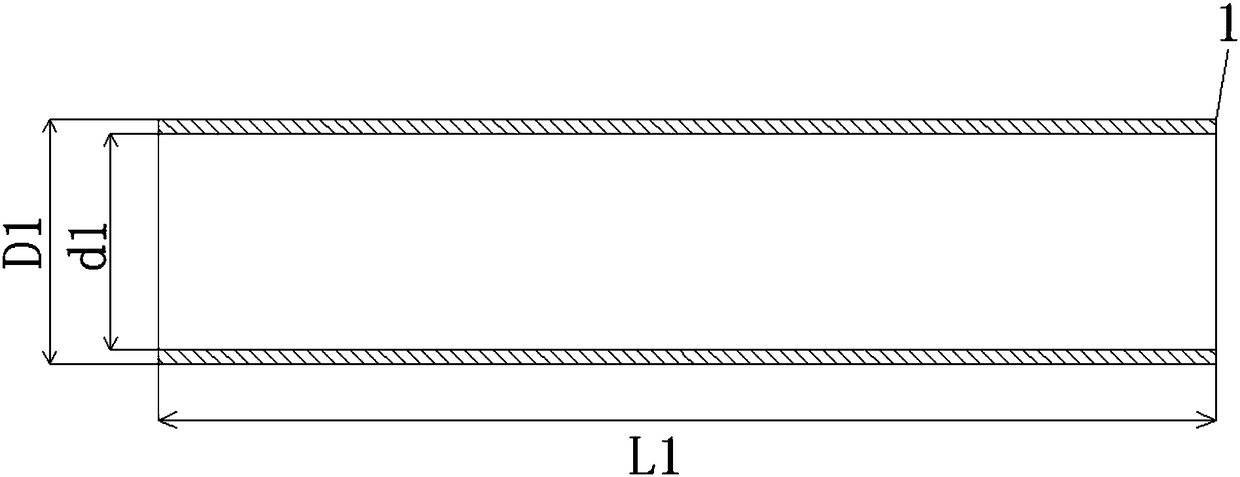

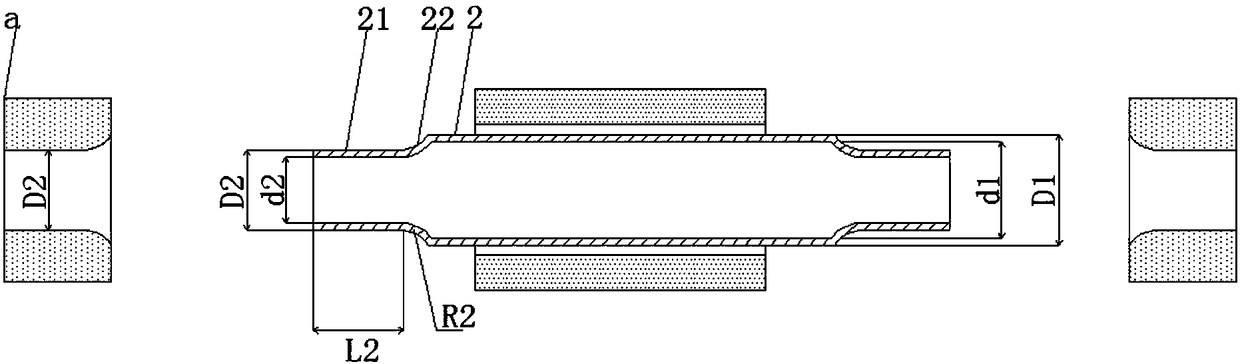

The invention provides a gas buoyancy auxiliary welding device. The gas buoyancy auxiliary welding device comprises a welding platform (1) and a gas pressure supporting device (2). The gas buoyancy auxiliary welding device is characterized in that in the welding process, a gas pressure controller (201) in a gas chamber (205) continuously reads the value of the gas pressure in the gas chamber through a gas pressure sensor (207), the read gas pressure value is compared with a target gas pressure value, and accordingly, the gas pressure in the gas chamber keeps stable by controlling the flow rateof a gas outlet solenoid valve (206) and a gas inlet solenoid valve (208). According to the gas buoyancy auxiliary welding device, the pressure of gas under welding seams counteracts the gravity borne by a welding pool, thus, collapse, humps and other welding defects are eliminated, the welding quality is improved, the welding thickness of a laser device is increased, and the gas buoyancy auxiliary welding device is simple in structure and easy to apply and popularize.

Owner:HUNAN UNIV

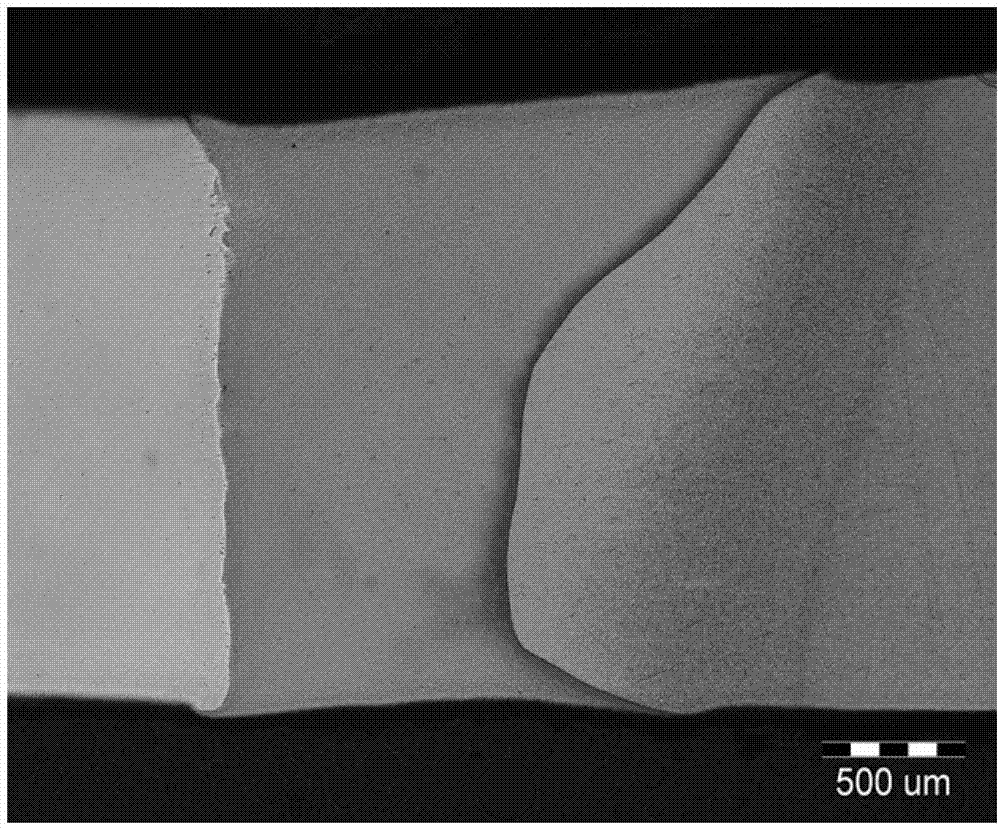

Electron beam filler wire welding method of TC4 titanium alloy and QCr0.8 copper alloy

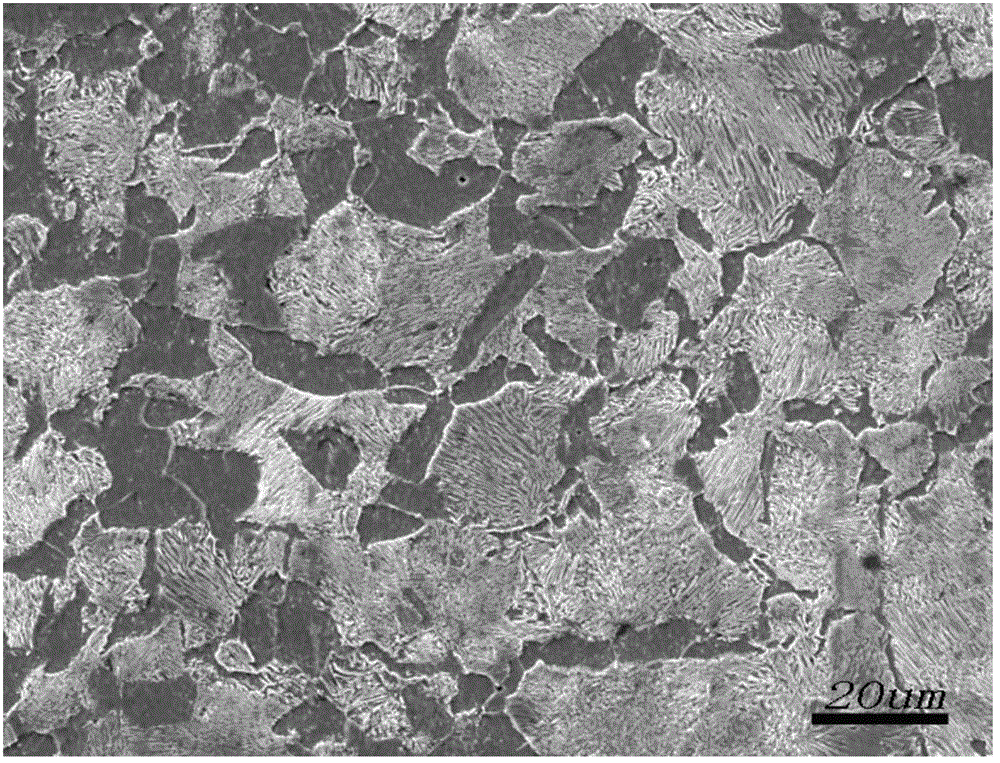

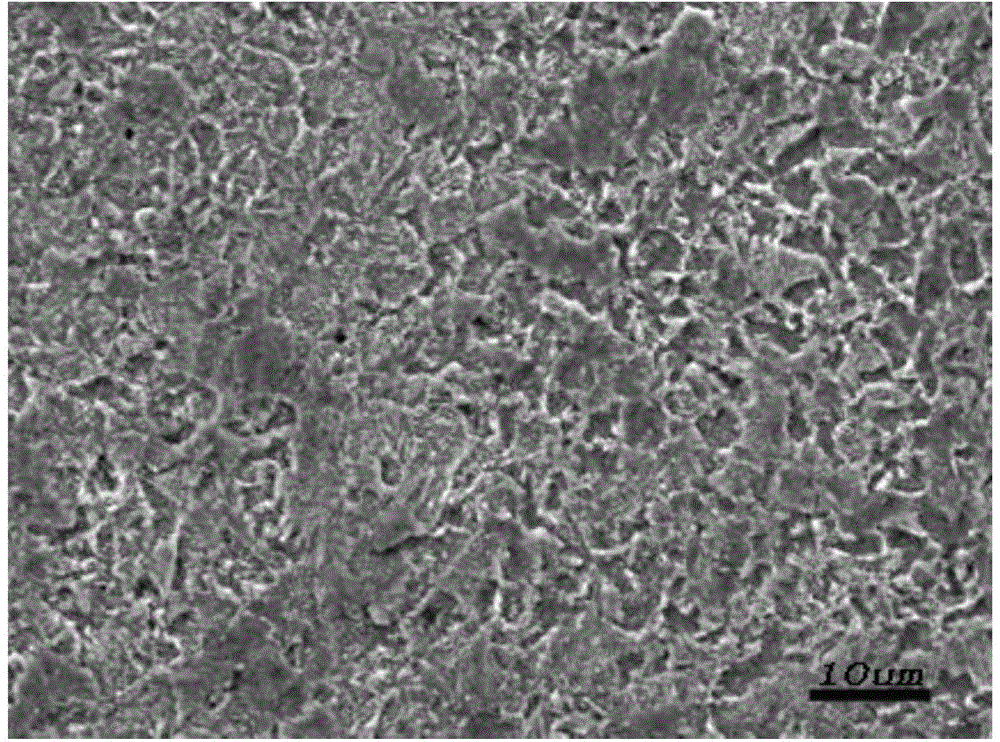

InactiveCN102785020AWell formed weldEliminate Welding DefectsElectron beam welding apparatusWelding/cutting media/materialsTitanium alloyMechanical property

The invention discloses an electron beam filler wire welding method of a TC4 titanium alloy and a QCr0.8 copper alloy, which relates to a welding method of the TC4 titanium alloy and the QCr0.8 copper alloy, to solve the problem that mechanical property requirement of a welding line cannot be met because of metallurgy incompatibility and physical performance mismatching in the prior art in which common welding process is applied between different materials of the TC4 titanium alloy and the QCr0.8 copper alloy. The welding method comprises the following steps: firstly, preparing before welding; secondly, sending a copper-vanadium alloy welding wire from a wire feeding mechanism to a lower beam spot position of an electron beam through a wire feeding nozzle; and thirdly, accomplishing welding of the TC4 titanium alloy and the QCr0.8 copper alloy under the vacuum condition. The welding line obtained by using the method disclosed by the invention is smooth, level, continuous and defect-free, and is as high as 315MPa in tensile strength; and the welding method disclosed by the invention can be applied to the field of welding engineering of different materials.

