Carrier gas purification filter pipe for oxygen-nitrogen-hydrogen analyzer, furnace head and oxygen-nitrogen-hydrogen analyzer

An oxygen, nitrogen and hydrogen analyzer and filter tube technology, applied in the field of oxygen, nitrogen and hydrogen analysis, can solve the problems of increased test cost, inaccurate graphite powder content, frequent replacement of quartz wool, etc., and achieve the effect of improving accuracy and reducing analysis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of oxygen nitrogen hydrogen analyzer of the present invention:

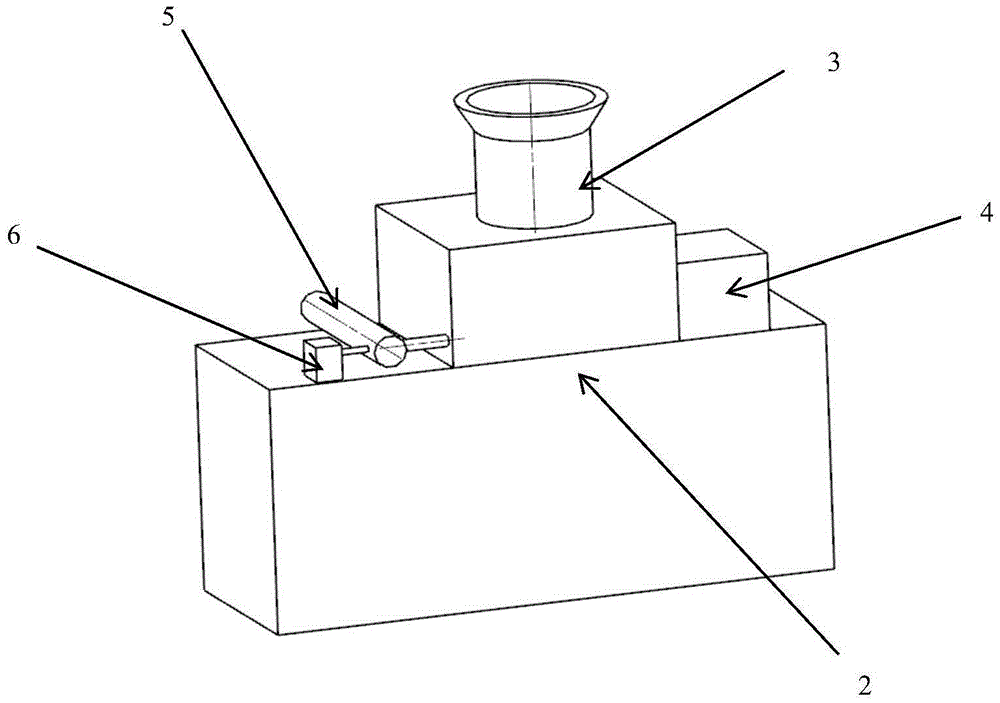

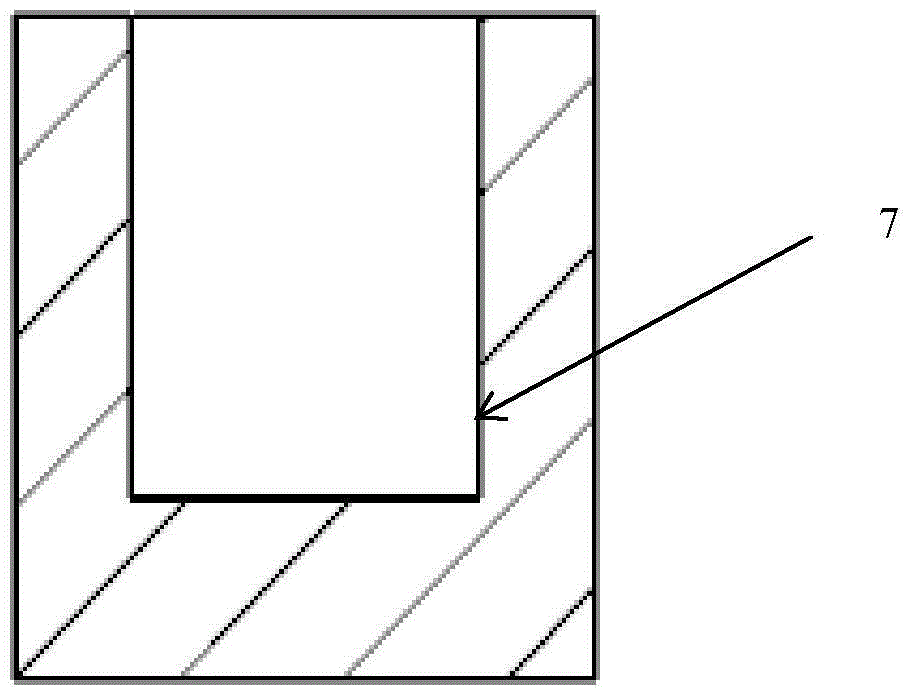

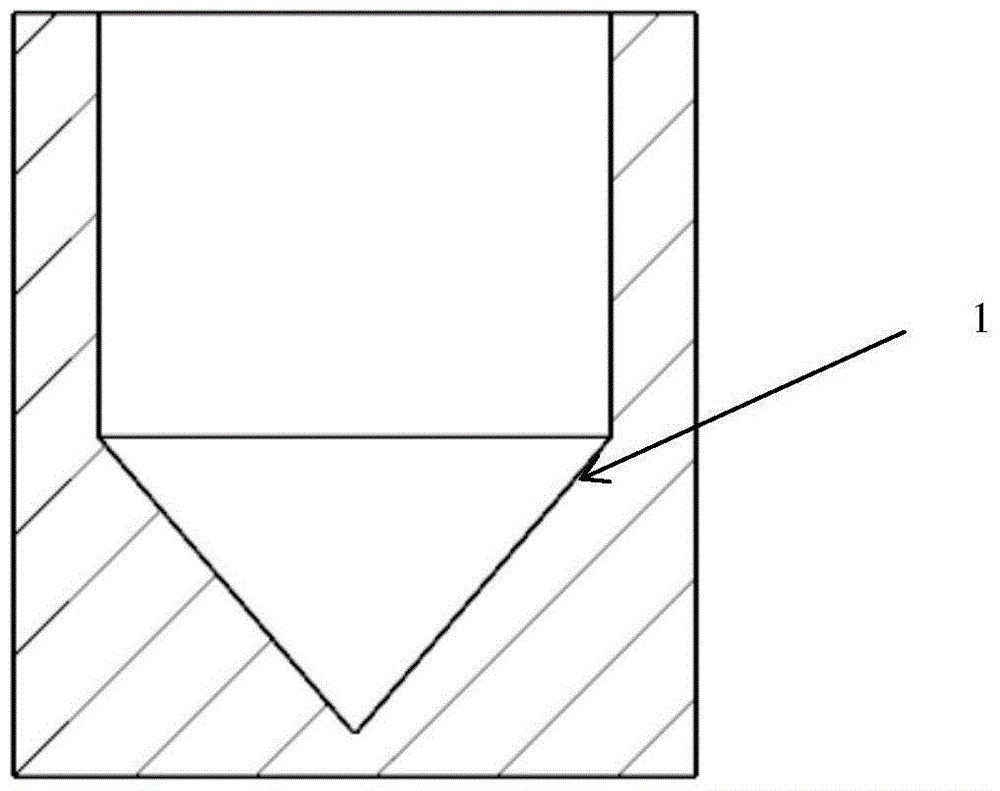

[0024] Such as Figure 1-2 As shown, the oxygen, nitrogen and hydrogen analyzer in this embodiment is used to analyze the oxygen, nitrogen and hydrogen in the titanium alloy, including a furnace head, the furnace head includes a furnace body 2, the furnace body has a furnace chamber inside, and the furnace chamber is provided with a furnace chamber for containing The graphite crucible for placing the sample is fixed on the furnace body with a carrier gas purification filter tube for purifying the gas and a feeding mechanism 3 for putting samples into the graphite crucible inside the furnace cavity. An upper electrode is arranged above the graphite crucible, and the graphite crucible A lower electrode is arranged below, and the furnace head also includes a temperature detector 4 for detecting the temperature inside the furnace cavity and a pneumatic lifting mechanism for controlling the movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com