Patents

Literature

65results about How to "Uniform and dense distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

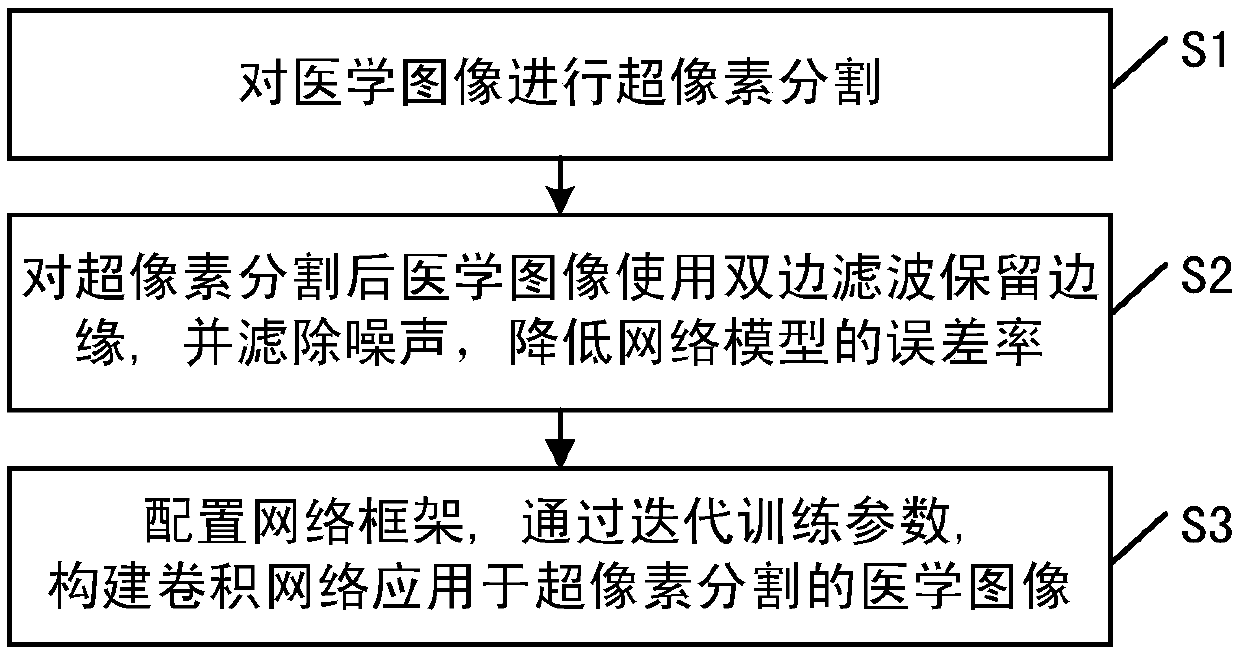

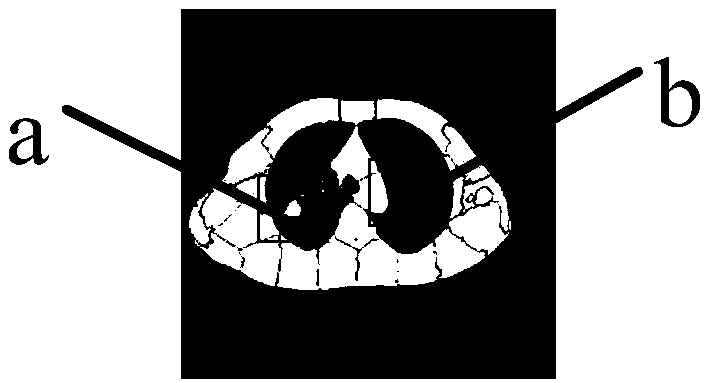

A superpixel method for medical image segmentation

ActiveCN109035252AMake up for the defect of inaccurate edge segmentationSolve the fuzzy classification problemImage analysisAnatomical structuresPattern recognition

The invention provides a superpixel method for medical image segmentation. The method comprises the steps of: processing a medical image into a superpixel; for the medical images obtained after superpixel segmentation, using bilateral filtering to preserve the edge and filter the noise to reduce the error rate of the network model; configuring a network framework, and constructing a convolution network for the medical images obtained after superpixel segmentation by iterative training parameters. Based on the linear iterative clustering segmentation method, this method applies the thought of the U-Net network to the post-optimization of super-pixels, which makes up the defect of inaccurate segmentation of inner edge of super-pixel, increases the standard layer to improve the weight sensitivity of each network layer, improves the convergence performance of the network, and makes the segmentation result closer to the actual value. Because the anatomical structure and pathological tissueof medical images are very clear, the medical images segmented by SLIC algorithm can obtain more comprehensive super-pixel, and the edge accuracy of super-pixel can be further improved by convolutionnetwork.

Owner:SHANDONG UNIV OF FINANCE & ECONOMICS

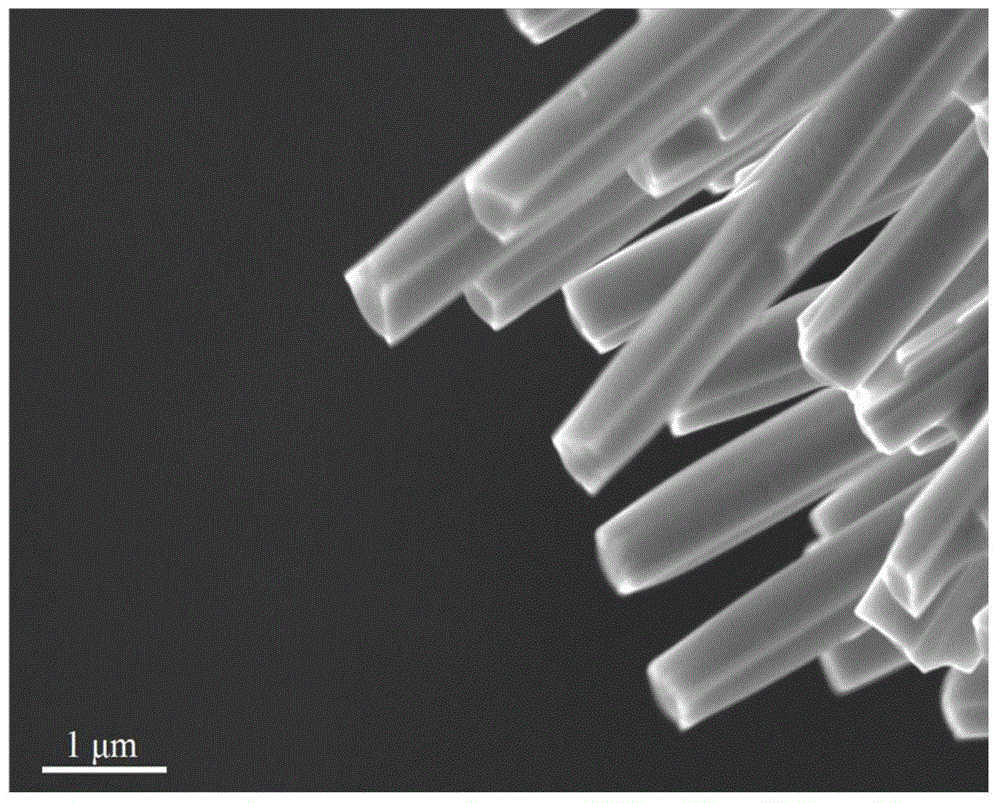

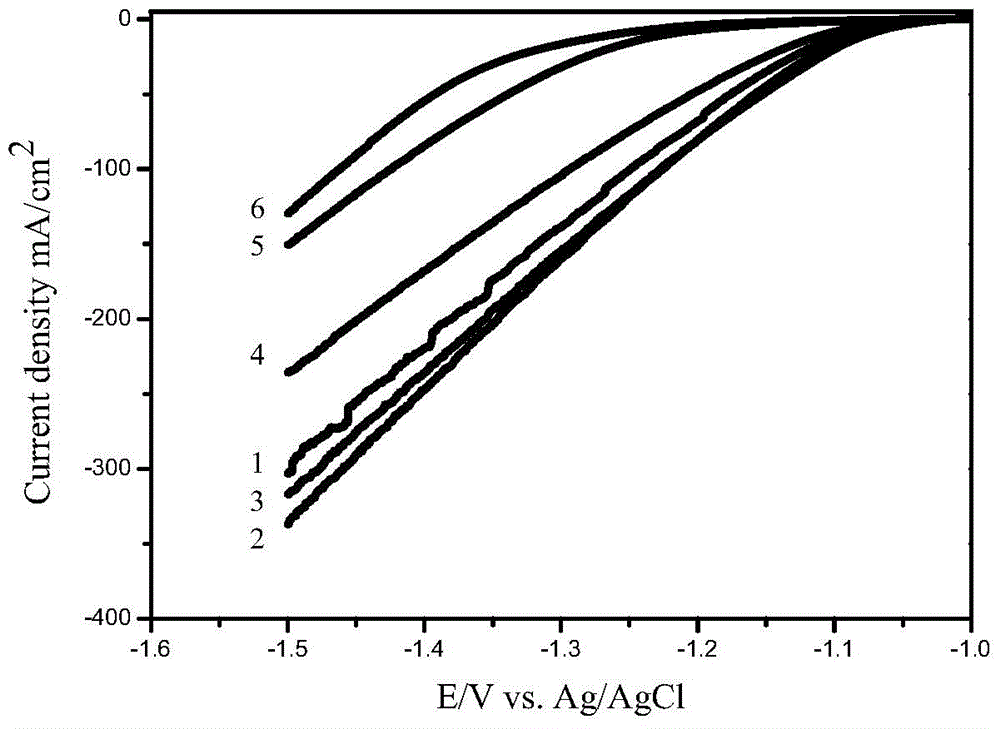

Method for preparing high-performance molybdenum-based hydrogen evolution electrode by phosphatizing molybdate precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode by phosphatizing a molybdate precursor and belongs to the fields of water electrolysis and electric catalytic hydrogen evolution in the chlor-alkali industry. The method comprises the steps of pre-processing foamed nickel, growing the molybdate precursor in situ on the surface of a pre-processed foamed nickel base with the hydrothermal synthesis method, and finally placing the prepared precursor and a phosphorus source into a rube furnace together for phosphating of the molybdate precursor so that the high-performance molybdenum-based hydrogen evolution electrode can be prepared. The method is novel, the technology adopted is simple, production cost is low, the requirement for equipment is low, and the method is suitable for industrial production. Furthermore, the electrode is large in specific area, can be combined with the base firmly, has excellent hydrogen evolution activity and stability, and can be widely applied to the fields of water electrolysis and hydrogen evolution in the chlor-alkali industry.

Owner:CHONGQING UNIV

Method for preparing water absorption polymer with high liquid absorption speed, dispersity and dried degree

The invention discloses a preparation method of absorbent polymer which is characterized in high speed rate of liquid absorption, good dispersibility and high dry-touch degree. Acrylic acid is added into sodium hydroxide aqueous solution, which is uniformly mixed with acrylamide and then crosslinking agent, and foam stabilizer aqueous solution is added; while being aerated with nitrogen gas, the solution is ordinally added with polymerization initiator azodi (2-amidinopropane hydrochloride) aqueous solution, ammonium persulphate aqueous solution, sodium bisulfite aqueous solution and uniformly mixed; the aeration of nitrogen gas is stopped, and when the temperature of the solution is raised to 35 to 45 DEG C, the solution is added with foamer aqueous solution and uniformly mixed, so that porous gel is obtained; when the temperature is raised to 100 DEG C to 110 DEG C, the porous gel is put in the temperature environment of 80 to 90 DEG C for two the three hours; after being cooled down, the porous gel is taken out of a container, scissored into pieces, dried, crumbled and filtered, and grains are collected; crosslinking treatment agent is sprayed on the surface of grains, and after stirring and heating, the absorbent polymer is obtained. In three minutes, the volume of saline absorbed by the product prepared by the invention can reach 70 ml / gSAP.

Owner:段梦麟

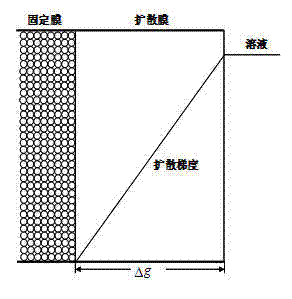

Improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement and preparation method thereof

InactiveCN102507388AImprove physical strengthLittle flexibilitySurface/boundary effectMoisturePolyacrylamide

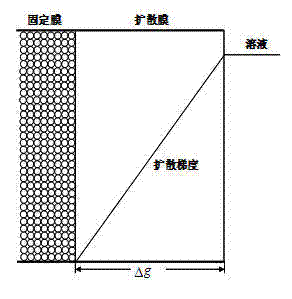

The invention provides an improved phosphorus fixing film used in DGT (diffusive gradients in thin films) measurement. The improved phosphorus fixing film is a polyacrylamide gel film containing zirconium dioxide (ZrO2) and is characterized in that ZrO2 particles of which the particle size is less than or equal to 5mu m are uniformly distributed on the surface of the phosphorus fixing film. A preparation method of the improved phosphorus fixing film comprises the following steps: uniformly mixing ZrO2 powder with the moisture content of 45-55% with an acrylamide solution at the weightmeasurement ratio of (1:3)-(1:6); grinding and then carrying out ultrasonication; standing for removing precipitates, adding tetramethylethylenediamine of which the volume is (1:1600)- (1:1400) of that of acrylamide and a 10% ammonium persulfate solution of which the volume is (1:60)-(1:40) of that of acrylamide, uniformly mixing and injecting into a glass mold; horizontally placing the glass mold at room temperature; After the zirconium powder is freely precipitated, raising the temperature to 40-60DEG C until the mixed solution forms a gel film; and soaking in de-ionized water for more than 12 hours, thus obtaining the phosphorus fixing film. The phosphorus fixing film provided by the invention can be used for maintaining high phosphorus ion adsorption capacity and simultaneously improving the resolution ratio of DGT in phosphorus analysis.

Owner:HOHAI UNIV

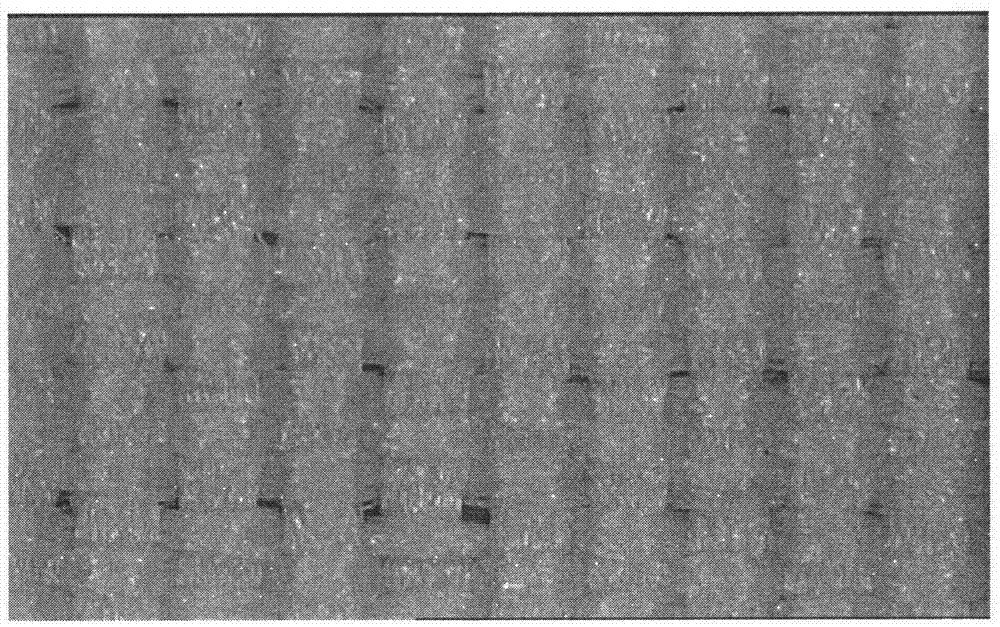

Method for acquiring two-dimensional distribution of sediment dissolved reactive phosphorus (DRP)

ActiveCN102507471AHigh-resolutionUniform and dense distributionColor/spectral properties measurementsDiffusionSolid content

