High-performance polyurethane cold storage heat insulation board and preparation method thereof

A polyurethane, high-performance technology, applied in the field of polyurethane boards, can solve the problems of insufficient strength, low closed cell rate, and finer cells, and achieve the effect of high closed cell rate, sufficient foaming, and fine cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

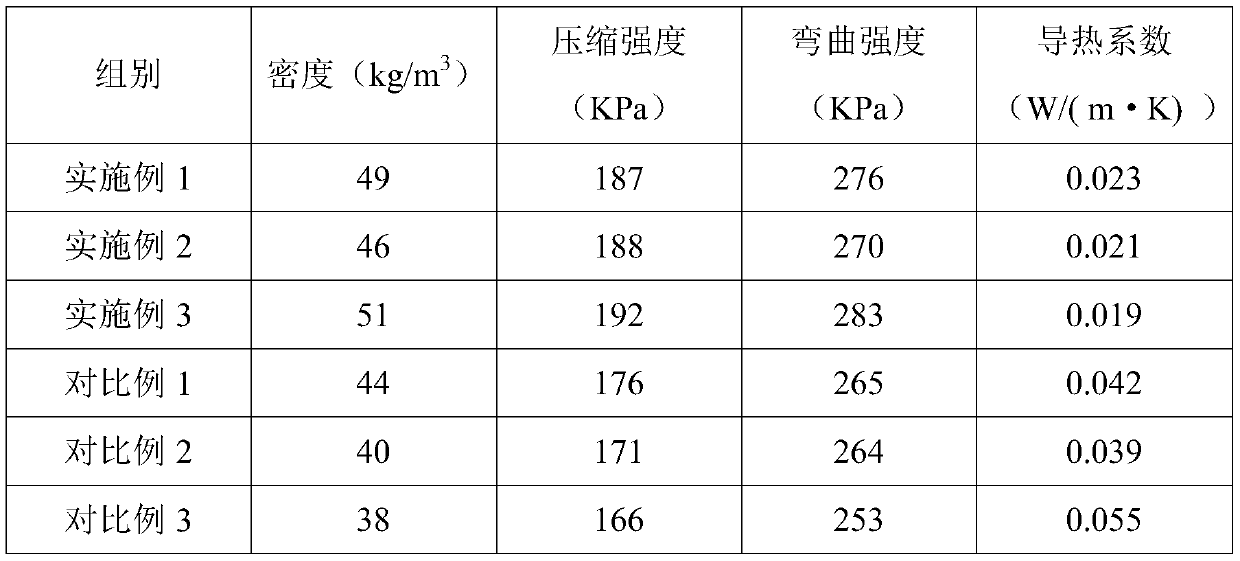

Examples

Embodiment 1

[0027] A preparation method of a high-performance polyurethane cold storage insulation board, comprising the following steps:

[0028] S1: Mix the polyurethane, catalyst, and blowing agent evenly and add to the autoclaved pre-expander, after the autoclaved pre-expander is preheated to 100°C, under the steam pressure of 0.2MPa in the autoclaved pre-expansion machine, perform aging for 1h;

[0029] S2: After mixing trientine, foam stabilizer, and nano-silica, preheat at 30°C for 45 minutes, cool to 20°C, mix with mixture A, add to the mixer and stir at 150rpm to obtain mixture B. The mixer is equipped with a circulating water pipe for material preheating;

[0030] S3: Add the rest of the components together with the mixture B into the blender, mix the blender at a speed of 180 rpm, a temperature of 25°C, and a blending time of 6 hours to obtain raw materials;

[0031] S4: Apply a release agent in the mold cavity first, and then perform preheating treatment. The preheating tempe...

Embodiment 2

[0043] A preparation method of a high-performance polyurethane cold storage insulation board, comprising the following steps:

[0044] S1: Mix the polyurethane, catalyst, and blowing agent evenly and add to the autoclaved pre-expander, after the autoclaved pre-expander is preheated to 120°C, under the steam pressure of 0.6MPa in the autoclaved pre-expansion machine, perform aging for 3 hours;

[0045] S2: After mixing trientine, foam stabilizer, and nano-silica, preheat at 60°C for 80 minutes, cool to 20°C, mix with mixture A, add to the mixer and stir at 220rpm to obtain mixture B. The mixer is equipped with a circulating water pipe for material preheating;

[0046] S3: Add the rest of the components together with the mixture B into the mixer, mix the ingredients at the mixer speed of 180 rpm, the temperature of 35°C, and the mixing time of 6 hours to obtain the raw materials;

[0047] S4: Apply a release agent in the mold cavity first, and then perform preheating treatment....

Embodiment 3

[0059] A preparation method of a high-performance polyurethane cold storage insulation board, comprising the following steps:

[0060] S1: Mix the polyurethane, catalyst, and blowing agent evenly and add to the autoclaved pre-expander. After the autoclaved pre-expander is preheated to 113°C, it is matured for 2 hours under the steam pressure of 0.4MPa in the autoclaved pre-expansion machine;

[0061] S2: After mixing trientine, foam stabilizer, and nano-silica, preheat at 45°C for 62 minutes, cool to 20°C, mix with mixture A, add to the mixer and stir at 190rpm to obtain mixture B. The mixer is equipped with a circulating water pipe for material preheating;

[0062] S3: Add the rest of the components together with the mixture B into the mixer, and mix the ingredients at the mixer speed of 180 rpm and the temperature of 29°C for 6 hours to obtain the raw materials;

[0063] S4: Apply a release agent in the mold cavity first, and then perform preheating treatment. The preheatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com