Method for accurately measuring steel hydrogen evolution temperature range

A temperature range, hydrogen evolution technology, applied in the investigation stage/state change and other directions, can solve the problems of high sample requirements, unable to give the actual trajectory of hydrogen, unable to accurately determine and other problems, to save energy, improve the effect of hydrogen evolution, dehydrogenation quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is described in further detail.

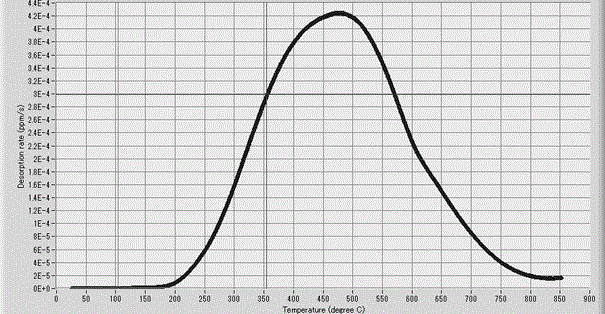

[0012] The method for measuring the hydrogen evolution temperature range of the steel material in this embodiment is to take a steel sample with an equivalent diameter in the range of Φ5mm×5mm~Φ20mm×50mm, and perform pretreatment on the steel sample: clean it with anhydrous alcohol in an ultrasonic scrubber Take the sample for 15 minutes, take out the sample and dry it with cold wind, weigh the sample mass with an electronic balance (accurate to 0.0001g) and record it.

[0013] Send the sample into the sampling chamber of the mass analysis electric furnace, vacuumize, and wait for the vacuum degree of the sampling chamber to reach 10 -6 After that, use the magnetic coupling guide rod to introduce the sample into the electric furnace, set the heating rate to 100-300°C / h, and the heating target temperature to be 800-850°C, and the target temperature should be higher than the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com