The invention discloses a method for acquiring two-dimensional distribution of sediment dissolved reactive phosphorus (DRP), which comprises: vertically placing a diffusion gradient in thin-films (DGT) device containing a modified phosphorus immobilizing film in a sediment to extract the DRP in the section of the sediment by using modified ZrO2 polyacrylamide gel thin film, in which the particle size of zirconium dioxide is less than or equal to 5mu m, as a phosphorus immobilizing film based on a DGT principle, and keeping 3 to 5 centimeters of overlying water; marking a sediment-water interface, taking out the immobilizing film, and performing two-dimensional and submillimeter slicing on the part below the interface; and extracting the DRP in the slices by using NaOH, measuring the DRP content in the extract by using microcolorimetry, converting the DRP content into the DRP solid content in the slices, calculating the DRP concentration at the corresponding position in the section of the sediment based on Fick's first law of diffusion, and drawing a two-dimensional distribution map.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

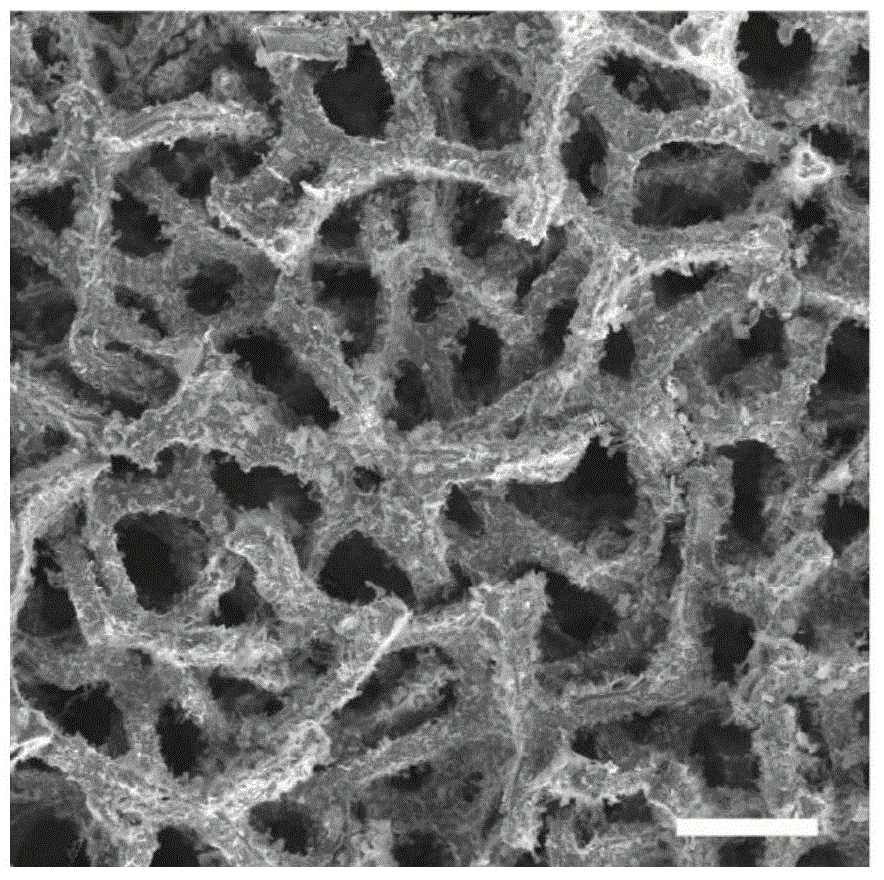

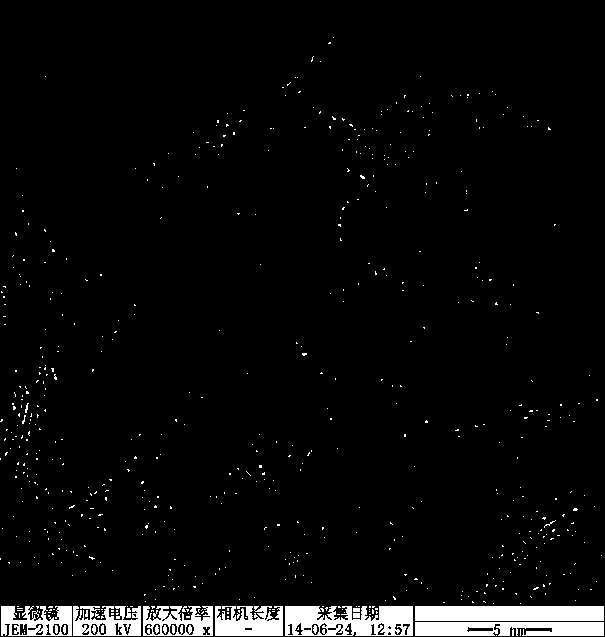

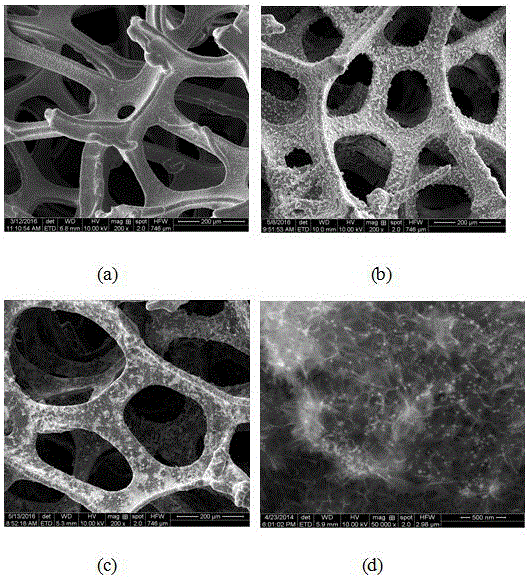

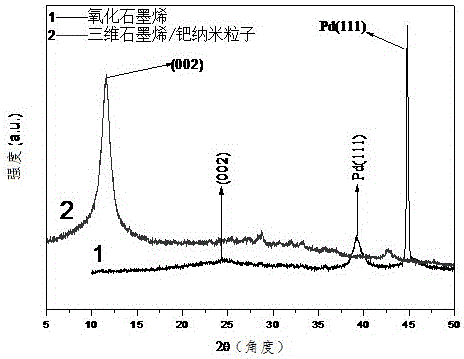

Preparation method of nanometer palladium-graphene three-dimensional porous composite electrocatalyst

ActiveCN104549242AEasy to controlLarge specific surface areaCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPorous graphenePotassium

The invention discloses a preparation method of a nanometer palladium-graphene three-dimensional porous composite electrocatalyst. The preparation method comprises the following steps: cleaning foamed nickel by sequentially adopting glacial acetic acid, acetone, ethanol and deionized water; preparing a graphene oxide water solution with the mass concentration of 0.5-10 mg / mL, then directly soaking the foamed nickel into the graphene oxide water solution, and standing for reaction to form a three-dimensional porous structural foamed nickel-graphene product; directly soaking the foamed nickel-graphene product into a potassium chloropalladate water solution with the molar concentration of 0.05-1 mmol / L; and after the reaction is finished, taking out the foamed nickel-graphene product so as to generate a graphene composite electrocatalyst product which has a three-dimensional porous structure and is loaded with a palladium nanoparticle. By the preparation method disclosed by the invention, the three-dimensional porous graphene foamed product loaded with the palladium nanoparticle can be obtained only through simple two-step soaking operation; and in addition, the three-dimensional porous graphene foamed product is excellent in property and high in stability and can be directly used as the positive pole of an ethanol fuel cell.

Owner:HUAZHONG UNIV OF SCI & TECH

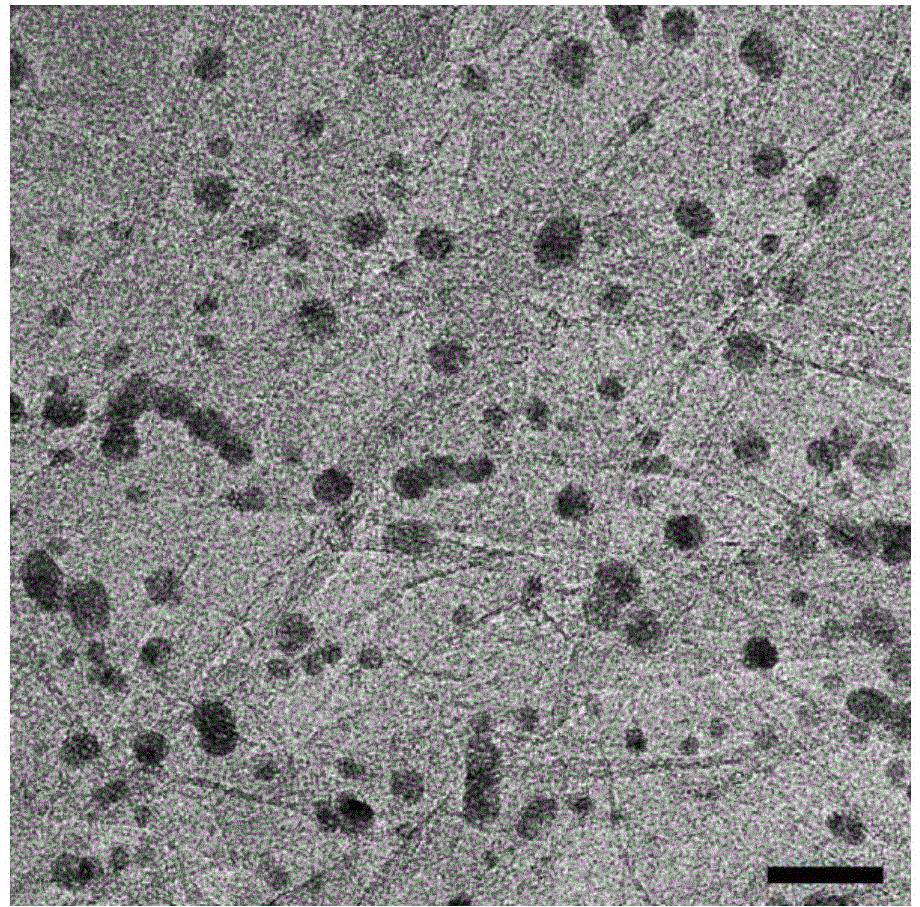

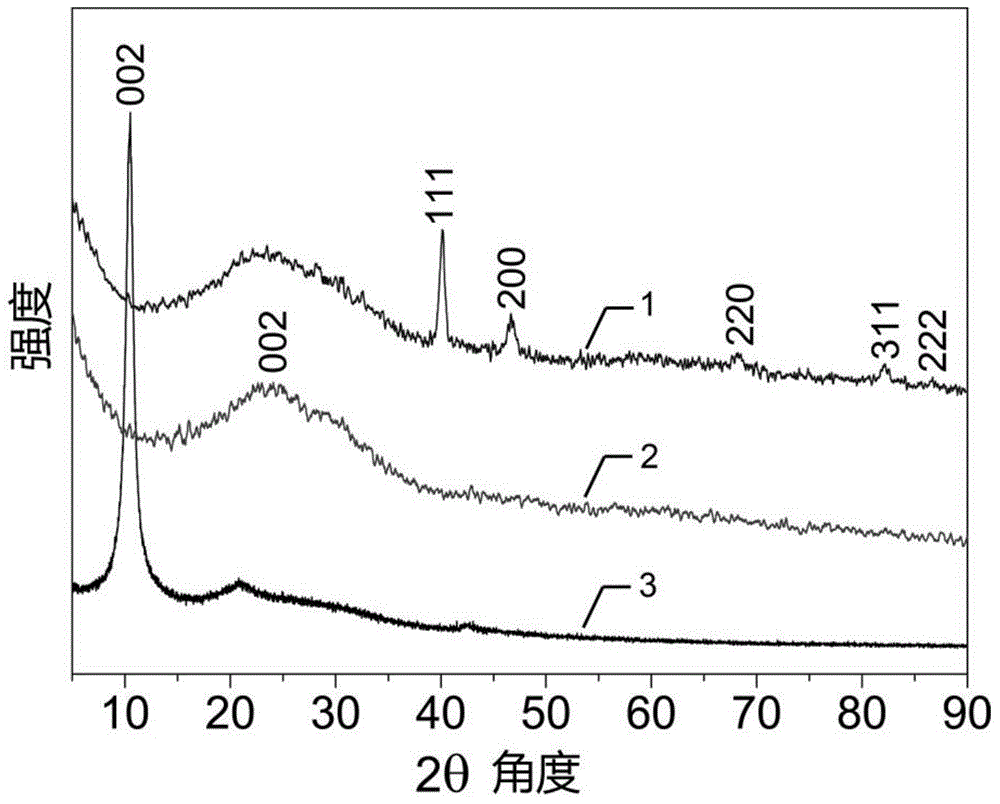

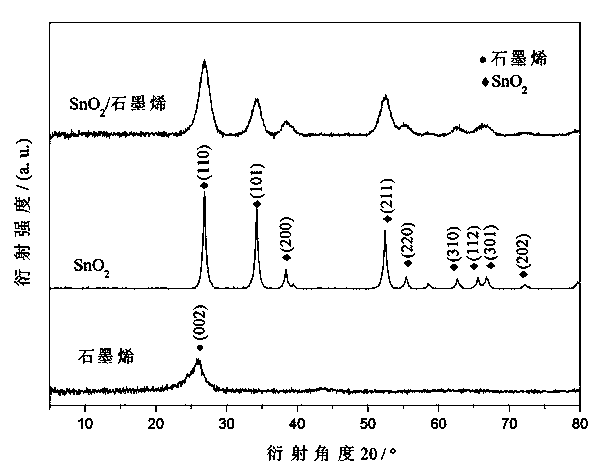

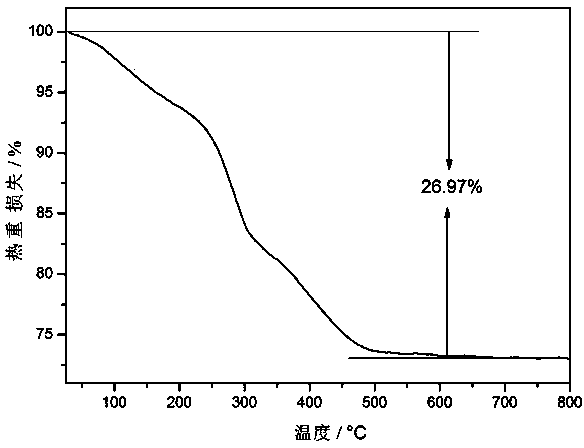

Preparation method of graphene-modified tin oxide lithium ion battery negative material

InactiveCN104218232AAchieve redoxThe principle is simpleCell electrodesSecondary cellsPhysical chemistryBattery cell

The invention discloses a method for preparing a graphene-modified tin oxide lithium ion battery negative material by adopting a sol in-situ electrostatic copolymerization sedimentation method, and belongs to the technical fields of material science and secondary power sources. The preparation process comprises the steps of dropwise feeding prepared Sn(OH)2 sol with positive surface charges into graphene oxide sol with negative surface charges, and enabling the two kinds of sol to be subjected to in-situ electrostatic copolymerization sedimentation under the action of electrostatic force to generate black flocculated precipitate; and centrifuging, washing, drying the precipitate, and then reducing by calcining the dried precipitate at the temperature of 400-600 DEG C under a nitrogen atmosphere to obtain the graphene-modified tin oxide lithium ion battery negative material. According to the method, the reaction process is carried out in a neutral water solution, other reagents are not needed, the precipitation reaction is fully carried out, the phenomenon is obvious, and the separating and the washing are easily carried out; the prepared lithium ion battery negative material has the excellent electrochemical capacity performance, cycle performance and rate capability, and has the very wide market application prospect in the lithium ion battery industry.

