Patents

Literature

53 results about "Hydrogen analyzer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrogen analyzer is a device used to measure the hydrogen concentration in steels and alloys. It also has industrial applications for corrosion monitoring.

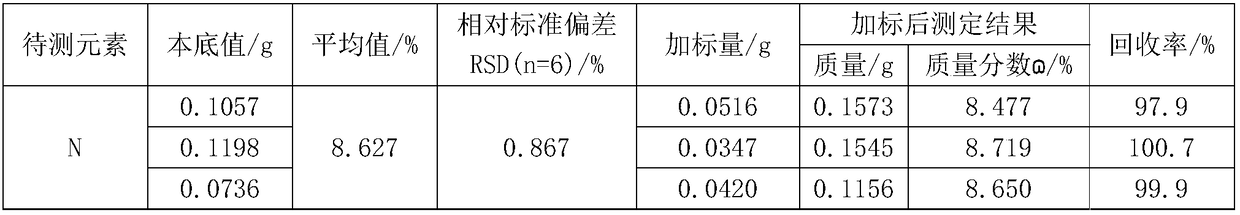

Analytical method of nitrogen content in scrap like steel

InactiveCN102539468ASolving Your Nitrogen Analysis ProblemsAccurate analysisMaterial thermal conductivityCopper oxideOxygen