Owner:HARBIN INST OF TECH

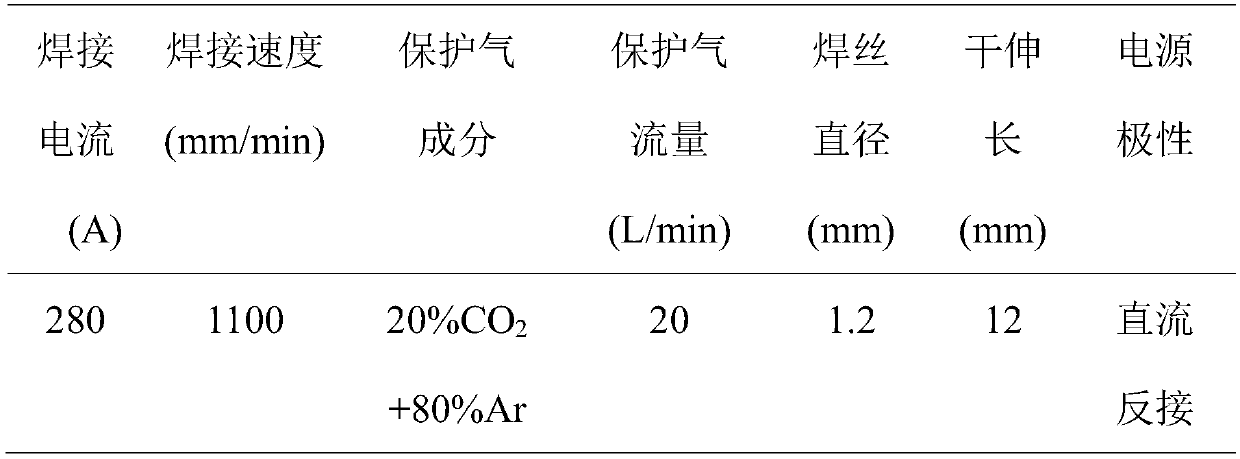

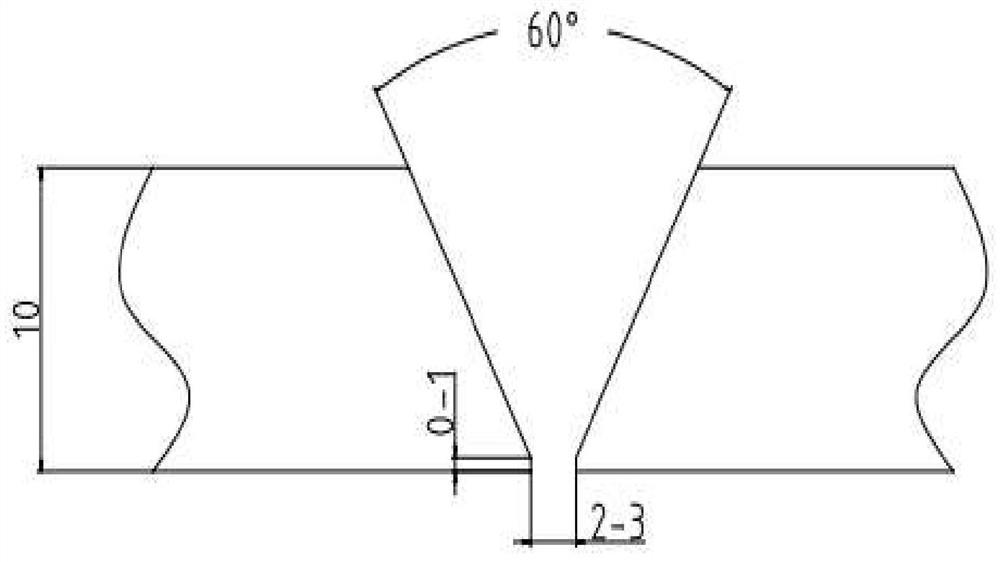

Making process of high strength steel straight seam steel tube

The invention discloses a making process of a high strength steel straight seam steel tube. The making process comprises the following steps of: (1) beveling single grooves at two longitudinal sides of a high strength steel plate; (2) bending the high strength steel plate into a preforming steel tube with longitudinal seams; (3) adjusting gaps of the longitudinal seams to make a precise-forming steel tube and carrying out spot welding connection on the longitudinal seams of the manufactured precise-forming steel tube every other distance; and (4) carrying out a welding process on the longitudinal seams of the precise-forming steel tube to make a finished product of the steel tube, wherein the welding process comprises the following steps of: a, carrying out back welding on the longitudinal seams by using CO2 gas shield welding; and b, carrying out cover surface welding on the longitudinal seams through the back welding. The making process requires fewer equipment, has simple processing procedure and high quality of the manufactured finished product tube, and can completely satisfy production requirements of a steel tube tower; and manufacturers per se of the steel tube tower can process the straight seam steel tube under the premise of low investment, thereby greatly reducing the production cost of the steel tube tower and improving the economic benefit.

Owner:潍坊长安铁塔股份有限公司

High-amorphous nanocrystalline protection tubular welding wire

ActiveCN105499826AHigh amorphous and nanocrystalline contentTroubleshoot the transitionWelding/cutting media/materialsSoldering mediaWear resistantCore component

The invention relates to a self-protection welding material, in particular to a tubular welding wire for surfacing capable for forming high amorphous nanocrystalline content, and belongs to the technical field of wear-resistant and corrosion-resistant materials. The tubular welding wire comprises the following powder core components in percentage by mass: 19-22% of Al, 17-20% of Zr, 15-18% of Ti, 9-12% of V, 6-9% of Cu, 5-8% of Ni, 4-7% of B, 2-3% of Mn, 1-2% of P, 1-1.5% of N, 4-9% of hafnium carbide, 2-5% of graphite, and the balance of rare earth nanometer additive. The self-protection powder core tubular welding wire can directly perform surfacing under the conditions of adding of no flux and protective gas; the formed surfacing layer is higher in amorphous nanocrystalline content; the amorphous and basal body transition problem is preferably solved; the bonding strength is improved; and the cladding layer is excellent in wear and corrosion resistance.

Owner:JIANGXI HENGDA HI TECH CO LTD

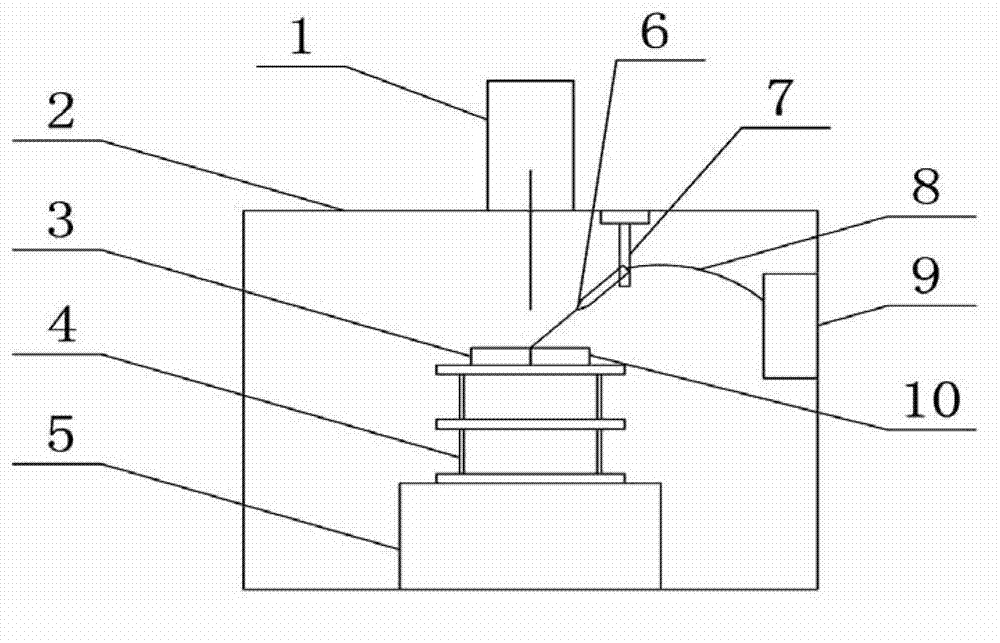

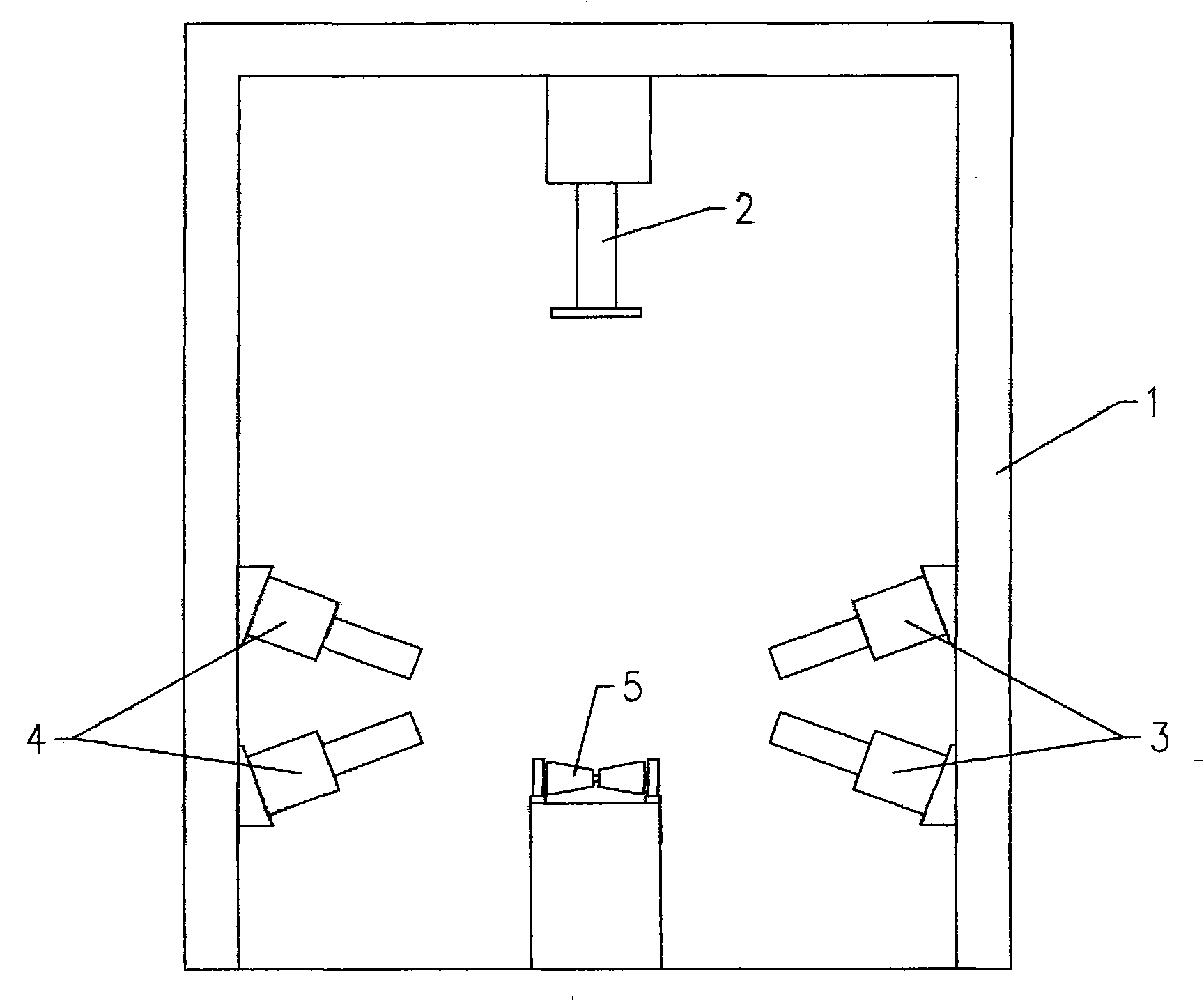

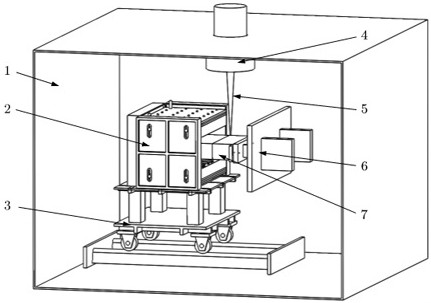

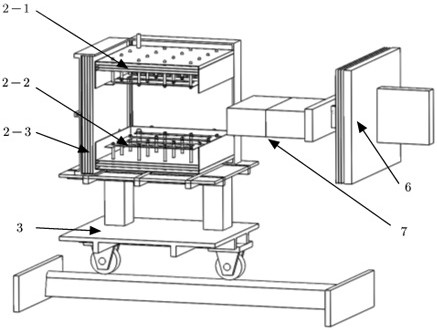

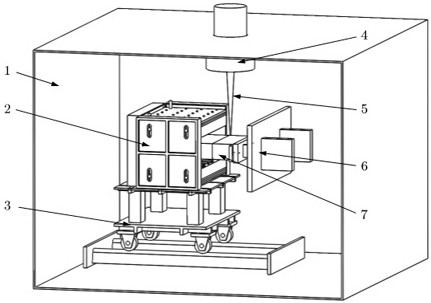

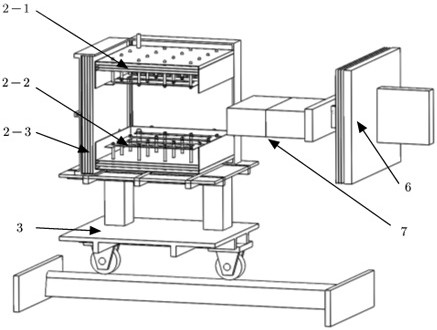

Large-thickness workpiece vacuum preheating and electron beam welding device

ActiveCN111761193AAvoid it happening againSolve the problems of large weld crack tendency and poor weld plasticity and toughnessElectron beam welding apparatusHeat-affected zoneWeld seam

The invention relates to a large-thickness workpiece vacuum preheating and electron beam welding device which comprises a vacuum chamber, a heating device, a moving platform, an electronic gun, a clamping tool and a to-be-welded workpiece. The to-be-welded workpiece is composed of two large-thickness workpieces. The heating device comprises an upper heating assembly, a lower heating assembly and three side wall heat insulation protection assemblies. In the vacuum environment, workpiece high-temperature preheating is achieved, the cooling speed is effectively reduced, generation of quenched structures in welding seams and heat affected zones is avoided, and the problems that the welding seam crack tendency of high-strength steel and high-strength titanium alloys and other products is large,and ductility and toughness of welding seams are poor are solved through a high-temperature preheating and electron beam welding method.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Welding method for tapered aluminum product

ActiveCN106624278ARealize argon arc weldingReduce welding porosityWelding/cutting auxillary devicesArc welding apparatusPower flowEngineering

