Patents

Literature

32 results about "Hydrogen analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

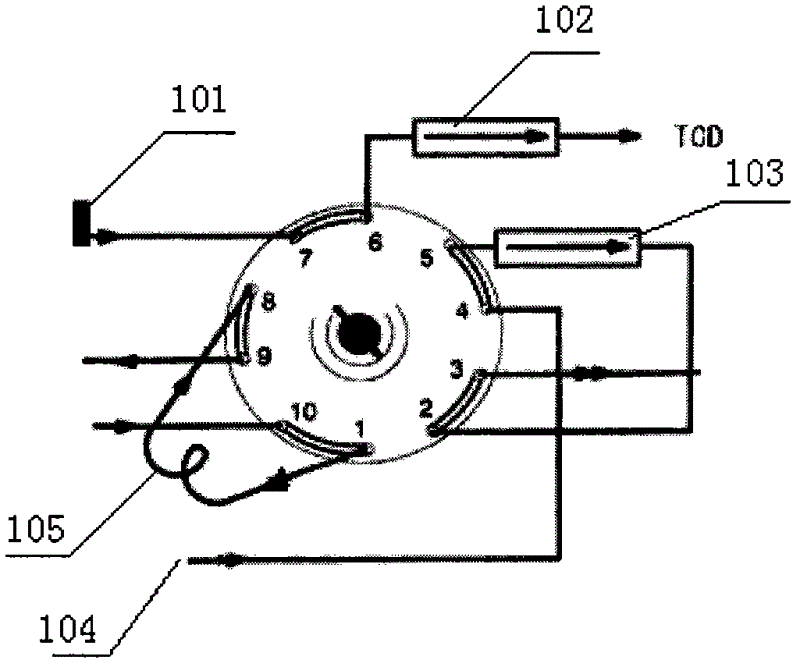

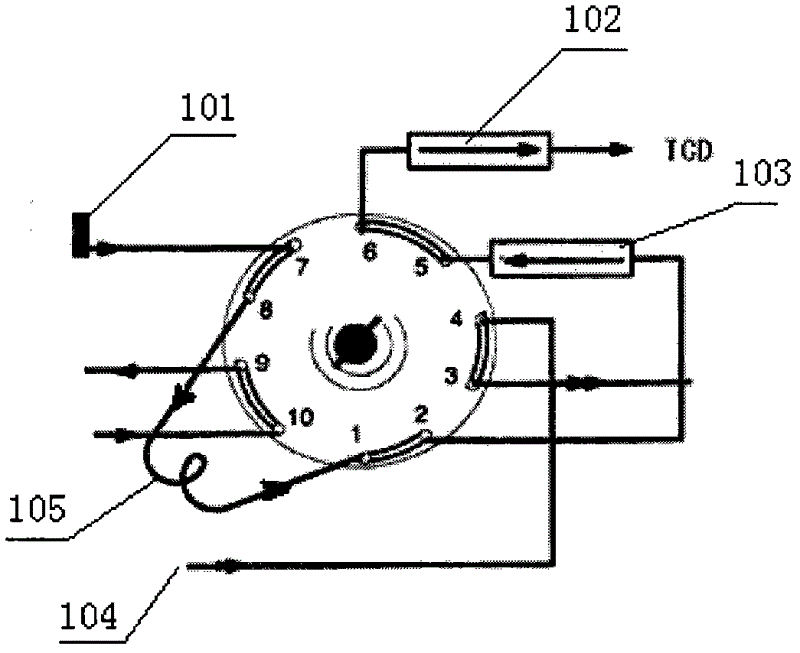

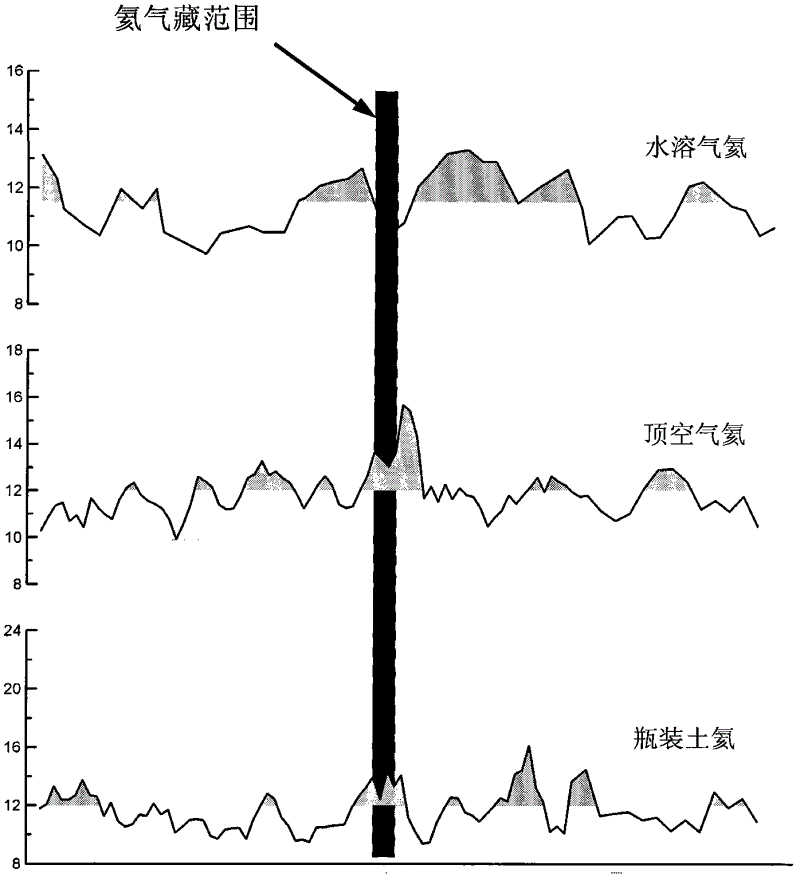

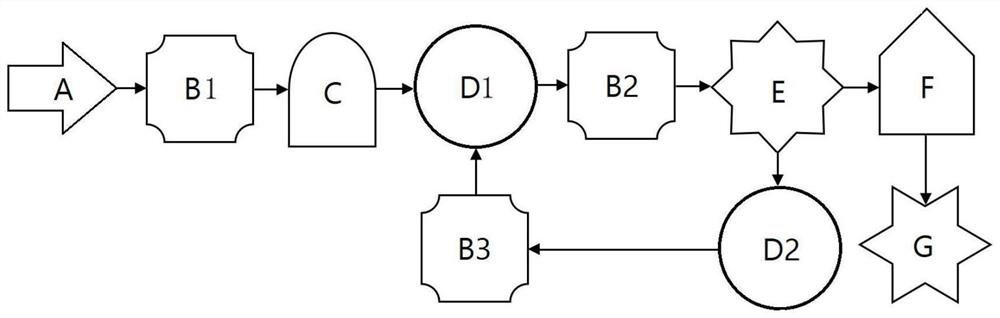

Trace helium, neon and hydrogen gas analysis method and device

InactiveCN102621251AEfficient separationConducive to re-separationComponent separationGas analysisGas liquid chromatographic

The invention provides a trace helium, neon and hydrogen gas analysis method and device, belonging to the field of separation and detection of helium, neon and hydrogen in natural gas. The method comprises the following steps: firstly carrying out a first separation on a mixed gas sample, separating helium, neon and hydrogen gases from other heavy gas components, then carrying out a second separation on the mixed gas sample without the other heavy gas components, separating helium, neon and hydrogen gases out respectively, and finally inputting the helium, neon and hydrogen one by one in a high-sensitivity gas chromatograph thermal conductivity detector for detection, and venting the separated heavy gas components by back flushing while conducting the detection. The device of the invention adopts a double-column series structure, and simultaneously optimizes chromatographic column packing materials and chromatographic analysis conditions. According to the invention, the effective separation and detection of trace helium, neon and hydrogen are realized, the analysis time is shortened, the analytical chromatographic columns are protected, and the service life of the chromatographic column is prolonged. The method can be continuously applied for trace helium, neon and hydrogen analysis of mass samples.

Owner:CHINA PETROLEUM & CHEM CORP +1

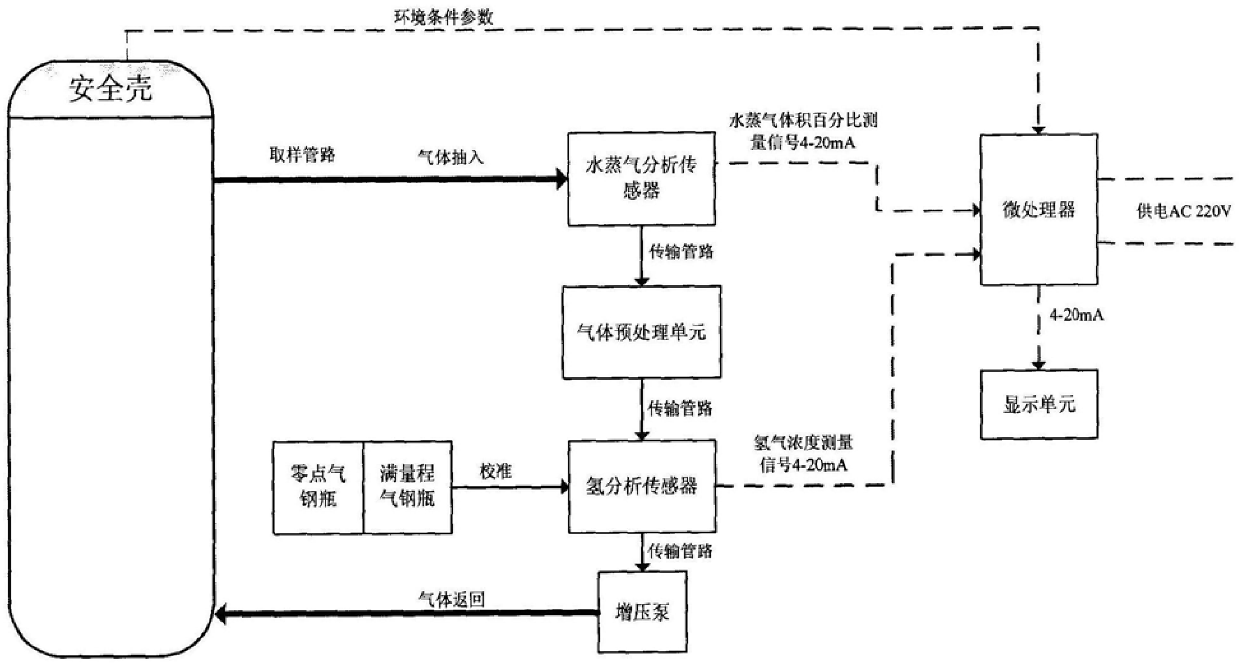

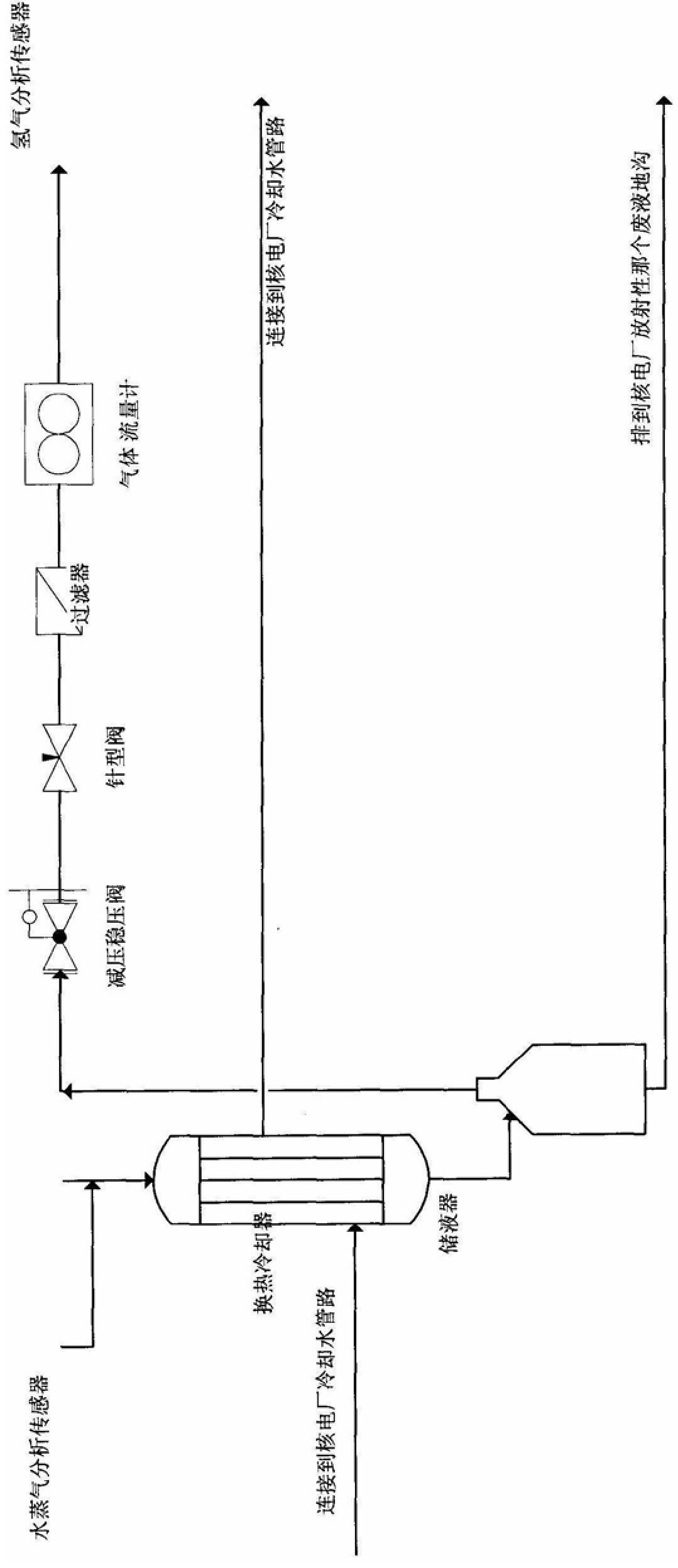

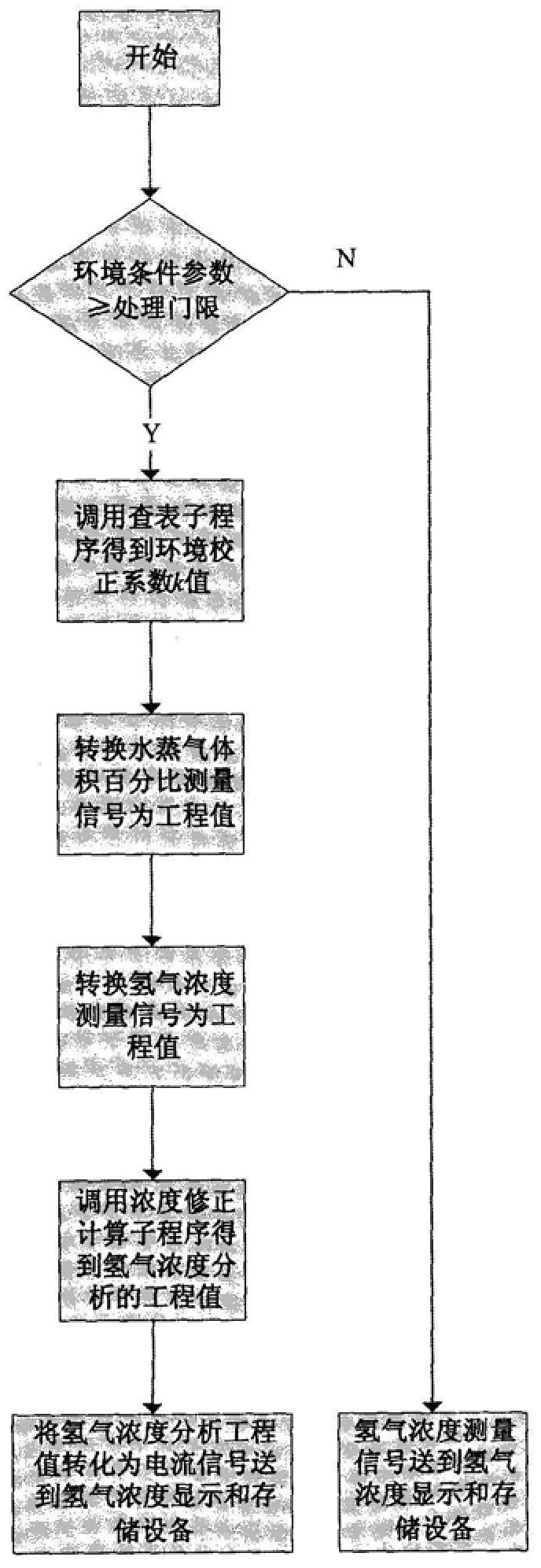

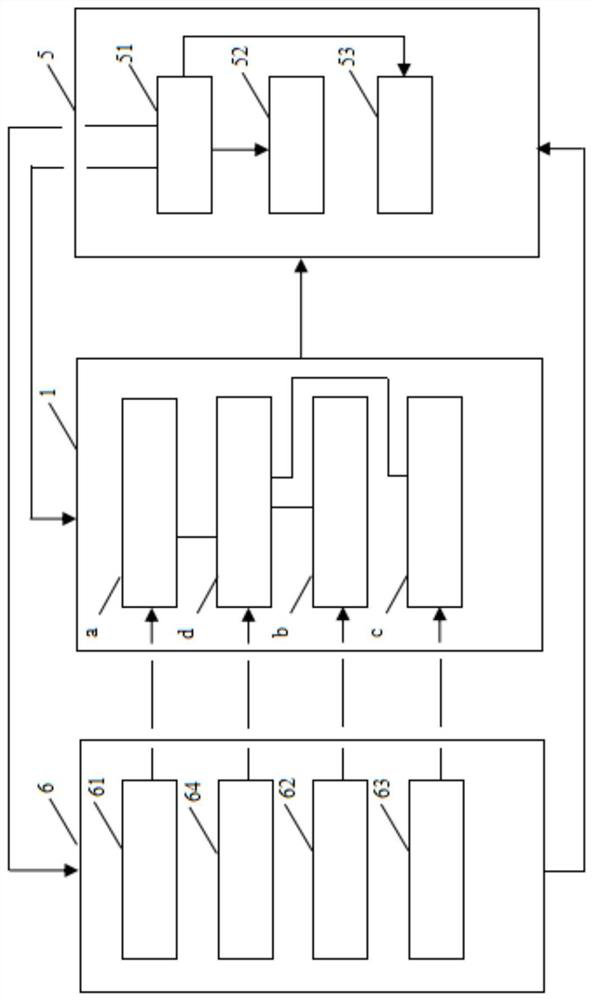

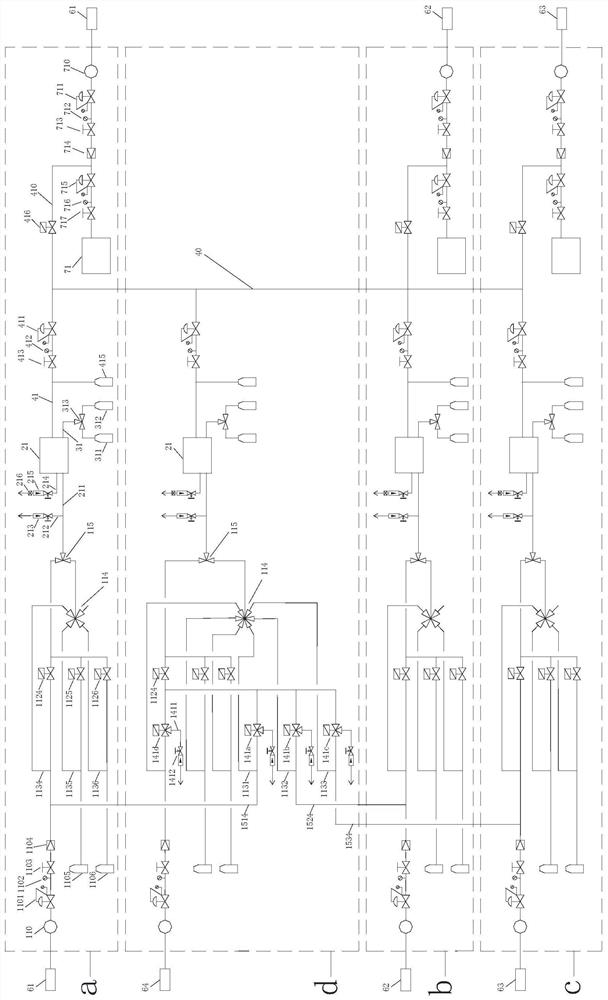

A Sampling and Analysis System for Measuring Hydrogen Concentration in Containment Vessel

ActiveCN106342210BMeet the requirements of long-term monitoringAvoid destructionWeighing by removing componentSamplingGas analysisHydrogen concentration

A sampling analysis system for measuring the concentration of hydrogen in the containment vessel, comprising: a sampling pipeline, a transmission pipeline, a water vapor analysis sensor, a gas pretreatment unit, a hydrogen analysis sensor, a booster pump, a microprocessor, and a display unit; The gas in the containment is extracted by the sampling pipeline with thermal insulation treatment function, and the gas is processed to normal temperature and pressure by the pretreatment unit after passing through the water vapor analysis sensor, and the hydrogen volume in the pretreated gas is measured by the hydrogen analysis sensor Concentration, the microprocessor determines the current hydrogen volume concentration in the containment according to the measurement results of the sensor and outputs and displays it. It adapts to the use requirements of common gas analysis sensors and eliminates the influence of water vapor on the gas extraction measurement method in the containment by preprocessing the measured gas and combining with the preset algorithm program in the microprocessor. It is especially suitable for accurate measurement of the volume concentration of hydrogen or other explosive gas components in the containment under accident conditions of nuclear power plants.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

