Patents

Literature

32results about How to "Little impact on other performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-fiber-emergence low-warping high-tenacity flame-retardant PET/PETG composite material and preparation method

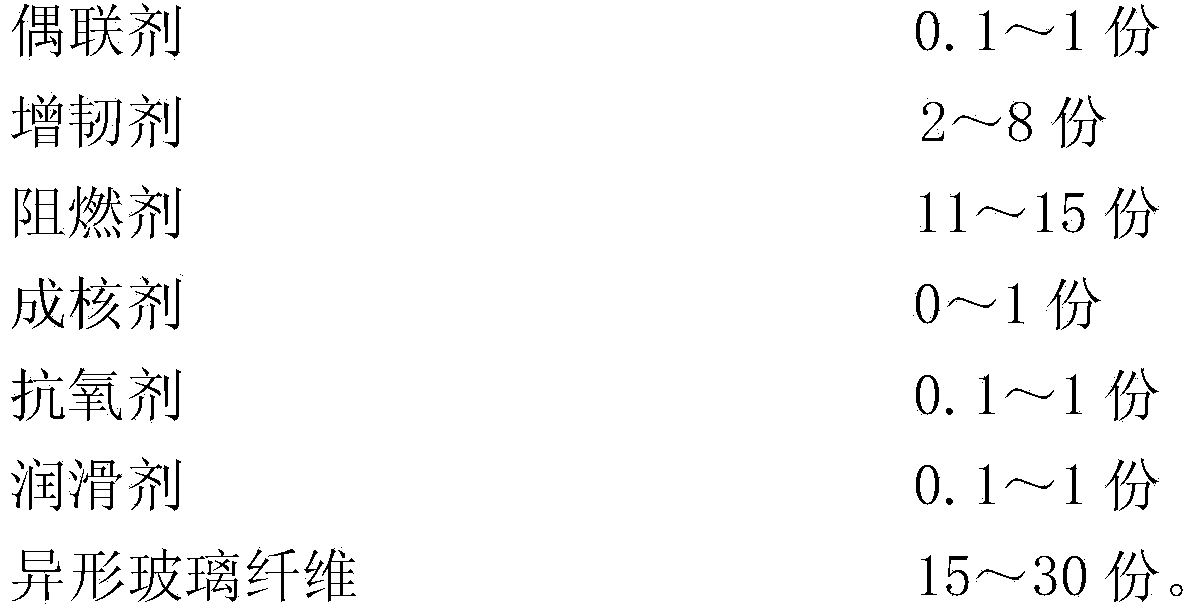

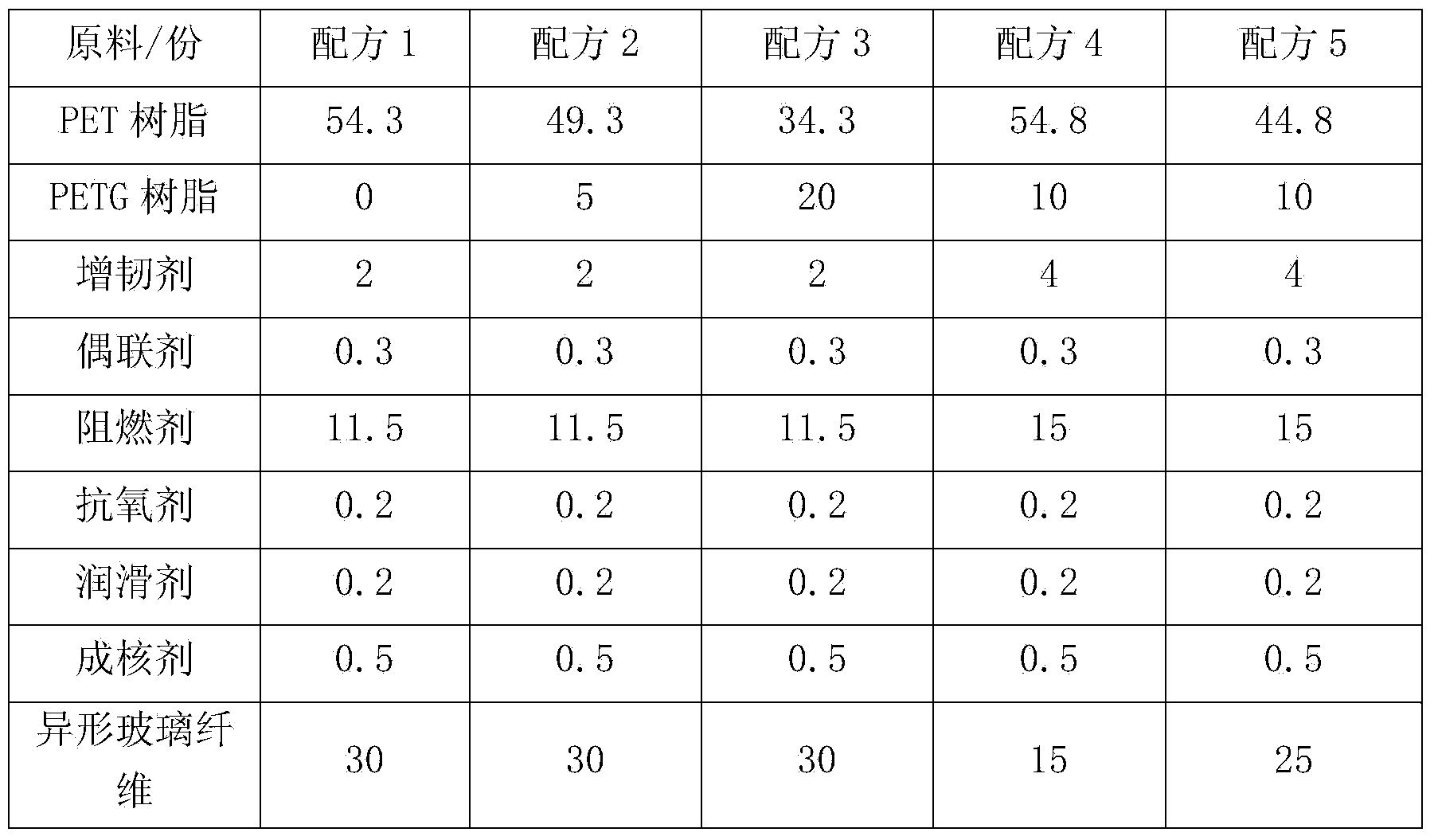

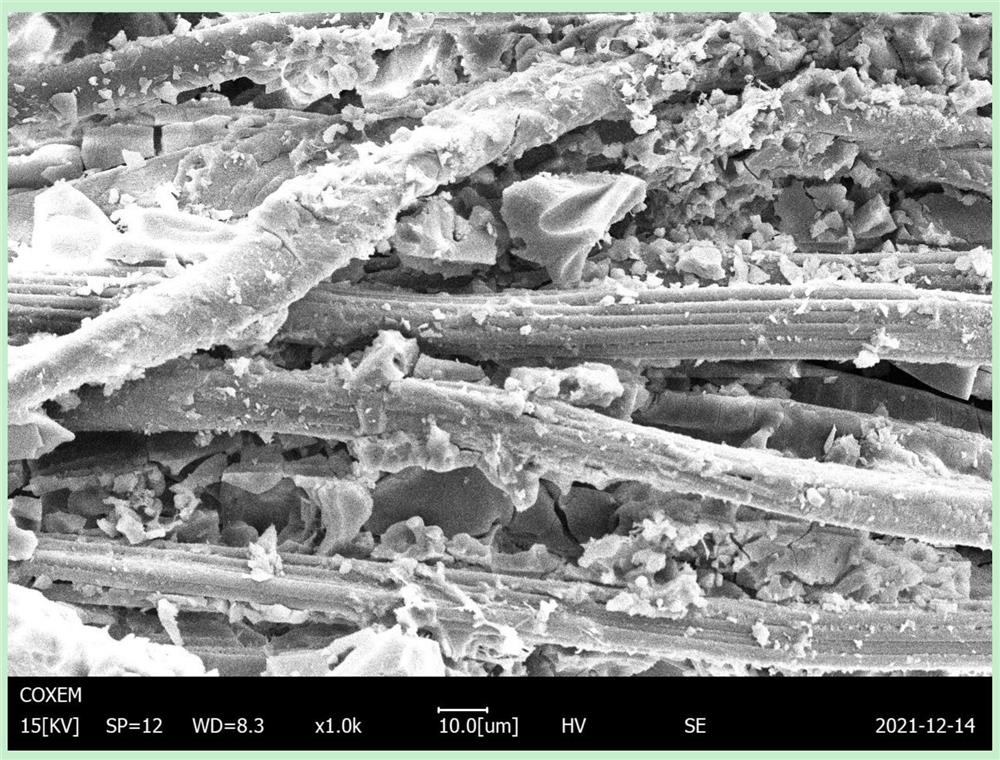

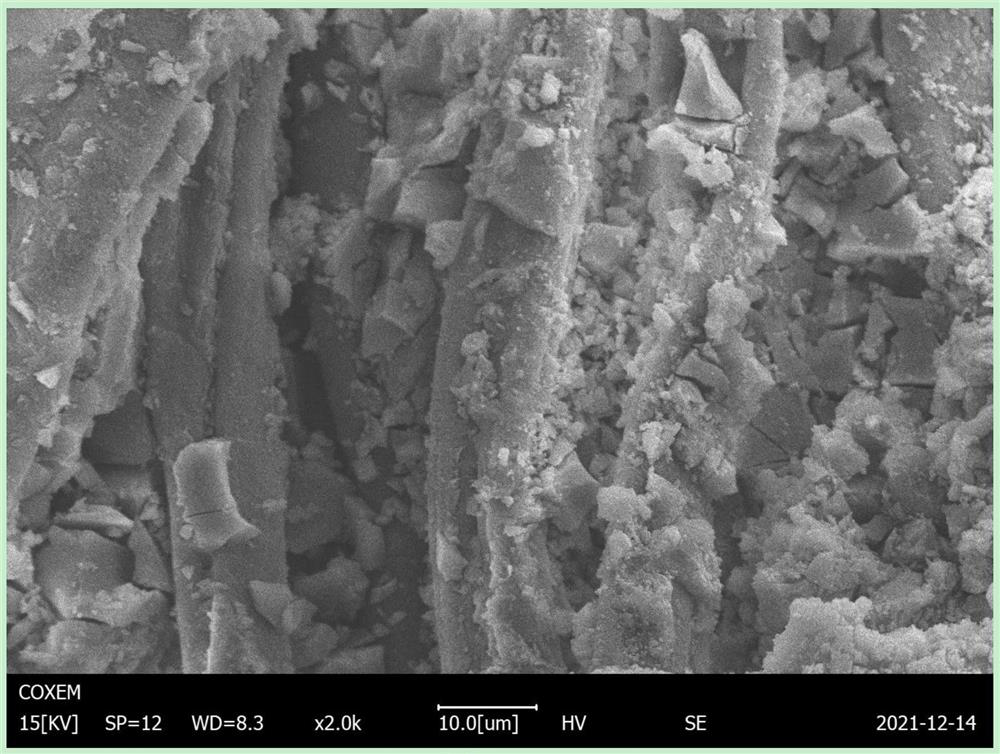

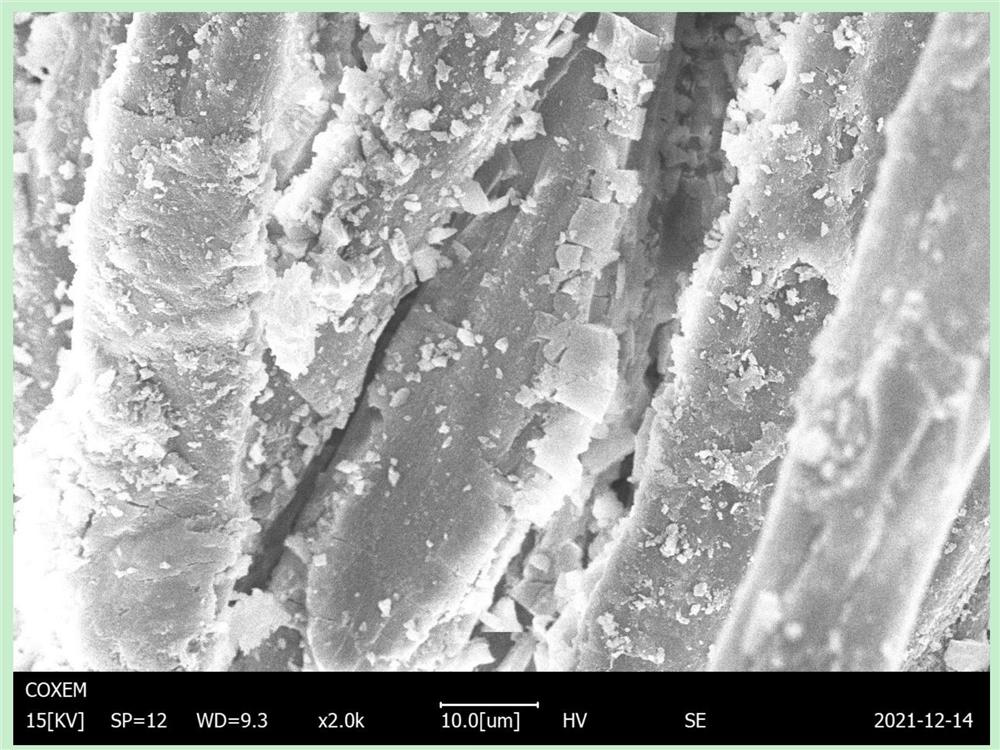

The invention discloses a low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material and a preparation method, and relates to the field of high polymer materials. The composite material is prepared by mixing 30-50 parts of PET resin, 5-20 parts of PETG resin, 0.1-1 part of a coupling agent, 2-8 parts of a flexibilizer, 11-15 parts of a fire retardant, 0-1 part of a nucleating agent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricating agent, adding 15-30 parts of irregular-shaped glass fibers during the extrusion process of a twin-screw extruder, extruding, and pelletizing to obtain. The preparation method of the low-fiber-emergence low-warping high-tenacity flame-retardant PET / PETG composite material disclosed by the invention utilizes the characteristic that the PETG resin is well compatible with the PET resin; the addition of the flame-retardant system PETG, the flexibilizer and the nucleating agent greatly improves the processing performance, the surface performance and the impact performance of the composite material, while influencing the other performances a little; meanwhile, the addition of the PETG and the irregular-shaped glass fibers reduces the crystallization temperature and the crystallization rate of the material, and lowers the warping degree.

