Patents

Literature

53results about How to "Accelerate the ripening speed" patented technology

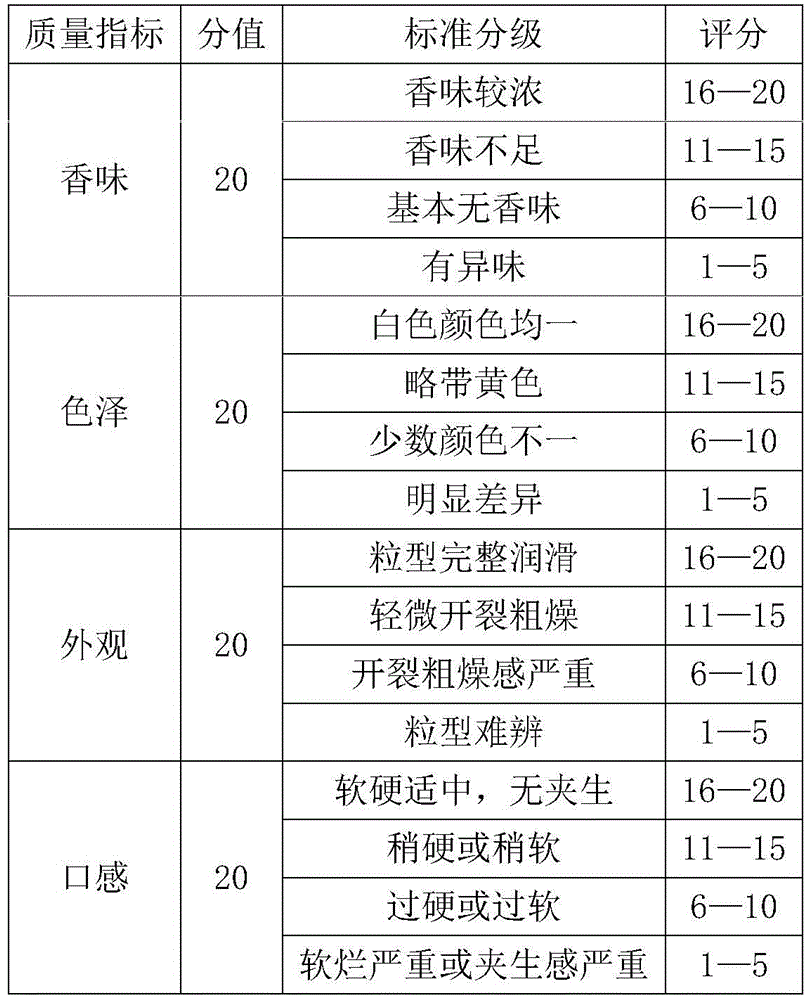

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

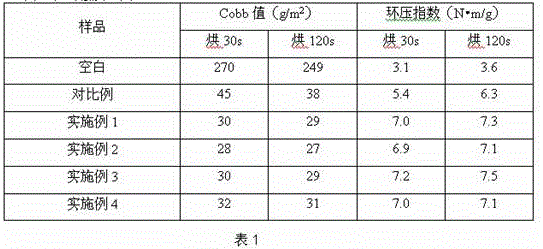

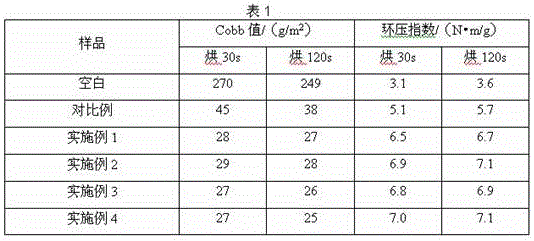

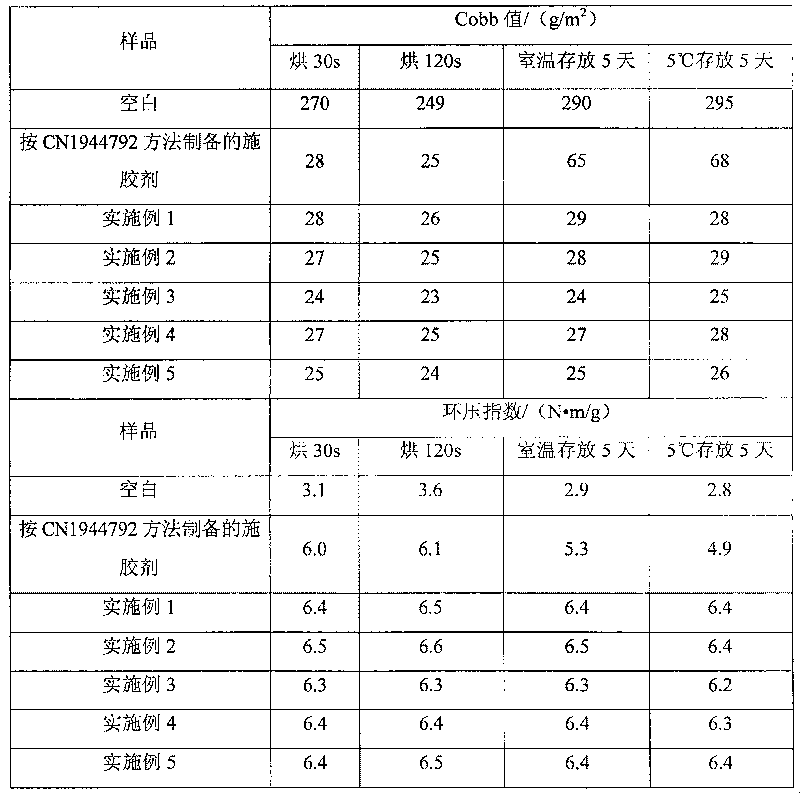

Paper surface sizing agent and preparation method thereof

ActiveCN101148842AIncreased ring compressive strengthLose weightWater-repelling agents additionPaper/cardboardCross-linkEmulsion

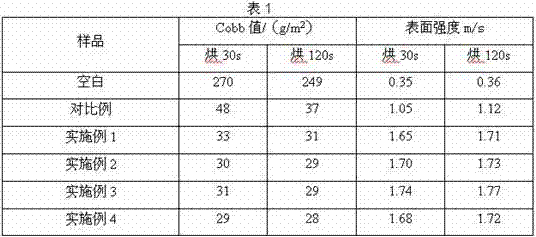

The present invention relates to paper surface treating agent, and is especially one kind of paper surface sizing agent and its preparation process. The paper surface sizing agent is prepared with cationic monomer, cross-linking monomer, (methyl) acrylate monomer and (methyl) styrene, and through free radical emulsion polymerization in mixture emulsion comprising dispersant, emulsifier and initiator. It has high performance and environment friendship. It is applied in sizing paper surface together with starch to raise the compression strength of paper, raise Cobb value and improve other performance of paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

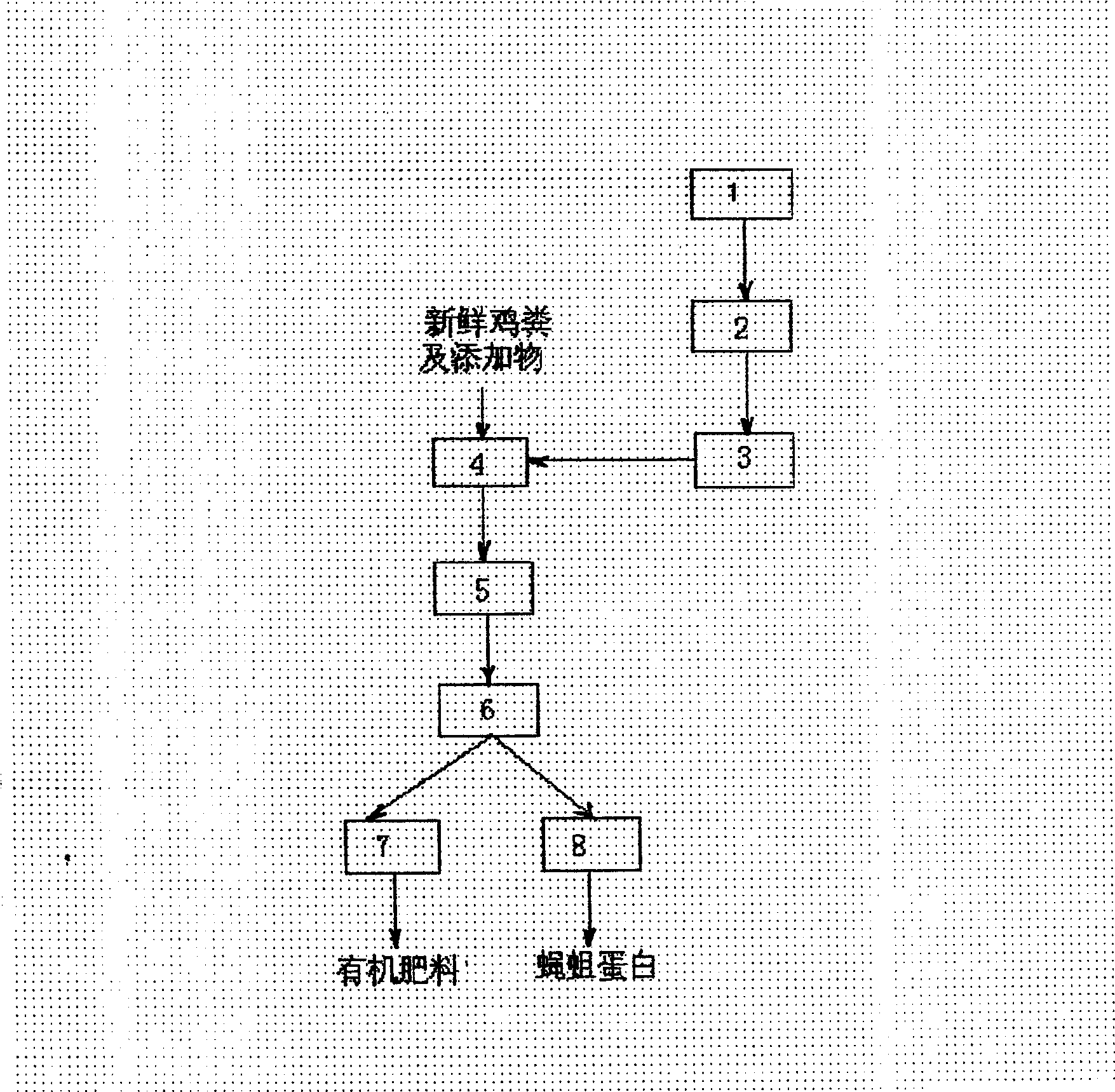

Method for producing organic fertilizer and muscidian larvina protein by using ecologically-treated chicken manure

InactiveCN1443728AAccelerate the ripening speedReduce lossesClimate change adaptationExcrement fertilisersFecesHousefly

The present invention provides a method for preparing organic biological fertilizer and fly-maggot protein by using domestic muscidian larva to treat chicken manure. It includes the following procedures of fly culture, fly-blows production, fly-blows collection, fly-blows inoculation, chicken manure treatment, fly and maggot separation, processing biological fertilizer and processing fly-maggot protein, so that the odourless chicken manure biological fertilizer and fly-maggot protein product can be obtained.