The invention provides a welding method for a tapered aluminum product. The welding method includes the steps that (a), an aluminum weldment hexagon pipe is chamfered, and the six edges of the hexagon pipe are mechanically chamfered; (b), surface treatment is carried out on the hexagon pipe, and then the hexagon pipe is dried; (c), the hexagon pipe is assembled with a connector to be welded and a welding fixture, after being assembled, the hexagon pipe, the connector and the welding fixture are wholly preheated, and welding arc is used for local preheating before welding; (d), welding is carried out, aluminum silicon welding wires are adopted, according to the welding process parameters, the welding current is 120-160 A, and the flow rate of the protective gas argon is 5-15 L / min. By reasonably selecting and matching groove size design, welding wire selection, a clearing method before welding and parameters such as preheating temperature and argon flow, welding pores and micro cracks are reduced, weld penetration meets the requirement, weld joints meet the I level weld joint standard, and therefore argon arc welding of the tapered aluminum hexagon pipe and the special-shaped connector is achieved.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

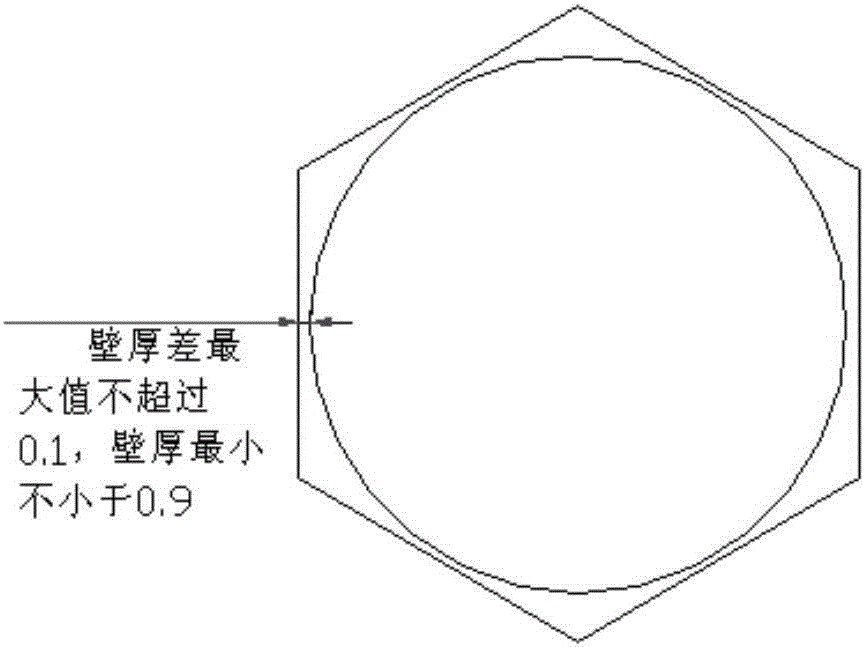

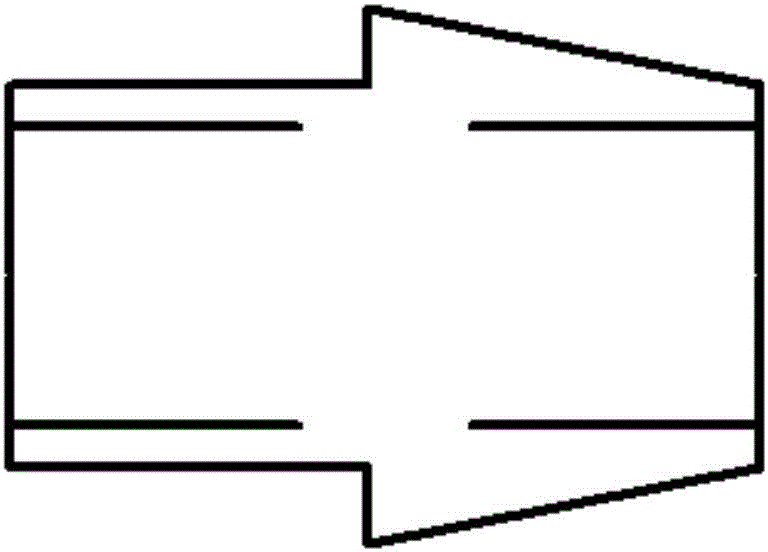

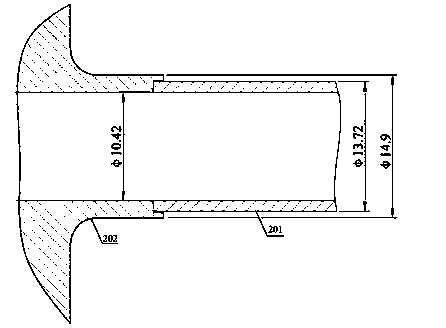

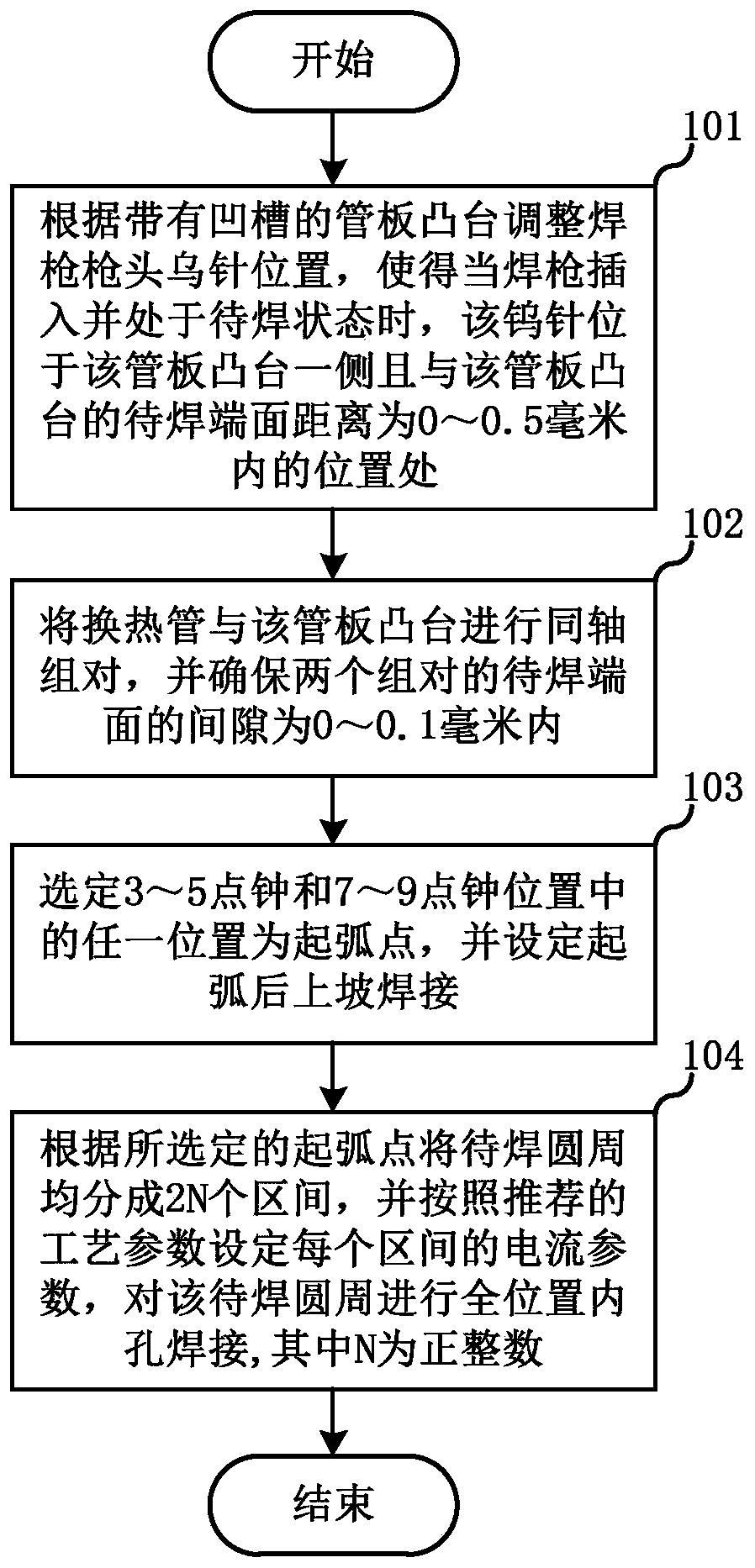

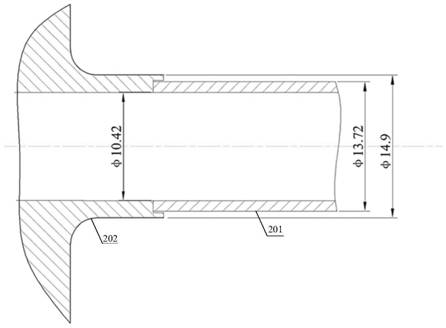

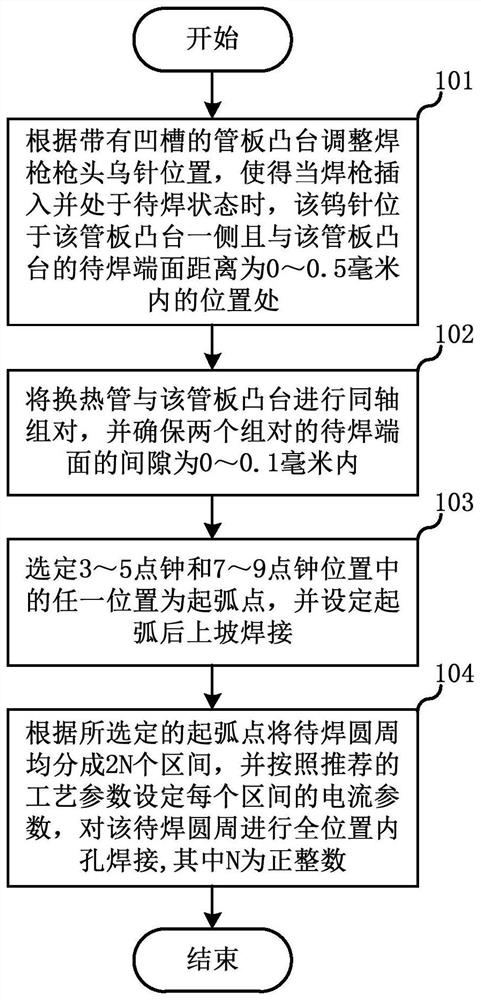

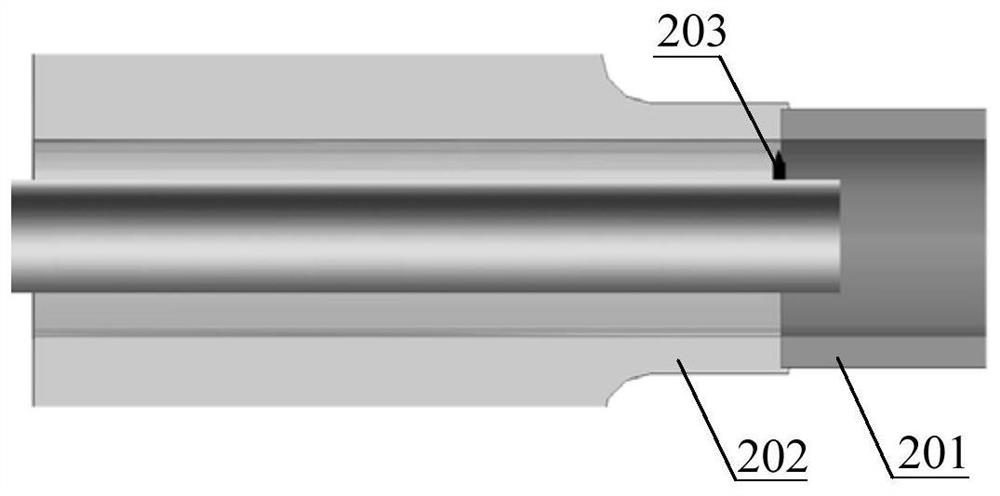

Pipe plate inner hole welding method for small-aperture heat exchange pipe

ActiveCN111037065AImprove aestheticsImprove welding qualityArc welding apparatusHeat exchange apparatusEngineeringWelding defect

The invention relates to a welding technology, discloses a pipe plate inner hole welding method for a small-aperture heat exchange pipe, and can effectively eliminate the welding defects that the outer surface of a joint is concave inwards and arc extinguishing pits are formed in the back surface of the joint. The inner hole diameter of the heat exchange pipe is 9-15 mm, and the wall thickness is1-2 mm. The method comprises the steps that the position of the tungsten pin of a welding gun head is adjusted according to a pipe plate boss with a groove so that when the welding gun is inserted andis in a to-be-welded state, the tungsten pin is located on one side of the pipe plate boss and the distance between the tungsten pin and the to-be-welded end face of the pipe plate boss is within 0-0.5 mm; the heat exchange pipe and the pipe plate boss are coaxially assembled, and it is ensured that the gap between the to-be-welded end faces of the two assemblies is within 0-0.1 mm; any one of the positions of 3-5 o'clock and 7-9 o'clock is selected as an arcing point, and uphill welding is set after arcing; and the circumference to be welded is equally divided into 2N sections according to the selected arcing points, the current of each section is set according to the recommended process parameters and all-position inner hole welding is performed on the circumference to be welded.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Automobile axle housing

PendingCN108160857AEliminate Welding DefectsEliminate Industry DefectsAxle unitsWeld seamAutomotive engineering

The invention relates to an automobile axle housing. The automobile axle housing is a hollow housing, and the upper bottom surface and the lower bottom surface of the automobile axle housing are a pair of parallel end surfaces; and an axle housing body comprises an axle housing middle part which is expanded into a round shape through a mould in the width direction and axle housing end parts whichare symmetrically distributed on the two sides of the axle housing middle part, and round through holes are formed in the upper bottom surface and the lower bottom surface of the axle housing middle part correspondingly. According to the automobile axle housing, compared with a traditional process, a long straight weld seam and a triangular plate weld seam of the axle housing can be omitted, a weld defect is avoided, and the defect of oil leakage is eliminated correspondingly, so that the integrity and the structural strength of the axle housing are greatly improved.