Owner:古道尔工程塑胶(深圳)有限公司

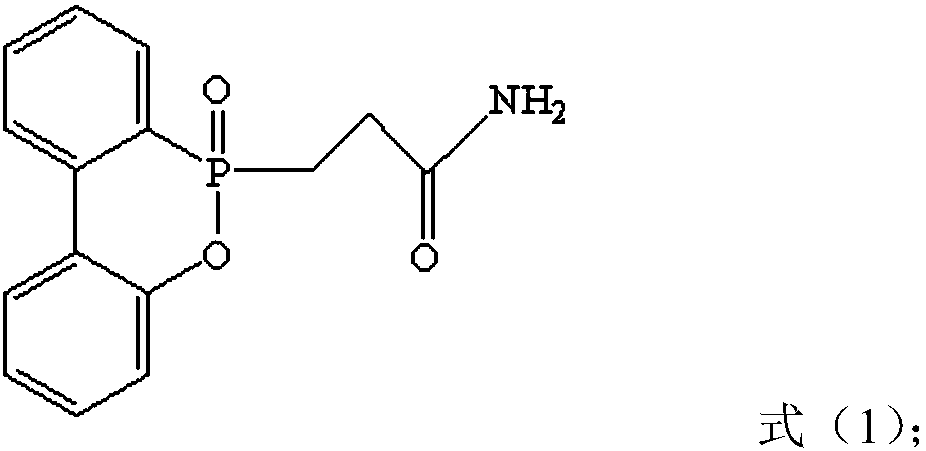

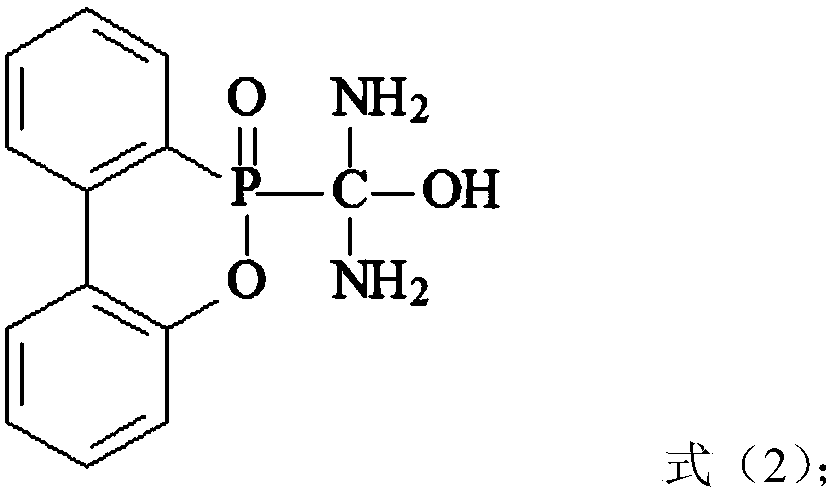

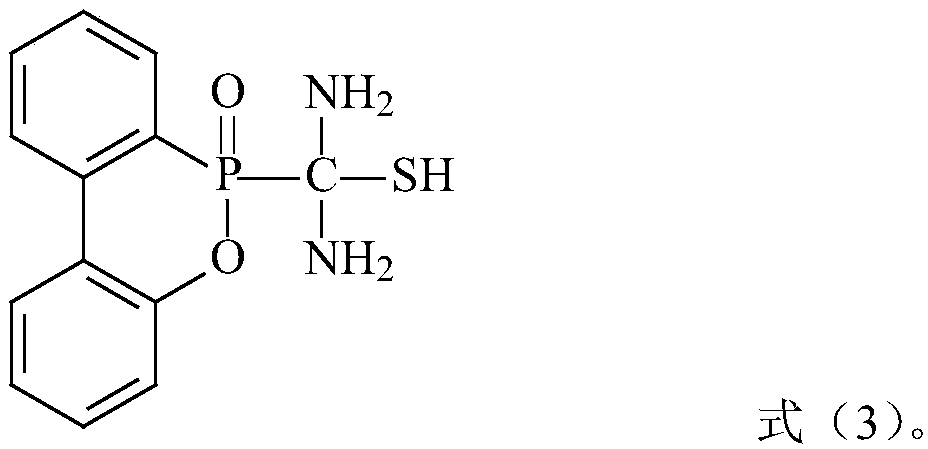

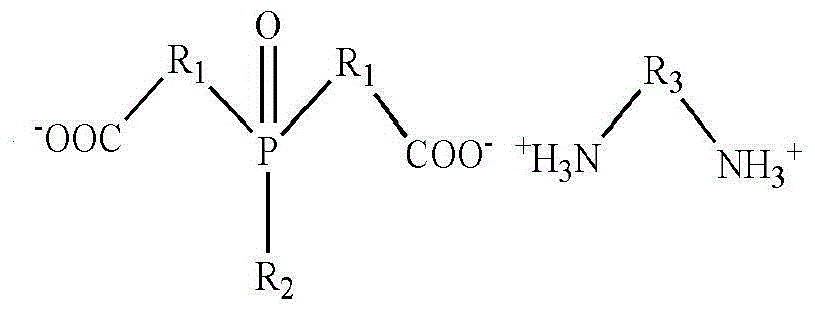

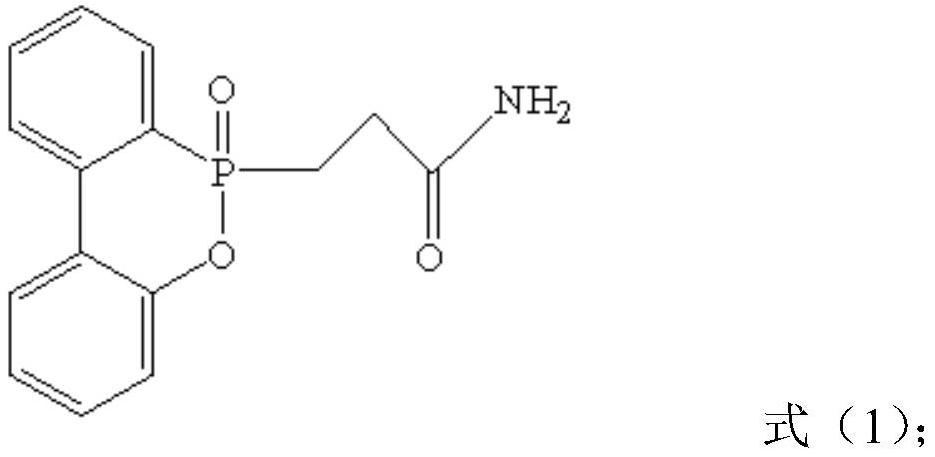

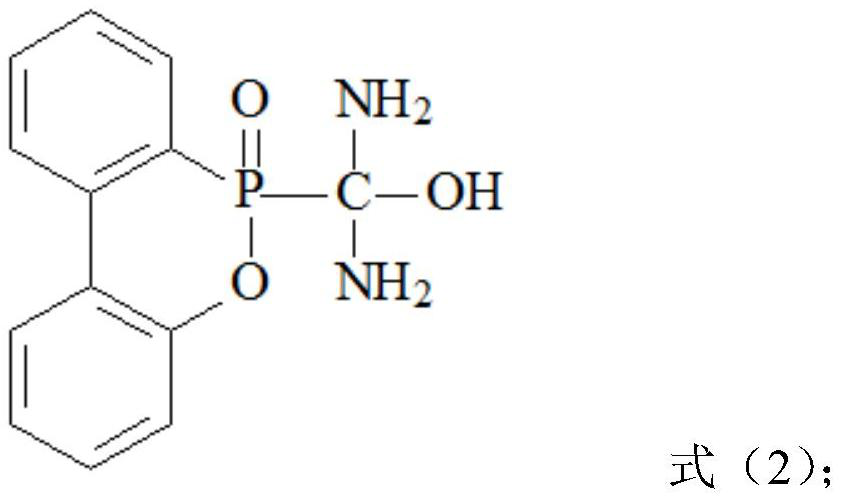

Reactive flame retardant for epoxy resin and flame retardant epoxy resin of reactive flame retardant

The invention provides a reactive flame retardant for epoxy resin and flame retardant epoxy resin of the reactive flame retardant, wherein the reactive flame retardant for epoxy resin comprises at least one of DOPO-AM, DOPO-Urea and DOPO-THU. DOPO is subjected to a reaction with acrylamide, urea and thiourea, and the obtained DOPO-AM, DOPO-Urea and DOPO-THU are reactive organo-phosphorus flame retardants, all of which contain an amine group. When the reactive flame retardants are added into epoxy resin, the amine groups can react with epoxy resin, so as to graft the flame retardants onto a main chain of epoxy resin, so that the migration problem of additive flame retardants is solved; the flame retardant has very good flame retardant properties, and has relatively less effect on the mechanical properties and other properties of epoxy resin, so that epoxy resin also maintains good physical and mechanical properties; moreover, the flame retardant can also improve the refractive index ofepoxy resin.

Owner:SHENZHEN POLYTECHNIC

Preparation method of cationic dyeable halogen-free flame retardant polyester fiber

ActiveCN101864612AInhibit side effectsDoes not affect dyeabilityMonocomponent copolyesters artificial filamentFiberPolymer science

The invention relates to a preparation method of the cationic dyeable halogen-free flame retardant polyester fiber, which comprises the following process steps: 1. adding monosodium isophthalic sulfonate, 2-propyloic hypophosphorous acid and de-ionized water into a reaction container, filtering out reaction products after the reaction is completed, and carrying out baking to obtain cationic dyeable flame retardant compounds; 2. adding terephthalic acid, products in the first step and glycol into an esterification kettle, then, adding antimony ethylene glycalate, conducting the materials into a polycondensation kettle, and carrying out reaction and material outlet to obtain cationic dyeable flame retardant polyester slices; and 3. drying the cationic dyeable flame retardant polyester slices prepared in the second step through a vacuum drum drying machine, carrying out spinning on the dried slices on a spinning machine according to a conventional polyester spinning process to obtain the cationic dyeable halogen-free flame retardant polyester fiber. The invention realizes the flame retardant performance and the cationic dyeable performance of the polyester through one-step addition, avoids the complicated process and the occurrence of various kinds of secondary reaction caused by a traditional method of adding flame retardant agents and cationic dyeable auxiliary agents in two steps, and has more stable and obvious flame retardant and cationic dyeable effect.

Owner:JIANGSU XINGYE PLASTIC

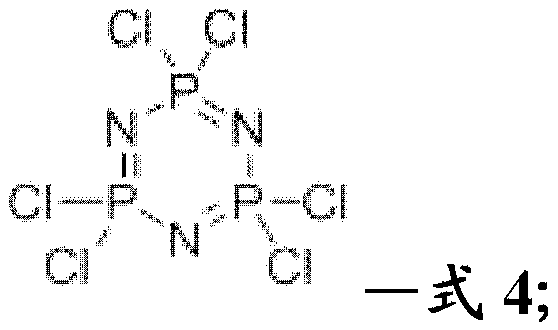

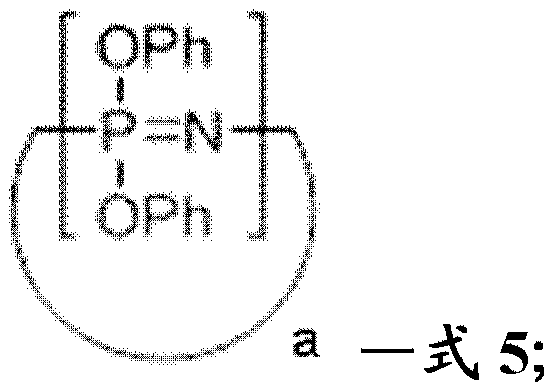

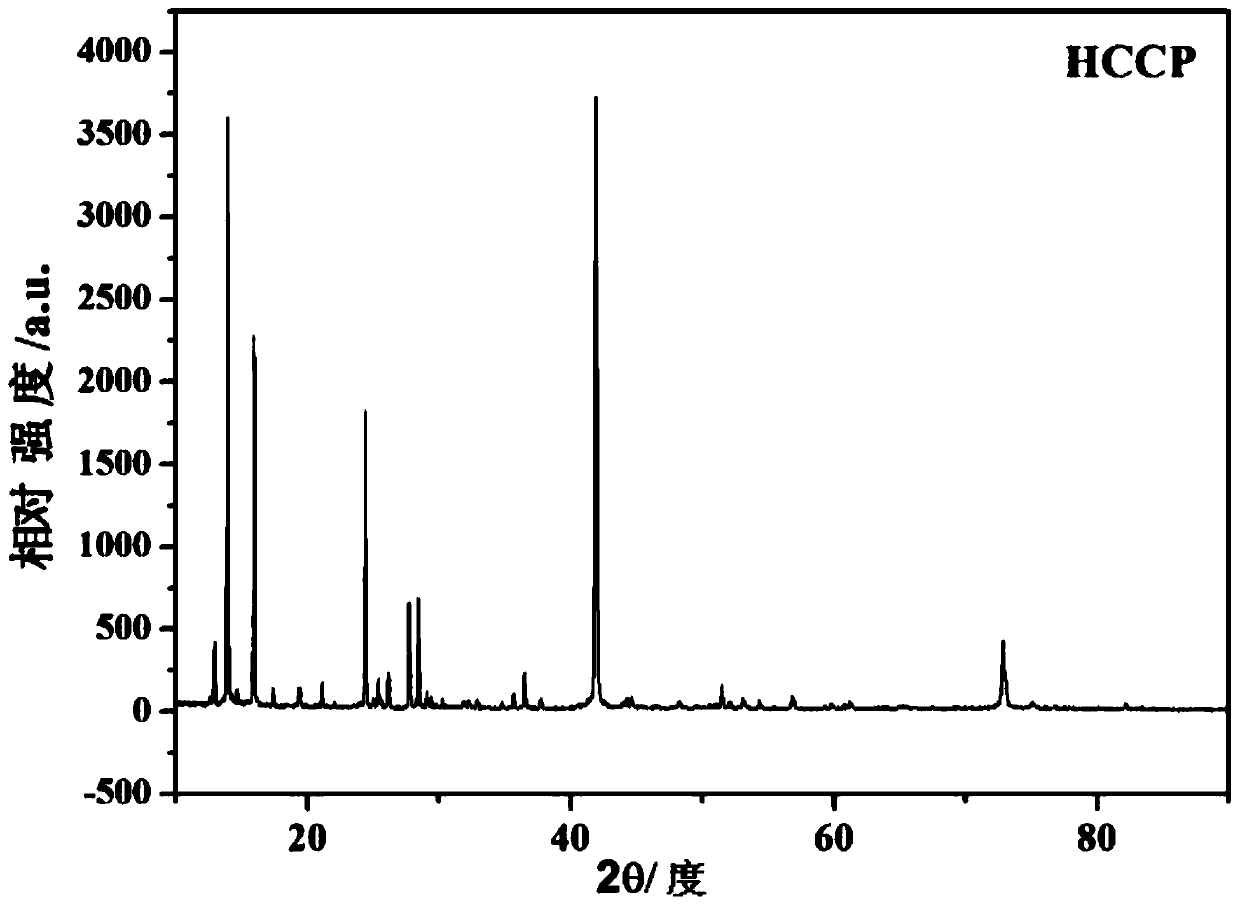

Phosphazene compound, composite containing phosphazene compound, flame retardant containing composite and application

ActiveCN109134544AImprove performanceRaw materials are easy to obtainGroup 5/15 element organic compoundsGeneral purposePolymer science

The invention relates to a phosphazene compound, a composite containing the phosphazene compound, a flame retardant containing the composite and application. The crystal form of the cyclotriphosphazene derivative flame retardant synthesized by using the method is most stable, and the cyclotriphosphazene derivative flame retardant is high in heat stability and high in flame retardant efficiency; moreover, when the crystal type cyclotriphosphazene derivative flame retardant synthesized by using the method is added into a material, such as engineering plastics, general-purpose plastics, a lithiumion battery electrolyte, a flame retardant fabric and flame retardant paper, a high flame retardant performance is achieved, the crystal form is stable, the flame retardant is resistant to drip, onlyan extremely small adding amount is needed, the flame retardant performance of the material can reach the V-0 standards, and other properties of the material are little affected.

Owner:WEIFANG MEDICAL UNIV +3

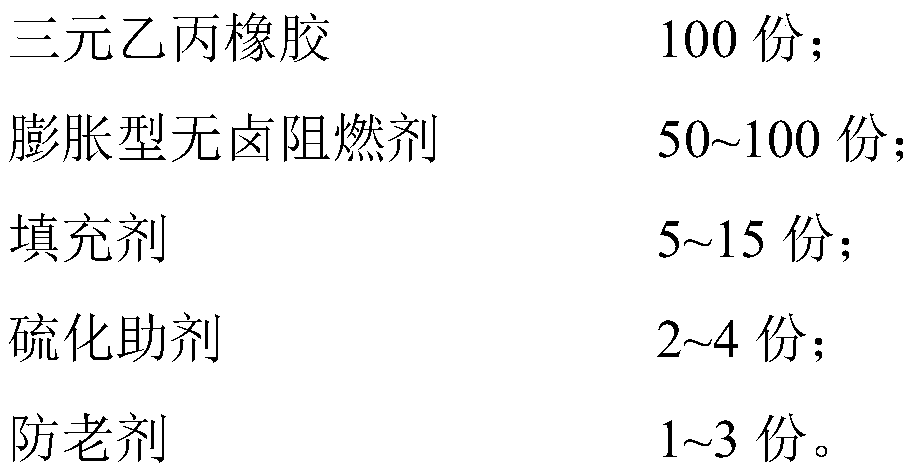

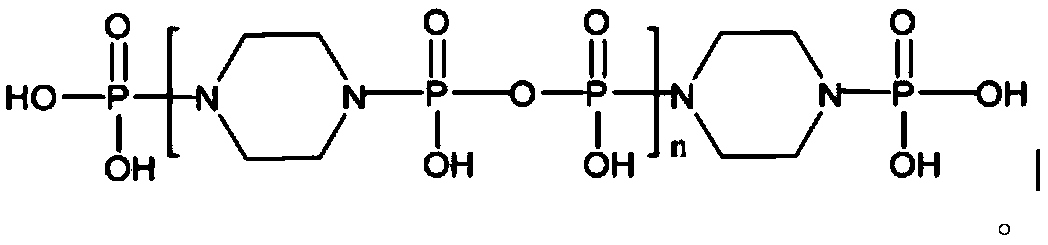

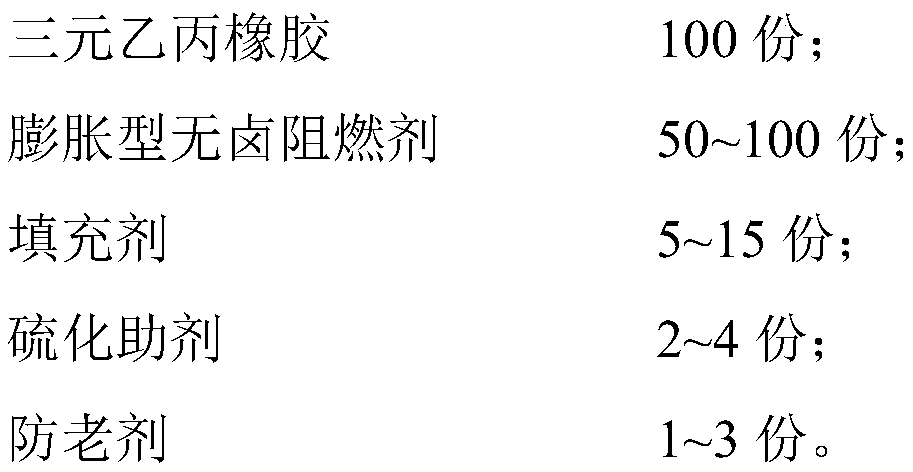

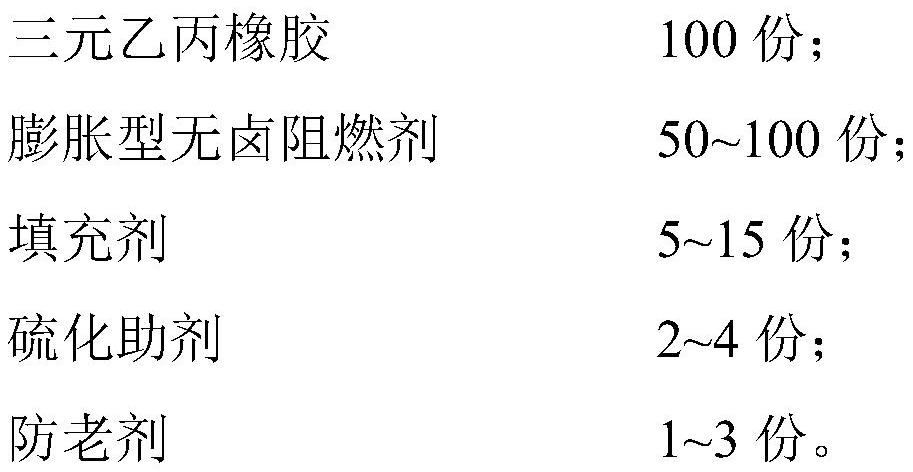

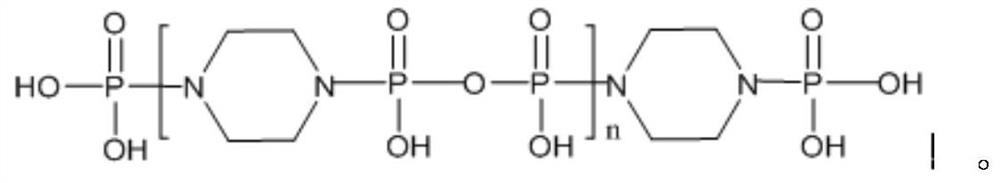

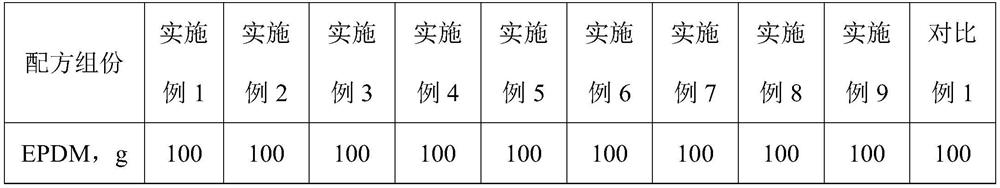

Low-smoke zero-halogen ethylene-propylene-diene monomer rubber composition and preparation method

The invention relates to a low-smoke zero-halogen ethylene-propylene-diene monomer (EPDM) rubber composition and a preparation method. The composition comprises, by weight, 100 parts of EPDM rubber, 50-100 parts of an intumescent zero-halogen flame retardant, 5-15 parts of a filling agent, 2-4 parts of a vulcanizing agent and 1-3 parts of an anti-aging agent. Compared with the prior art, the prepared flame-retardant EPDM rubber is low in smoke and free of halogen, reaches a UL94 (1.6mm) V-0 grade and has good mechanical properties; and meanwhile, the product is white and can be subjected to color matching, so that the application of the flame-retardant rubber in the fields of automobiles, electronic appliances, buildings and the like is expanded.