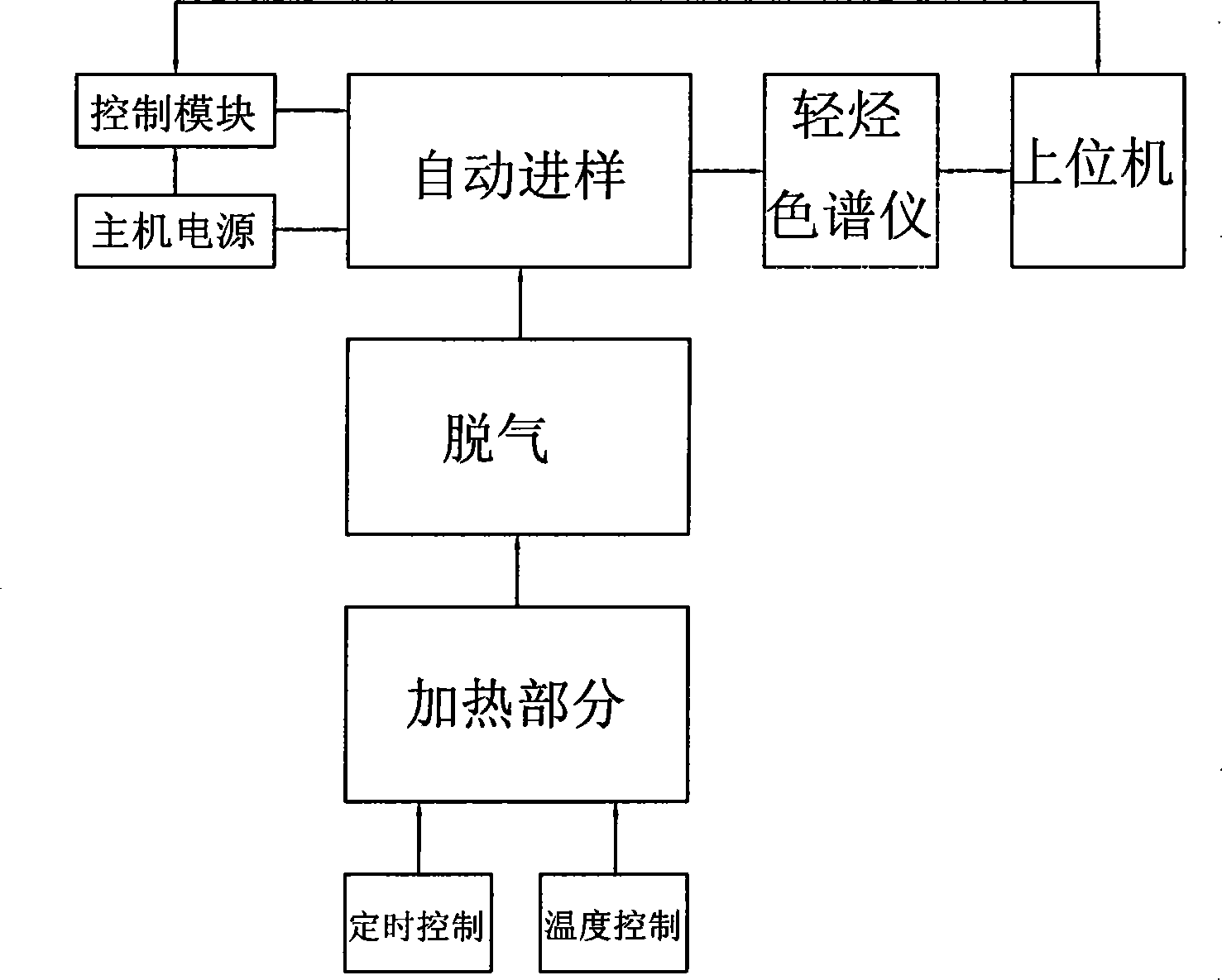

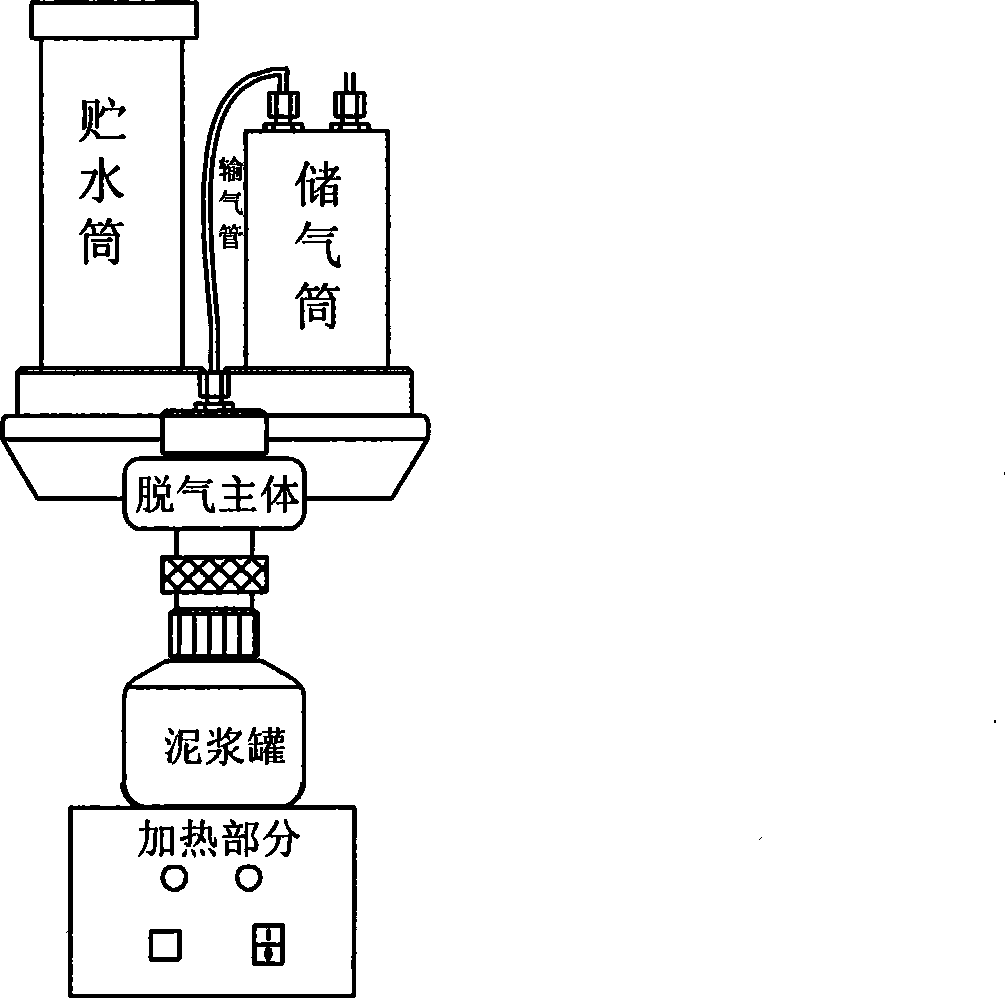

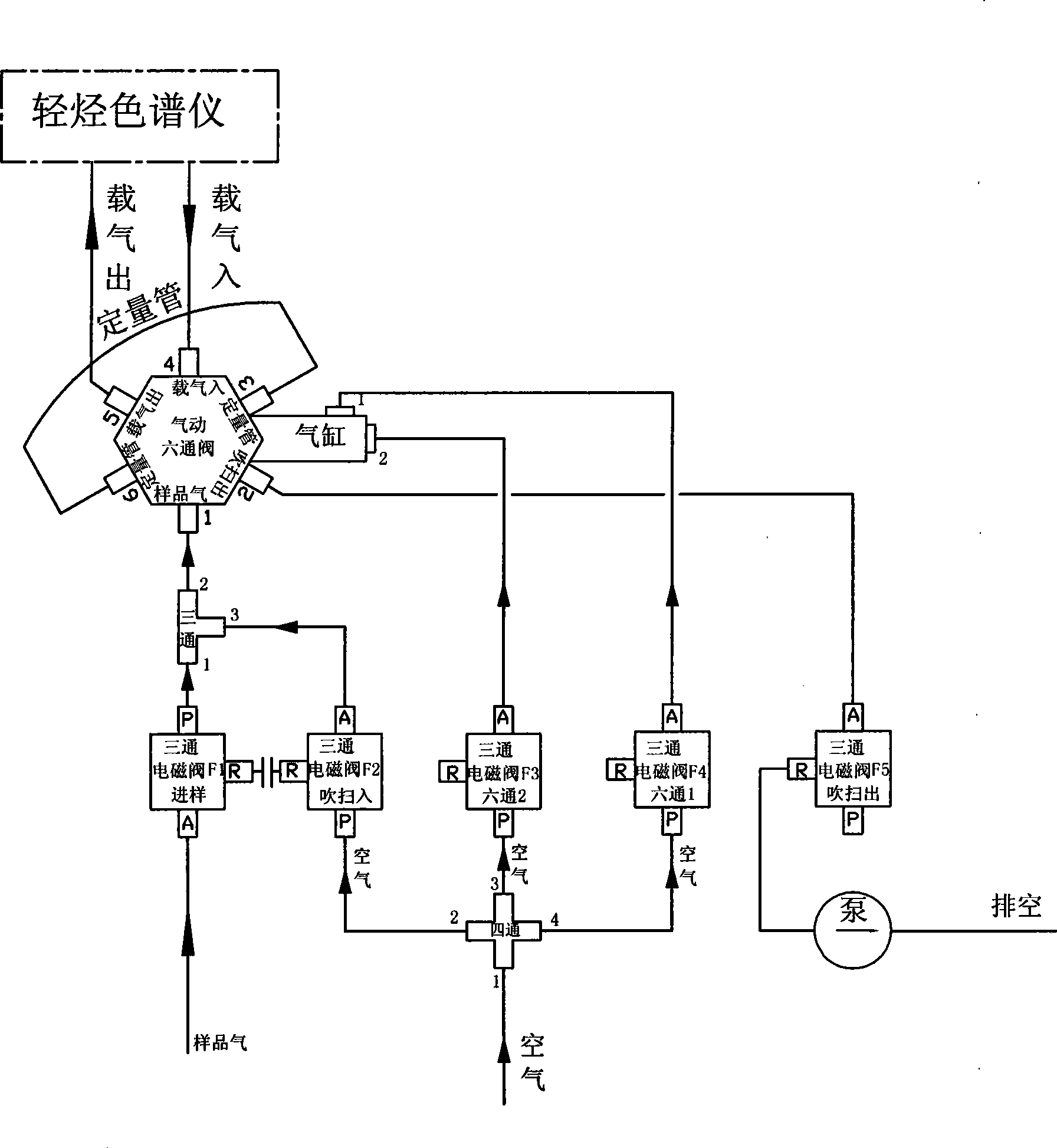

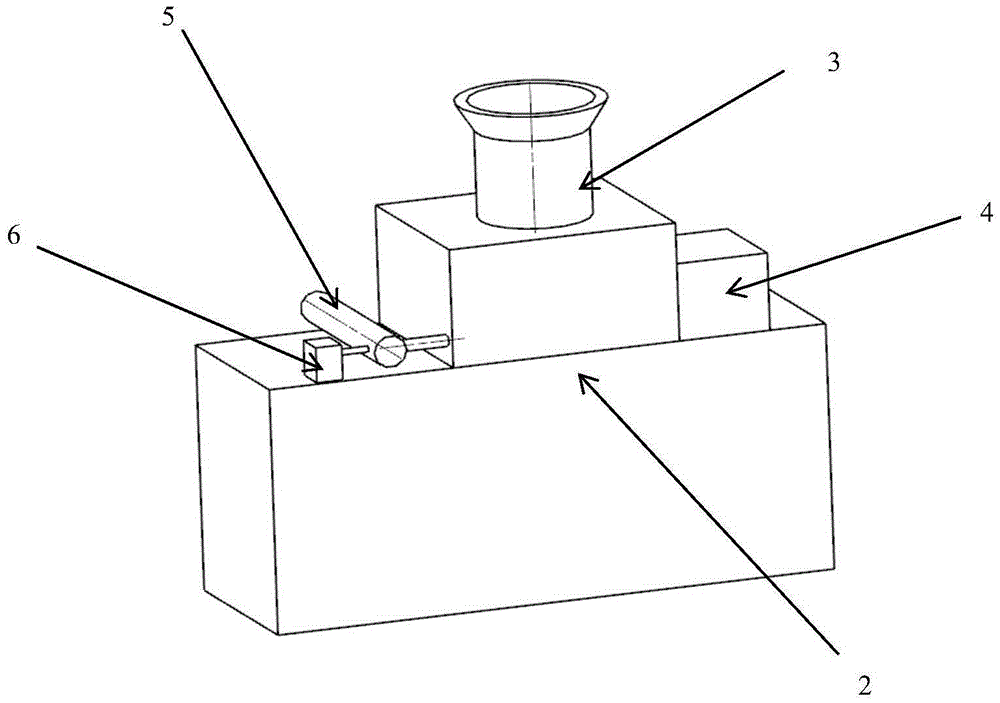

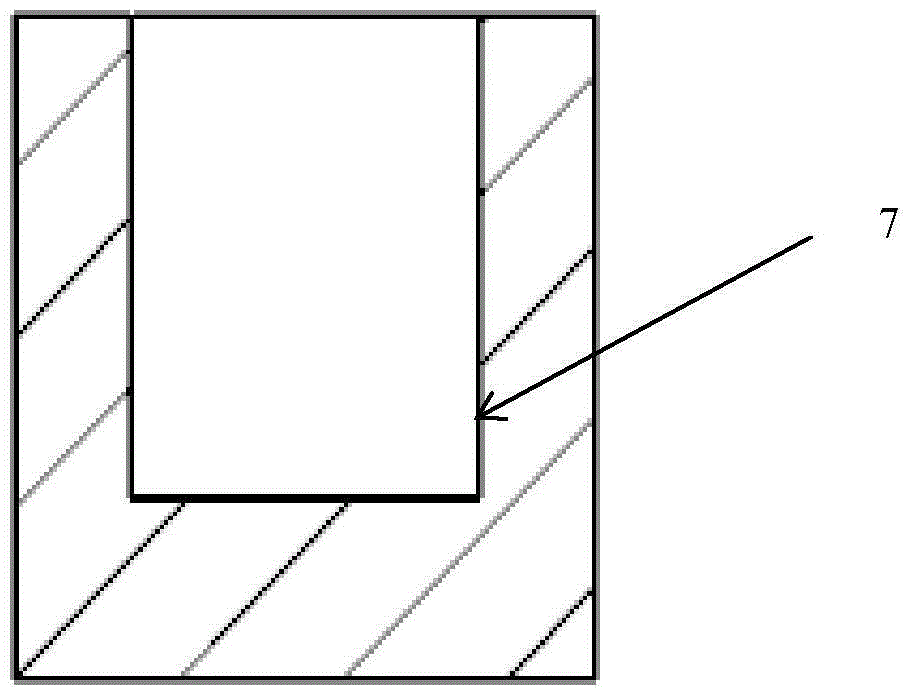

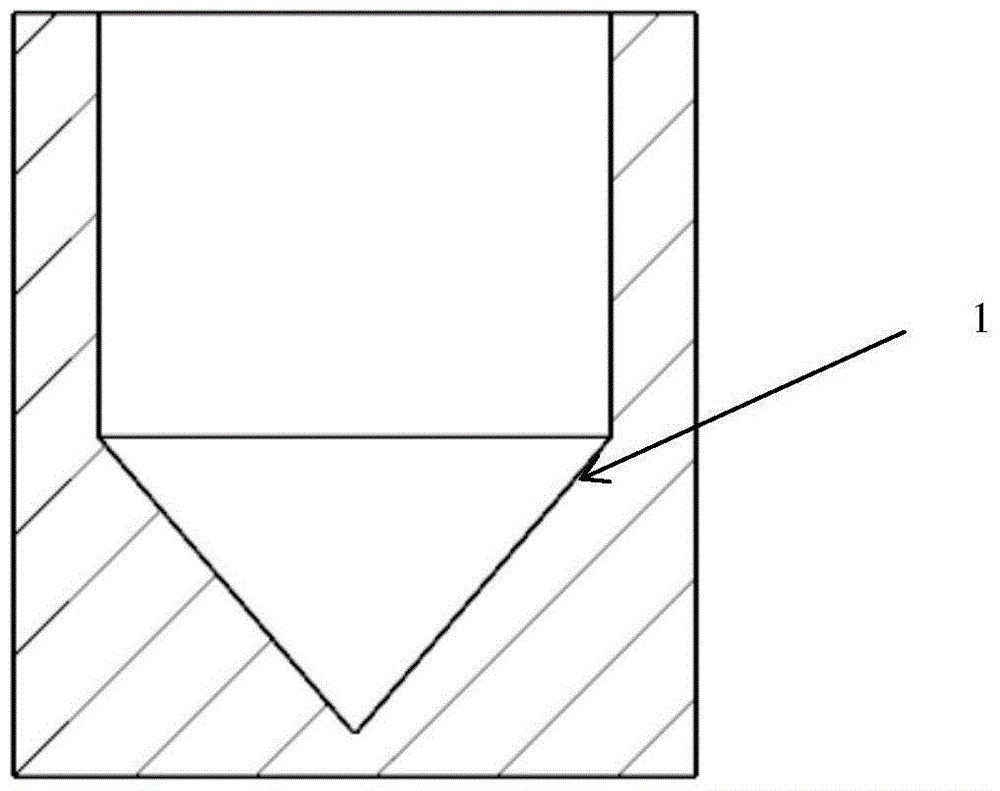

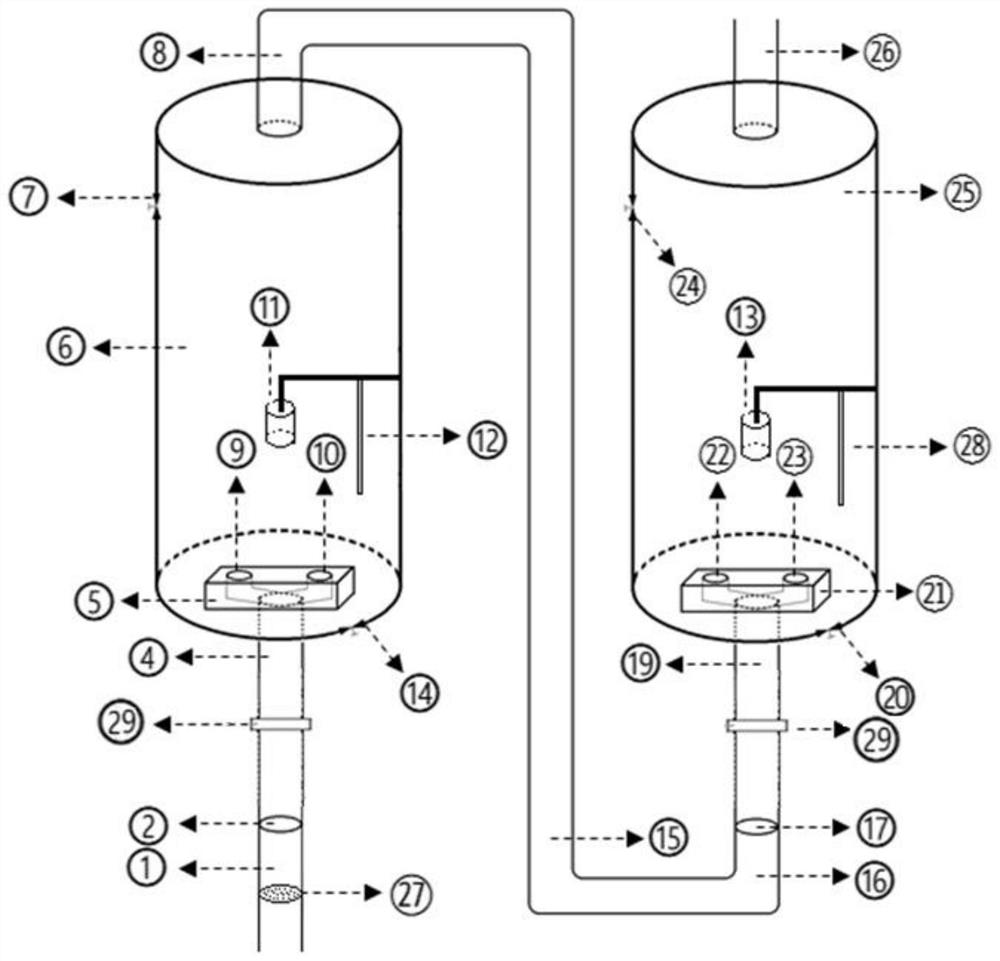

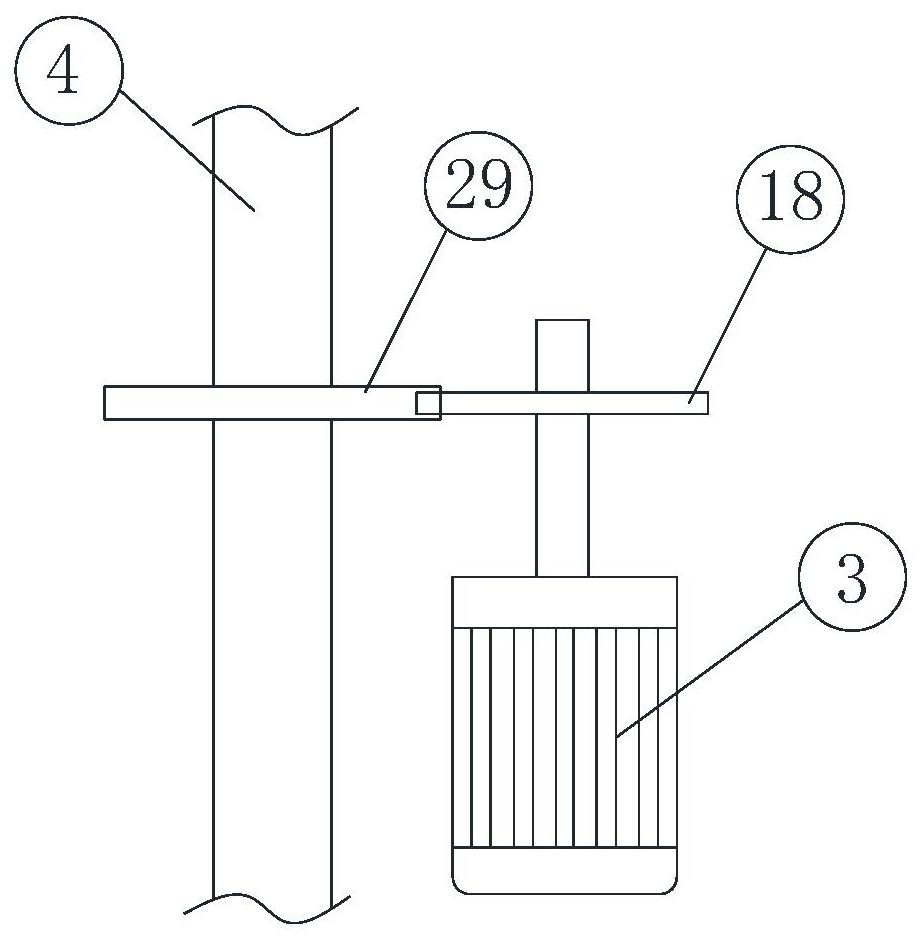

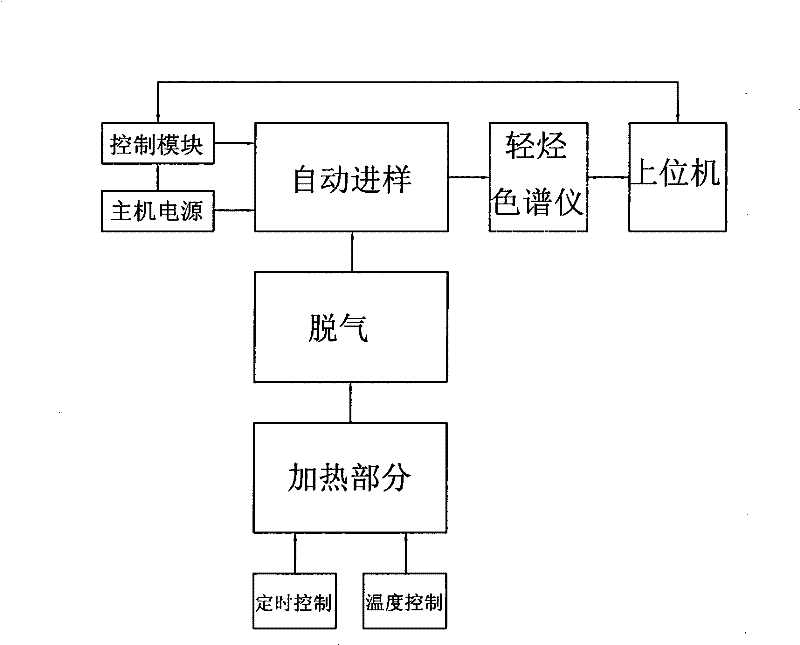

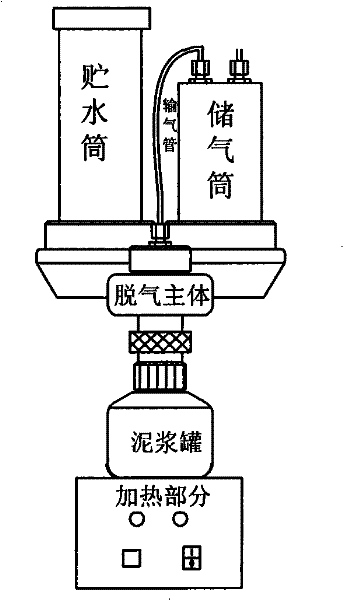

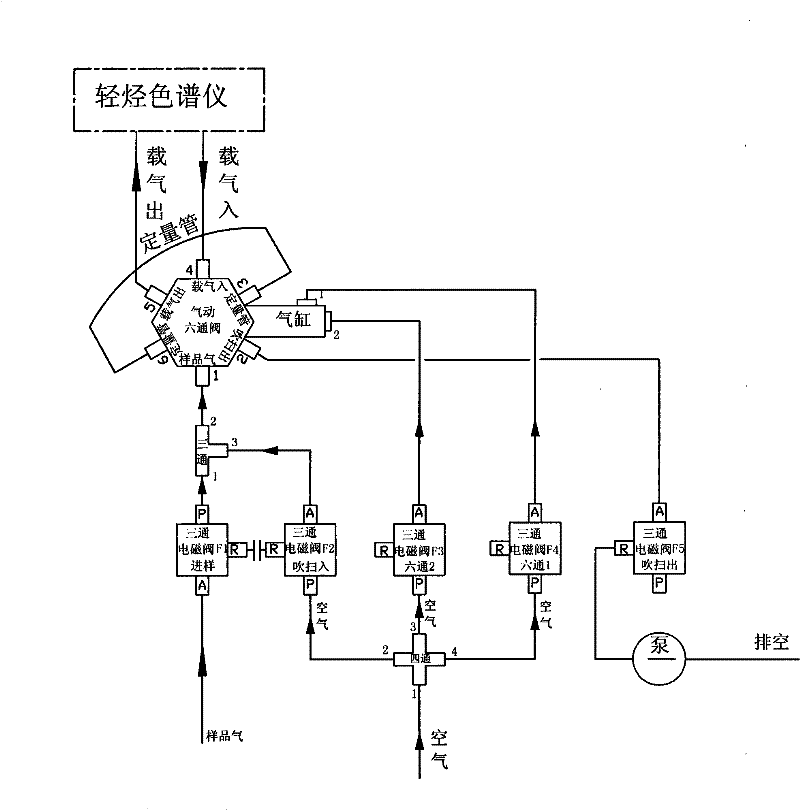

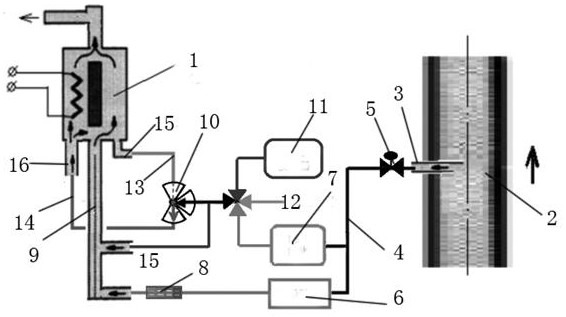

Complete-releasing-light hydrocarbon automatic sample handling system

ActiveCN101424669AAvoid pollutionEnsure consistencyComponent separationWithdrawing sample devicesEngineeringSlurry

The invention relates to a full-degassing-lighter-hydrocarbon automatic sample introducing system used for lighter hydrogen analysis. The full-degassing-lighter-hydrocarbon automatic sample introducing system comprises a heating part, a timing control part, a temperature control part, a heat distilling degasser, an automatic sample introducing system, a power supply and an R232 circuit which are assembled in a casing, wherein the timing control part, the temperature control part and the heating part are connected together. A mud slurry pot of the heat distilling degasser is arranged on the heating part, the heat distilling degasser and the automatic sample introducing system are connected with the A end of a T-shaped electromagnetic valve of the automatic sample introducing system by the sample gas outlet of the heat distilling degasser, and the automatic sample introducing system is connected with the R232 circuit. The invention has the advantages of full automation, and no boiling phenomenon if the mud slurry is heated; the danger is reduced, the pollution of the chromatogram post caused by the separation of heavy hydrocarbon is avoided, quantitative tubes are used for sample introduction, the consistency of the sample introducing quantity at each time is guaranteed, and the analyzing performance of the instrument is improved.

Owner:天津陆海石油设备系统工程有限责任公司

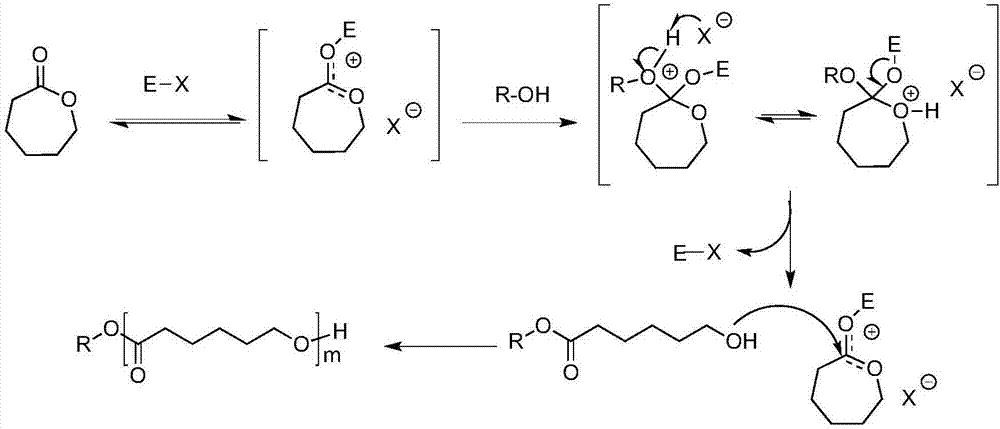

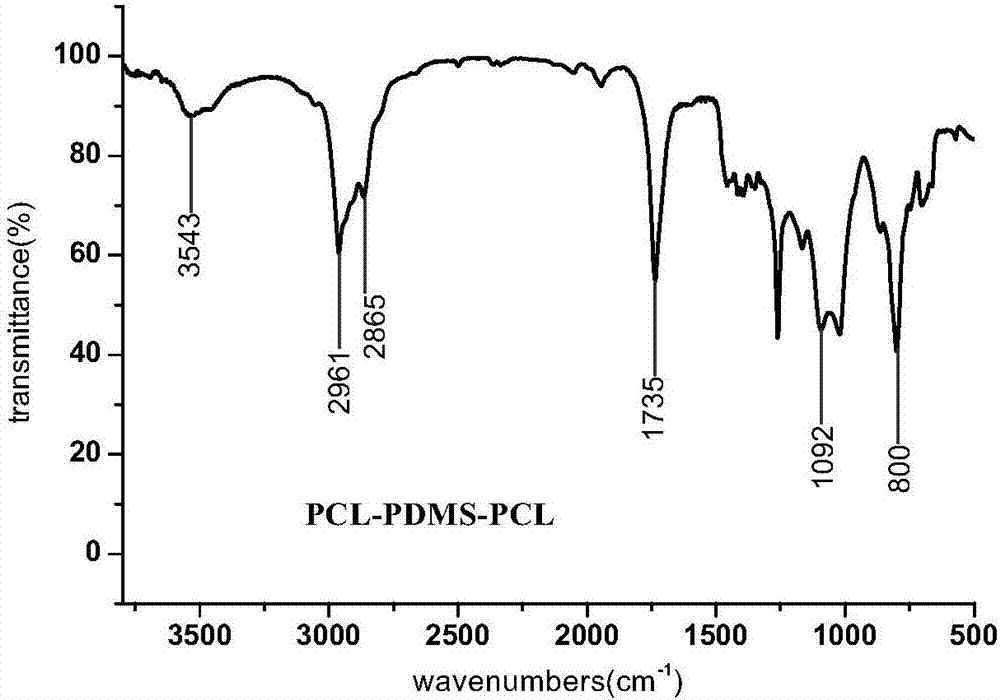

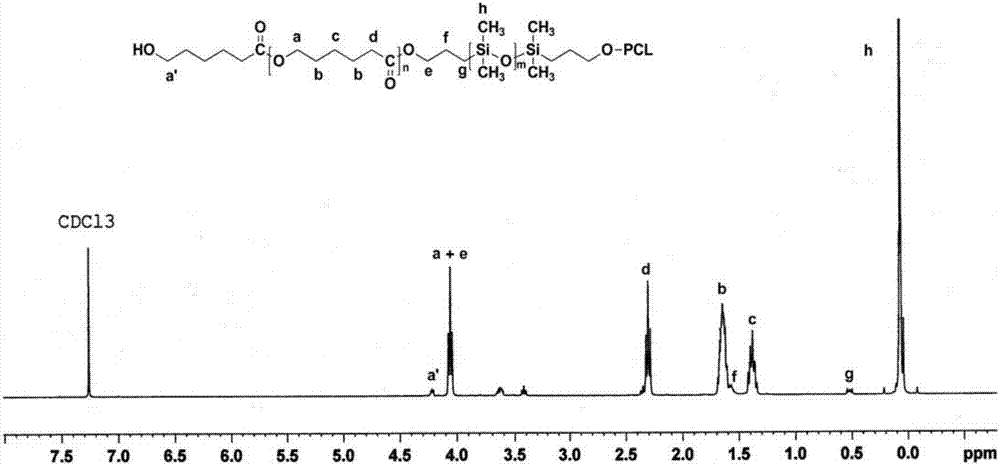

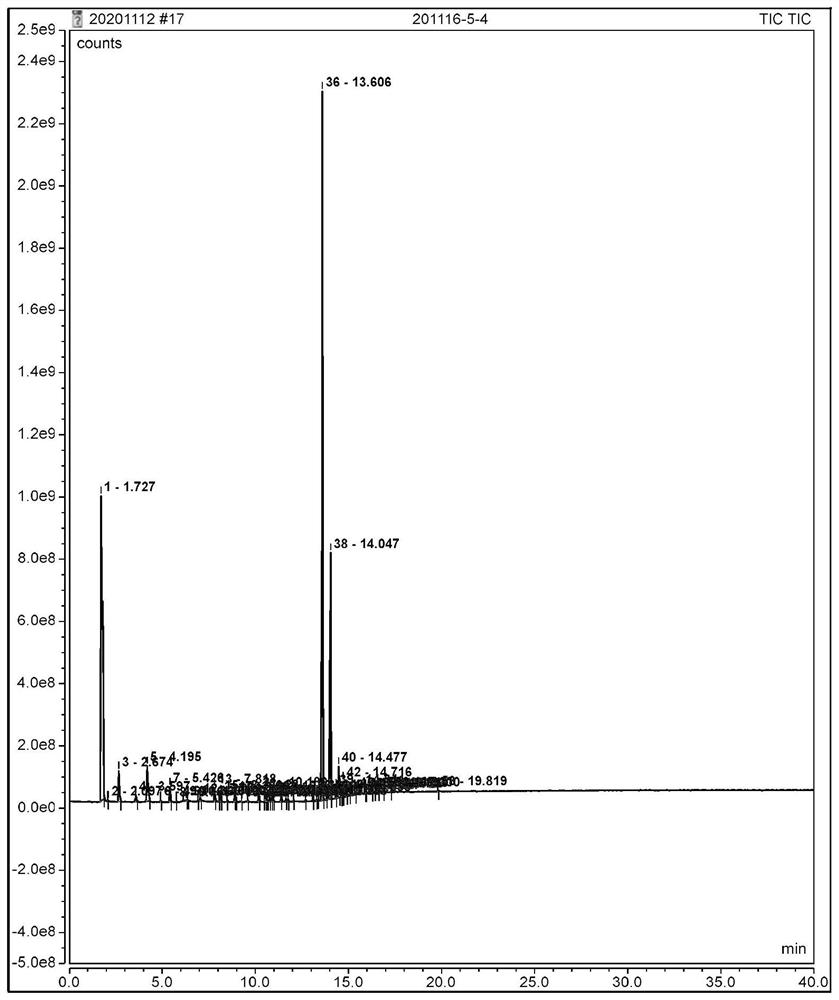

Method for preparing PCL-PDMS-PCL stabilizing agent by hydrogen chloride/ether solution catalysis

InactiveCN107163237AAvoid side effectsMild reaction conditionsBulk chemical productionDiethyl etherRing-opening polymerization

The invention relates to a method for preparing a PCL-PDMS-PCL stabilizing agent by hydrogen chloride / ether solution catalysis. The method comprises the following steps: initiating epsilon-caprolactone (epsilon-CL) ring opening polymerization by adopting hydroxypropyl terminated polydimethylsiloxane (HTPDMS) as an initiator and a hydrogen chloride / ether solution (HCL.Et20) as a catalyst to prepare a tri-block stabilizing agent polycaprolactone-b-polydimethylsiloxane-b-polycaprolactone (PCL-PDMS-PCL). Infrared spectroscopy and nuclear magnetic resonance hydrogen analysis indicate that the synthesized molecules are accordant with the structure of a target molecule. The optimized reacting conditions include a reacting temperature of 25 DEG C, a reacting time of 4 hours and a molar ratio of HCL.Et2O to HTPDMS being 2:1. The method can be used for solving a conventional problem caused by adopting a metal catalyst since the hydrogen chloride / ether solution is adopted as the catalyst, the preparation environment is environment-friendly, the reacting time is remarkably shortened, and the prepared tri-block stabilizing agent can be applied to a dispersing agent of biopharmaceutical polymerization in supercritical fluids.

Owner:DALIAN UNIVERSITY

A kind of preparation method of p-acetoxybenzoic acid

ActiveCN102276454AReduce dosageImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationBenzoic acidAcetic anhydride