Owner:GUIYANG MEDICAL UNIVERSITY

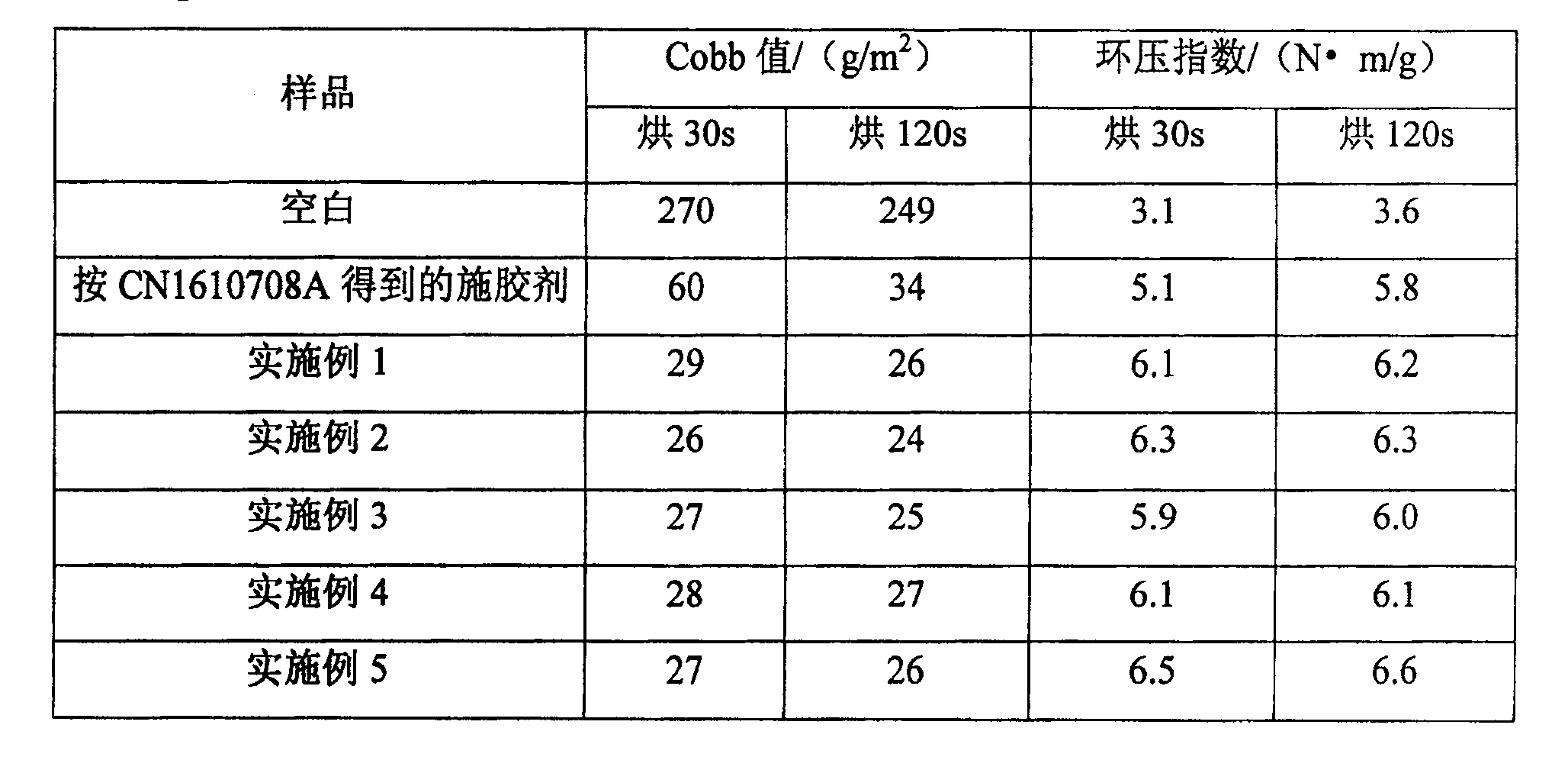

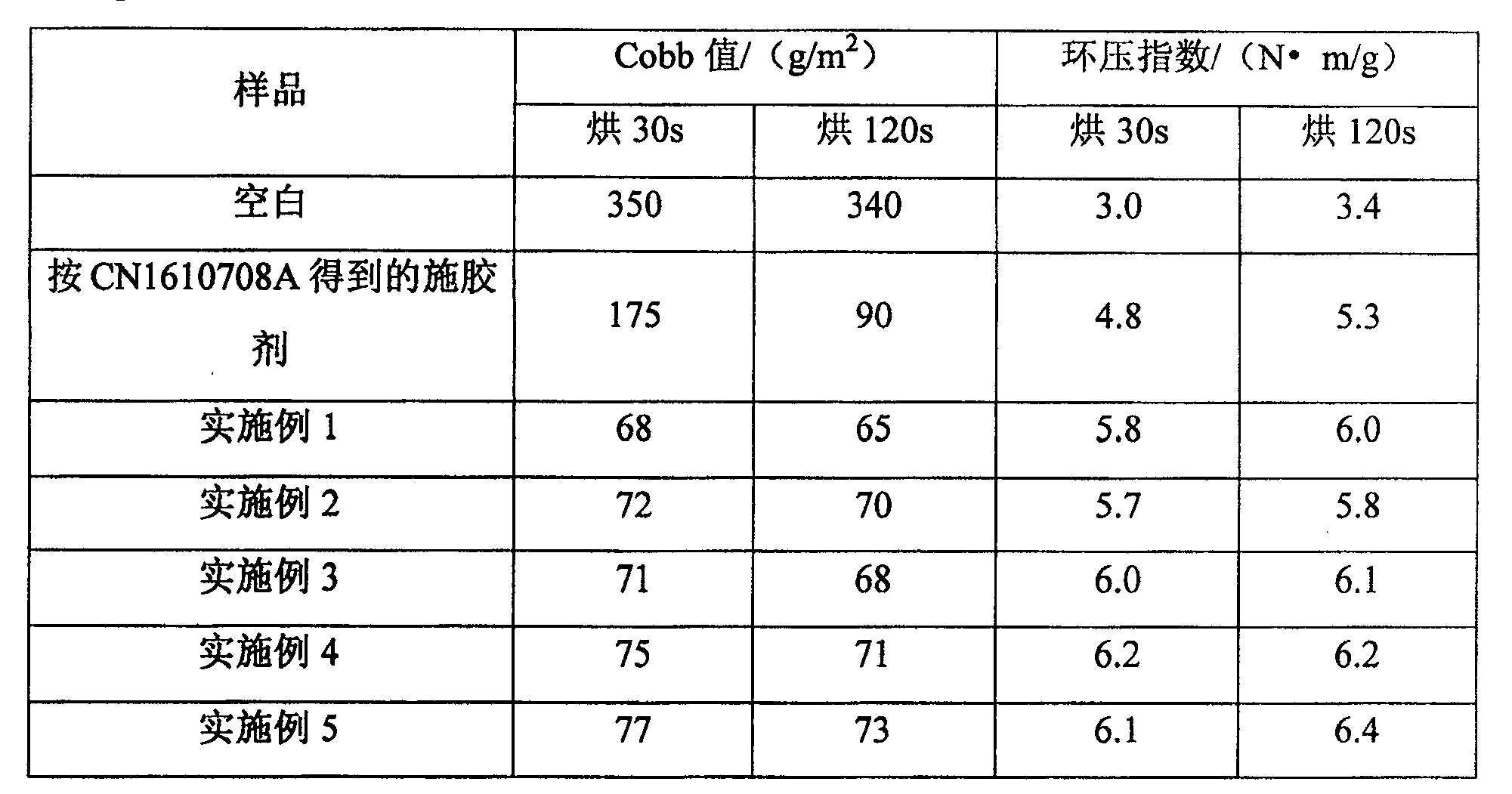

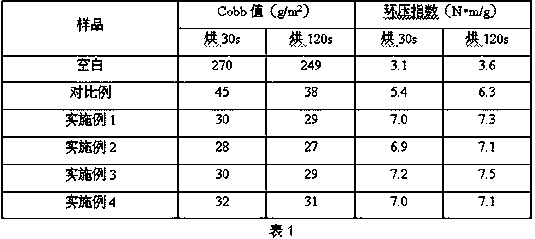

Surface sizing agent for corrugated paper as well as preparation method and application thereof

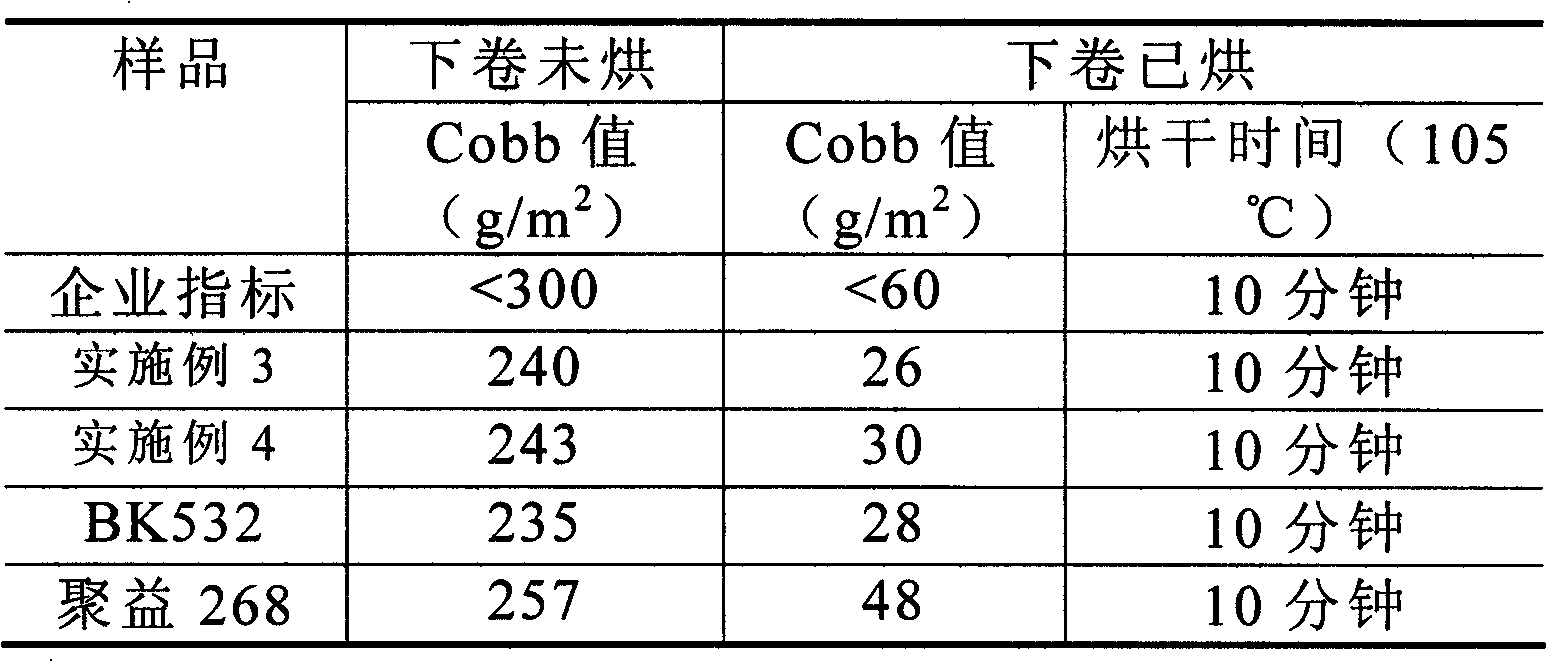

ActiveCN102011343AImprove Cobb valueAccelerate the ripening speedWater-repelling agents additionPaper sheetSizing

The invention provides a surface sizing agent for corrugated paper as well as a preparation method and application thereof. The surface sizing agent for the corrugated paper comprises the following components in parts by weight: 100 parts of base stocks of the surface sizing agent for the corrugated paper and 5-10 parts of cationic additives, wherein the cationic additives are emulsified materials formed by stearic acids and cationic emulsifiers. The surface sizing agent for the corrugated paper is a high-performance environmental-friendly product which can meet the requirements for surface sizing of paper sheets; the product carries out the surface sizing on raw corrugated paper with starch together, thereby not only improving the Cobb value of the corrugated paper and accelerating the curing speed, but also greatly enhancing the surface ring crush strength of the corrugated paper and reducing the using amount of the starch; and in addition, the invention can be suitable for the need of the development of the high-strength corrugated paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

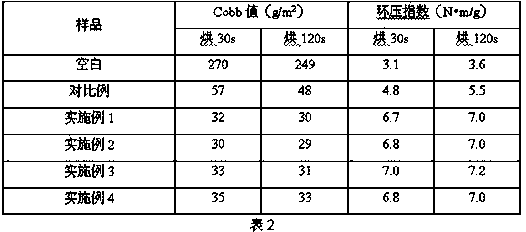

Surface sizing agent for paperboard and preparation method thereof

ActiveCN102011342AImprove Cobb valueReduce dosageWater-repelling agents additionWhiteboardBiochemical engineering

The invention discloses a surface sizing agent for a paperboard as well as a preparation method and application thereof. The surface sizing agent for the paperboard comprises the following components in part by weight: 100 parts of surface sizing agent base stocks for the paperboard, and 5-10 parts of cationic additives. The surface sizing agent for the paperboard can be used for the surface treatment of white board body paper. The surface sizing agent for the paperboard is a high-performance and environmental-protection product capable of meeting the requirement of the high-performance and environmental protection products for paper surface sizing. When the product conducts surface sizing on the white board body paper together with starch, the surface sizing agent can greatly improve the Cobb value of the paperboard, accelerate the curing speed, reduce the dosage of the starch, and can meet the requirement on the development of the high-strength paperboard.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

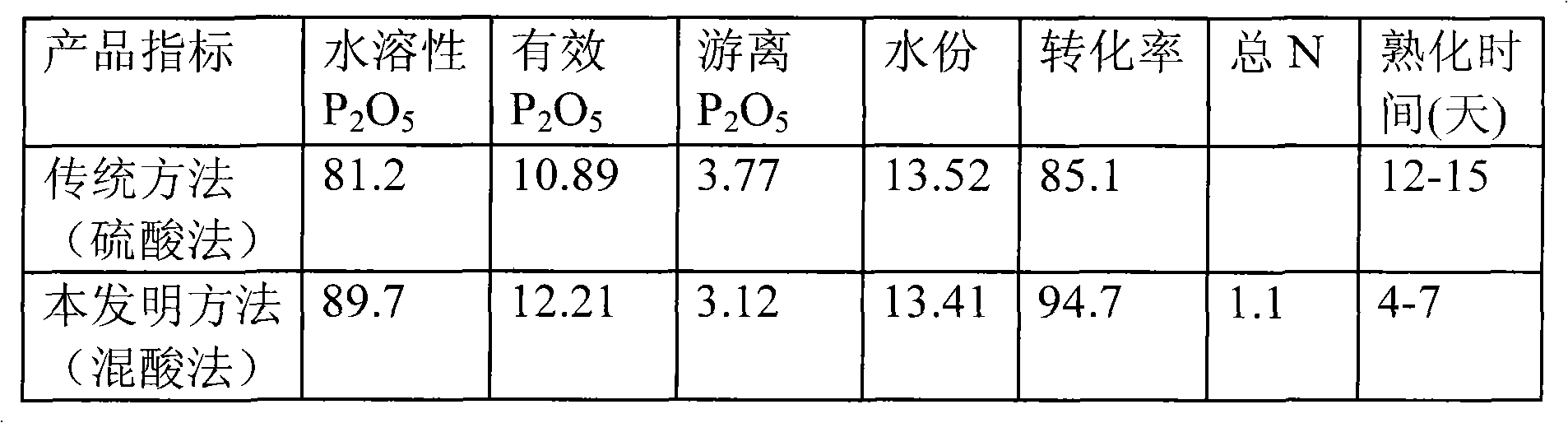

Method for producing qualified calcium superphosphate fertilizer with low-grade phosphate ore

InactiveCN102050642AImprove decomposition rateIncrease profitSuperphosphatesDecompositionLower grade

The invention discloses a method for producing qualified calcium superphosphate fertilizer with low-grade phosphate ore. The method is characterized by comprising the following steps: phosphate ore the P2O5 content of which is 22-23% is used as a raw material to prepare ore pulp with the water content of 27wt% by using 100 parts of dry phosphate ore powder as the reference; ore pulp reacts with the mixed acid of 45-55 parts of concentrated sulfuric acid and 5-15 parts of concentrated nitric acid by weight while the concentration of the free acid in the mixture system is controlled to 17-20%, the mixture system is transferred to an aging chamber and aged for 1 hour to prepare fresh fertilizer with the free acid concentration of 5.5-6.5%; and the fresh fertilizer is aged for 4-7 days to obtain the qualified calcium superphosphate fertilizer product with the P2O5 content of more than 12%. In the method of the invention, by adding nitric acid, the decomposition rate of phosphate ore is increased by 7-9% and the aging speed of the product is increased; the production cycle is only 4-7 days, which is reduced by about 50% compared with the traditional production method; and the production cost is reduced by 15-20%.

Owner:徐杰

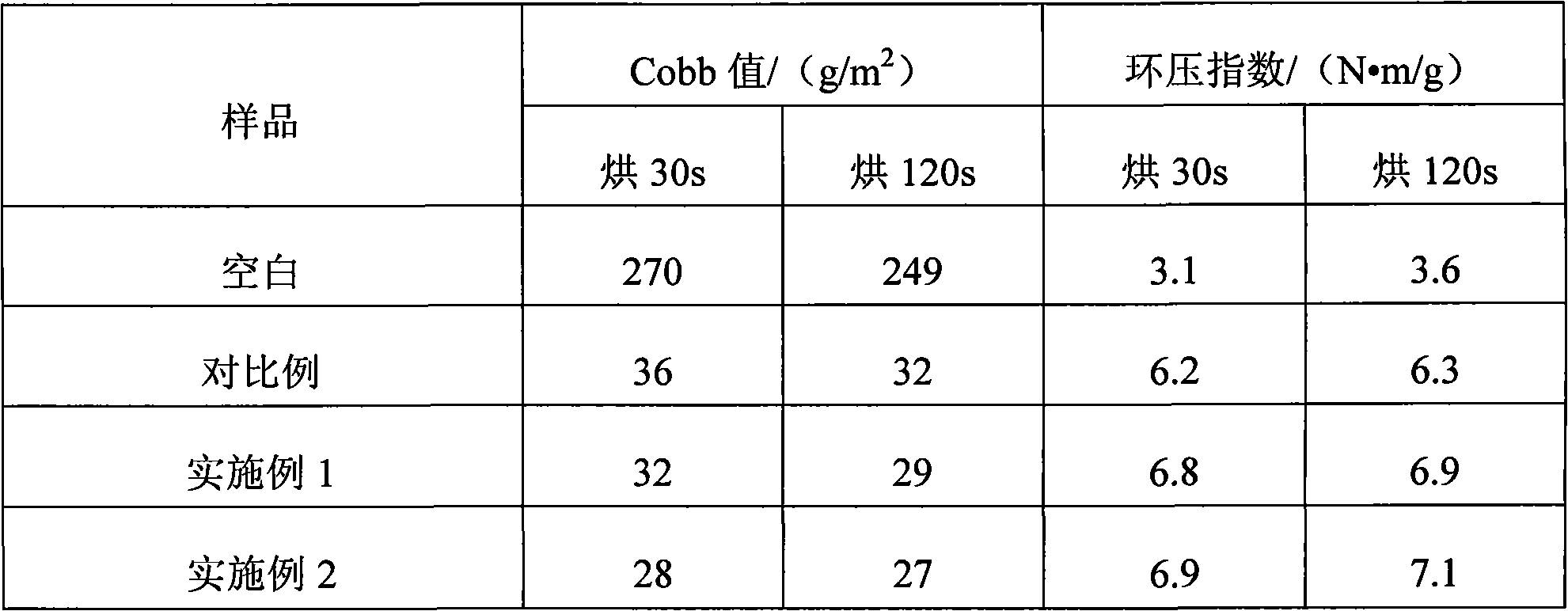

Preparing method of surface sizing agent for corrugated paper, product and application of surface sizing agent

ActiveCN106368059AReduce the Cobb valueIncreased ring compressive strengthWater-repelling agents additionCoated paper substrateAcetic acidPulp and paper industry

The invention provides a preparing method of a surface sizing agent for a corrugated paper, a product and an application of the surface sizing agent. The surface sizing agent for the corrugated paper is prepared by uniformly mixing a base stock of the surface sizing agent for the corrugated paper with a cationic additive. The preparing method for the base stock of the surface sizing agent for the corrugated paper comprises the steps of adding cationic monomer, siloxane, (metyl)acrylic monomer, (metyl)styrene, an initiator, acetic acid, and water into a reaction vessel, carrying out free radical polymerization reaction to obtain the base stock of the surface sizing agent for the corrugated paper. The preparing method for the cationic additive comprises the steps of adding alkylketene dimmer into an aqueous solution of cationic emulsifier, fully stirring the solution and carrying out emulsification and dispersion to obtain the cationic additive. The surface sizing agent for the corrugated paper obtained through the method can not only cure quickly, sharply improve ring crush compression resistance of the corrugated paper and sharply reduce a COBB value, but also has a very strong anti-dampness performance.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Preparation method for paper nanometer level surface sizing agents capable of realizing fast curing

ActiveCN102351973AOvercome the disadvantage of strong water absorptionIncrease the effective contact areaWater-repelling agents additionFiberPolyamide

The invention relates to a paper surface sizing agent, in particular to a preparation method for paper nanometer level surface sizing agents capable of improving the paper water resistance, surface intensity and annular pressure intensity and realizing the fast curing, which belongs to the technical field of chemical engineering and solves the technical problems of poor product quality and the like in the prior art. The surface sizing agent is prepared by the method of firstly preparing cation type polymer emulsifying agents and then preparing nanometer styrene-acrylates microemulsion. The method has the advantages that the defect of strong self water absorption performance of small molecular emulsifying agents is overcome, and in addition, the effective contact area between the surface sizing agent and the paper surface fiber is greatly improved, so the curing speed after the paper surface sizing and the sizing effect can be respectively and obviously accelerated and improved. The characteristic that paper making wet reinforcing agents of polyamide propylene oxide chloride resin can be fast combined with the fiber, and the cation type polymer emulsifying agents are adopted for taking reaction with epoxy chloropropane to obtain cation charges, so the fast combination of products with the paper surface fiber in the sizing process is promoted, and the curing speed is accelerated.

