Patents

Literature

85results about How to "Improve other properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-corrosion resistance high-toughness high-chromium ferrite stainless steel plate and manufacturing method thereof

ActiveCN103276307AImprove corrosion resistanceImprove low temperature toughnessTransition temperatureImpurity

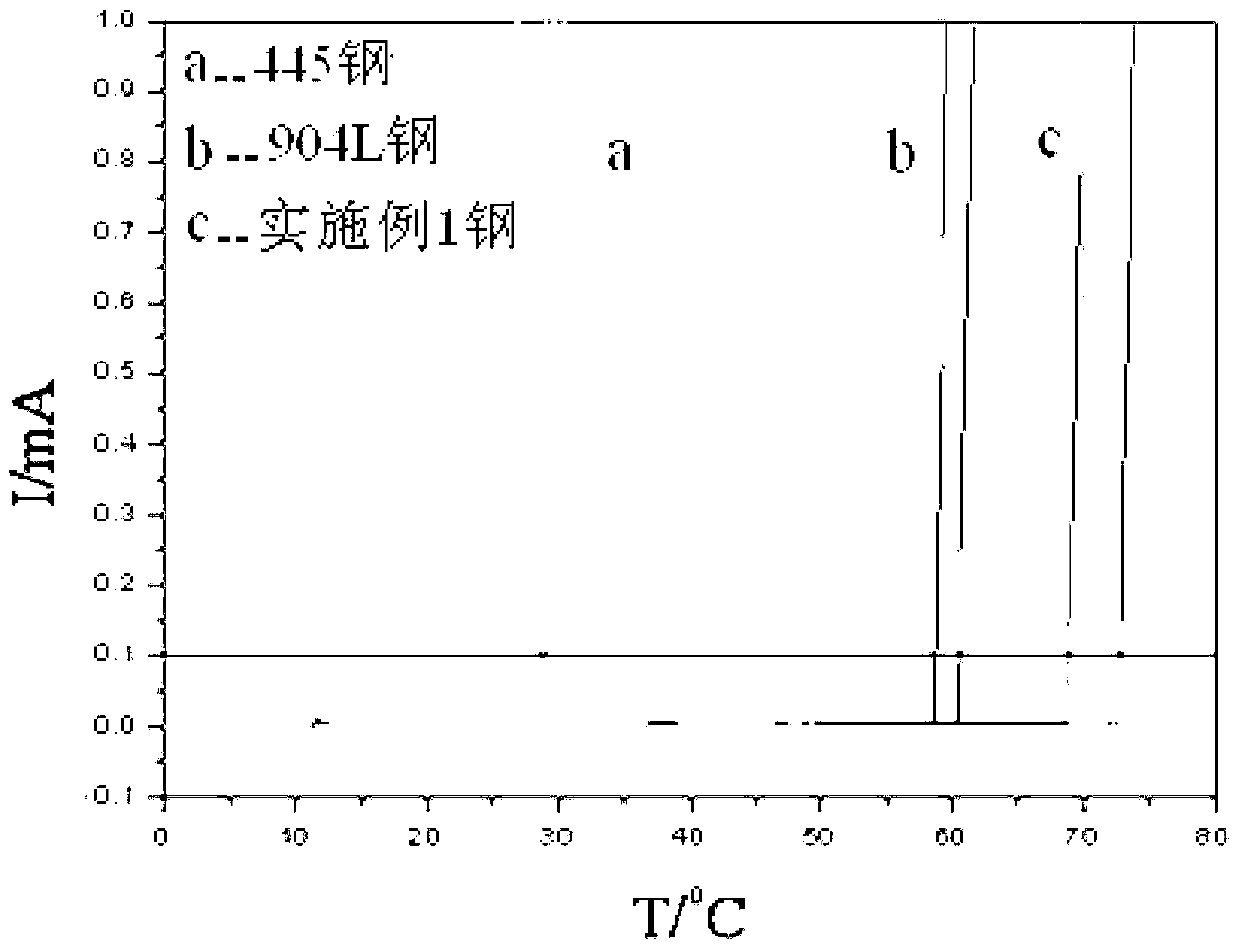

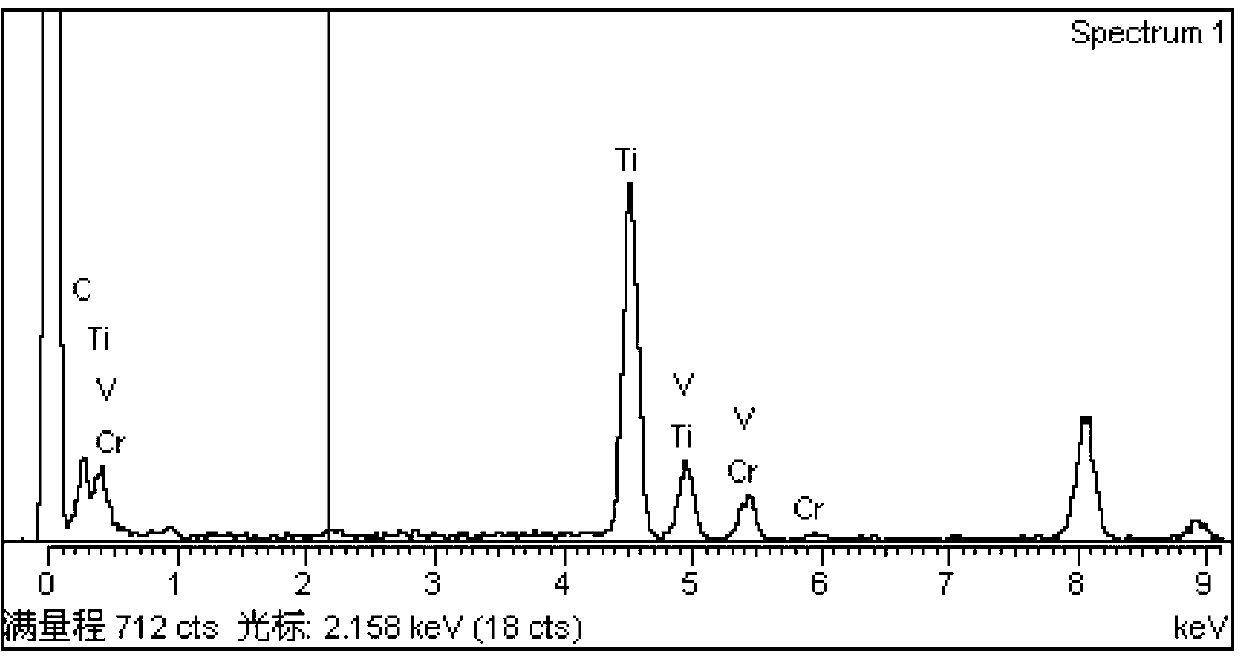

The invention discloses a high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate and a manufacturing method thereof. The high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate comprises, by weight, 0.005 to 0.015% of C, 0.005 to 0.020% of N, 0.2 to 0.5% of Si, 0.2 to 0.5% of Mn, less than or equal to 0.035% of P, less than or equal to 0.010% of S, 25 to 28% of Cr, less than or equal to 4.0% of Ni, 2.0 to 4.0% of Mo, 0.1 to 0.3% of V, 0.10 to 0.30% of Ti, 0.2 to 0.4% of Nb, less than or equal to 0.005% of Al, less than or equal to 0.005% of O, and the balance Fe and unavoidable impurities, wherein based on Cr content, Mo content, Ti content, Nb content, C content and N content respectively represented by Cr, Mo, Ti, Nb, C and N, Cr+3.3*Mo is greater than or equal to 35% and Ti+Nb is greater than or equal to 16(C+N). The high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate has a ductile-brittle transition temperature below -40 DEG C, pitting potential above 1000mv, a critical pitting temperature above 70 DEG C, a corrosion rate below 0.2g / m<2>h in boiling hydrochloric acid having a concentration of 1wt%, yield strength above 380MPa, tensile strength above 520MPa, an elongation rate A50mm above 25% and Vickers hardness of 180 to 220, and can be used in various harsh environments.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

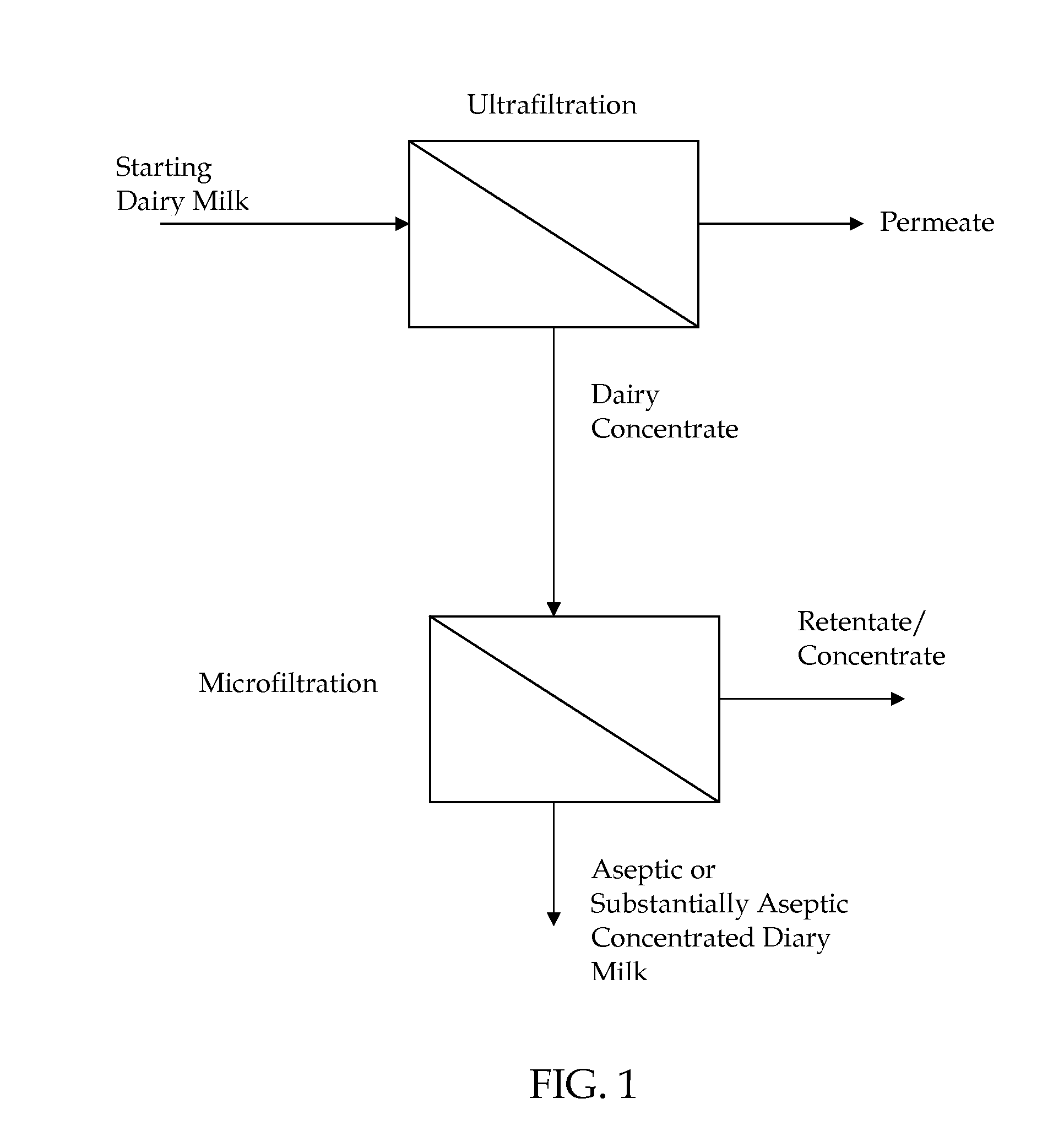

Method Of Producing Concentrated Liquid Dairy Products

InactiveUS20080160134A1Add flavorGreat tasteMilk preparationMilk preservationUltrafiltrationMicrofiltration membrane

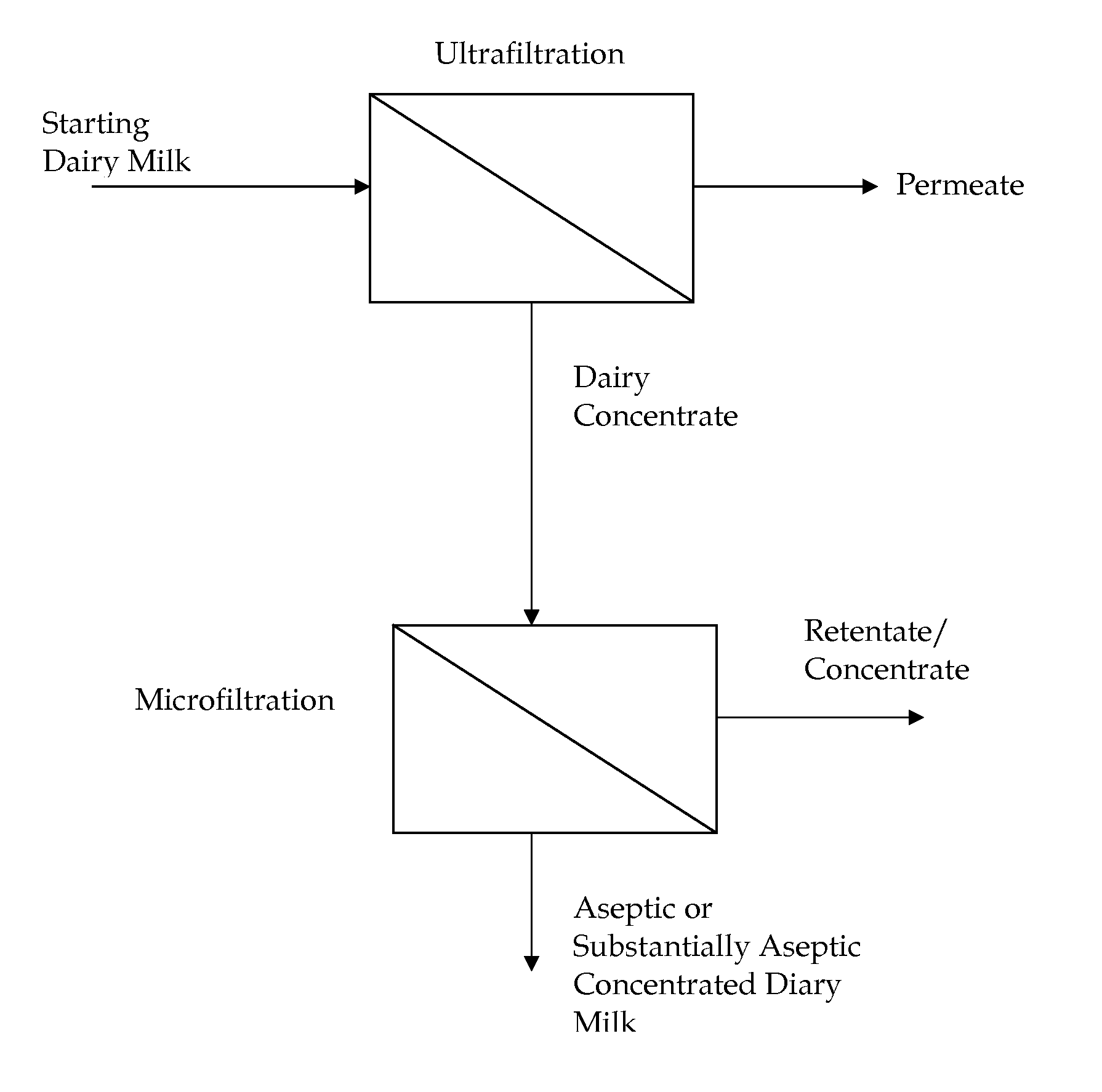

A method is provided for forming aseptic or substantially aseptic concentrated dairy liquid, such as dairy milk, without significant heat treatment. In one form, the method first concentrates a starting dairy milk to about 2× to about 7× concentration using an ultrafiltration membrane to form a dairy concentrate. Thereafter, the dairy concentrate is filtered using a microfiltration membrane to provide the aseptic or substantially aseptic concentrated dairy milk. The resultant concentrated dairy milk has less than about 0.5 percent total bacteria and less than about 5 colony forming units of spore forming bacteria per gram. The substantially aseptic concentrated dairy milk is not subjected to significant heat treatment during processing.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method for cultivating selenium-rich wheat

ActiveCN101347074APromote absorptionImprove bindingBio-organic fraction processingFertilising methodsPhosphatePotassium

The invention relates to a breeding method of a selenium rich crop, in particular to a breeding method of selenium rich wheat; the method comprises the following steps: bagasse is taken as major raw material, and added with sodium selenite, ammonium sulfate and lactobacillus fermented substance, the proportion by weight of the added raw materials is as follows: 35-50 parts of bagasse, 0.5-2 parts of sodium selenite, 2-5 parts of ammonium sulfate and 0.05-0.1 part of lactobacillus fermented substance; the selenium rich fermented fertilizer is produced by a fermentation method; before planting wheat, 10-20kg of fertilizer obtained from step a is fertilized on each mu of wheat field; the sodium selenite, the ammonium sulfate and potassium dihydrogen phosphate are mixed according to a weight ratio of 1:1:1, evenly stirred and added with water to be made into a foliar fertilizer with concentration of 0.05-0.2%; the foliar fertilizer is sprayed in the shooting stage, early grain filling stage and middle grain filling stage of wheat; after the wheat is ripe and harvested, the selenium rich wheat product is obtained. The breeding method solves the problem that the former selenium rich products are not ideal enough in selenium content, and increases the content of selenium in the wheat.