Owner:SHANGHAI RES INST OF CHEM IND

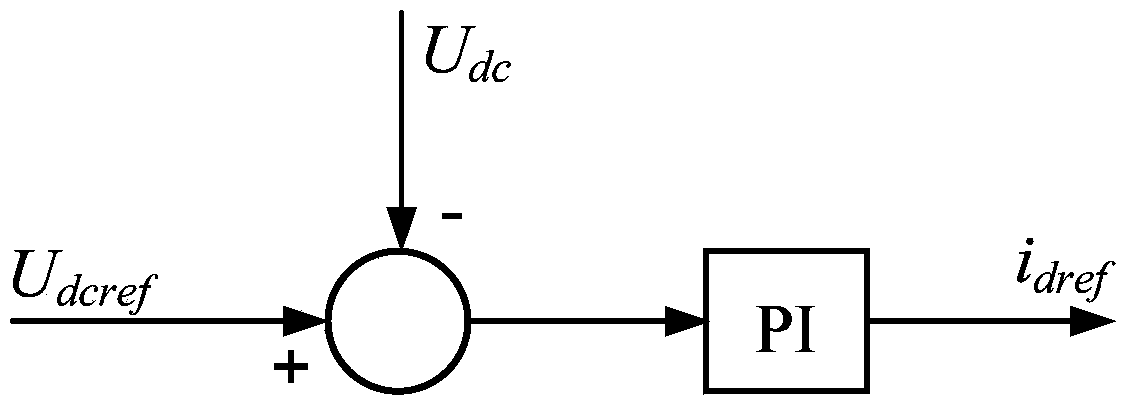

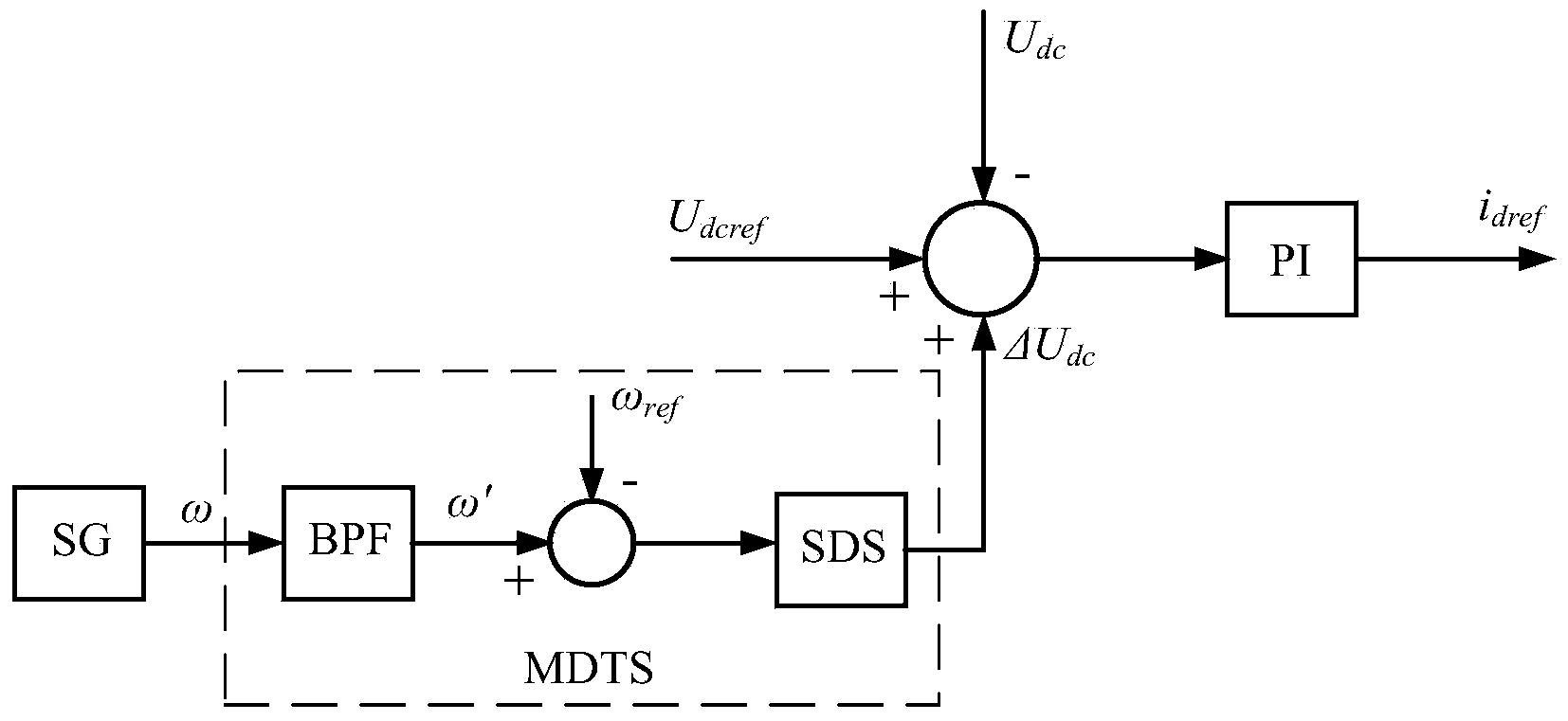

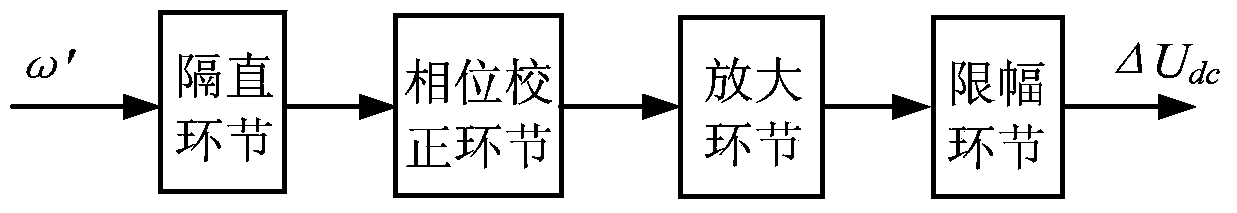

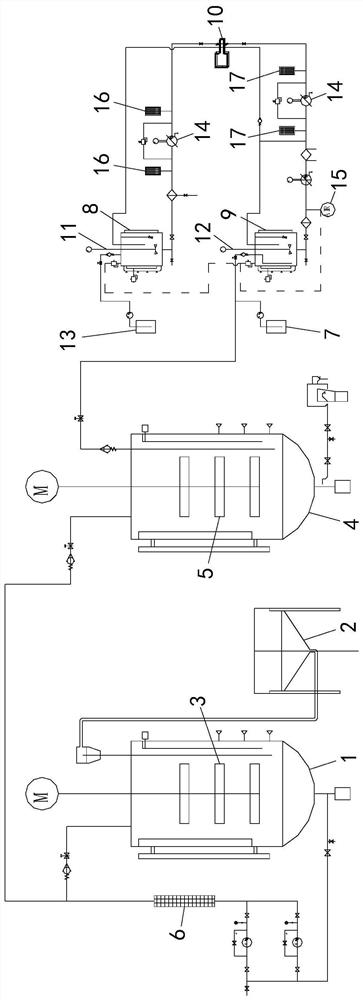

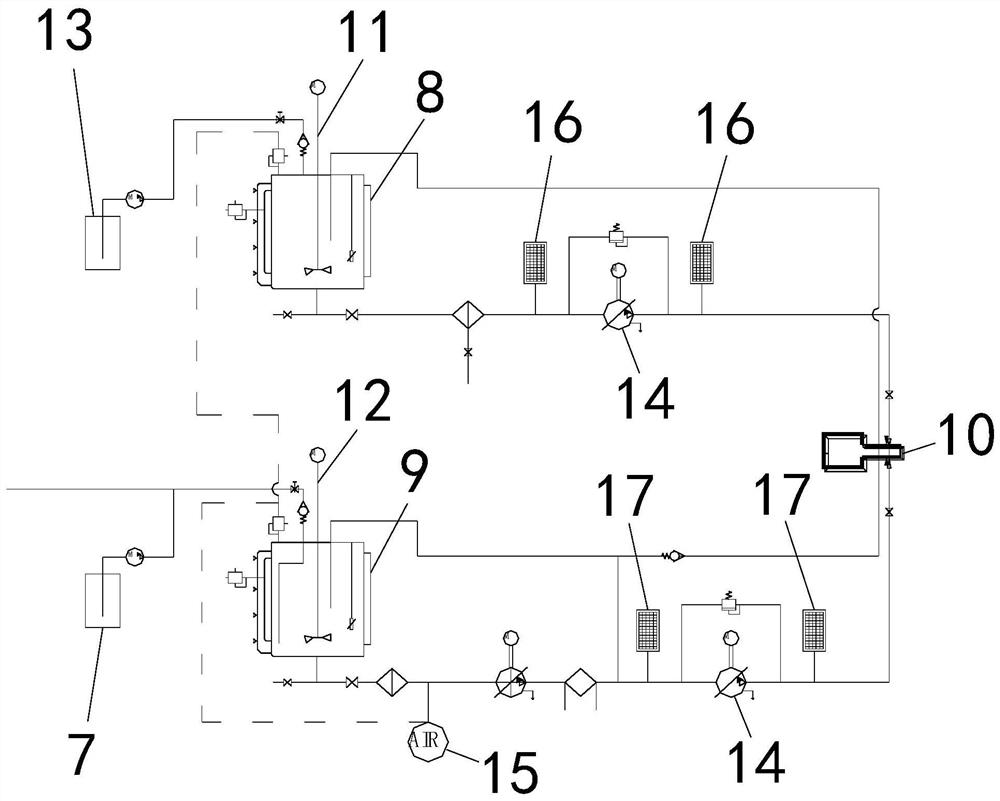

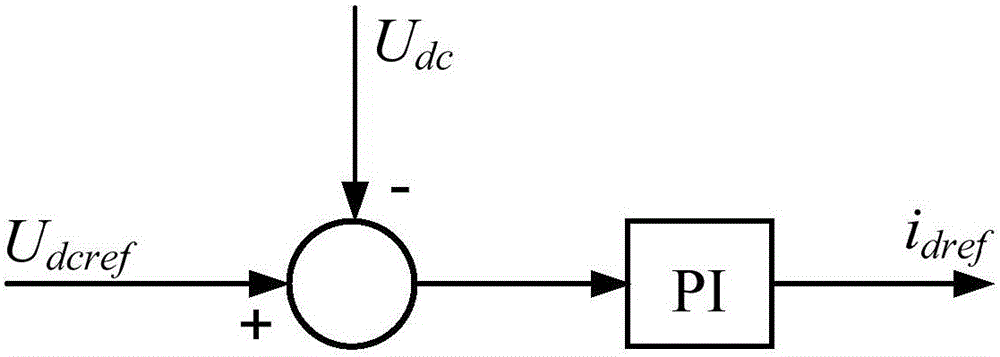

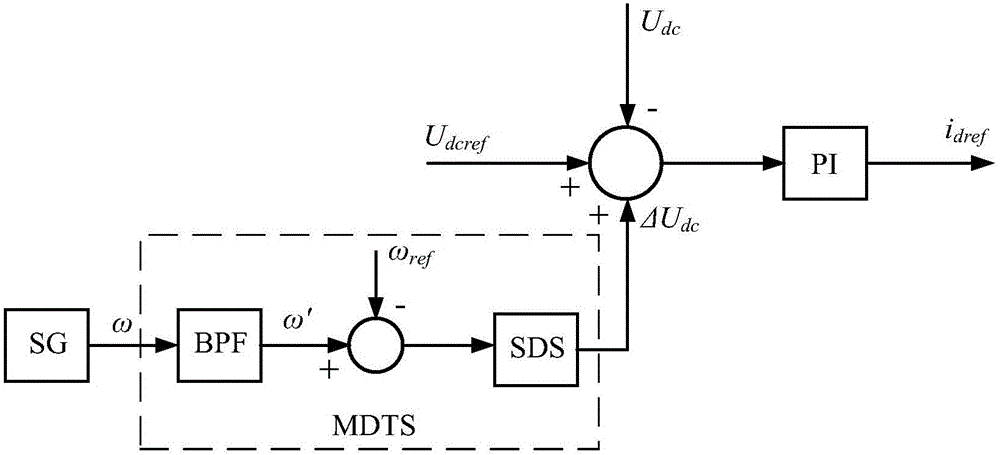

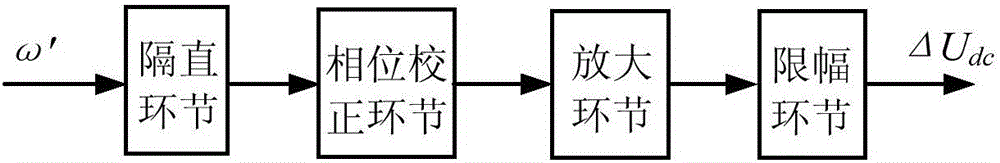

Method for improving operation stability of mechanical transmission chain of direct-drive wind turbine generator

ActiveCN103457528AGood effectAccelerate subsideElectric generator controlElectricityData acquisition

The invention provides a method for improving operation stability of a mechanical transmission chain of a direct-drive wind turbine generator. A data collecting card collects an operation variable X of the direct-drive wind turbine generator in real time. The method comprises the specific steps that 1, a mechanical transmission chain stabilization system is set according to the operation variable X and mechanical characteristics of the mechanical transmission chain; 2, the mechanical transmission chain stabilization system carries out filtering processing on the operation variable X; 3, the mechanical transmission chain stabilization system carries out dynamic compensation on a voltage reference value of the direct current capacitor end of a converter of the direct-drive wind turbine generator. Compared with the prior art, the method is simple in operation and easy to achieve. Mechanical transmission chain vibration of the direct-drive wind turbine generator caused by rotation speed changes can be quickly relieved, and the influence on unit output active power and power grid electric energy quality is little.

Owner:STATE GRID CORP OF CHINA +1

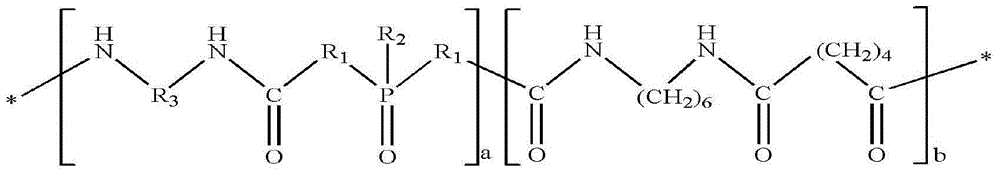

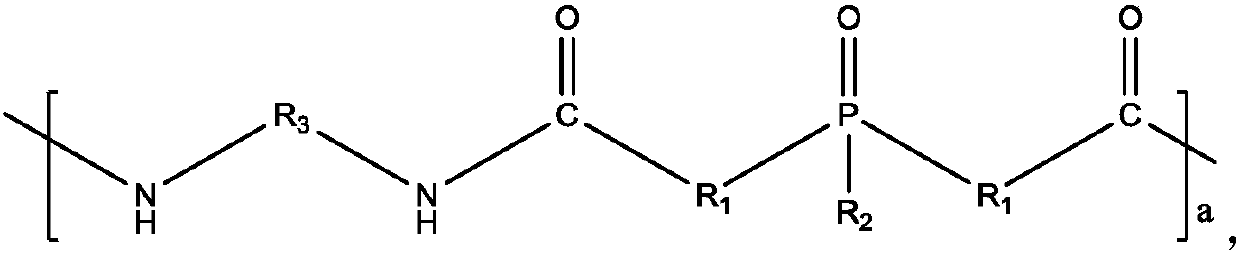

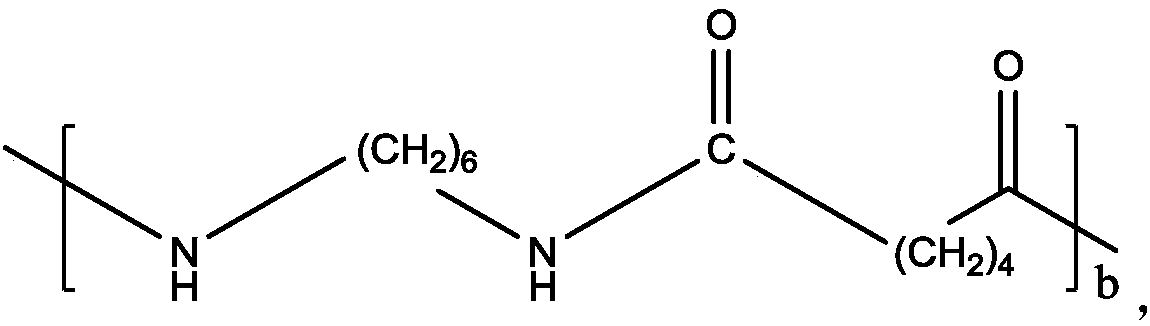

Halogen-free flame-retardant co-polymerized polyamide 66 resin and preparation method thereof

