a mos 2 -rgo-nio@ni foam composite photoelectric catalytic hydrogen evolution material and preparation method

A mos2-rgo-nio, composite material technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of high hydrogen evolution overpotential and poor material cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

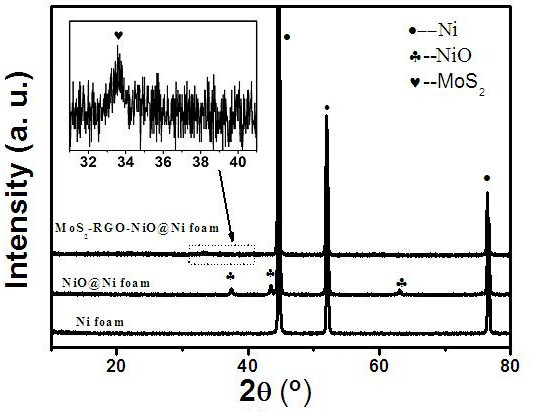

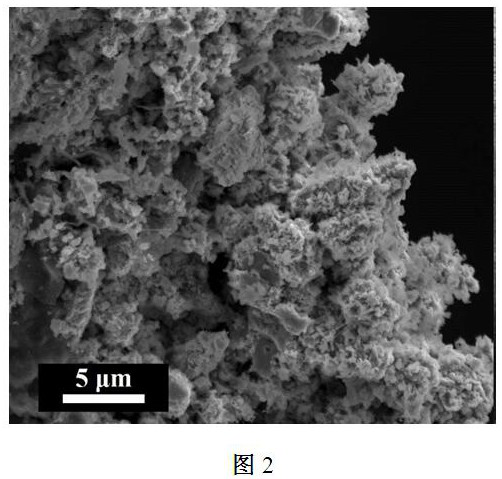

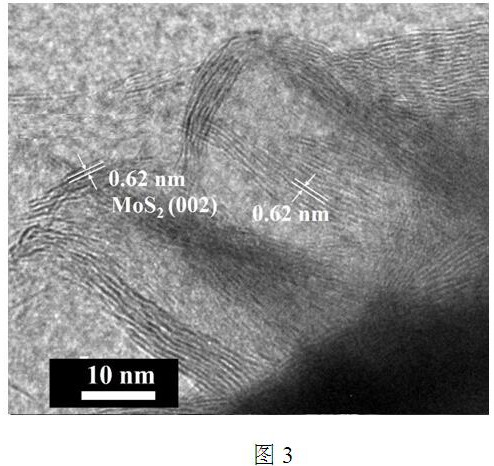

[0028] (1) Dodemolybdenum phosphoric acid, methyl isothiourea and polysorbate were dissolved in 120 mL of deionized water at a weight ratio of 5:6:1 under constant stirring, and the mixed solution was transferred into polytetrafluoroethylene. lined stainless steel autoclave, hydrothermally treated at 180 °C for 24 h, the obtained MoS 2 Wash with deionized water, centrifuge, and vacuum dry for use. (2) RGO was prepared by treating natural graphite powder with a modified Hummer method. (3) Add 18g of PEG4000 to 100mL of deionized water, heat to dissolve, and dissolve the MoS obtained in step (1). 2 Take 0.4 g and 0.05 g of the RGO obtained in step (2) and disperse them in a PEG solution in turn, and ultrasonically treat them for 30 min to form a suspension sol. (4) The nickel foam was soaked in 0.2 M nitric acid solution for 30 min to obtain pre-oxidized NiO@Ni. (5) The NiO@Ni obtained in step (4) was immersed in the suspension sol obtained in step (3) for 2 min, then pulled ...

Embodiment 2

[0030] (1) Dissolve ammonium molybdate, thiourea and fatty acid glycerides in 120 mL of deionized water at a weight ratio of 4:7:1 under constant stirring, and transfer the mixed solution to a PTFE-lined stainless steel high pressure In the reaction kettle, hydrothermal treatment was performed at 160 °C for 30 h, and the obtained MoS 2 Wash with deionized water, centrifuge, and vacuum dry for use. (2) RGO was prepared by treating natural graphite powder with a modified Hummer method. (3) Add 16g PEG6000 to 100mL deionized water, heat to dissolve, and dissolve the MoS obtained in step (1). 2 Take 0.3 g and 0.06 g of the RGO obtained in step (2) and disperse them in the PEG solution in turn, and ultrasonically treat for 30 min to form a suspension sol. (4) The nickel foam was soaked in a 0.8 M hydrogen peroxide solution for 50 min to obtain pre-oxidized NiO@Ni. (5) The NiO@Ni obtained in step (4) was immersed in the suspension sol obtained in step (3) for 1 min, then pulled a...

Embodiment 3

[0032] (1) Dissolve sodium molybdate, vinyl thiourea and fatty acid sorbitan in 120 mL of deionized water at a weight ratio of 6:8:1 under constant stirring, and transfer the mixed solution into a polytetrafluoroethylene-lined In a stainless steel autoclave, the obtained MoS was hydrothermally treated at 170 °C for 26 h. 2 Wash with deionized water, centrifuge, and vacuum dry for use. (2) RGO was prepared by treating natural graphite powder with a modified Hummer method. (3) Add 20g PEG2000 to 100mL deionized water, heat to dissolve, and dissolve the MoS obtained in step (1). 2 Take 0.5 g and 0.07 g of the RGO obtained in step (2) and disperse them in the PEG solution in turn, and ultrasonically treat for 30 min to form a suspension sol. (4) The nickel foam was soaked in a solution of potassium permanganate with a concentration of 0.5 M for 40 min to obtain pre-oxidized NiO@Ni. (5) The NiO@Ni obtained in step (4) was immersed in the suspension sol obtained in step (3) for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com