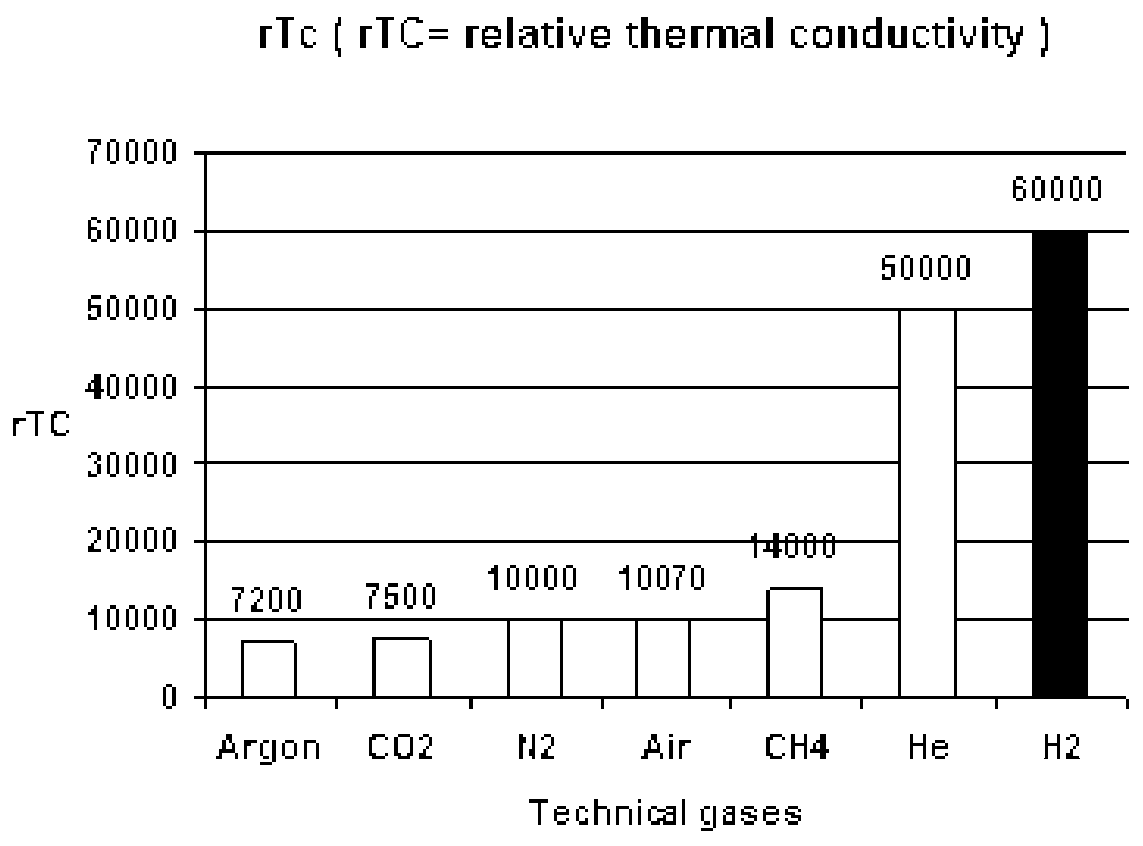

The invention relates to an analytical method of nitrogen content in scrap like steel. The analytical method comprises the following steps: placing a scrap like steel test sample into a beaker, adding acetone, cleaning through an ultrasonic cleaner, and removing pollutants in the test sample for standby; placing a graphite crucible into a heating furnace of an oxygen-nitrogen-hydrogen analyzer for heating and degassing; weighing the test sample after cleaning, and adding the test sample into the graphite crucible after degassing; placing the graphite crucible in which the test sample is placed back into the heating furnace for melting the test sample and releasing mixed gas of carbon monoxide, hydrogen and nitrogen; enabling the mixed gas containing the carbon monoxide, the hydrogen and the nitrogen to enter into a pipeline of the oxygen-nitrogen-hydrogen analyzer and pass through heated copper oxide so as to transform the carbon monoxide in the mixed gas to carbon dioxide and transform the hydrogen into water; absorbing the carbon dioxide and the water, and introducing the remaining nitrogen and helium in the mixed gas into a thermal conductivity cell; enabling the nitrogen and the helium to pass through the thermal conductivity cell to get a curve diagram of changes in thermal conductivity; performing curve calibration on a standard sample according to the steps and then figuring out the nitrogen content in the test sample; and further solving the analysis problem of the nitrogen content in the non-cylindrical steel test sample through a gas analyzer.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