Owner:ZHENGZHOU UNIV

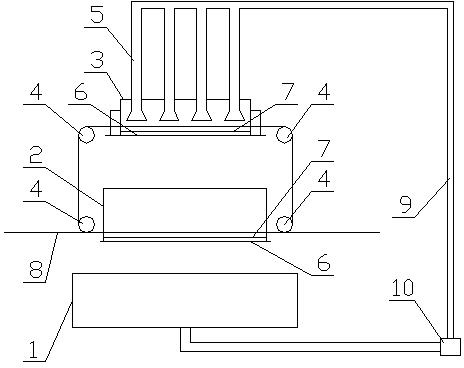

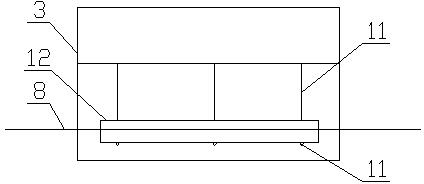

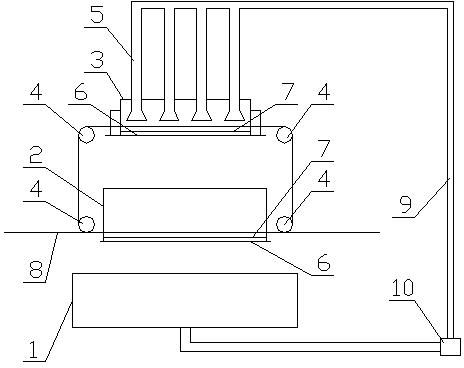

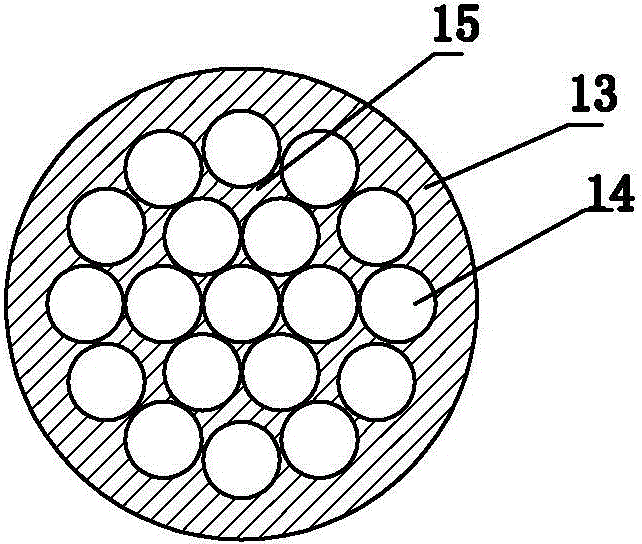

Sand charging groove for manufacturing electroplated diamond fretsaw

InactiveCN102586844AUniform and dense distributionSimple structureElectrolytic coatingsDiamond wire sawEngineering

The invention discloses a sand charging groove for manufacturing an electroplated diamond fretsaw, which comprises a circulation groove, a lower sand charging groove and an upper sand charging groove, wherein the lower sand charging groove and the upper sand charging groove are arranged above the circulation groove in a layering way at intervals, the bottom of the lower sand charging groove and the bottom of the upper sand charging groove are respectively provided with liquid leaking plates with liquid leaking holes, a liquid charging hole communicated with the circulation groove by a liquid pipe is arranged above the upper sand charging groove, and the liquid pipe is connected with a chemical pump; and two sides of the lower sand charging groove and the upper sand charging groove are respectively provided with electric conducting rollers, and the lower sand charging groove and the upper sand charging groove are internally provided with nickel plates respectively. The sand charging groove is simple and reasonable in structure, and easy to manufacture, and the impact of the flow of plating solution on the consolidation of diamond micropowder can be avoided since a stirrer device is not needed to be arranged in the plating solution, so that the sand charging groove is high in sand charging efficiency; and the diamond fretsaw produced from the sand charging groove has the advantages of being even and compact in micropowder grain distribution, sharp to cut, high in cutting efficiency and long in service life.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of novel anti-UV textile fabric

InactiveCN104726833AEasy to prepareEasy to operateFibre treatmentVacuum evaporation coatingThermal energyUltraviolet

The invention discloses a preparation method of a novel anti-UV textile fabric and belongs to the field of textile processing. By a magnetron sputtering technology, nano-silver, nano-zinc oxide and nanometer titania particles are respectively sputtered onto a fabric base material to form an uniform nanocomposite film so as to finally obtain the anti-UV fabric. The novel anti-UV textile fabric has advantages of simple preparation method, simple operation, low cost, no pollution, high chemical stability and thermal stability, no odor, nontoxicity, no irritating performance, using safety, especially high capability of absorbing ultraviolet rays and shielding effect on ultraviolet rays in UV-A zone and UV-B zone. Absorptivity or reflectivity of ultraviolet rays reaches more than 90%. In addition, the fabric not only has a reflection effect on ultraviolet radiation but also has special selection and absorption properties. By the fabric, ultraviolet energy can be converted to thermal energy or other harmless low-energy forms. Thus, the fabric provided by the invention has properties of heat stroke prevention, heat insulation and cool handtouch.

Owner:JIANGNAN UNIV +1

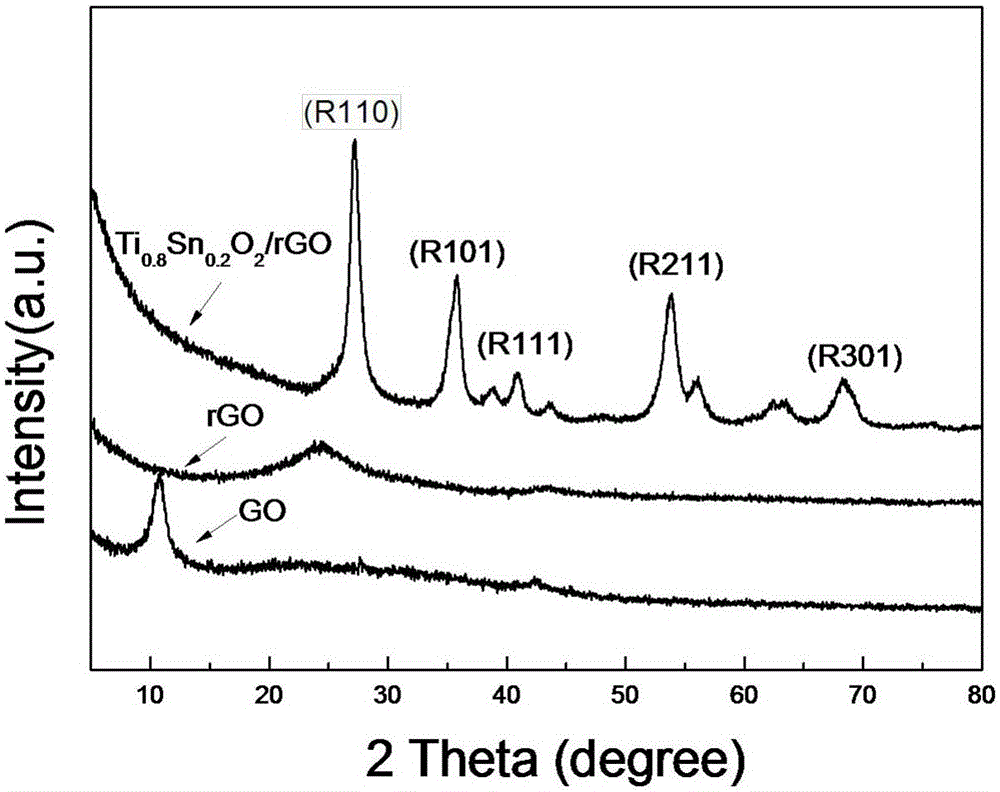

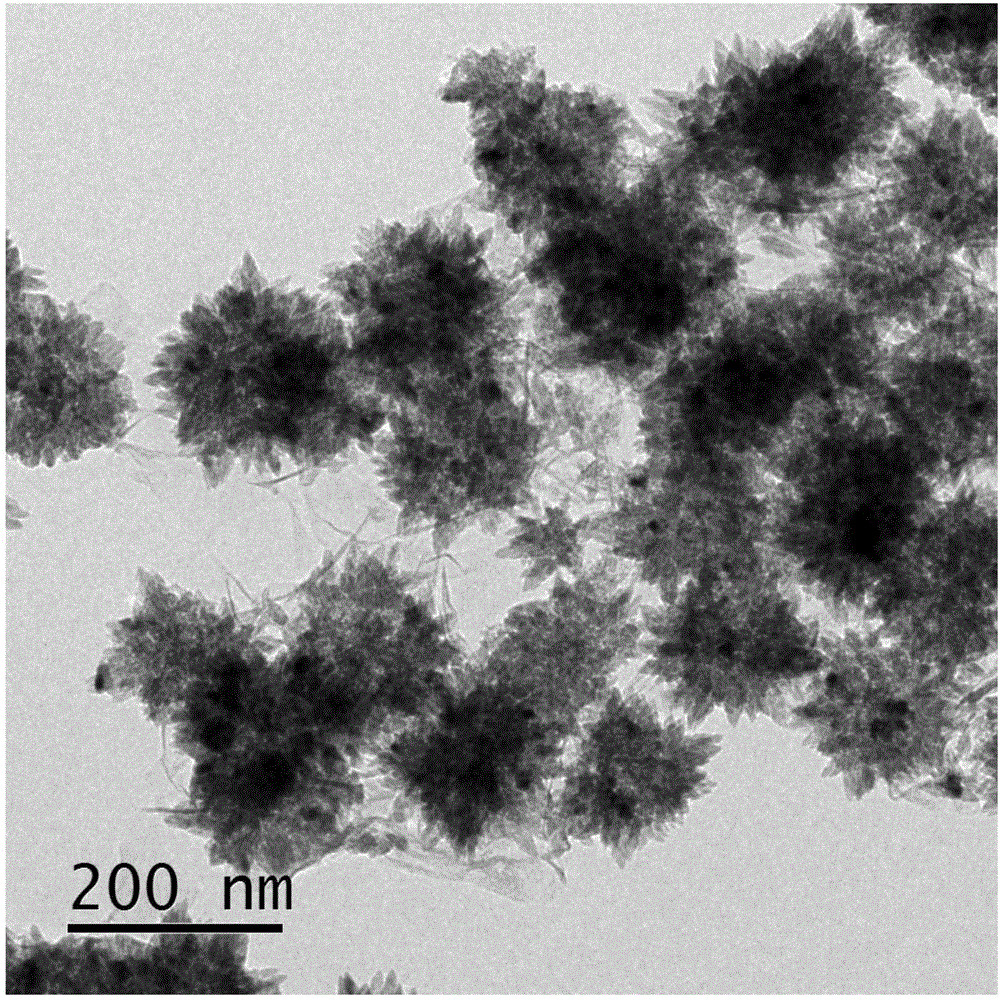

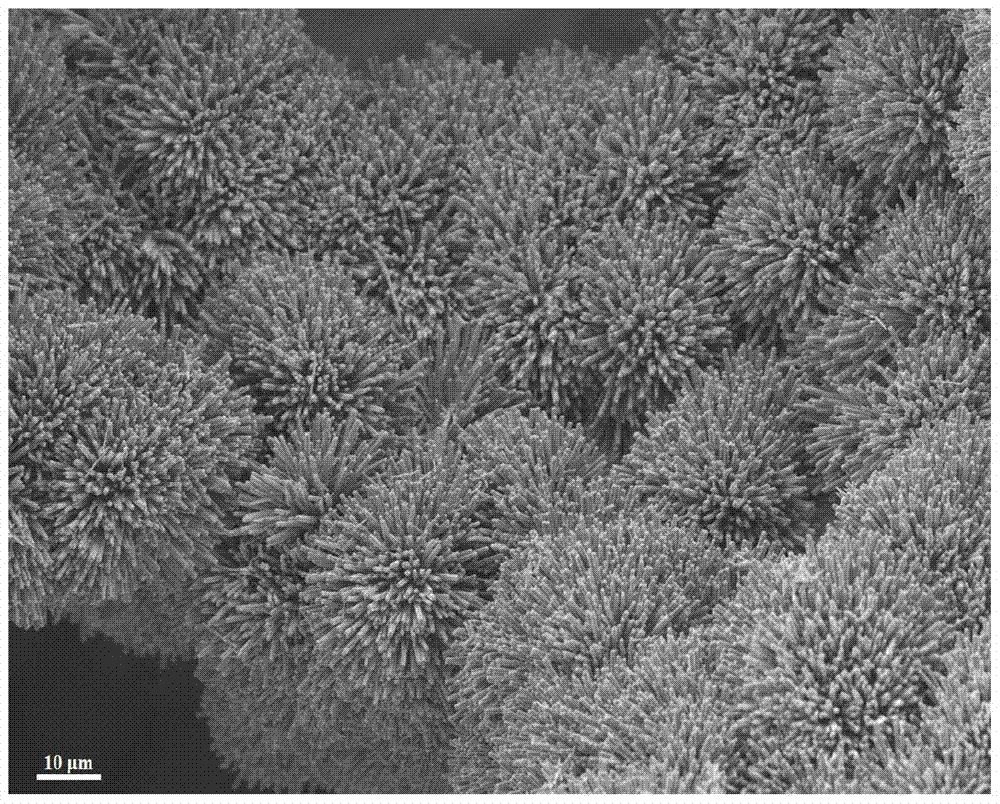

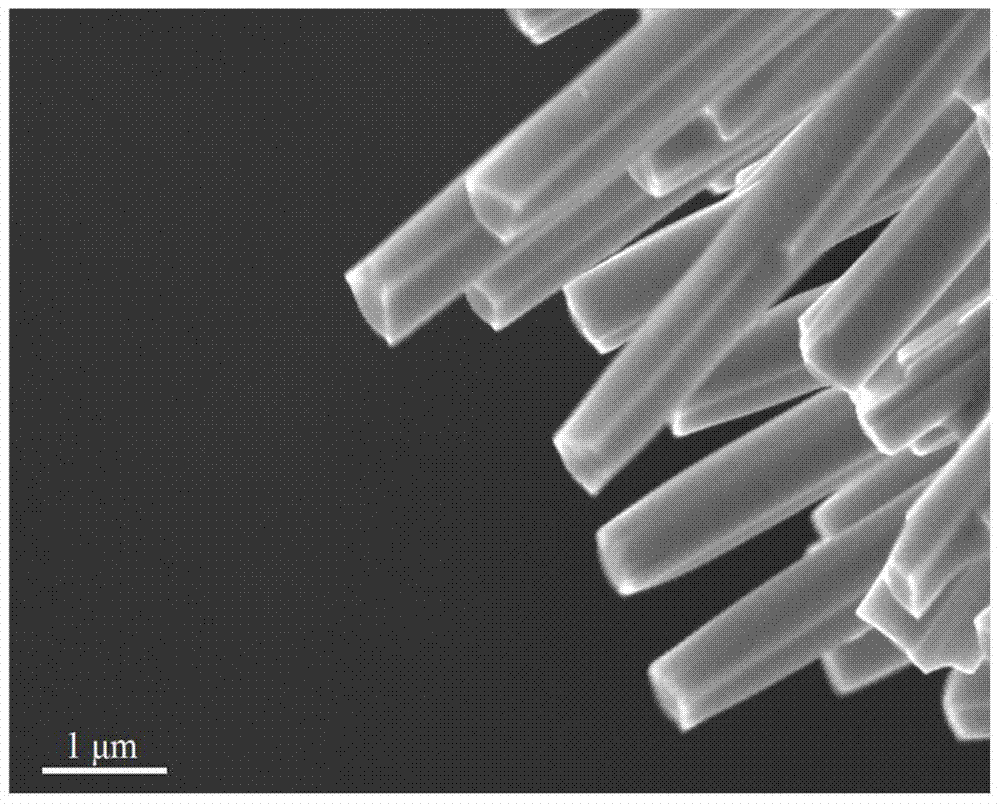

Method for producing urchin-like nano TixSn1-xO2/graphene three-dimensional composite material and application of composite material on negative electrode of lithium ion battery

InactiveCN106252607AThe principle is simpleEasy to operateNon-aqueous electrolyte accumulator electrodesElectronLithium electrode

The invention discloses a method for producing an urchin-like nano TixSn1-xO2 / graphene three-dimensional composite material and an application of the composite material on a negative electrode of a lithium ion battery. The urchin-like nano TixSn1-xO2 / graphene three-dimensional composite material is produced by a one-step hydro-thermal synthesis technology through self-assembly by using a coordination principle and a molecule self-assembly method. The method comprises the following steps: 1) preparing oxidized graphene, 2) preparing a graphite oxide sol with surface having negative electricity; and 3) producing the urchin-like nano TixSn1-xO2 / graphene three-dimensional composite material through reduction. The reaction process is carried out in an aqueous solution, other reagents are not required, and the method has the advantages of simple process, low cost, energy saving, environmental protection, and easy industrial batch production. As the negative electrode material of lithium ion battery, the three-dimensional composite structure of the material is in favor of diffusion of an electrolyte in the composite material as well as transmission of electron and ion in the material, and performances such as charge and discharge capacity, cycle life and multiplying power of the composite material can be effectively increased.