Owner:张秉文

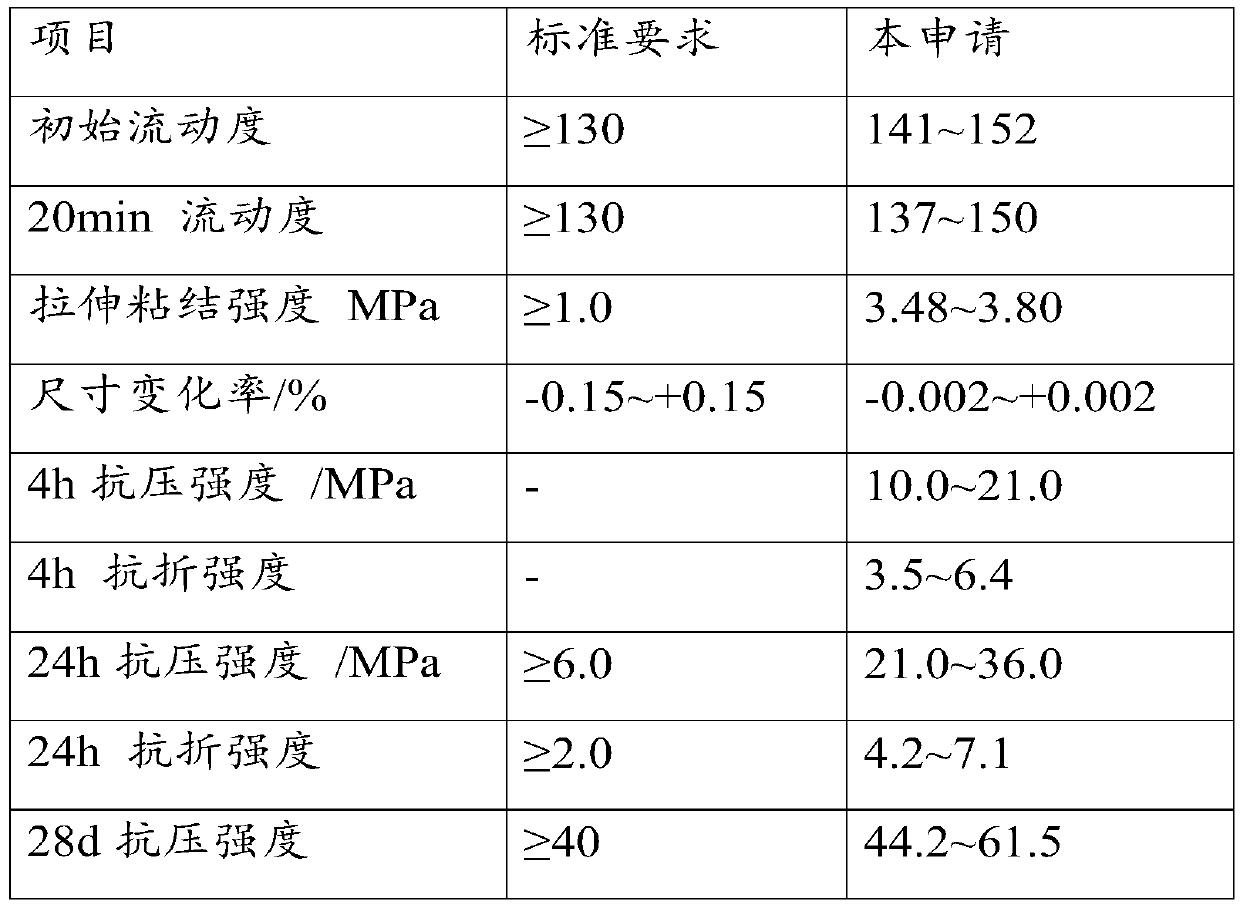

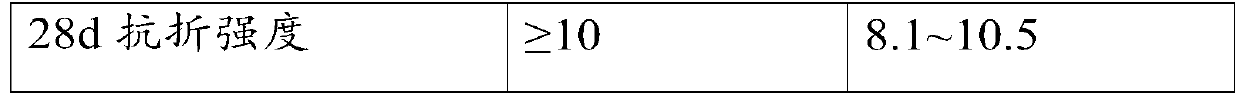

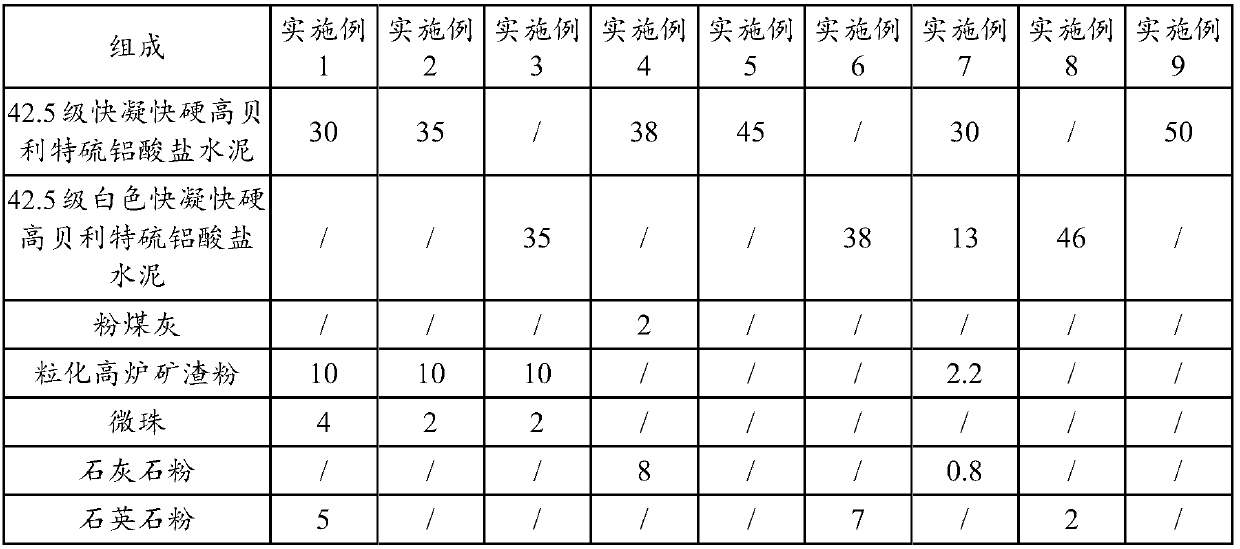

Quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and preparation method thereof

PendingCN109836106AImprove initial fluidityNo significant decrease in fluidity after 20 minutesAcid corrosionSlurry

The invention provides quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and a preparation method, and relates to the field of building materials. The mortar powder comprises the following raw materials in percentage by weight: 30%-50% of quick-cementing and -hardening high-belite sulphoaluminate cement, 46.19%-51.97% of a fine aggregate, 0.15%-0.3% of a waterreducing agent, 0%-0.04% of a thickening agent, 0.05%-0.2% of a defoaming agent, 0.5%-3.5% of latex powder, 0.075%-0.25% of a retarder and 0.15%-0.3% of a coagulation accelerator. The self-leveling mortar has the excellent properties of acid corrosion resistance, small shrinkage, high tensile bonding strength, high setting and hardening speed and the like, and is suitable for self-leveling floors,industrial floors, civil floors, artistic floors and the like in an acid salt environment.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

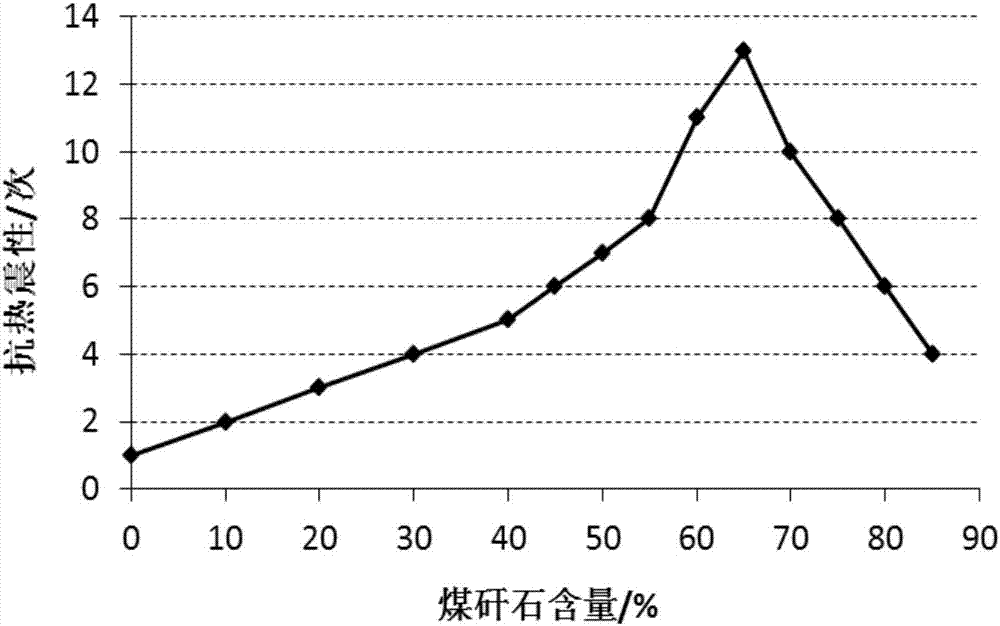

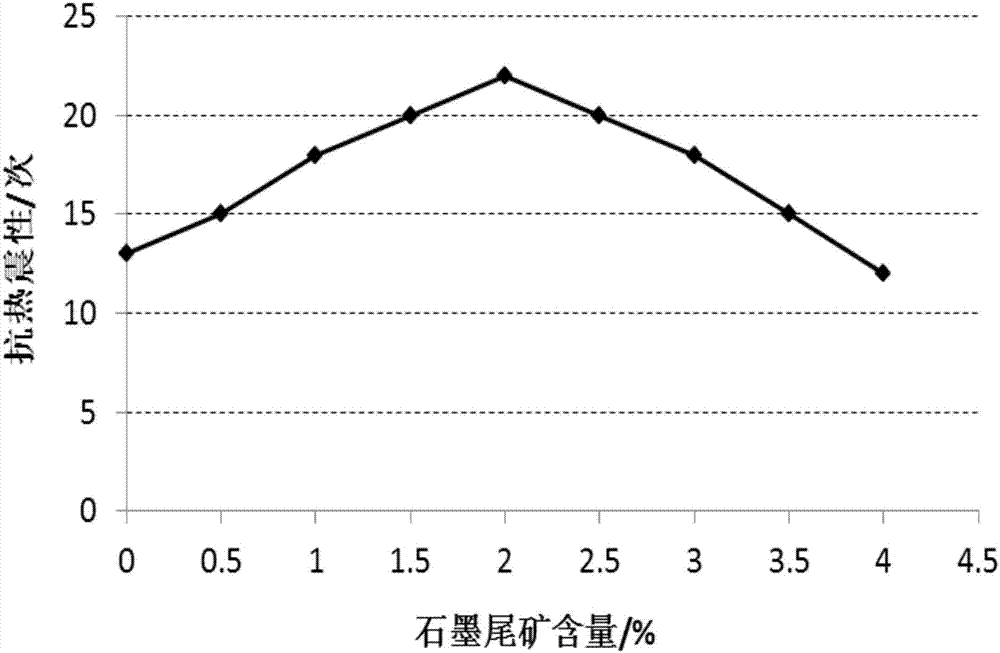

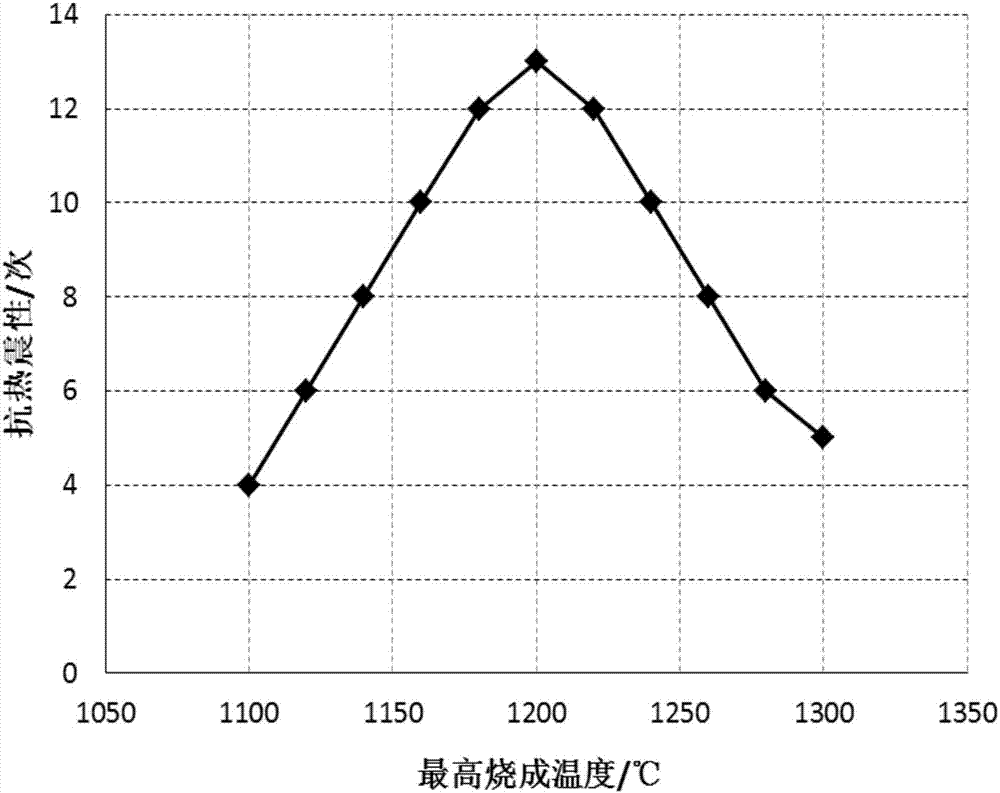

Foamed ceramic light inner wall board prepared from coal gangue and graphite tailings and preparation method

ActiveCN107352972AImprove thermal shock resistanceImprove other propertiesHeat proofingSound proofingThermal insulationChemical stability

The invention belongs to the technical field of foamed ceramic light inner wall board preparation, and particularly relates to a foamed ceramic light inner wall board prepared from coal gangue and graphite tailings and a preparation method. The foamed ceramic light inner wall board is prepared from, by weight, 60-70% of coal gangue, 10-15% of albite, 1-3% of foaming agent and 15-25% of microlite aggregates. The foamed ceramic light inner wall board has the advantages of being good in chemical stability, high in strength, resistant to quick heating and cooling, capable of achieving class-A fire protection, resistant to corrosion, high in adsorption performance, low in specific gravity, good in heat preservation performance, capable of achieving sound insulation, easy to cut and the like. The foamed ceramic light inner wall board is the fireproof thermal insulation material needed in the market; in addition, the foamed ceramic light inner wall board has the advantages that the comprehensive cost is low, installation is convenient, the foamed ceramic light inner wall board can be repeatedly used, the construction speed is twice faster than that in the prior art, energy is saved, consumption is reduced, the wall body is a half or less as thin as a traditional building block, the usable area of a house can be increased, the service life of the foamed ceramic light inner wall board is as long as the building, and the foamed ceramic light inner wall board is an ideal interior and exterior wall material for a fabricated building.