ActiveCN105131280AImprove flame retardant performanceImprove mechanical propertiesMonocomponent polyamides artificial filamentFiberPolymer science

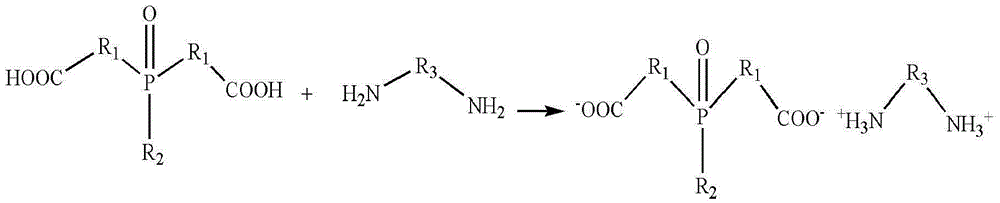

The invention discloses halogen-free flame-retardant co-polymerized polyamide 66 resin and a preparation method thereof. The preparation method is characterized in that phosphine oxide binary acid and conventional diamine are used for preparing organic ammonium phosphate which is used as a flame-retardant component to be co-polymerized with polyamide salt to prepare the halogen-free flame-retardant co-polymerized flame-retardant polyamide 66 resin. The halogen-free co-polymerized flame-retardant polyamide 66 resin is a milk-white non-crystallized glass-like polymer, a melting range is 260 to 270 DEG C, and the relative viscosity is 2.75 to 2.90; total phosphorus content of the halogen-free co-polymerized flame-retardant polyamide 66 resin material is 0.6 to 0.8 percent, the flame-retardant level is UL-94V-0 level, the tensile strength is greater than or equal to 80.0 MPa, and an elongation at break is 64.5 percent to 68.5 percent. The halogen-free flame-retardant co-polymerized polyamide 66 resin has characteristics of no halogen, flame retardance, high viscosity, no melting drop and high mechanical strength and can be widely applied to the field of fibers and spinning.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

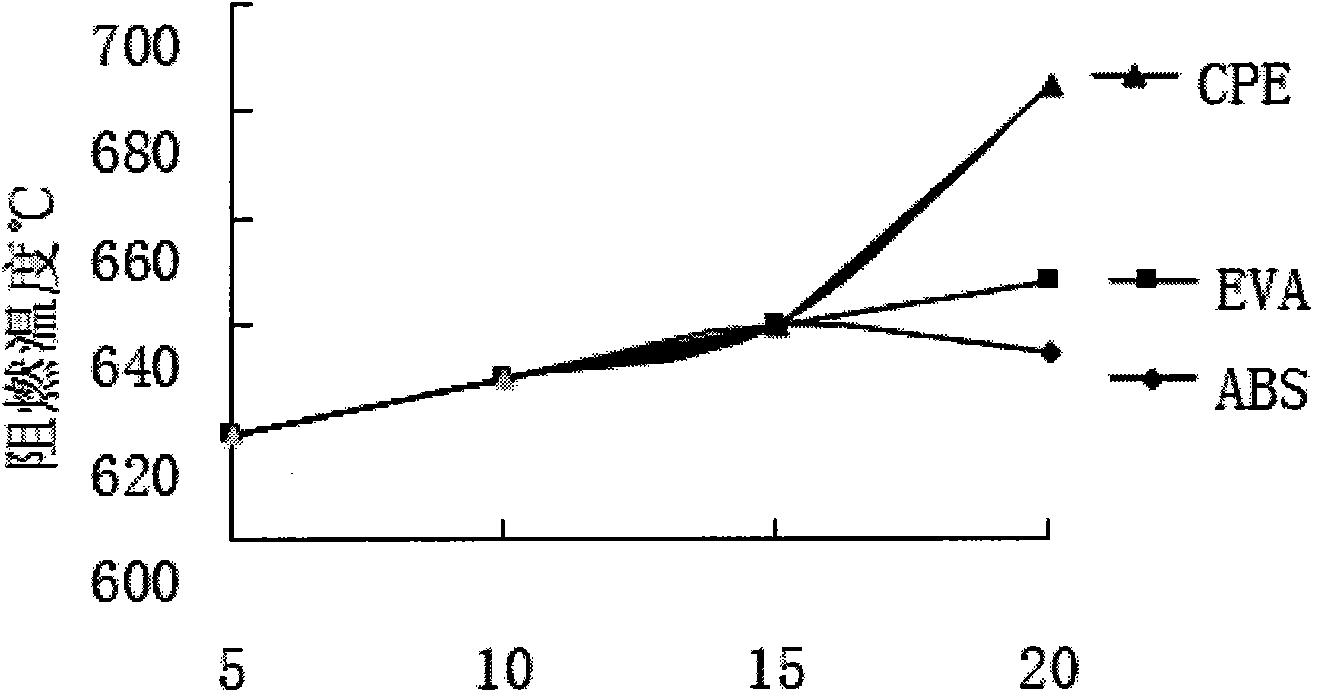

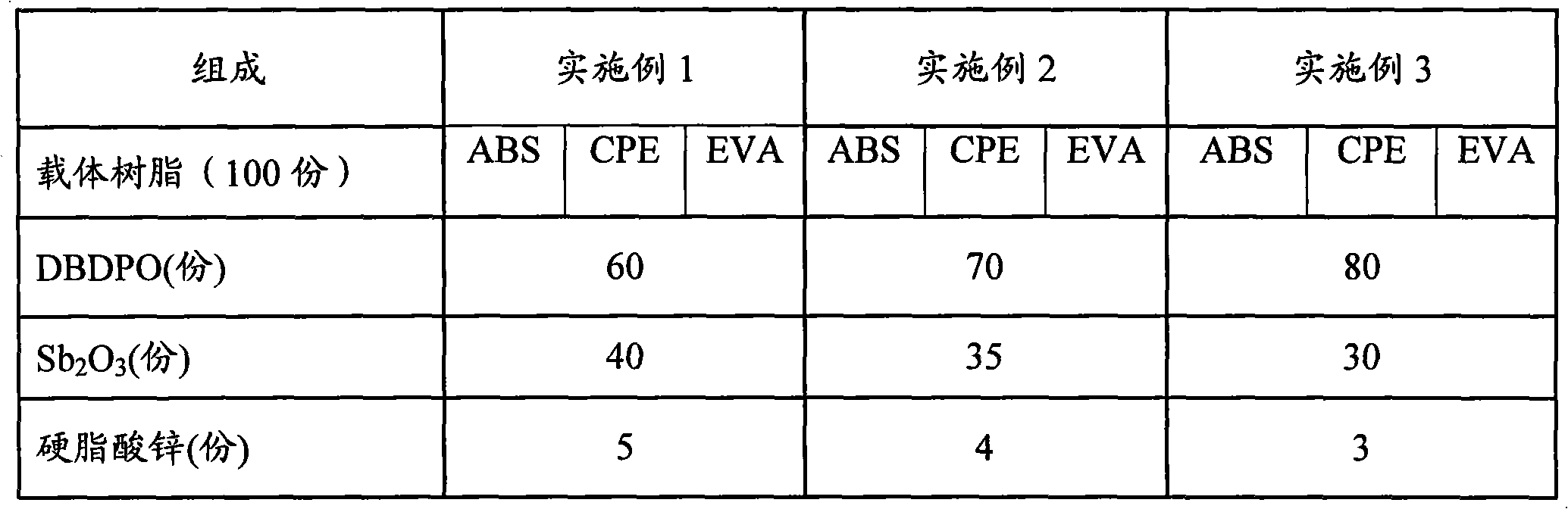

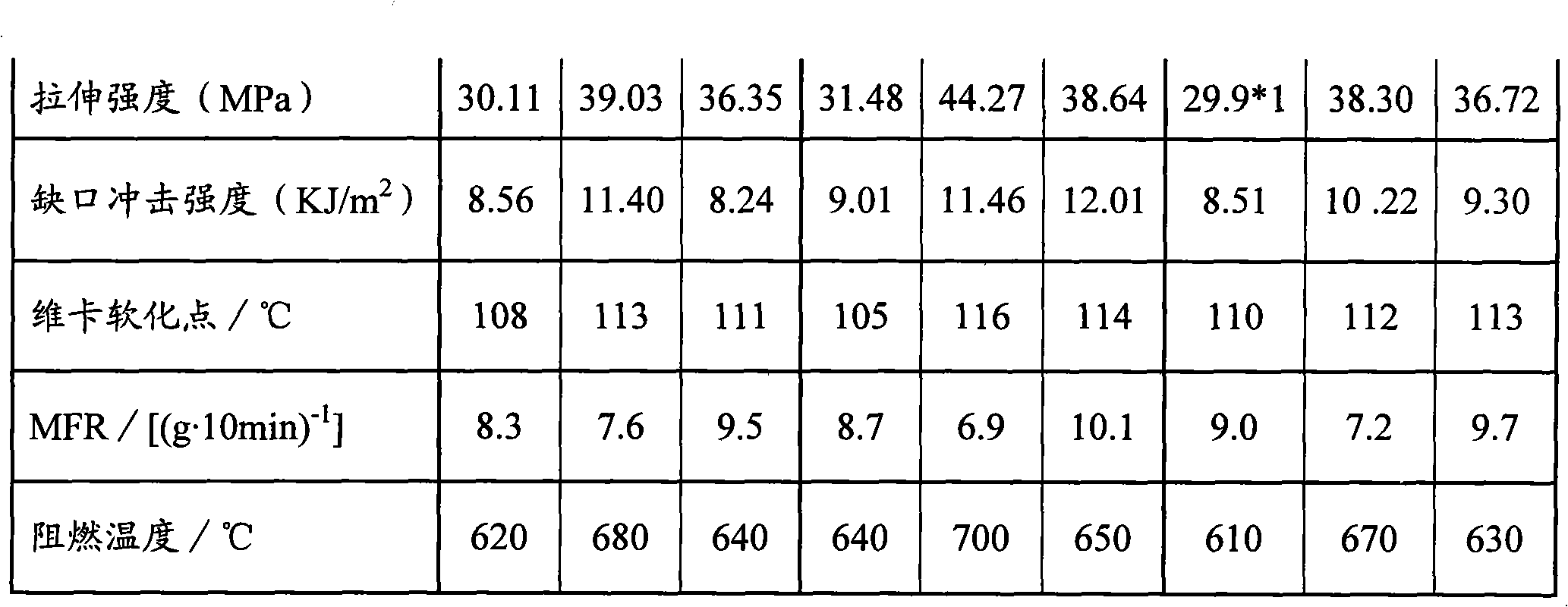

Flame retardant ABS master batch and preparation method thereof

InactiveCN101948605ALittle impact on other performanceImprove flame retardant performanceEngineeringExtrusion Granulation

The invention is suitable for the field of polymer, and provides a flame retardant ABS master batch and a preparation method thereof. The method uses a DBDPO / Sb2O3 composite flame retardant system, which comprises 60-80 parts of DBDPO, 30-40 parts of Sb2O3, 100 parts of different carrier resin and other adjuvants. Various flame retardant master batches are prepared through melt blending and extrusion granulation, and then are mixed with ABS to make performance contrast research, thus the ABS master batch, which takes CPE as carrier resin and has good flame retardance and other performances, is obtained. The flame retardant master batch prepared by the invention has small influences on other performances of ABS resin, can reach UL94 V0-level flame retardance, has simpler processing technology, and provides conditions for ABS resin to being applied to military, automobiles, electronic and electrical appliances.

Owner:SHENZHEN KEJU NEW MATERIAL

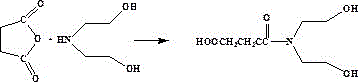

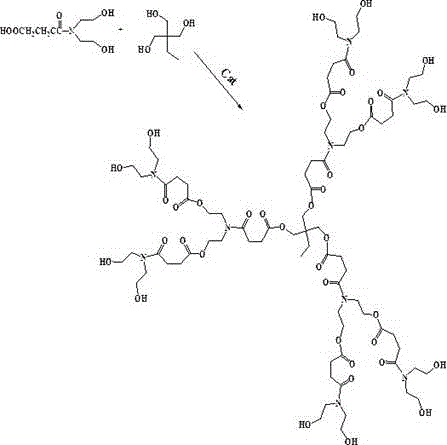

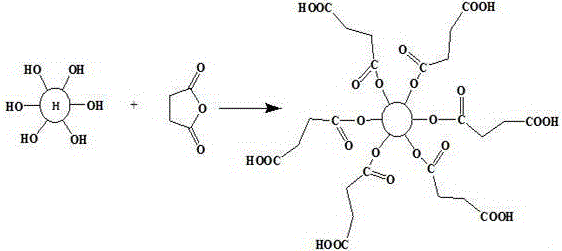

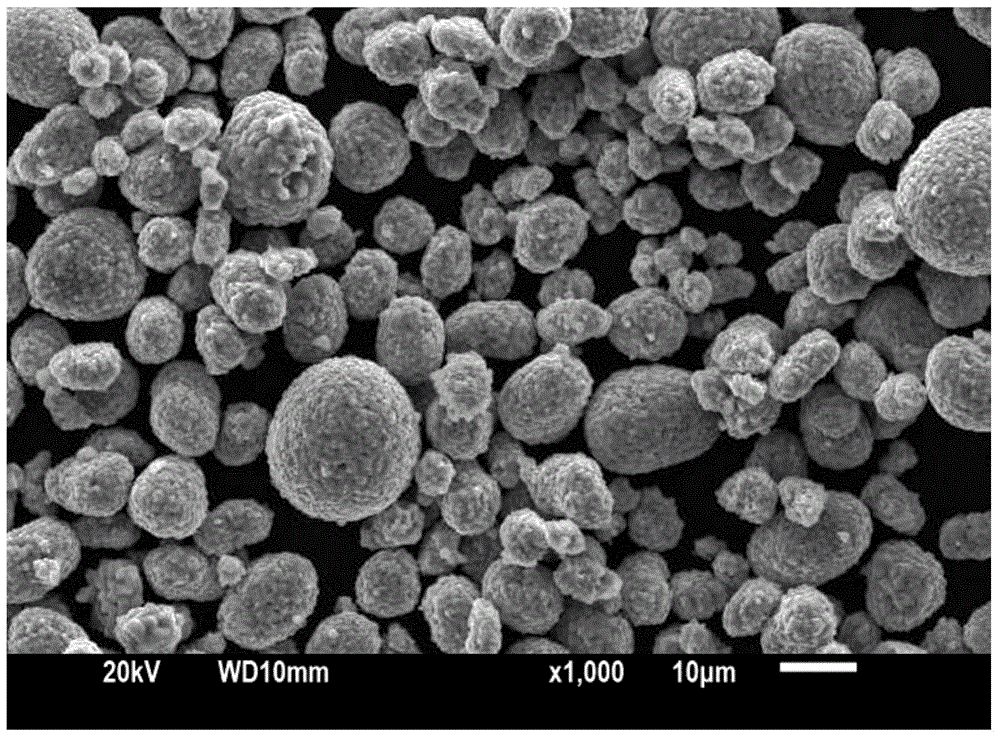

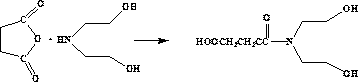

Application of hyperbranched dyeing assistant to increasing of dyeability of superfine-fiber polyurethane synthetic leather

The invention relates to the field of superfine-fiber polyurethane synthetic leather, in particular to application of a hyperbranched dyeing assistant to the increasing of the dyeability of superfine-fiber polyurethane synthetic leather.Hyperbranched polymer with terminal hydroxyl is synthesized first, then succinic anhydride modification is used to introduce carboxyl to the terminal of the hyperbranched polymer so as to synthesize hyperbranched polymer with terminal carboxyl.The hyperbranched polymer with terminal carboxyl is applied to the field of polyurethane dyeing assistants and is good in dyeing assisting effect, good in stability and lasting in effect, the synthesizing process of the hyperbranched polymer with terminal carboxyl is simple, industrialized synthesizing of the hyperbranched polymer with terminal carboxyl can be achieved easily, and the hyperbranched polymer with terminal carboxyl is a good polyurethane synthetic leather dyeing assistant with excellent performance.