Owner:闫永东

High amorphous and nanocrystalline self-shielding tubular welding wire

ActiveCN105499826BHigh amorphous and nanocrystalline contentTroubleshoot the transitionWelding/cutting media/materialsSoldering mediaWear resistantShielding gas

The invention relates to a self-protection welding material, in particular to a tubular welding wire for overlay welding capable of forming high amorphous and nanocrystalline content, and belongs to the technical field of anti-wear and anti-corrosion materials. The mass percentage range of tubular welding wire powder core is as follows: Al 19‑22%, Zr 17‑20%, Ti 15‑18%, V 9‑12%, Cu 6‑9%, Ni 5‑8%, B 4‑7 %, Mn 2‑3%, P 1‑2%, N1‑1.5%, the rest is hafnium carbide 4‑9%, graphite 2‑5% and the balance of rare earth nano additives. The self-shielding powder-cored tubular welding wire of the present invention can be directly surfacing without adding any flux and shielding gas, and the surfacing layer formed has a relatively high content of amorphous and nanocrystalline, and solves the problems of amorphous and nanocrystalline The transition problem of the matrix improves the bonding strength, and the cladding layer has good anti-wear and anti-corrosion functions.

Owner:JIANGXI HENGDA HI TECH CO LTD

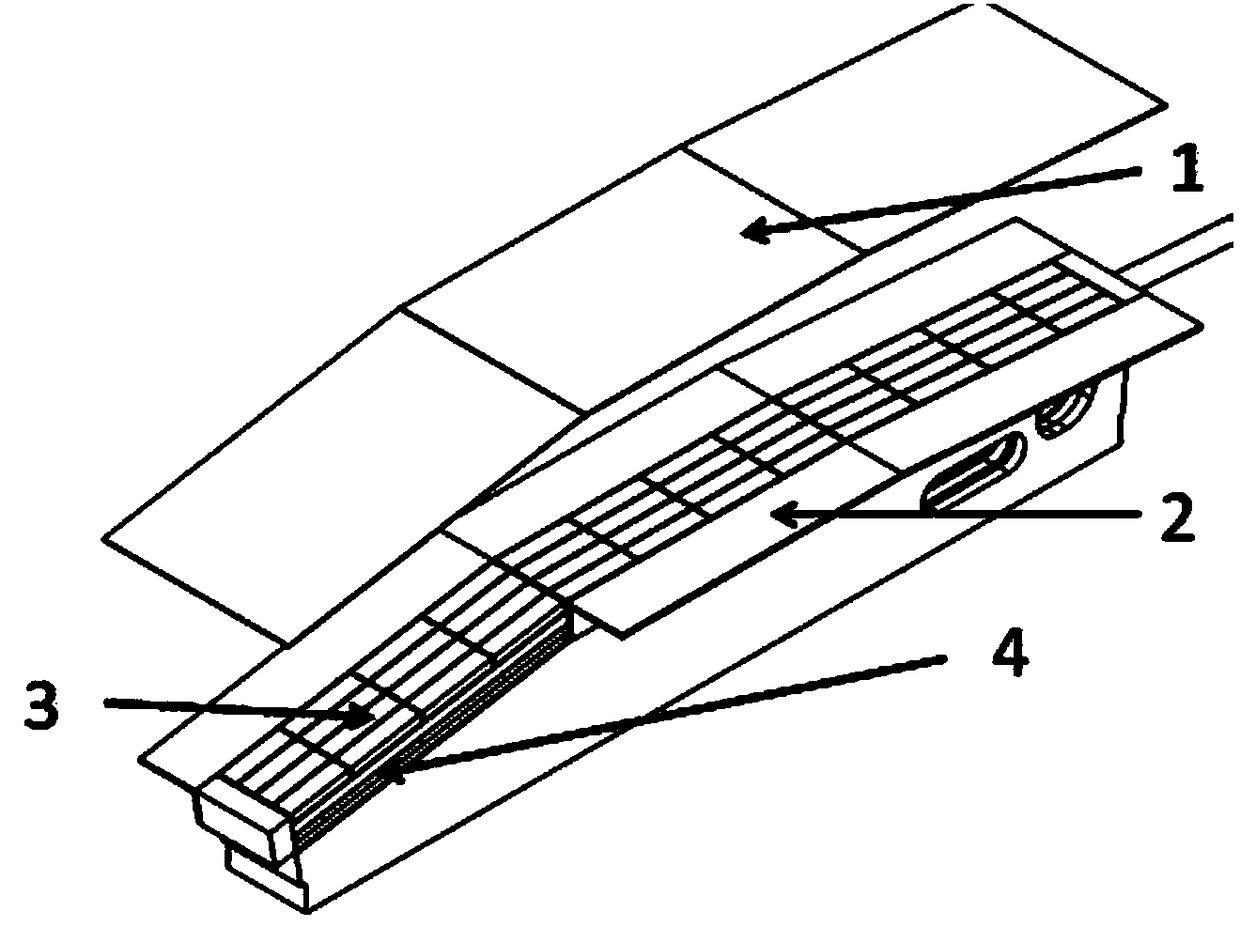

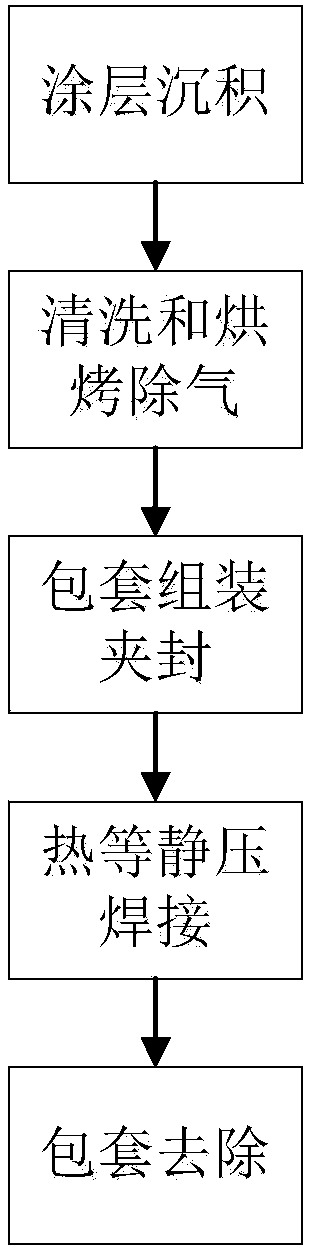

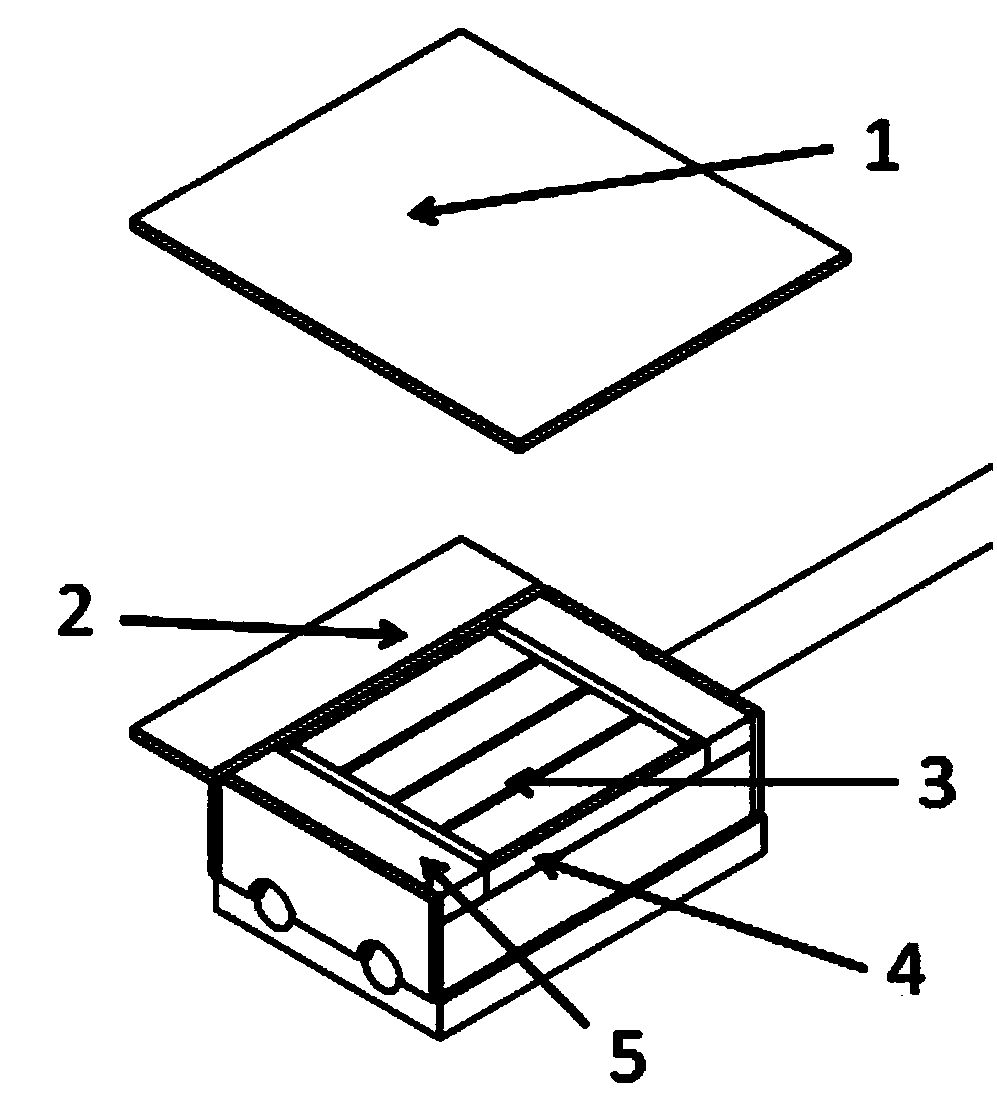

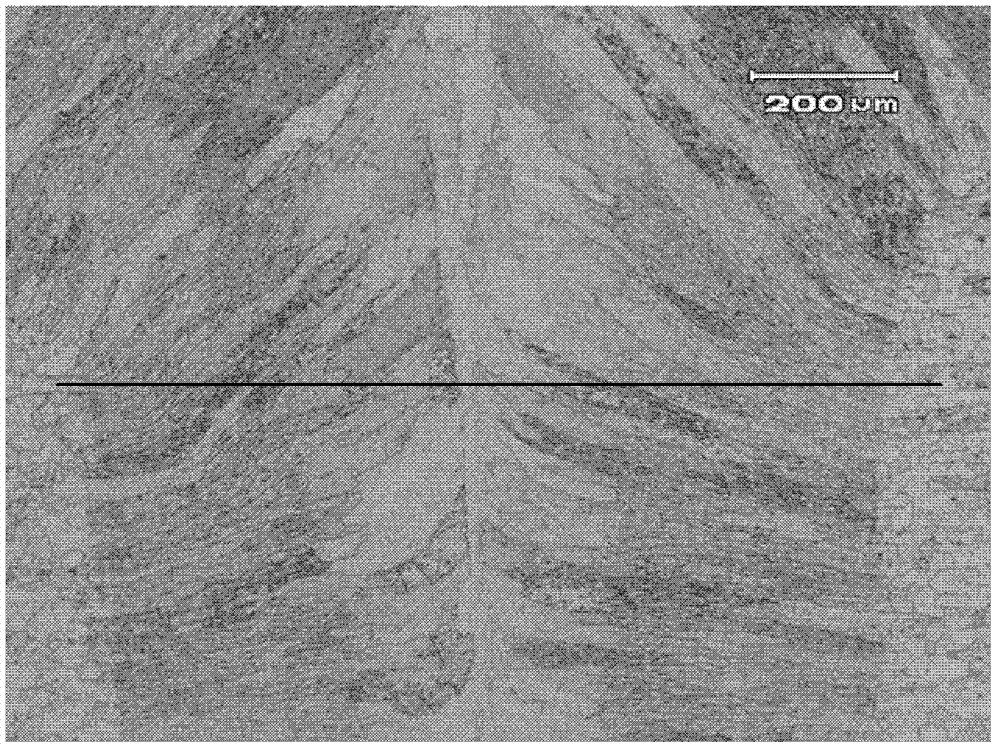

Hot isostatic pressing method for preventing adhesion between welding part and package sleeve.

InactiveCN108247191ANo adhesionEasy to separateVacuum evaporation coatingSputtering coatingCoating depositionMaterials science

The invention belongs to the technical field of hot isostatic pressing welding, and particularly relates to a hot isostatic pressing method for preventing adhesion between a welding part and a packagesleeve. The methods specifically comprise the steps that coating deposition is performed, the cleaning and baking degassing are performed, the package sleeve is subjected to packaging and sealing, the hot isostatic pressing welding is performed, and the package sleeve is removed. According to the hot isostatic pressing method for preventing the adhesion between the welding part and the package sleeve, the problems that the existing hot isostatic pressing method to prevent adhesion between the welding part and the bag sleeve is prone to causing the defect of a welding interface and the uncompleted anti-adhesion effect are solved; after the hot isostatic pressure diffusion welding, non-adhesion exists between the welding part and the package sleeve, the welding part are easily separated from the package sleeve, and the welding part is completed under the condition of maintaining good welding interface quality; and the requirement of product technical index can be met, the follow-up process is simplified, the production efficiency is improved, the batch production of the hot isostatic pressure diffusion welding can be achieved economically and environmentally.