Owner:ZHENGZHOU UNIV

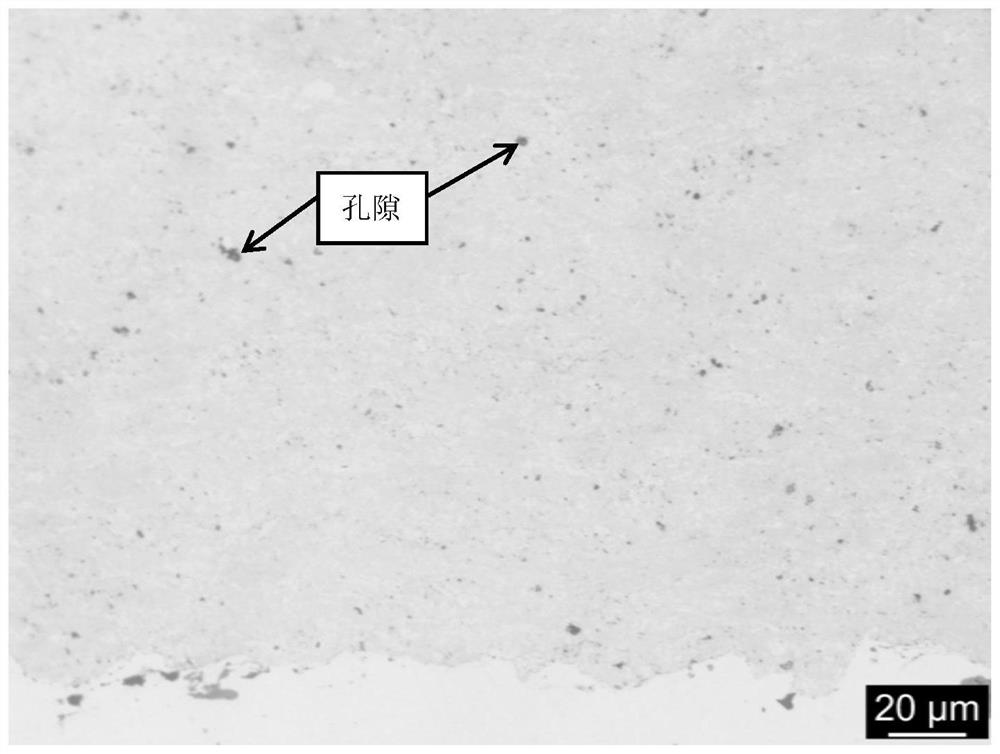

Method for performing surface modification on metal by ultrasonic nano-welding

ActiveCN102500912ATake full advantage of enhancementsGood interface wettabilityNon-electric welding apparatusMechanical bondMetal substrate

The invention relates to a method for performing surface modification on a metal by ultrasonic nano-welding and belongs to the technical field of nanomaterials. The method comprises the following steps: cleaning a to-be-treated region of the surface of the metal, coating a nanopowder material on the metal surface after cleaning, and performing ultrasonic nano-welding process on the nanopowder material on the metal surface to obtain a modified metal surface. The method is simple to operate and has controllable welding parameters. The nanomaterial and the welding region of the metal substrate form a local miscible body, leading to good interface infiltration, which enhances mechanical bonding effect and gives full play to reinforcement function of the nanomaterial. The nanomaterial is distributed densely and uniformly on the metal surface, and the surface is smooth and clean and has no cracks or air hole.