Owner:ZHEJIANG KESIKE CHEM NEW MATERIAL CO LTD

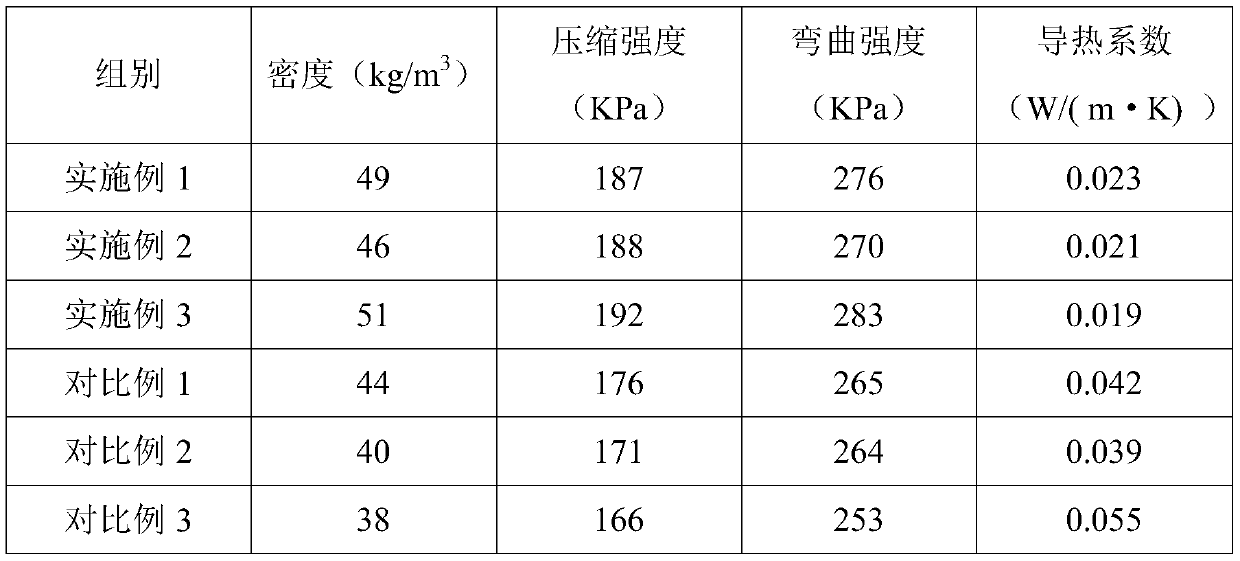

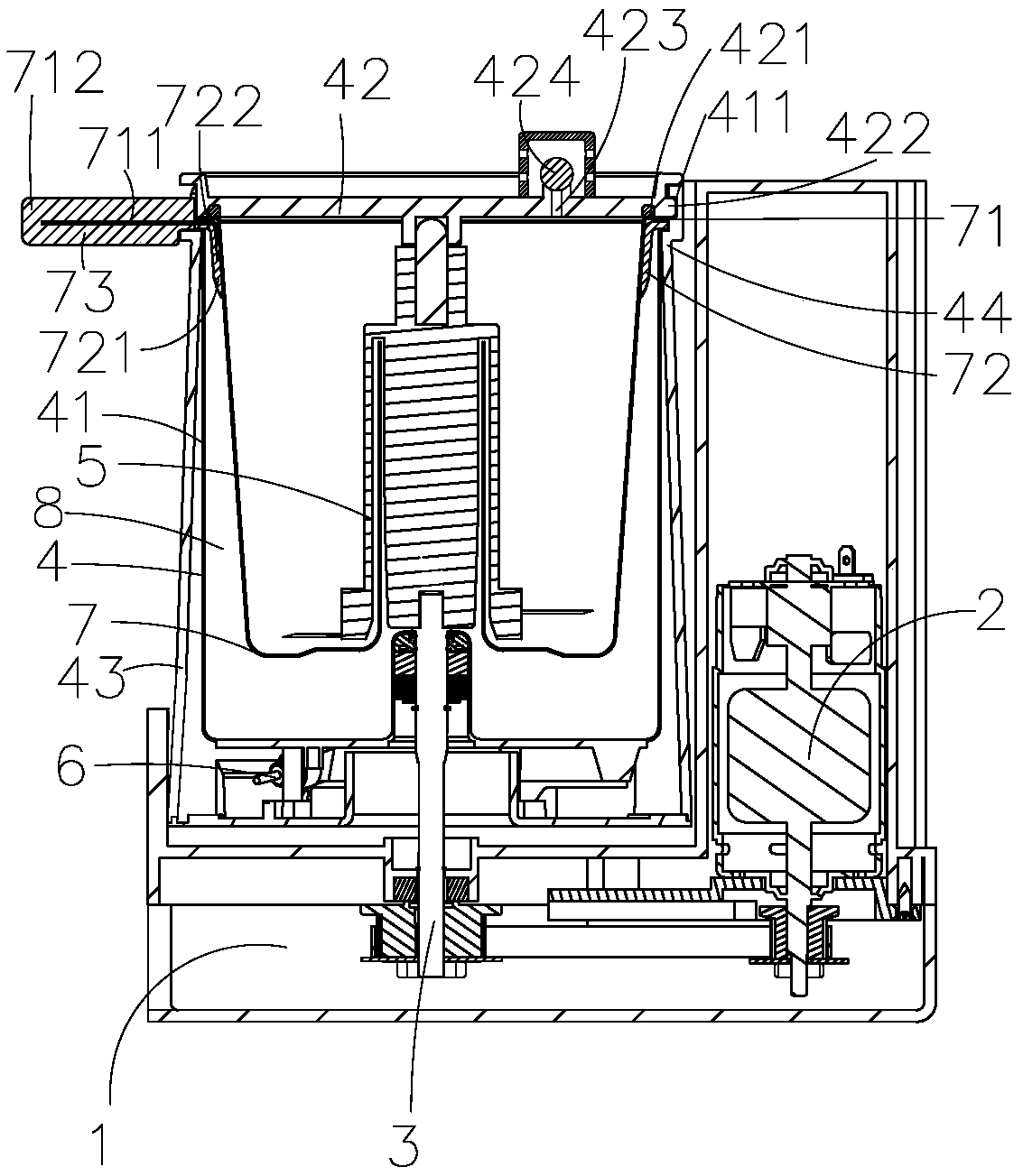

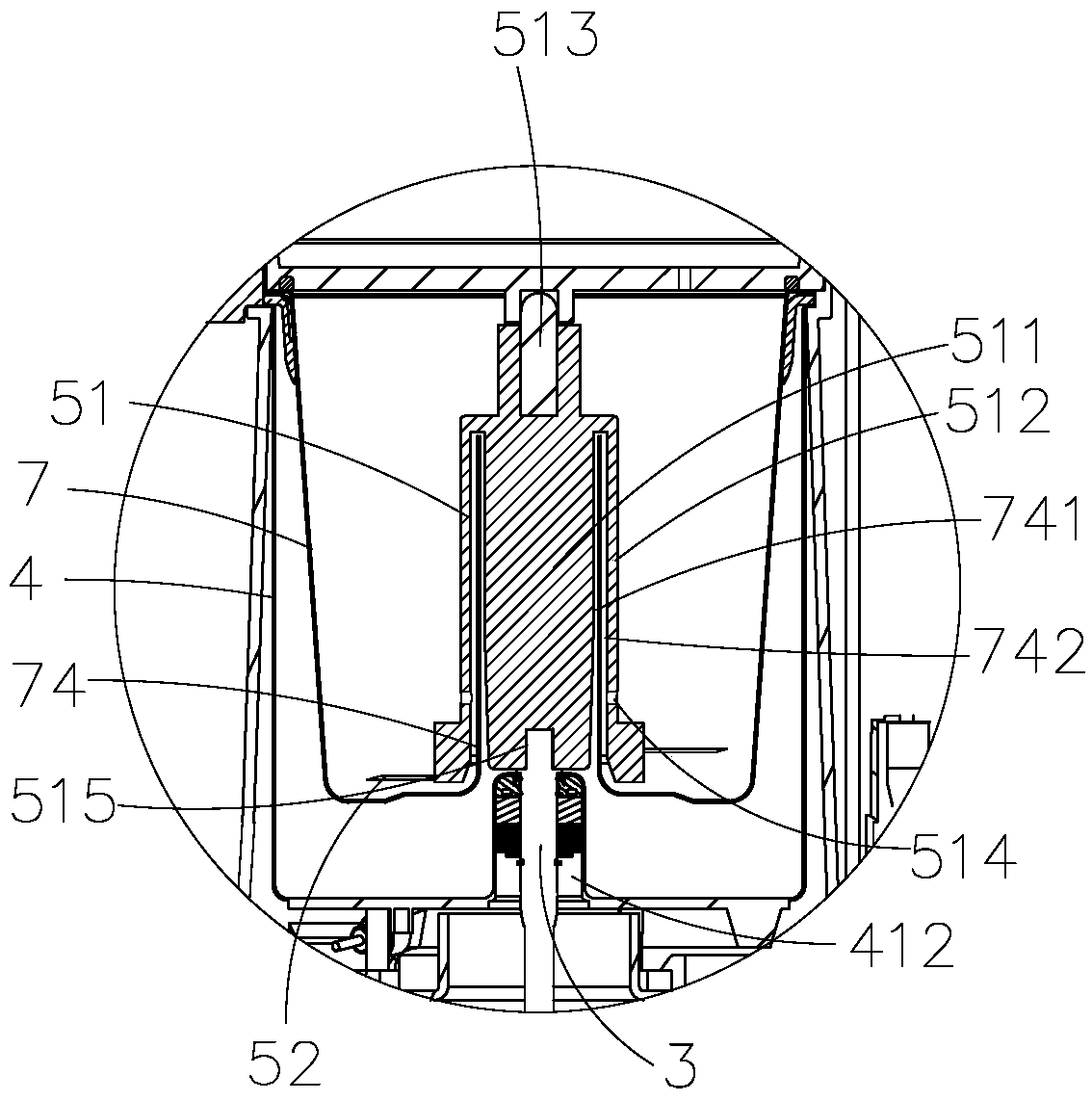

Steam food processor

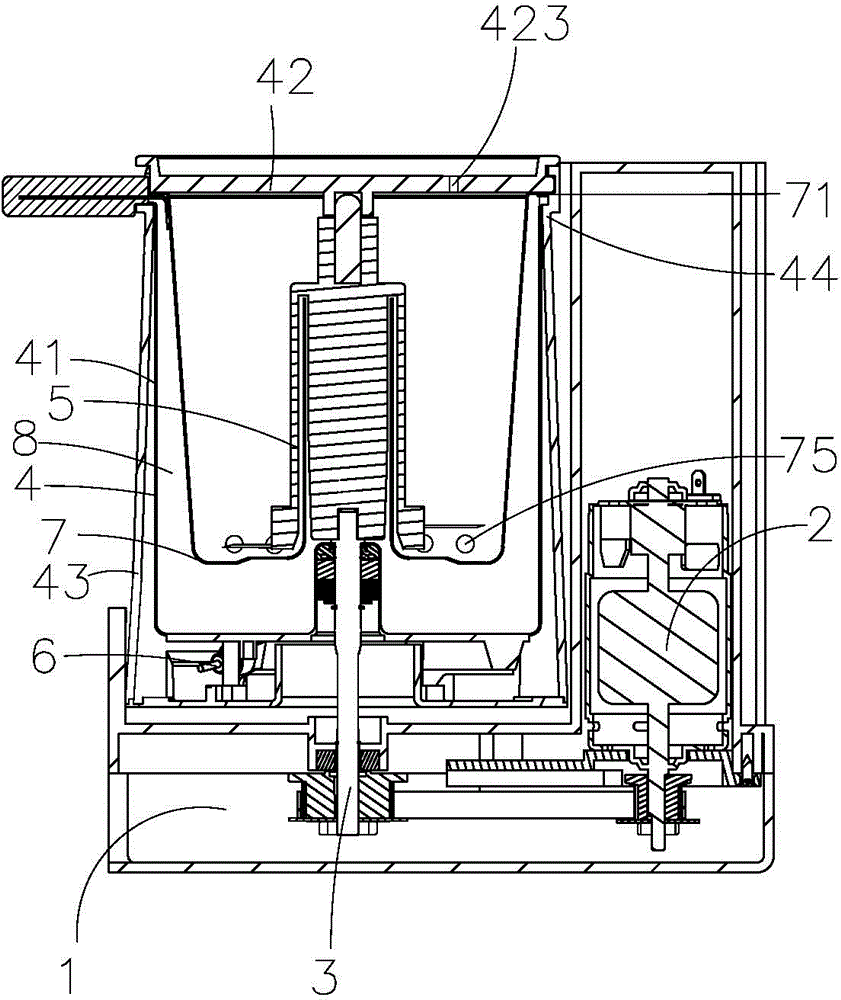

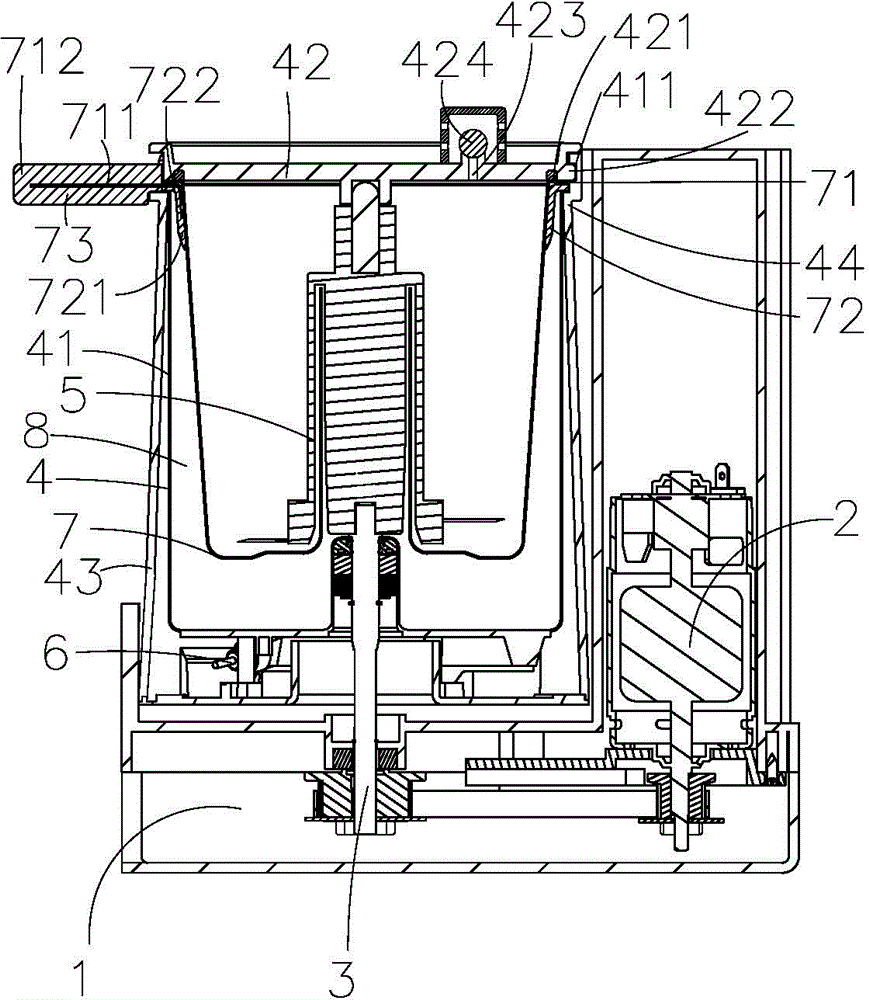

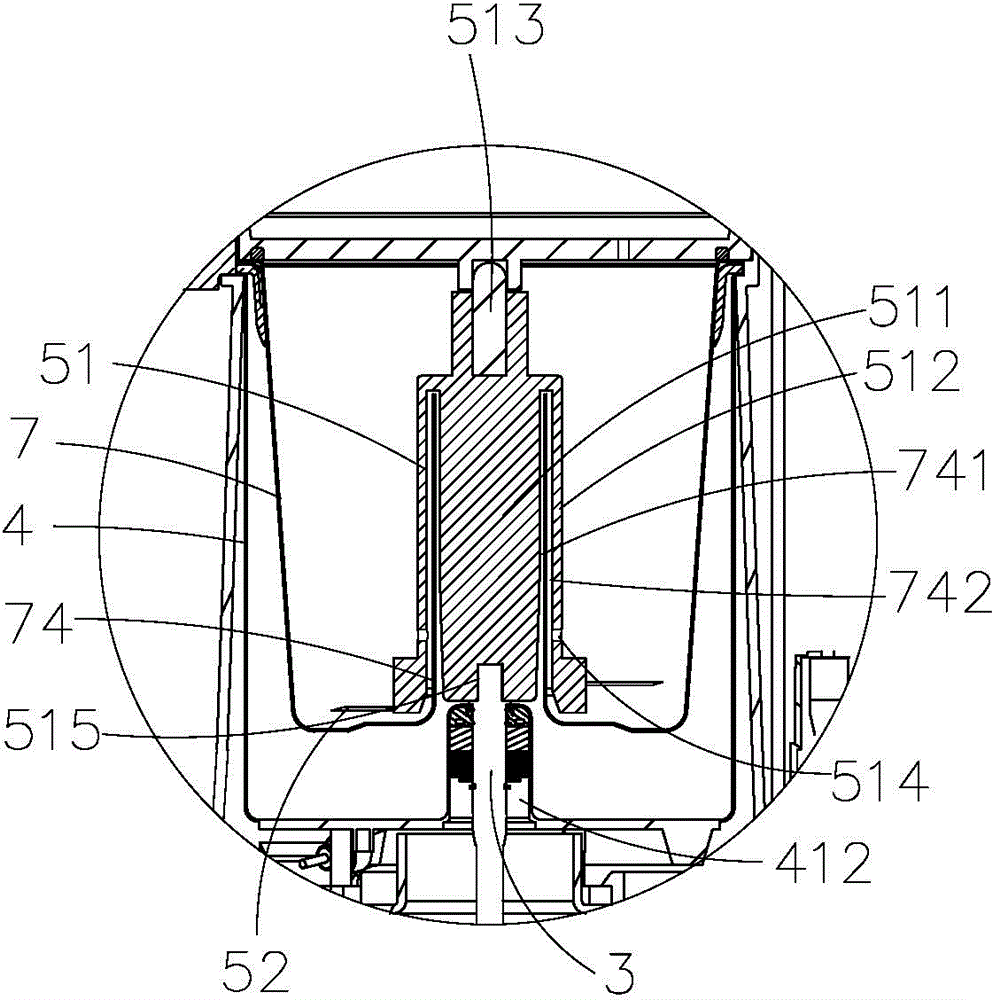

ActiveCN105411373AReduce consumptionReduce distanceSteam cooking vesselsCooking insertsEngineeringSteam generation

The invention discloses a steam food processor which comprises a machine base, a motor, an output shaft, an outer cup, a smashing cutter and a steam generation device. The motor is arranged in the machine base and drives the output shaft to rotate, the outer cup further comprises an outer cup body and an upper cover, the outer cup body is closed by the upper cover, a steam discharging channel is formed in the outer cup, the outer cup is arranged on the machine base, an inner cup is arranged in the outer cup, the smashing cutter is arranged in the inner cup, and the output shaft and the smashing cutter are separately connected. A partition part is arranged between the outer cup and the inner cup so as to form an interlayer region for containing water, the volume ratio of the interlayer region to the outer cup is 1:16 to 1:2, steam is produced in the interlayer region, the inner cup is provided with a steam through hole, and the steam flows into the inner cup through the steam through hole. The steam food processor adopts the inner cup and the outer cup to replace an independent steam generator, steam is produced in the interlayer region formed between the inner cup and the outer cup, the distance between the steam generation region and a food making region is shortened, and the efficiency of heat utilization is improved.

Owner:JOYOUNG CO LTD

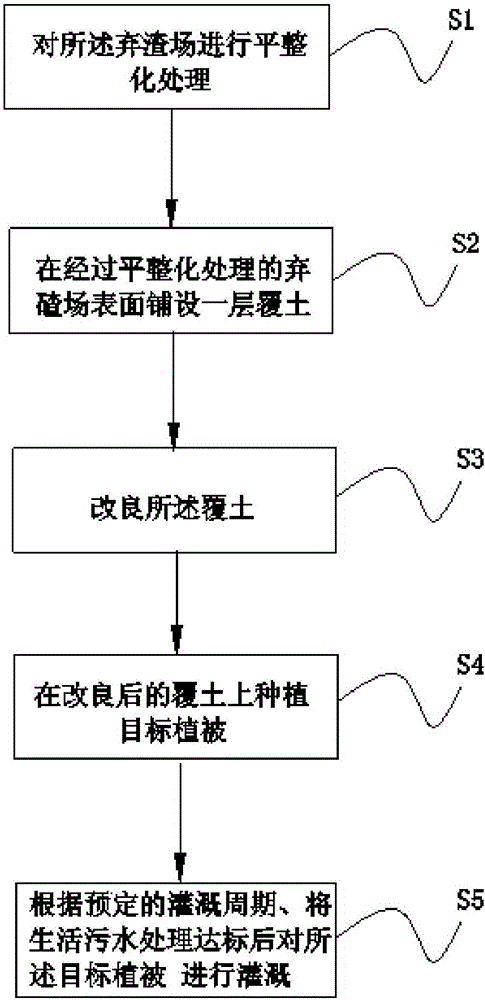

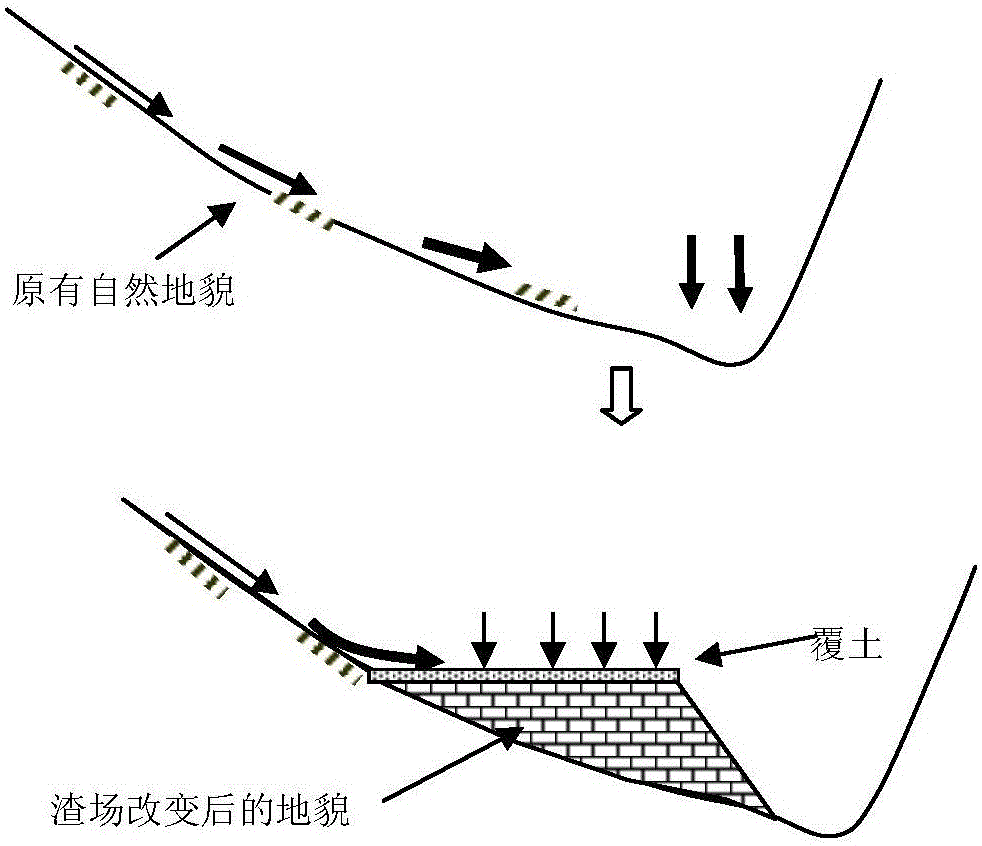

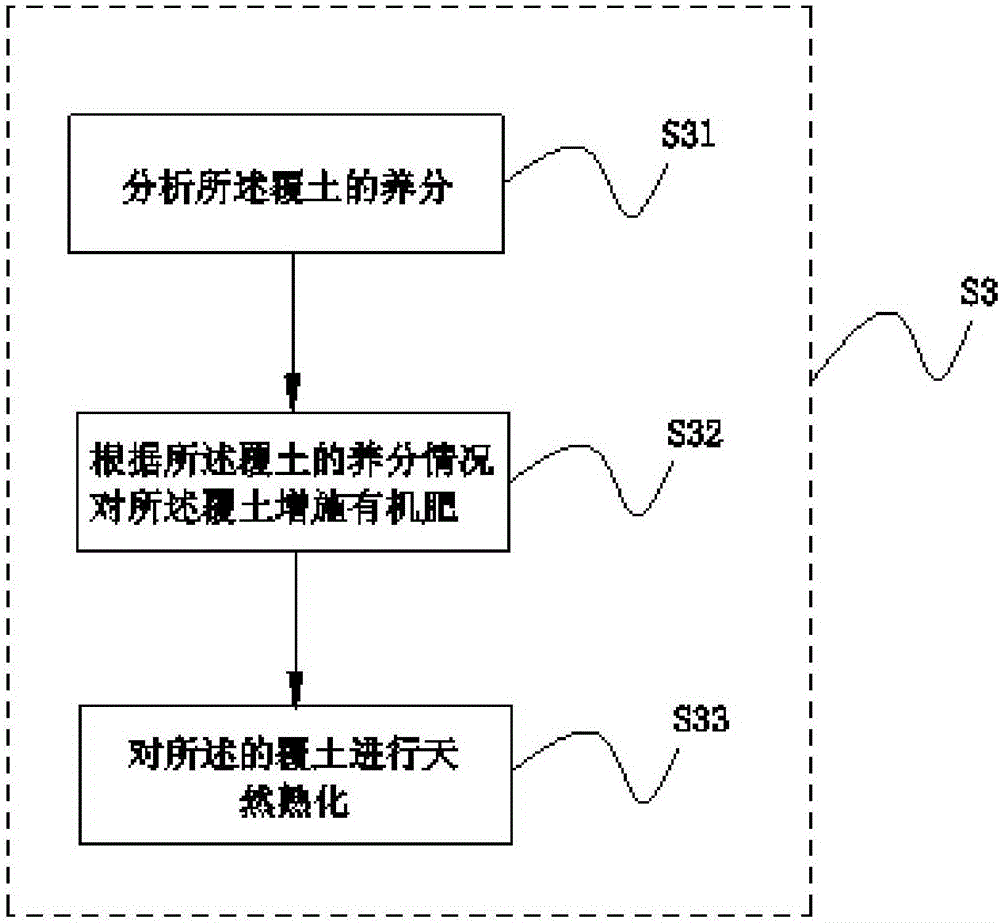

Vegetation ecological restoration method for spoil area

InactiveCN105766124AAccelerate the ripening speedEasy to reinforceWatering devicesCultivating equipmentsGrowth plantVegetation