Owner:SOUTHWESTERN INST OF PHYSICS +1

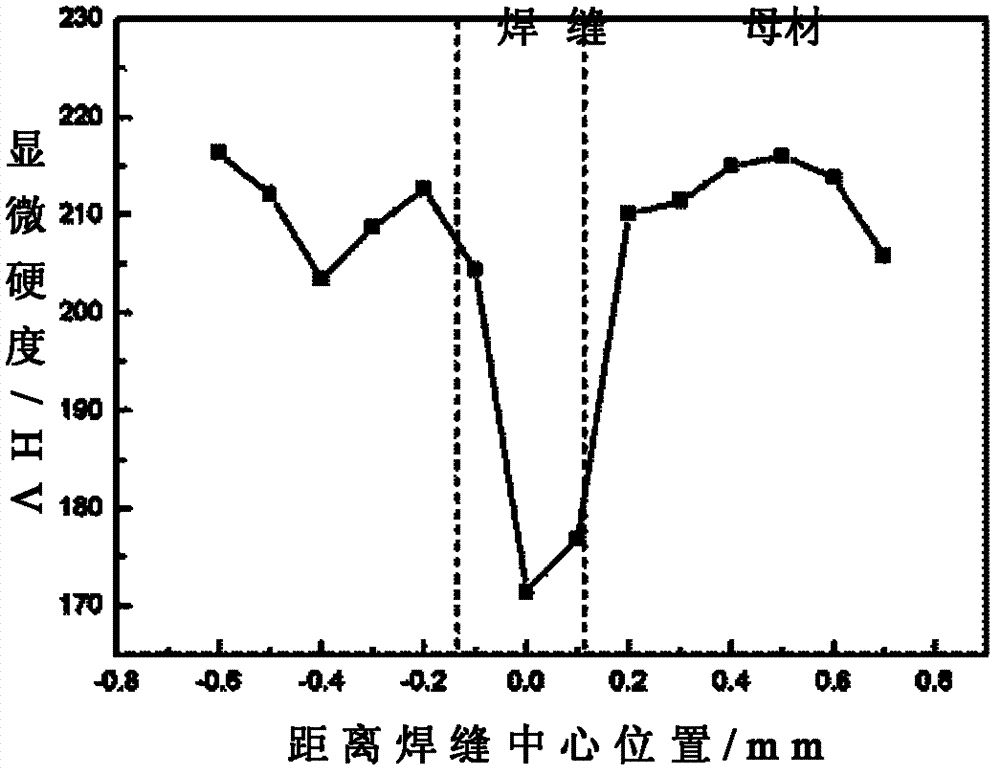

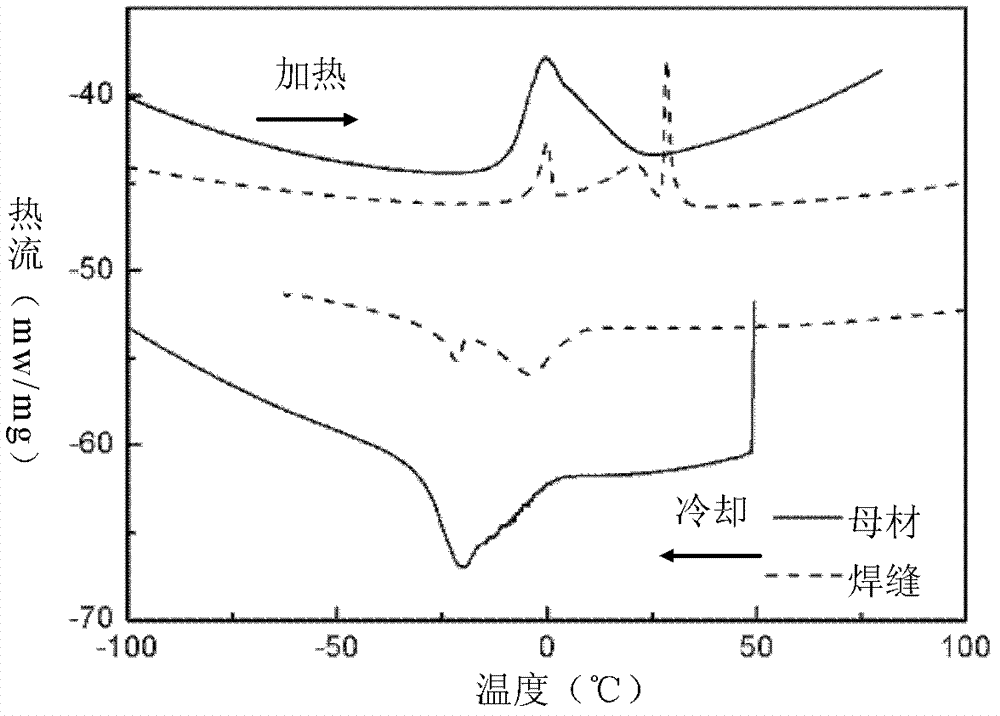

Ti-Ni based shape memory alloy vacuum electron beam connecting technology

InactiveCN103358013ASmall stretchReduced memory lossElectron beam welding apparatusHeat-affected zoneShape-memory alloy

The invention provides a Ti-Ni based shape memory alloy vacuum electron beam connecting technology. Concretely, vacuum electron beams are used for achieving connection of Ti-Ni-X alloy, wherein X can be Nb, Mo, Cu, Hf and the like. An existing connecting mode of Ti-Ni based shape memory alloy has the problems of being low in weld strength, thick and big in grain structure, prone to generating cracks and the like. The electron beams which are strong in penetrating power, high in energy transformation ratio and good in controllability are adopted as a welding hot source, therefore, time of the whole connecting process is shortened, a heat affected zone is reduced, weld defects are reduced, moreover, narrow weld seams can be obtained (the width is smaller than 1mm), mechanical performance and the memory effect of welded material are ensured to the maximum extent, after parameter optimization, the strength of a electron beam welding connector can reach over 75% that of parent material, and the memory effect can reach over 85% that of the parent material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

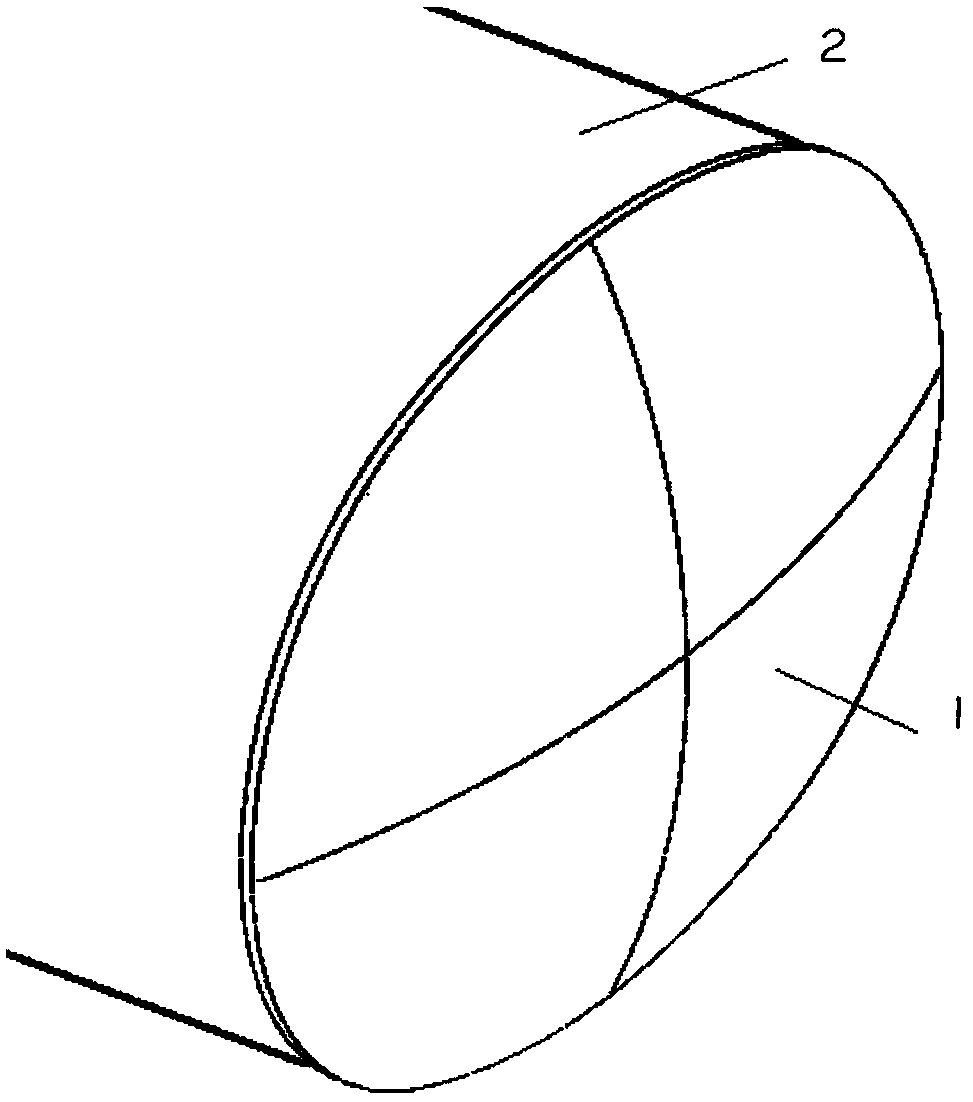

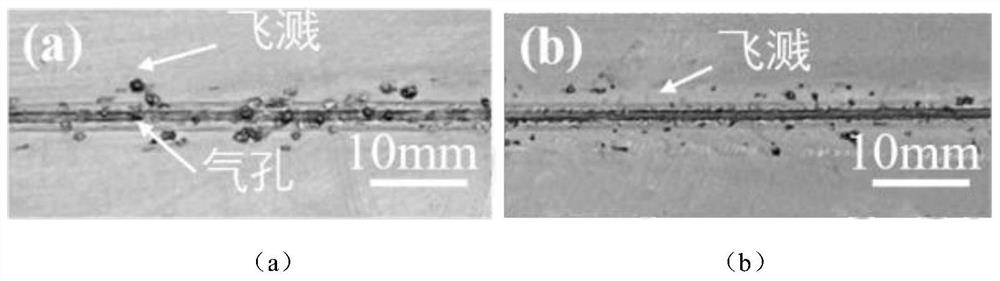

Welding technology of shell covers and cylinder body of aluminum alloy tank

InactiveCN107695557AEliminate Welding DefectsReduce the number of weldsArc welding apparatusWorkpiece edge portionsWelding defectAluminium alloy

The invention relates to a welding technology of shell covers and a cylinder body of an aluminum alloy tank. The welding positions of the shell covers and the cylinder body are polished before welding; gaps are left between the shell covers and the cylinder body in advance, and then TIG is used for welding and fixing on the outer side; finally, the shell covers and the cylinder body adopt the two-side arc-alignment TIG for welding. The welding technology eliminates the situation that when a manual TIG welding method is used for welding the circular seams between the front shell cover and the cylinder body and between the back shell cover and the cylinder body, chain-shaped air hole welding defects exist at the longitudinal center positions of welding seams, the qualified welding seams canbe obtained, and the safety of a tank assembly is ensured.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

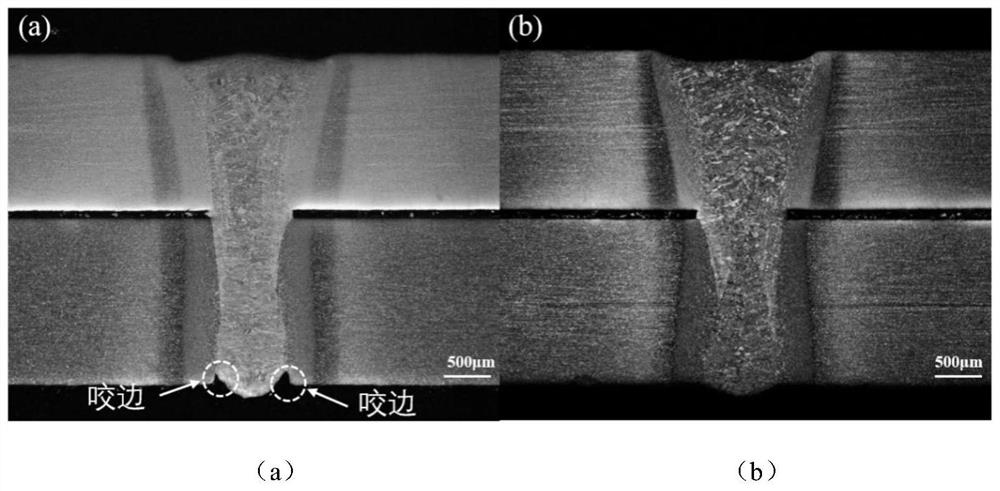

Low-carbon steel high-speed MAG welding active agent and using method thereof

ActiveCN109570710AImprove wettabilityGood spreadabilityArc welding apparatusWelding/cutting media/materialsActive agentSlurry

The invention relates to a low-carbon steel high-speed MAG welding active agent and a using method thereof. The active agent is composed of CaF2 powder particles, MgF2 powder particles, SiO2 powder particles, TiO2 powder particles, Cr2O3 powder particles and CeO2 powder particles of which the powder sizes are all smaller than 200 meshes. The active agent comprises the components of, by weight, 30-40% of CaF2, 15-20% of MgF2, 5-10% of SiO2, 25-30% of TiO2, 6-9% of Cr2O3 and 4-6% of CeO2, and all the components are uniformly and sufficiently mixed into active agent powder; the surface of a low-carbon workpiece is polished through a mechanical method till metallic luster occurs, and wiped with acetone so that greasy dirt on the surface can be removed; the prepared active agent powder is mixedwith the appropriate amount of acetone to form slurry convenient to paint, and then, the slurry is uniformly brushed on the surface of a to-be-welded weld pass of the low-carbon workpiece; and afterthe coating layer is dried, high-speed MAG welding is conducted. The weld width of a welded seam is increased, hump weld passes, welded seam undercuts and other welding defects are eliminated, and thewelded seam forming quality and the welding efficiency are improved.