Owner:SHANGHAI JIAO TONG UNIV

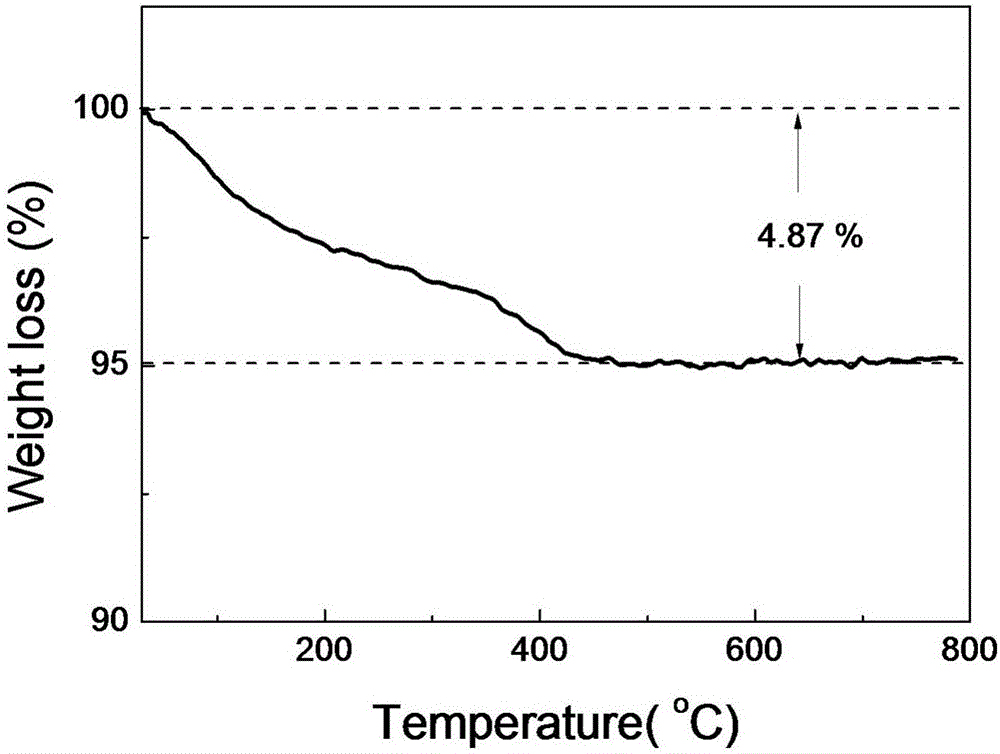

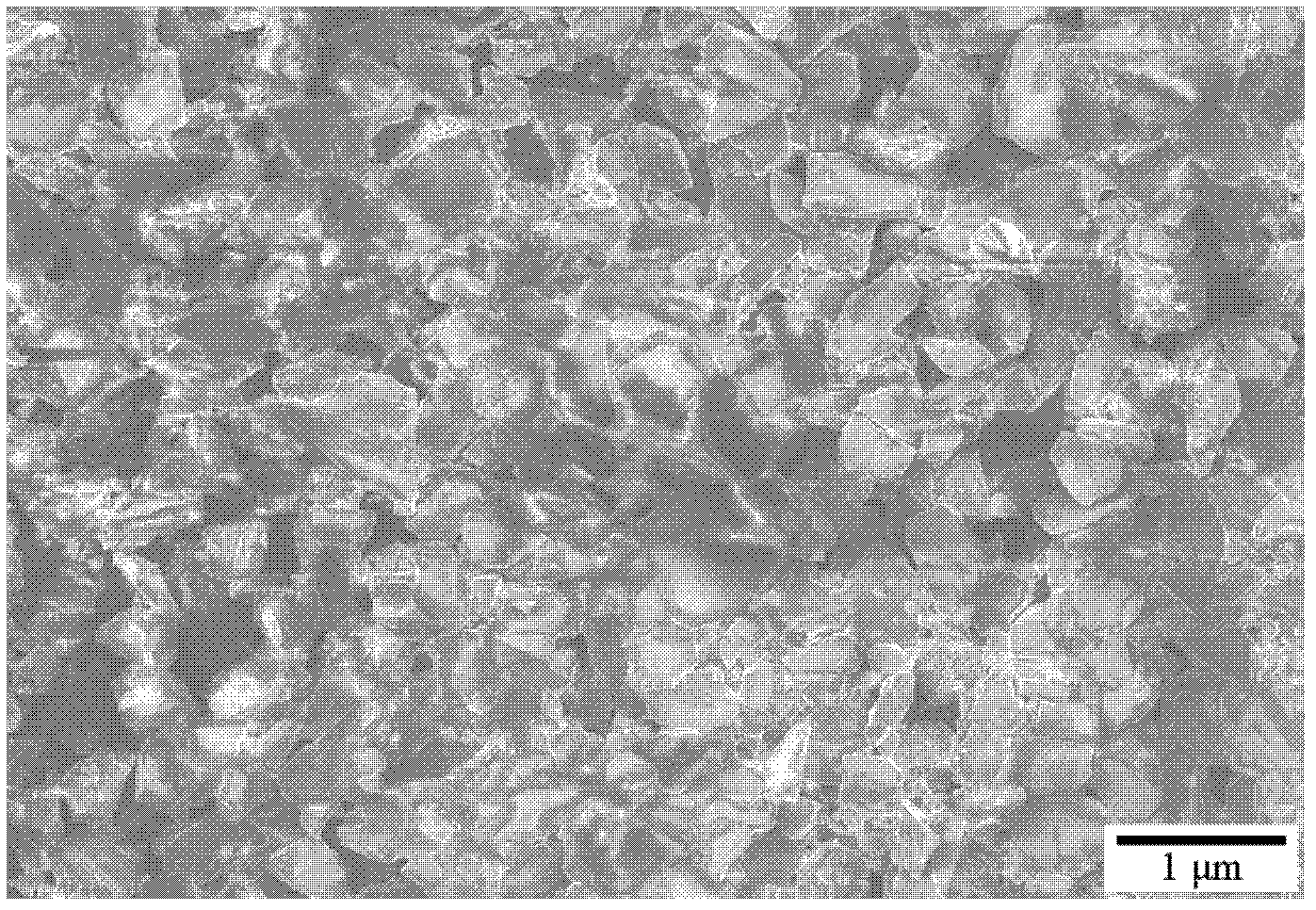

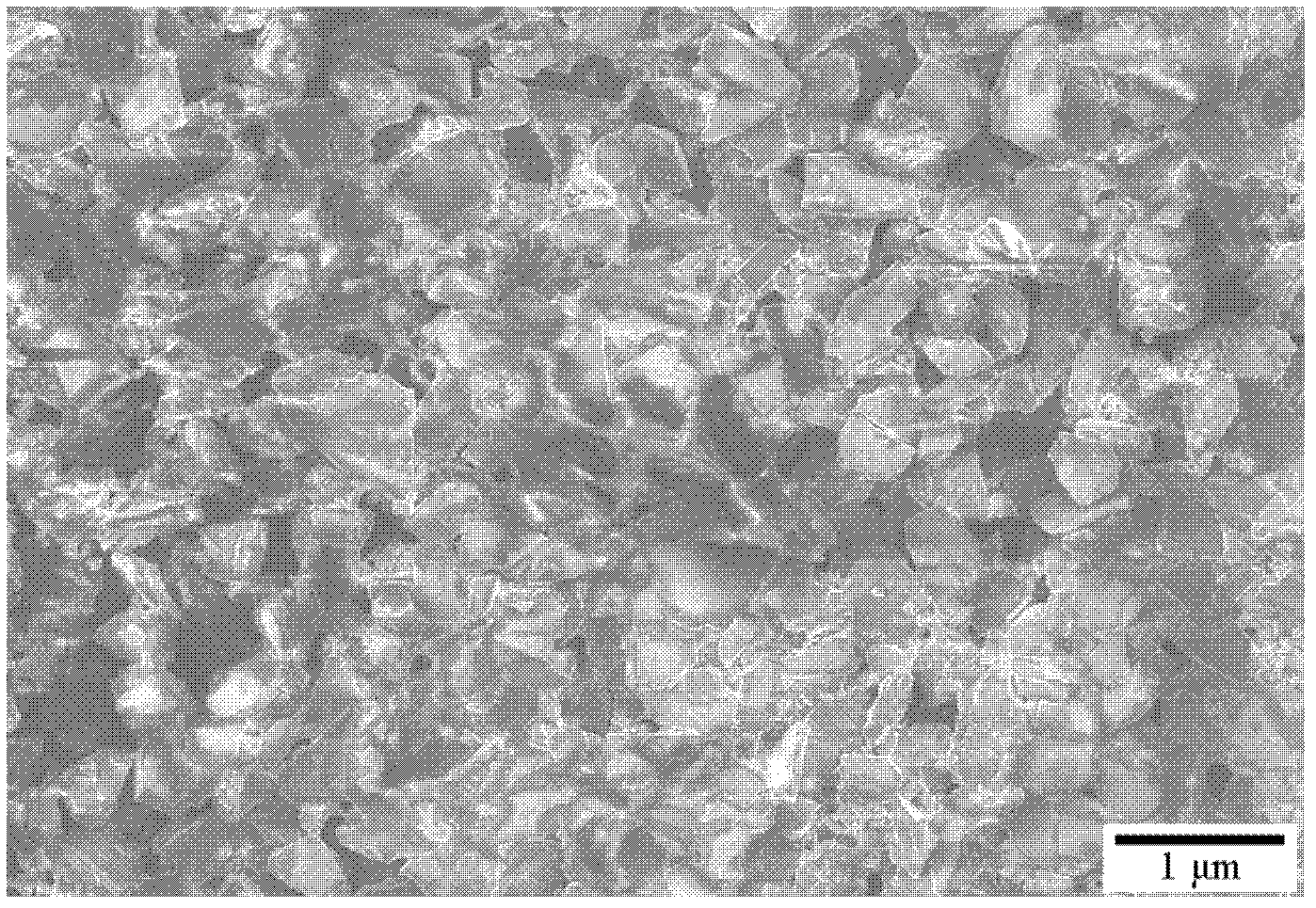

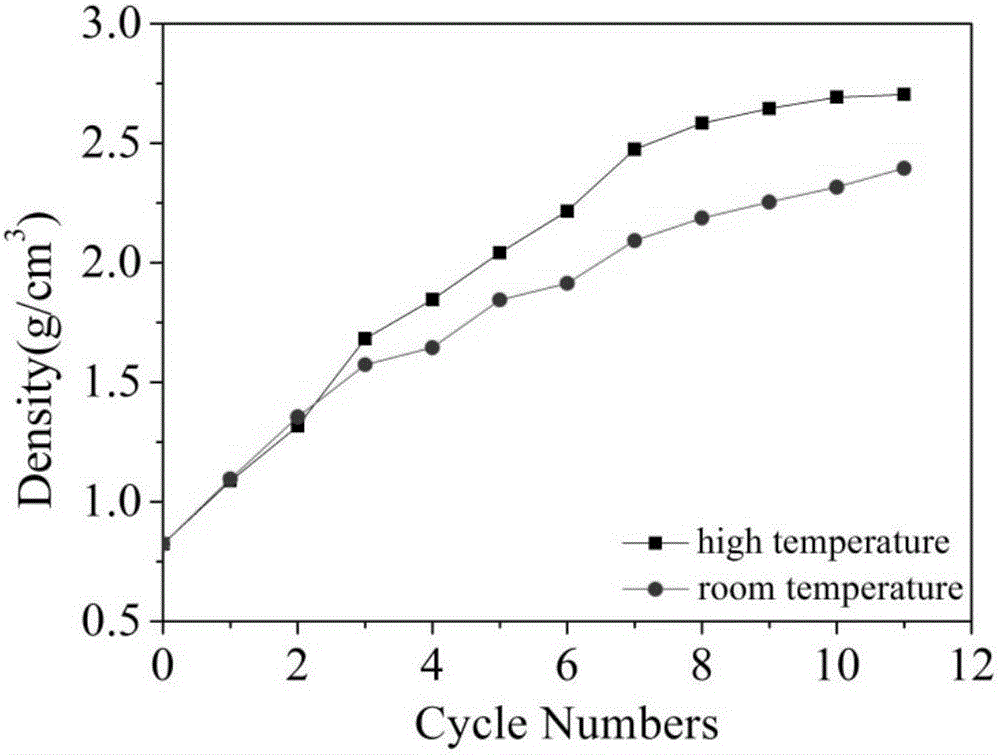

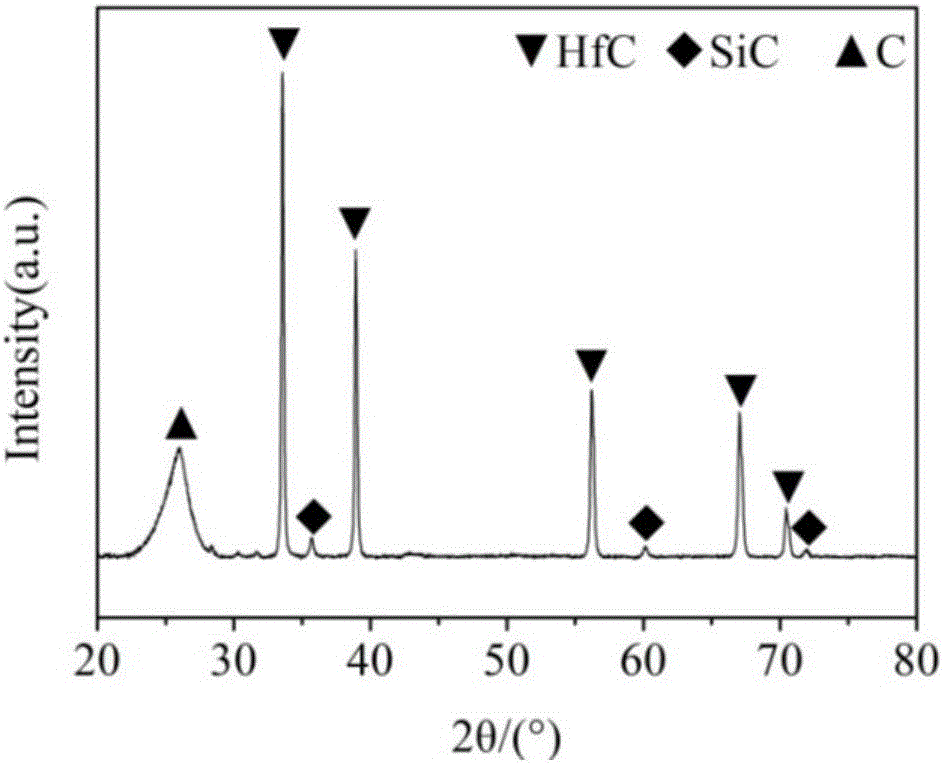

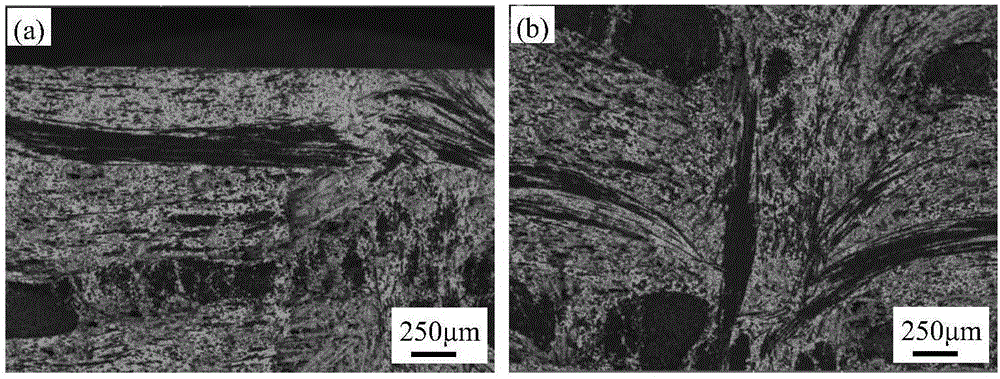

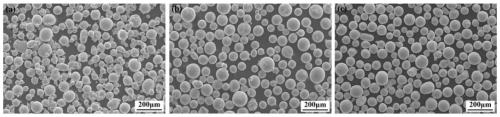

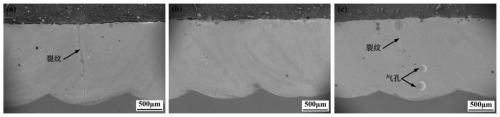

Method for preparing HfC-SiC modified C/C composite with high-temperature infiltration-pyrolysis process

The invention relates to a method for preparing an HfC-SiC modified C / C composite with a high-temperature infiltration-pyrolysis process. The method comprises the following steps: a carbon felt is cleaned and dried, and a low-density porous preform is prepared through isothermal chemical vapor deposition; an HfC precursor and polycarbosilane mixed solution is prepared to be taken as a precursor of an HfC-SiC ceramic phase, subjected to vacuum infiltration in an environment at about 110 DEG C and infiltrated into the preform, pyrolysis is performed, the high-temperature infiltration-pyrolysis process is repeated until the material gets densified, and the HfC-SiC modified C / C composite is prepared. The method has the beneficial effects as follows: based on the characteristic that the viscosity of the high-concentration polycarbosilane and HfC precursor mixed solution decreases with increasing temperature, the precursor mixed solution with high concentration is infiltrated into the porous C / C preform when the temperature is 90-110 DEG C, so that the porous C / C preform is filled fully faster, ceramic is uniformly and densely distributed in the preform, the final density reaches 2.4-2.7 g / cm<3>, the material preparing period is shortened, and the material preparing efficiency and the distribution uniformity of the ceramic phase in the material are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

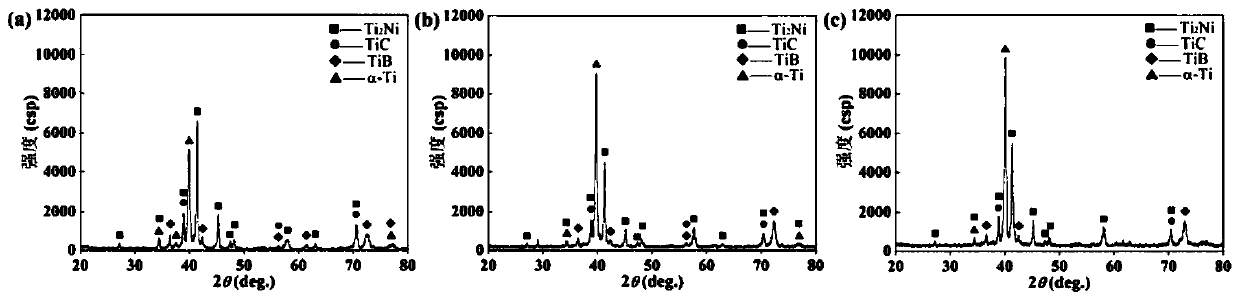

Copper-bearing titanium-based wear-resisting laser cladding layer on surface of titanium alloy and preparation method of copper-bearing titanium-based wear-resisting laser cladding layer

InactiveCN111118493AImprove toughnessInhibit growthMetallic material coating processesSurface engineeringTitanium

The invention belongs to the field of titanium alloy surface engineering, and particularly relates to a copper-bearing titanium-based wear-resisting laser cladding layer on the surface of a titanium alloy and a preparation method of the copper-bearing titanium-based wear-resisting laser cladding layer. Cladding layer comprises 65wt% of TC4 powder, 25-35wt% of Ni60 powder and 0-10wt% of Cu powder.The TC4 powder comprises 6.36wt% of Al, 4.06wt% of V, 0.011wt% of N, 0.05wt% of Fe, 0.077wt% of O and the balance Ti. The Ni60 powder comprises 15.5wt% of Cr, 0.8wt% of C, 3.5wt% of B, 4.0wt% of Si, 5.0wt% of Fe, 3.0wt% of W and the balance Ni. The purity of the Cu powder is larger than 99%. The forming quality of the laser cladding layer is improved, the friction and wear performance of the surface of the titanium alloy can be obviously improved, and the service life of the titanium alloy can be prolonged.

Owner:CIVIL AVIATION UNIV OF CHINA

Composite material taking foam nickel as matrix and preparation method of composite material

ActiveCN105810960ASlow down cascadingHigh specific surface areaCell electrodesCvd grapheneDimethyl formamide

The invention relates to a composite material taking foam nickel as a matrix and a preparation method of the composite material. The preparation method includes following steps: (1), preparing a graphene oxide water solution of 1.0-10.0 mg / mL; (2), soaking the foam nickel in the graphene oxide water solution, and performing ultrasonic treatment and material drying to obtain a foam nickel-graphene oxide composite product; (3), dissolving palladium acetylacetonate and potassium halide in N, N-dimethyl formamide, soaking the foam nickel-graphene oxide composite product in an N, N-dimethyl formamide solution for reaction for 1-6 h at 100-200 DEG C, cooling, separating, cleaning, and drying to obtain the composite material. By using the preparation method, the problems of stacking and irreversible aggregation of reduced graphene oxide are relieved effectively, size of palladium particles obtained by reduction reaches nanoscale, and the palladium particles are uniformly distributed on graphene, so that electrocatalytic activity of the palladium particles is improved fully.

Owner:鲁焱工程技术咨询有限公司

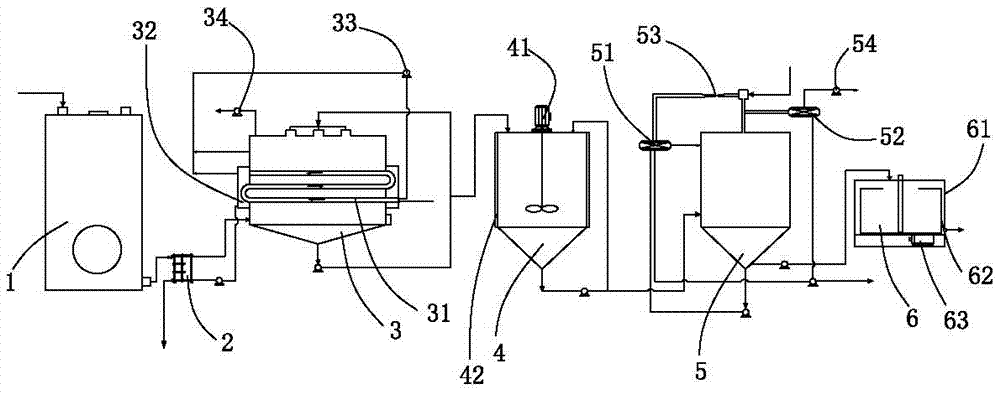

Evaporative crystallization zero-emission system and method for industrial high-salinity wastewater

PendingCN107265737AUniform cellsFine cellsWater/sewage treatment by centrifugal separationWater/sewage treatment bu osmosis/dialysisWastewaterProcess engineering

The invention relates to the technical field of wastewater purification, in particular to an evaporative crystallization zero-emission system and method for industrial high-salinity wastewater; the system comprises: a heat exchanger for heating high-salinity wastewater; an evaporative tank for receiving the high-salinity wastewater from the heat exchanger and heating for evaporating; an insulation tank for receiving the high-salinity wastewater from the evaporative tank and performing heat-insulated stirring; a crystallizing tank for receiving the high-salinity wastewater from the insulation tank and performing flashing condensation; a centrifugal separation device for receiving the high-salinity wastewater from the crystallizing tank and performing centrifugal separation. The industrial high-salinity wastewater processed via the system can be condensed to 30-60 times, derivatives are solid and condensate, the solid is a composite salt and may be separated and dried to obtain industrial finished salt, the condensate may be recycled to a production line, and accordingly zero emission of the high-salinity wastewater is achieved.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

Automobile sheet metal piece welding material and welding technology

InactiveCN108620765AUniform and dense distributionGood corrosion resistanceArc welding apparatusWelding/cutting media/materialsCorrosionMagnesium

The invention discloses an automobile sheet metal piece welding material and welding technology, and belongs to the technical field of machining. The automobile sheet metal piece welding material comprises the following raw materials of tin, zinc, neodymium, cadmium, copper, magnesium, aluminum, silver chloride, rare metal alloy, manganese, calcium, phosphorus, sulphur, bauxite powder, silicone and super-fine inorganic cellucotton. The automobile sheet metal piece welding technology comprises the steps of welding rod preparing, preheating, spot welding, annealing and the like. According to theautomobile sheet metal piece welding material and welding technology, the bauxite powder, the silicone and the super-fine inorganic cellucotton are adopted as a reinforcement system, and the weldingstrength and corrosion resistance of the automobile sheet metal piece welding material are improved.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

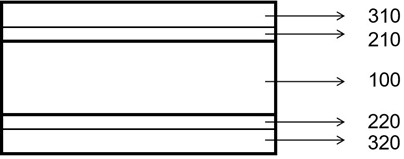

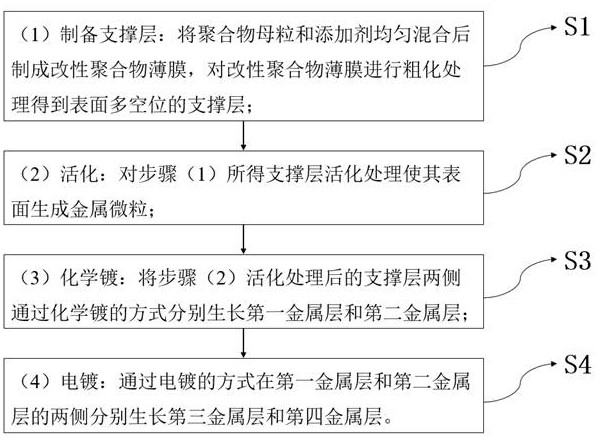

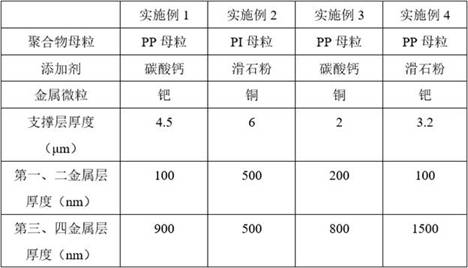

Preparation method of negative electrode composite current collector and product prepared by preparation method

PendingCN114678534ATightly boundUniform and dense distributionElectrode carriers/collectorsSecondary cellsChemical platingElectrical battery

The invention discloses a preparation method of a negative electrode composite current collector and a product prepared by the preparation method, and belongs to the technical field of lithium ion batteries. According to the method, polymer master batches and an additive are uniformly mixed to prepare a modified polymer film, the modified polymer film is subjected to roughening treatment to obtain a supporting layer with multiple vacancies on the surface, and metal particles are generated on the surface of the supporting layer through activating treatment; respectively growing a first metal layer and a second metal layer with a certain thickness on the two sides of the activated supporting layer in a chemical plating mode, and finally respectively depositing a third metal layer and a fourth metal layer on the two sides of the first metal layer and the second metal layer in an electroplating mode. The negative electrode composite current collector prepared by the method has the advantages of no surface defect, small internal stress of the plating layer, small resistivity of the plating layer, low production cost and easy realization of large-scale mass production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

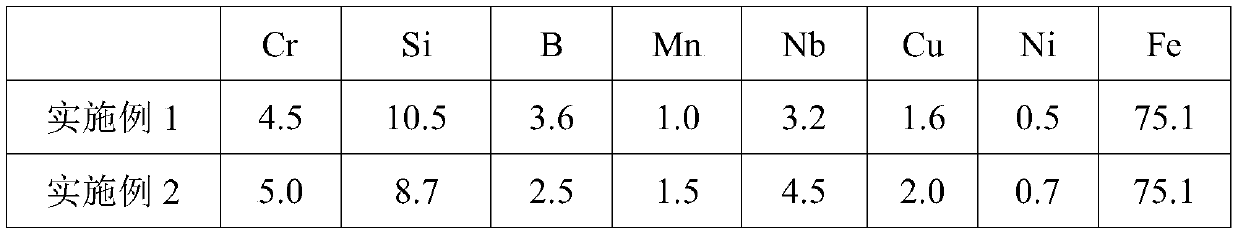

Anti-rust nanocrystal alloy and fabrication method thereof

ActiveCN109754973AOptimized formulaExcellent anti-rustInductances/transformers/magnets manufactureMagnetic materialsMaterials preparationThermal treatment