The invention provides a vegetation ecological restoration method for a spoil area. The method includes: leveling the spoil area and keeping a preset flatness; laying a layer of soil to the surface of the leveled spoil area; improving the soil to make the soil suitable for agriculture and forestry; planting target vegetations on the improved soil, and using qualified treated domestic wastewater for irrigating the target vegetations according to a preset irrigation period. By the vegetation ecological restoration method for the spoil area, the soil is modified according to nutrients of the soil, then parameter information of the target vegetations and the soil is analyzed to obtain water requirements of the target vegetations according to the parameter information, and finally the target vegetations are irrigated according to the obtained water requirements. The vegetation ecological restoration method has the advantages that soil mellowing is accelerated, soil improvement is promoted, quickness in plant growth is guaranteed, water resources are saved, and environment friendliness and cost saving are realized.

Owner:QINGHAI HUANGHE HYDROPOWER DEV

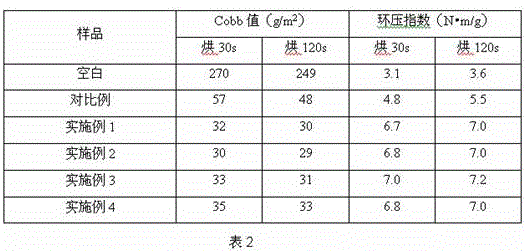

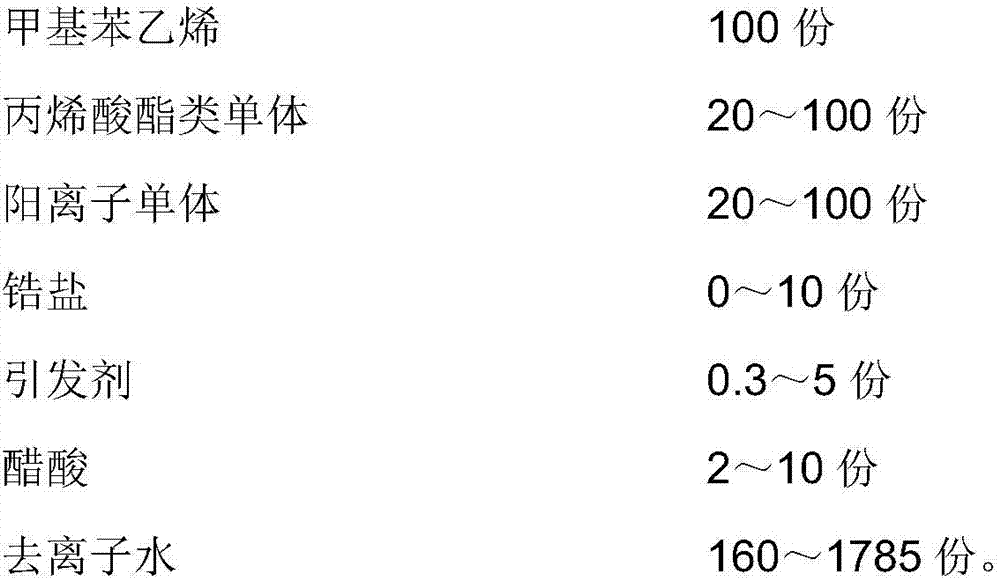

Novel surface sizing agent and preparation method thereof

ActiveCN106368062AIncreased ring compressive strengthReduce the Cobb valueWater-repelling agents additionPaper coatingAcetic acidGram

The invention discloses a novel surface sizing agent and a preparation method thereof. The preparation method comprises the following steps: 1, uniformly mixing methyl styrene, an acrylate monomer, a cationic monomer and an initiator to form a mixed monomer; 2, adding 10-20% of the mixed monomer obtained in the step 1 into a four-necked flask, heating to the temperature of 80-140 DEG C, reacting for 5-20 minutes, and dripping the residual mixed monomer; 3, adding acetic acid, and reacting at the temperature of 80-140 DEG C for 20-60 minutes; 4, adding preheated deionized water at the temperature of 80-140 DEG C, continuously reacting for 0.5-2 hours, adding siloxane for reacting 0.5-3 hours, cooling, and filtering, thereby obtaining the novel surface sizing agent. The novel surface sizing agent disclosed by the invention is capable of greatly reducing a Cobb value, promoting rapid curing, and greatly improving the ring crush compression resistance of corrugated paper and reducing gram weight of paper on the premise of maintaining invariable sizing agent amount.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