The invention discloses a method for preparing p-acetoxy-benzoic acid. The method comprises the following steps of: reacting p-hydroxybenzoic acid as a raw material, acetic anhydride as an acylating agent and pyridine as a catalyst in a condition of 1.2-1.5 times of the excessive acetic anhydride: firstly, adding a certain amount of the p-hydroxybenzoic acid and the acetic anhydride into a reactor; dropwise adding the pyridine while stirring and raising the temperature to 80-85 DEG C; controlling the dropwise adding speed, wherein preferentially the temperature raising speed of a reactant is not beyond 10 DEG C; keeping the reaction temperature and continuously stirring for 2-3 h after adding the p-hydroxybenzoic acid and the pyridine and completely converting the reactant into crystals; and finally, repetitively washing the cooled reactant till the pH value of filtrate is 3-4 so as to obtain a crude product of acetoxy-benzoic acid. Both purities of a liquid chromatogram analysis result and a nuclear magnetic resonance hydrogen analysis result of the p-acetoxy-benzoic acid are more than 99.5%. According to the method disclosed by the invention, the conversion rate of the p-acetoxy-benzoic acid is more than 96%; furthermore, the content of by-products is low; and the difficultly for further refining and purifying the product is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

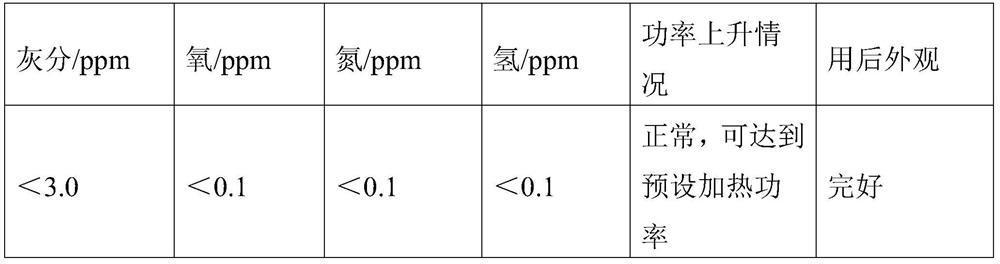

Carrier gas purification filter pipe for oxygen-nitrogen-hydrogen analyzer, furnace head and oxygen-nitrogen-hydrogen analyzer

ActiveCN105223135AHigh precisionReduce analysis costsMaterial heat developmentMaterial analysis by optical meansNitrogenGraphite

The invention relates to a carrier gas purification filter pipe for an oxygen-nitrogen-hydrogen analyzer, a furnace head and an oxygen-nitrogen-hydrogen analyzer, and belongs to the technical field of oxygen-nitrogen-hydrogen analysis. The carrier gas purification filter pipe for the oxygen-nitrogen-hydrogen analyzer comprises a filter pipe and a filtering material arranged in the filter pipe and used for filtering gas, as well as a linear displacement detector used for detecting the displacement of the filtering material. According to the carrier gas purification filter pipe for the oxygen-nitrogen-hydrogen analyzer, the linear displacement detector is used for precisely displaying the amount of graphite powder adsorbed by the filtering material in the filter pipe, and the filtering material can be timely replaced, so that the precision of an analysis result is improved, and the analysis cost is reduced.

Owner:LUOYANG PENGQI IND

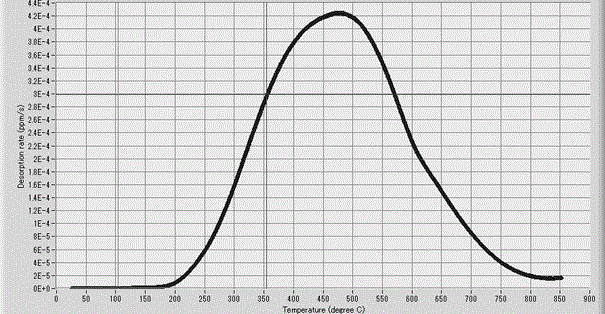

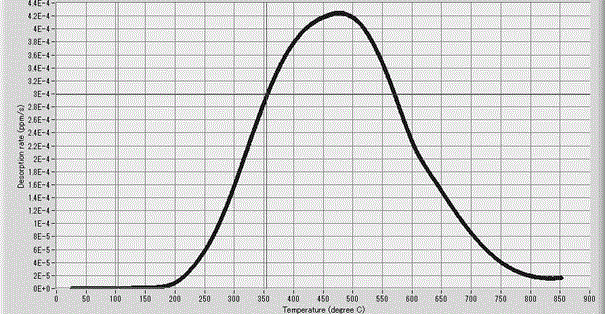

Method for accurately measuring steel hydrogen evolution temperature range

InactiveCN105842271ASolve problems that cannot be tested directlyReliable test resultsInvestigating phase/state changeUltra-high vacuumHeating temperature

The invention relates to a method for accurately measuring the hydrogen evolution temperature range of steel materials, which is to uniformly heat the pretreated steel samples to the target temperature in an ultra-high vacuum state, the heating rate is 100-300 °C / h, and the target temperature is 800 °C ~850°C; during the uniform heating process, use a hydrogen analysis mass spectrometer to measure the change of the hydrogen evolution rate of the sample with temperature, and find out the temperature range corresponding to the fastest range of hydrogen evolution rate according to the change law of hydrogen evolution rate with temperature, which is the test The optimal hydrogen evolution temperature range of the sample. It solves the problem that the temperature range is difficult to set in the traditional hydrogen expansion process, and can solve the problem that the previous hydrogen measurement method has limitations on the sample requirements. It is a simple, fast, accurate, and environmentally friendly method for measuring the optimum temperature of hydrogen evolution, which fills the blank that cannot accurately measure the hydrogen evolution temperature range of steel materials.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Dual-mode full-range oxygen-nitrogen-hydrogen analyzer