Owner:BRIGHT OCEANS CORP

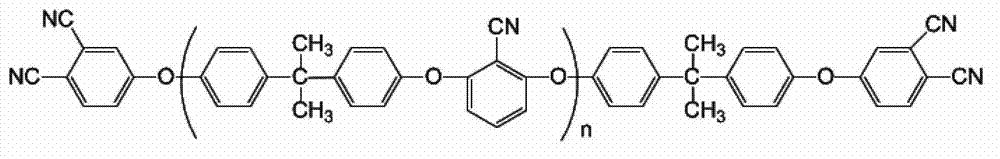

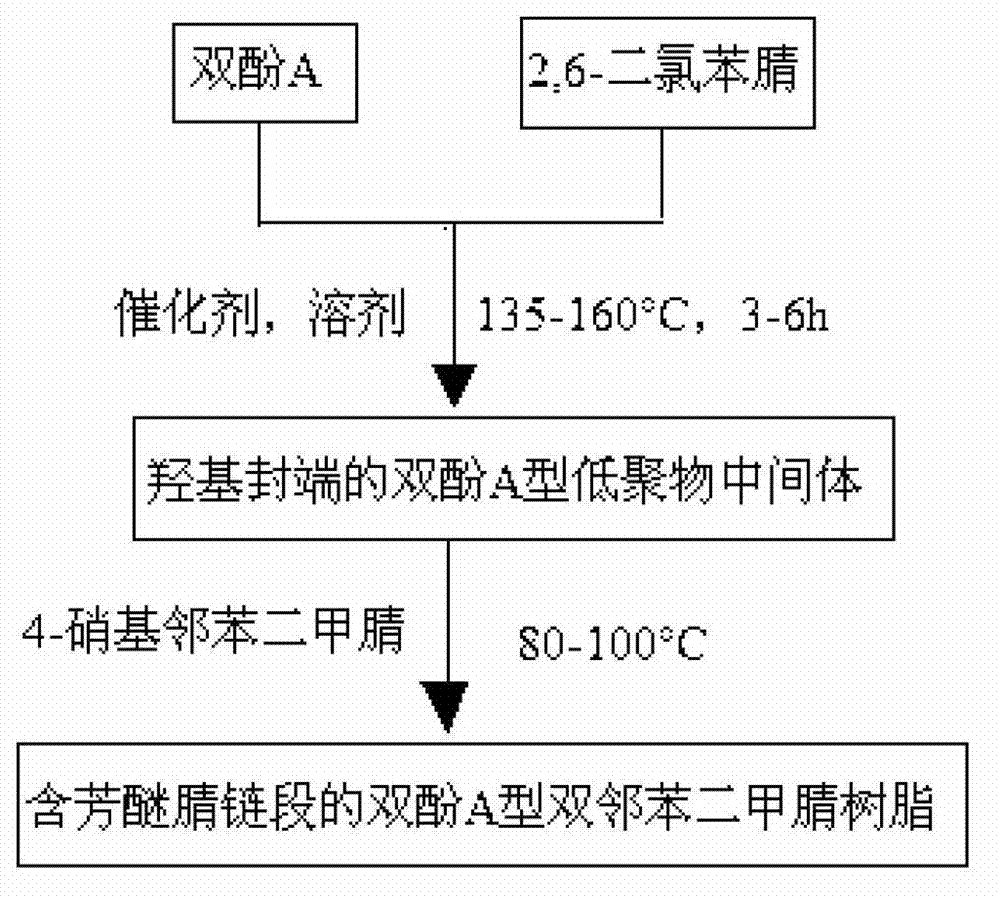

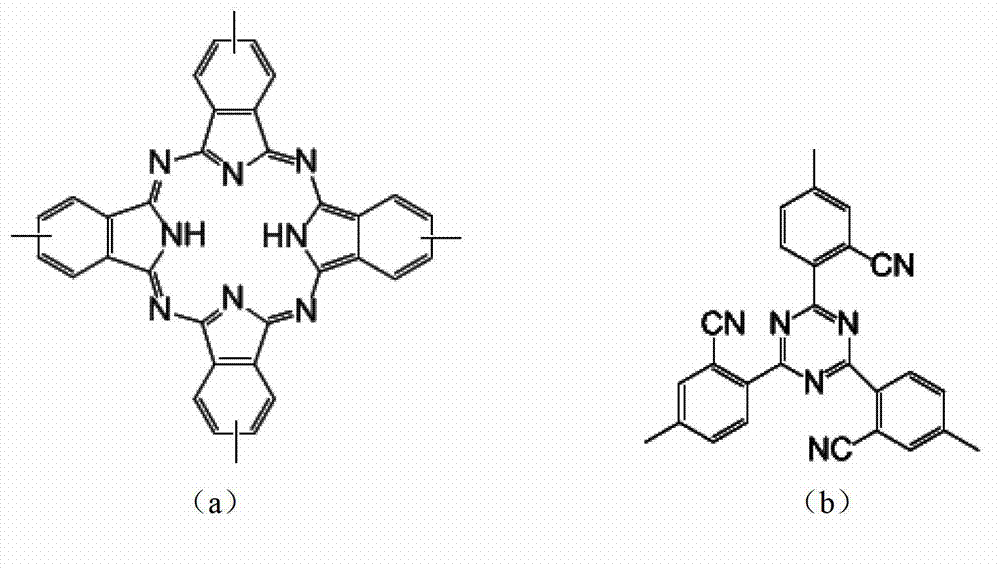

Bisphenol A bisphthalonitrile resin containing arylethernitrile chain segment, cured resin and preparation method thereof

InactiveCN102887999AWide processing temperature windowEasy to solidify and processPolymer sciencePhthalocyanine

The invention relates to a bisphenol A bisphthalonitrile resin containing an arylethernitrile chain segment, a cured resin and a preparation method thereof, belonging to the field of high polymer materials. The preparation method comprises the following steps: performing nucleophilic substitution reaction on bisphenol A and 2,6-dichlorobenzonitrile used as raw materials in a strongly polar solvent / methylbenzene mixed solution in the presence of anhydrous potassium carbonate or anhydrous sodium carbonate used as a catalyst, thus forming a hydroxyl-terminated bisphenol A low polymer intermediate; then, substituting hydroxyl therein with 4-nitrophthalonitrile, thus obtaining the target resin; and adding curing crosslinking agent of which the mass is equivalent to 5% of that of the resin into the resin, precuring at 220-240 DEG C, and performing heat treatment at a temperature not lower than 375 DEG C to obtain the cured resin. The bisphthalonitrile resin provided by the invention has different chain lengths, contains an arylethernitrile chain segment, and has a low melting point and a wide curing processing temperature; the cured resin is in a network structure comprising phthalocyanine rings and triazine rings, and has excellent heat stability; and the provided preparation method of the resin and the cured resin is simple and controllable, and is suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

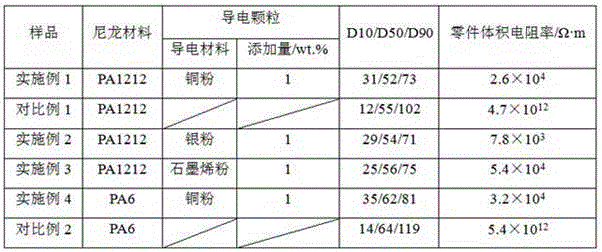

Nylon conductive powder preparation method for laser sintering

ActiveCN106832910AUniform particle size distributionUniform and concentrated particle size distributionMicrosphereSolvent

The invention provides a nylon conductive powder preparation method for laser sintering. The nylon conductive powder preparation method comprises the following steps: adding conductive particles and a surfactant into an alcohol-water solvent; stirring, dispersing, drying and grinding to obtain surface-activated conductive particles; then, adding the surface-activated conductive particles into a nylon solution; heating, cooling and crystalizing; uniformly coating the inside of the nylon microspheres with the conductive particles, filtering, drying and screening to obtain a nylon powder material coated with the conductive particles. By adopting the nylon conductive powder preparation method, the prepared nylon conductive powder has uniform and concentrated particle size distribution, the conductive particles are distributed more uniformly, the powder is prevented from being separated easily in a using process, and the conductive performance and other relevant performance of nylon three-dimensional parts are improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

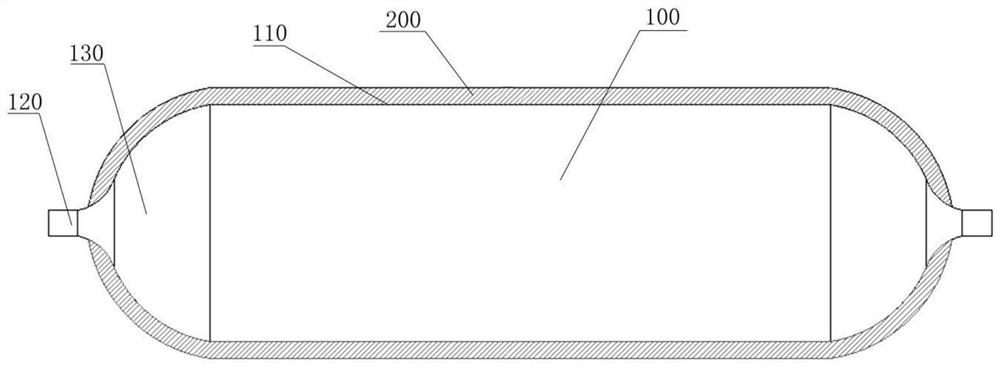

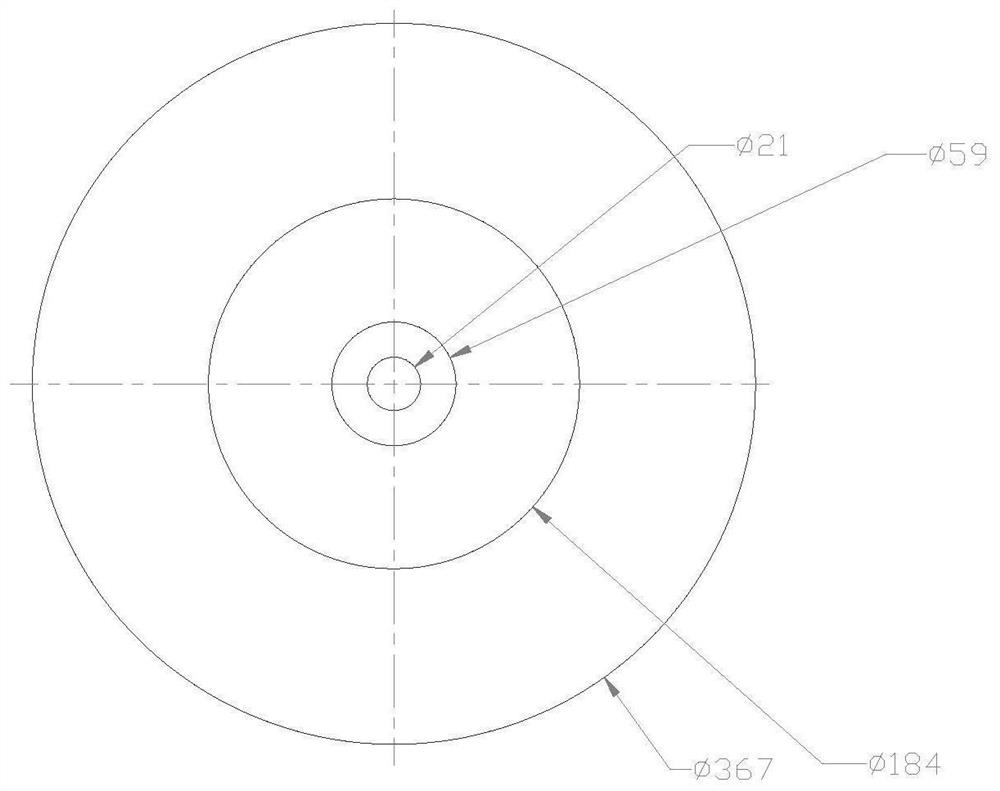

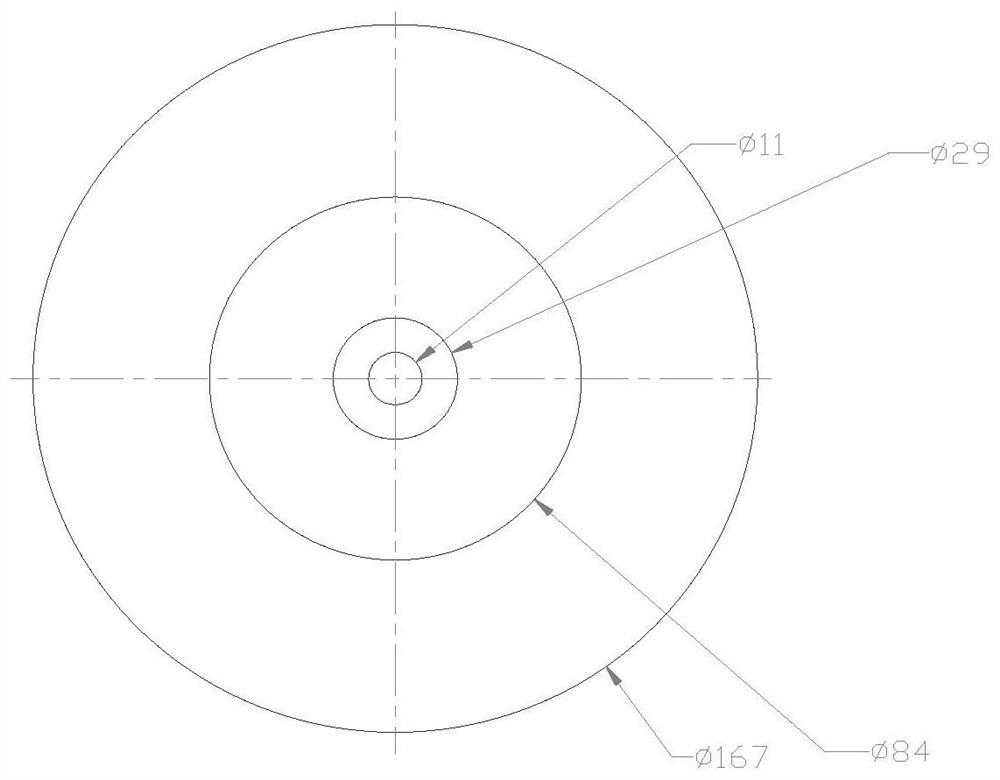

Fiber composite material high-pressure hydrogen storage cylinder and preparation method thereof

The invention provides a fiber composite material high-pressure hydrogen storage cylinder and a preparation method thereof. The preparation method comprises the steps that S100, a cylinder inner container is provided, and the cylinder inner container comprises an inner container body and a cylinder opening; S200, fiber yarns are adopted to conduct two-dimensional multi-spindle weaving on the outer surface of the cylinder inner container, so that a composite material weaving layer comprising multiple layers of fiber two-dimensional fabric is formed, the weaving angle of the fiber two-dimensional fabric at the position of the inner container body is 56-67 degrees, and the weaving angle of the fiber two-dimensional fabric at the position of the cylinder opening is 15-55 degrees; S300, in the composite material weaving layer, a sewing thread in the axis direction of the cylinder is additionally arranged between every 3-5 layers of adjacent fiber two-dimensional fabric for fixing, and a woven preformed body is obtained; and S400, resin is adopted to cure the woven preformed body through a vacuum bag vacuum resin infusion method, and the fiber composite material high-pressure hydrogen storage cylinder with the fiber composite material layer is obtained. The fiber composite material high-pressure hydrogen storage cylinder is light in weight, high in strength, resistant to fatigue, large in structural rigidity and good in high and low temperature impact resistance stability.