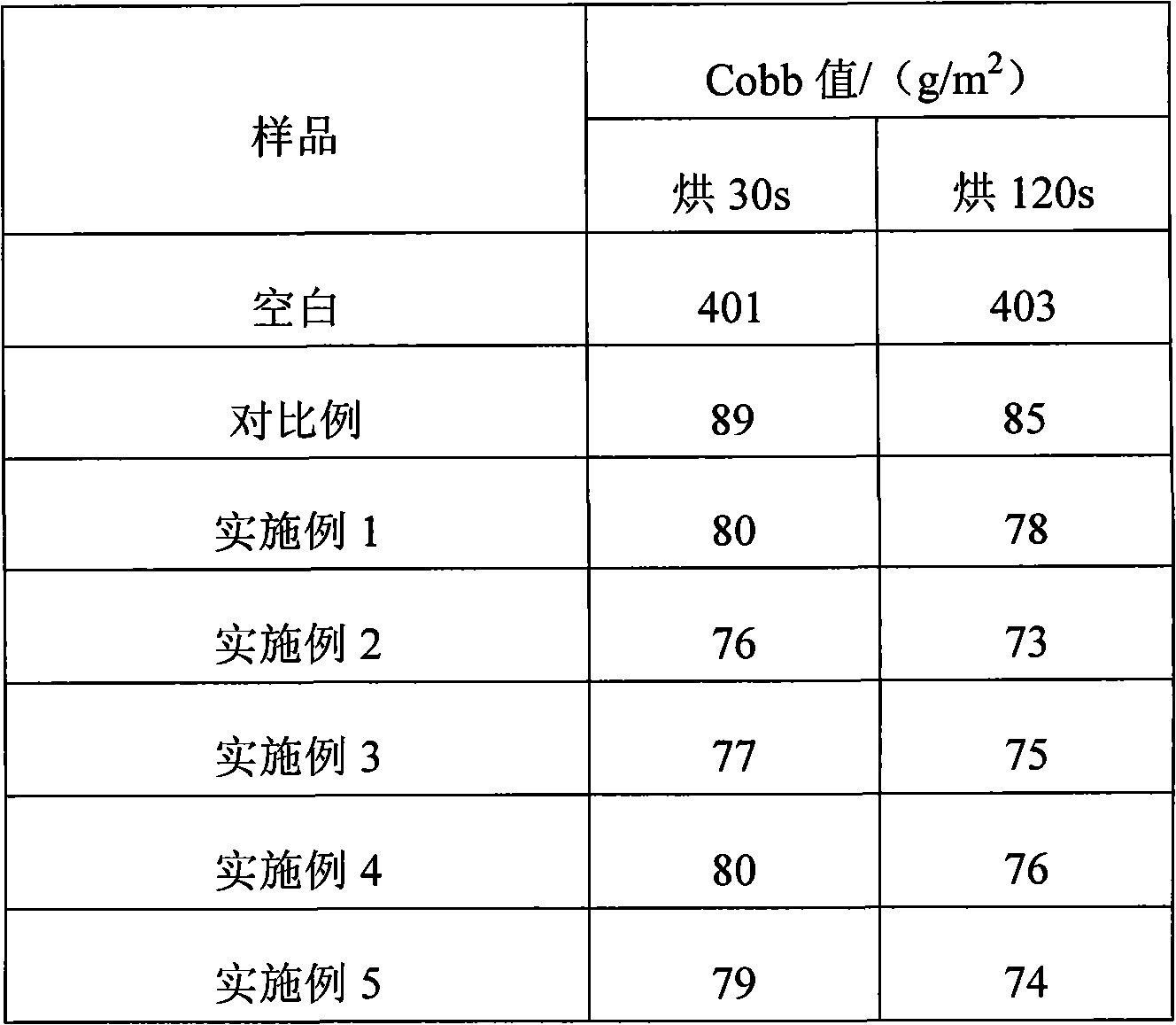

Water-resistant and moisture-proof method for corrugated base paper

ActiveCN111560790AImprove water resistanceImprove moisture resistanceWater-repelling agents additionPaper recyclingAmylaseAluminum sulphate

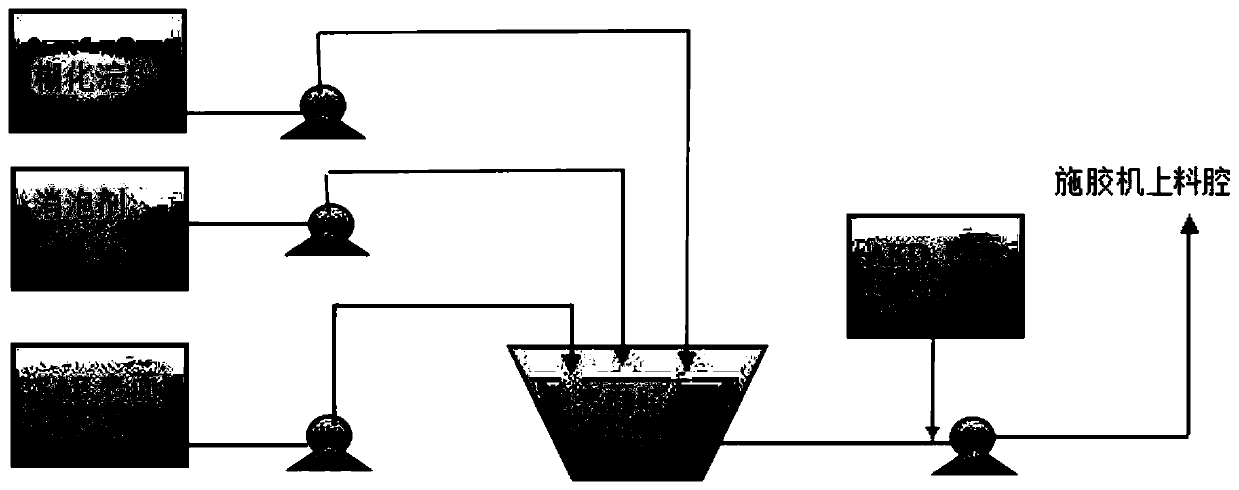

The invention provides a water-resistant and moisture-proof method for corrugated base paper. The method comprises the following steps: 100% local waste serves as a raw material and is used to preparepaper pulp, the uniformity of the paper pulp is improved in the dehydration stage and the forming stage of a net part, and corrugated base paper subjected to uniformity treatment is obtained; starchis gelatinized by using biological amylase to obtain gelatinized starch, the gelatinized starch, aluminum sulfate and a defoaming agent are pumped into a surface sizing working tank and are mixed, anSAE surface sizing agent is pumped into the surface sizing working tank and is mixed to obtain a mixture, and the mixture and an AKD surface sizing agent are conveyed into a sizing machine through a conveying pump to obtain a sizing material for surface sizing; and surface sizing treatment is carried out on corrugated base paper at a certain temperature by using the sizing material on a sizing machine to obtain the finished product. The retention rate of the sizing agent can be increased, the loss of the sizing agent is greatly reduced, the cost is reduced, and the water resistance and moisture resistance of the corrugated base paper can be improved.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Novel foaming forming die

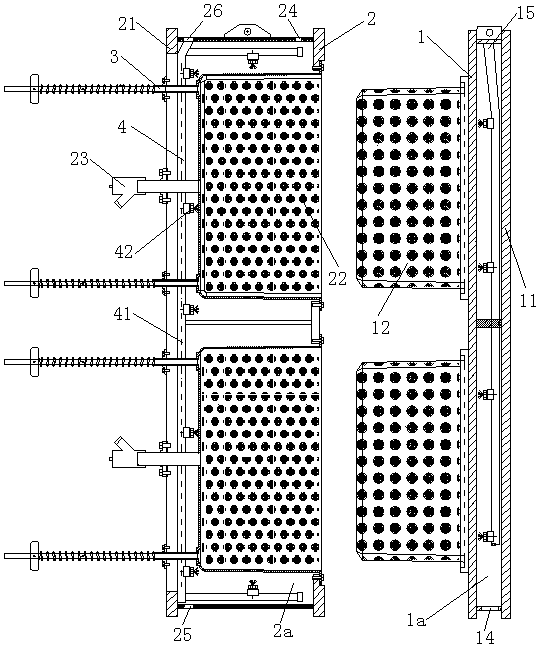

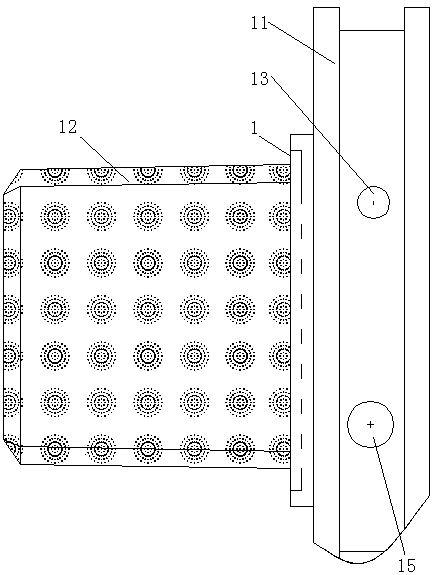

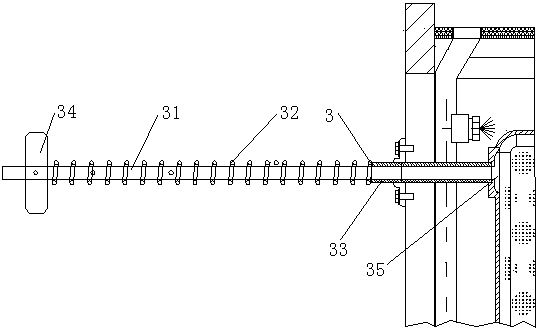

The invention relates to a novel foaming forming die which is composed of a convex die, a concave die, a demoulding mechanism and cooling devices, wherein each of a convex die core and a concave die core is formed through bending and welding a 2mm-6mm stainless steel plate; a circular air penetrating hole with the diameter being 0.3-1.2 mm is perpendicularly formed in each of the convex die core and the concave die core; as the convex die core and the concave die core are provided with the circular circular air penetrating holes, the strength is greatly improved compared with the stainless steel die core provided with an air penetrating groove and with the same thickness, and the situation that the air penetrating groove at the original bending part is likely to deform is avoided; as the air penetrating holes are formed, the phenomenon that scuffing is likely to take place when product demoulding is carried out is avoided when the air penetrating groove structure is adopted, the product surface quality is improved, and the holes are unlikely to block after long-time application; as a first air chamber and a second air chamber are provided with the cooling devices, cooling to the die cores is accelerated; and the novel foaming forming die is reasonable in structure and convenient to use and has great practical and popularization value.

Owner:顾志元

Sizing agent for treating paper surface and its preparing method and use

InactiveCN100500995CIncreased ring compressive strengthImprove Cobb valueWater-repelling agents additionEmulsion polymerizationStyrene Monomer

The present invention discloses one kind of paper surface sizing agent and its preparation process and application. The preparation process includes the free radical emulsion polymerization of dispersant, emulsifier, initiator, cationic monomer, (methyl) acrylate monomer and (methyl) styrene monomer at 30-95 deg.c for 2-6 hr. The dispersant is gelatin, and the initiator is persulfate. The paper surface sizing agent has high performance and environment friendship, and when it is used together with starch in sizing paper surface, it can raise the ring pressure strength greatly, improve Cobb value obviously and speed the curing obviously.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

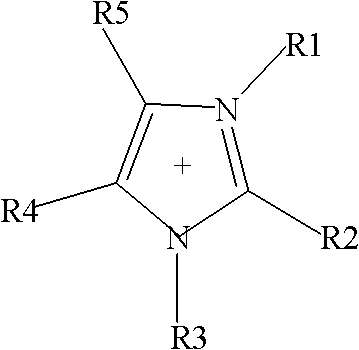

Method for preparing PIR (polyisocyanurate) material with ionic liquid catalyst

The invention discloses a method for preparing a PIR (polyisocyanurate) material with an ionic liquid catalyst. By utilizing the catalytic activity and other performances of an ionic liquid to prepare a PIR material, the method comprises: first mixing an ionic liquid with a combined polyether, then injecting the mixture and isocyanates into a mould for reaction by a high-pressure foaming machine, or directly injecting the ionic liquid, the combined polyether and isocyanates into a mould for reaction by a high-pressure foaming machine, conducting demoulding after reaction, thus obtaining a PIR material. The method of the invention accelerates the curing speed of PIR, avoids using a volatile catalyst, and also optimizes performances of the PIR material.

Owner:JIANGSU KETAI NEW HEAT INSULATION MATERIAL

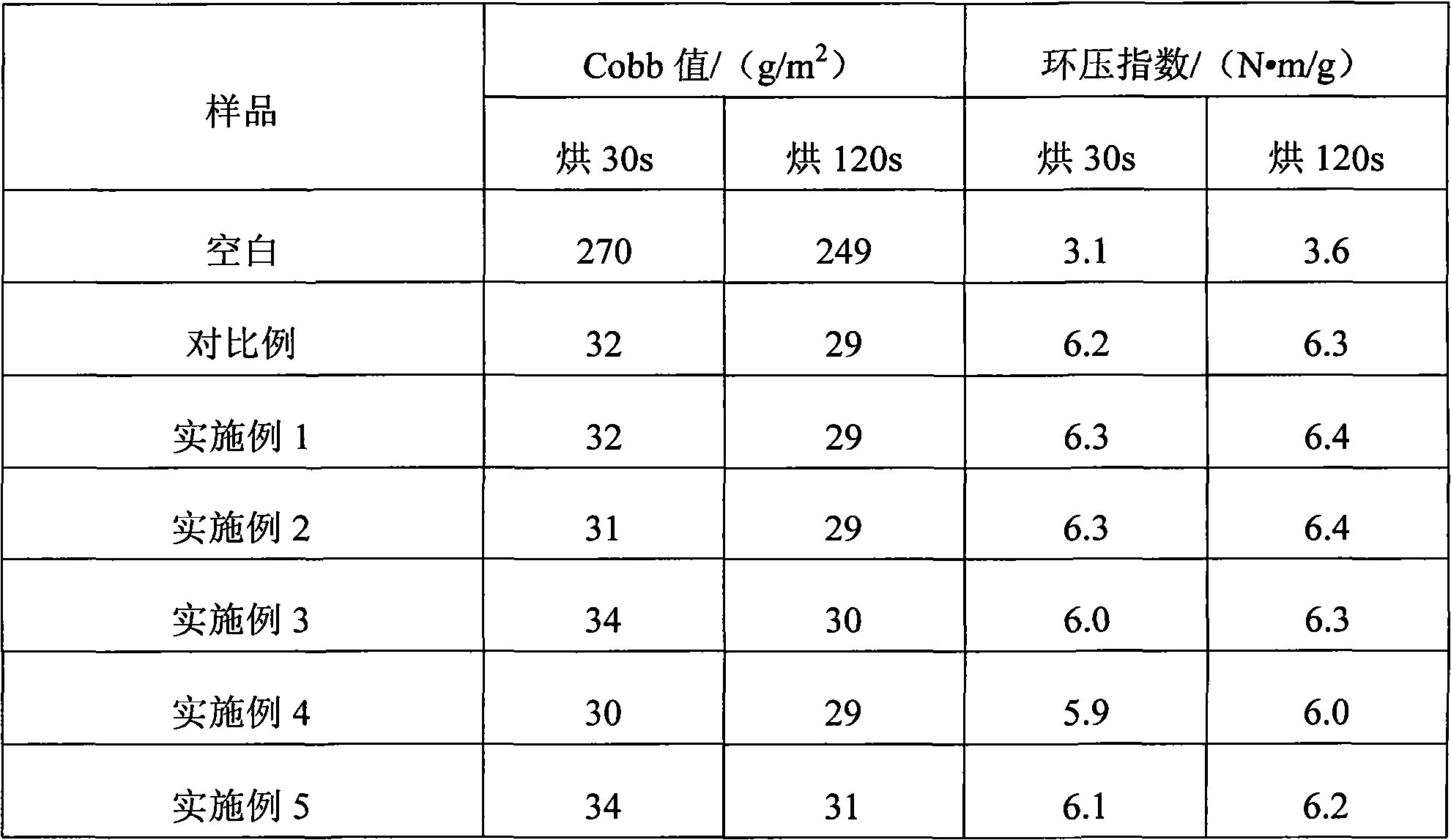

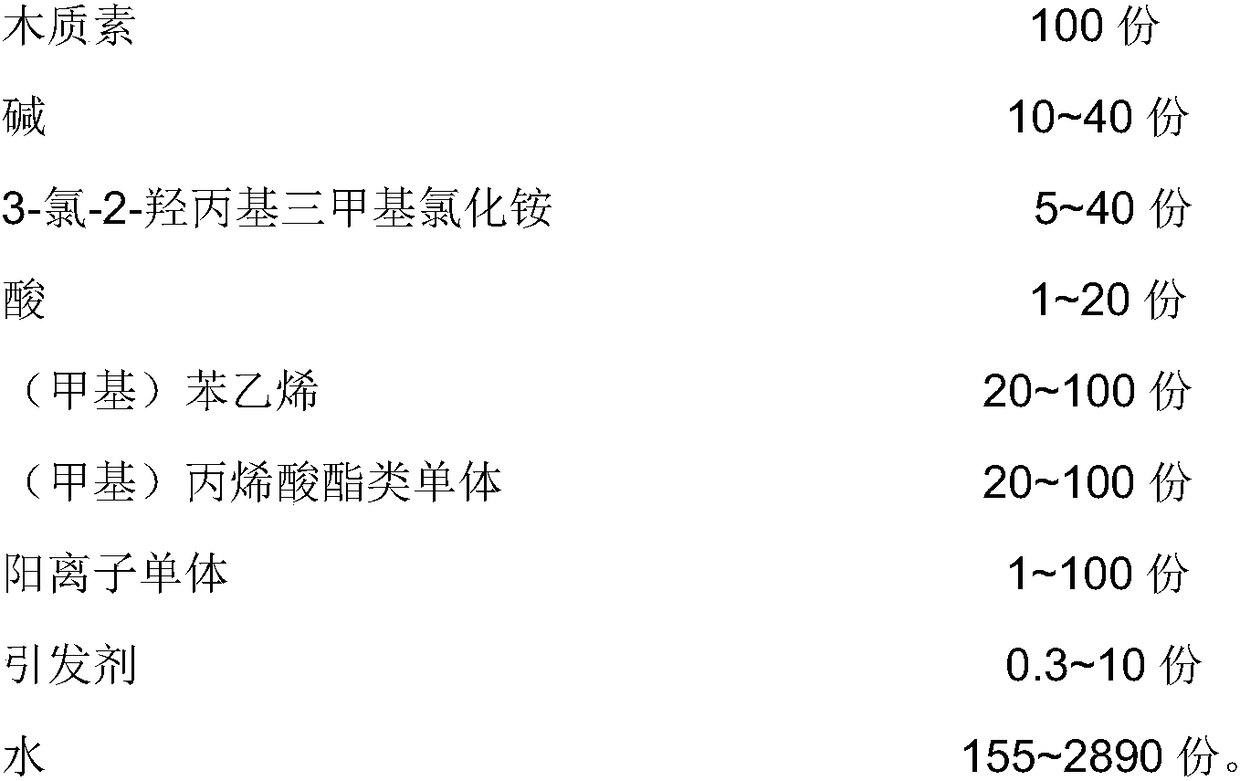

Lignin sizing agent and method for preparing same

InactiveCN108532362AImprove Cobb valueAccelerate the ripening speedWater-repelling agents additionChemistrySizing