Owner:NANJING INST OF TECH

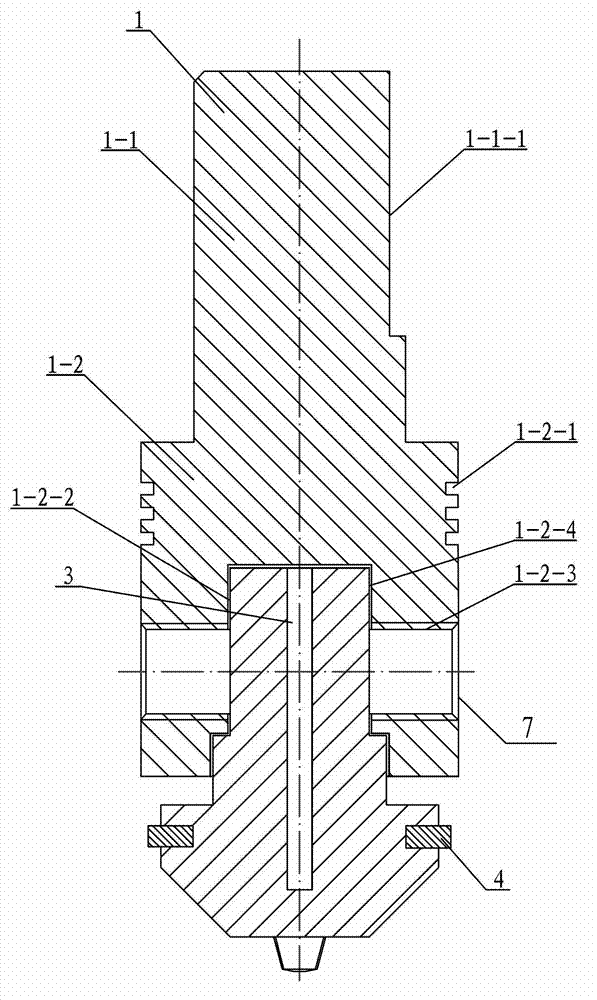

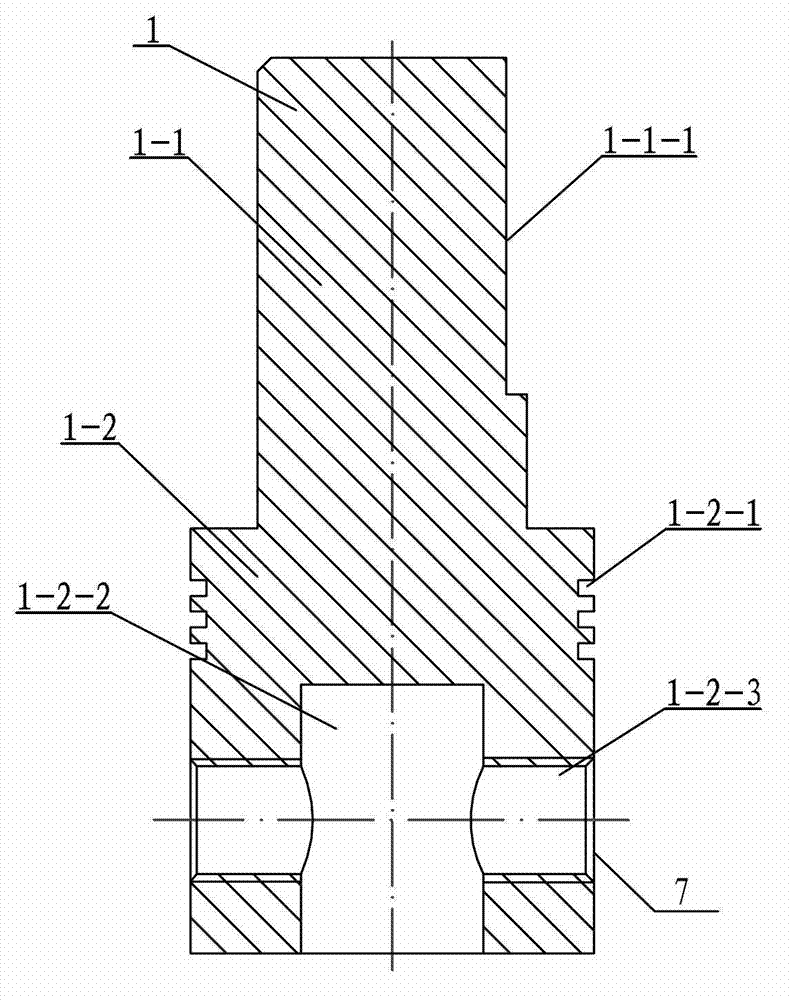

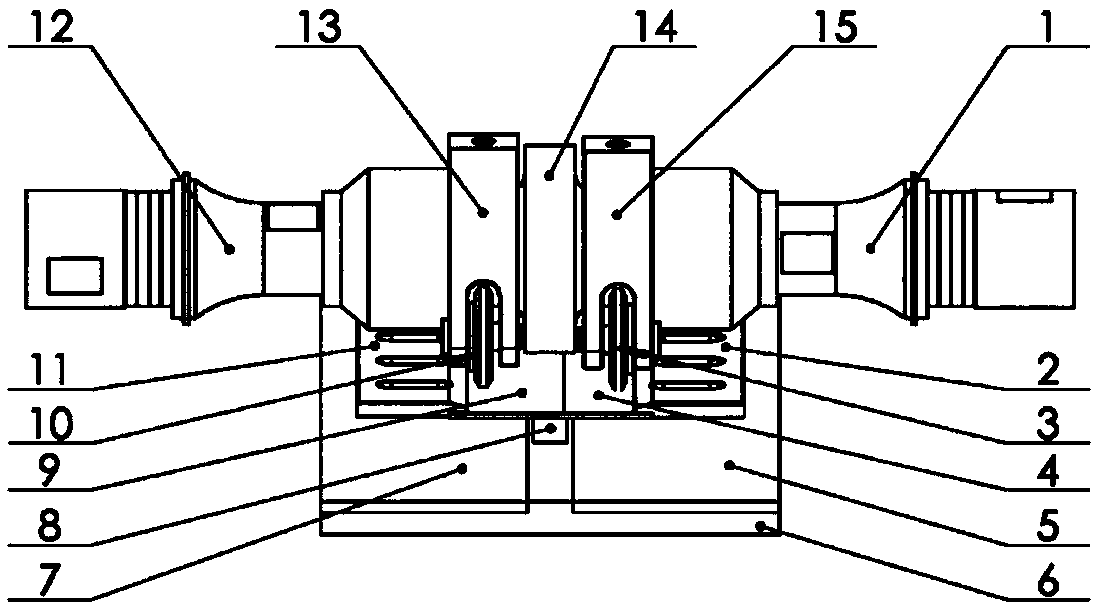

Ultrasonic roll welding and resistance internal heat composite metal seam welding device

ActiveCN109365970AAvoid softeningEliminate Welding DefectsResistance welding apparatusWelding power supplyElectrical impulse

The invention relates to an ultrasonic roll welding and resistance internal heat composite metal seam welding device. The welding device is characterized by being provided with an ultrasonic roll welding mechanism and a resistance internal heat welding mechanism, the ultrasonic roll welding mechanism is provided with an ultrasonic generator and a roll welding pressure head (14), the two sides of the roll welding pressure head (14) are correspondingly provided with a transducer (1) and a transducer (12), the resistance internal heat welding mechanism is provided with a medium frequency / high frequency resistance welding power supply used for outputting medium / high-frequency pulse currents, electric pulses output by the medium frequency / high frequency resistance welding power supply are sentto conductive rolling wheels through electrode supports, the conductive rolling wheels are in contact with a metal plate to be welded, two paths of electric pulse signals which are the same output bythe medium frequency / high frequency resistance welding power supply are sent to the two electrode supports correspondingly, the two electrode supports are correspondingly connected with the two conductive rolling wheels, and the two conductive rolling wheels are used for outputting electric signals to the contact surface of the metal plate to be welded. According to the welding device, the joint softening phenomenon caused by melting welding can be effectively avoided, the welding defects such as air holes are overcome, and a wide application prospect is realized.

Owner:HARBIN INST OF TECH AT WEIHAI

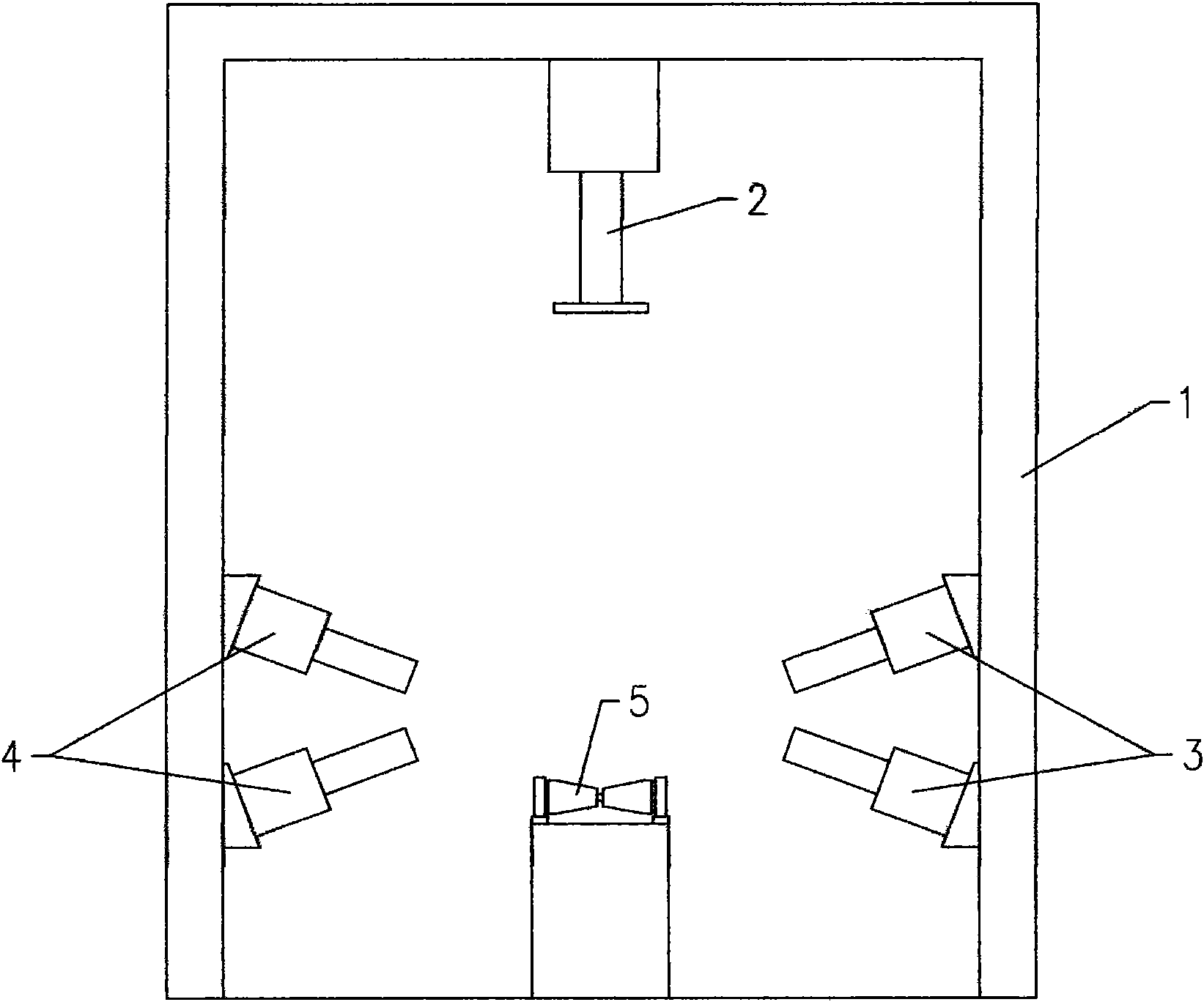

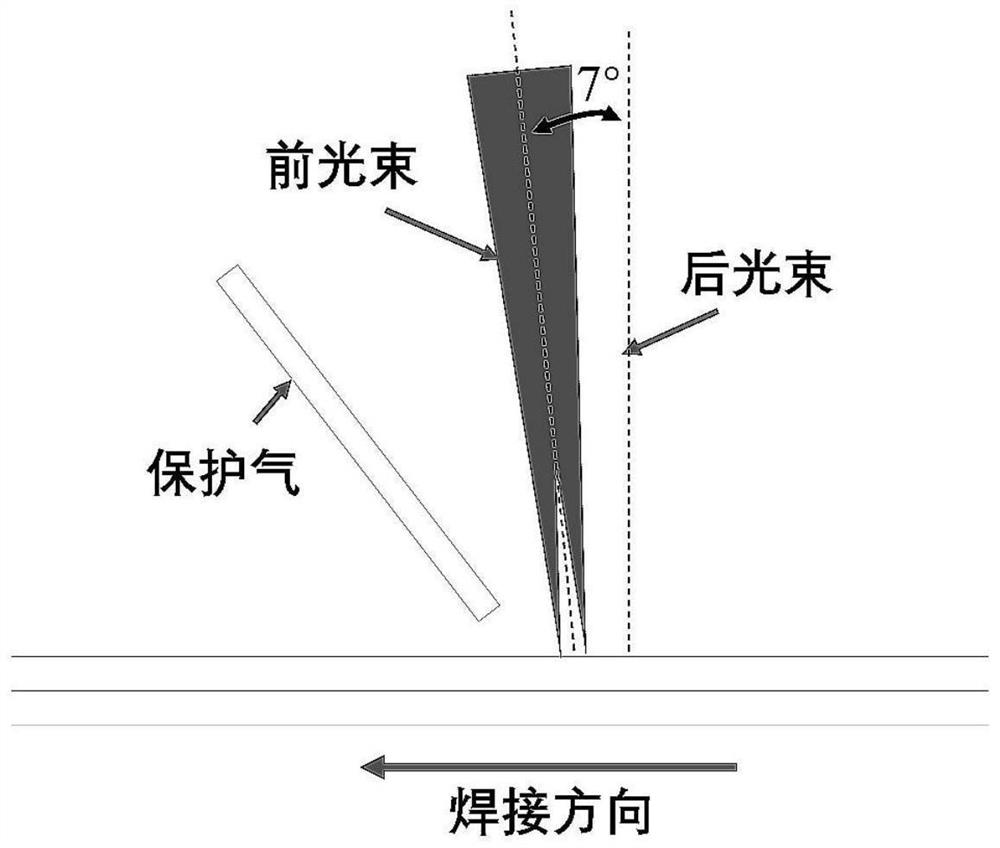

Serial double-beam high-speed laser welding method and system for galvanized double-phase steel plates and medium

ActiveCN111958109AEliminate Welding DefectsHigh joint strengthLaser beam welding apparatusLaser solderingDual beam

The invention provides a serial double-beam high-speed laser welding method and system for galvanized double-phase steel plates and a medium. The method includes the steps that a double-phase DP steelplate with Zn cladding and a double-phase DP steel plate without cladding are obtained, and the surfaces are purified; the two DP steel plates obtained after surface purification are lapped and arranged on a workbench; a double-beam laser welding working head is arranged above a to-be-welded test plate; a shielding gas side blowing device is arranged in front of the laser welding working head, ablowing port is adjusted to point to a welding pool, and a 45-degree included angle is formed between the direction of the blowing port and the laser incidence direction; and laser welding process parameters are adjusted according to the steel plate thickness combination, and laser welding of a lapping connector for the DP steel plate with the Zn cladding and the DP steel plate without the cladding is completed. It is only needed to adjust proper double-beam laser welding parameters, the influences of Zn steam in the welding process are reduced through the mutual effect of a front laser beam and the test plate, the front laser beam and a rear laser beam mutually cooperate to achieve high-speed welding, welding defects are eliminated, and the connector strength is improved.

