Evaporative crystallization zero-emission system and method for industrial high-salinity wastewater

A high-salt wastewater, evaporation and crystallization technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of high difficulty in acclimating activated sludge, increased investment and operating costs, and ineffective salinity Eliminate other problems to achieve the effect of superior compatibility, low operating cost and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

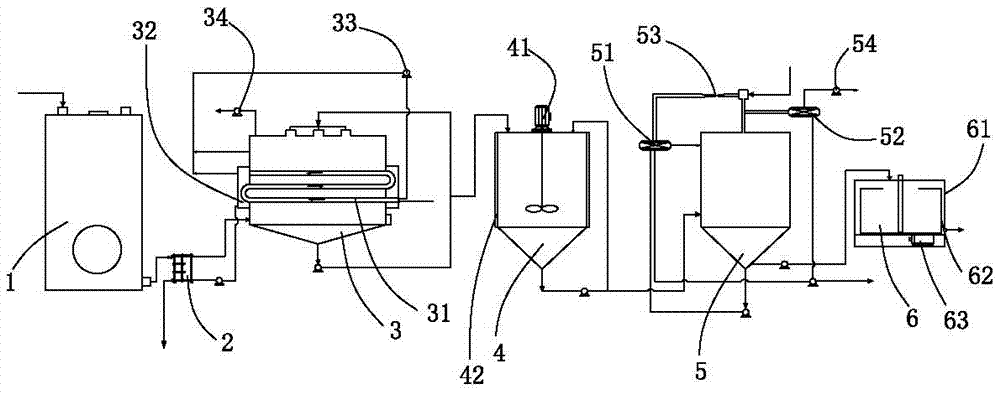

[0048] See figure 1 , a zero-discharge system for industrial high-salt wastewater evaporation and crystallization, the zero-discharge system includes:

[0049] The heat exchanger 2 is used to heat the high-salt wastewater;

[0050] The evaporation tank 3 is used to receive the high-salt wastewater from the heat exchanger 2 and conduct heating and evaporation;

[0051] The insulation tank 4 is used to receive the high-salt wastewater from the evaporation tank 3 and carry out insulation and stirring;

[0052] The crystallization tank 5 is used to receive the high-salt wastewater from the insulation tank 4 and perform flash concentration;

[0053] The centrifugal separation device 6 is used for receiving the high-salt wastewater from the crystallization tank 5 and performing centrifugal separation.

[0054]The present invention treats high-salt wastewater through evaporation, concentration and crystallization, finally realizes zero discharge, and is economical and efficient. ...

Embodiment 2

[0074] The difference between this embodiment and embodiment 1 is:

[0075] A method for evaporation and crystallization of industrial high-salt wastewater, comprising the steps of:

[0076] (1) Heating: use the heat exchanger 2 to heat the high-salt wastewater at room temperature to 35°C;

[0077] (2) Evaporation: use the evaporation tank 3 to heat the high-salt wastewater heated by the heat exchanger 2 to 45°C to evaporate under reduced pressure;

[0078] (3) Thermal insulation and stirring: add the high-salt wastewater evaporated from the evaporation tank 3 into the thermal insulation tank 4 for thermal insulation and stirring for later use;

[0079] (4) Flash evaporation: heat the high-salt waste water in the insulation tank 4 to 60°C with the heater 51 and pass it into the crystallization tank 5 for flash evaporation, and collect the condensed water from the condensed water outlet of the heater 51 and the condenser 52 for recycling. use;

[0080] (5) Centrifugal separa...

Embodiment 3

[0082] The difference between this embodiment and embodiment 1 is:

[0083] A method for evaporation and crystallization of industrial high-salt wastewater, comprising the steps of:

[0084] (1) Heating: use the heat exchanger 2 to heat the high-salt wastewater at room temperature to 45°C;

[0085] (2) Evaporation: use the evaporation tank 3 to heat the high-salt wastewater heated by the heat exchanger 2 to 75°C to evaporate under reduced pressure;

[0086] (3) Thermal insulation and stirring: add the high-salt wastewater evaporated from the evaporation tank 3 into the thermal insulation tank 4 for thermal insulation and stirring for later use;

[0087] (4) Flash evaporation: heat the high-salt waste water in the insulation tank 4 to 75°C with the heater 51 and pass it into the crystallization tank 5 for flash evaporation, and collect the condensed water from the condensed water outlet of the heater 51 and the condenser 52 for recycling. use;

[0088] (5) Centrifugal separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com