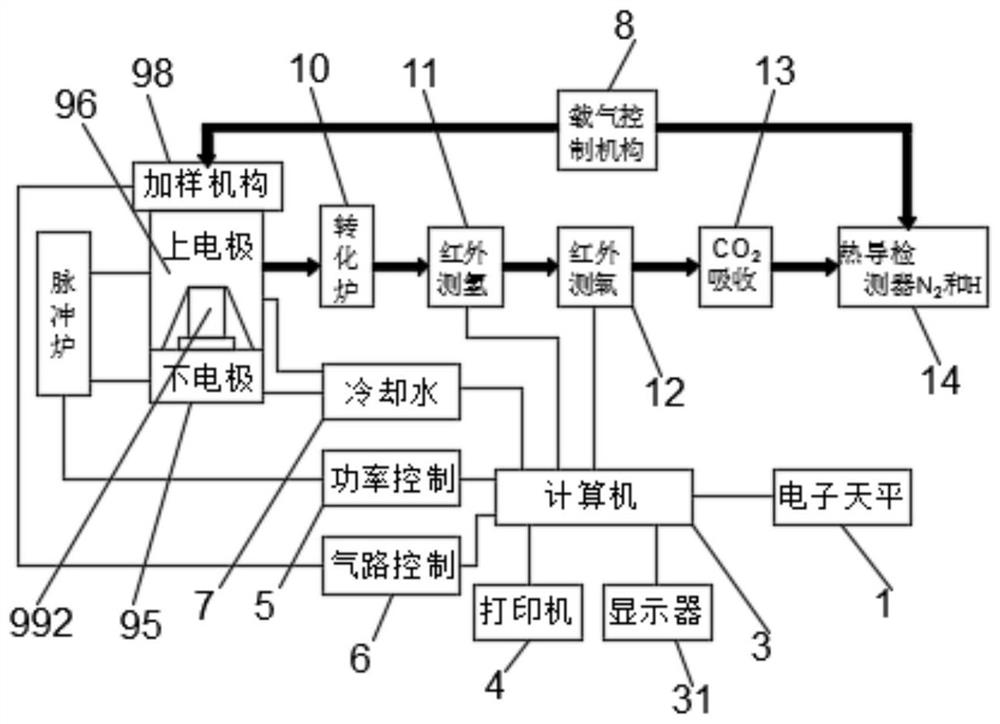

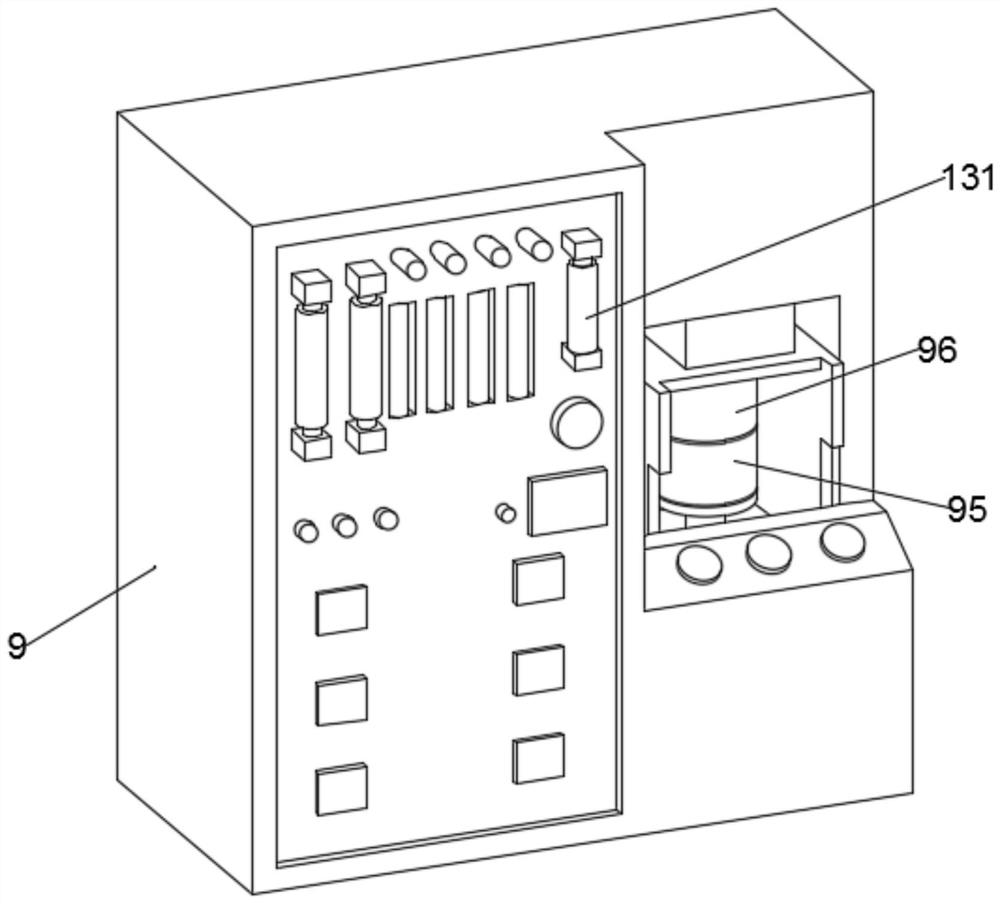

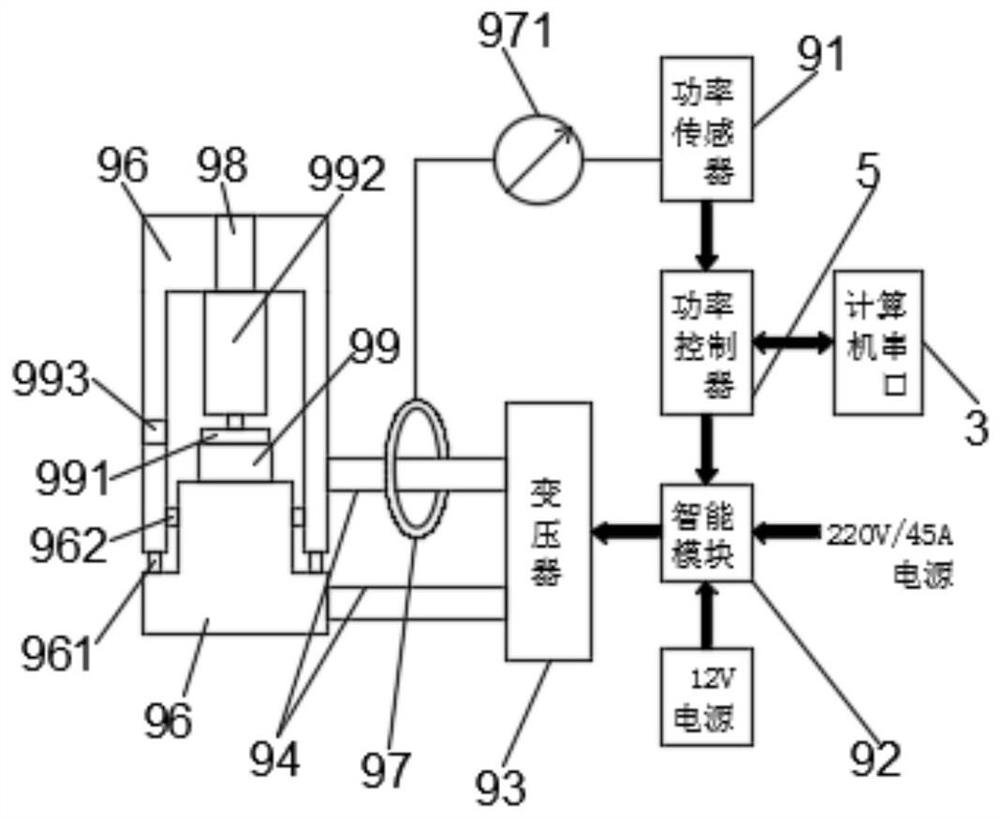

PendingCN114486797AHigh precisionSimple and elegant appearanceMaterial analysis by optical meansFluid pressure measurementAutomatic controlComputer printing

The invention provides a dual-mode full-range oxygen-nitrogen-hydrogen analyzer, relates to the technical field of oxygen-nitrogen-hydrogen analyzers, solves the problems of low automation degree and inaccurate analysis of the existing oxygen-nitrogen-hydrogen analyzer, and comprises an electronic balance, an analysis host, a computer and a printer, the analysis host is connected with the computer through a power controller and a gas circuit controller, the analysis host is connected with a cooling-water machine, and the cooling-water machine is controlled through the computer. According to the method, the temperature of a pulse furnace heating device reaches 2000-3000 DEG C, nitrogen in a sample is released, and the percentage content of oxygen and the percentage content of hydrogen in the detected sample are indirectly determined through an infrared hydrogen measurement analysis pool and an infrared oxygen measurement analysis pool respectively; finally, CO2 in the gas is filtered through a CO2 treatment device, the percentage content of nitrogen is determined through a thermal conductivity detection pool, and the analysis accuracy can be effectively improved through automatic control of a gas path system.

Owner:上海品彦光电科技有限公司

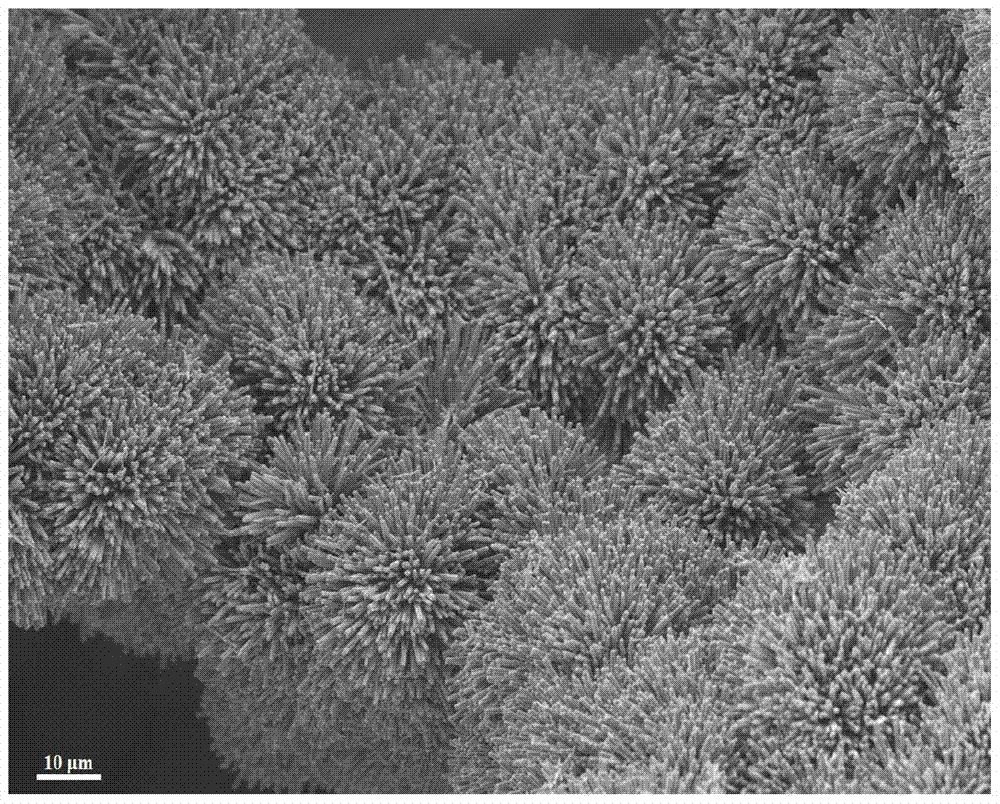

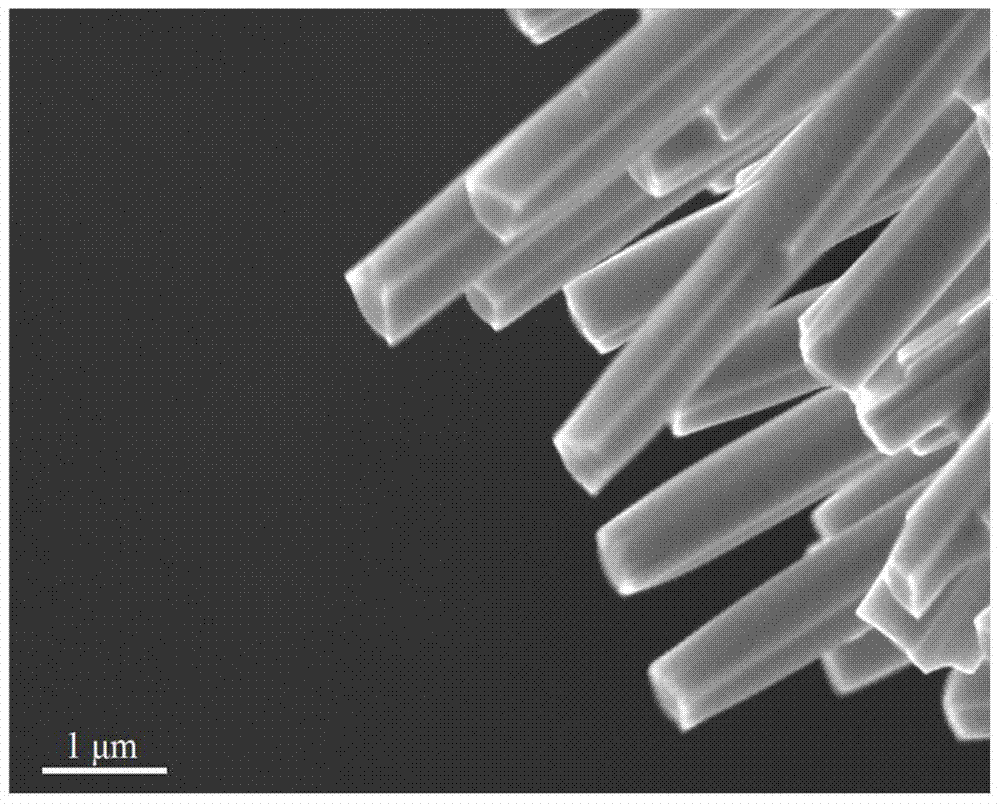

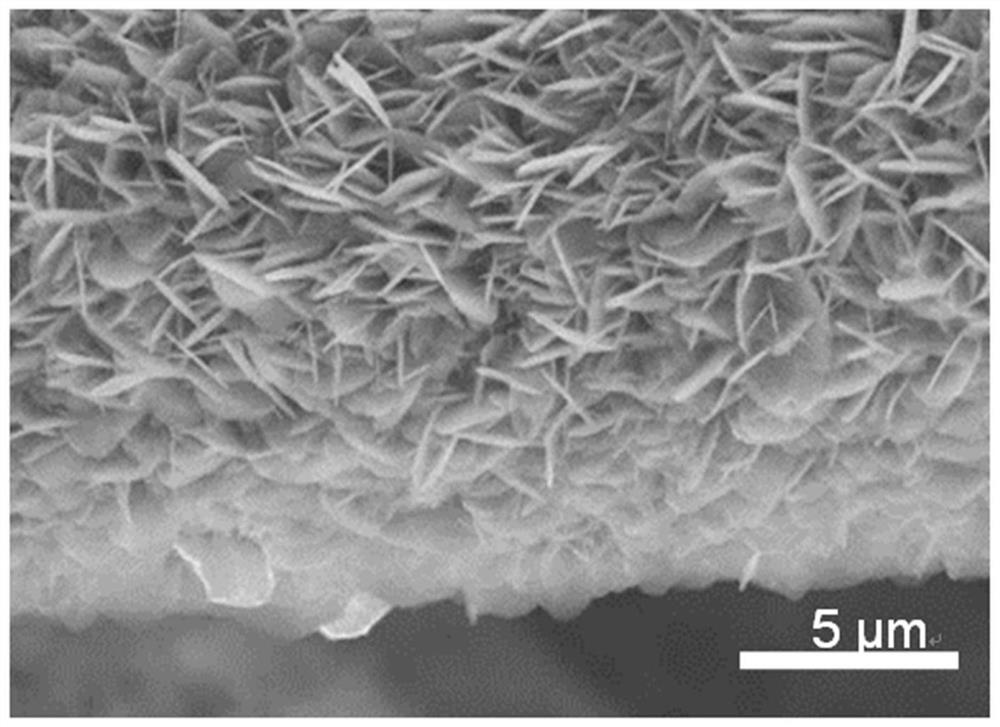

A method for preparing a high-performance molybdenum-based hydrogen evolution electrode from a molybdenum phosphide precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode from a phosphide molybdate precursor, which belongs to the field of electrocatalytic hydrogen evolution in water electrolysis and chlor-alkali industry. In the present invention, the nickel foam is firstly pretreated, and then the molybdate precursor is grown in situ on the surface of the pretreated nickel foam substrate by a hydrothermal synthesis method, and finally the prepared precursor and the phosphorus source are put into a tube furnace together. The molybdate precursor was phosphated to prepare a high-performance molybdenum-based hydrogen evolution electrode. The method of the invention is novel, the required process is simple, the production cost is low, the requirements for equipment are low, and it is suitable for industrial production, and the electrode has a large specific surface area, is firmly combined with the substrate, has excellent hydrogen evolution activity and stability, and can be widely used in water Electrolysis, chlor-alkali industry hydrogen analysis field.

Owner:CHONGQING UNIV

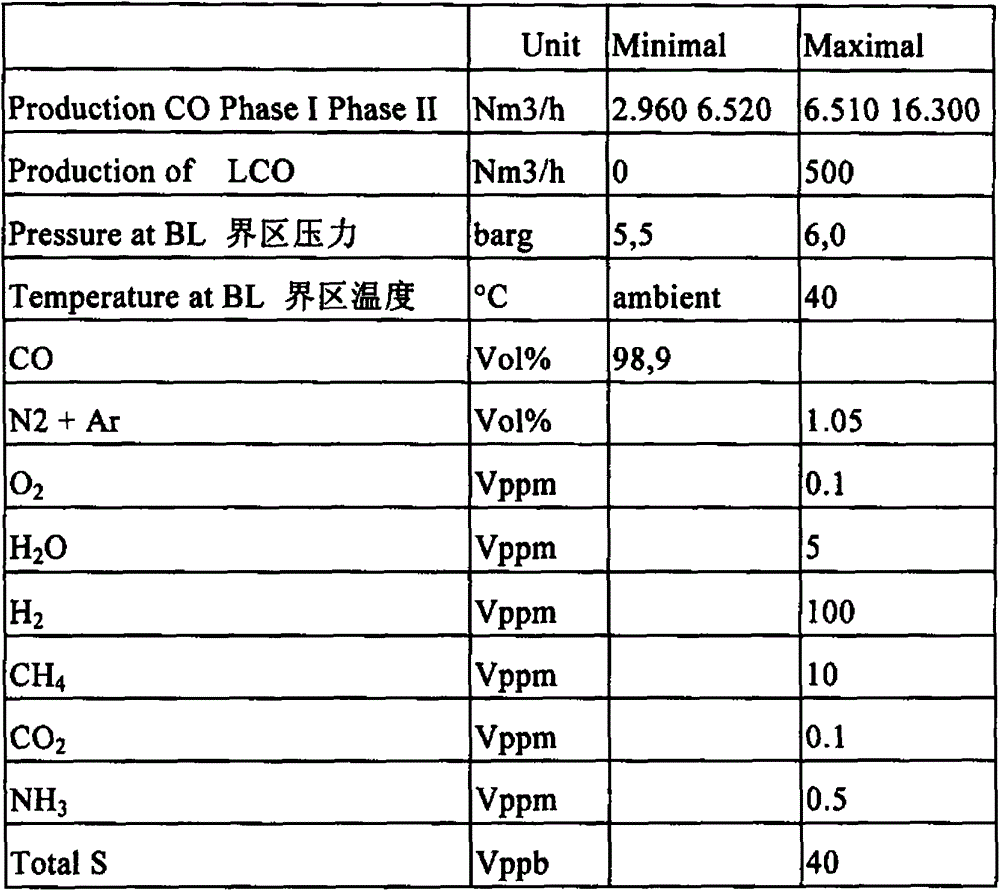

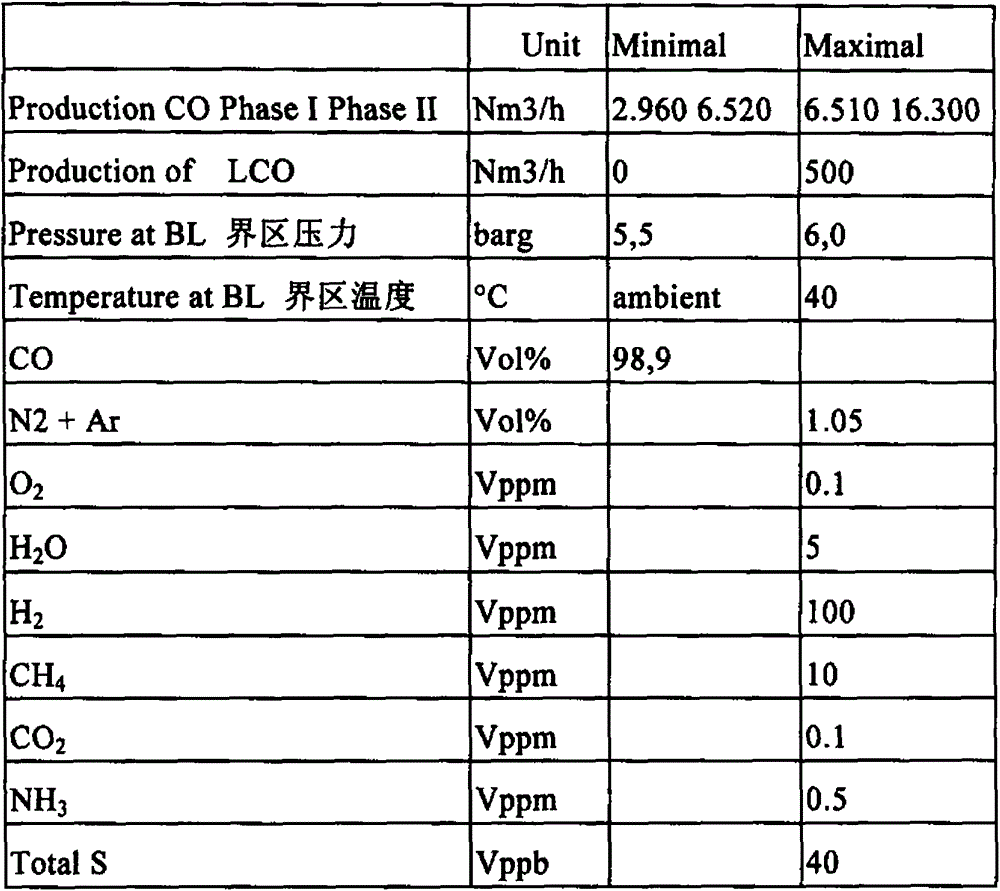

Method for increasing hydrogen analysis detection rate of hydrogen and carbon monoxide production apparatus

The present invention relates to a method for increasing the hydrogen analysis detection rate of a hydrogen and carbon monoxide production apparatus, wherein the method is used for detecting the water content, the methane content, the hydrogen content and the carbon monoxide content in a CO product. According to the method, the output section of the detection apparatus is provided with a hydrogen analyzer, the hydrogen analyzer is connected with a sampling pipeline, the subsequent pipeline is provided with a rapid shut-off valve, the sampling pipeline is a sampling pipe with a diameter of 6 mm, testing is performed through the hydrogen analyzer after sampling is performed by using the sampling pipe, and the rapid shut-off valve on the subsequent pipeline is closed within 40 s when the detected hydrogen content achieves the alarm value. Compared with the method in the prior art, the method of the present invention has the following characteristics that: the response of the on-line analyzer can be increased by 4 times, the result action time is 26 s, the apparatus testing is smoothly passed through, and the on schedule gas supply is performed after the CO product customer approves.