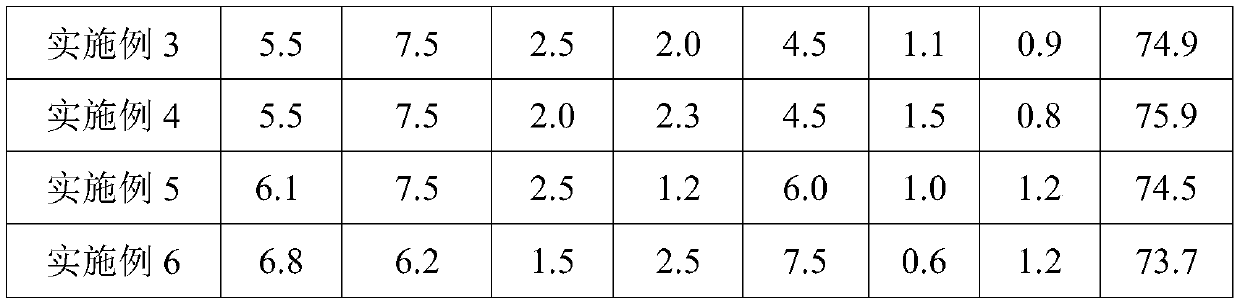

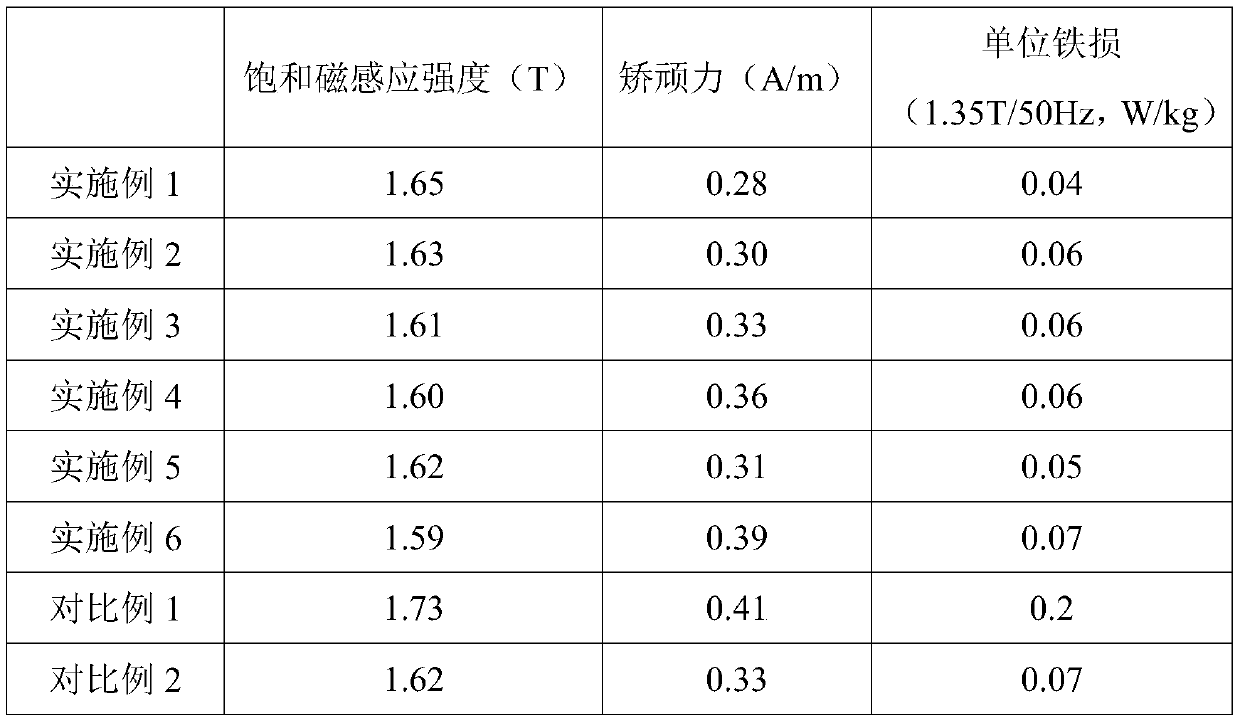

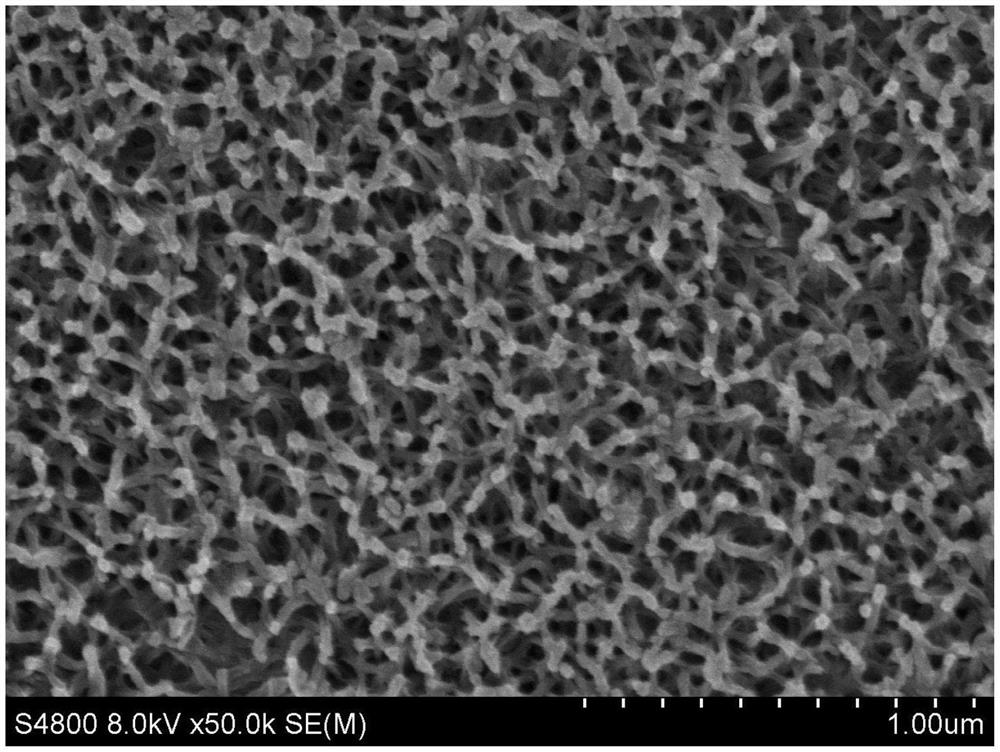

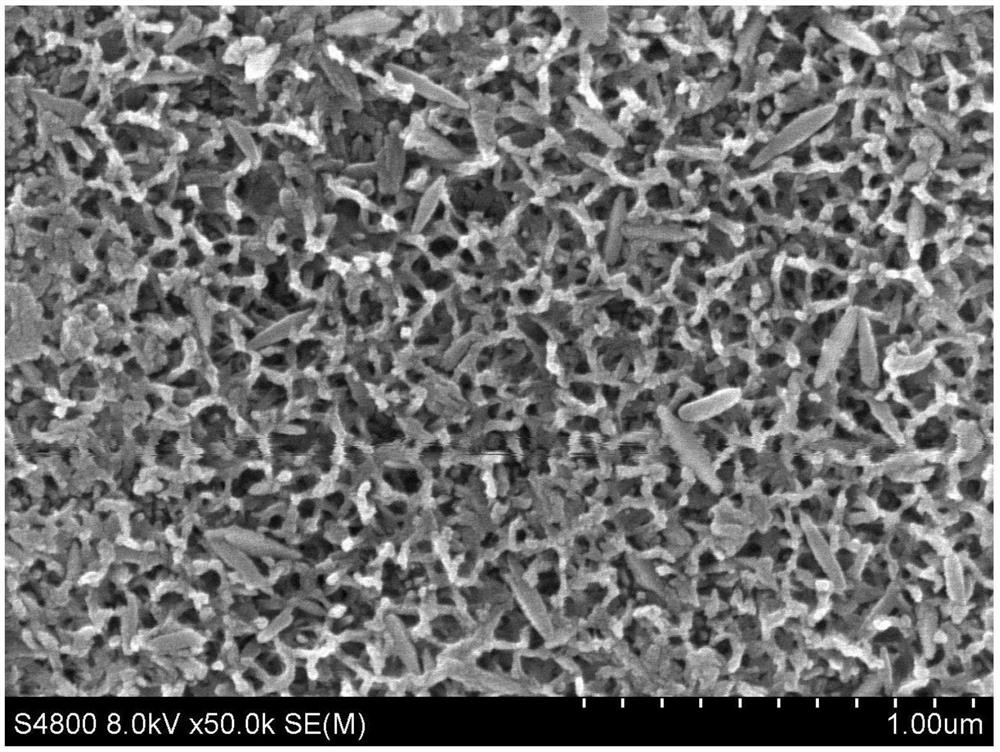

The invention provides an anti-rust nanocrystal alloy and a fabrication method thereof, and belongs to the technical field of magnetic material preparation. The anti-rust nanocrystal alloy comprises the following element constituents based on percent by mass: 4.5-6.8% of Cr, 6.2-10.5% of Si, 1.5-3.6% of B, 1.0-2.5% of Mn, 3.2-7.5% of Nb, 0.6-2.0% of Cu and 0.5-1.2% of Ni with the balance being Fe.By optimizing alloy element constituents and proportion and improving a thermal treatment mode, the nanocrystal alloy product compatible with excellent anti-rust performance and favorable soft magnetic performance is obtained.

Owner:安徽智磁新材料科技有限公司

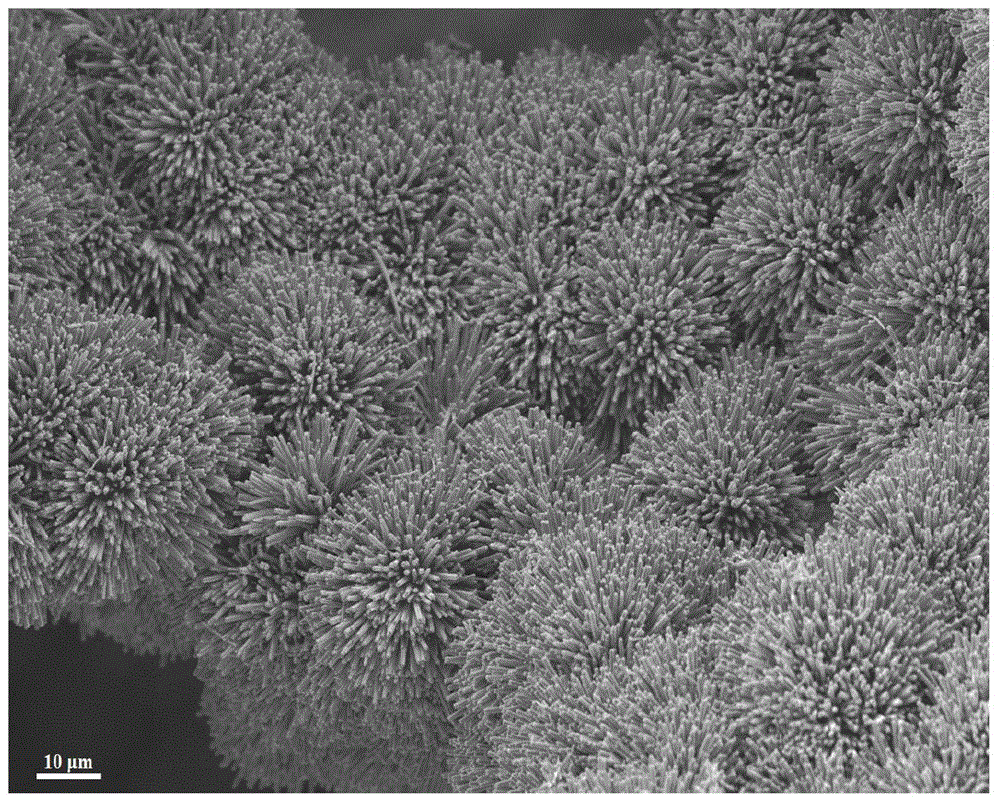

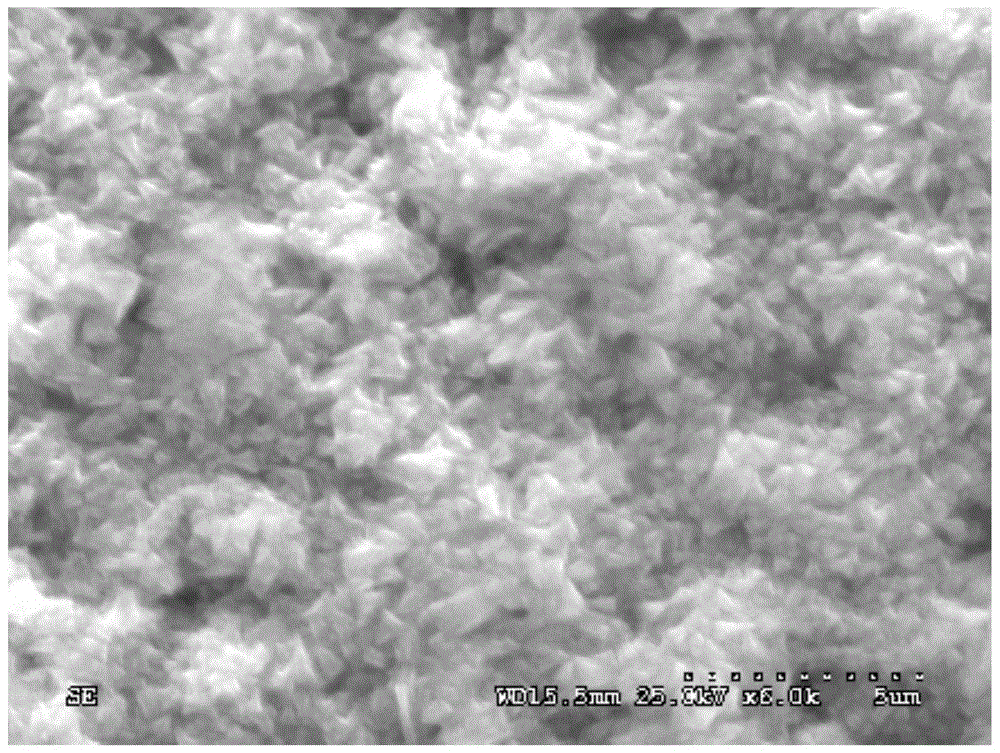

Method for growing titanium dioxide nano-particles on surface of titanium or titanium alloy substrate

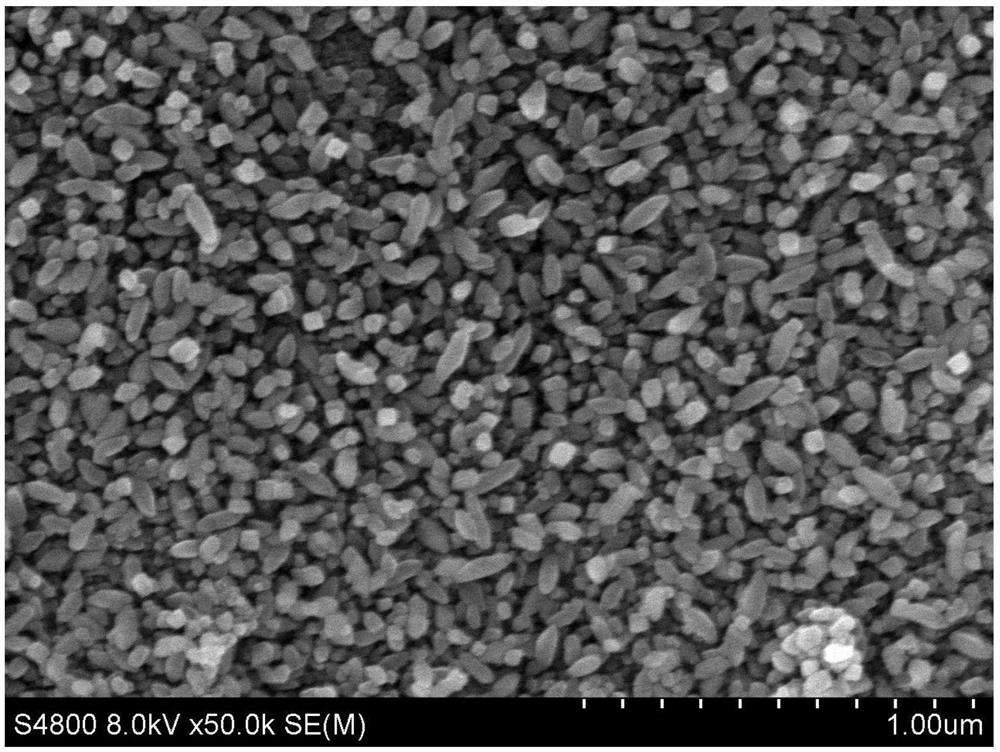

ActiveCN111647880AUniform and dense distributionThe size is easy to controlNanotechnologyLiquid/solution decomposition chemical coatingTitanium surfaceNanoparticle

The invention discloses a method for growing titanium dioxide nano-particles on the surface of a titanium or titanium alloy substrate. The method comprises the following steps of carrying out hydrothermal treatment on the surface of the titanium or titanium alloy substrate by using a hydrothermal solution to grow and form the titanium dioxide nano-particles on the surface of the substrate, and thehydrothermal solution adopts a salt solution containing chloride ions and / or fluoride ions. According to the method, the nano-particles which are uniform and compact in distribution and controllablein size can be obtained on the surface of the titanium or titanium alloy substrate; the method is simple and convenient in process, low in treatment temperature, low in cost, clean, environment-friendly, high in practicability and high in operability, can be used for regulating and controlling the nano-particles with different sizes on the titanium surface, can be used for modifying the surface ofthe titanium and titanium alloy substrate, and provides a new method for titanium surface treatment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Aluminum alloy workpieceblackening treatment method

InactiveCN108220945AStable in natureUniform and dense distributionLiquid/solution decomposition chemical coatingZincBonding strength

The invention discloses an aluminum alloy workpieceblackening treatment method, which comprises the following operation steps of (1) after cleaning a formed aluminum alloy workpiece, putting the aluminum alloy workpiece into an activate fluid, and activating; (2) putting the aluminum alloy workpiece treated through the step (1) into a zinc dipping solution, dipping for 30 to 40min, taking out, andcleaning a surface;(3) putting the aluminum alloy workpiece treated through the step (2) into a blackening solution, dipping for 5 to 8min, taking out, cleaning the surface, and obtaining a finishedproduct. The aluminum alloy workpieceblackening treatment method provided by the invention is simple to operate, low in cost, and suitable for treating smaller aluminum alloy workpieces; the processedaluminum alloy workpiece is uniform in blackening film and high in bonding strength.