The invention provides a lignin sizing agent and a method for preparing the same. The lignin sizing agent is an aqueous dispersion. Lignin, alkali, 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride, acid, cationic monomers, (methyl) acrylate monomers, (methyl) styrene and initiators are copolymerized to obtain the aqueous dispersion. The lignin sizing agent and the method have the advantagesthat the lignin sizing agent is a paper surface sizing high-performance environment-friendly product; surface sizing can be carried out on corrugated body paper by the aid of the product and starch, accordingly, Cobb values of corrugated paper can be improved, the aging speeds can be increased, the surface ring crush compression resistance of the corrugated paper can be greatly improved, and the lignin sizing agent and the method can adapt to high-strength corrugated paper development requirements; the lignin generated in papermaking procedures is used as a starting material, and accordingly the method for preparing the lignin sizing agent is low in cost and suitable for large-scale industrial production and includes simple operation steps.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

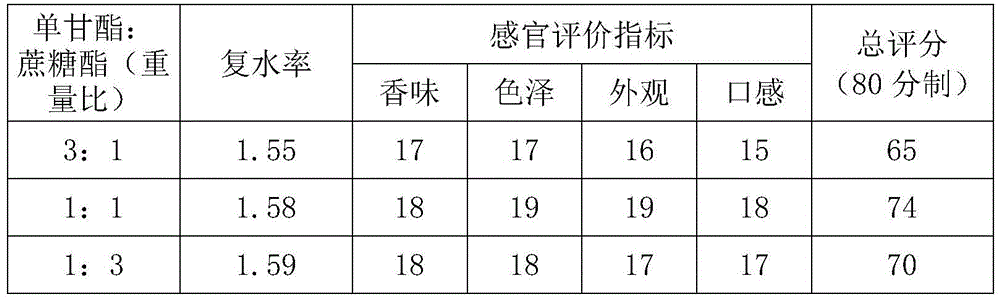

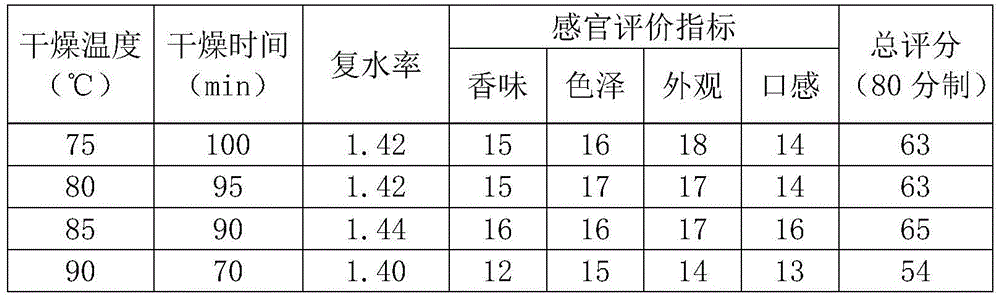

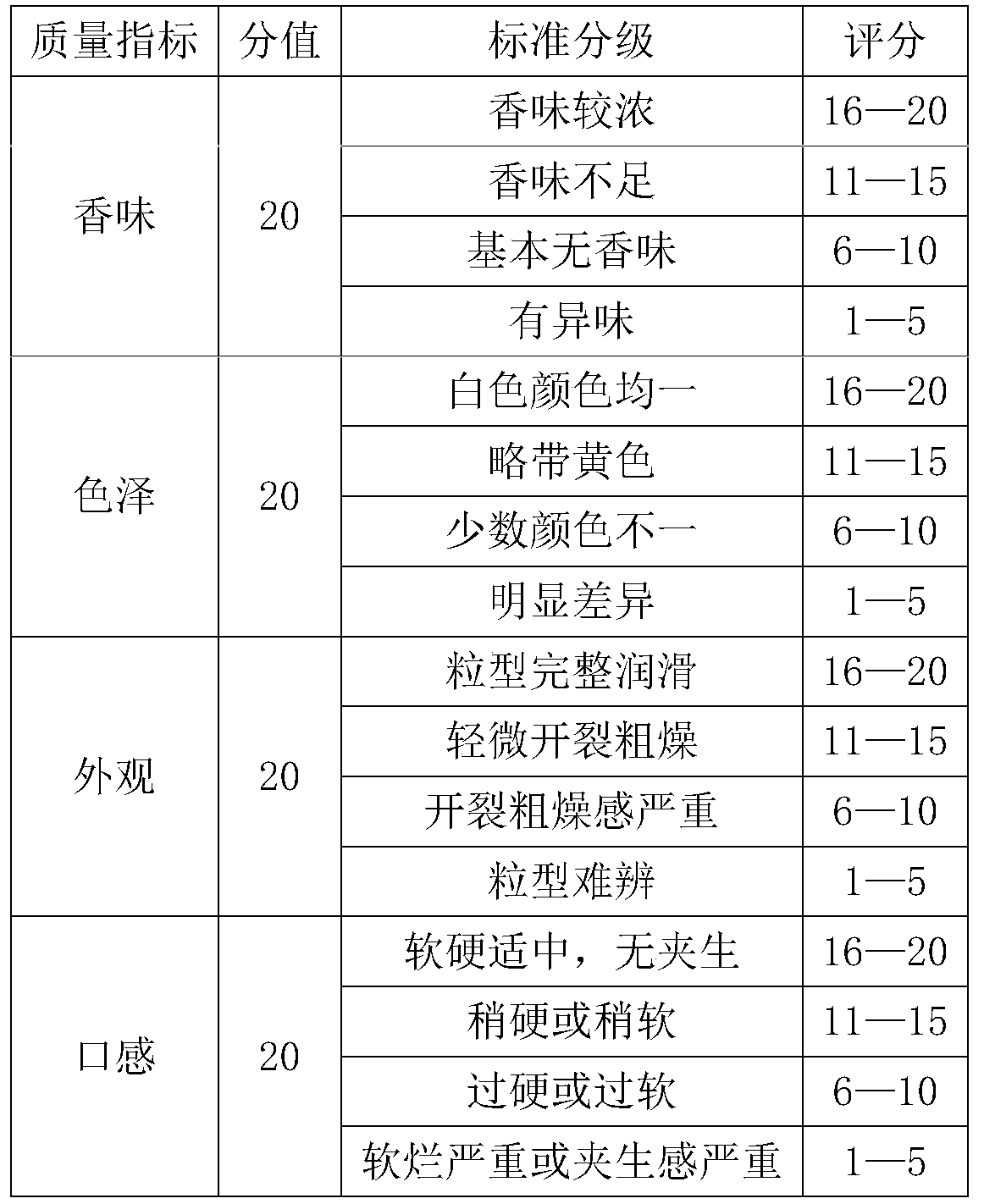

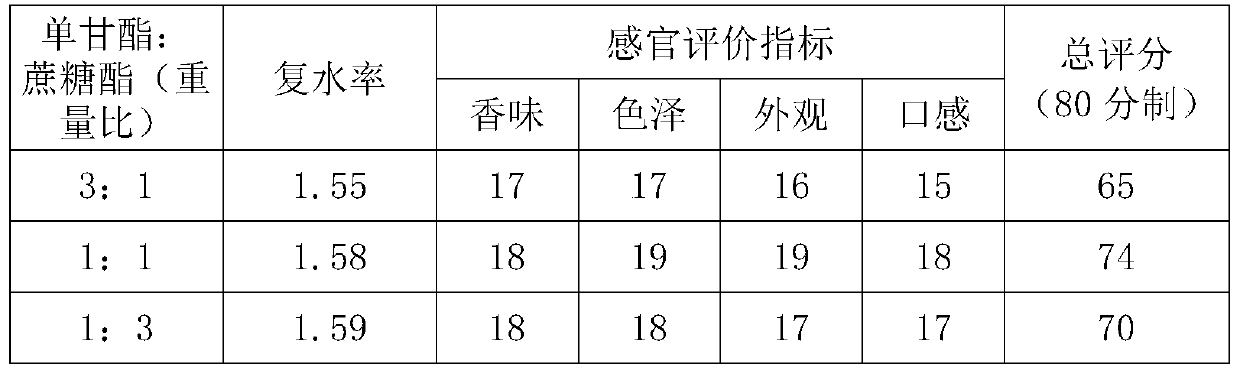

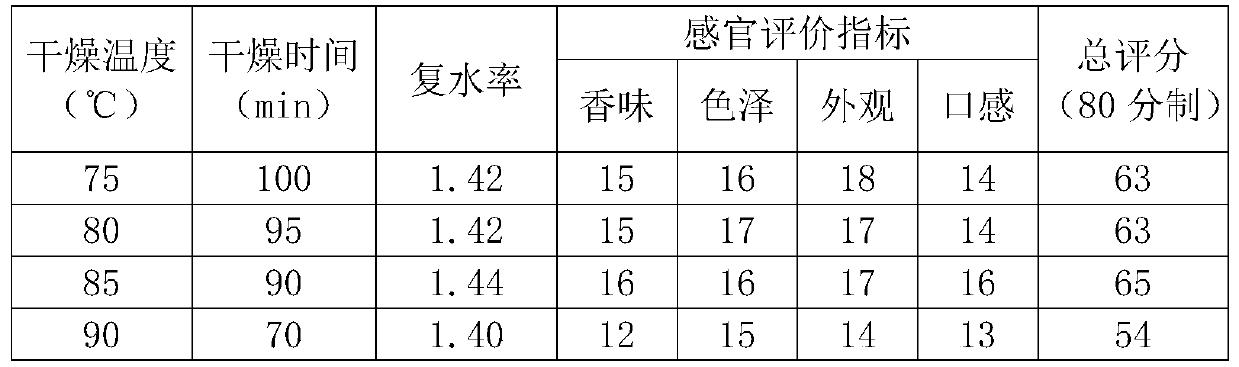

Coix seed instant slices and processing method thereof

The invention provides coix seed instant slices and a processing method thereof. Coix seeds are used as raw materials, and the coix seed instant slices which are convenient to eat are prepared through the following steps of performing soaking in alkali liquor, performing extrusion and crushing, performing steam cooking, performing cooling and airing, performing pressing so as to obtain slices, and performing vacuum microwave drying. The coix seed instant slices disclosed by the invention are short in drying time, high in production efficiency, good in rehydration, high in sensory evaluation value and nourishing in mouth feel. According to the coix seed instant slices and the processing method thereof disclosed by the invention, the step of soaking in the alkali liquor and the step of performing treatment with a composite emulsifying agent are adopted, so that the ageing speed of products is increased, and the ageing of the products in the drying process is reduced. The vacuum microwave drying is adopted, so that the drying speed of the coix seed slices is increased, the ageing and film formation phenomena of the surfaces of the coix seed slices are weakened, the products prepared through drying present a loose porous structure, the rehydration speed and the rehydration uniformity of the products are obviously improved, and the brewing convenience of the coix seed instant slices is improved.