Owner:SHANGHAI HUALIN IND GASES

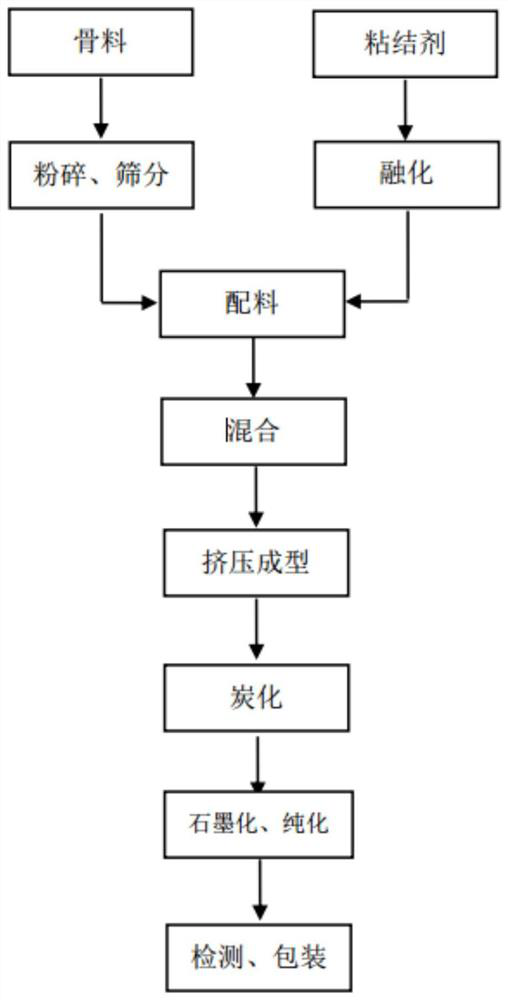

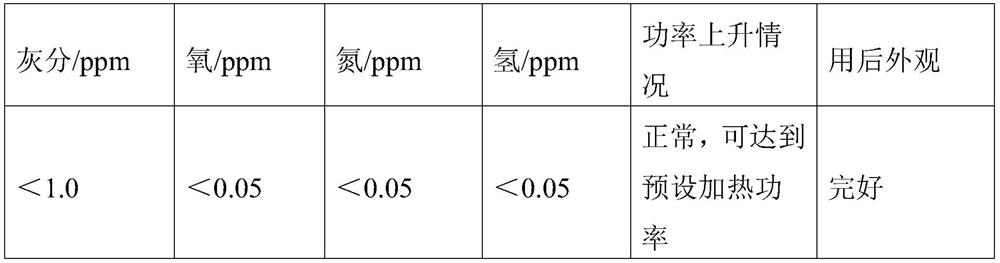

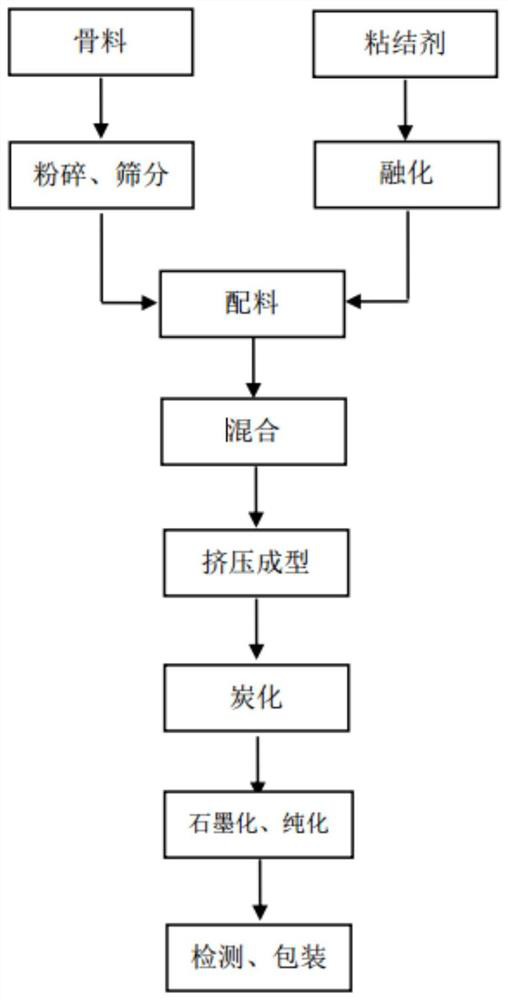

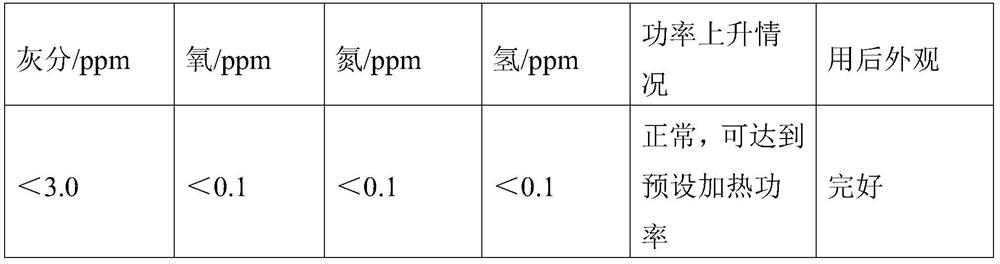

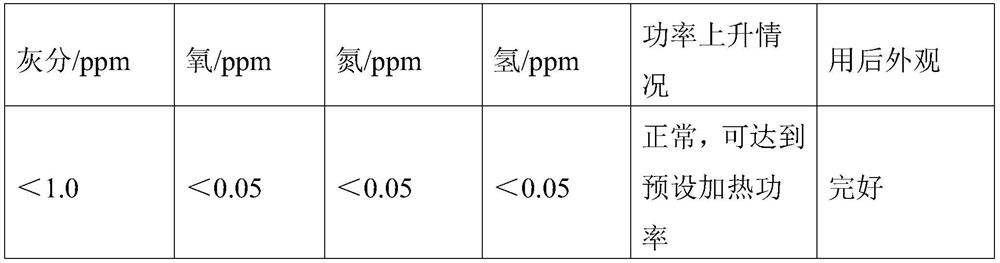

Preparation method of graphite material for oxygen-nitrogen-hydrogen analysis instrument

ActiveCN111751311AHigh degree of graphitizationImprove the lubrication effectMaterial analysis by optical meansCarbonizationGraphite

The invention discloses a preparation method of a graphite material for an oxygen-nitrogen-hydrogen analysis instrument. The preparation method comprises the following steps: 1) preparing a paste material; 2) extruding into a green body bar; 3) carbonizing to prepare a carbonized bar; and 4) purifying to obtain the high-purity graphite material for the oxygen-nitrogen-hydrogen analysis instrument.The low-nitrogen natural microcrystalline graphite is used as a main raw material so that compared with the existing production technology which generally adopts calcined petroleum coke and calcinedpitch coke as raw materials, the nitrogen content of the raw materials is remarkably reduced, and the production of the graphite material meeting the requirements of oxygen-nitrogen-hydrogen analysisinstruments is facilitated. The natural microcrystalline graphite has the advantages of high graphitization degree, good lubricity and the like so that the natural microcrystalline graphite is used asa raw material to be beneficial to reducing the resistance among materials during forming, and a product with a fine and compact structure and good uniformity is obtained; in the carbonization process, a specific heating system is adopted so that the product can be effectively prevented from cracking, the carbon residue rate of the binder is improved, and the density and strength of the product are further improved.

Owner:CENT SOUTH UNIV +1

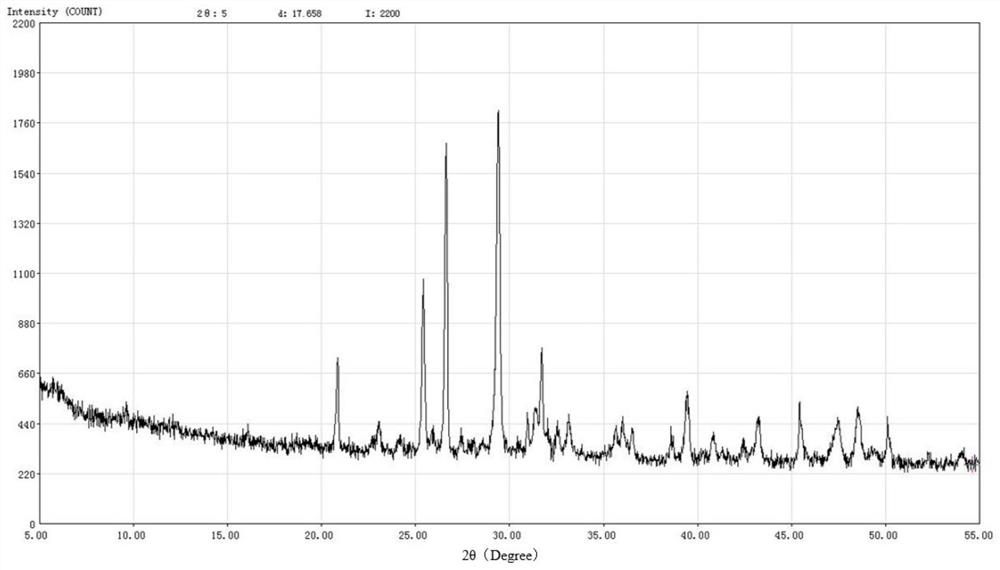

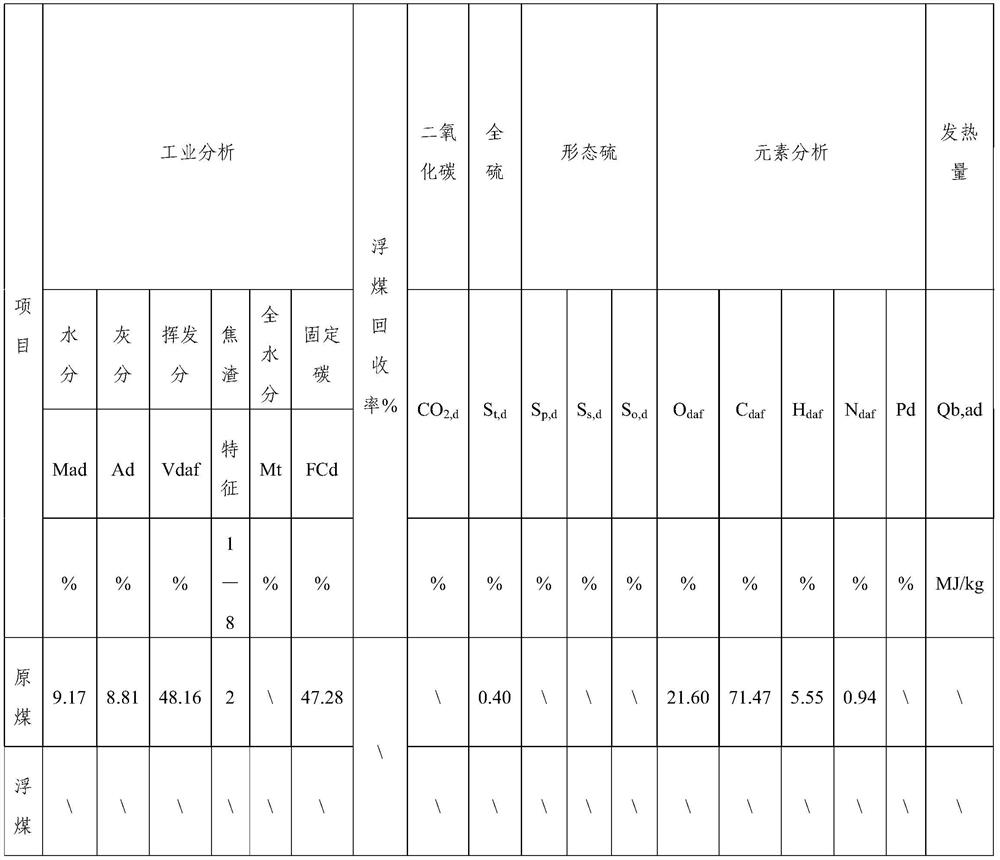

Analysis method of oil-rich coal

InactiveCN113234460AImprove pyrolysis efficiencyHigh yieldSpecial form destructive distillationScanning electron microscopeComponents of crude oil

The invention relates to the field of oil-rich coal resource evaluation and oil product extraction, in particular to an analysis method of oil-rich coal. The analysis method comprises the following steps: firstly, carrying out industrial analysis, total sulfur analysis, hydrocarbon analysis, ash component analysis, nitrogen analysis, Gray-King low-temperature dry distillation analysis, vitrinite reflectivity analysis, maceral classification analysis, scanning electron microscope analysis, energy spectrum quantitative analysis and X-ray diffraction total rock analysis on the oil-rich coal, and then carrying out pyrolysis treatment. The pyrolysis treatment conditions are as follows: heating is started from room temperature, the temperature is raised to 550-650 DEG C at the rate of 15 + / -0.5 DEG C / min, and the temperature is kept for 25-35 minutes. The pyrolysis treatment conditions of the oil-rich coal are determined by analyzing the oil-rich coal, and high-quality pyrolysis coke, pyrolysis liquid and pyrolysis gas can be obtained by performing pyrolysis treatment on the oil-rich coal under the conditions.

Owner:中国煤炭地质总局勘查研究总院

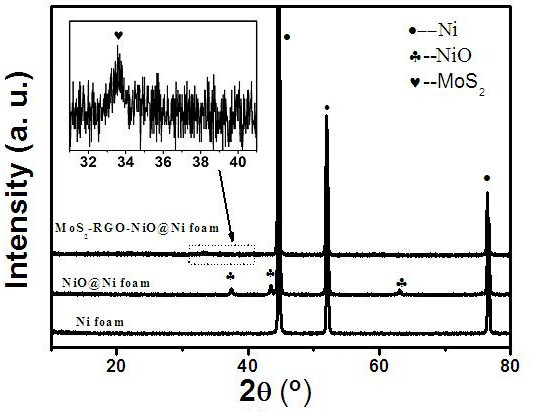

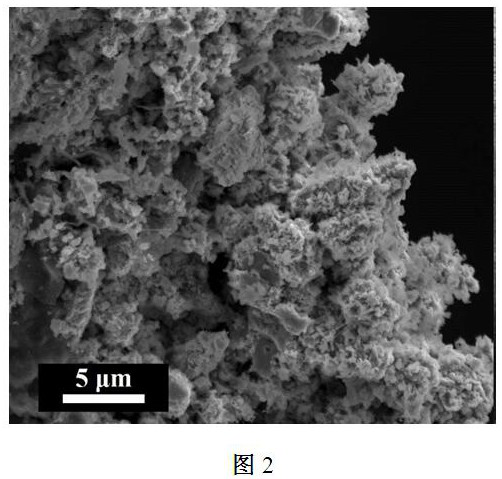

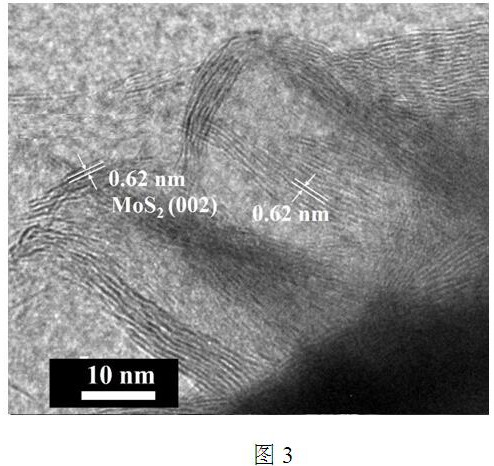

a mos 2 -rgo-nio@ni foam composite photoelectric catalytic hydrogen evolution material and preparation method

ActiveCN110876946BGood HER performanceHas photocatalytic propertiesPhysical/chemical process catalystsElectrodesActive agentSurface-active agents

The present invention disclosed a solitary immersion coating method to prepare MOS 2 ORgo‑nio@ni bubble hydrogen analysis method and preparation method, including the following steps: (1) Molybdenum compounds, sulfur compounds and non -ion surface active agents (2‑10): (4‑12): 1 Weight ratio dissolved dissolvedIn the ion water, the water heat treatment at 140‑200 ° C is 16‑36 h, and MOS is obtained 2 ; (2) Use the improved Hummer method to handle the natural graphite powder for RGO; (3) soak the foam nickel to the concentration of 0.2‑1.0m in the solution of 20‑50min in the solution containing the oxidant, get NIO@ni; (4) The preparation will be preparedMOS 2 , RGO is scattered in the PEG solution, which is suspended solid solution; (5) NiO@ni on the suspended solid solid fluid through multiple impregnation, lifting, drying, and the procedure under the protection of the atmosphere is heated and baked.Catalytic hydrogen composite material.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

A kind of preparation method of graphite material for oxygen, nitrogen and hydrogen analysis instrument

ActiveCN111751311BHigh degree of graphitizationImprove the lubrication effectMaterial analysis by optical meansCarbonizationGraphite

The invention discloses a preparation method of a graphite material for an oxygen, nitrogen and hydrogen analysis instrument, comprising the following steps: 1) preparing a paste; 2) extruding into a green bar; 3) carbonizing to prepare a carbonized bar; 4) purifying Obtain high-purity graphite materials for oxygen, nitrogen and hydrogen analysis instruments. In the present invention, low-nitrogen natural microcrystalline graphite is used as the main raw material, which significantly reduces the nitrogen content of the raw material compared with the current production technology that generally uses calcined petroleum coke and calcined pitch coke as raw materials, and is more conducive to production to meet the requirements of oxygen, nitrogen and hydrogen analysis. Graphite material for instruments. The natural microcrystalline graphite of the present invention has the advantages of high degree of graphitization and good lubricity, so the use of natural microcrystalline graphite as a raw material is beneficial to reduce the resistance between materials during molding, and obtain products with fine and compact structure and good uniformity; during the carbonization process, Using a specific heating system can effectively prevent the product from cracking, increase the carbon residue rate of the binder, and then increase the density and strength of the product.