Owner:安徽玉成光华铝业有限公司

Polyvinyl chloride composite foaming material and production method thereof

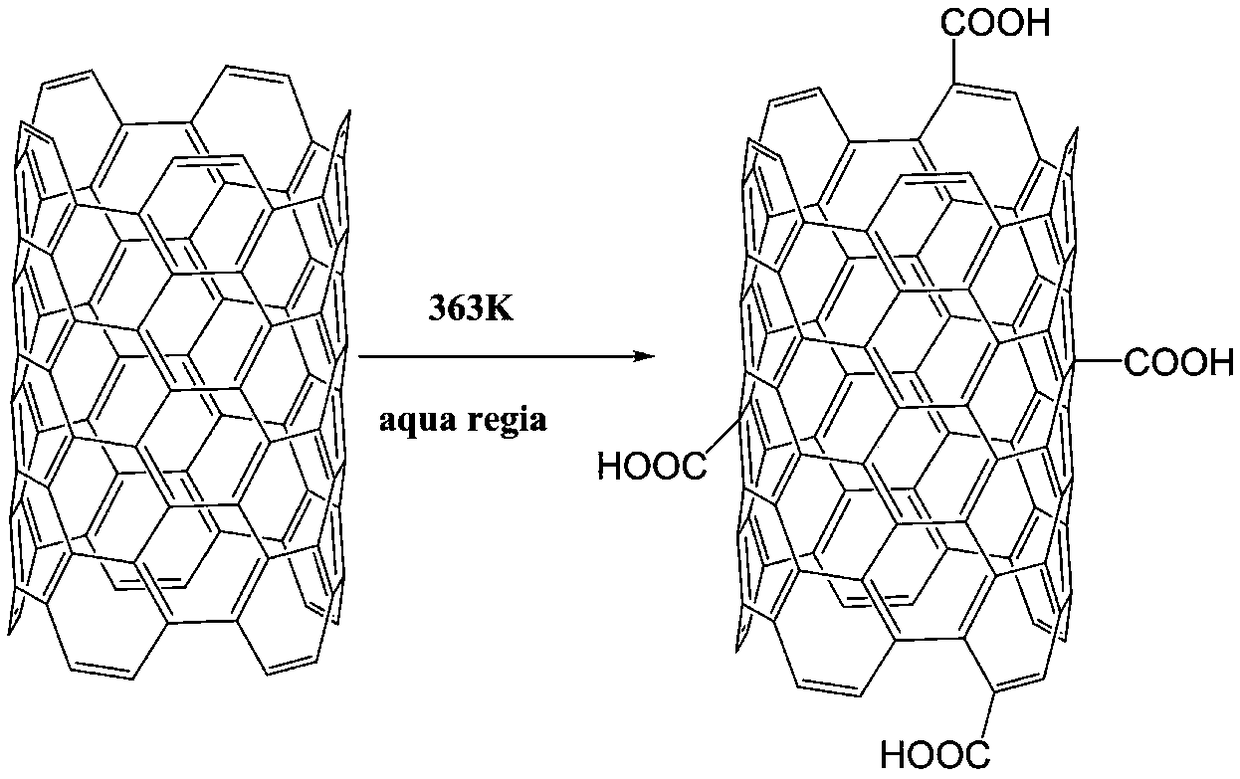

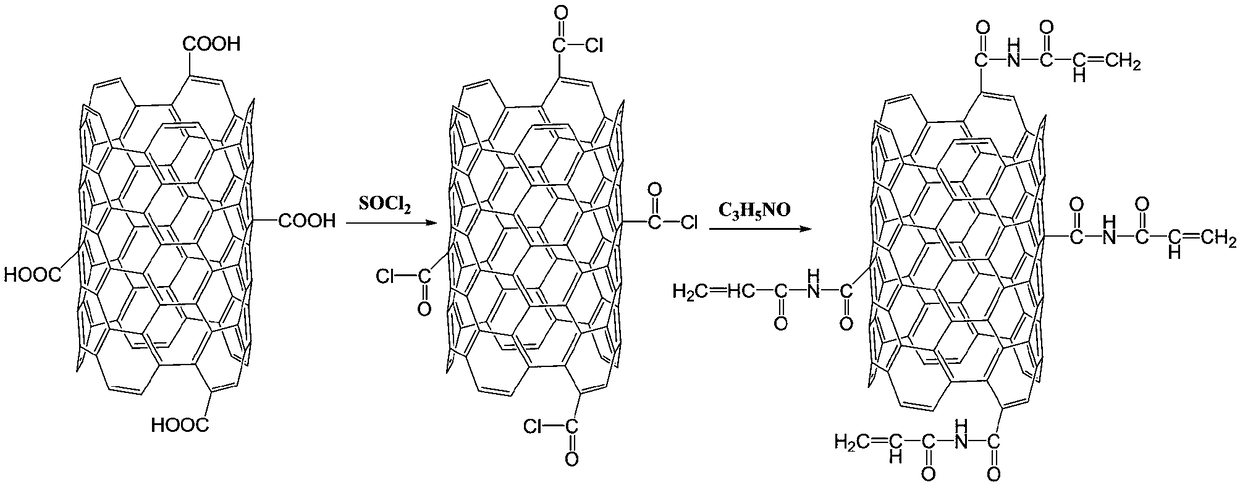

InactiveCN109293841AImproves tensile strength and impact resistanceImprove heat resistanceCarbon nanotubePlasticizer

The invention discloses a polyvinyl chloride composite foaming material comprising the following raw materials in parts by weight: 68-72 parts of polyvinyl chloride resin, 12-14 parts of dibutyltin maleate, 15-17 parts of a composite carbon nanotube monomer, 68-73 parts of an initiator, 1-2 parts of a plasticizer, 2-3 parts of an antioxidant, 5-7 parts of an anti-aging filler, 6-9 parts of formaldehyde, 3-5 parts of a polyurethane foaming agent, and 170-180 parts of tetrahydrofuran. By addition of the composite carbon nanotube monomer in the material, carbon nanotubes can be grafted onto a polyvinyl chloride branch chain through free radical polymerization, the tensile strength and the impact resistance ability of a foaming material can be greatly improved, particularly, the foaming material is not easy to break and deform when bearing large pressure or impact force, the problem that a conventional polyvinyl chloride foaming material has many bubble holes in the material so as to leadto reduction of the impact resistance of the foaming material is solved, and then the material can keep a shape unchanged under the relatively strong action.

Owner:黄杏兰

Material surface electrostatic self-assembling cladding method

InactiveCN103825010AUniform and dense distributionControl concentration differenceCell electrodesCentrifugationSolvent

The invention discloses a material surface electrostatic self-assembling cladding method. The method comprises the following steps: carrying out surface modification on primary particles and secondary particles by adopting ionic surfactants having different charge states to obtain primary particles and secondary particles having different surface charge properties, controlling the concentrations of the surface modified primary particles and the surface modified secondary particles in a dispersion solvent to effectively clad the primary particles, and carrying out centrifugation, drying, heat treatment and the like to obtain a primary particle modified material with a uniform cladding layer. The electrostatic action between different ionic surfactants promotes the uniform and tight distribution of the secondary particles in the periphery of the primary materials in order to realize a uniform cladding effect, so a non-uniform cladding phenomenon caused by chemical cladding, mechanical cladding and the like adopted in general cladding technologies is avoided.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

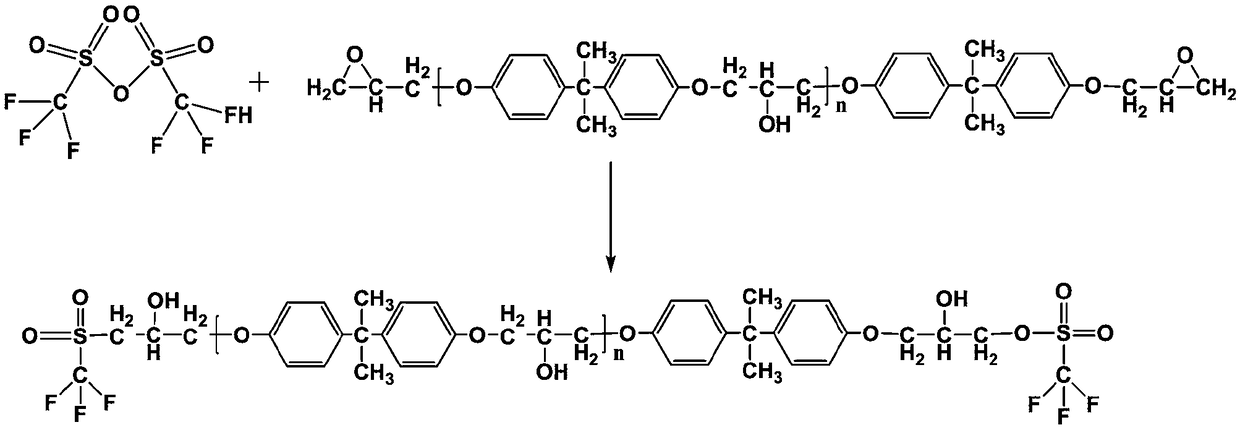

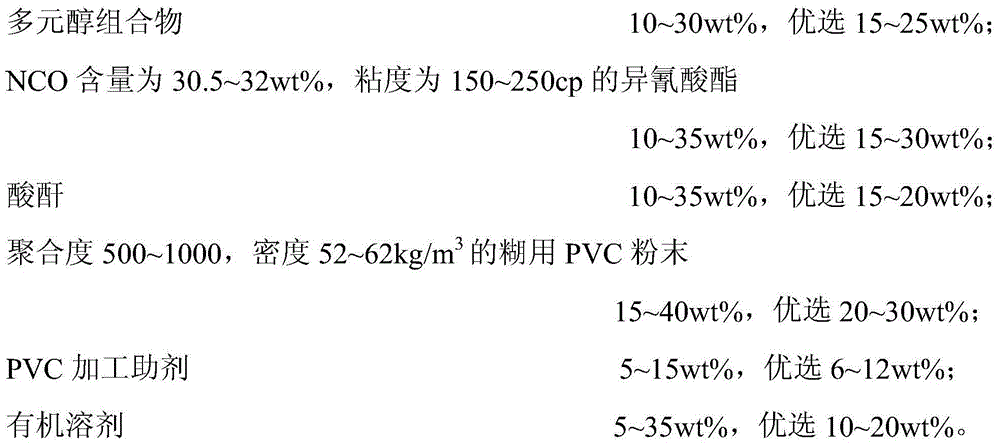

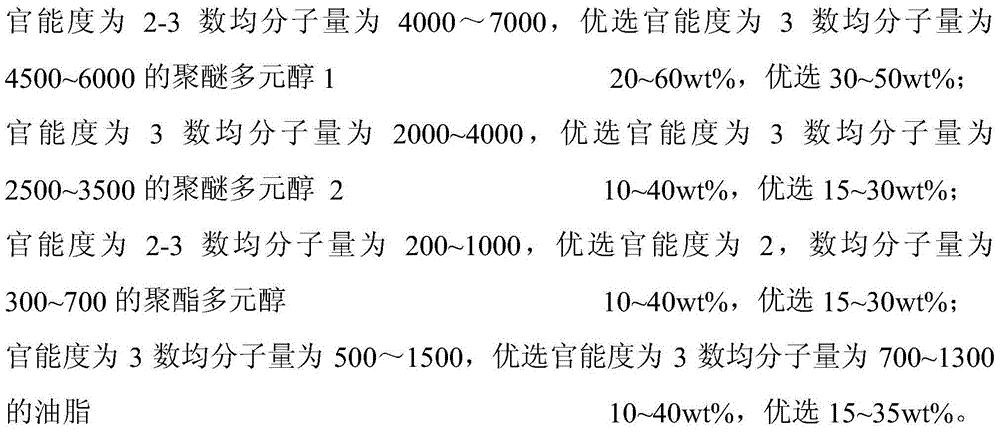

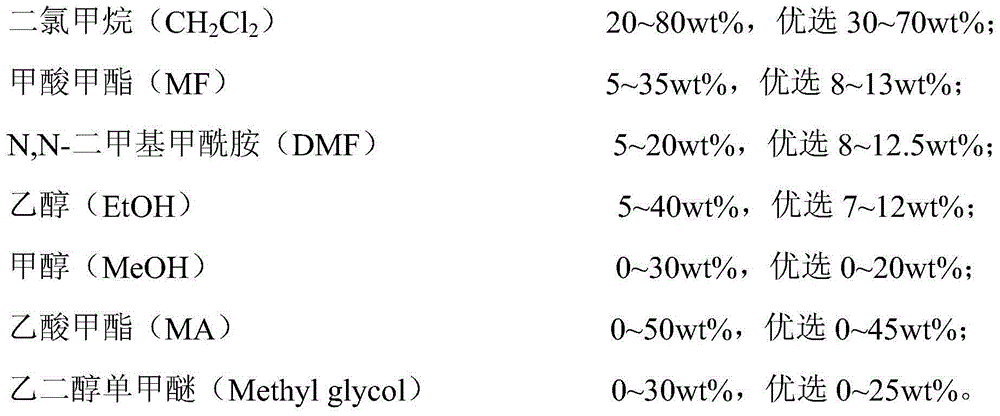

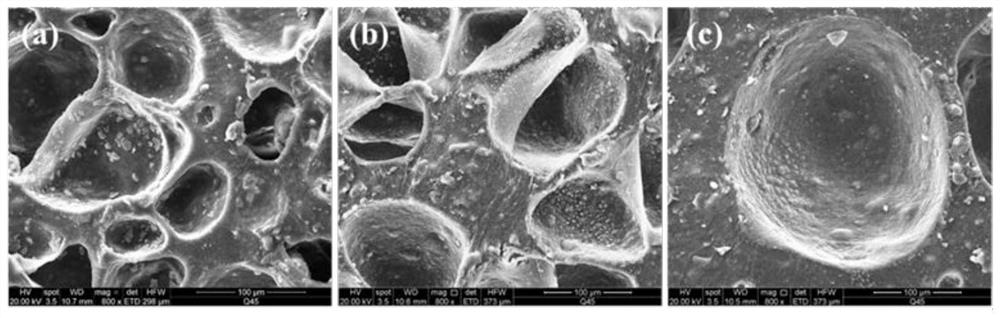

Composite material for preparing polyimide-polyvinyl chloride composite foam material and polyimide-polyvinyl chloride composite foam material

The invention relates to a nontoxic environment-friendly stable-foaming ultralow-density composite material for producing a polyimide-polyvinyl chloride composite foam material, a method for producing the polyimide-polyvinyl chloride composite foam material from the composite material and a polyimide-polyvinyl chloride composite foam material produced by the method. The minimum density of the prepared foam is 30 kg / m<3>, the compression strength is greater than 0.7 MPa, the tensile strength is greater than 1.7 MPa, the heat conductivity coefficient is less than 0.033 w / m.k, the oxygen index is greater than 28%, the water absorptivity is less than 10%, the closed-cell ratio is greater than 80%, the 70-DEG C relative humidity is 95%, and the foam does not shrink after being placed for more than 96 hours. The preparation process is safe and nontoxic, does not use any chemical foaming agent, and prepares the foam under ordinary pressure. Compared with the traditional formula, the tensile strength and compression strength of the foam are obviously enhanced, and the foam density is obviously lowered.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of rubber foaming material with bubble inner wall shell

PendingCN111704755AEnhanced mechanical properties and dimensional stabilityGood dimensional stabilityVinyl acetateButadiene-styrene rubber

The invention relates to a preparation method of a rubber foaming material with a bubble inner wall shell. In order to improve the dimensional stability of the rubber foam material, a thermoplastic polymer and inorganic particles (including spheres, rods and sheets) are usually added into a foam matrix to construct a scaffold structure for hindering molecular chain recovery; since the rigid strength of the thermoplastic polymer that can be processed and foamed together with rubber is insufficient to solve the problem of its dimensional stability. A large number of inorganic particles are introduced, so that the mechanical property of the foaming material is reduced, and meanwhile, organic modification needs to be carried out, which brings difficulty to industrial production. According to the invention, styrene butadiene rubber and an ethylene-vinyl acetate copolymer are used as foaming matrixes, and a small amount of epoxy resin is introduced to regulate and control zinc oxide to be compactly and uniformly dispersed on the inner walls of bubbles to form a layer of inner shell structure; the size stability and the mechanical property of the foaming material are enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