Owner:SOUTHWEST UNIVERSITY

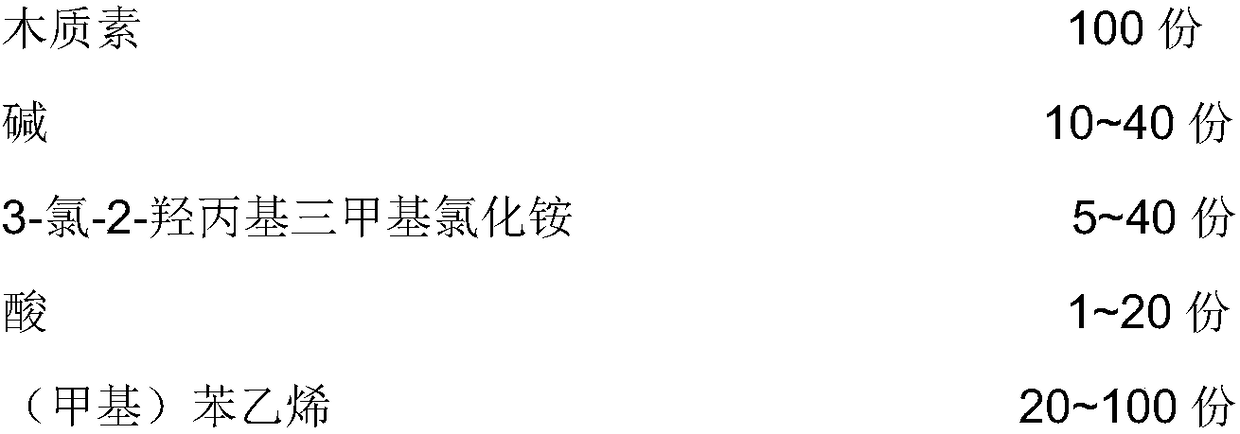

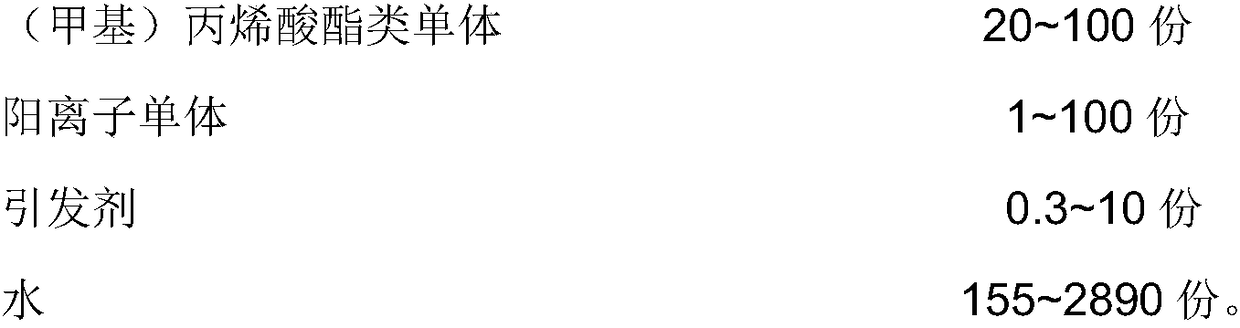

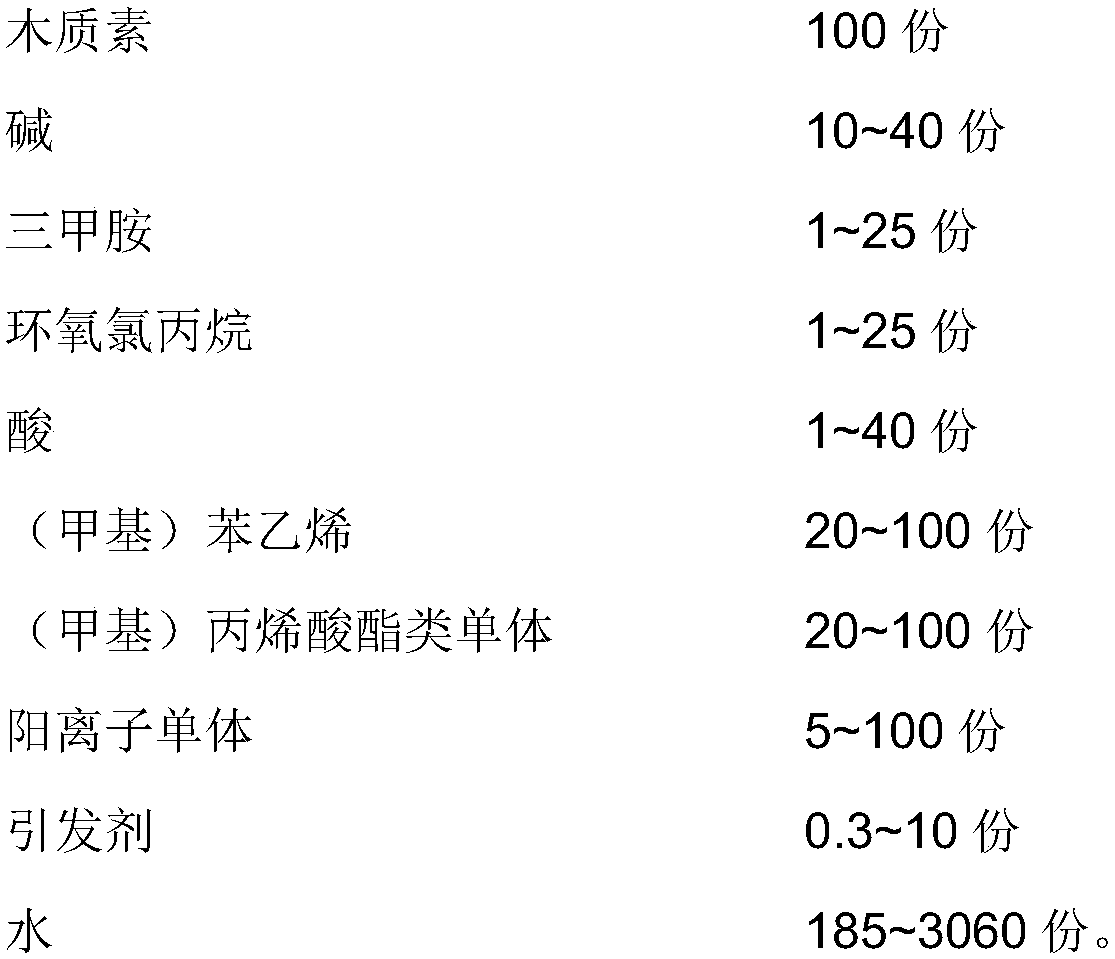

Lignin surface sizing agent and preparation method thereof

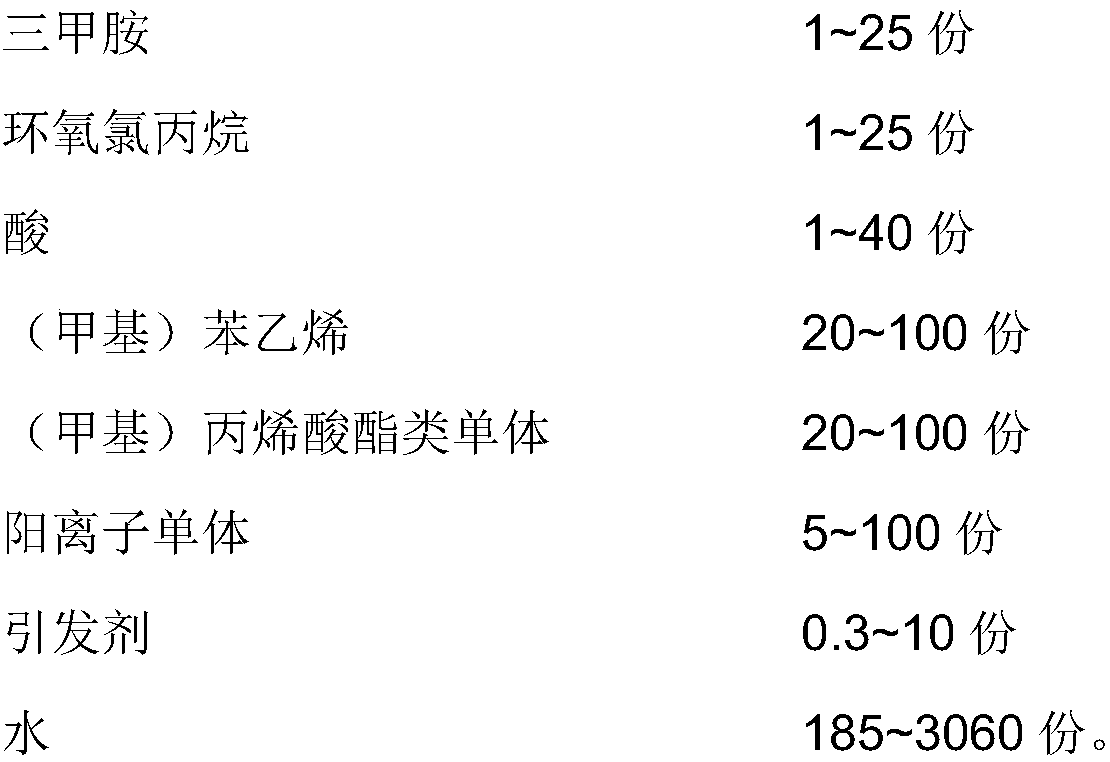

InactiveCN108642959AImprove Cobb valueImprove surface ring compressive strengthWater-repelling agents additionPaper coatingPapermakingUltimate tensile strength

The invention provides a lignin surface sizing agent, and a preparation method of the lignin surface sizing agent. The lignin surface sizing agent is a water dispersion by copolymerizing lignin, alkali, trimethylamine, chloropropylene oxide, acid, a cation monomer, a (methyl)acrylic ester monomer, (methyl)styrene, and an initiator. The lignin surface sizing agent is suitable for surface treatmentof corrugated medium. The product and starch realize surface sizing on the corrugated medium, a Cobb value of the corrugated paper can be improved, the slaking speed is accelerated, the surface ring crush strength of the corrugated paper is greatly increased, the development requirement of the high strength corrugated paper can be adapted, in addition, during the preparation method of the lignin surface sizing agent, the lignin generated during a papermaking process is used as an initial raw material, the cost is low, the operation step is simple, and the preparation method of the lignin surface sizing agent is suitable for large-scale industrial production.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

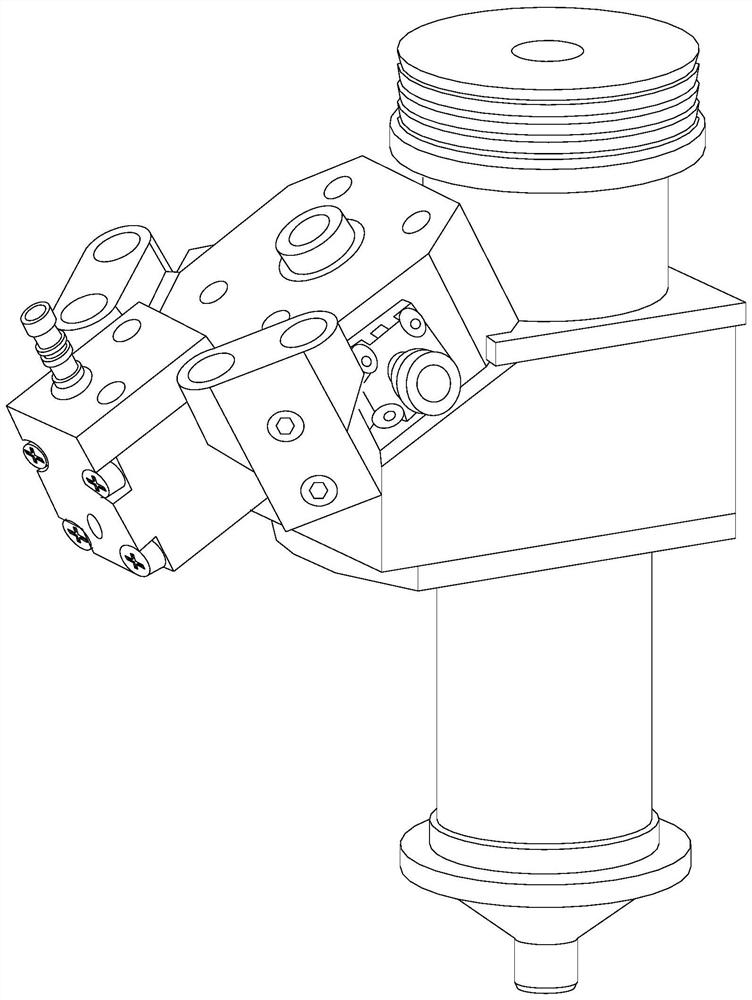

Noodle processing, stirring, and cooking device

InactiveCN109527019AAccelerate the ripening speedImprove thermal conductivityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsBiochemical engineeringSupport plane

The invention discloses a noodle processing, stirring, and cooking device, which comprises a motor, a stirring barrel, a stirring shaft, and a supporting frame. A decelerator is arranged under the motor. A frame is arranged under the decelerator. The stirring shaft is arranged under the frame. The stirring shaft is arranged in the stirring barrel. A steam outlet is arranged in the upper part of one side of the stirring barrel. A steam inlet port is arranged in the lower part of one side of the stirring barrel. Support racks are uniformly arranged on the periphery of the lower part of the stirring barrel. A sealing cover is arranged on the stirring barrel and is provided with a feed inlet. The lower part of the stirring barrel is provided with a material outlet. The design of the device isreasonable, the device is convenient to use, the noodle stirring and cooking efficiency in industrial production is effectively improved, and the labor is largely reduced.

Owner:湖北十星杂粮食品有限公司

A kind of surface sizing agent and preparation method thereof

ActiveCN106223116BImprove surface strengthIncrease forceWater-repelling agents additionInorganic compound additionAcetic acidZircon

The invention discloses a preparation method of a surface sizing agent. The preparation method comprises the following steps that firstly, methyl styrene, acrylic monomers, cationic monomers and an initiating agent are mixed to be uniform to form a mixed monomer; secondly, 10% of the mixed monomer obtained in the first step is added into a four-opening flask, the temperature is raised to 80-140 DEG C, residual mixed monomer is added dropwise after a reaction is carried out for 5-20 minutes, and then the temperature of 80-140 DEG C is kept for 0.5-1.5 hours; thirdly, acetic acid is added, and at the temperature of 80-140 DEG C, a reaction is carried out for 20-60 minutes; fourthly, preheated deionized water with the temperature being 80-100 DEG C is added, a reaction continues to be carried out for 0.5-2 hours, and the mixture is cooled to 25-35 DEG C, zircon salt is added, the mixture is stirred to be uniform, filtering is carried out, and the surface sizing agent is obtained. According to the surface sizing agent, the Cobb value can be greatly reduced, the surface sizing agent can be quickly cured and is basically cured as soon as the surface sizing agent is loaded to a machine, and the surface strength of body paper can be greatly improved under the situation that the dosage of the sizing agent is not changed.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Enriched superphosphate and preparation method for same

InactiveCN106699453AAccelerate the ripening speedSimple processFertilizer mixturesEconomic benefitsCarbonate apatite

The invention discloses enriched superphosphate, which is prepared from the following components in parts by weight: 20 to 40 parts of carbonate apatite, 5 to 15 parts of a sulfuric acid, 5 to 15 parts of a waste acid and 5 to 15 parts of an active porous agent. According to the enriched superphosphate, the adopted active porous agent has the effect of increasing the curing speed, so that the production time is greatly reduced; a process is simple and easy to implement; moreover, the raw materials are extensive, and the enriched superphosphate is low in cost and suitable for industrial production, and has broad market prospect and good social and economic benefits.

Owner:贵州越都化工有限公司

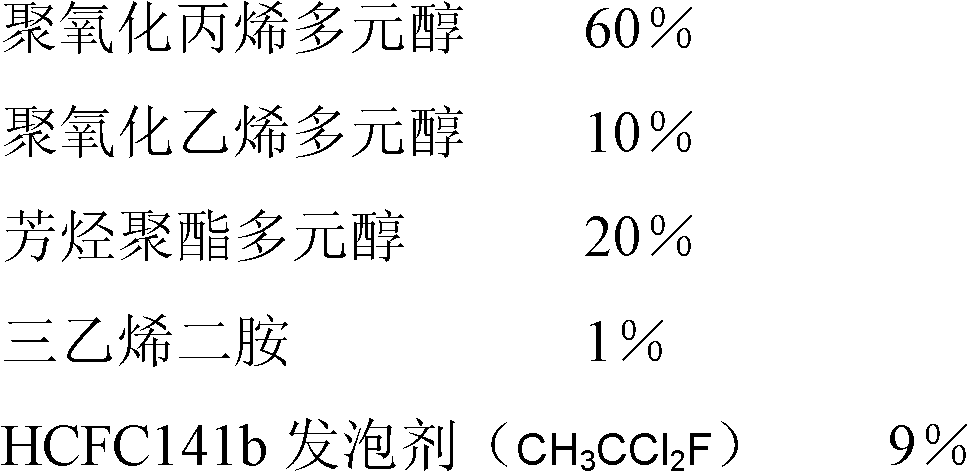

A process for adding expanded graphite to core raw materials on a color steel insulation board production line

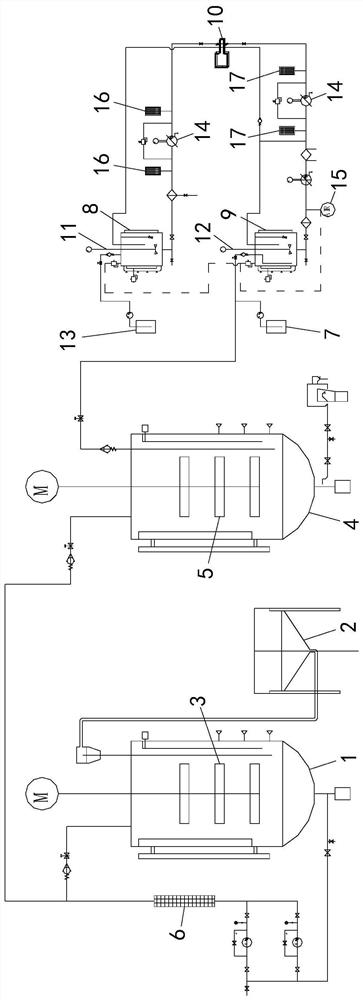

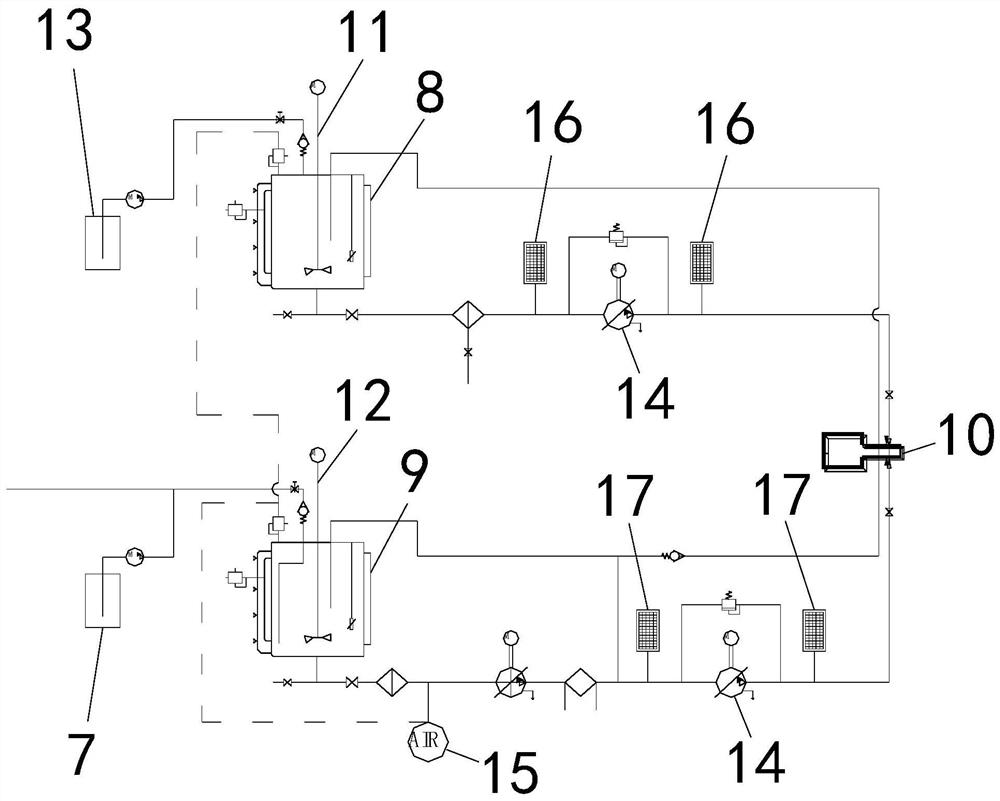

ActiveCN111729599BAccelerate the ripening speedFine foamTransportation and packagingMixing methodsProduction linePolyol

A process for adding expanded graphite to the core material raw material on the color steel insulation board production line, including using a batching tank for batching, stirring and transporting to the storage tank, and sending it to the POLY unit for storage after stirring; sending the isocyanate stored in the ISO unit into The first working tank, after the stirring is completed, it is sent into the distribution mixer through the metering pump; the polyol composition containing expanded graphite stored in the POLY unit is sent to the second working tank, and sent to the distribution mixer after stirring; mixed with expanded graphite The polyol composition and isocyanate are mixed by a cloth mixer and then foamed. The present invention establishes a production process suitable for adding expanded graphite to polyol raw materials on the production equipment of polyurethane double-sided color steel insulation board continuous line double crawler machine, including a device for adding expanded graphite, graphite is added to the raw material through a batching unit Neutralize and stir, and then through the stirring of the constant temperature unit and the mixing of the mixing unit, it ensures the uniform mixing of graphite in the raw materials and the quality of the product.