Owner:BEIJING NEW ENERGY VEHICLE TECH INNOVATION CENT CO LTD

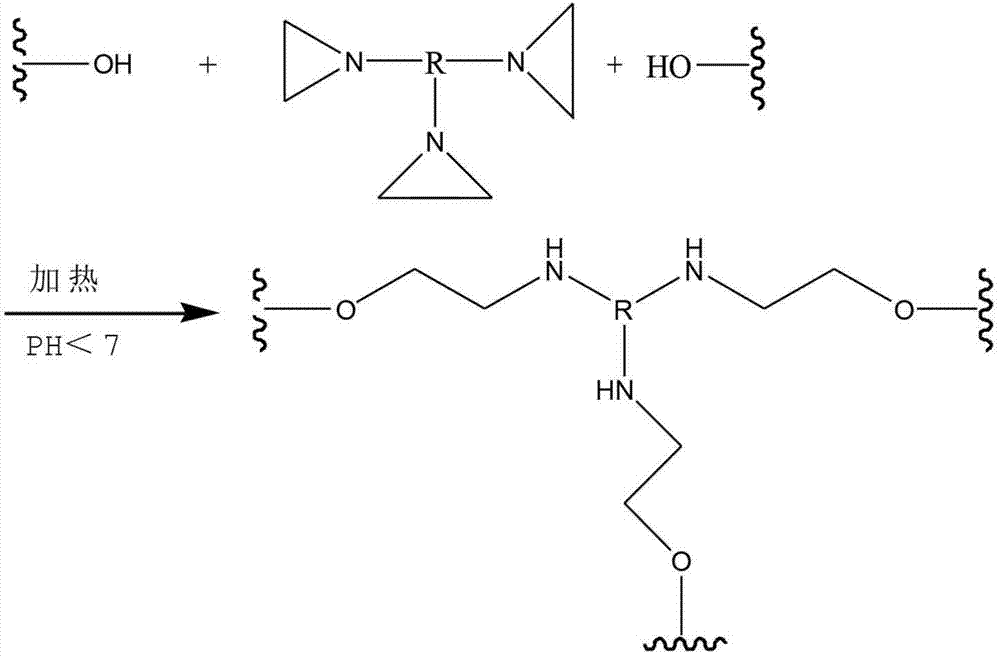

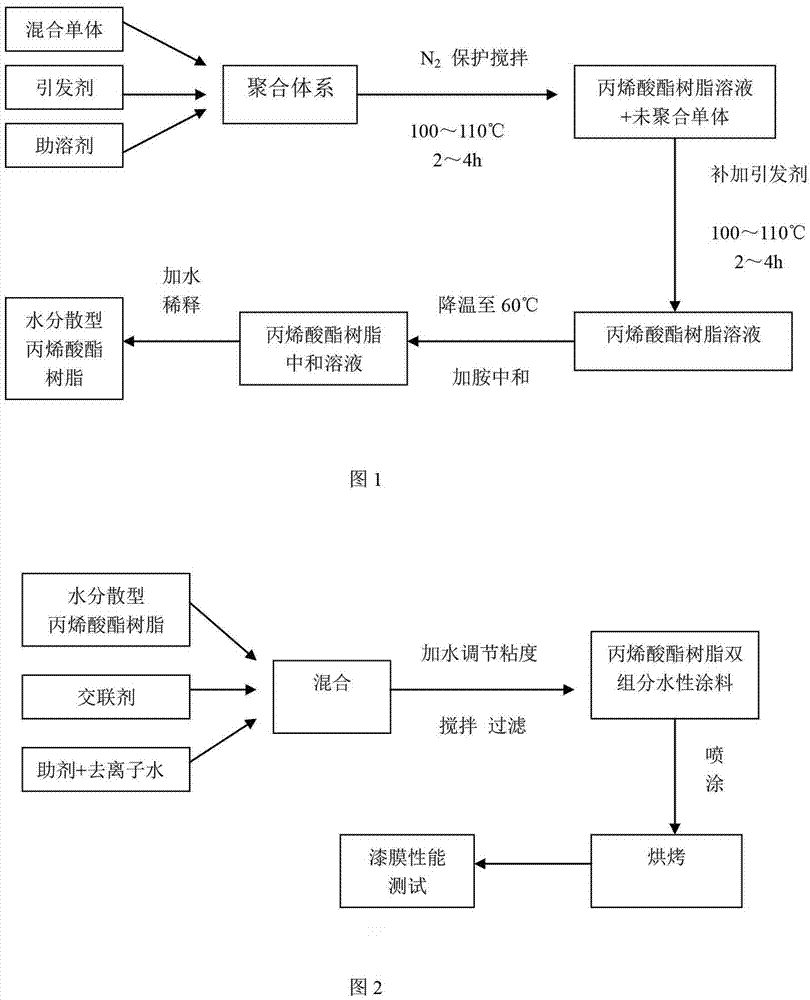

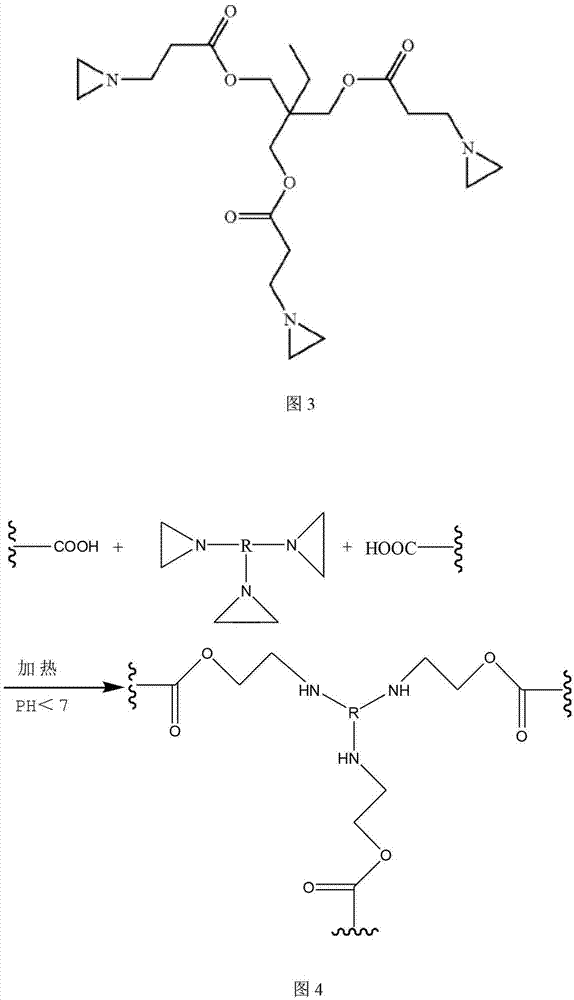

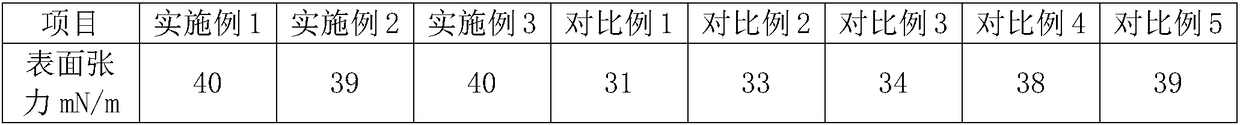

Aziridine crosslinked acrylate resin two-component water-based automobile coating and preparation method thereof

The invention discloses aziridine crosslinked and solidified acrylate resin two-component water-based automobile coating and a preparation method thereof. Water-dispersed acrylate resin used for preparing the two-component water-based coating is prepared by initiating polymerization by virtue of a free radial initiator in an organic cosolvent by a mixture of a monomer component A, a monomer component B and a monomer component C, and then an amine neutralizer is added for neutralization to form aqueous dispersion. The aziridine crosslinked acrylate resin two-component water-based automobile coating is formed by mixing water-dispersed acrylate resin, an aziridine crosslinking agent and other auxiliaries, a paint film formed after spraying and solidification has high gloss, high hardness, high impact resistance and excellent water resistance, interlayer bonding is tight, firm adhesion on a substrate is achieved, and operating requirements of automobile coating are met.

Owner:GUANGDONG YATU CHEM

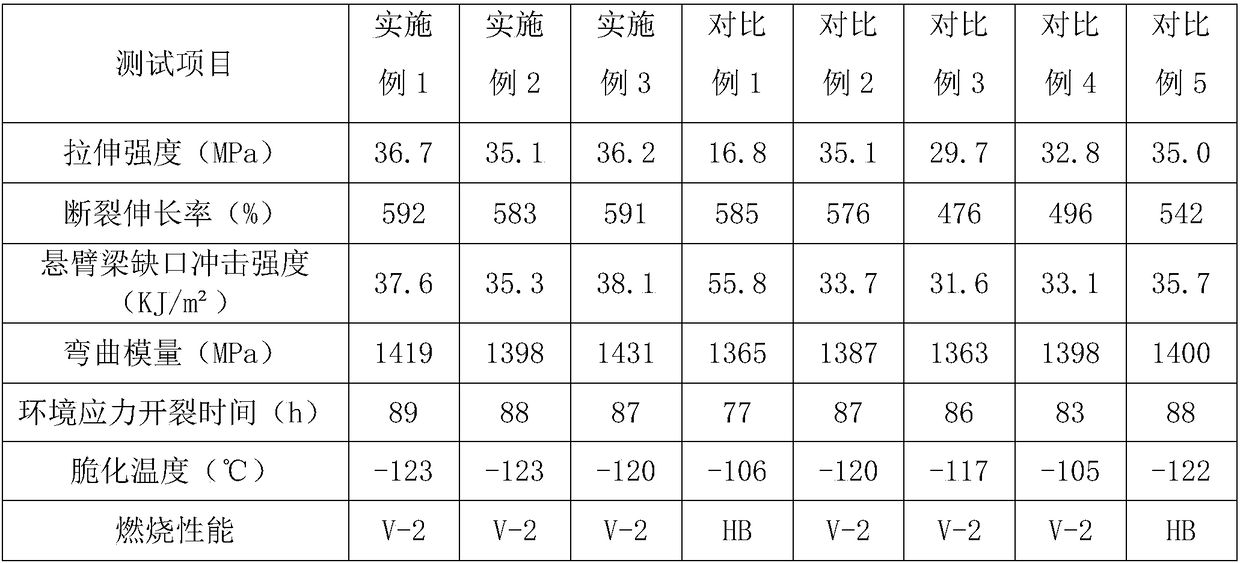

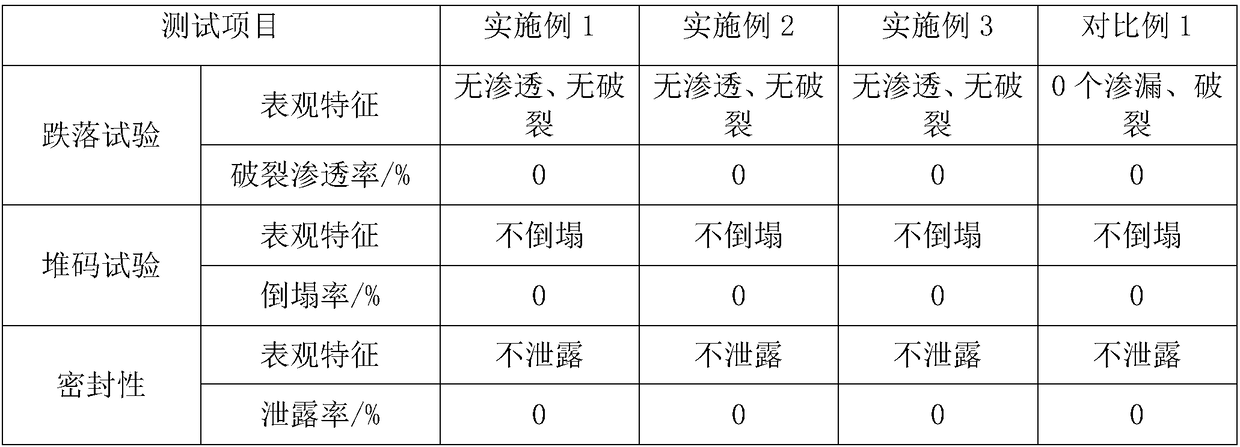

Cold-resistant plastic bucket and preparation method thereof

ActiveCN108822385AImprove cold resistanceImprove heat resistanceLinear low-density polyethylenePolymer science

The invention discloses a cold-resistant plastic bucket and a preparation method thereof, and belongs to the technical field of a plastic packaging container. The cold-resistant plastic bucket is characterized in that the cold-resistant plastic bucket is prepared from the components in parts by weight: 60 to 80 parts of high-density polyethylene, 15 to 25 parts of linear low-density polyethylene,10 to 20 parts of maleic anhydride grafted high-density polyethylene, 5 to 7 parts of high-polymerization-degree polyvinyl chloride, 6 to 8 parts of ethylene-vinyl acetate copolymer, 0.5 to 1.0 part of ultraviolet absorption agent, 1 to 1.5 parts of antioxidant, 2 to 3 parts of plasticizer and 5 to 7 parts of silica power; the high-density polyethylene has a density of 0.936 g / cm<3> and a melt index of 1.4 g / 10 min; the linear low-density polyethylene has a density of 0.920 g / cm<3> and a melt index of 1.0 g / 10 min. The invention reaches the technical effect of enabling the polyethylene plasticbucket to also have excellent printing performance when having cold resistance.

Owner:青岛邦德化工有限公司

Fireproof building coating

InactiveCN105038463AGood gloss and color retentionEasy constructionFireproof paintsAnti-corrosive paintsSilicone resinWeather resistance

The invention provides a fireproof building coating. A main body of the fireproof coating adopts combination of thermoplastic acrylic resin, hydroxy acrylic resin and organic silicon resin, and due to the combination of the resin, the coating not only has the good light and color preserving property and the water and chemical resistance property, but also is convenient to construct, high in drying speed and economical in energy. According to the fireproof building coating, mullite fibers and silica fibers which can resist high temperature are added, and therefore not only can the mechanical strength of a coating layer be significantly improved, but also the weather resistance and corrosion resistance of the coating layer can be improved. When a fire disaster occurs, through the synergistic effect of all the components in the formula, the fire retardant effect is good, and smoke formation is little.

Owner:章俊

High-specific-heat-capacity substance based electric welding protective plus material and preparation method thereof

ActiveCN109112836AImprove performanceExcellent flame retardantLiquid repellent fibresVegetal fibresCross-linkLiquid water

The invention relates to a high-specific-heat-capacity substance based electric welding protective plus material and a preparation method thereof. The high-specific-heat-capacity substance based electric welding protective plus material is prepared from an inflaming-retarding textile, a high-water-absorption coating composition and a water-repellency finishing layer. The preparation method of theelectric welding protective plus material comprises the following steps of applying the high-water-absorption coating composition to the front surface of an inflaming-retarding plus material, next, oven-drying for 1 min to 10 min at 120 DEG C, and baking for 1 min to 5 min at 160 DEG C, wherein the high-water-absorption coating composition is prepared from oily polyurethane, a cross-linking agent,high-water-absorption resin, a dispersant and lignin powder and the like; locally or fully applying a water-repellency finishing agent to the back surface of the front surface coated inflaming-retarding textile obtained in the former step; and before use, spraying or atomizing liquid water with an application amount of 100 g / m<2> to 300 g / m<2> to the high-water-absorption coating on the front surface. Through the way, an electric welding spark in contact with the plus material can be quickly extinguished after the surface of the electric welding protective plus material provided by the invention absorbs water; the heat is absorbed or quickly moved away; thus, the heat reaching a skin is reduced; and the purpose of protecting the skin from being burned is achieved.

