Polyisocyanurate material catalyzed by using ionic liquid and preparation method of polyisocyanurate material

A polyisocyanurate, ionic liquid technology, applied in the field of polymer materials, can solve the problems of flame retardants containing halogen atoms, poor dimensional stability at low temperature, short service life, etc., achieving simple preparation process, ensuring thermal insulation performance, The effect of fast reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

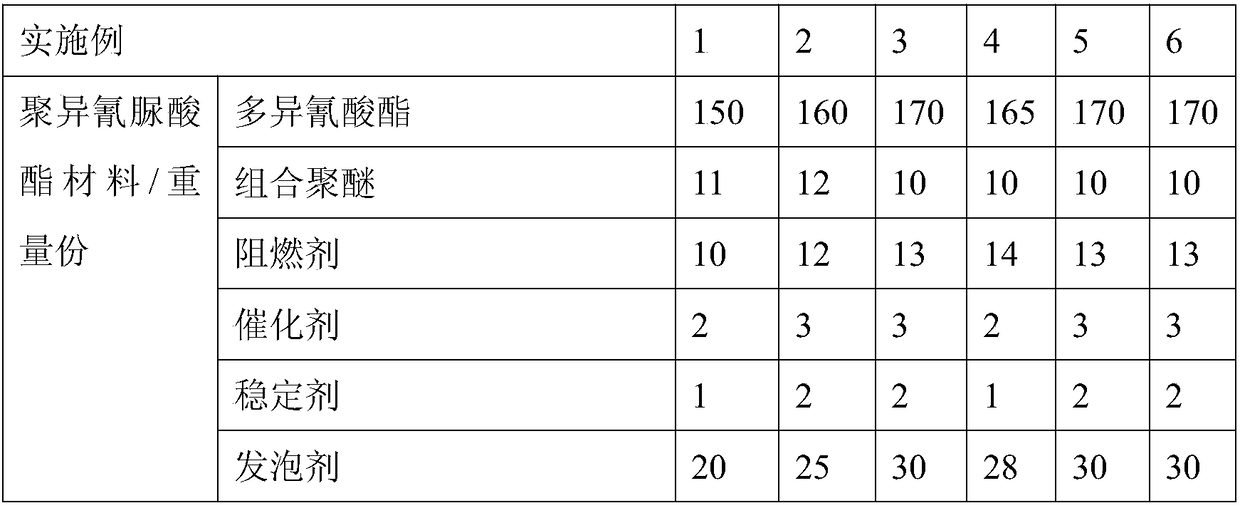

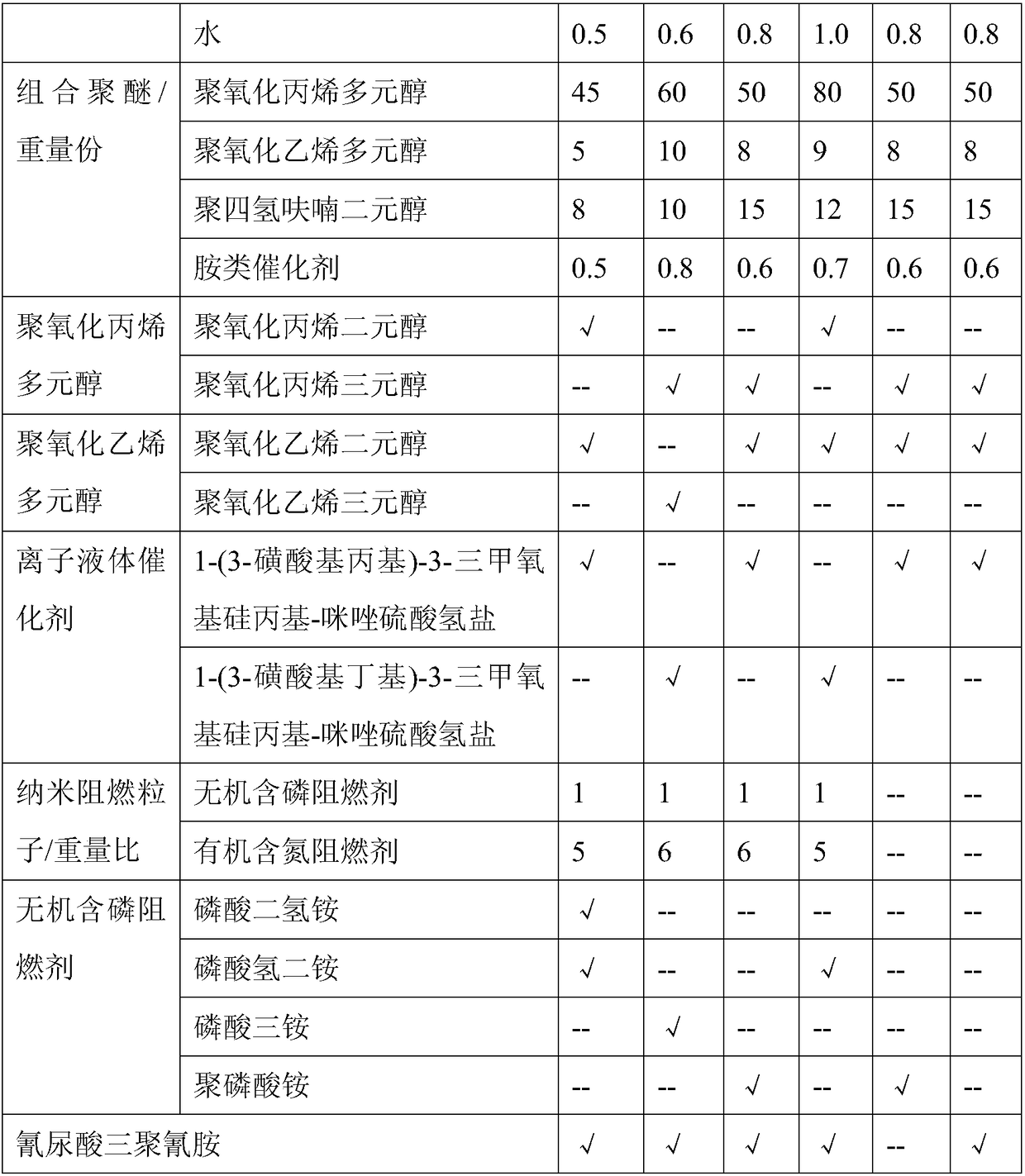

[0032] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0033] A polyisocyanurate material catalyzed by an ionic liquid is composed of the following parts by weight: 150-170 parts of polyisocyanate, 10-12 parts of combined polyether, 10-14 parts of flame retardant, 2-3 parts of catalyst, 1-2 parts of stabilizer, 20-30 parts of foaming agent, 0.5-1.0 parts of water;

[0034] The flame retardant is a nano particle flame retardant;

[0035] The catalyst is an ionic liquid catalyst.

[0036] Specifically, the polyisocyanurate material is composed of the following parts by weight: 170 parts of polyisocyanate, 10 parts of combined polyether, 13 parts of flame retardant, 3 parts of catalyst, 2 parts of stabilizer, 30 parts of foaming agent, 0.8 parts of water;

[0037] The flame retardant is a nano particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com