Owner:苏州德亨节能环保科技有限公司

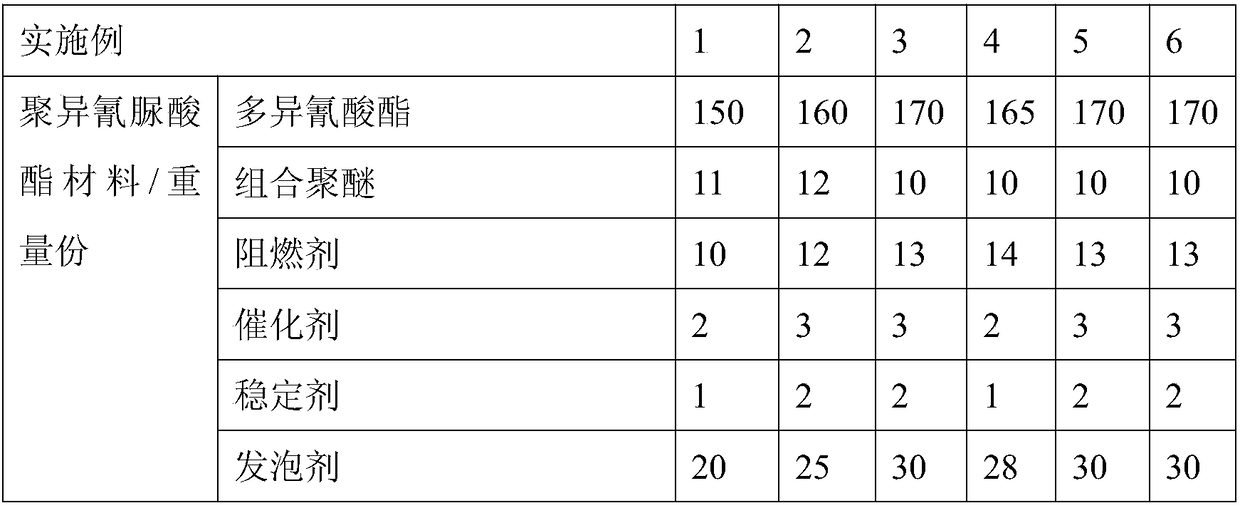

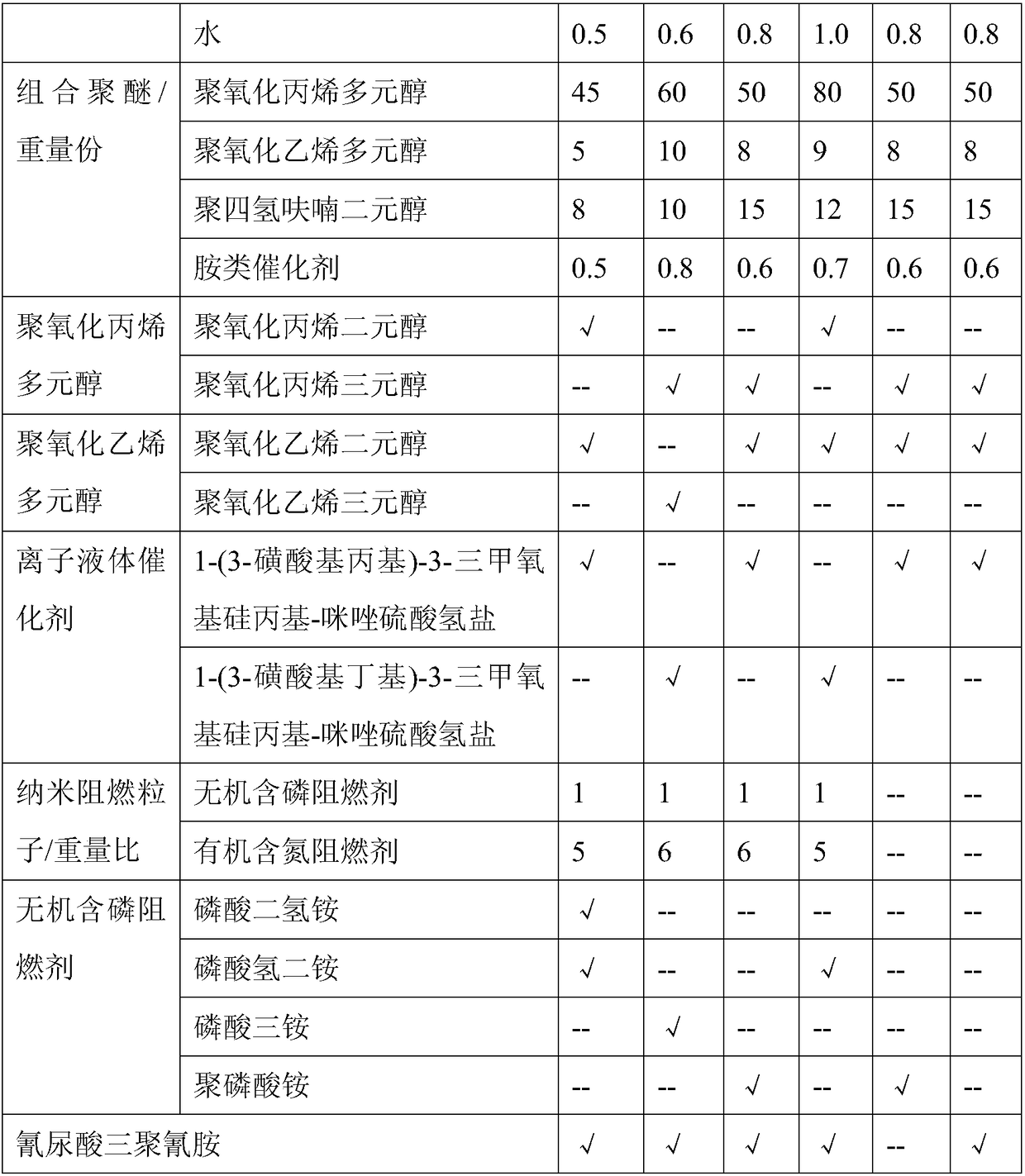

Polyisocyanurate material catalyzed by using ionic liquid and preparation method of polyisocyanurate material

The invention relates to a polyisocyanurate material catalyzed by using an ionic liquid and a preparation method of the polyisocyanurate material. The polyisocyanurate material is composed of the following raw materials in parts by weight: 150-170 parts of polyisocyanate, 10-12 parts of a combined polyether, 10-14 parts of a flame retardant, 2-3 parts of a catalyst, 1-2 parts of a stabilizer, 20-30 parts of a foaming agent, and 0.5-1.0 part of water, wherein the flame retardant is a nanoparticle flame retardant, and the catalyst is an ionic liquid catalyst. The preparation method comprises thefollowing steps: firstly mixing the ionic liquid and the combined polyether, then pouring the mixed material and the remaining raw materials into a mold through a high-pressure foaming machine, performing a reaction, and performing demolding to obtain the polyisocyanurate material. The polyisocyanurate material provided by the invention has the advantages that a product has good low-temperature dimensional stability, the flame retardant and the foaming agent do not contain halogen atoms, and the service life is long.

Owner:江苏中昌绝热技术工程有限公司

A kind of coicis instant food tablet and processing method thereof

Owner:SOUTHWEST UNIV

Calcium superphosphate

InactiveCN108218479AAccelerate the ripening speedShorten production timeSuperphosphatesApatiteEconomic benefits

The invention discloses calcium superphosphate which comprises the following components in parts by weight: 20-40 parts of apatite, 10-20 parts of sulfuric acid, 5-15 parts of potassium chloride, 5-15parts of ammonium chloride and 5-15 parts of an activating loosening agent. The activating loosening agent used in the calcium superphosphate has a function of accelerating the aging speed, the production time can be greatly shortened, and the calcium superphosphate is simple in process, easy to use, wide in raw material source, low in price, applicable to industrial large-scale production, widein market prospect and good in social and economic benefit.

Owner:贵州越都化工有限公司

Method for manufacturing organic fertilizer by utilizing pig manure

InactiveCN109422589AAccelerate the ripening speedReduce breedingBio-organic fraction processingExcrement fertilisersPig farmsFood chain

The invention discloses a method for manufacturing an organic fertilizer by utilizing pig manure. The method comprises the following steps: (1) culturing breeding flies; (2) inoculating fly eggs; (3)culturing fly maggots; (4) screening out the fly maggots; and (5) preparing a finished product. According to the method disclosed by the invention, the curing speed of the pig manure is accelerated byutilizing activity of the housefly larvae, and nutrients in the pig manure is recycled in a form of fly maggot protein, so that loss of the nutrients is prevented, and caused harm of environment pollution and mosquito and fly breeding are effectively prevented. Biopotency of a food chain is improved, a pollution-free biological fertilizer and fly maggot protein feed are provided for agriculture development by comprehensively utilizing biological resources, and the method has good social benefits, economic benefits and environmental benefits, is suitable for intensive pig farms and is also suitable for small-sized raising farmers.

Owner:临湘市欣牧养猪专业合作社

Paper surface sizing agent and preparation method thereof

ActiveCN101148842BIncreased ring compressive strengthLose weightWater-repelling agents additionPaper/cardboardCross-linkEmulsion

The present invention relates to paper surface treating agent, and is especially one kind of paper surface sizing agent and its preparation process. The paper surface sizing agent is prepared with cationic monomer, cross-linking monomer, (methyl) acrylate monomer and (methyl) styrene, and through free radical emulsion polymerization in mixture emulsion comprising dispersant, emulsifier and initiator. It has high performance and environment friendship. It is applied in sizing paper surface together with starch to raise the compression strength of paper, raise Cobb value and improve other performance of paper.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

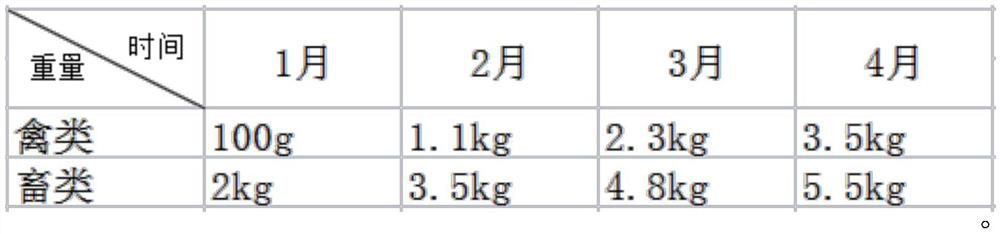

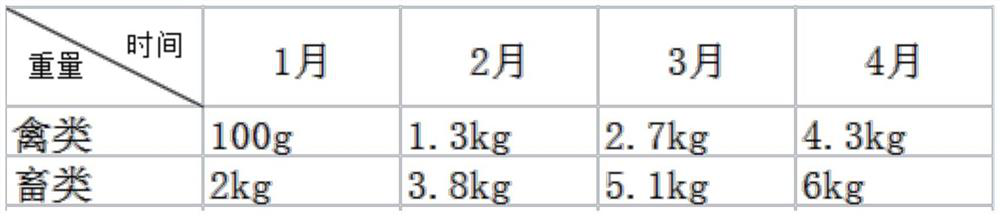

Preparation method of livestock and poultry feed prepared from reed edible mushroom waste mushroom sticks

InactiveCN113100338AShorten the production cycleImprove the immunityFood processingAnimal feeding stuffBiotechnologyAgricultural science

The invention discloses a preparation method of a livestock and poultry feed prepared from reed edible mushroom waste mushroom sticks, and particularly relates to the field of feeds. The preparation method specifically comprises the following steps: q1, recycling waste; 2, performing drying and dehydrating; 3, crushing waste materials; 4, selecting and preparing feed raw materials; 5, pretreating the raw materials; 6, making preparation in groups; 7, performing curing and fermenting; 8, performing experimental feeding; 9, performing data analysis. According to the method disclosed by the invention, the production cycle of the feed is shortened, the resistance of the livestock is increased, the variety of nutrients absorbed by the livestock is increased, and the meat quality of the livestock is effectively improved.

Owner:河北雄安立本农业生态科技有限公司

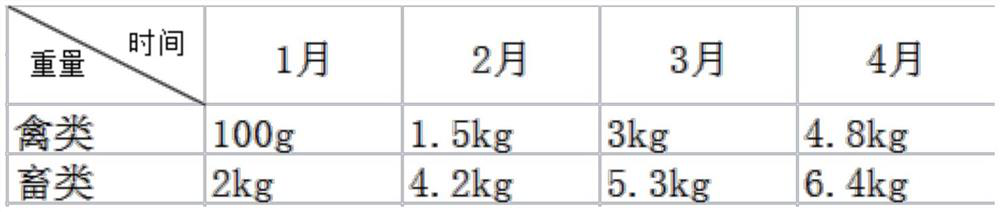

High-performance polyurethane cold storage heat insulation board and preparation method thereof

The invention discloses a high-performance polyurethane cold storage heat insulation board and a preparation method thereof, and belongs to the field of polyurethane boards. The heat insulation boardis prepared through the process steps of curing and mixing, foaming, curing, trimming and the like. Processes such as pressurization curing, preheating stirring, autoclaved curing and the like are used, and optimal process parameters are combined, so that the performances of the prepared polyurethane cold storage heat insulation board are effectively improved. Foaming is sufficient and uniform, sothe obtained board is fine in foam holes and high in closed-cell rate, the comprehensive performances of the obtained plate are good, and the polyurethane board is suitable for large-scale production.

Owner:广西鸿匠保温材料有限公司

A steam food processor

ActiveCN105411373BReduce consumptionReduce distanceSteam cooking vesselsCooking insertsEngineeringSteam generation

The invention discloses a steam food processor which comprises a machine base, a motor, an output shaft, an outer cup, a smashing cutter and a steam generation device. The motor is arranged in the machine base and drives the output shaft to rotate, the outer cup further comprises an outer cup body and an upper cover, the outer cup body is closed by the upper cover, a steam discharging channel is formed in the outer cup, the outer cup is arranged on the machine base, an inner cup is arranged in the outer cup, the smashing cutter is arranged in the inner cup, and the output shaft and the smashing cutter are separately connected. A partition part is arranged between the outer cup and the inner cup so as to form an interlayer region for containing water, the volume ratio of the interlayer region to the outer cup is 1:16 to 1:2, steam is produced in the interlayer region, the inner cup is provided with a steam through hole, and the steam flows into the inner cup through the steam through hole. The steam food processor adopts the inner cup and the outer cup to replace an independent steam generator, steam is produced in the interlayer region formed between the inner cup and the outer cup, the distance between the steam generation region and a food making region is shortened, and the efficiency of heat utilization is improved.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com