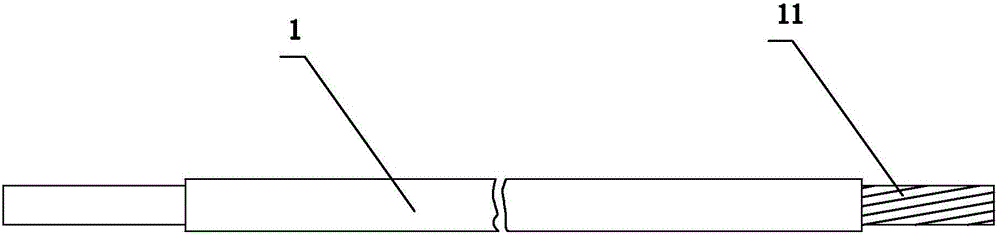

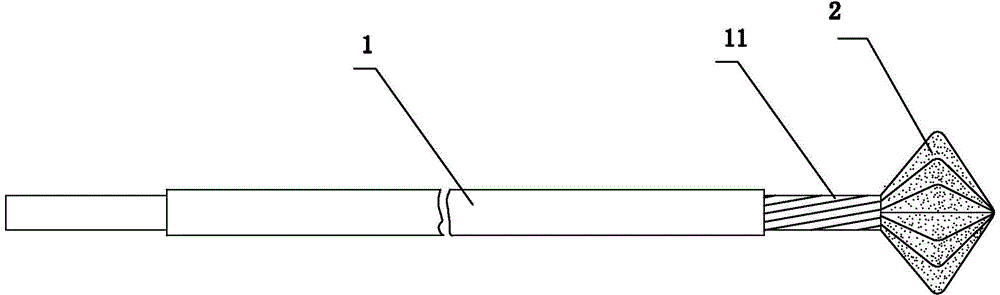

Tension end machining method for car parking and braking cables

The invention discloses a tension end machining method for car parking and braking cables. The method includes the specific steps: 1) peeling one end of one cable; 2) treating the front end of the peeled cable with a punching process to enable the front end of the cable to form a wire rope expansion structure; 3) utilizing high-pressure hot air to blow away plastic fillers in the wire rope expansion structure; 4) subjecting the wire rope expansion structure to treatment of a die casting process to form a die-casting head serving as the tension end of the cable. The method has the advantages that after the plastic fillers in the wire rope expansion structure are blown away with the high-pressure hot air, the die-casting head is formed by means of treatment of the die-casting process; due to the fact that the plastic fillers are removed, air holes cannot be left inside the die-casting head, metal materials on die castings are distributed more uniformly and densely, pulling-out force of the die-casting head is increased effectively and can be increased to about 9000N, and fatigue test can reach 100,000-120,000 times under the same conditions.

Owner:宁波华骏机械有限公司

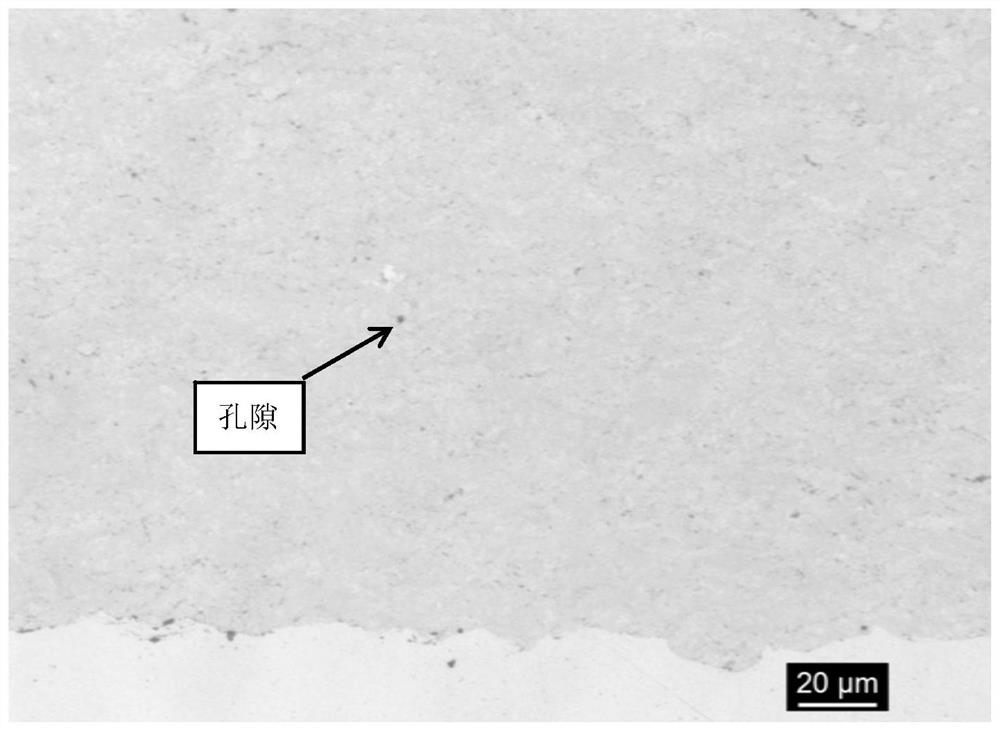

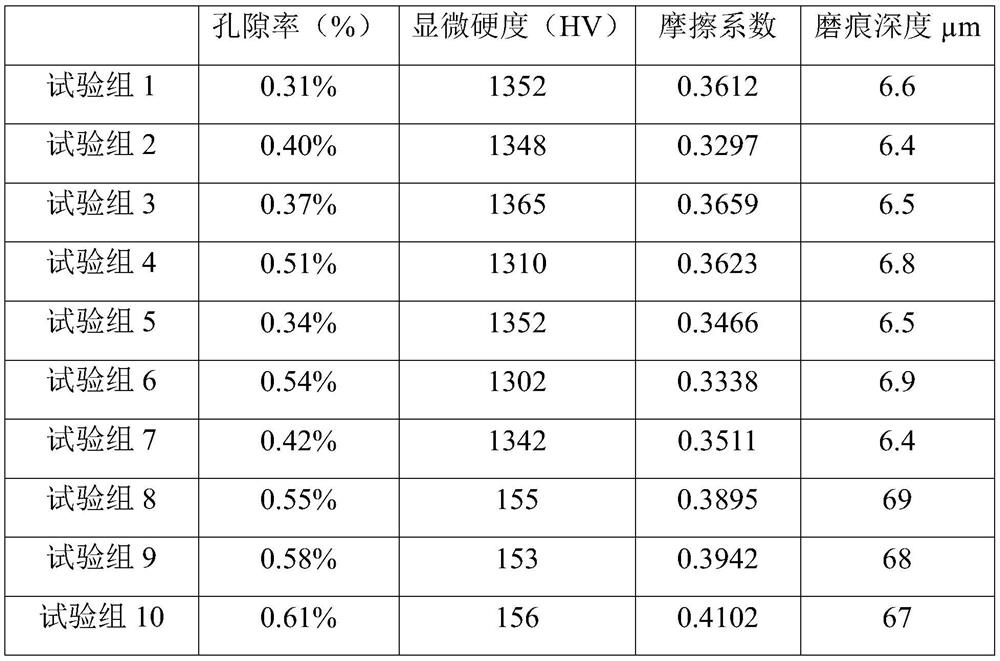

Coating roller, preparation method and application thereof and copper-clad plate

ActiveCN111617926AReduce porosityImprove wear resistanceLiquid surface applicatorsMolten spray coatingCopper coatingChromium coating

The invention discloses a coating roller, a preparation method and application thereof and a copper-clad plate, and belongs to the technical field of copper-clad plates. The coating roller is mainly prepared by spraying a nano tungsten carbide coating on the surface of a roller body in an HVOF supersonic flame spraying mode. When the coating roller is used for preparing the copper-clad plate, copper slurry can be accurately transferred, the loss of the coating is avoided, and meanwhile, the prepared coating can be uniformly and densely distributed and can have a large thickness. By adopting the method of spraying the nano tungsten carbide coating on the surface of the roller body in the HVOF supersonic flame spraying mode, the nano tungsten carbide coating with smaller porosity and bettermicrohardness and wear resistance compared with an existing chromium coating can be prepared on the surface of the roller body. The coating roller is suitable for preparing the copper-clad plate, so that the prepared copper-clad plate has the copper coating with smaller porosity and better microhardness and wear resistance.

Owner:广州粤鑫激光科技有限公司

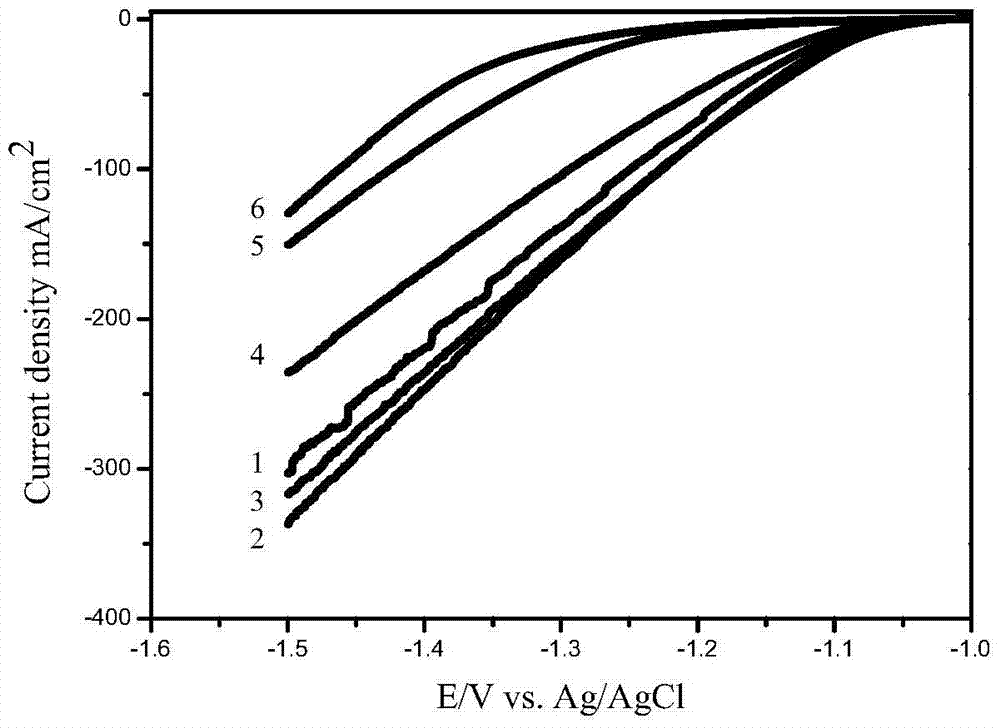

A method for preparing a high-performance molybdenum-based hydrogen evolution electrode from a molybdenum phosphide precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode from a phosphide molybdate precursor, which belongs to the field of electrocatalytic hydrogen evolution in water electrolysis and chlor-alkali industry. In the present invention, the nickel foam is firstly pretreated, and then the molybdate precursor is grown in situ on the surface of the pretreated nickel foam substrate by a hydrothermal synthesis method, and finally the prepared precursor and the phosphorus source are put into a tube furnace together. The molybdate precursor was phosphated to prepare a high-performance molybdenum-based hydrogen evolution electrode. The method of the invention is novel, the required process is simple, the production cost is low, the requirements for equipment are low, and it is suitable for industrial production, and the electrode has a large specific surface area, is firmly combined with the substrate, has excellent hydrogen evolution activity and stability, and can be widely used in water Electrolysis, chlor-alkali industry hydrogen analysis field.

Owner:CHONGQING UNIV

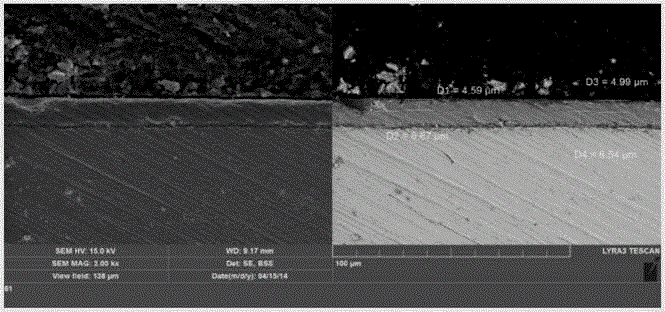

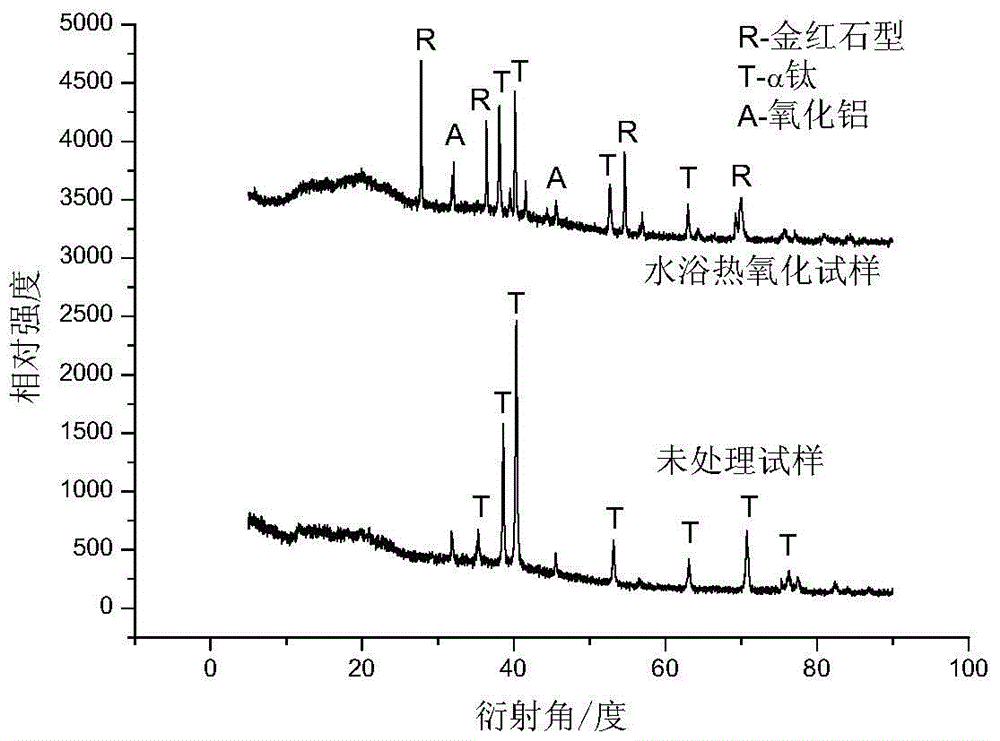

A water-bath thermal oxidation treatment method for the surface of medical titanium and titanium alloys

InactiveCN104498865BGood value for moneySimple processSolid state diffusion coatingWater bathsTitanium

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Anti-corrosion treatment method for inner wall of drill pipe

ActiveCN112626572AGuaranteed anti-corrosion abilityGuaranteed binding conditionsElectrolytic inorganic material coatingTungstenZirconium oxide

The invention discloses an anti-corrosion treatment method for an inner wall of a drill pipe. The inner wall of the drill pipe is electroplated, an electroplating treatment process is divided into two stages, the first stage is electroplating of a semi-bright nickel plating layer, and the thickness of a plating layer is 8-25; and in the second stage, a nickel-tungsten-phosphorus-zirconium oxide plating layer is electroplated, and the thickness of the plating layer is 18-30. The technological process is perfect and effective. The corrosion resistance of the plating layer can be effectively guaranteed, and the production cost can be reduced. The plating layer is uniform in color and luster, smooth in surface, wear-resistant, high in stability, economical and effective, and the abrasion loss of the tool is reduced.

Owner:KARAMAY SHUANGXIN ANTICORROSION TECH

Chinese zodiac bread and preparation method thereof

PendingCN111357794AHigh nutritional valueDelicate tasteBakery productsBiotechnologySodium bicarbonate

The invention discloses Chinese zodiac bread and a preparation method thereof. The Chinese zodiac bread comprises the following raw materials in parts by weight: 20-40 parts of wheat flour, 5-15 partsof egg liquid, 5-10 parts of butter, 1-5 parts of white granulated sugar, 1-2 parts of sodium bicarbonate, 2-5 parts of yeast, 0.5-1 part of a bread modifier, 0.5-1 part of sorbitol liquid, 1-3 partsof edible salt, 0.2-0.5 part of a preservative additive and 2-4 parts of water. According to the Chinese zodiac bread and the preparation method thereof, various Chinese zodiac patterns are formed onthe prepared bread, air holes of the bread are uniformly distributed, and the bread has a high nutritional value, contains water, and has a fine taste.

Owner:麦肯嘉顿(江苏)食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com