Owner:SWOTO PROTECTION & TECH CO LTD +1

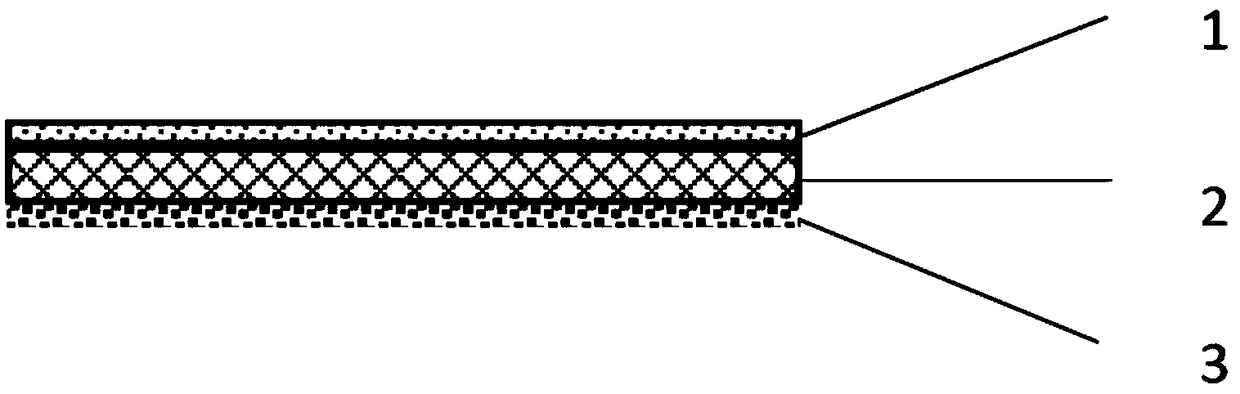

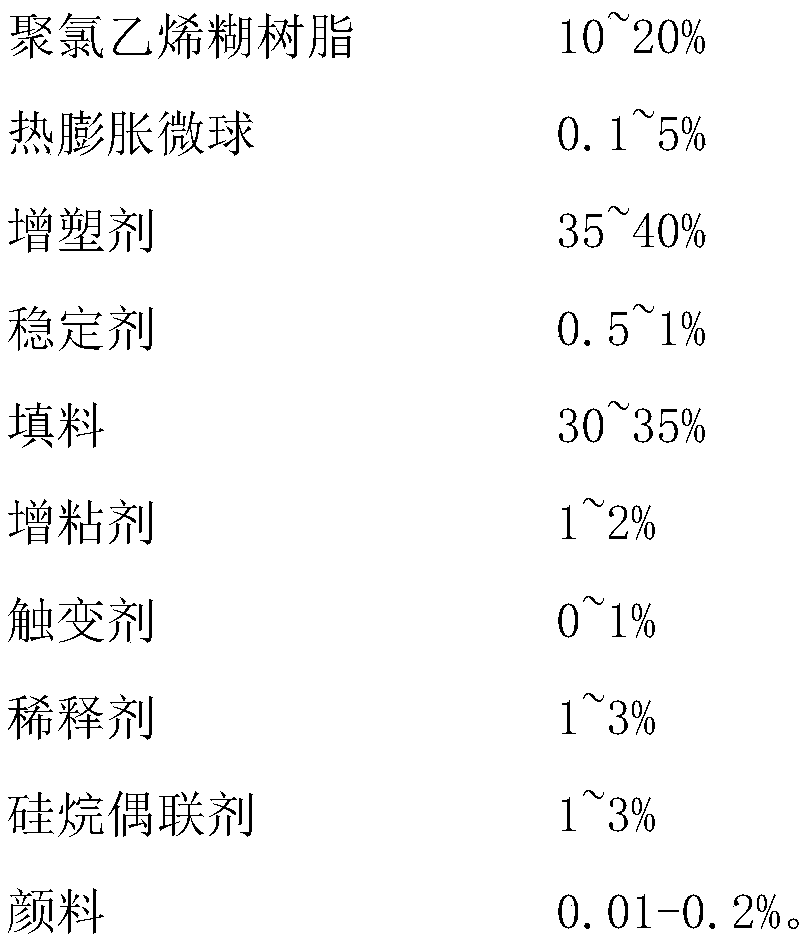

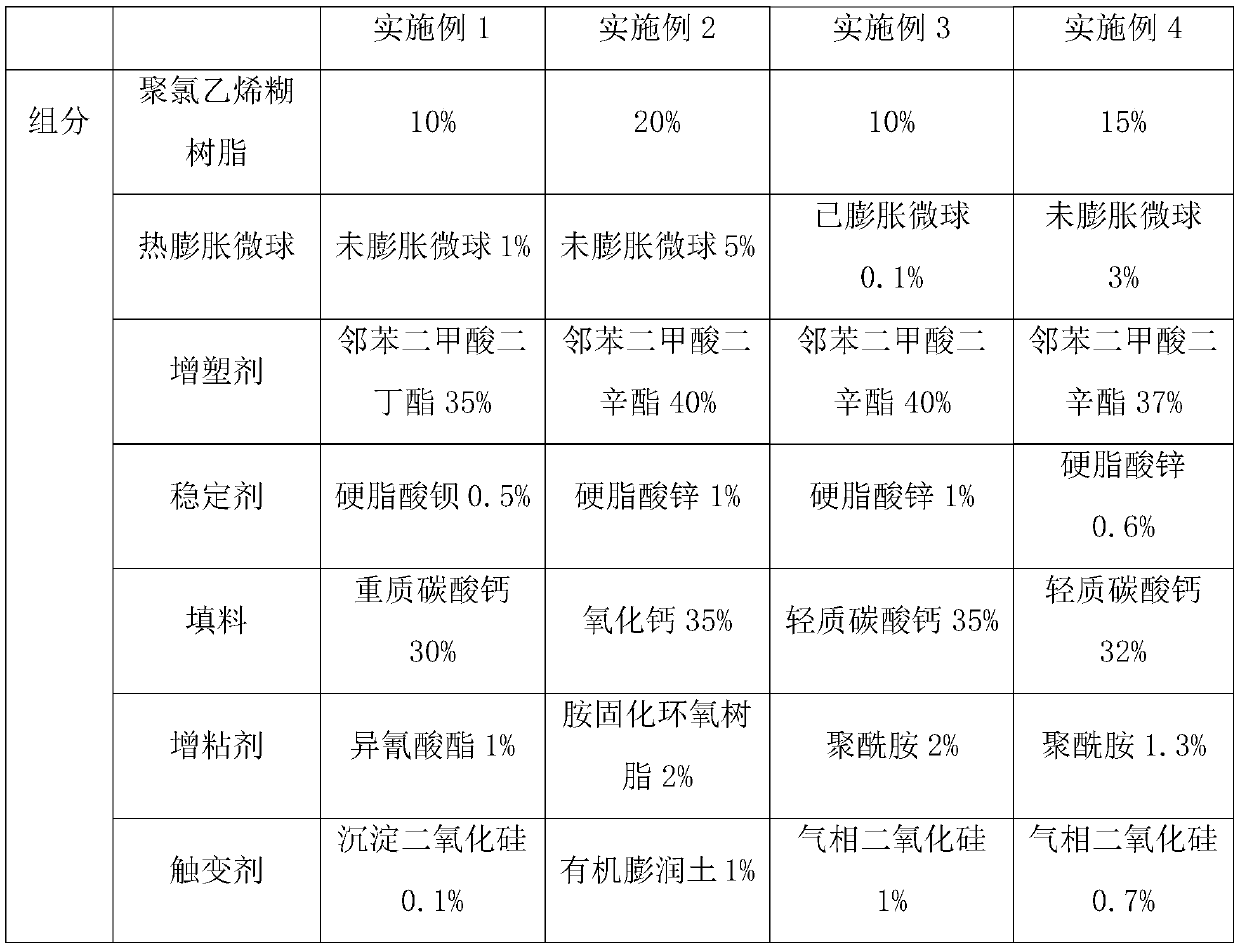

Automotive PVC stone chip resistant paint and preparation method thereof

The invention discloses automotive PVC stone chip resistant paint and a preparation method and application thereof. The automotive PVC stone chip resistant paint comprises, by weight, 10-20% of polyvinyl chloride paste resin and 0.1-5% of thermal expansion microspheres. Weight of the stone chip resistant paint can be reduced by 50% and reaches about 5kg, so that automobile lightweight is realized.Bubbles formed by the expansion microspheres are of closed structures, hole channeling is avoided, and the bubbles are uniform in size and regular in distribution and have no impact on mechanical performance of a paint film like bad consequences such as low wear resistance, corrosion resistance reduction and proneness of moisture to going deeply and being retained. Compact structure of the expansion microspheres enables the expansion microspheres to be integrated with a high-resistance matrix to generate good protective effect, and other performances of the paint film can be improved.

Owner:NANOSPHERE SHANGHAI

Preparation method of fireproof coating

ActiveCN105062291AGood gloss and color retentionGood water and chemical resistanceFireproof paintsWeather resistanceAcrylic resin

The invention provides a preparation method of a fireproof coating. The preparation method has the beneficial effects that thermoplastic acrylic resin, hydroxy acrylic resin and organic silicon resin are combined to be used as a main body of the fireproof coating; through combination of the three kinds of resin, the coating not only has good light and color retention properties and water and chemical resistance but also is convenient to construct, has high drying speed and saves energy; as high temperature resistant mullite and silica fibers are also added to the coating, not only can the mechanical strength of coats be obviously improved but also the weather and corrosion resistance of the coats can be improved; in case of a fire, through synergy of various components in the formula, the coating has good flame retardant effects and is less in fuming.

Owner:北京昊天防火材料厂

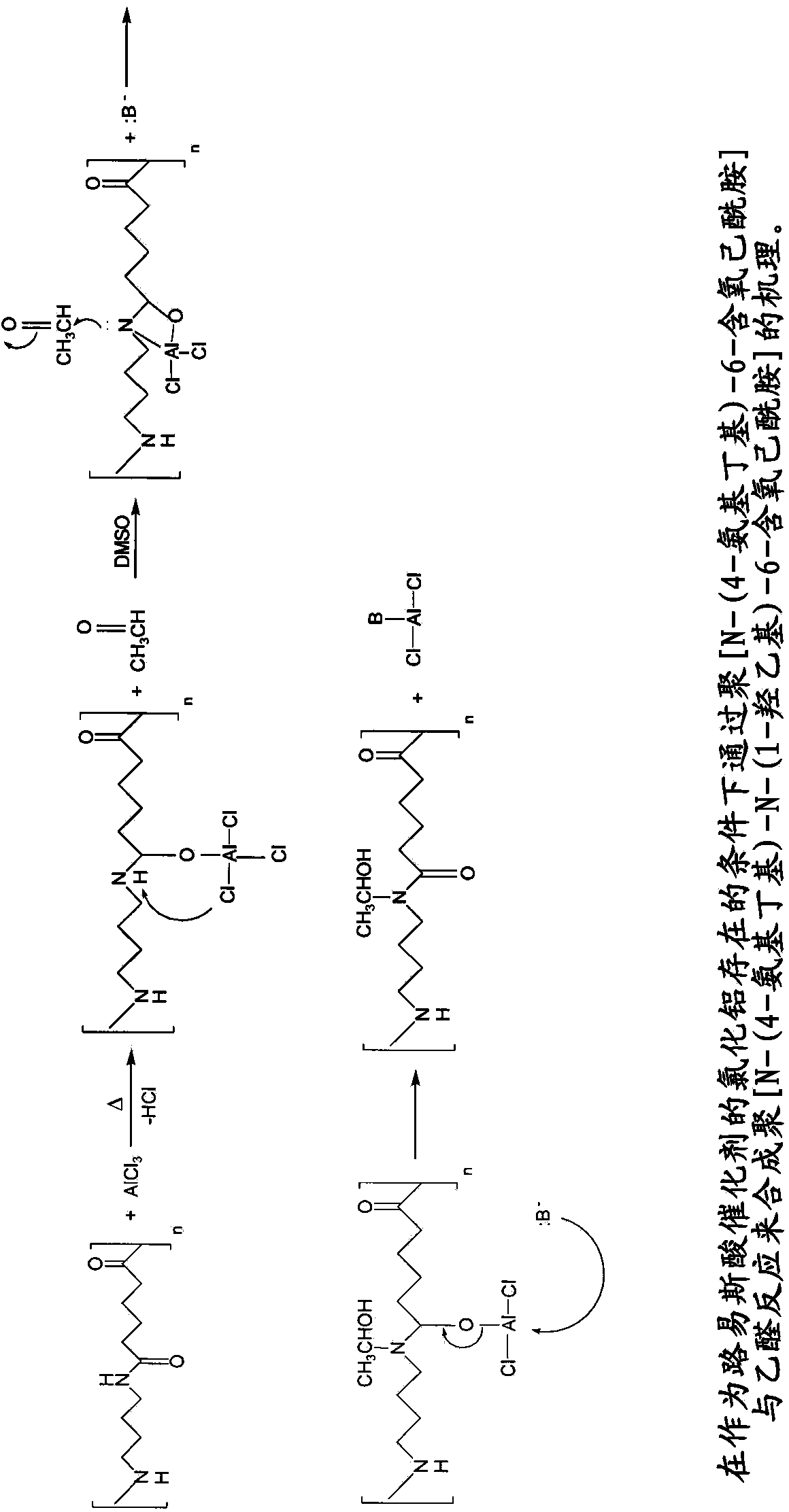

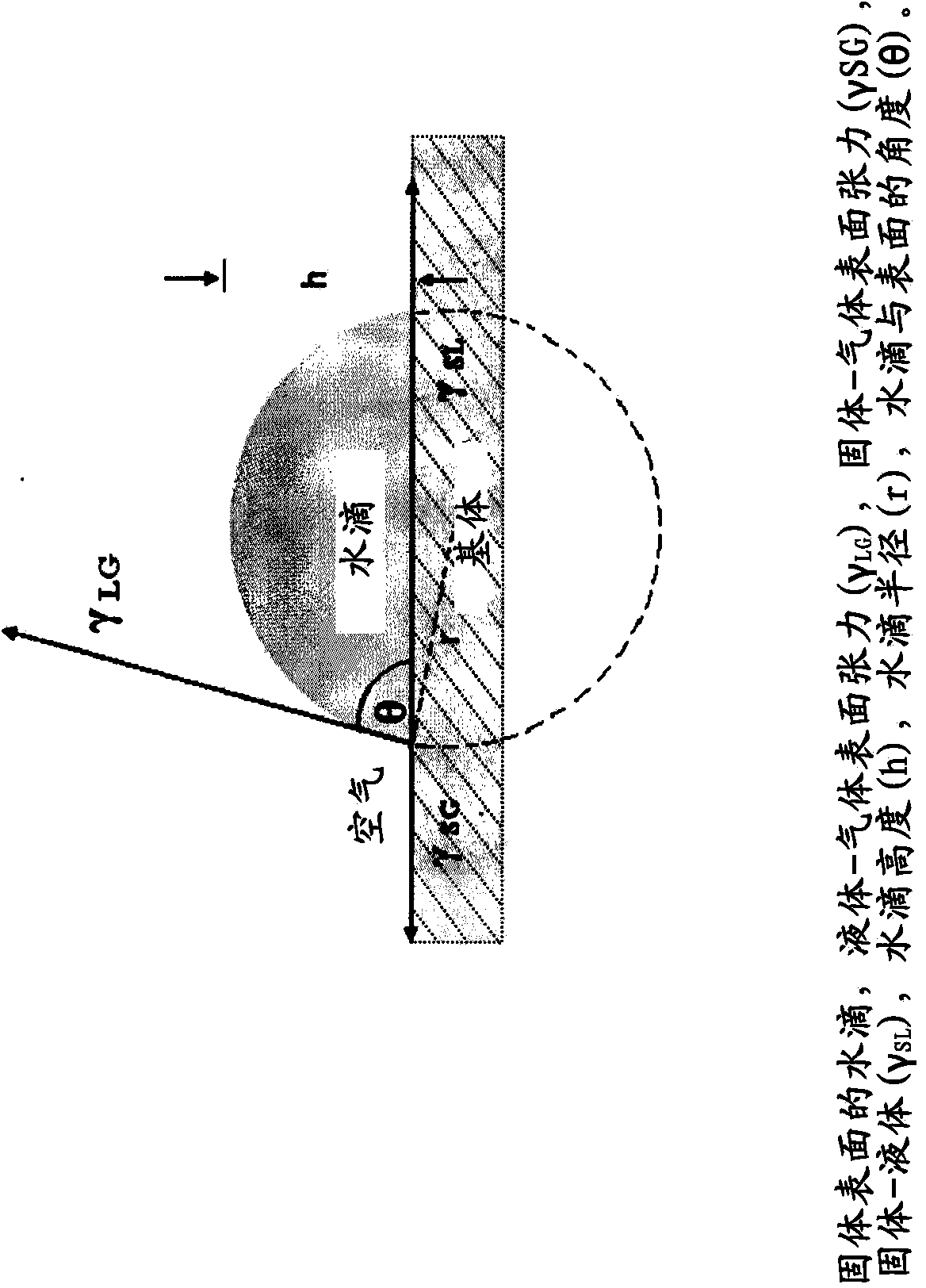

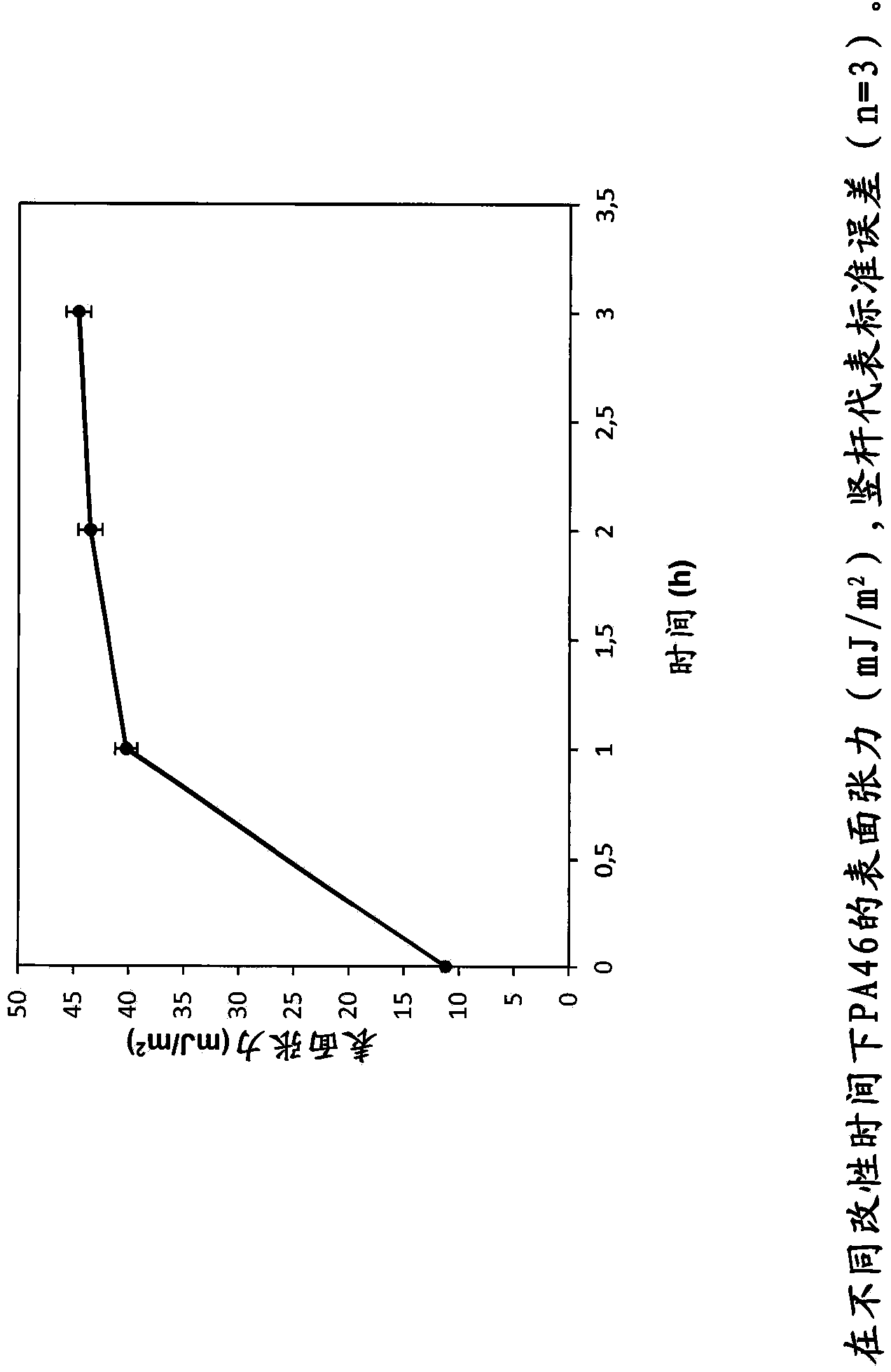

Bulk hydrophilic funtionalization of polyamide 46

InactiveCN103917578AHigh crystallinityImprove other propertiesPhysical/chemical process catalystsAbsorbent padsPorosityPerfusion

