A welding method for inner hole welding of tube and tube sheets of small-aperture heat exchange tubes

A welding method and technology of heat exchange tubes, applied in welding equipment, heat exchange equipment, arc welding equipment, etc., can solve the problem of thick welding torch tip, inapplicability of small-diameter heat exchange tubes and tube sheets, no nickel and nickel Alloy small-diameter tube tube sheet technology research results and other issues, to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

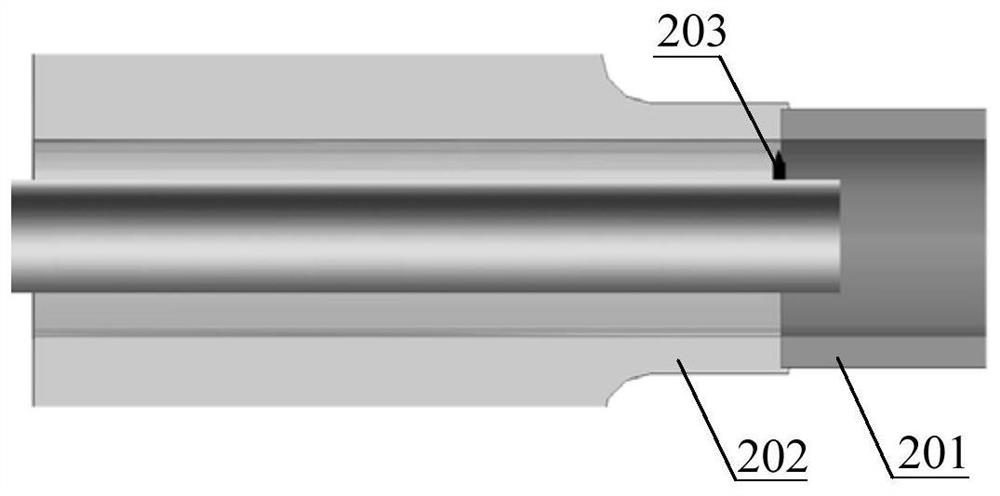

[0077] This embodiment 1 is the inner hole welding of pipe A and pipe B.

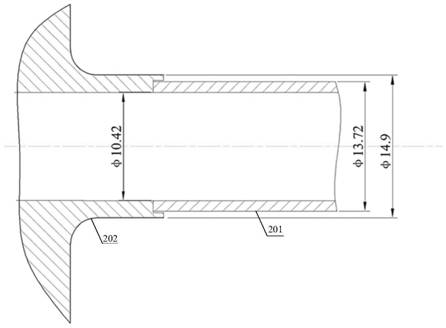

[0078] Both pipe A and pipe B are made of UNS N10003 nickel-based alloy pipes, with an outer diameter of 13.72mm and a wall thickness of 1.65mm; the weight percentage of alloy chemical composition: 70.8Ni, 6.96Cr, 16.7Mo, 4.2Fe, 0.35Si, 0.053C, 0.001S, 0.002P, 0.002B, 0.71Mn, 0.014Al, 0.011Ti, others≤0.5.

[0079] Step 1: Preparation before welding

[0080] Clean the ends of pipe A and pipe B to be welded with an organic solvent such as alcohol, acetone, etc., to remove the burrs on the end faces, and ensure that the end faces to be welded are flat.

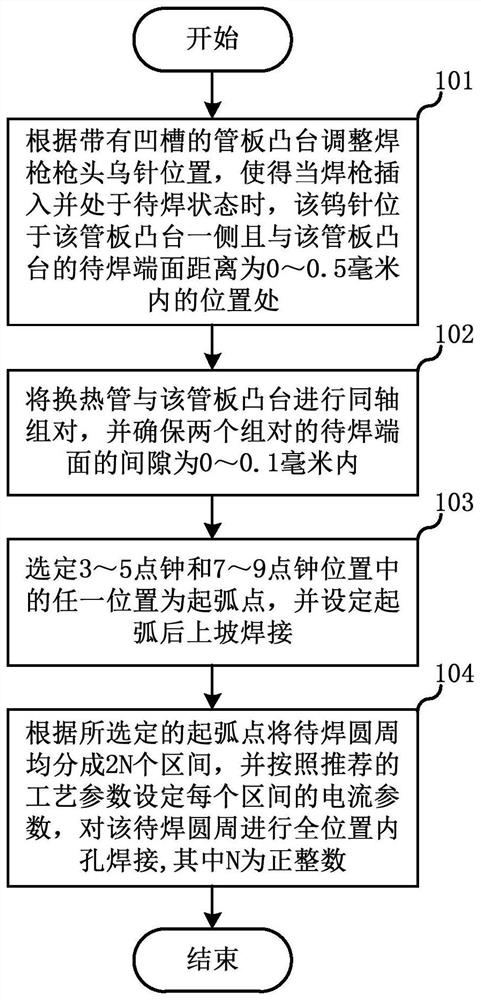

[0081] Process 2: Tungsten needle positioning

[0082] Adjust the position of the tungsten needle of the torch head according to the pipe A with the groove, so that when the welding torch is inserted and in the ready-to-weld state, the tungsten needle is located on the side of the pipe A and the distance from the end face of the pipe A to be welded is wi...

Embodiment 2

[0103] In this embodiment, the inner holes of the tube sheet and the heat exchange tube are welded.

[0104] The type of material used is the same as in Example 1, which is still UNS N10003 alloy. Considering that the tube sheet has a strong ability to transfer and absorb welding heat, the welding process is slightly adjusted.

[0105] Among them, embodiment 2 is the same as the method of process 1 to process 5 of embodiment 1, and the arc starting parameters and arc terminating parameters of embodiment 2 and process 6 of embodiment 1 are the same, and the difference between embodiment 2 and embodiment 1 lies in: different intervals in the welding process The current parameter settings of the positions are different, as shown in Table 5.

[0106] Table 5 Current parameters of different interval positions in the welding process

[0107] interval Peak current A Ratio of base value% 1 stage 60 45 2 stages 58 45 3 stages 56 45 4 stages 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com