Owner:UNIV OF JINAN

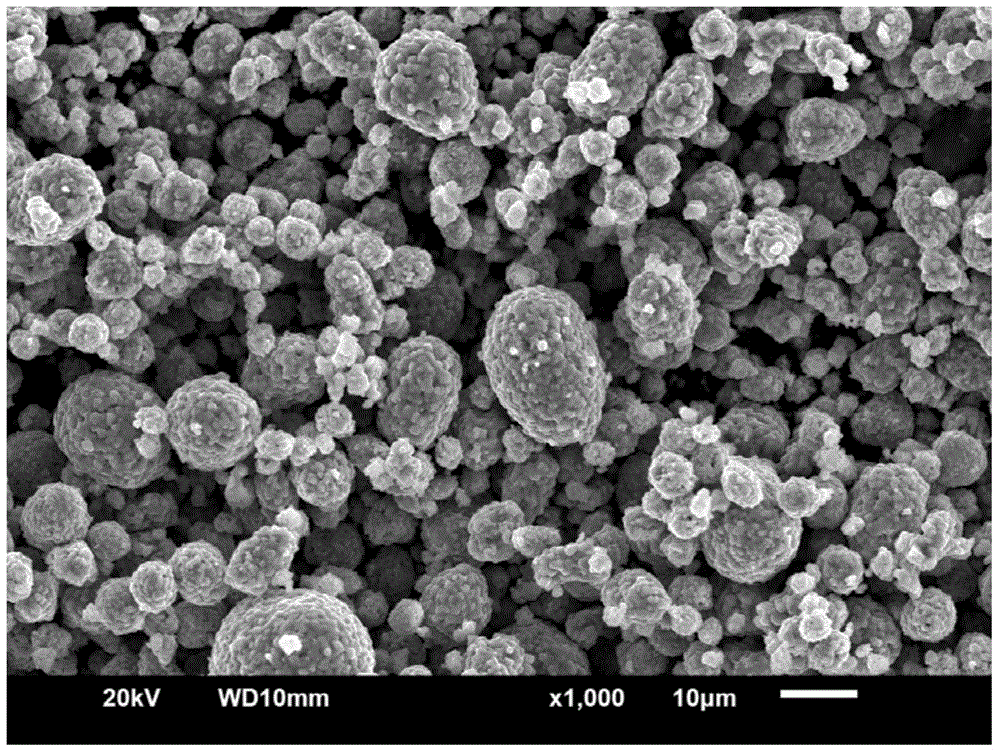

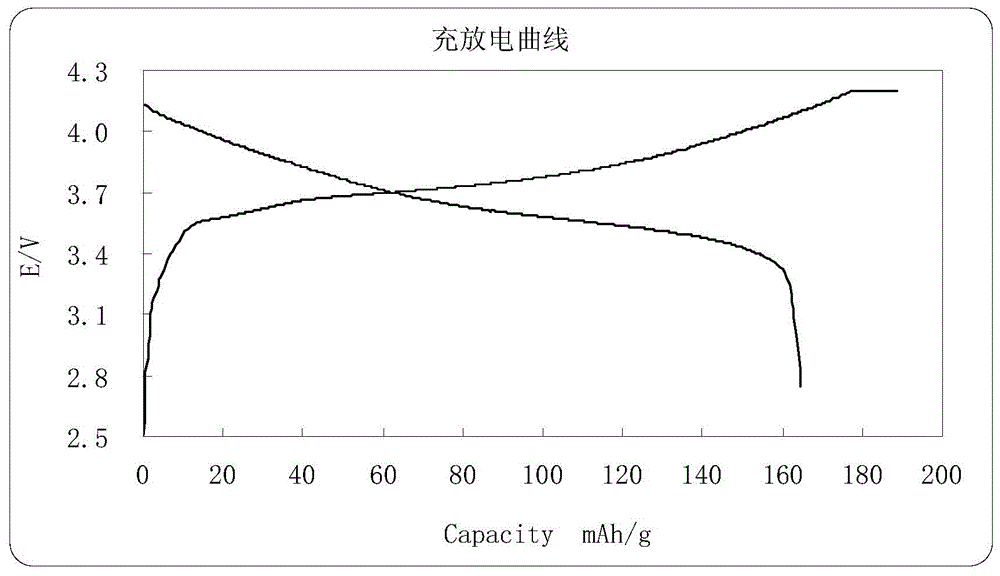

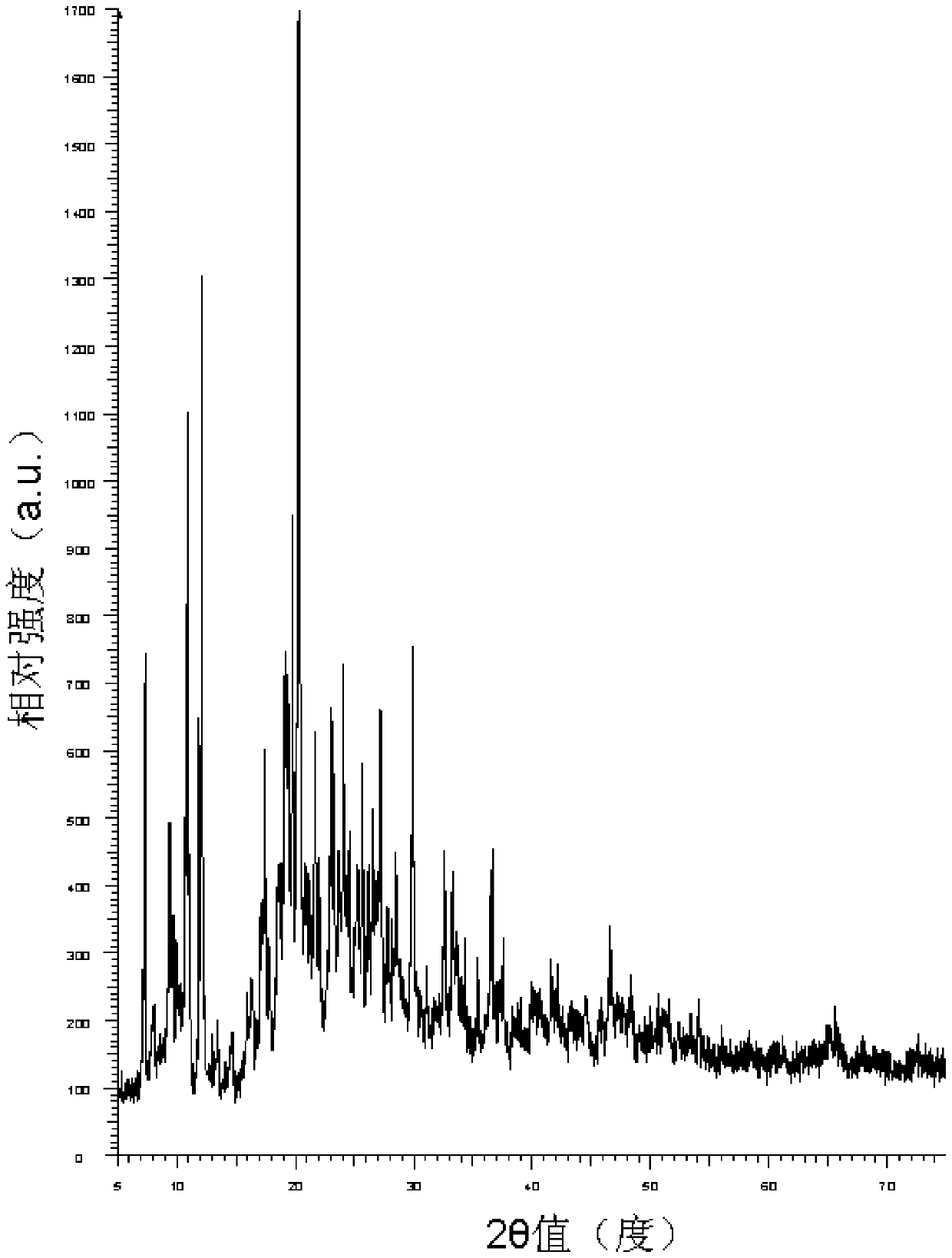

Lithium cobalt oxide-doped lithium nickel cobalt manganate and preparation method thereof, and lithium ion battery containing lithium cobalt oxide-doped lithium nickel cobalt manganate

PendingCN105720243ALittle impact on other performanceCell electrodesSecondary cellsChemistryLithium electrode

The invention discloses a lithium cobalt oxide-doped lithium nickel cobalt manganate and a lithium ion battery. A preparation method for the lithium cobalt oxide-doped lithium nickel cobalt manganate comprises the following steps: a) mixing a nickel salt, a manganese salt and a cobalt salt according to a certain mol ratio and dissolving the obtained mixture; b) titrating a mixed solution obtained in the step a) by using a hydroxide solution and carrying out stirring while titrating so as to obtain spherical cobalt manganese nickel hydroxide precursor; c) washing the precursor obtained in the step b) and drying the washed precursor at a certain temperature; and d) mixing a material obtained in the step c) with Co3oO4 and Li2CO3 according to a certain proportion and carrying out calcining at high temperature so as to obtain the lithium cobalt oxide-doped lithium nickel cobalt manganate with spheroidic morphology. A compaction coefficient is increased to 3.70 g / cm<3> from original 3.56 g / cm<3>, and influence on other performance of the material is small.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

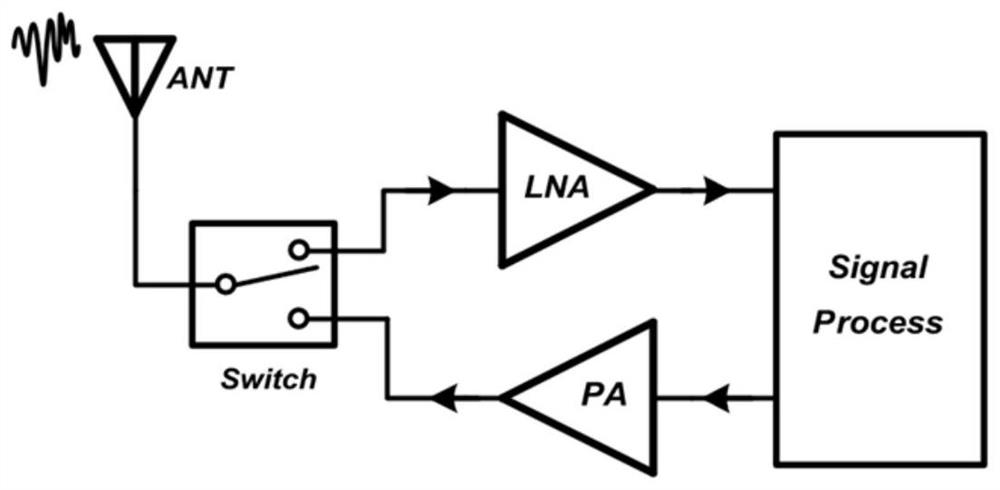

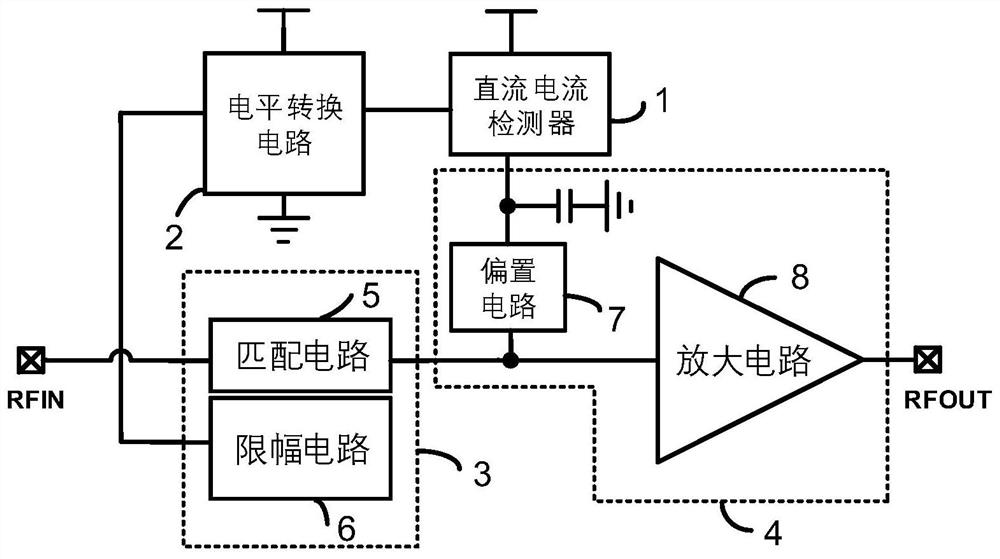

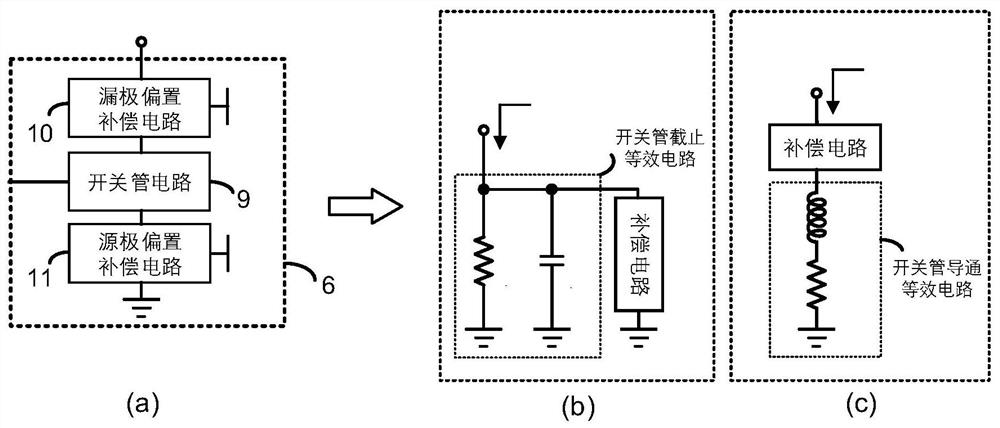

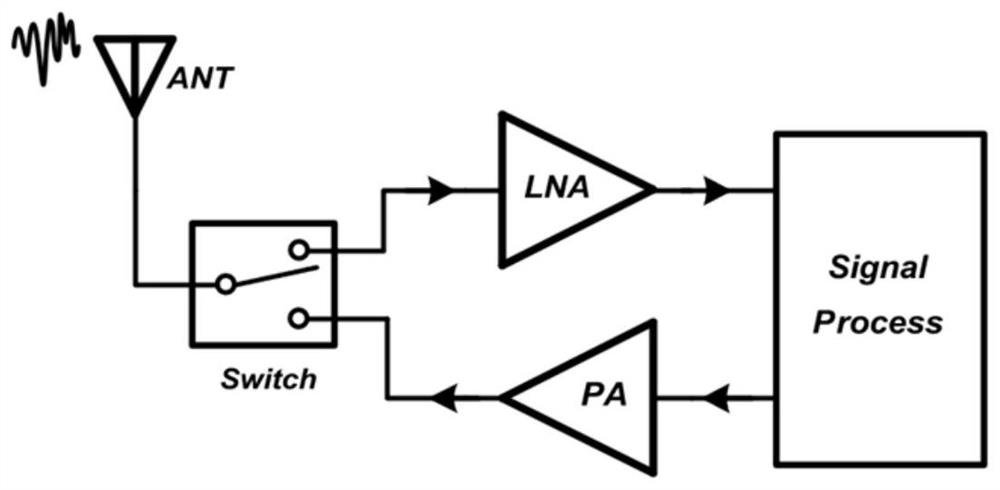

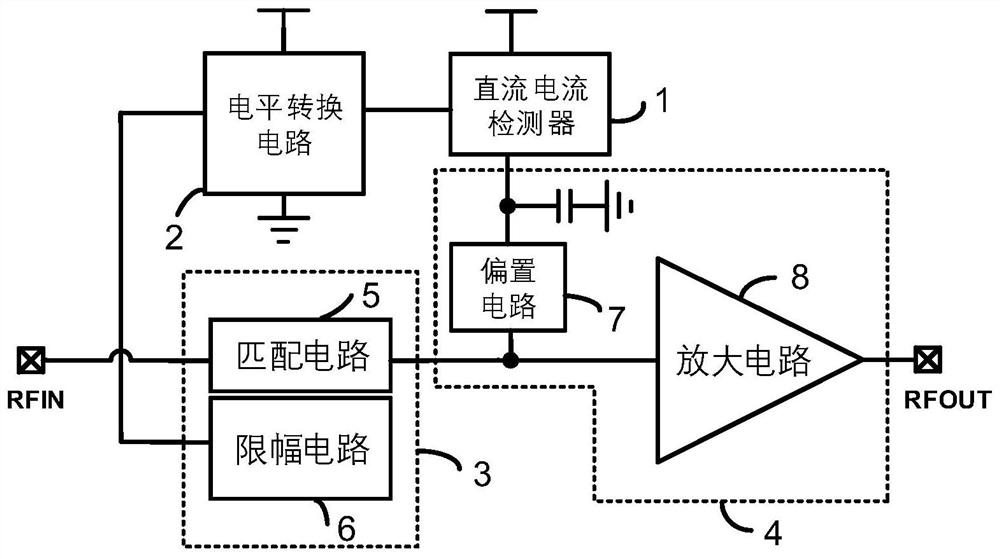

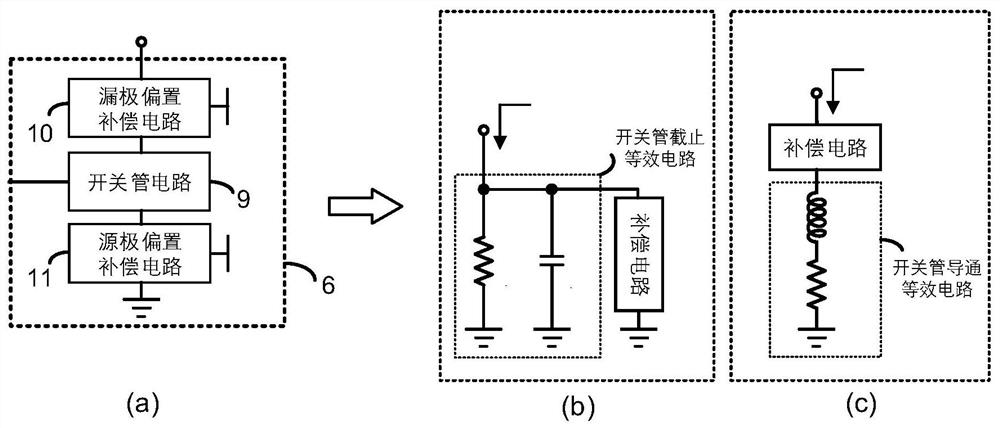

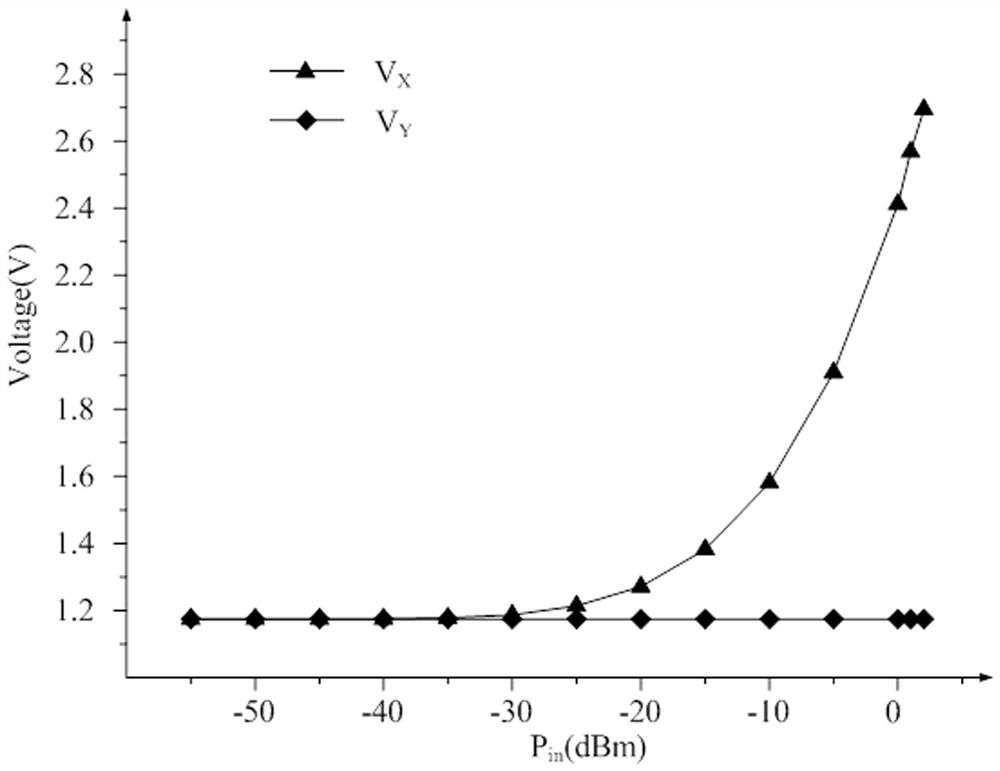

High-reliability low-noise amplifier

ActiveCN113131875APerformance is not affectedImprove performanceAmplifier modifications to reduce noise influenceHigh frequency amplifiersCapacitanceLow noise

The invention relates to a high-reliability low-noise amplifier, which comprises a high-power input protection module and an amplifier module, wherein the amplifier module comprises an amplifying circuit, an input bias circuit and a decoupling capacitor; the first end of the input bias circuit is connected to the input end of a first-stage amplifier of the amplifying circuit; the second end of the input bias circuit is grounded through the decoupling capacitor; the high-power input protection module comprises a matching circuit used for input impedance matching of the low-noise amplifier and DC isolation, a direct current detector used for detecting the direct current of the input end of the first-stage amplifier and converting the direct current into detection voltage and outputting the detection voltage, a level conversion circuit used for outputting a control signal after the detection voltage exceeds a pre-configured threshold value, and an amplitude limiting circuit one end of which is connected with the matching circuit, the other end of which is grounded, the control end of which is connected with the output end of the level conversion circuit, and which is turned on to protect the amplifying circuit after receiving the control signal. Compared with the prior art, the reliability of the amplifier is improved, and meanwhile, the influence on other performances of the amplifier is small.