A modified polymer as result of a bulk functionalization of polyamide 46 (PA 46) is presented, as well as methods for synthesizing the modified polymer. This functionalization of PA 46 is performed to provide a homogenous semi-permeable polyamide 46 capable of different charges and different porosities with particles of nanoscale size in order to replace or improve other polyamide fibers used in the textile industry, filtering processes, selective sorption, controlled release devices, phase transfer catalysts, chromatography media, biocompatible capsules, artificial skins, organs, bone void repair as well as in cell bioreactors and incubators, dental impliments, medical devices, clothing, detectors, perfusion devices, in regenerative medicine, and fuel cells.

Owner:ENCUBATOR

Ceramic material

InactiveCN106187279AReduce consumptionLow costCeramic materials productionCeramicwareSludgeSilicon dioxide

The invention discloses a ceramic material. The ceramic material is prepared from the following raw materials in parts by weight: 42-85 parts of dry sludge, 32-48 parts of crop straw, 10-24 parts of limestone, 10-22 parts of dolomite, 10-16 parts of diatomite, 8-12 parts of ferric oxide, 6-10 parts of silicon dioxide, 6-12 parts of zirconium dioxide, 4-6 parts of broken aluminum blocks, 2-3 parts of glass fibers, 2-3 parts of a water reducing agent, 0.6-1.2 parts of a foaming agent, 0.4-1 part of a foaming regulator, 0.4-0.6 part of a catalyst, 0.4-0.6 part of a cross-linking agent, 0.2-0.4 part of a foam stabilizer, 30-40 parts of a hydrogen peroxide solution and 350-480 part of water. According to the ceramic material disclosed by the invention, the utilization field is opened up for sludge waste materials and the crop straw, the making cost of ceramics is effectively reduced, energy consumption is reduced, and waste is turned into wealth.

Owner:广西南宁桂尔创环保科技有限公司

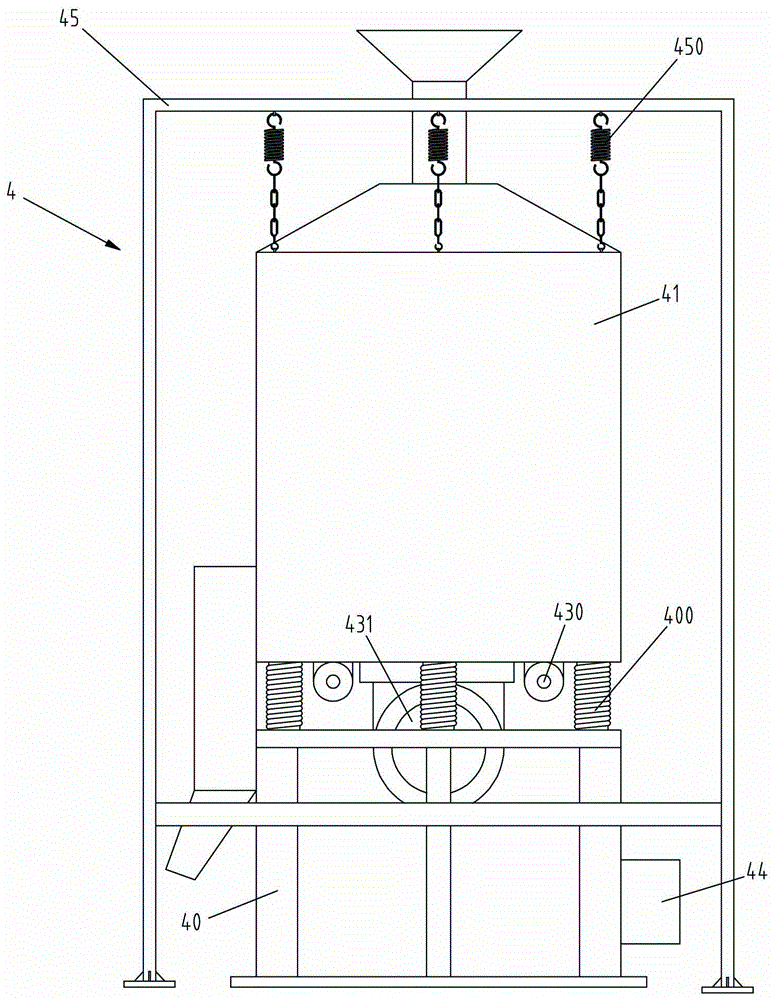

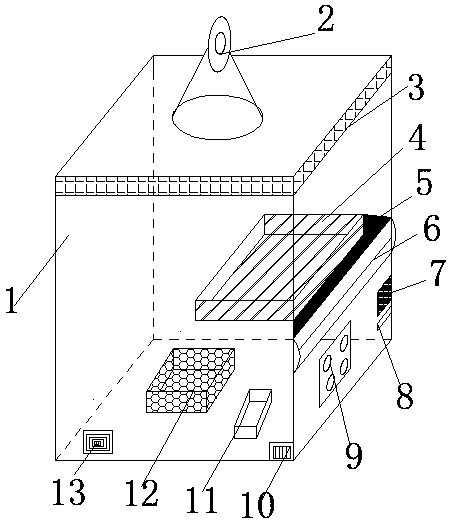

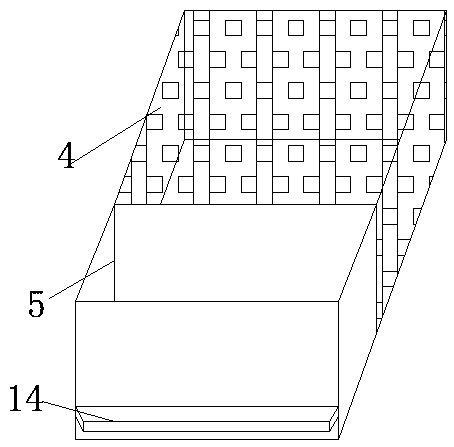

Activation system for powder materials

ActiveCN104609747AHigh strengthImprove other propertiesSolid waste managementCement productionEngineeringBiological activation

The invention discloses an activation system for powder materials. The activation system comprises an activation chamber, an activator container storing an activator, and a controller, wherein a feeding hole, a discharging hole and an atomizing device are arranged on the activation chamber; the activator in the activator container is input into the atomizing device through an activator pipeline; the atomizing device is used for atomizing the activator and spraying the atomized activator into the activation chamber; the activation chamber is also equipped with a microwave emission device; the controller is used for controlling the microwave emission device to input microwaves into the activation chamber. The activation system provided by the invention can activate various potential active powder materials and especially can be used for producing tailing micro-powder or directly activating a mixture of tailing powder, master batch, aggregates and the like to obtain dry-mixed mortar, a filling cementing material, and other finished products.

Owner:厦门兑泰新材料科技有限公司

Finishing liquid for hot-galvanized plate and preparation method for finishing liquid

ActiveCN104194908AGood anti-rust functionImprove rust resistanceLubricant compositionSodium metasilicateTricarboxylic acid

The invention relates to finishing liquid for a hot-galvanized plate and a preparation method for the finishing liquid. The finishing liquid comprises a component I and a component II, wherein the component I comprises following ingredients in parts by weight: 23-33 parts of water, 5-8 parts of dibasic acid, 8-12 parts of tricarboxylic acid and 54-57 parts of triethanolamine; the component II comprises following ingredients in parts by weight: 47-68 parts of water, 4-8 parts of sodium carbonate, 3-5 parts of potassium hydroxide, 2-4 parts of disodium ethylenediamine tetraacetate, 6-10 parts of sodium metasilicate pentahydrate, 8-12 parts of reverse block polyether, 6-8 parts of neodecanoic acid and 3-6 parts of sodium benzoate. The finishing liquid has relatively good rust-proof and lubricating effects, has excellent wetting and cleaning properties and relatively high cleaning ability, and can lubricate and repair the surface of a roll; the finished galvanized plate is smooth in surface, and defects of finishing spots and coating moire can be effectively eliminated or reduced; the finishing liquid has good foam-inhibiting and defoaming functions, so that liquid can be avoided from remaining on the surfaces of the roll and a steel plate and the foam can be avoided from overflowing around to affect the working environment.

Owner:江苏苏北能源科技有限公司

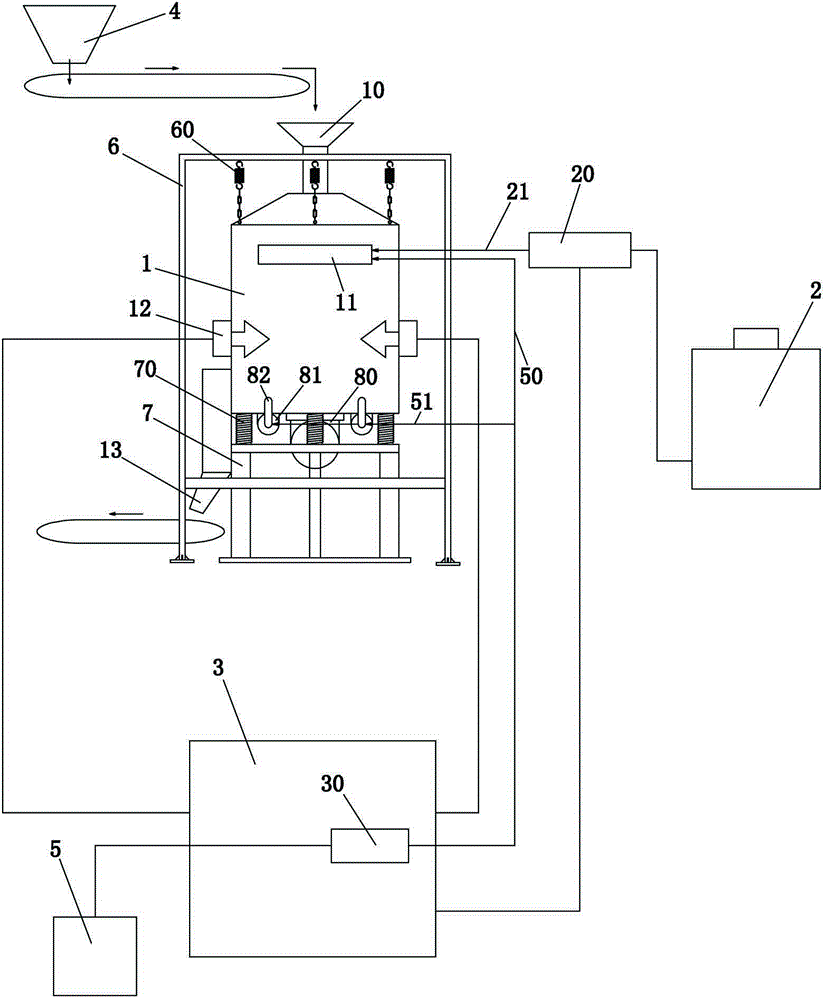

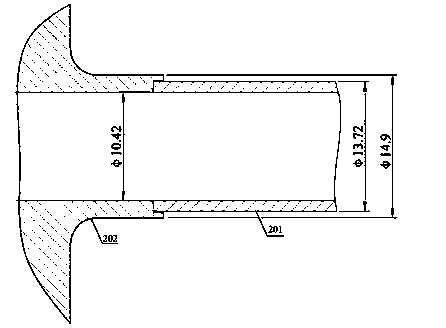

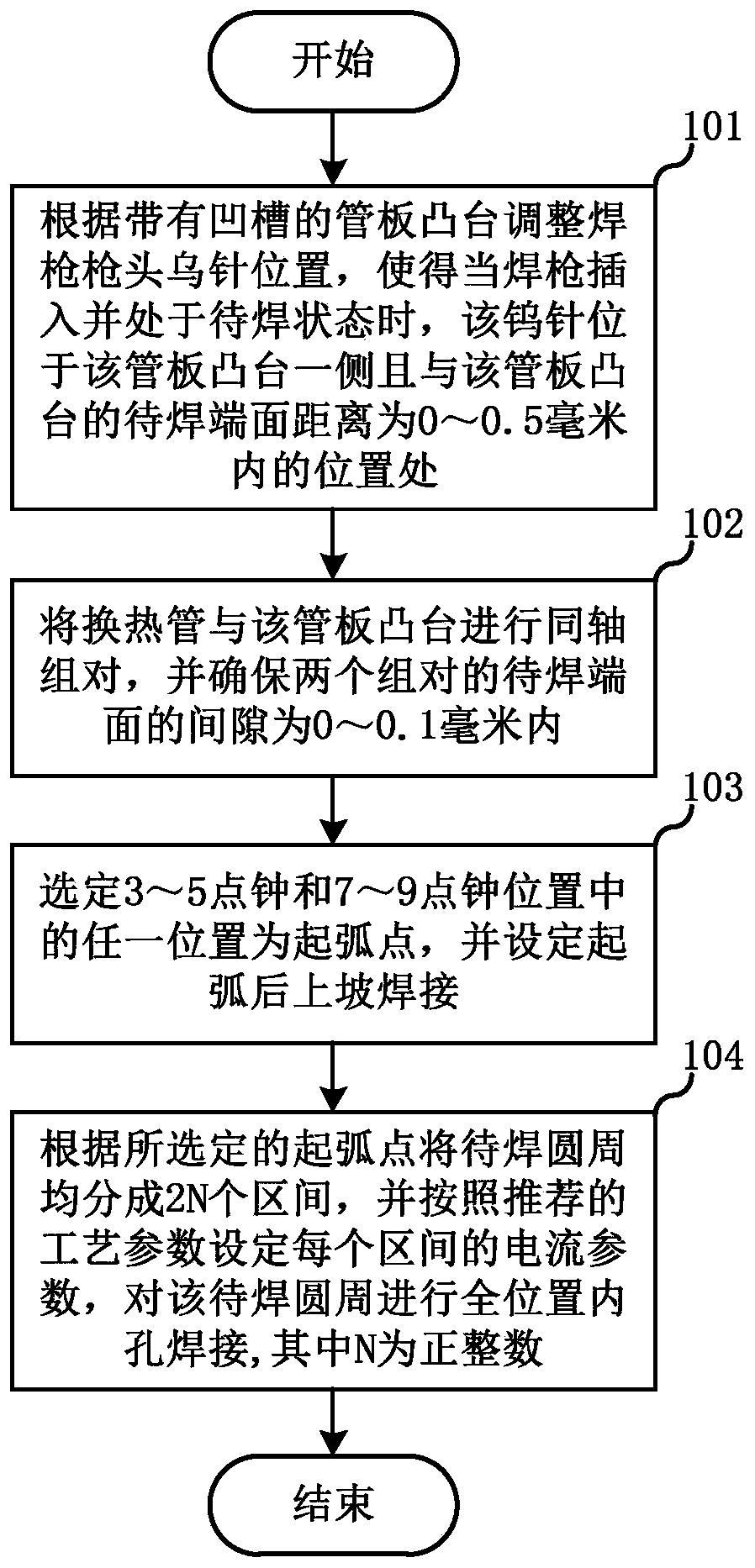

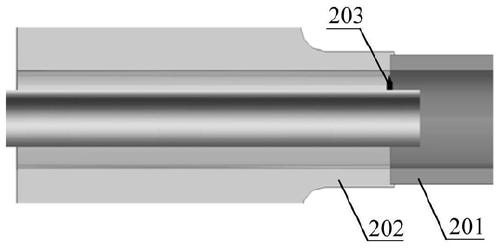

Pipe plate inner hole welding method for small-aperture heat exchange pipe

ActiveCN111037065AImprove aestheticsImprove welding qualityArc welding apparatusHeat exchange apparatusEngineeringWelding defect