Owner:CENT SOUTH UNIV +1

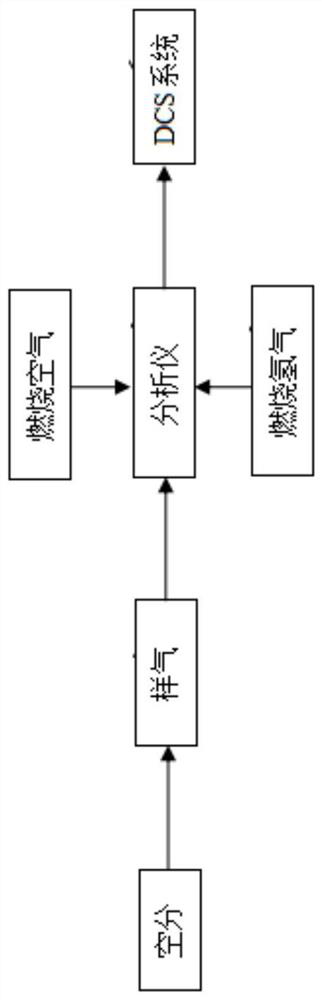

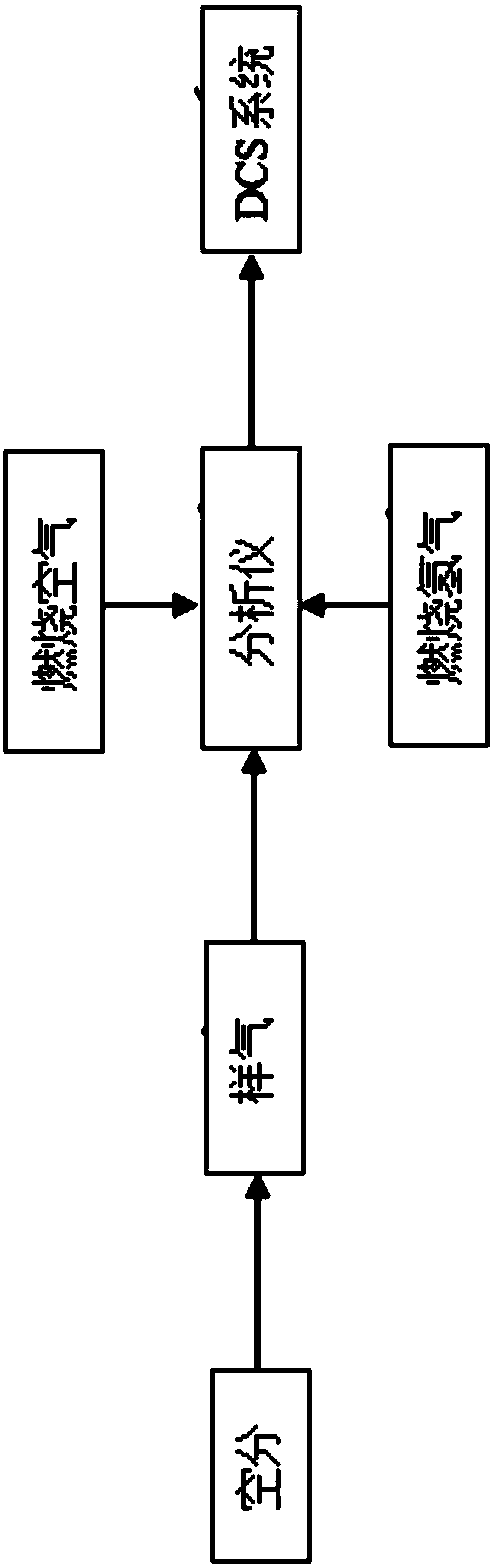

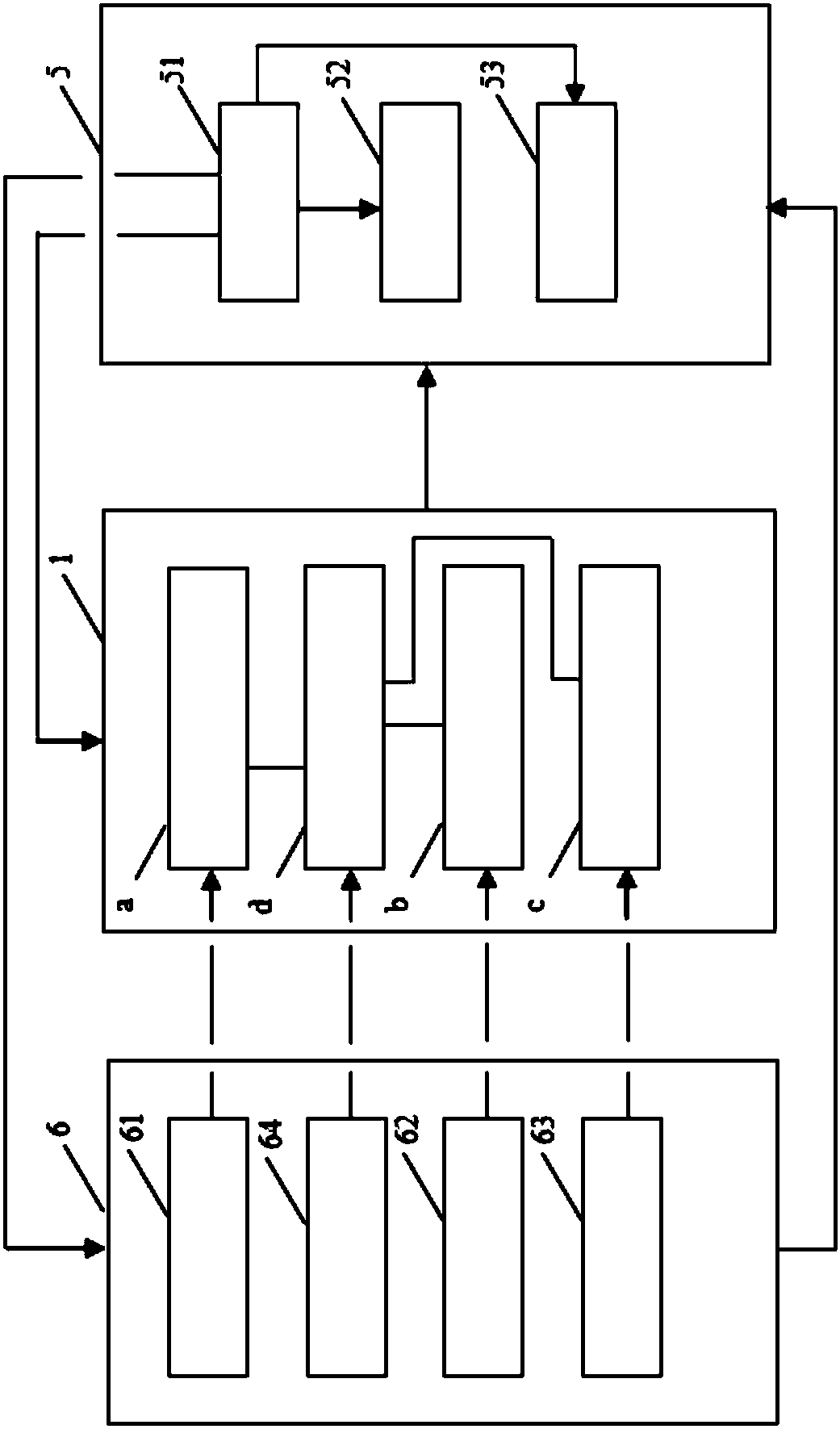

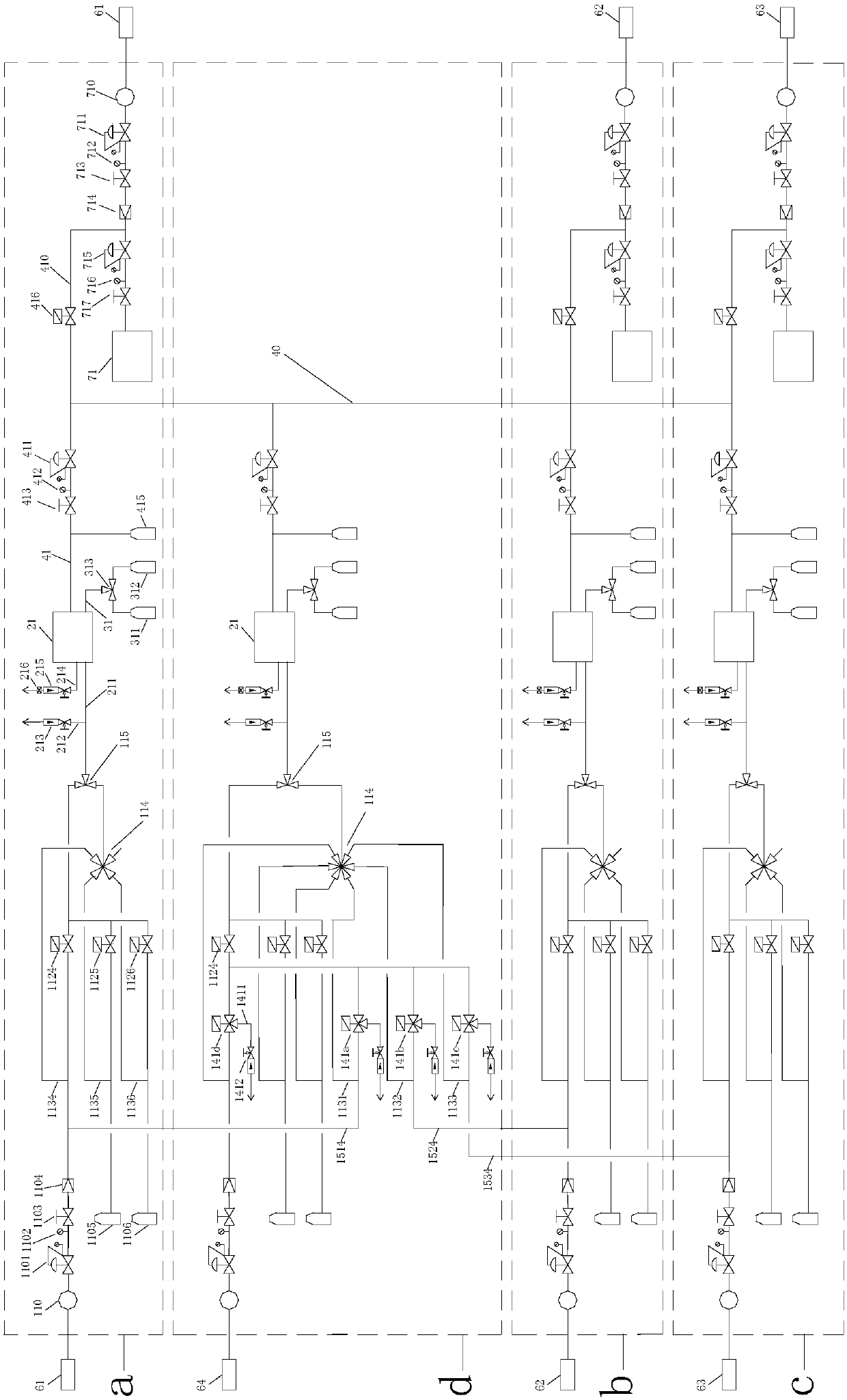

Oxygen total hydrocarbon analysis control system and control method

ActiveCN107765720BMonitor total hydrocarbon contentAvoid explosion riskControlling mixing ratio of fluids with different temperaturesThermodynamicsCombustion

The present invention provides an oxygen production total hydrocarbon analysis control system and control method. The control system includes: an oxygen generator system, an analysis system and a DSC system. The oxygen generator system includes a first air separation system and a second air separation system. , the third air separation and liquid oxygen tank, the analysis system includes a first analysis channel, a second analysis channel, a third analysis channel and a hot standby analysis channel, and the DSC system includes a control unit. The control method includes: S1, input of combustion air; S2, input of combustion hydrogen; S3, input of total hydrocarbon sample gas; S4, input of total hydrocarbon analyzer; S5, analysis and control of the total hydrocarbon content of the oxygen generator system. Compared with the prior art, the present invention has the following beneficial effects: when any air separation analyzer or its unit parts fails or is damaged, or when the analyzer is off-line due to calibration and maintenance, it can continue to monitor the total of the corresponding air separation. Hydrocarbon content, to avoid the risk of explosion caused by excessive accumulation of total hydrocarbons in air separation.

Owner:BAOSHAN IRON & STEEL CO LTD

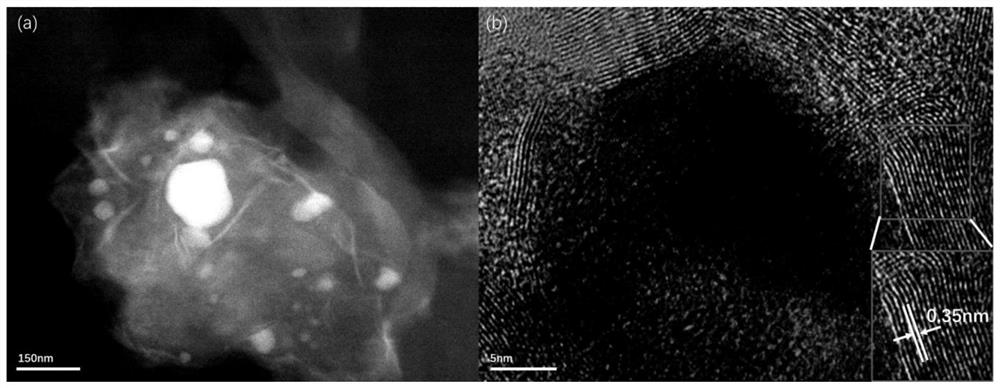

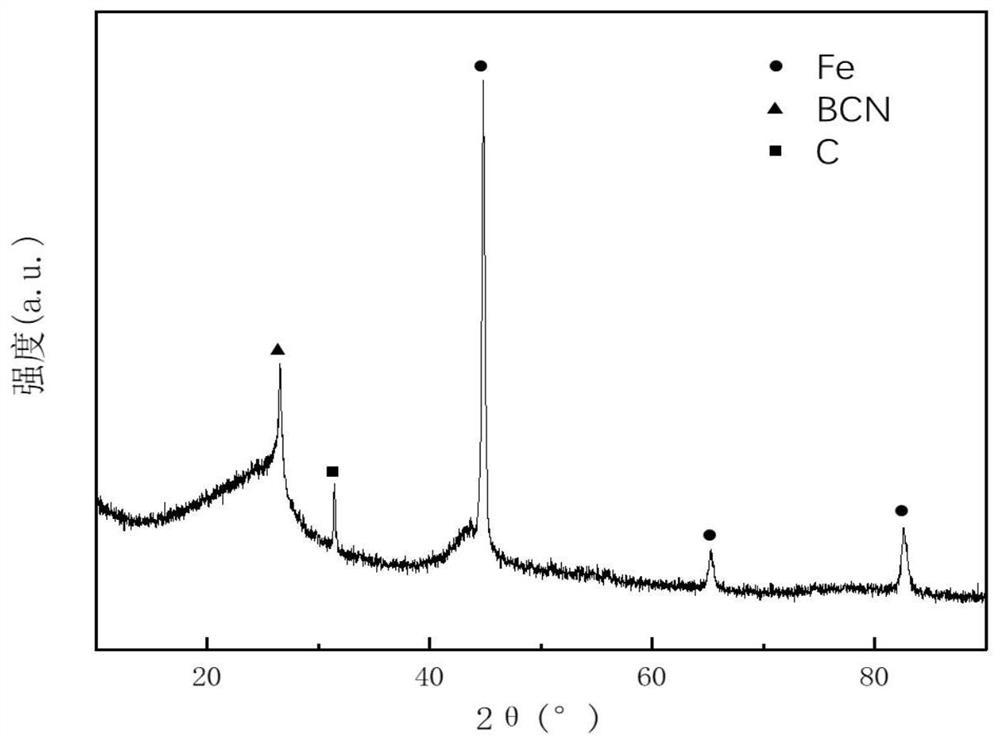

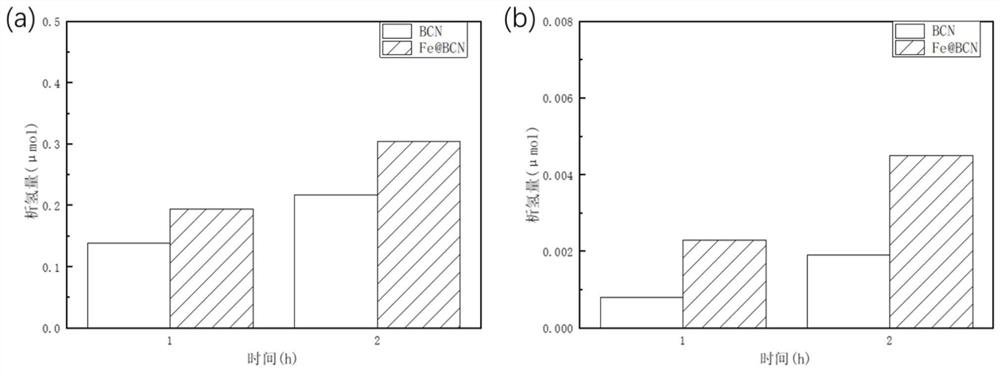

A preparation method of iron@bcn ceramics for photocatalytic hydrogen production

ActiveCN112517045BLarge specific surface areaImprove adjustabilityPhysical/chemical process catalystsHydrogen productionFreeze-dryingUltraviolet lights

The present invention is a method of preparing iron @BCN ceramics with photocatalytic hydrogen -produced hydrogen.This method includes the following steps: (1) Add sodium alginate, boric acid, and urea to dissolve in water to obtain a hybrid solution; (2) add iron ion solution to the hybrid solution to obtain the cross -linking solution;The solution is frozen and dry; (4) at the temperature of 1100 to 1200 ° C in the tube furnace, it is cracked by 4 to 5 hours at high temperature and obtained iron @BCN ceramics.The iron @BCN ceramics prepared by the present invention under the condition of ultraviolet light, the efficiency of the original BCN ceramic hydrogen analysis is increased by 1 to 2 times; under the condition of visible light, the efficiency of the original BCN ceramic hydrogen analysis is improved by 2 ~3 times.

Owner:HEBEI UNIV OF TECH

Total hydrocarbon analysis control system and control method for oxygen generation

ActiveCN107765720AMonitor total hydrocarbon contentAvoid explosion riskControlling mixing ratio of fluids with different temperaturesCombustionHydrogen

The invention provides a total hydrocarbon analysis control system and control method for oxygen generation. The control system is composed of an oxygen generator system, an analysis system and a DSCsystem. The oxygen generator system consists of a first air separation unit and a second air separation unit, a third air separation unit and a liquid oxygen tank. The analysis system consists of a first analysis channel, a second analysis channel, a third analysis channel, and a hot standby analysis channel. And the DSC system includes a control unit. Besides, the control method comprises: S1, injecting combustion air; S2, injecting combustion hydrogen; S3, injecting total hydrocarbon sample gas; S4, operating a total hydrocarbon analysis meter; and S5, analyzing and controlling a total hydrocarbon content of the oxygen generator system. Compared with the prior art, the control system and control method have the following beneficial effects: when any air separation analyzer or other unitcomponent has a fault problem or is damaged or the analyzer is in an off-line state because of checking and maintenance, the total hydrocarbon content of the corresponding air separation unit can be monitored continuously, so that an explosion risk caused by excessive accumulation of total hydrocarbons in air separation is avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

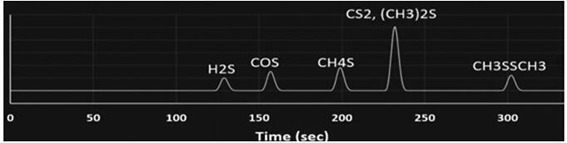

Method for analyzing trace hydrogen sulfide in coal gas

PendingCN114813449AEnsure full absorptionPromote absorptionDispersed particle separationCombustible gas purificationAir pumpPhysical chemistry

The invention relates to a method for analyzing trace hydrogen sulfide in coal gas, which comprises the following steps: 1) preparing an absorption liquid: measuring the H2S concentration of the absorption liquid which is a mixed solution of NaOH and KOH, and putting the absorption liquid into a reaction tank at a position where the liquid level of the absorption liquid is not lower than half of the height of the tank body; (2) sequentially connecting a coal gas inlet, a sucking pump I, a flow meter, a gas storage bag I, a sucking pump II, an absorber, a gas storage bag II, a sucking pump III and a gas storage bag I through gas conveying pipes; the absorber, the liquid volume measuring instrument and the liquid component analysis equipment are sequentially connected through a liquid conveying pipe; 3) carrying out online absorption on hydrogen cyanide in the coal gas; 4) completely discharging the absorption liquid out of the absorber, and measuring the volume of the absorption liquid and the concentration of H2S; and 5) calculating the H2S concentration. The method has the advantages that the to-be-detected gas is circulated for multiple times, the hydrogen sulfide in the coal gas is completely absorbed, and the method is extremely high in accuracy, low in cost and high in efficiency.

Owner:ANGANG STEEL CO LTD

Complete-releasing-light hydrocarbon automatic sample handling system

ActiveCN101424669BAvoid pollutionEnsure consistencyComponent separationWithdrawing sample devicesEngineeringSlurry

Owner:天津陆海石油设备系统工程有限责任公司

Method for accurately measuring hydrogen evolution temperature range of steel product

InactiveCN106093105ASolve problems that cannot be tested directlyReliable test resultsInvestigating phase/state changeTest sampleSpectrometer

The invention relates to a method for accurately measuring a hydrogen evolution temperature range of a steel product. Under an ultrahigh vacuum state, a pre-treated steel product test sample is uniformly heated to a target temperature; a heating speed is 100 DEG C / h-300 DEG C / h, and a target temperature is 800 DEG C-850 DEG C; in a uniform heating process, the change of a hydrogen evolution amount along the temperature is measured by utilizing a hydrogen analysis mass spectrometer; and a temperature region corresponding to the rapidest range of a hydrogen evolution speed is found out according to a change rule of the hydrogen evolution speed along the temperature, and an optimal hydrogen evolution temperature range of the test sample is obtained. The problem in a traditional hydrogen diffusion process that the temperature range is difficult to set is solved, and the problems that a previous hydrogen measurement method has limitation on sample requirements and the like can be solved. The method is a simple, rapid, accurate and environment-friendly method for measuring an optimal temperature of hydrogen evolution, and the blank that the hydrogen evolution temperature range of the steel product cannot be accurately measured is filled.