Owner:FUDAN UNIV

A process for adding expanded graphite to core raw materials on a color steel insulation board production line

ActiveCN111729599BAccelerate the ripening speedFine foamTransportation and packagingMixing methodsProduction linePolyol

A process for adding expanded graphite to the core material raw material on the color steel insulation board production line, including using a batching tank for batching, stirring and transporting to the storage tank, and sending it to the POLY unit for storage after stirring; sending the isocyanate stored in the ISO unit into The first working tank, after the stirring is completed, it is sent into the distribution mixer through the metering pump; the polyol composition containing expanded graphite stored in the POLY unit is sent to the second working tank, and sent to the distribution mixer after stirring; mixed with expanded graphite The polyol composition and isocyanate are mixed by a cloth mixer and then foamed. The present invention establishes a production process suitable for adding expanded graphite to polyol raw materials on the production equipment of polyurethane double-sided color steel insulation board continuous line double crawler machine, including a device for adding expanded graphite, graphite is added to the raw material through a batching unit Neutralize and stir, and then through the stirring of the constant temperature unit and the mixing of the mixing unit, it ensures the uniform mixing of graphite in the raw materials and the quality of the product.

Owner:苏州德亨节能环保科技有限公司

A kind of low-smoke halogen-free EPDM rubber composition and preparation method

Owner:SHANGHAI RES INST OF CHEM IND

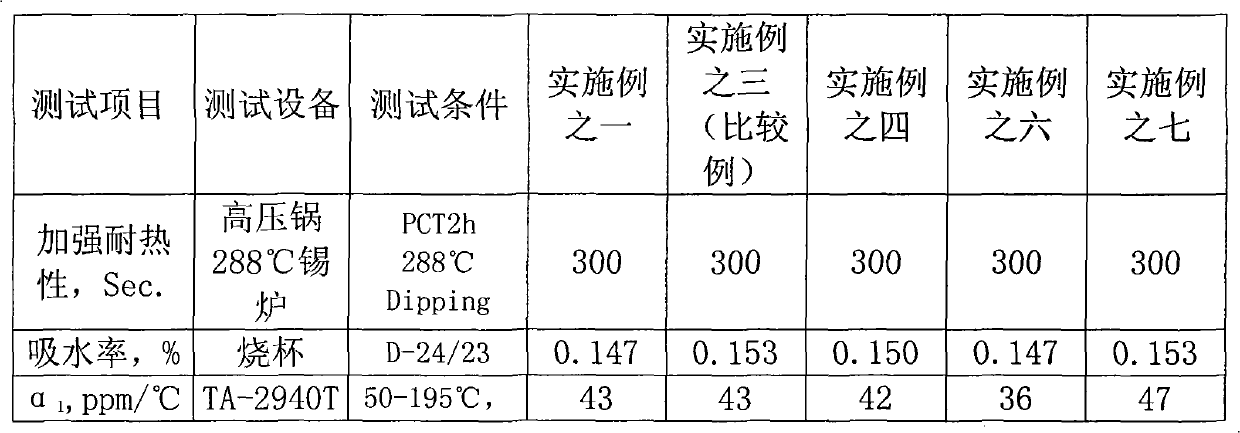

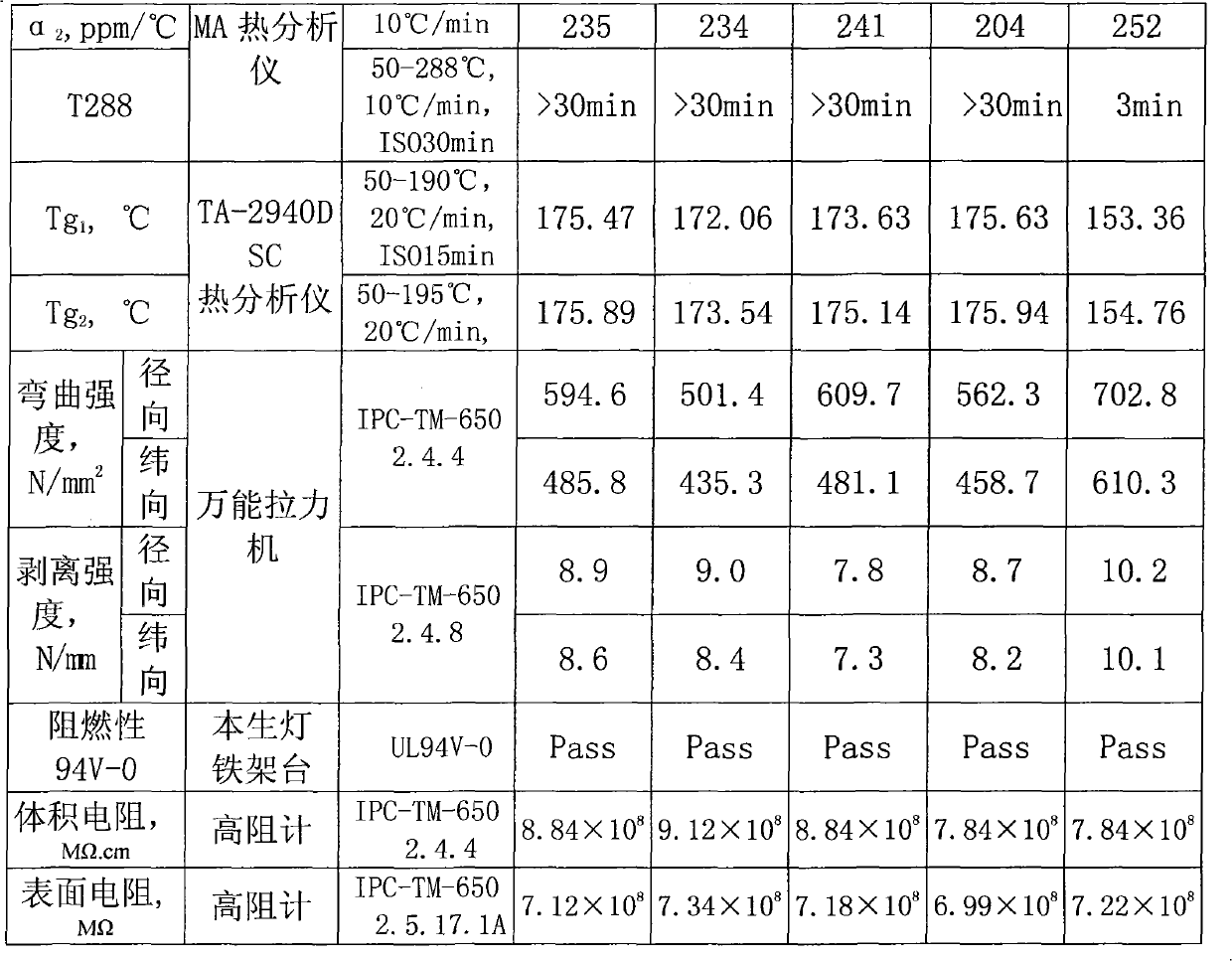

Copper clad base plate and preparation method thereof

ActiveCN101547558BLow costSmall coefficient of thermal expansionCircuit susbtrate materialsFurnace temperatureRoom temperature

The invention discloses a copper clad base plate and a preparation method thereof. The copper clad base plate is formed by pressing prepreg and copper clad and adding compound quartz powder functioning as inorganic filler to glue solution made of the prepreg, wherein the weight of the compound quartz powder occupies 5-50 percent of the total weight of the glue solution. The preparation method of the copper clad base plate comprises the following steps: (1) under the room temperature, respectively adding base raw materials for preparing the glue solution to a dispensing container and mixing the base raw materials, adding the compound quartz powder functioning as inorganic filler to the mixture and mixing with the same for 6h, sampling the gel time of the test glue solution and controlling the time between 200s and 300s; (2) making adhesive plaster impregnated with the glue solution pass through a vertical or horizontal impregnating machine, and preparing the prepreg by controlling windtemperature and furnace temperature; and (3) pressing: after combining the cut prepreg with the copper clad, the cut prepreg and the copper clad are put into a vacuum hot press to be pressed for obtaining the copper clad base plate. The invention can greatly lower the cost of the glue solution, lower the coefficient of heat expansion of the product, improve the reliability of the copper clad baseplate in the preparation of printed circuit boards, and ensure the improvement on the mechanical property and the electric property of the product.

Owner:无锡宏仁电子材料科技有限公司

A kind of scratch-resistant polypropylene material and preparation method thereof

The invention relates to a scratch-resistant polypropylene material and a preparation method thereof. 0-1 part of agent, 0-0.5 part of white oil, 0.1-1 part of ZrB2. In the present invention, the inorganic material ZrB2 is added into the polypropylene material as a scratch-resistant agent, and its scratch-resistant effect can reach the first level of five-finger scratch; In a long-term high-temperature aging environment, it is easy to precipitate and migrate to the surface, and there are problems such as odor and VOC, which can be used for automotive interior parts.

Owner:HEFEI GENIUS NEW MATERIALS

A high reliability low noise amplifier

ActiveCN113131875BPerformance is not affectedImprove performanceAmplifier modifications to reduce noise influenceHigh frequency amplifiersCapacitanceLow noise

The invention relates to a high-reliability low-noise amplifier, comprising a high-power input protection module and an amplifier module. The amplifier module includes an amplifier circuit, an input bias circuit and a decoupling capacitor. The first end of the input bias circuit is connected to the amplifier circuit. The input end of the first stage amplifier, the second end is grounded through a decoupling capacitor, and the high-power input protection module includes: a matching circuit for input impedance matching and DC isolation of the low-noise amplifier; a DC current detector for detecting the first stage The DC current at the input end of the amplifier is converted into a detection voltage for external output; a level conversion circuit is used to output a control signal after the detection voltage exceeds a pre-configured threshold; a limiter circuit is connected to the matching circuit at one end and grounded at the other end, and The control terminal is connected with the output terminal of the level conversion circuit, and is turned on after receiving the control signal to protect the amplifying circuit. Compared with the prior art, the present invention has little influence on other performances of the amplifier while improving the reliability of the amplifier.

Owner:FUDAN UNIV

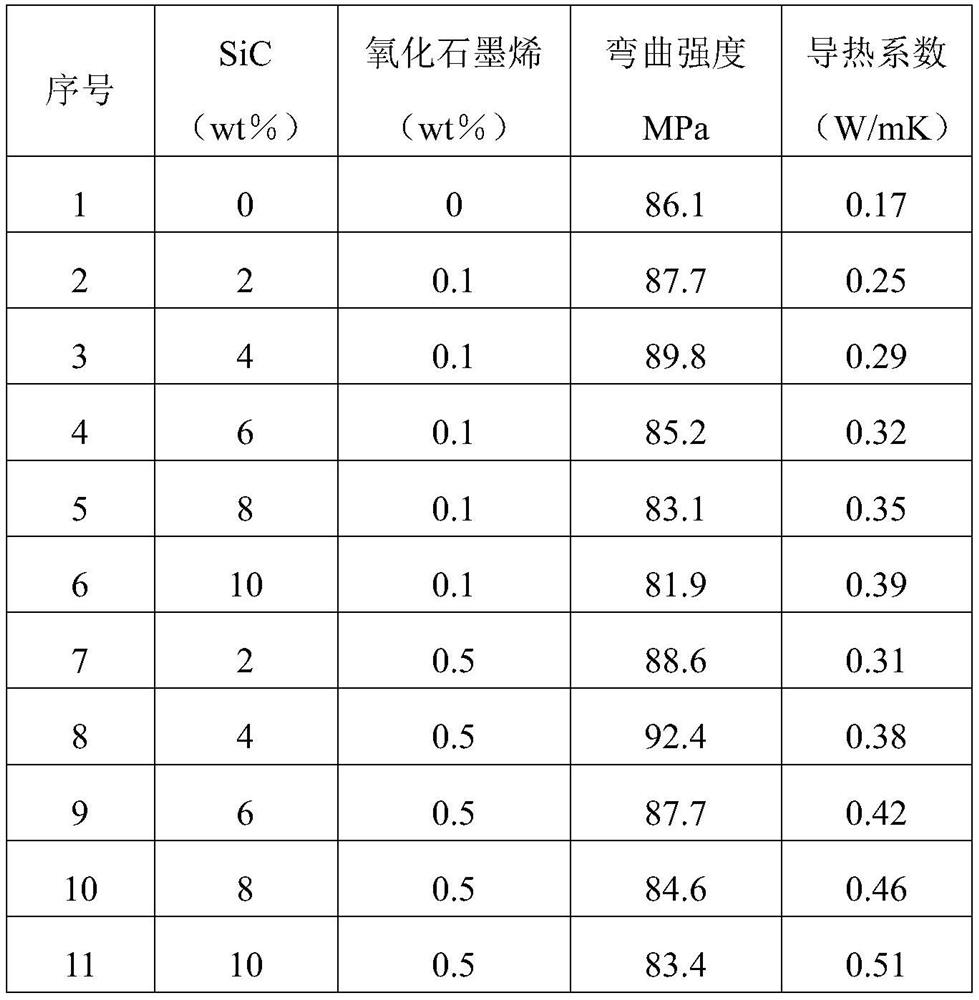

The method of sic/graphene oxide composite modified epoxy resin

ActiveCN108659467BGuaranteed nanoscale dispersionAvoid reunionHeat-exchange elementsEpoxyPolymer science

The invention relates to a method for preparing SiC / graphene oxide composite modified epoxy resin. The method specifically comprises the following processes: adding nano SiC and a silane coupling agent into an aqueous graphene oxide dispersion for ultrasonic treatment; then replacing moisture in a system with an epoxy active diluent; mixing an obtained mixture with epoxy resin and a processing aid; and curing and molding to obtain an SiC / graphene oxide modified epoxy resin composite. After treatment, SiC and graphene oxide achieves nanoscale uniform dispersion in an epoxy resin matrix and forms a heat conducting network; and since SiC and graphene oxide have relatively high heat conductivity, the two fillers are collocated to significantly improve the heat conductivity of the epoxy resin.

Owner:WUHAN UNIV OF TECH

A kind of halogen-free flame-retardant copolymerized polyamide 66 resin and preparation method thereof

ActiveCN105131280BImprove flame retardant performanceImprove mechanical propertiesMonocomponent polyamides artificial filamentFiberPolyamide

The invention discloses a halogen-free flame-retardant copolymerized polyamide 66 resin and a preparation method thereof. Copolymerization is carried out to prepare a halogen-free copolymerization flame-retardant polyamide 66 resin. The halogen-free copolymerized flame-retardant polyamide 66 resin of the present invention is a milky white non-crystalline glass-like polymer, the melting range is 260-270°C, and the relative viscosity is 2.75-2.90; The phosphorus content is 0.6% to 0.8%, the flame retardant level is UL-94V-0, the tensile strength is not less than 80.0MPa, and the elongation at break is 64.5% to 68.5%. The halogen-free copolymerized flame-retardant polyamide 66 resin of the present invention has the characteristics of halogen-free flame retardancy, high viscosity, no droplet and high mechanical strength, and can be widely used in the fields of fibers and textiles.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

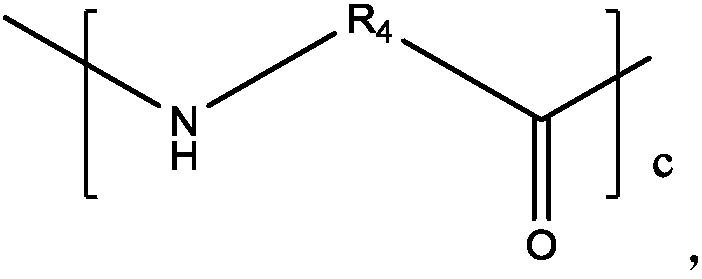

Polyamide composite material as well as preparation method and application thereof

The invention provides a polyamide composite material which comprises the following components in parts by weight: 80-100 parts of short-carbon-chain polyamide; and 0.1-6 parts of an amide oligomer. In the repeating units of the short-carbon-chain polyamide, the number of carbon atoms on a main chain is smaller than or equal to 6. According to the polyamide composite material as well as the preparation method and application thereof, a small amount of amide oligomer is added, so that the injection molding property of the polyamide composite material can be obviously improved, the problems of mucous membrane, top bulge and the like in the production link are improved, the production efficiency is improved, and other properties such as mechanical properties of the polyamide composite material will not be obviously reduced.