The invention relates to a welding technology, discloses a pipe plate inner hole welding method for a small-aperture heat exchange pipe, and can effectively eliminate the welding defects that the outer surface of a joint is concave inwards and arc extinguishing pits are formed in the back surface of the joint. The inner hole diameter of the heat exchange pipe is 9-15 mm, and the wall thickness is1-2 mm. The method comprises the steps that the position of the tungsten pin of a welding gun head is adjusted according to a pipe plate boss with a groove so that when the welding gun is inserted andis in a to-be-welded state, the tungsten pin is located on one side of the pipe plate boss and the distance between the tungsten pin and the to-be-welded end face of the pipe plate boss is within 0-0.5 mm; the heat exchange pipe and the pipe plate boss are coaxially assembled, and it is ensured that the gap between the to-be-welded end faces of the two assemblies is within 0-0.1 mm; any one of the positions of 3-5 o'clock and 7-9 o'clock is selected as an arcing point, and uphill welding is set after arcing; and the circumference to be welded is equally divided into 2N sections according to the selected arcing points, the current of each section is set according to the recommended process parameters and all-position inner hole welding is performed on the circumference to be welded.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Fireproof corrosion resistant coating

InactiveCN105062288AGood gloss and color retentionGood water and chemical resistanceFireproof paintsAnti-corrosive paintsWeather resistanceAcrylic resin

The invention provides a fireproof corrosion resistant coating. The fireproof corrosion resistant coating has the beneficial effects that thermoplastic acrylic resin, polyurethane resin and organic silicon resin are combined to be used as a main body of the fireproof corrosion resistant coating; through combination of the three kinds of resin, the coating not only has good light and color retention properties and water and chemical resistance but also is convenient to construct, has high drying speed and saves energy; as high temperature resistant mullite and silica fibers are also added to the coating, not only can the mechanical strength of coats be obviously improved but also the weather and corrosion resistance of the coats can be improved; in case of a fire, through synergy of various components in the formula, the coating has good flame retardant effects and is less in fuming.

Owner:章俊

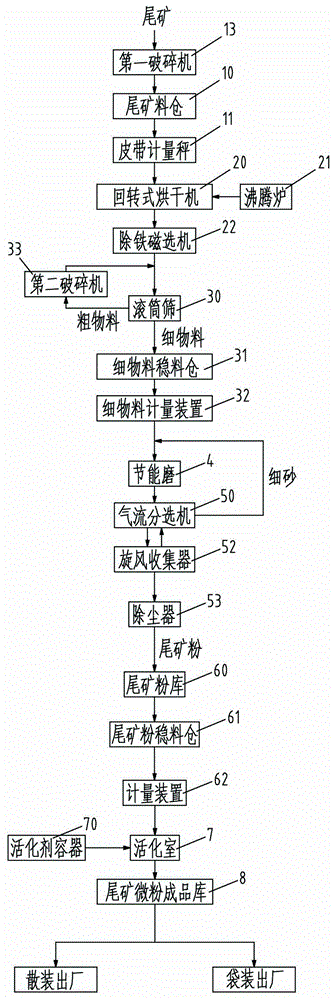

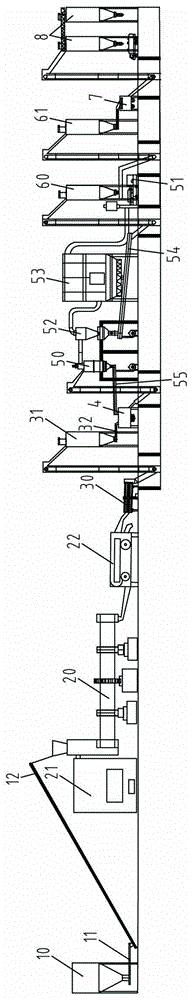

Production equipment for tailing micro powder

ActiveCN105944813AElicit activityHigh degree of automationSolid waste managementGrain treatmentsEngineeringBiological activation

Owner:厦门兑泰新材料科技有限公司

Single-component chromium-free environment-friendly non-oriented electrical steel insulated surface treatment agent

InactiveCN110305574AImprove insulation performanceReduce porosityAnti-corrosive paintsPolyurea/polyurethane coatingsChromium freeWeldability

The invention discloses a single-component chromium-free environment-friendly non-oriented electrical steel insulated surface treatment agent which is composed of, by weight, 20.0-50.0% of waterbornepolyurethane resin, 1.0-10.0% of film forming aid, 1.0-5.0% of inorganic acid salt, 0.1-1.0% of boric acid, 1.0-5.0% of acidic corrosion inhibitor, 0.5-5.0% of magnesium hydroxide, 0.1-1.0% of organicsolvent and the balance of water. The treatment agent is free of chromium, so that the problems of hexavalent chromium heavy metal hidden danger and water pollution are avoided during use and waste liquid treatment; the treatment agent has excellent insulativity, corrosion resistance, adhesiveness, laminated weldability, punching performance, heat resistance and oil resistance, and performance ofa coating formed by the treatment agent is equivalent to that of a chromium-containing coating.

Owner:上海优梓新材料科技有限公司

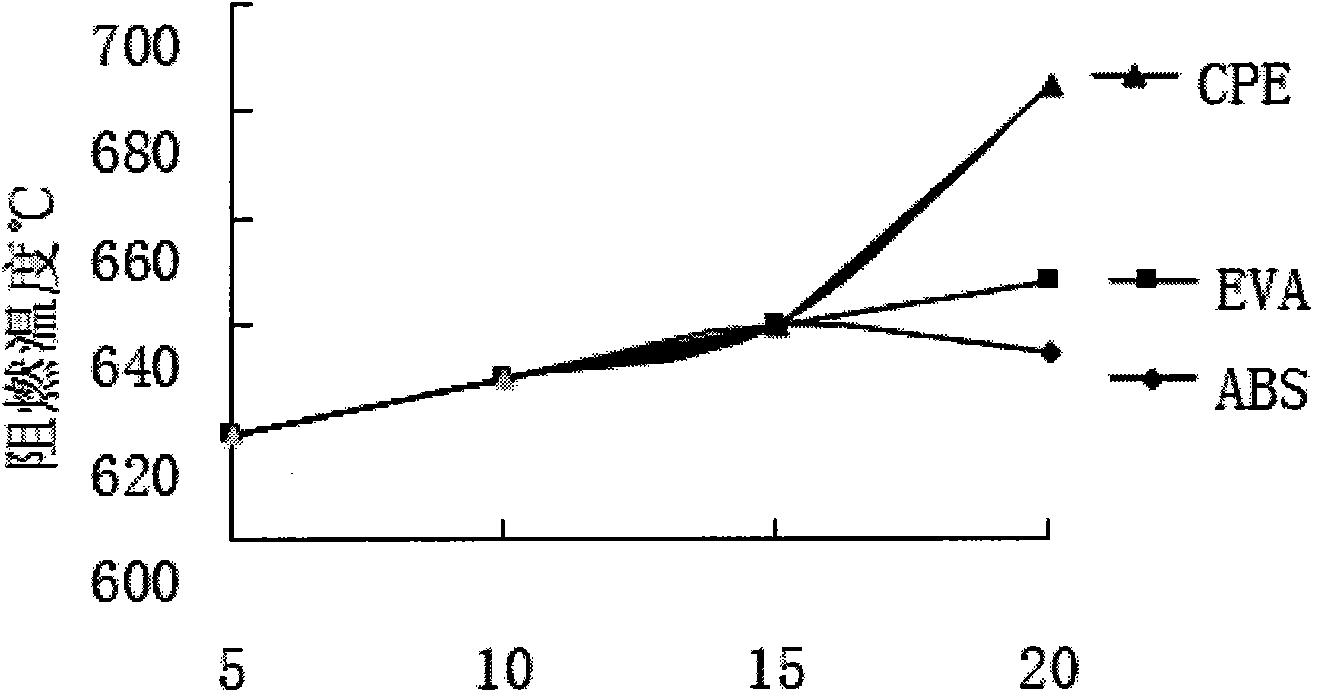

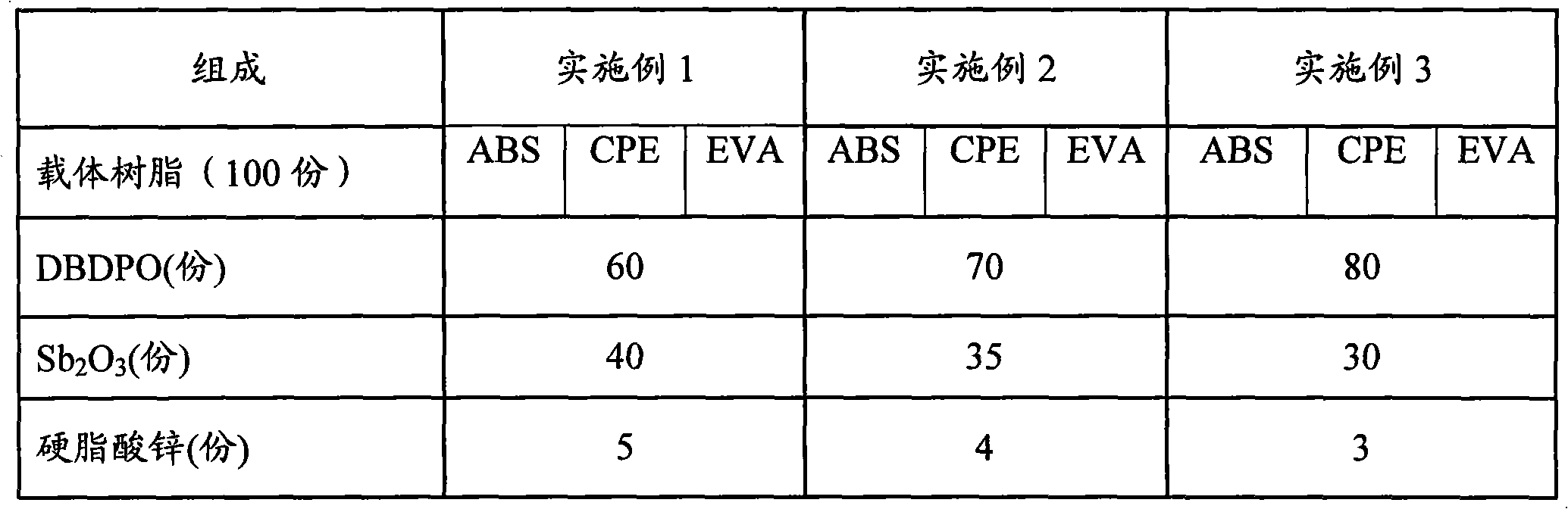

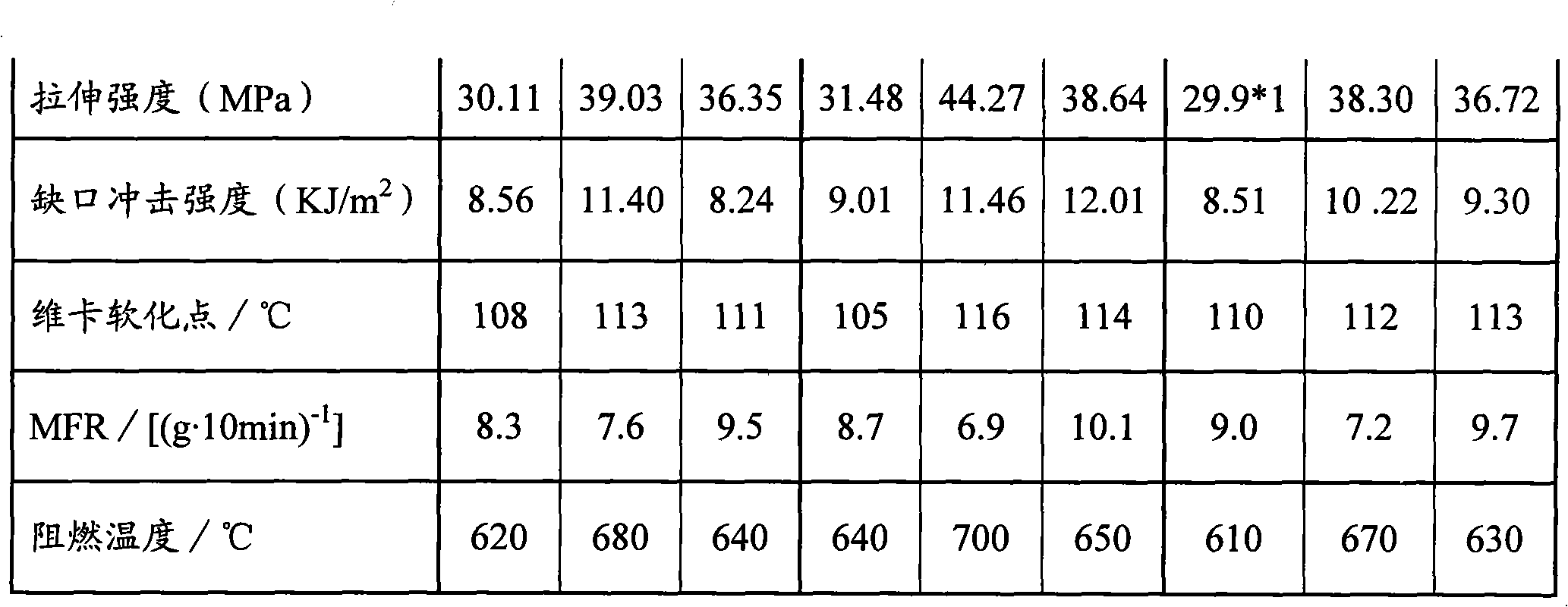

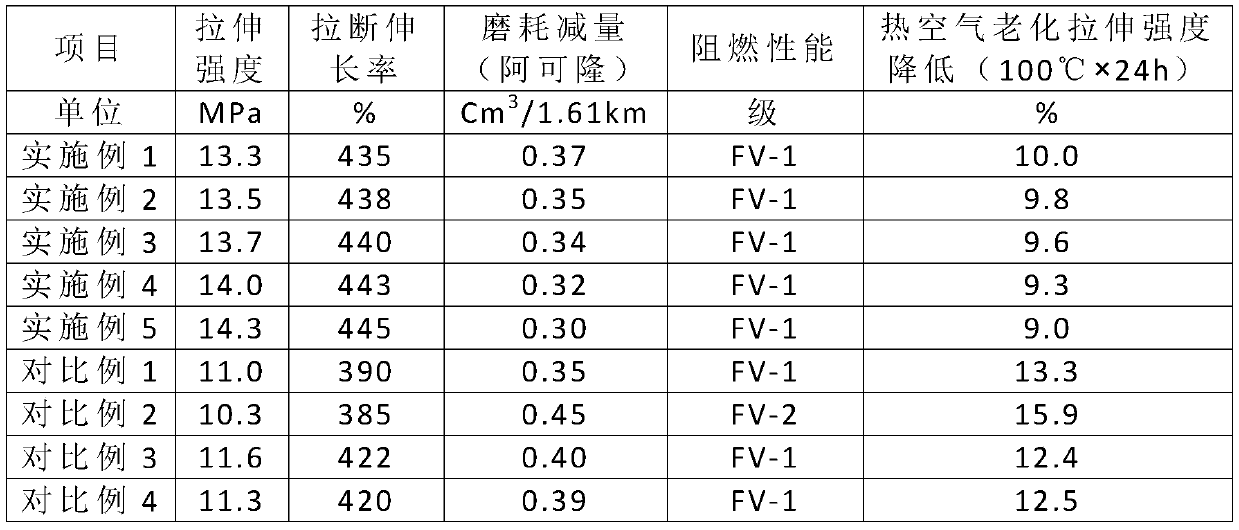

Flame retardant ABS master batch and preparation method thereof

InactiveCN101948605ALittle impact on other performanceImprove flame retardant performanceEngineeringExtrusion Granulation

The invention is suitable for the field of polymer, and provides a flame retardant ABS master batch and a preparation method thereof. The method uses a DBDPO / Sb2O3 composite flame retardant system, which comprises 60-80 parts of DBDPO, 30-40 parts of Sb2O3, 100 parts of different carrier resin and other adjuvants. Various flame retardant master batches are prepared through melt blending and extrusion granulation, and then are mixed with ABS to make performance contrast research, thus the ABS master batch, which takes CPE as carrier resin and has good flame retardance and other performances, is obtained. The flame retardant master batch prepared by the invention has small influences on other performances of ABS resin, can reach UL94 V0-level flame retardance, has simpler processing technology, and provides conditions for ABS resin to being applied to military, automobiles, electronic and electrical appliances.