Owner:中信泰富特钢投资有限公司

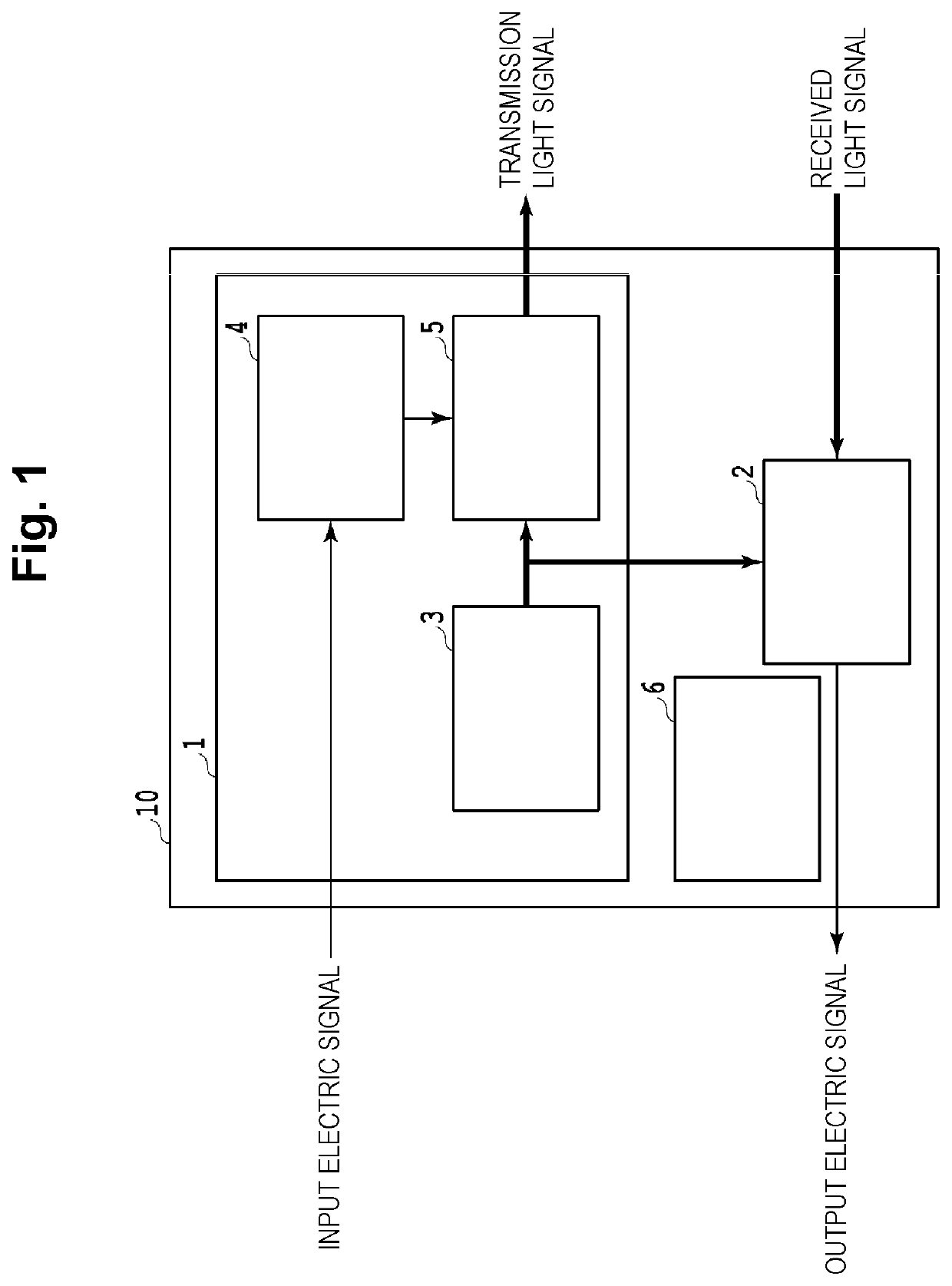

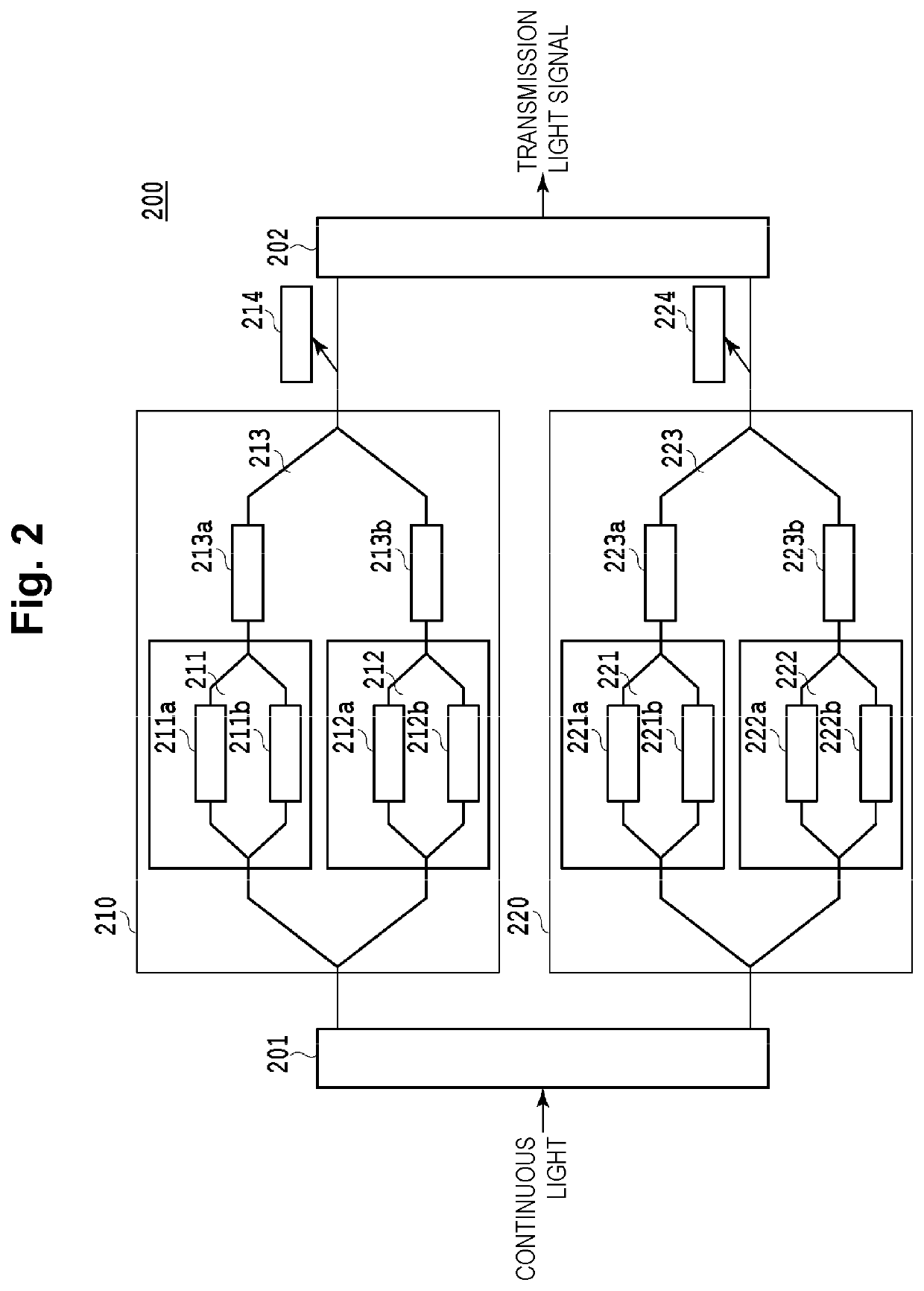

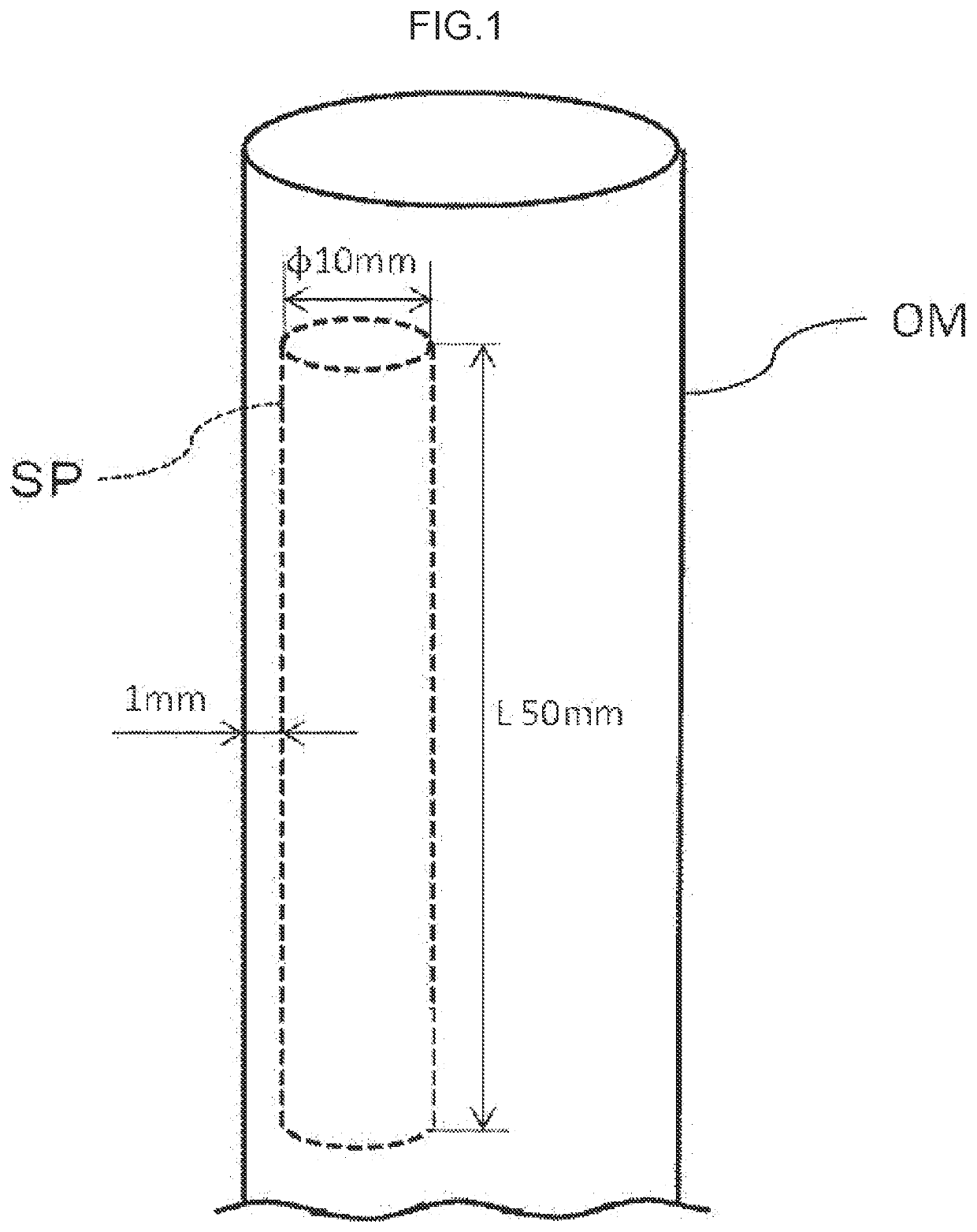

Hydrogen Analysis System

PendingUS20210293694A1Shorten test timeGood reproducibilityWeather/light/corrosion resistancePreparing sample for investigationEngineeringTested time

A test time for measuring hydrogen diffusion in a steel material is improved. The reproducibility of a position where hydrogen exists in the steel material is improved. A control terminal controls a solution supply / discharge control device, a gas supply control device, a first potentiostat / galvanostat, and a second potentiostat / galvanostat on the basis of a predefined procedure, so that a plurality of processing steps, which are performed for analyzing hydrogen diffused from the inside to the surface of a steel material to be measured, are performed continuously. Further, the processing of inactivating the surface of the steel material to be measured is performed before the main processing using a metal ion replacement method, or an inert gas is injected into the solution during the main processing.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

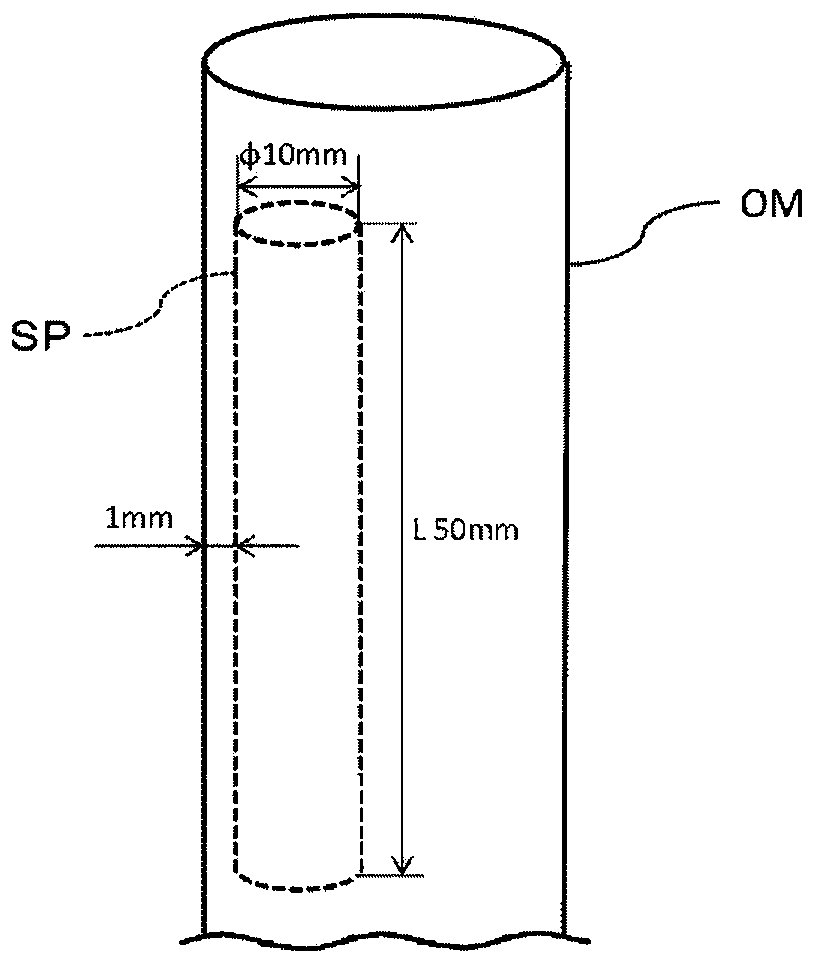

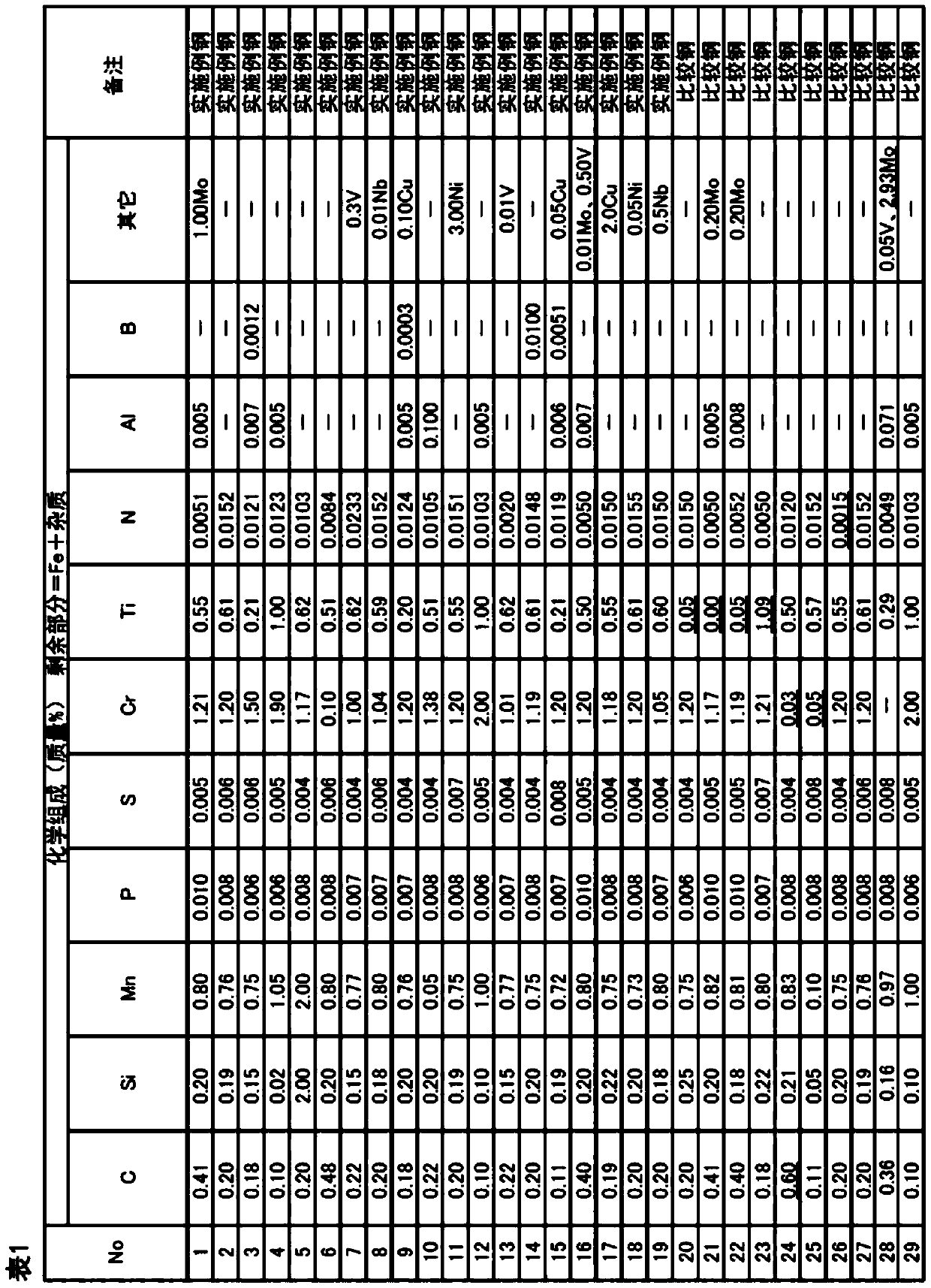

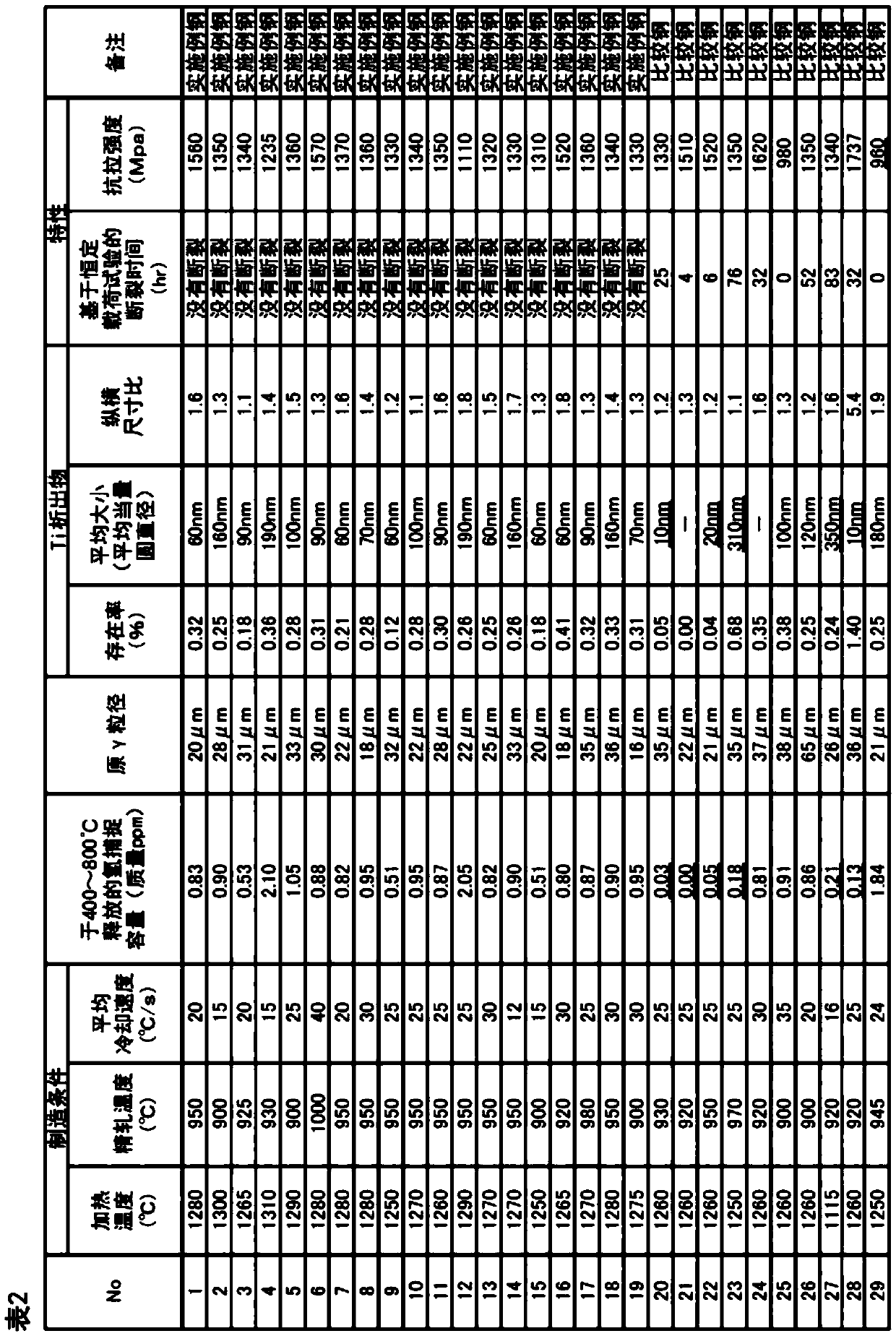

High-strength steel member

Provided is a high-strength steel member which has a predetermined chemical composition, and a tensile strength of at least 1000 Mpa, and which contains: at least 0.10% by area of at least one Ti precipitate which has an average circle equivalent diameter of 30-200 nm at a position of 1 mm deep from the surface of the steel member, and is selected from the group consisting of Ti carbides, Ti nitrides and composite compounds thereof; and at least 0.5 mass ppm of non-diffusible hydrogen, in hydrogen temperature-programmed desorption analysis, released in a temperature range of 400-800 DEG C.

Owner:NIPPON STEEL CORP

Method for Improving the Hydrogen Analysis and Detection Rate of Hydrogen Production and Carbon Monoxide Devices

The present invention relates to a method for increasing the hydrogen analysis detection rate of a hydrogen and carbon monoxide production apparatus, wherein the method is used for detecting the water content, the methane content, the hydrogen content and the carbon monoxide content in a CO product. According to the method, the output section of the detection apparatus is provided with a hydrogen analyzer, the hydrogen analyzer is connected with a sampling pipeline, the subsequent pipeline is provided with a rapid shut-off valve, the sampling pipeline is a sampling pipe with a diameter of 6 mm, testing is performed through the hydrogen analyzer after sampling is performed by using the sampling pipe, and the rapid shut-off valve on the subsequent pipeline is closed within 40 s when the detected hydrogen content achieves the alarm value. Compared with the method in the prior art, the method of the present invention has the following characteristics that: the response of the on-line analyzer can be increased by 4 times, the result action time is 26 s, the apparatus testing is smoothly passed through, and the on schedule gas supply is performed after the CO product customer approves.

Owner:SHANGHAI HUALIN IND GASES

High-strength steel member

InactiveUS20200131609A1Excellent delayed fracture resistanceReduce resistanceChemical compositionCarbide

A high-strength steel member having a predetermined chemical composition, having a tensile strength of 1,000 MPa or higher, containing 0.10% or more of, in terms of percent (%) by area, at least one Ti precipitate that has an average size of from 30 to 200 nm in terms of an average equivalent circle diameter and is selected from the group consisting of a Ti carbide, a Ti nitride, and a composite compound thereof, at a location of 1 mm in depth from a surface of the steel member, and containing 0.5 ppm by mass or more of non-diffusible hydrogen that is released in a temperature range of from 400 to 800° C. in a thermal desorption hydrogen analysis.

Owner:NIPPON STEEL CORP

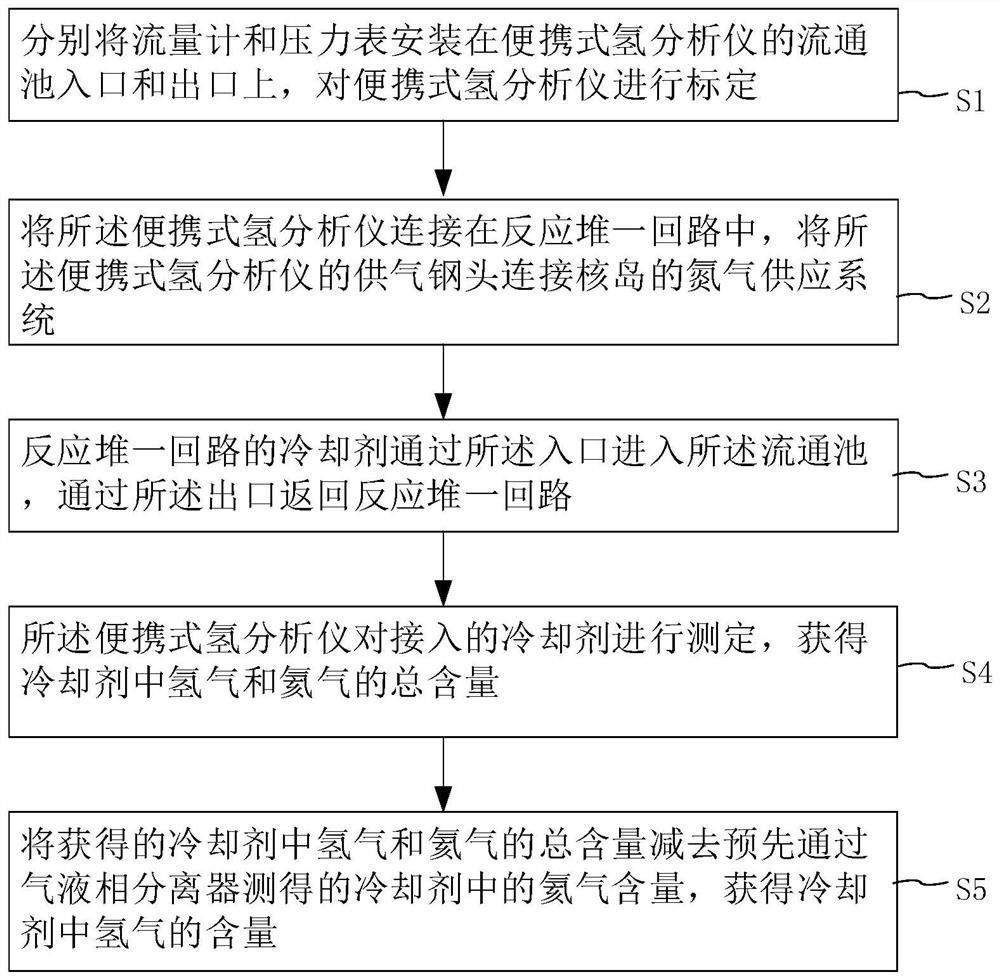

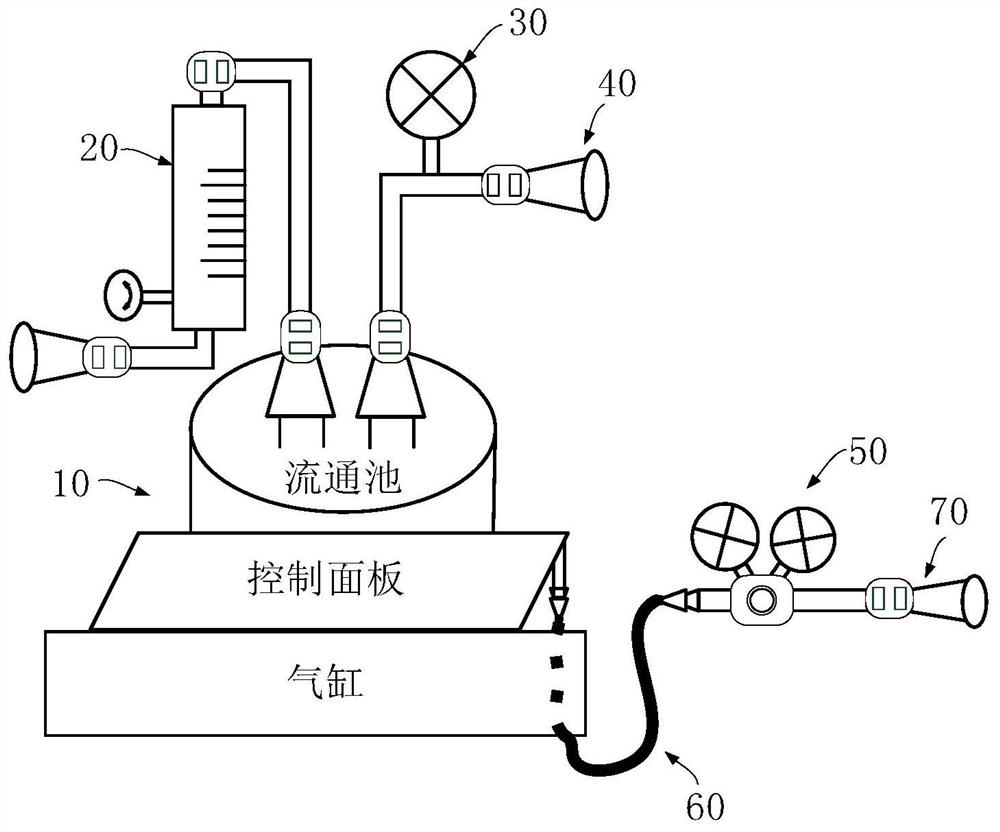

Reactor primary loop dissolved hydrogen content determination method

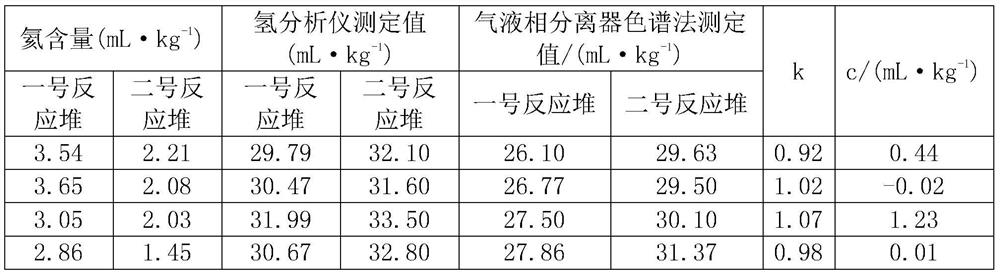

PendingCN112858376AReduce radiation doseEnable recyclingMaterial thermal conductivityComponent separationFluid phaseEngineering

The invention discloses a reactor primary loop dissolved hydrogen content determination method. The method comprises the following steps: S1, respectively installing a flowmeter and a pressure gauge on an inlet and an outlet of a flow cell of a portable hydrogen analyzer, and calibrating; S2, connecting a portable hydrogen analyzer into a primary loop of the reactor, and connecting a gas supply steel head of the portable hydrogen analyzer with a nitrogen supply system; S3, enabling the coolant of the reactor primary loop to enter the flow cell through the inlet and return to the reactor primary loop through the outlet; S4, determining the coolant by the portable hydrogen analyzer to obtain the total content of hydrogen and helium in the coolant; and S5, subtracting the content of helium in the coolant, which is measured by a gas-liquid phase separator in advance, from the total content of hydrogen and helium to obtain the content of hydrogen in the coolant. According to the invention, online continuous measurement of the dissolved hydrogen content in the reactor primary loop coolant is realized, the accuracy, stability and sensitivity of dissolved hydrogen content measurement are improved, the radiation dose of personnel during dissolved hydrogen analysis is reduced, and the working efficiency is improved.