Owner:KINGFA SCI & TECH CO LTD

Preparation method of cationic dyeable halogen-free flame retardant polyester fiber

ActiveCN101864612BInhibit side effectsDoes not affect dyeabilityMonocomponent copolyesters artificial filamentFiberPolymer science

The invention relates to a preparation method of the cationic dyeable halogen-free flame retardant polyester fiber, which comprises the following process steps: 1. adding monosodium isophthalic sulfonate, 2-propyloic hypophosphorous acid and de-ionized water into a reaction container, filtering out reaction products after the reaction is completed, and carrying out baking to obtain cationic dyeable flame retardant compounds; 2. adding terephthalic acid, products in the first step and glycol into an esterification kettle, then, adding antimony ethylene glycalate, conducting the materials into a polycondensation kettle, and carrying out reaction and material outlet to obtain cationic dyeable flame retardant polyester slices; and 3. drying the cationic dyeable flame retardant polyester slices prepared in the second step through a vacuum drum drying machine, carrying out spinning on the dried slices on a spinning machine according to a conventional polyester spinning process to obtain thecationic dyeable halogen-free flame retardant polyester fiber. The invention realizes the flame retardant performance and the cationic dyeable performance of the polyester through one-step addition, avoids the complicated process and the occurrence of various kinds of secondary reaction caused by a traditional method of adding flame retardant agents and cationic dyeable auxiliary agents in two steps, and has more stable and obvious flame retardant and cationic dyeable effect.

Owner:JIANGSU XINGYE PLASTIC

Preparation method of flame-retardant cotton fabric

ActiveCN114672990ASimple processReduce typesHeat resistant fibresVegetal fibresFlame resistancePolymer chemistry

The invention discloses a preparation method of a flame-retardant cotton fabric, and relates to the technical field of flame retardance of biomass materials, and the preparation method comprises the following steps: (1) preparing an ammonium polyphosphate-aluminum hydroxide compound; (2) preparing a flame retardant solution; (3) pretreatment of the cotton fabric; and (4) dipping and flame-retardant treatment of the cotton fabric. Compared with the prior art, the preparation method of the flame-retardant cotton fabric, provided by the invention, has the advantages that the process is simple and convenient, the used flame-retardant smoke suppressant is few in variety, small in addition amount and relatively low in treatment cost, the flame-retardant efficiency on the cotton fabric is high, the flame retardance of the cotton fabric is improved, and meanwhile, the influence on other properties of the fabric is relatively small; therefore, the application range of the cotton fabric is widened, and the flame-retardant cotton fabric prepared by the method is suitable for the fields with strict flame-retardant requirements, such as furniture and indoor building decoration.

Owner:NORTHEAST FORESTRY UNIVERSITY

Reactive flame retardant for epoxy resin and its flame retardant epoxy resin

The invention provides a reactive flame retardant for epoxy resin and flame retardant epoxy resin of the reactive flame retardant, wherein the reactive flame retardant for epoxy resin comprises at least one of DOPO-AM, DOPO-Urea and DOPO-THU. DOPO is subjected to a reaction with acrylamide, urea and thiourea, and the obtained DOPO-AM, DOPO-Urea and DOPO-THU are reactive organo-phosphorus flame retardants, all of which contain an amine group. When the reactive flame retardants are added into epoxy resin, the amine groups can react with epoxy resin, so as to graft the flame retardants onto a main chain of epoxy resin, so that the migration problem of additive flame retardants is solved; the flame retardant has very good flame retardant properties, and has relatively less effect on the mechanical properties and other properties of epoxy resin, so that epoxy resin also maintains good physical and mechanical properties; moreover, the flame retardant can also improve the refractive index ofepoxy resin.

Owner:SHENZHEN POLYTECHNIC

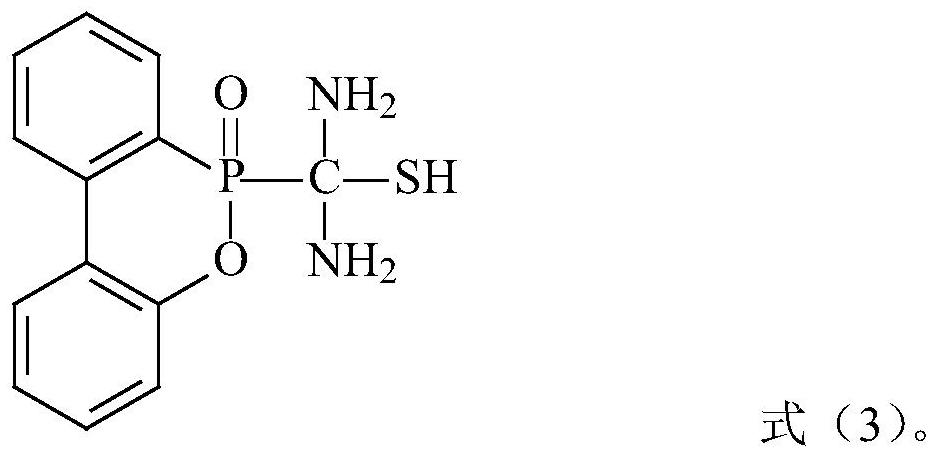

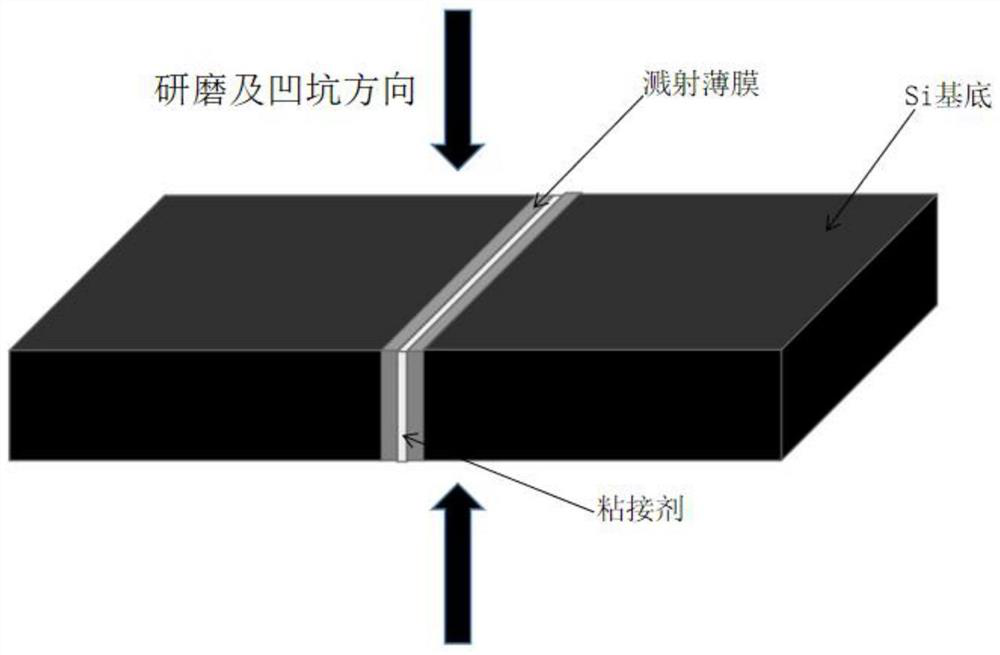

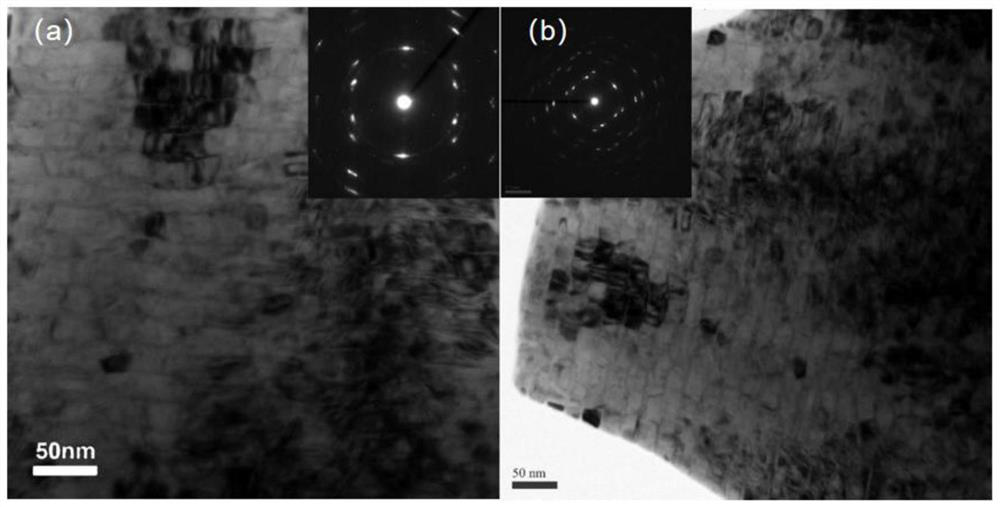

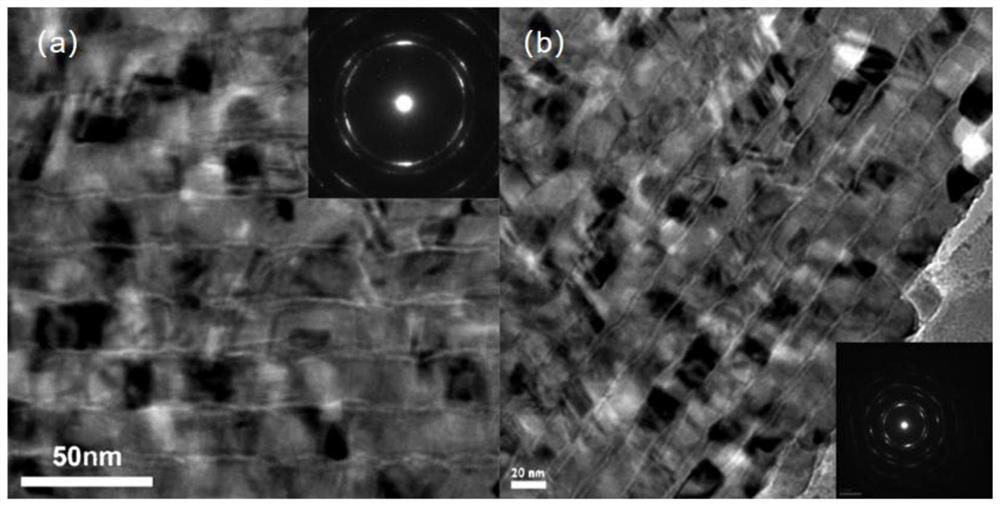

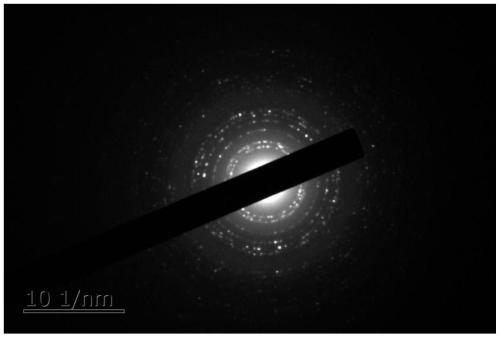

High-hardness Cu-based material containing interface layers and preparation method thereof

PendingCN112323032ASimple processLow priceVacuum evaporation coatingSputtering coatingInterface layerLayer thickness

The invention discloses a high-hardness Cu-based material containing interface layers and a preparation method thereof. The material comprises Cu matrix layers and the interface layers, wherein the Cumatrix layers and the interface layers are alternately superposed; an initial layer and a final layer are Cu layers; the interlayer modulation ratio is 10:1-50:1; the interface layers are Nd, Zr, Ag,CuZr amorphous and CuNb amorphous; the thicknesses of the Cu layers are the same; the thickness range of the single Cu layer is 5-50 nm; the thicknesses of the interface layers are the same; and thethickness range of the single interface layer is 0.5-2 nm. The prepared high-hardness Cu-based material has such mechanical properties as higher hardness; and the interface layers generate no side effect on the matrix Cu. The preparation method of the Cu-based material is simple in production process, low in cost and suitable for industrial application and automatic batch production, and has unique structure and performance advantages in such fields as microelectronic components, power transmission devices, integrated circuits and printed circuits.

Owner:HEBEI UNIV OF TECH

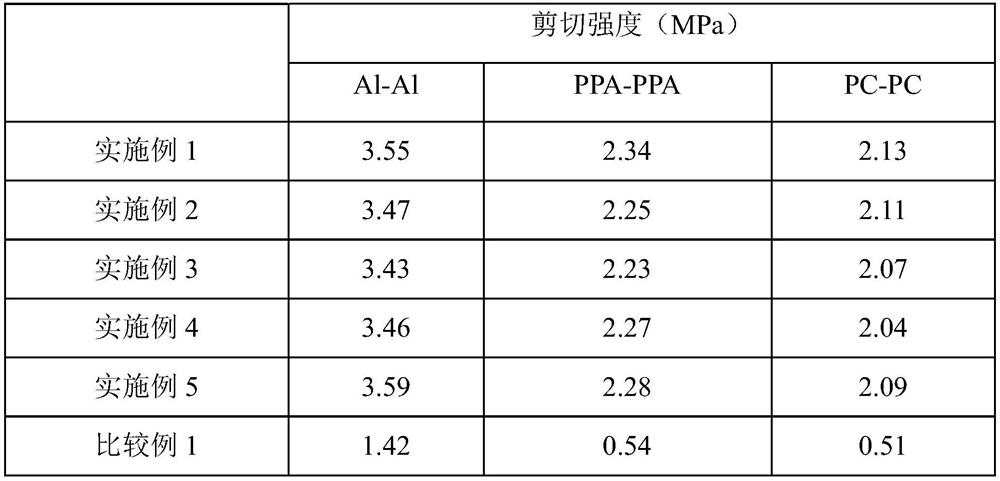

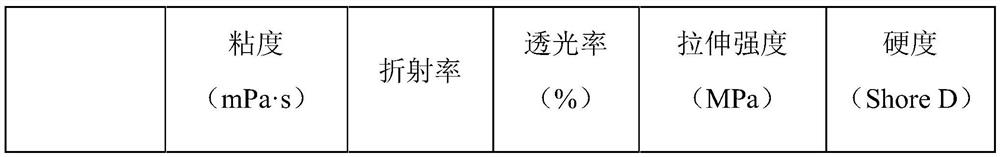

Preparation method of adhesion promoter for high refractive index addition type silicone encapsulation adhesive

ActiveCN108164704BAvoid side reactions such as ring openingHigh refractive indexMacromolecular adhesive additivesEpoxyPolymer science

The invention discloses a preparation method of a high-refractive index addition type adhesion promoter for an organosilicone sealing adhesive. The method comprises the following steps: uniformly stirring phenylsilane and a capping agent at room temperature, adding a catalyst and deionized water, performing a reaction at 25-80 DEG C for 1-6 h, then adding epoxy silane, ester silane, boric acid andthe capping agent, performing a reaction at 40-80 DEG C for 1-6 h, and finally removing low-boiling-point substances to prepare the high-refractive index adhesion promoter. The adhesion promoter prepared in the invention has a high refractive index and a significant tackifying effect. The preparation method in the invention has the advantages of simplicity, easiness in implementation, avoiding ofring opening and other side reactions of epoxy groups, environmental protection, easily available raw materials, and easiness in realization of industrial production.

Owner:FOSHAN XINXIANGXING CHEM

A method for improving the running stability of the mechanical transmission chain of a direct-drive wind turbine

The invention provides a method for improving operation stability of a mechanical transmission chain of a direct-drive wind turbine generator. A data collecting card collects an operation variable X of the direct-drive wind turbine generator in real time. The method comprises the specific steps that 1, a mechanical transmission chain stabilization system is set according to the operation variable X and mechanical characteristics of the mechanical transmission chain; 2, the mechanical transmission chain stabilization system carries out filtering processing on the operation variable X; 3, the mechanical transmission chain stabilization system carries out dynamic compensation on a voltage reference value of the direct current capacitor end of a converter of the direct-drive wind turbine generator. Compared with the prior art, the method is simple in operation and easy to achieve. Mechanical transmission chain vibration of the direct-drive wind turbine generator caused by rotation speed changes can be quickly relieved, and the influence on unit output active power and power grid electric energy quality is little.