Owner:SHANGHAI JIAO TONG UNIV

Method for removing melting solder paste gas holes on heat pipe radiator

PendingCN111975160ATissueIncrease surface areaSoldering auxillary devicesHeating furnaceSolder paste

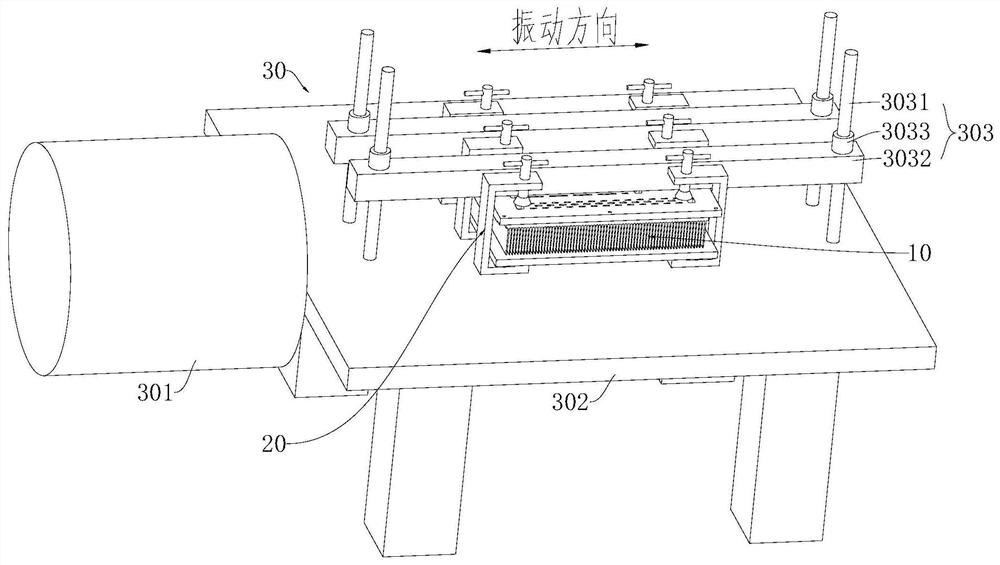

The invention discloses a method for removing melting solder paste gas holes on a heat pipe radiator. The method includes the steps that S1: at least a heat pipe and a base are provided, and a heat pipe slot is formed in the base; S2: the heat pipe and the heat pipe slot are made to be in clearance fit, solder paste is applied in a clearance between the heat pipe and the heat pipe slot, and then the heat pipe and the base are locked and fixed through a mold and placed in a heating furnace to be heated, so that the solder paste is melted; and S3: the mold and the heat pipe radiator are taken out from the heating furnace, then the mold and a heat pipe heater are placed on a vibration device and are fixed on the vibration device through a fixture, the vibration device is started to vibrate the heat pipe heater, and the molten solder paste flows and fills the gas holes quickly through vibration. The method can remove the gas holes inside a metal compound at the welding interface of the heat pipe radiator in time, improve the welding quality of the heat pipe radiator, so as to improve the heat dissipation performance of the heat pipe radiator.

Owner:广州龙辉电子科技有限公司

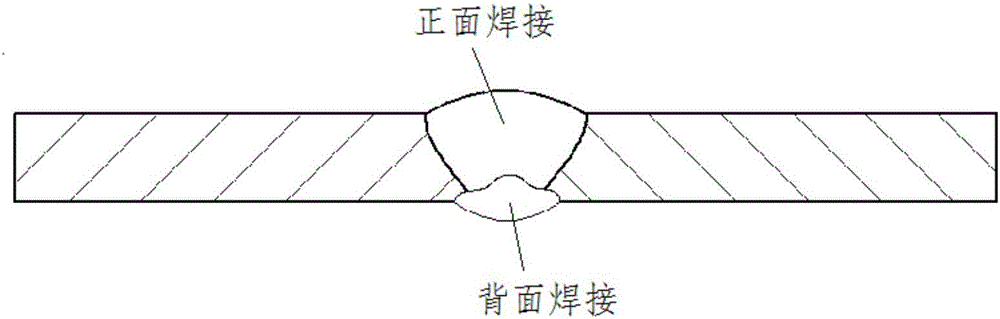

Automatic welding technique for splicing plates of cylinder body of oil tank truck

InactiveCN106670627AEliminate Welding DefectsGuarantee welding qualityArc welding apparatusDomestic vesselsTruckWelding defect

The invention discloses an automatic welding technique for splicing plates of a cylinder body of an oil tank truck and belongs to the technical field of oil tank truck machining. The automatic welding technique for the splicing plates of the cylinder body of the oil tank truck comprises the following steps that (I) obverse-side welding is conducted, specifically, cylinder body splicing plate ring bending joints are subjected to obverse-side through welding till double face forming is achieved; and (II) reverse-side welding is conducted, specifically, after the step (1) is completed, the splicing plates of the cylinder body are turned, and non-wire filling self-fusible welding is conducted on the excess weld metal of the back sides of weld joints. According to the automatic welding technique for the splicing plates of the cylinder body of the oil tank truck, the work procedure that non-wire filling self-fusible welding is conducted on the excess weld metal of the back sides of the weld joints is added, the back-side weld joints are re-melted, air holes in the excess weld metal of the back sides of the weld joints are melted again to enable air in the air holes to overflow, thus after welding, chain-shaped air hole welding defects at weld toes of the back sides of the weld joints and in the excess weld metal of the back sides of the weld joints are completely eliminated, and the weld joint quality of automatic welding of the splicing plates of the cylinder body of a tank body is ensured.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

Automatic bottoming process method for process pipeline robot

PendingCN114713938ABeautiful shapeImprove welding qualityArc welding apparatusMetal working apparatusProcess engineeringWelding defect

The invention discloses an automatic bottoming process method for a process pipeline robot, relates to the technical field of pipeline welding, ensures that the thickness of a bottoming weld joint is 4-5mm, realizes bottoming welding of a process pipeline by adjusting and controlling a welding position, welding parameters, interlayer temperature and the like, ensures penetration welding and attractive weld joint formation, obtains higher welding quality, and simultaneously ensures the welding quality of the process pipeline. The process is simplified, the welding wire is fully melted under the action of arc heat in the welding process, meanwhile, welding defects caused in the backing weld and operation process can be eliminated, the welding efficiency is improved, the welding cost is reduced, and the deposition efficiency is high.

Owner:奥特(南京)智能制造有限公司

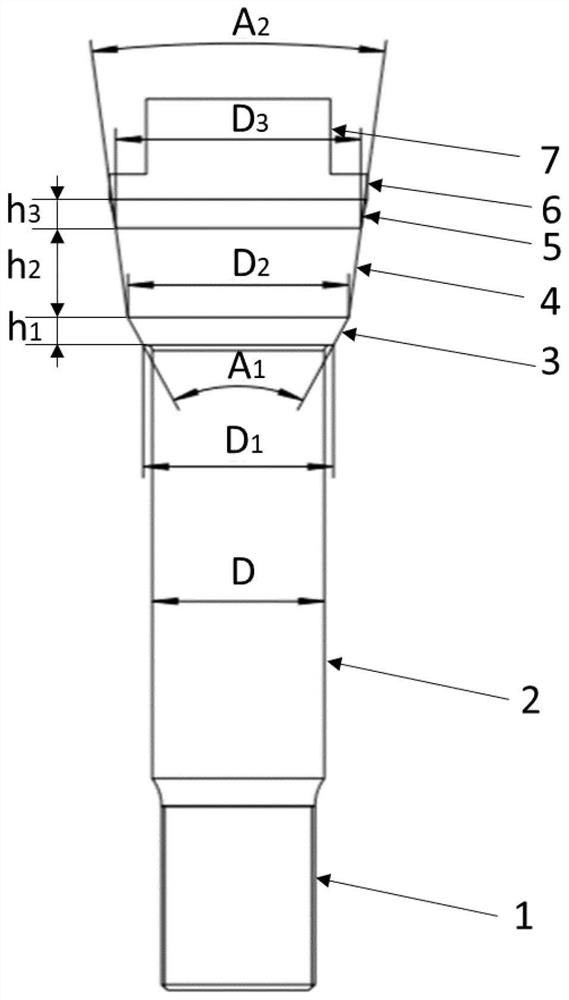

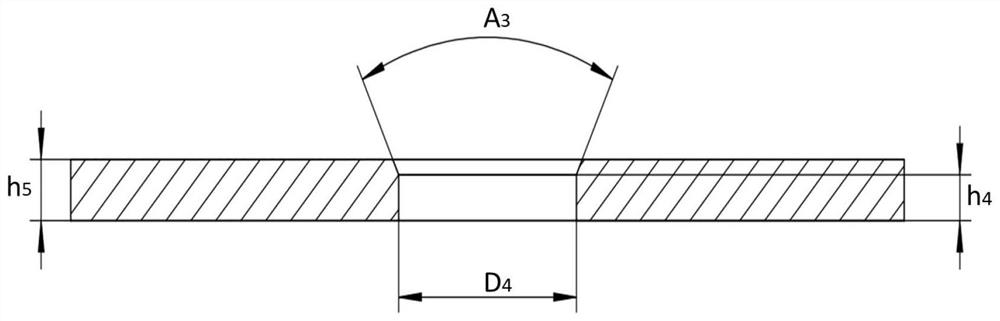

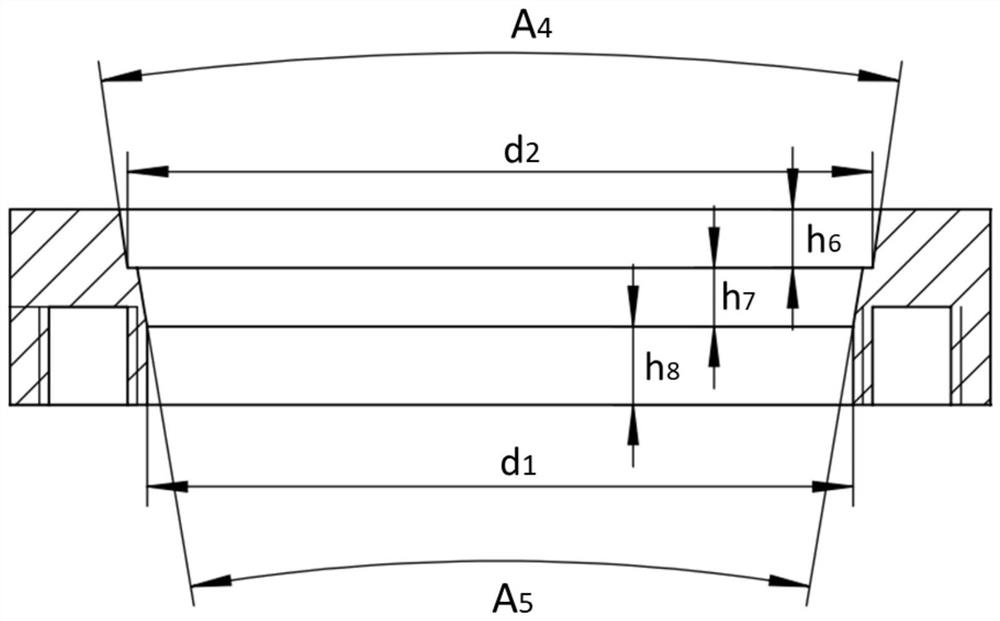

Aluminum alloy drawing type friction plug repair welding joint and machining method thereof

InactiveCN112658459AEliminate Welding DefectsNon-electric welding apparatusAluminium alloyWelding joint

