Preparation method of flame-retardant cotton fabric

A flame retardant cotton and cotton fabric technology, applied in flame retardant fibers, plant fibers, textiles and papermaking, etc., can solve problems such as poor washing resistance, achieve high flame retardant efficiency, improve application scope, and low processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

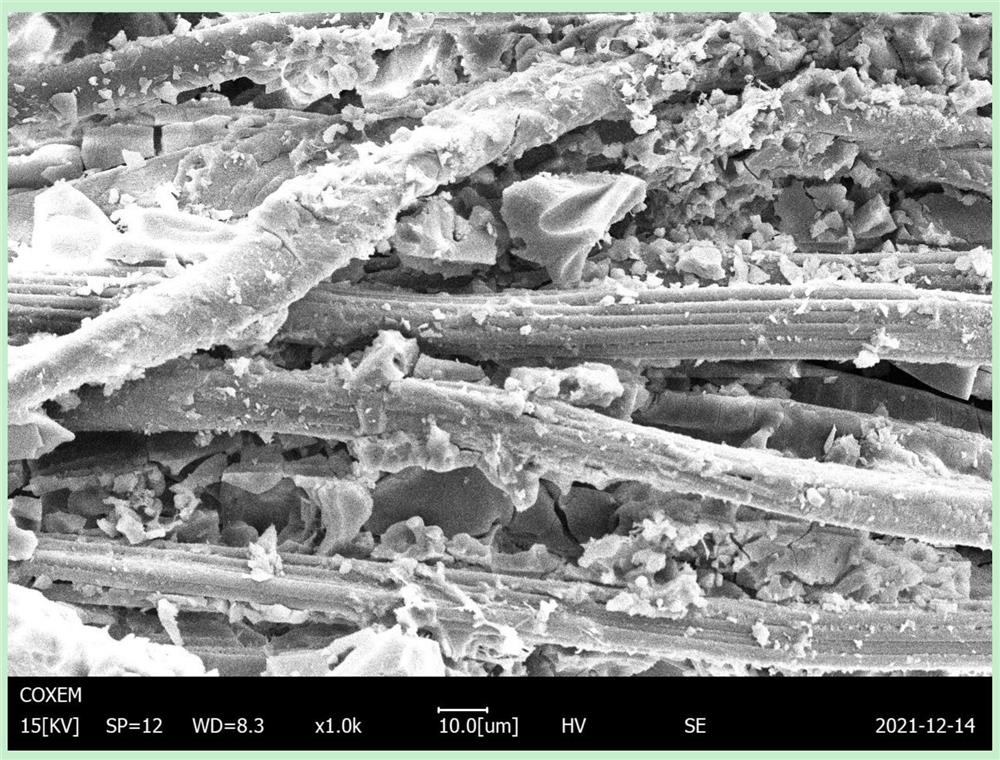

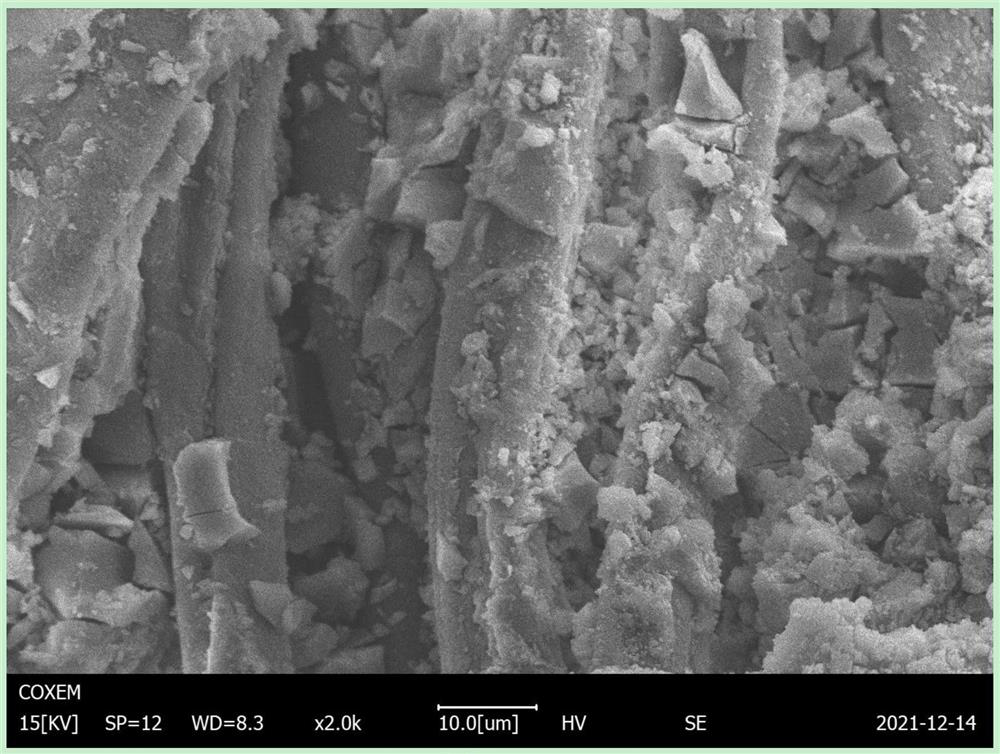

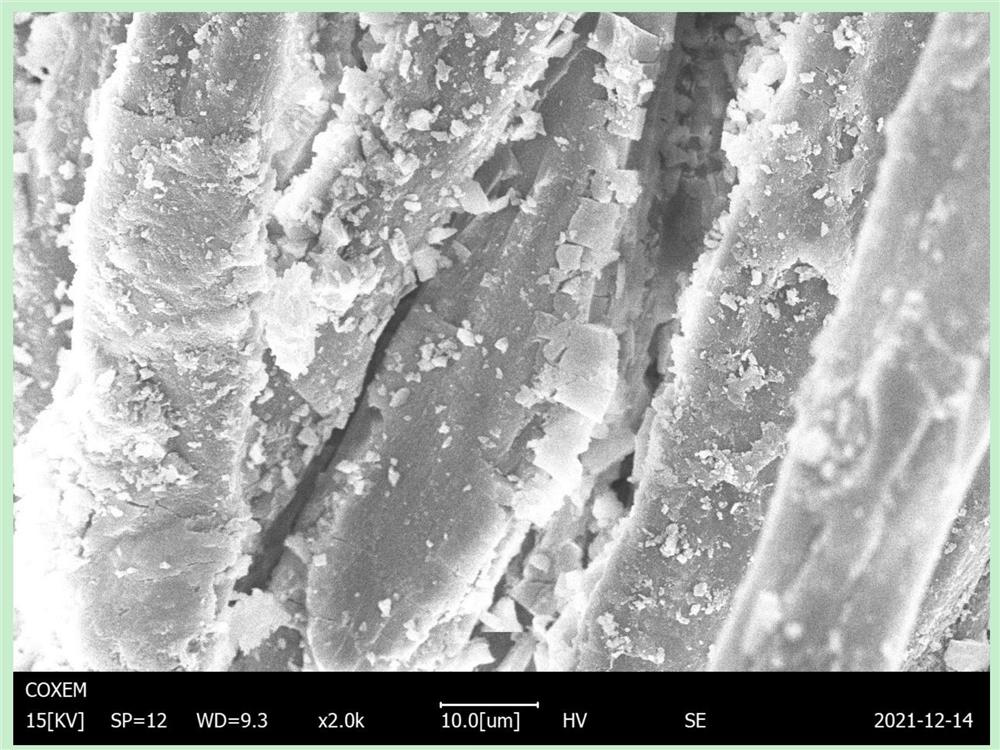

Image

Examples

Embodiment 1

[0028] A preparation method of flame retardant cotton fabric, comprising the following steps:

[0029] (1) Preparation of ammonium polyphosphate-aluminum hydroxide composite:

[0030] 1) 50g of ammonium polyphosphate was added to ethanol to form a suspension, which was transferred to a three-necked flask equipped with a stirring magnet and a condenser;

[0031] 2) Dissolve 2.00g of anhydrous aluminum chloride powder with 10mL of deionized water, slowly add it to the flask, and stir for 20min until it is completely uniform;

[0032] 3) Slowly add 5 mL of ammonia water and continue stirring until the pH value of the solution is 8, and let it settle for 2 hours in a constant temperature water bath at 60 °C;

[0033] 4) carrying out suction filtration and washing of the precipitated product, and pulverizing it into powder after drying;

[0034] (2) Preparation of flame retardant solution:

[0035] Weigh 0.9 part of ammonium polyphosphate-aluminum hydroxide composite, 45 parts o...

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that the ammonium polyphosphate-aluminum hydroxide compound added in the preparation of the flame retardant solution is 0.675 parts by mass. The preparation method of Example 2 is the same as that of Example 1.

Embodiment 3

[0044] The difference between Example 3 and Example 1 is that the ammonium polyphosphate-aluminum hydroxide compound added in the preparation of the flame retardant solution is 0.45 parts by mass. The preparation method of Example 3 is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com