Owner:GUANGXI FANGCHENGGANG NUCLEAR POWER +1

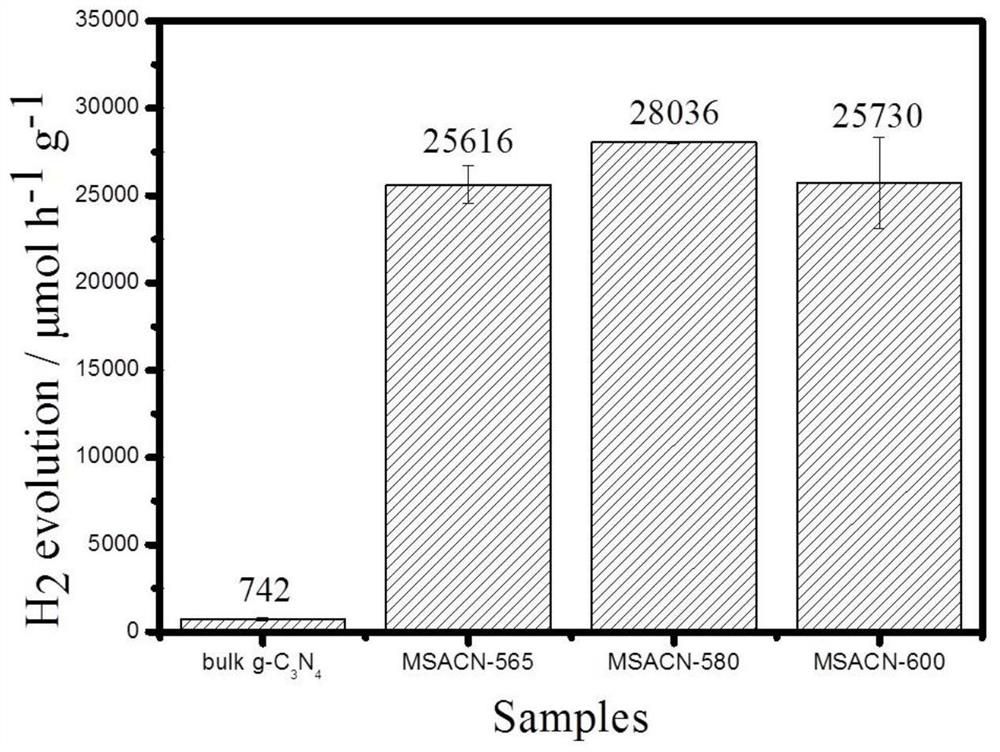

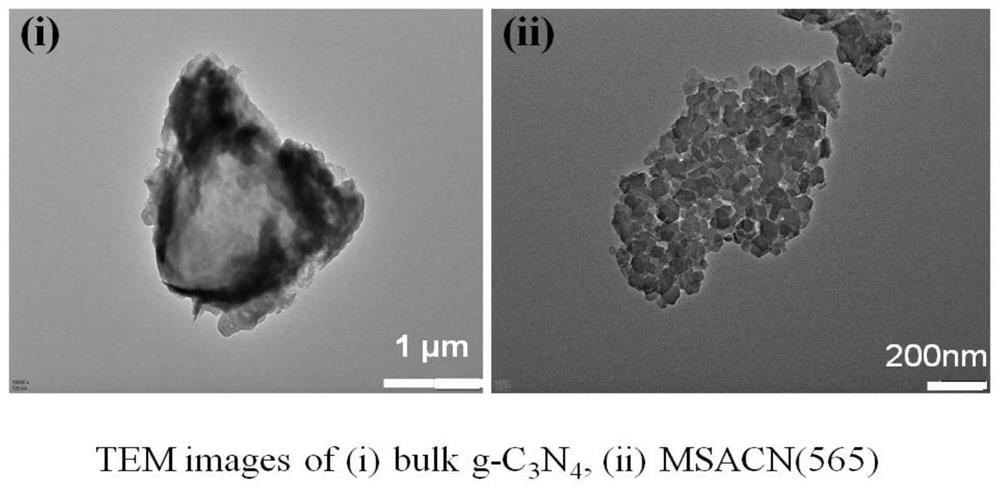

a scaly g-c 3 no 4 Nanosheet and its preparation method

ActiveCN110280299BUnique scaly structureHigh crystallinityPhysical/chemical process catalystsHydrogen productionElectron holePhotocatalytic water splitting

The invention relates to the technical field of nanomaterials, photocatalysis, and water splitting and desorption hydrogen detection, in particular to a scale-like g-C 3 N 4 Nanosheet and preparation method thereof, scaly g-C of the present invention 3 N 4 g‑C in nanosheets 3 N 4 Nanosheets are small and regular scale-like structures, and the g-C 3 N 4 Nanosheet size is 50~600nm, g‑C 3 N 4 The thickness of the nano sheet is 5-30nm. Scaly g-C of the present invention 3 N 4 The nanosheets are prepared by calcining after mixing three kinds of salts and nitrogen-containing organic raw materials. g-C of the present invention 3 N 4 Nanosheets have a unique scale-like structure, have higher crystallinity, and can effectively expand the range of light absorption, reduce the recombination probability of photogenerated electron-hole pairs, and improve their photocatalytic activity and water splitting hydrogen desorption performance. The invention can be effectively applied to the technical field of photocatalytic water splitting and decomposing hydrogen.

Owner:HEFEI UNIV OF TECH

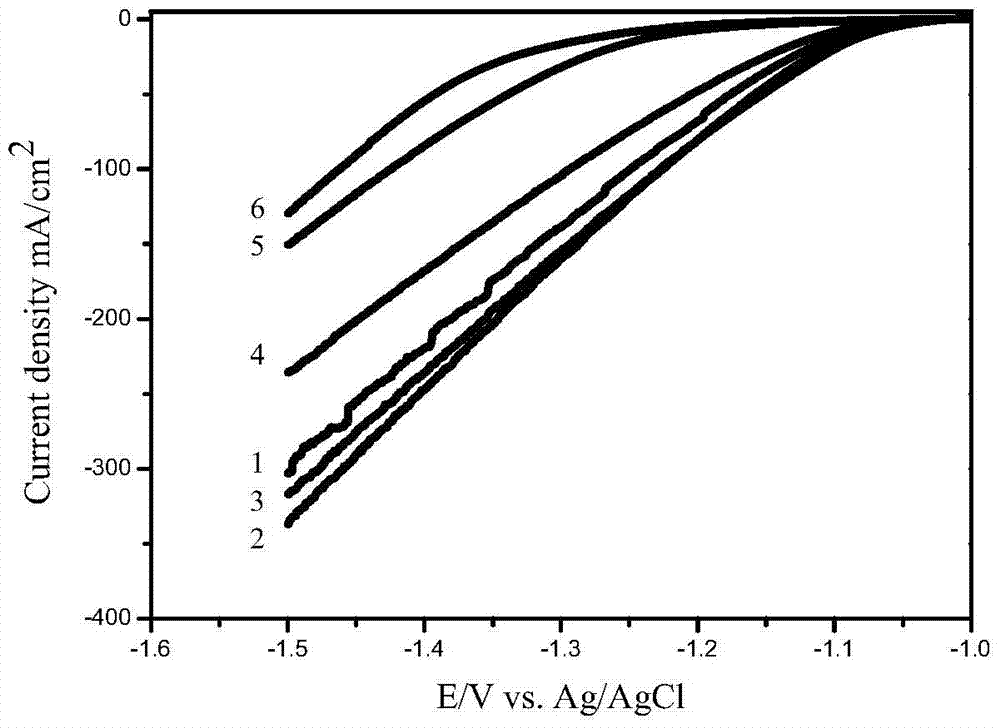

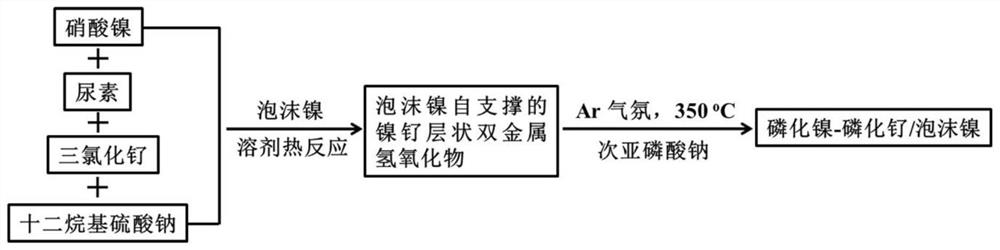

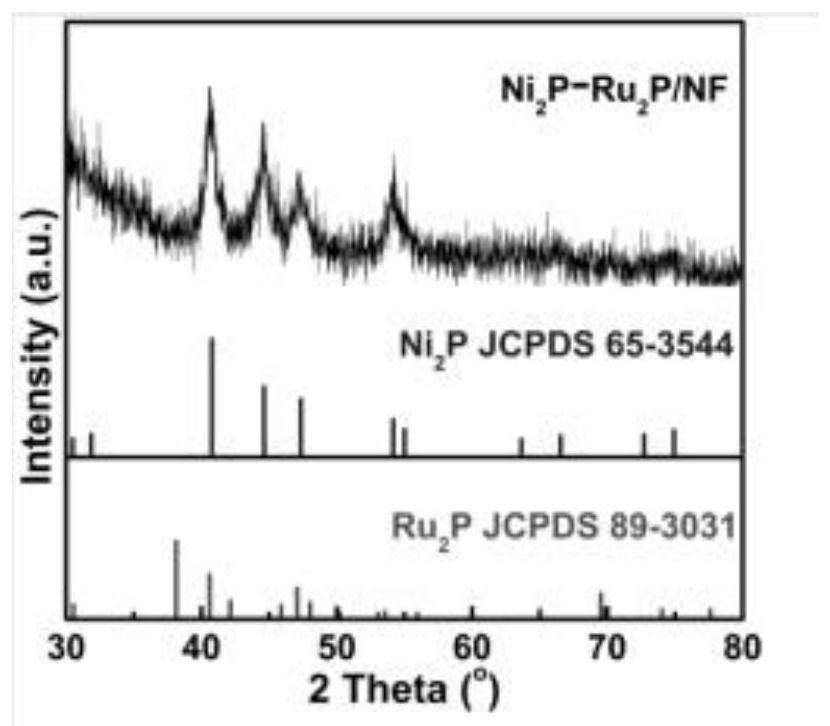

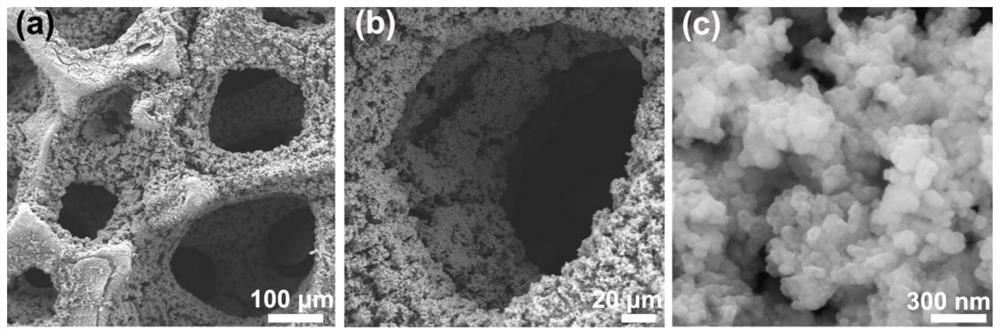

Preparation method and application of a nickel phosphide-ruthenium phosphide/nickel foam three-dimensional self-supporting electrode material

The invention belongs to the technical field of catalyst preparation, and specifically relates to a preparation method and application of a nickel phosphide-ruthenium phosphide / foamed nickel three-dimensional self-supporting electrode material, comprising the following steps: 1) preparing a foamed nickel self-supporting nickel-ruthenium layered bilayer Metal hydroxide; 2) Preparation of nickel phosphide-ruthenium phosphide / nickel foam three-dimensional self-supporting electrode material; application of nickel phosphide-ruthenium phosphide / foam nickel three-dimensional self-supporting electrode material in electrolyzed water. The preparation process of the present invention is convenient and simple, can greatly reduce the cost of the electrocatalyst, and has excellent performance in alkaline electrocatalytic hydrogen evolution, and also exhibits excellent catalytic performance in alkaline electrocatalytic oxygen evolution and full hydrolysis, and the three-dimensional porous The foamed nickel carrier has excellent conductivity, which can increase the loading capacity of the active sites and accelerate the transfer speed of electrons and protons; the in-situ growth method can effectively improve the interaction between nickel phosphide-ruthenium phosphide and the carrier foamed nickel, and then enhance its electrocatalytic stability.

Owner:JINING UNIV

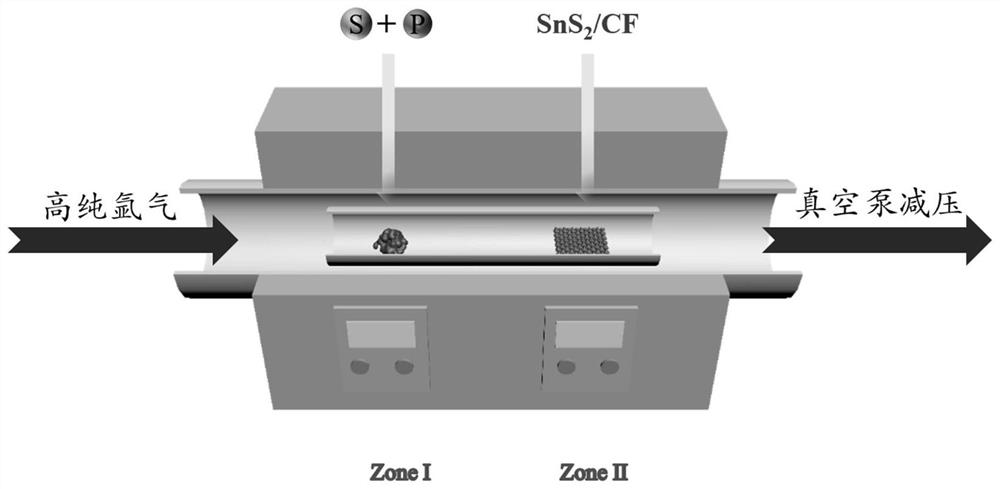

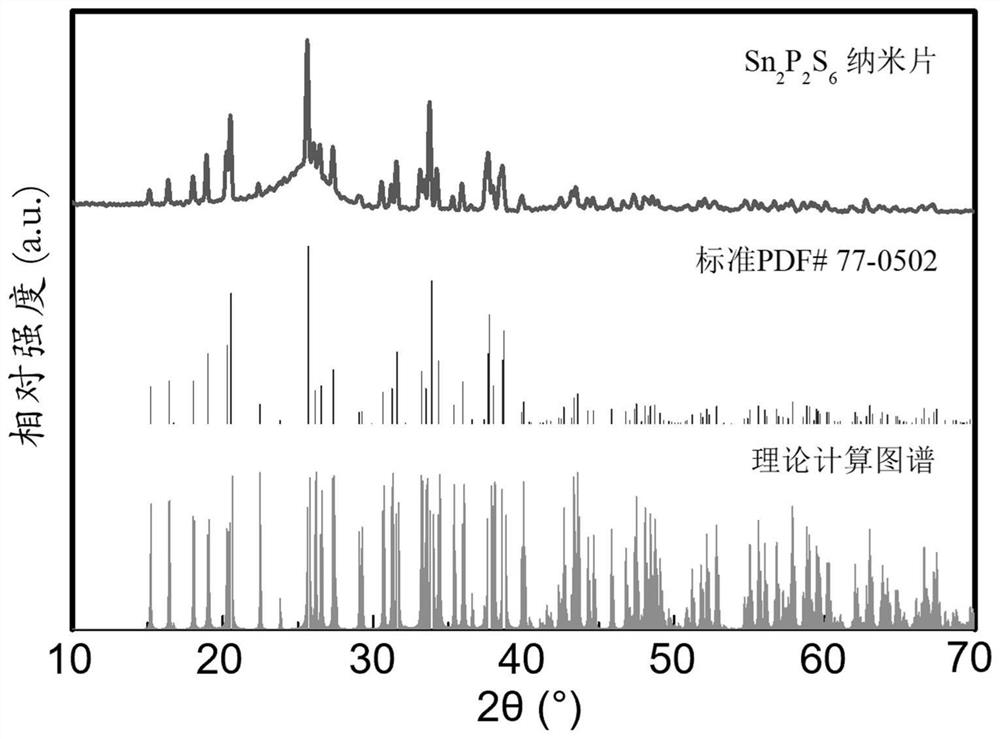

non-lamellar sn 2 p 2 s 6 Preparation method of nanosheets and its application in the field of photocatalytic hydrogen evolution

ActiveCN113104885BHigh crystallinityChemically stableMaterial nanotechnologyTin compoundsPhysical chemistryChemical vapor deposition

The present invention provides a non -layered SN 2 P 2 S 6 The preparation method of nanoscopic tablets and its application in the field of photocatalytic hydrogen analysis includes the method of mixing sulfur sulfur powder and SNS 2 The steps of nano crystal reaction of chemical gas deposition; of which, the mixed powder mixed powder is located on the upstream of the reactor, SNS 2 Nano -crystals are located in the downstream, the upstream heating temperature is set to 270 to 330 ° C, and the downstream heating temperature is set to 340 to 380 ° C.The method of the present invention can quickly and cost SN that is evenly distributed on the base with a uniform area on the base 2 P 2 S 6 Nano -table 2 P 2 S 6 Nano -sheet crystals are good, chemically stable, and have broad application prospects in the field of photocatalytic hydrogen.This method is easy to operate, the required equipment is simple, and can be applied to large -scale industrial production in high efficiency.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing p-acetoxy-benzoic acid

ActiveCN102276454BReduce dosageImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationBenzoic acidAcetic anhydride

The invention discloses a method for preparing p-acetoxy-benzoic acid. The method comprises the following steps of: reacting p-hydroxybenzoic acid as a raw material, acetic anhydride as an acylating agent and pyridine as a catalyst in a condition of 1.2-1.5 times of the excessive acetic anhydride: firstly, adding a certain amount of the p-hydroxybenzoic acid and the acetic anhydride into a reactor; dropwise adding the pyridine while stirring and raising the temperature to 80-85 DEG C; controlling the dropwise adding speed, wherein preferentially the temperature raising speed of a reactant is not beyond 10 DEG C; keeping the reaction temperature and continuously stirring for 2-3 h after adding the p-hydroxybenzoic acid and the pyridine and completely converting the reactant into crystals; and finally, repetitively washing the cooled reactant till the pH value of filtrate is 3-4 so as to obtain a crude product of acetoxy-benzoic acid. Both purities of a liquid chromatogram analysis result and a nuclear magnetic resonance hydrogen analysis result of the p-acetoxy-benzoic acid are more than 99.5%. According to the method disclosed by the invention, the conversion rate of the p-acetoxy-benzoic acid is more than 96%; furthermore, the content of by-products is low; and the difficultly for further refining and purifying the product is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Online circulating hydrogen analysis detector

PendingCN112378954AHigh sensitivityHigh selectivityMaterial heat developmentCalibration gasEngineering

The invention discloses an online circulating hydrogen analysis detector, which comprises a detector, a sampling port formed in a process pipeline, a sampling channel communicated with the sampling port, a control valve arranged on the sampling channel, a hydrocarbon remover, a purifier and an analysis membrane communicated with the hydrocarbon remover, wherein the hydrocarbon remover and the purifier are respectively communicated with the sampling channel and are arranged in parallel, the analysis membrane is communicated with the gas inlet pipeline of the detector, the purifier is communicated with a switching valve, the switching valve is connected with a hydrogen generator, a calibration gas inlet pipeline, a first reference gas pipeline, a second reference gas pipeline and a tail gasblowing pipeline, the tail gas blowing pipeline is communicated with the gas inlet pipeline of the detector, and the detector is provided with a first reference gas inlet communicated with the first reference gas pipeline and a second reference gas inlet communicated with the second reference gas pipeline. The online circulating hydrogen analysis detector is strong in functionality and high in sensitivity.

Owner:江阴金属材料创新研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com