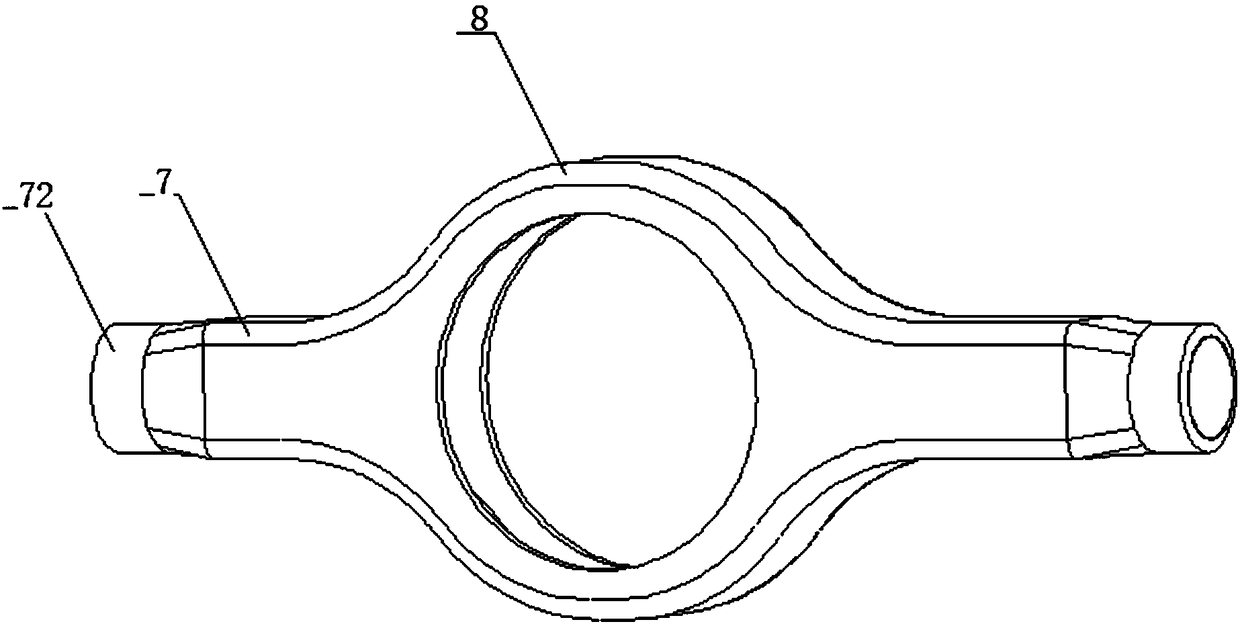

The invention discloses an aluminum alloy drawing type friction plug repair welding joint. According to the aluminum alloy drawing type friction plug repair welding joint and a machining method thereof, a repair welding mechanism comprises a plug rod and a plug hole, and a welding section is arranged on the plug rod; the plug hole is provided with a rigid forming ring for preventing the plug rod from deforming in the repair welding process and fully interacting with the plug rod under the action of axial force, wherein the forming ring is of a stepped hole structure, the upper portion of the forming ring is conical, one conical included angle A4 of an upper conical hole part is 20-30 degrees, the diameter d2 of the small end of a conical hole is larger than or equal to the diameter D2 of the small end of the welding section and is smaller than or equal to the diameter D3 of the large end of the plug rod welding section, and the depth h6 is 0.1-0.15 time of the plate thickness; the middle portion of the forming ring is conical, one conical included angle A5 of a middle conical hole part is reduced by 3-5 degrees compared with the upper conical hole, and the depth h7 is equal to the depth h6 of the upper conical hole; and the lower portion of the forming ring is a straight hole, and the diameter d1 of the straight hole is 1.1-1.25 times of the diameter D2 of the small end of the plug rod welding section. By means of the aluminum alloy drawing type friction plug repair welding joint and the machining method thereof, the problem that non-welding and weak-bonding defects are prone to being formed on the bonding interface of the plug rod and a base material is solved.

Owner:TIANJIN UNIV +1

Production method for preparing transistor by hot air welding method

InactiveCN104084659BQuality improvementImprove efficiencySoldering apparatusPrinted circuitsProcess engineeringLead frame

The invention discloses a production method for preparing a transistor through hot-gas welding. A chip and a lead frame are welded through the combination between segmented gradient preheating and hot-gas welding. A layer arrangement method of a first bonding layer and a second weldable layer is adopted in the welding process. Welding defects produced during welding are better eliminated, and meanwhile cold joints are reduced. The production method for preparing the transistor is high in efficiency, good in quality and low in cost.

Owner:FOSHAN NANHAI HONGQIAN ELECTRONICS

A kind of gradient material method brazing method for stainless steel and hard alloy

ActiveCN106862694BImprove mechanical propertiesMitigate the effects of differences in linear expansion coefficientsWelding/cutting media/materialsWelding/soldering/cutting articlesGradient materialGraphite

The invention provides a method for brazing stainless steel and cemented carbide through a gradient material method and relates to the method for brazing the stainless steel and cemented carbide. The method aims at solving the problems that by means of an existing cemented carbide and stainless steel brazing connecting technology, a lot of welding defects are formed and residual stress of welding joints is large in the welding process of the welding joints. The method comprises the steps of firstly, preparing composite solder powder; secondly, performing stirring; thirdly, preparing composite solder foil; fourthly, cleaning and stacking the stainless steel, the cemented carbide, interlayer metal and the composite solder powder into a graphite clamp and obtaining a part to be welded; and fifthly, performing brazing. According to the method, by the adoption of the gradient material method, auxiliary brazing is conducted on the cemented carbide and the stainless steel, through the gradient material method, the influence brought by the difference of the linear expansion coefficients is relieved greatly, the residual stress is reduced, and the welding defects are eliminated. The method is suitable for brazing of the stainless steel and the cemented carbide.

Owner:哈尔滨工大华策科技有限公司

A vacuum preheating electron beam welding device for large thickness workpieces

ActiveCN111761193BGuarantee welding qualityMeet the comprehensive mechanical propertiesElectron beam welding apparatusHeat-affected zoneTitanium alloy

The invention relates to a vacuum preheating electron beam welding device for large-thickness workpieces, comprising a vacuum chamber, a heating device, a mobile platform, an electron gun, a clamping tool and a workpiece to be welded. Two upper and lower heating components and three side wall heat insulation protection components are used to achieve high temperature preheating of workpieces in a vacuum environment, effectively reducing the cooling rate, avoiding the generation of hardened structures in welds and heat affected zones, using high temperature preheating and electron beams The welding method solves the problems of high-strength steel, high-strength titanium alloy and other products with a large tendency to crack in the weld and poor plastic toughness of the weld.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

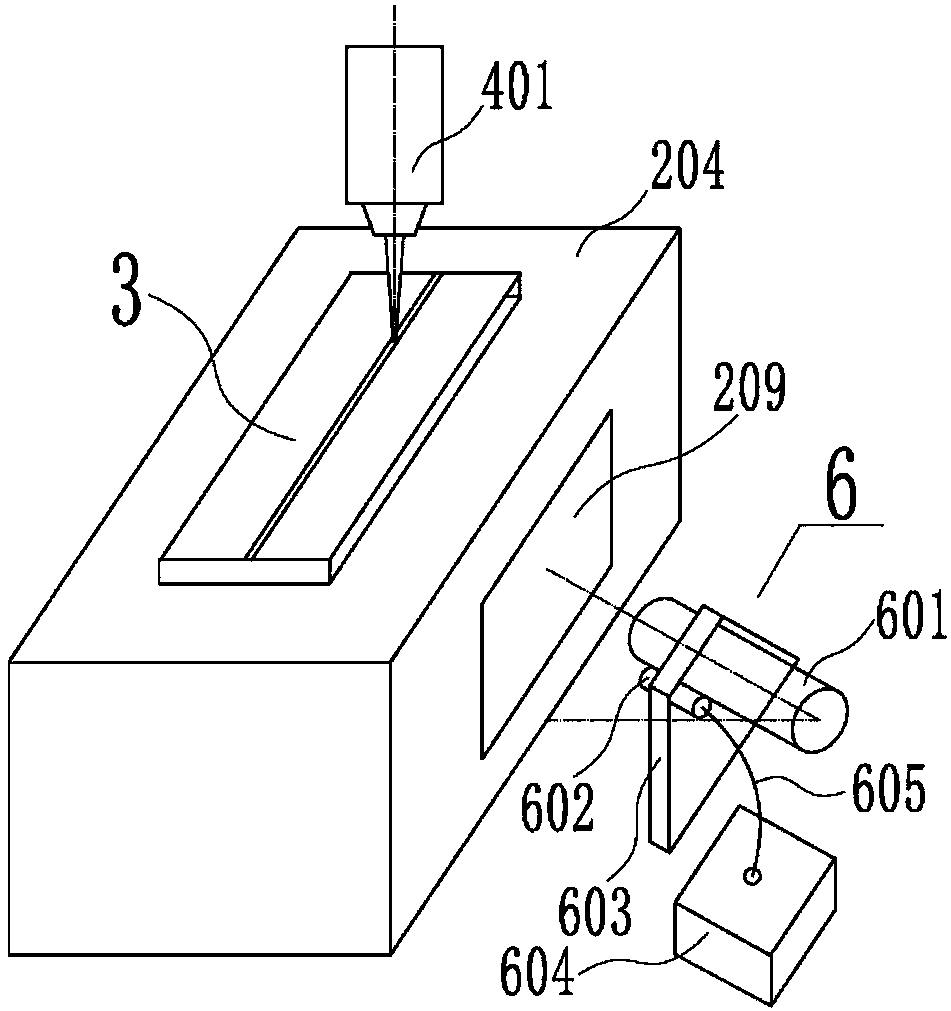

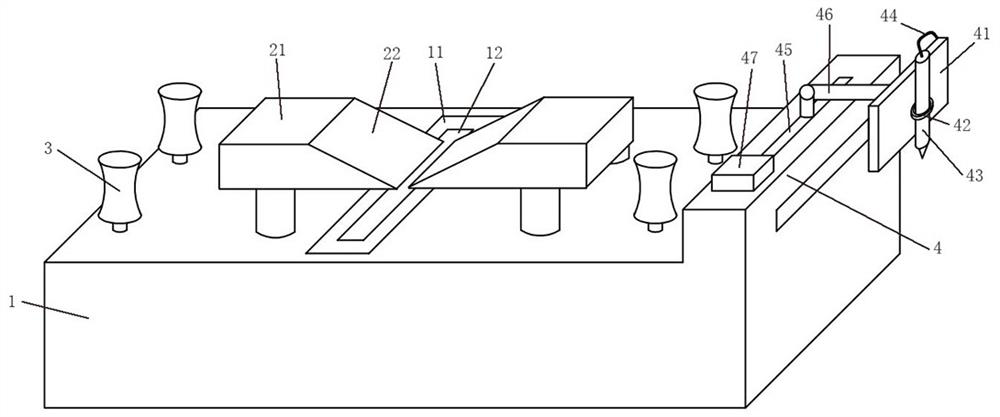

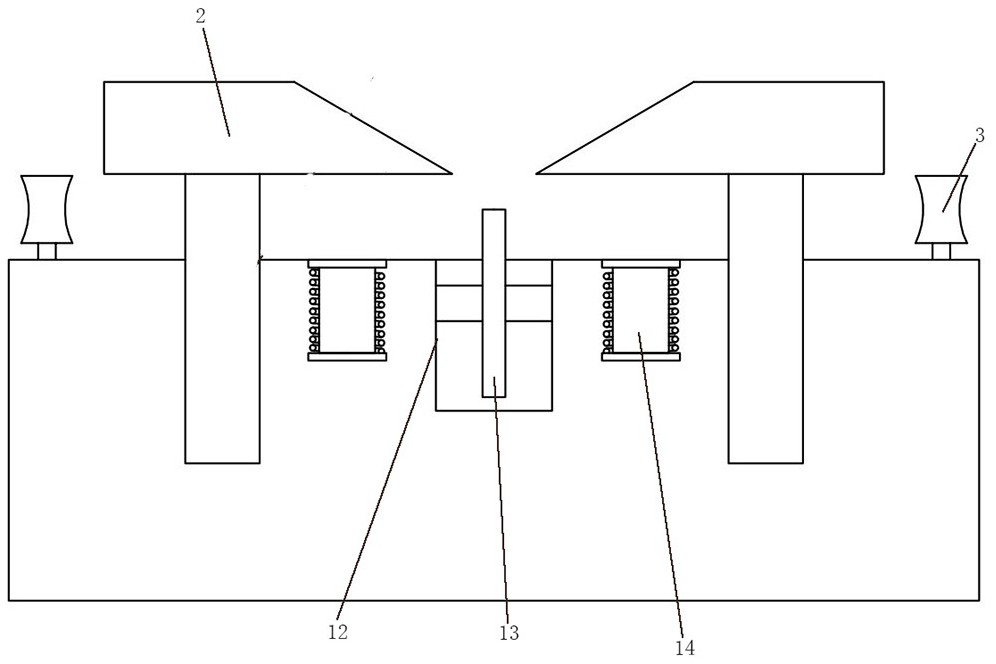

A stamping plate butt welding device

ActiveCN109434344BGood welding performanceEliminate Welding DefectsWelding/cutting auxillary devicesAuxillary welding devicesButt weldingWeld quality assurance

The invention relates to a butt welding device for stamping plate parts. The butt welding device for the stamping plate parts comprises a welding platform, a pair of press disks, a pair of limiting columns and a welding device, wherein the press disks and the limiting columns are arranged at the transverse ends of the welding platform, and the welding device is arranged on one side of the weldingplatform. The limiting columns comprise at least a pair of guide wheels horizontally opposite arranged; and the press disks comprise rectangle matrixes and press blocks extending outward from the sides of the matrixes, and the press blocks of the pair of press disks are opposite to each other. According to the butt welding device of the stamping plate parts, the two parts stamped out of the largerparts separately are facilitated to be welded, the welding quality of the welding place is ensured, and the actually seamless joint after welding is ensured; meanwhile, the shape of the periphery ofthe welding place is ensured to be aligned, and deforming does not appear due to the residual stress of welding; and meanwhile, the functions of automatic alignment and welding are achieved, and the production efficiency is improved. Through the beneficial effects, the integral forming of the large stamping parts after separating and stamping can be realized, and the cost of mold tools can be reduced and the quality of products produced can be improved at the same time.

Owner:ANHUI KEYUAN MACHINERY

A welding method for inner hole welding of tube and tube sheets of small-aperture heat exchange tubes

ActiveCN111037065BImprove aestheticsImprove welding qualityArc welding apparatusHeat exchange apparatusWelding defectWelding torch

The application relates to welding technology, and discloses a method for welding the inner hole of a tube plate of a small-diameter heat exchange tube, which can effectively eliminate welding defects such as concaves on the outer surface of the joint and arc craters on the back. The inner diameter of the heat exchange tube is 9-15 mm, and the wall thickness is 1-2 mm; the method includes: adjusting the position of the tungsten needle of the welding torch head according to the tube sheet boss with grooves, so that when the welding torch is inserted and is in the position to be welded In the normal state, the tungsten needle is located on one side of the tube plate boss and at a position within 0 to 0.5 mm from the end face of the tube plate boss to be welded; the heat exchange tube and the tube plate boss are coaxially assembled Yes, and ensure that the gap between the end faces of the two pairs to be welded is within 0-0.1 mm; select any position between 3-5 o'clock and 7-9 o'clock as the arc starting point, and set the arc starting point Back uphill welding; divide the circle to be welded into 2N intervals according to the selected arc starting point, and set the current of each interval according to the recommended process parameters, and perform all-position inner hole welding on the circle to be welded.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com