Owner:STATE GRID CORP OF CHINA +1

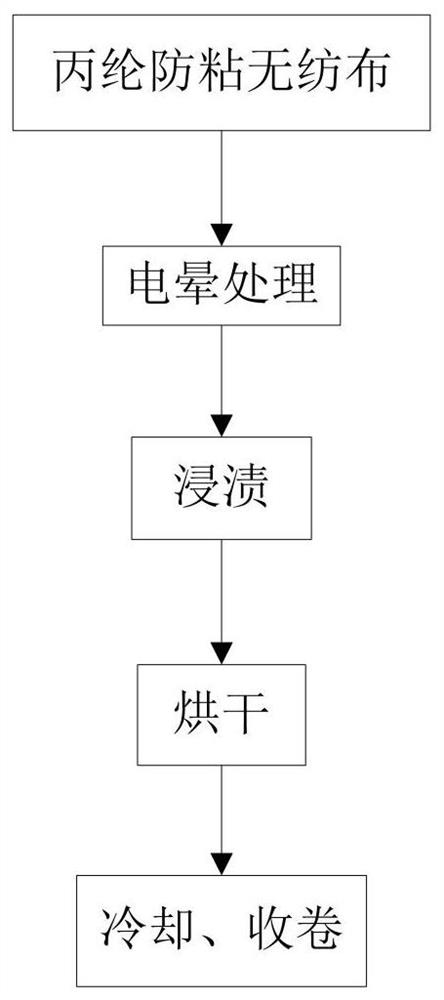

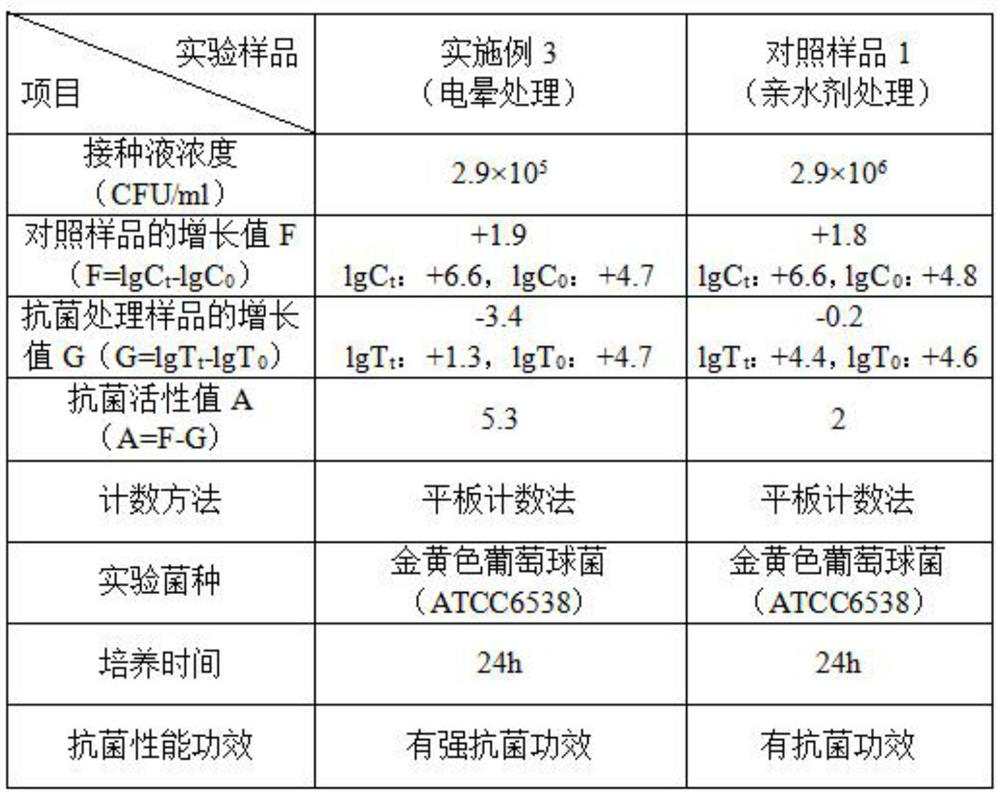

A kind of hydrophilic antibacterial non-woven non-woven fabric and preparation method thereof

ActiveCN109487532BImprove hydrophilicityLittle impact on other performanceBiochemical fibre treatmentFibre typesPolymer scienceNonwoven fabric

The invention discloses a hydrophilic antibacterial nonwoven nonwoven fabric and a preparation method thereof. The hydrophilic antibacterial nonwoven nonwoven fabric comprises a polypropylene anti-sticking nonwoven fabric base material and a water-based antibacterial layer. The hydrophilic antibacterial nonwoven fabric The preparation method of the woven non-woven fabric is that the polypropylene anti-sticking non-woven fabric substrate is subjected to corona treatment, dipped in an aqueous antibacterial solution, dried, cooled, and rolled up to obtain a hydrophilic antibacterial non-woven non-woven fabric; the present invention will The corona method used to treat film materials is introduced into the surface treatment of polypropylene anti-adhesive non-woven fabrics. After corona treatment, polypropylene anti-adhesive non-woven fabrics have good hydrophilic properties, and the treatment process is simple, fast, and low-cost. At the same time, it has little influence on other properties of polypropylene anti-sticking non-woven fabric.

Owner:江苏美舜生物科技有限公司

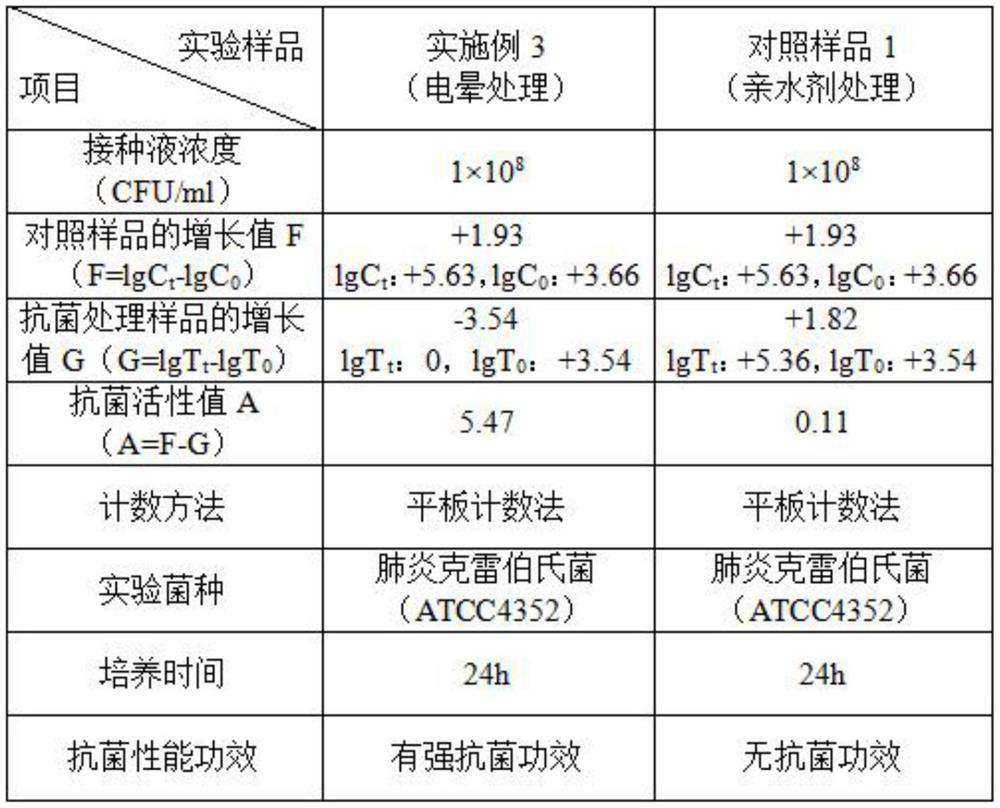

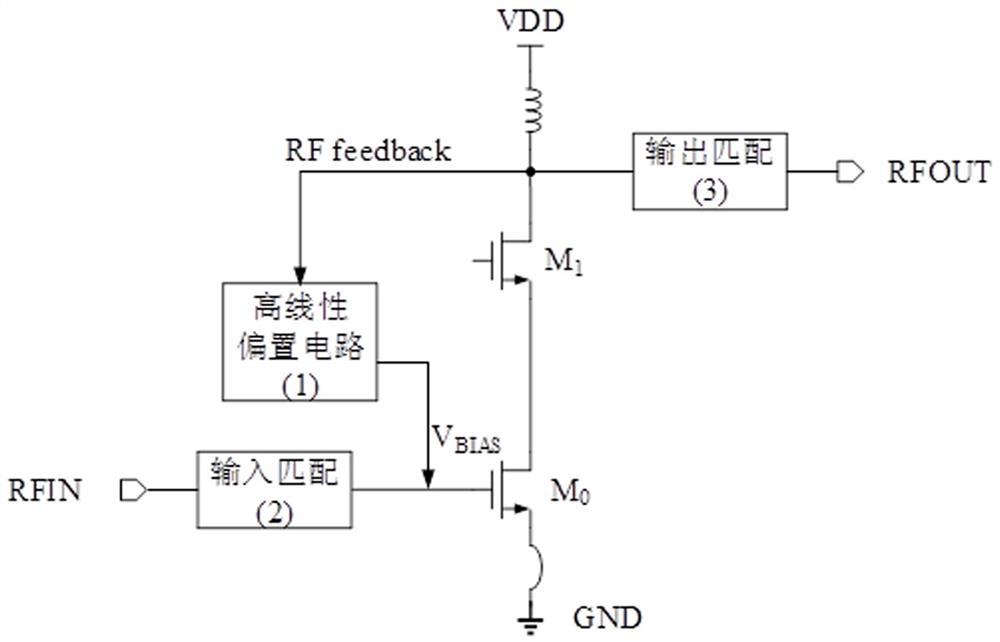

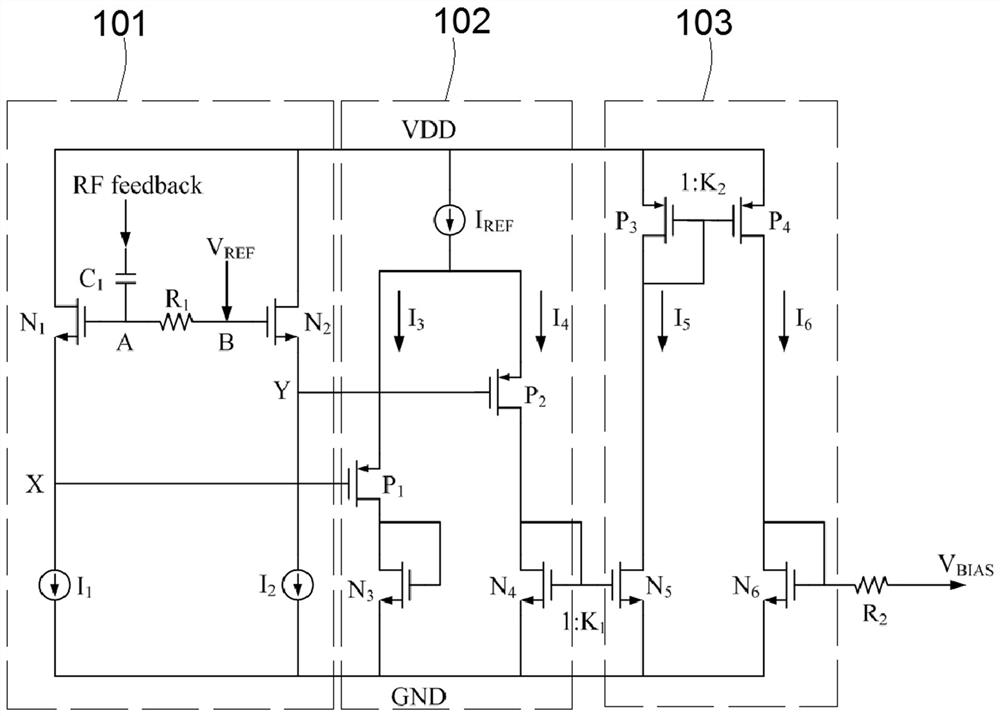

A High Linearity Bias Circuit Applied to RF Amplifier

ActiveCN113595515BSimple structureReduce manufacturing costAmplifier modifications to reduce non-linear distortionAmplifier with semiconductor-devices/discharge-tubesAudio power amplifierReference current

The invention discloses a high linearity bias circuit applied to a radio frequency amplifier, which overcomes the problems of large performance impact, power frequency offset and signal distortion introduced by the compensation circuit in the prior art, including an output signal power acquisition and conversion circuit, A reference current control circuit and a bias voltage generation circuit; the reference current control circuit is respectively connected with the output signal power acquisition and conversion circuit and the bias circuit generation circuit. The present invention automatically adjusts the bias voltage of the bias circuit by monitoring the output signal amplitude of the radio frequency amplifier, thereby increasing the bias voltage when processing high-power signals, and compensating for the power gain to improve the linearity of the radio frequency amplifier, and can realize full chip integration and circuit The structure is simple, the response speed is fast, the parasitic parameters are small, and the performance of the core circuit of the power amplifier is small.

Owner:杭州中科微电子有限公司

A phosphazene compound, a composition comprising the phosphazene compound, a flame retardant comprising it and applications

ActiveCN109134544BImprove performanceRaw materials are easy to obtainGroup 5/15 element organic compoundsGeneral purposeEngineering plastic

The present invention relates to a phosphazene compound, a composition comprising the phosphazene compound, a flame retardant comprising same, and the use thereof. The crystal form of a cyclotriphosphazene derivative flame retardant synthesized according to the present invention is the most stable crystal form, and same has a good heat stability and a high flame retardant efficiency; moreover, materials, whether engineering plastics or general-purpose plastics, as well as lithium ion battery electrolyte solutions, flame retardant fabrics and flame retardant papers, to which the crystal type cyclotriphosphazene derivative flame retardant synthesized according to the present invention has been added, are provided with an excellent flame retardant performance, a stable crystal form, and drip resistance, and only an extremely small addition amount is required to allow the flame retardant performance of a material to achieve V-0 standards, while the impact on the other properties of the material is relatively small.

Owner:WEIFANG MEDICAL UNIV +4

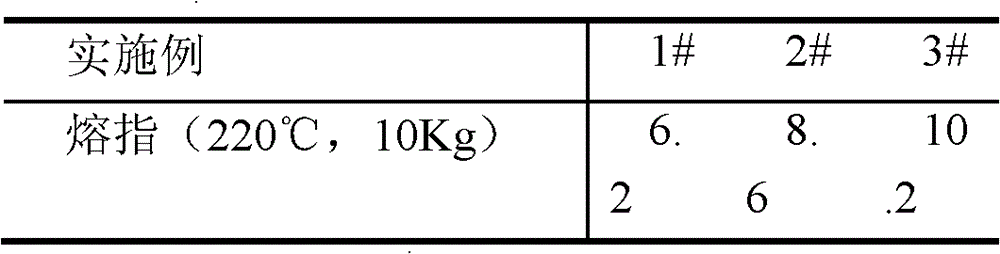

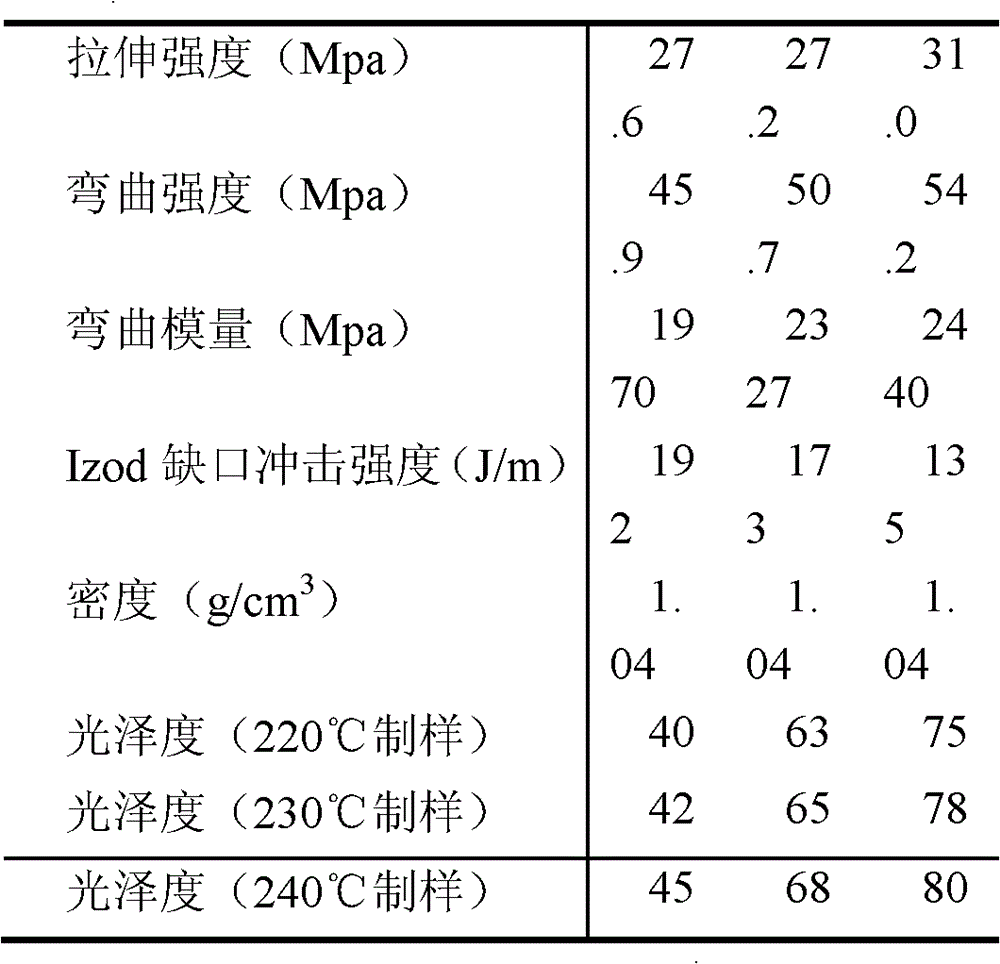

High impact polystyrene resin material with excellent glossiness and preparation method thereof

Owner:HEFEI GENIUS NEW MATERIALS

Application of a Hyperbranched Dyeing Auxiliary in Improving the Dyeability of Superfine Fiber Polyurethane Synthetic Leather

InactiveCN105755865BGood effectLittle impact on other performanceDyeing processPolymer scienceSuccinic anhydride

The invention relates to the field of superfine-fiber polyurethane synthetic leather, in particular to application of a hyperbranched dyeing assistant to the increasing of the dyeability of superfine-fiber polyurethane synthetic leather.Hyperbranched polymer with terminal hydroxyl is synthesized first, then succinic anhydride modification is used to introduce carboxyl to the terminal of the hyperbranched polymer so as to synthesize hyperbranched polymer with terminal carboxyl.The hyperbranched polymer with terminal carboxyl is applied to the field of polyurethane dyeing assistants and is good in dyeing assisting effect, good in stability and lasting in effect, the synthesizing process of the hyperbranched polymer with terminal carboxyl is simple, industrialized synthesizing of the hyperbranched polymer with terminal carboxyl can be achieved easily, and the hyperbranched polymer with terminal carboxyl is a good polyurethane synthetic leather dyeing assistant with excellent performance.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com