Owner:SHENZHEN KEJU NEW MATERIAL

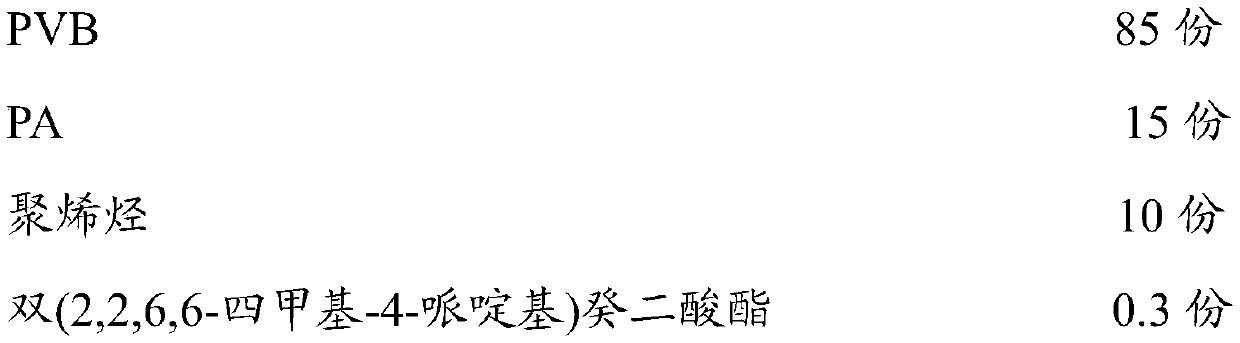

Low-shrinkage adhesive film for solar cell packaging and preparation method of adhesive film

InactiveCN110698998AGood weather resistanceImprove other propertiesNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterPolymer science

The invention belongs to the technical field of solar cell packaging, and particularly relates to a low-shrinkage adhesive film for solar cell packaging and a preparation method of the adhesive film.The adhesive film is formed by laminating and compounding three layers of polymer films including a PVB film, a PET (polyester) film and a PVB film in sequence, wherein the PET film is stretched at least twice. The preparation method comprises the following steps: compounding the PVB film, the PET film and the PVB film by melt lamination, performing dual-direction stretching on the composite film,performing cooling, performing far-infrared heating to 220-240 DEG C, and performing longitudinal secondary stretching. According to the technical solution provided by the invention, the thin PET film is added between the PVB films, the PET film is stretched twice, so that the problem of a high and imbalanced bidirectional shrinkage rate of the PVB films is controlled, the excellent weather resistance and other properties of the PVB films are fully utilized, and the adhesive film is particularly suitable for use in metal wrap through (MWT) solar cells.

Owner:SENSIN NEW MATERIAL BEIJING TECH

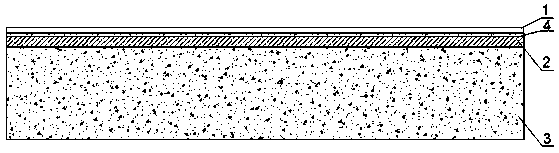

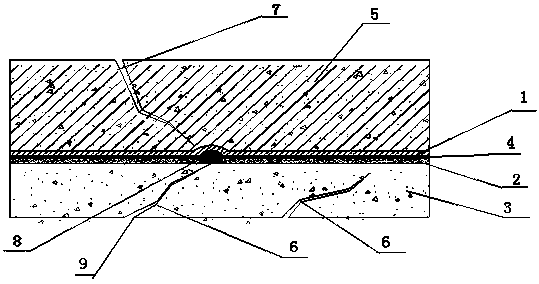

Composite waterproof structure and preparation method thereof

ActiveCN108859344ANo delaminationStrong chemical bondSynthetic resin layered productsLaminationPolymer modifiedSurface layer

The invention discloses a composite waterproof structure and a preparation method thereof, and belongs to the field of building waterproof materials. The composite waterproof structure is prepared from a waterproof coil layer, a reaction type macromolecular elastic coating layer and a waterproof base layer in turn from top to bottom, wherein the waterproof coil layer is prepared from an upper surface layer and a self-sticking material layer in turn from top to bottom; the self-sticking layer is self-sticking polymer modified asphalt. According to the composite waterproof structure and the preparation method thereof disclosed by the invention, separation between the coating and the coil is avoided, and the waterproof effect is perfect.

Owner:四川省威盾新材料有限公司

Weather-resistant wire and cable material and production process thereof

InactiveCN111154204ASimplify the production processReduce energy consumptionRubber insulatorsWeather resistanceTitanium isopropoxide

The invention discloses a weather-resistant wire and cable material. The material is characterized by being prepared from following raw materials in parts by weight: 70-80 parts of perfluorotriazine rubber, 15-25 parts of epichlorohydrin rubber, 20-30 parts of benzotriazole-1-carbothioic acid allyl amide / 2,4-diamino-6-vinyl-S-triazine / titanium triisopropanol methacrylate / 4-hydroxybutyl vinyl ethercopolymer, 5 to 10 parts of industrial solid waste, 5 to 10 parts of volcanic ash, 2 to 5 parts of epoxy asphalt, and 3 to 6 parts of a vulcanizing agent. The invention also discloses a production method of the weather-resistant wire and cable material. The weather-resistant wire and cable material is excellent in comprehensive performance, excellent in mechanical property, weather resistance andflame resistance, good in wear resistance, aging resistance and heat resistance, high in use safety and long in service life.

Owner:何先鹏

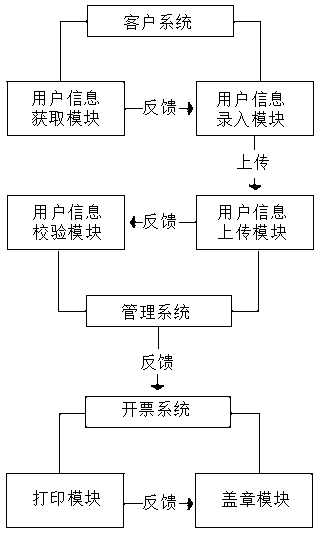

Unattended electronic invoice issuing system and device

ActiveCN109816898AGuaranteed uptimeEasy remote controlReceipt giving machinesInvoiceUser information

The invention discloses an unattended electronic invoice issuing system and device, and belongs to the technical field of electronic invoice application. The device is placed in a room and connected with a power supply, an information two-dimension code or a membership card is placed in a card reading area after consumption of a user for information identification, and after user information is received, the user information is automatically matched with and corresponds to database information; then, a main controller commands an invoice printing device to typeset the electronic invoices and print paper bills, and after the paper bills pass through a stamping device, stamped paper bills are obtained. The system and device have good social benefits and economic benefits.

Owner:新疆航天信息有限公司

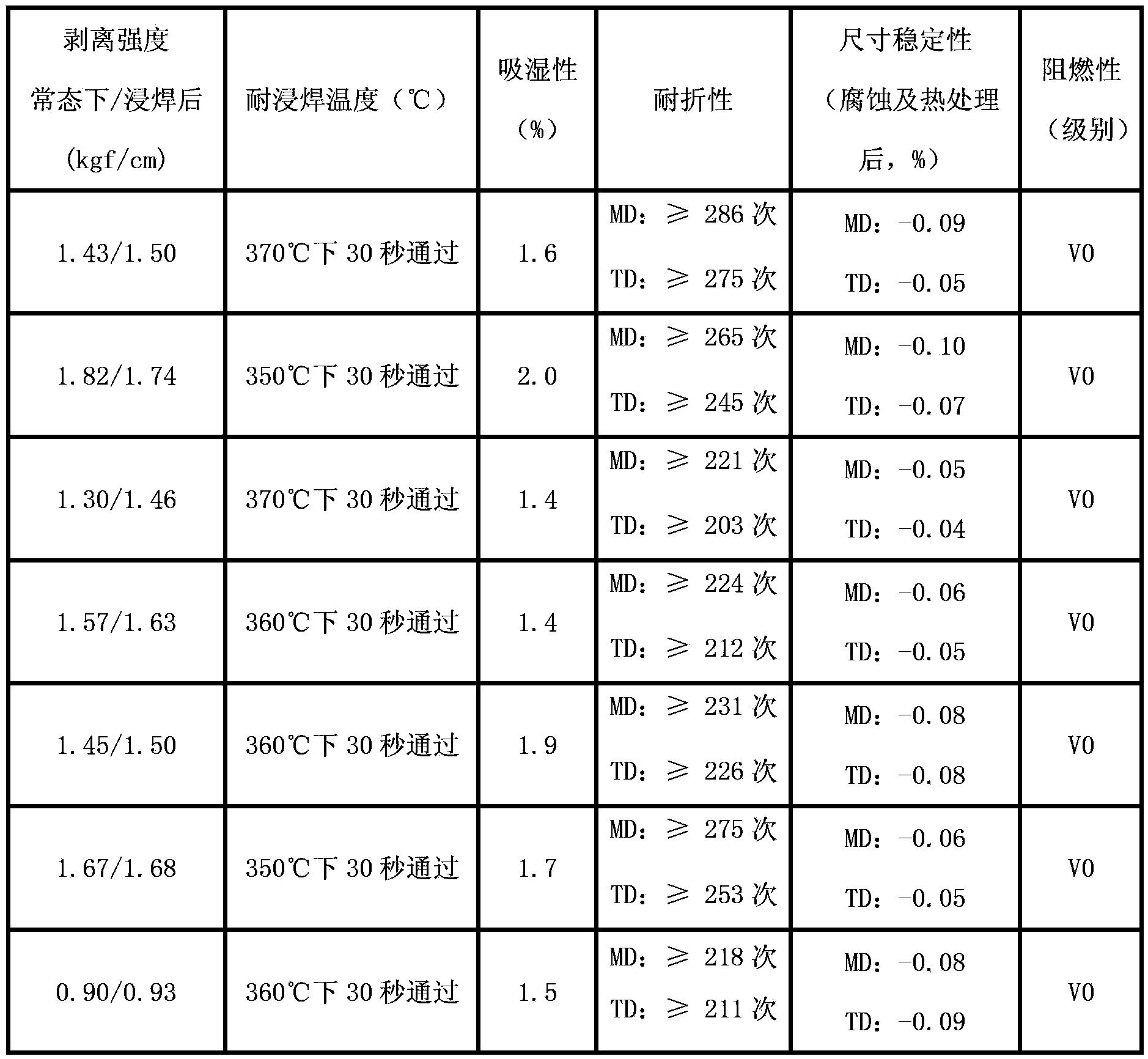

Polyimide film and method for preparing two-layer flexible copper clad laminate using the same

ActiveCN102993748BSmall coefficient of thermal expansionGood dimensional stabilityMetal layered productsCopper foilThermal expansion

The invention relates to thermoplastic polyimide (TPI) film with low coefficient of thermal expansion, a preparation method of the TPI film, and a method for preparing a double-layer flexible copper-clad plate (2L-FCCL) by utilizing the TPI film. The preparation method of the TPI film comprises the following steps in sequence: polymerizing bi(4-aminobenzene)-4-(tribromomethyl) phenylphosphine and 3-phenyl-2, 6-bi(4-aminobenzene) pyridine on a certain mole ratio with relative diamine and dianhydride in form of solution, so as to obtain a polyamide acid copolymer; drying to remove the solvent; and carrying out thermal imidization to process the copolymer, thus obtaining the TPI film which is excellent in hot melting performance and dimensional stability. According to the method for preparing the double-layer flexible copper-clad plate by the TPI film, the TPI film is compounded with a thermoset polyimide film and a copper foil under a certain pressure and temperature, thus obtaining the double-layer flexible copper-clad plate which is excellent in comprehensive performances, such as stripping quality and dimensional stability.

Owner:NANJING UNIV OF SCI & TECH

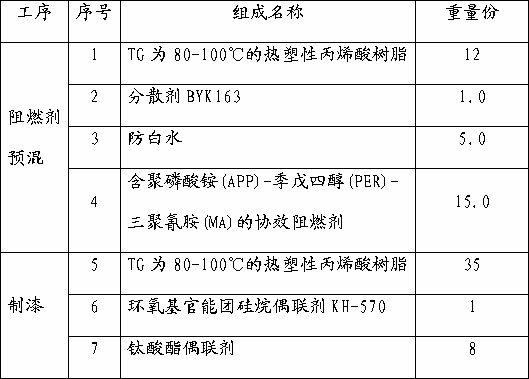

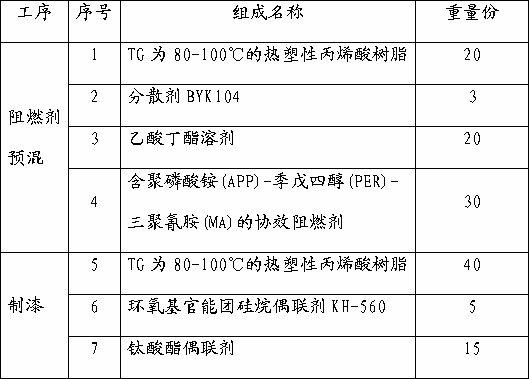

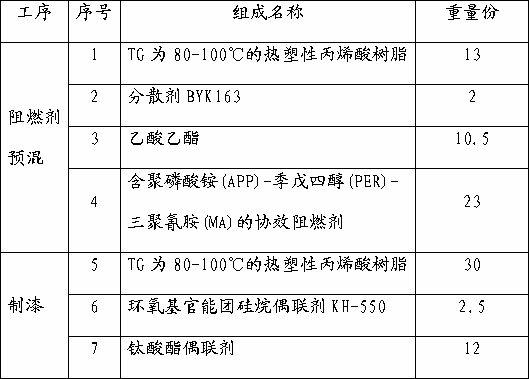

Plastic veneer type thermoplastic acrylic environment-friendly fireproof paint and method for preparing and using same

The invention provides a plastic veneer type thermoplastic acrylic environment-friendly fireproof paint and a method for preparing and using same. The environment-friendly fireproof paint is prepared by using thermoplastic acrylic resin as the primary material with halogen-free synergistic flame retardant ammonium polyphosphate (APP)- pentaerythritol (PER)- melamine(MA), adding a little coupling agent, dispersing auxiliary, pigment and proper solvent under a proper process. The environment-friendly fireproof paint can be used for coating plastic enclosures such as HIPS (High Impact Polystyrene), PS (Polystyrene), ABS (Acrylonitrile Butadiene Styrene), PMMA (Polymethyl Methacrylate), and can form a paint film with excellent fireproof effects after proper constructing and drying, so that fireproof and decoration purposes are achieved. The paint has the characteristics of a thermoplastic acrylic resin paint such as safety and environment protection, easy construction and re-construction, excellent adhesion, strong colour retention decoration, good waterproof performance, good chemical resistance and the like, thus, the fireproof level can reach UL94V-0 level; moreover, the paint is free of halogen and heavy metal, and the smoke quantity in a combustion process is very low, thus, the paint is an environment-friendly fireproof paint with high performances and high efficiency .

Owner:深圳市嘉卓成科技发展有限公司

Self-cleaning cement-based composite material and production method thereof

The invention discloses a self-cleaning cement-based composite material and a production method thereof, and the production method comprises the following steps: aramid fibers containing 18-38% wt of inorganic basalt fibers, glass fibers and ceramic fibers, fibers, aramid fibers, a photocatalytic material, nylon fibers, vinylon fibers are input in a fiber twisting machine for being knitted to 64 fiber threads; the obtained fiber lines can be input into a fiber cloth knitting machine to be knitted into net-shaped fiber cloth with the mesh being 1 m*1 m and the breadth being 2.00 m; a large amount of CO2 can be sucked in the curing process of fresh concrete, calcium silicate and a small amount of hydration products in cement clinker react with CO2 to generate calcium carbonate and silica gel, high early strength can be obtained, the concrete curing time is greatly shortened, good size stability and other performance are achieved, the process of emission reduction is achieved by introducing tailings as a modifying component, the nano-modified concrete component can continuously absorb carbon dioxide in the atmosphere, and meanwhile, the overall mechanical property and durability of the building material can be improved.

Owner:苏州阔凭环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com