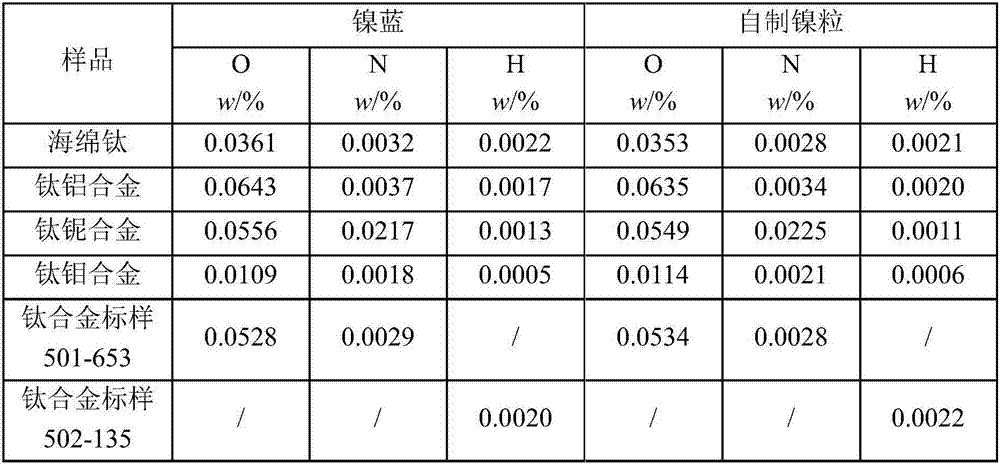

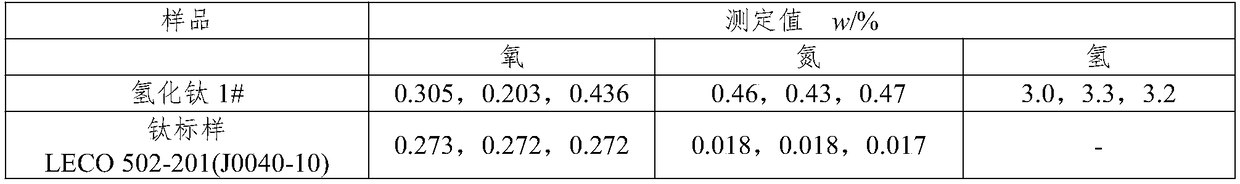

Method for measuring content of oxygen, nitrogen and hydrogen in titanium alloy

InactiveCN107192590AImprove accuracySimple methodPreparing sample for investigationTesting metalsElectrolysisTest sample

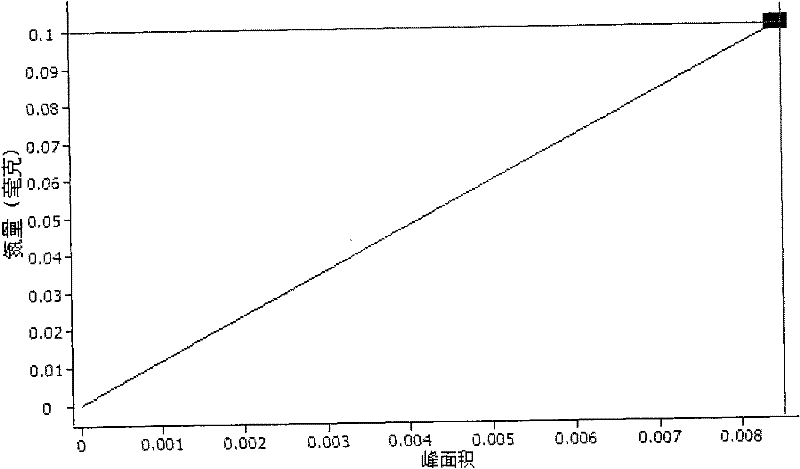

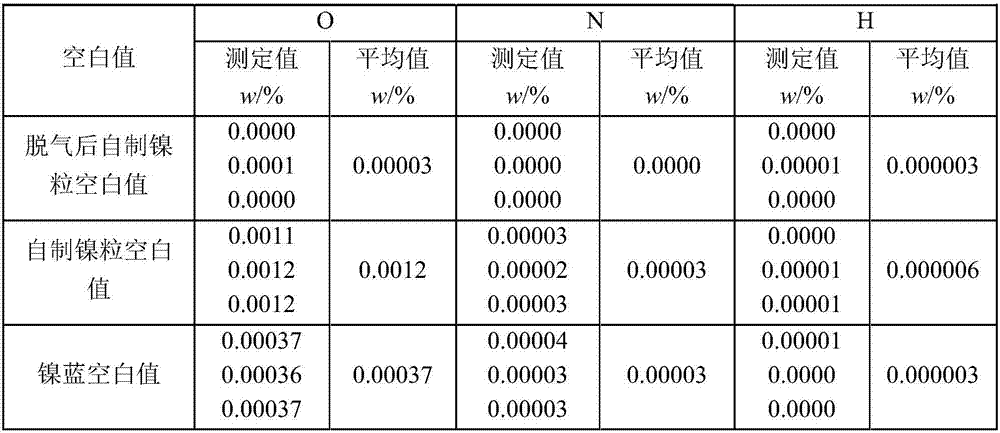

The invention discloses a method for measuring content of oxygen, nitrogen and hydrogen in a titanium alloy. The method comprises the following steps: (1) performing treatment such as cutting and polishing on a high-purity electrolysis nickel board, thereby preparing a nickel particle fluxing agent; (2) putting the nickel particle fluxing agent into an inner high-purity graphite crucible of a lower electrode of an oxygen, nitrogen and hydrogen analyzer, and performing degassing treatment under high power; (3) selecting a measuring condition, and measuring oxygen, nitrogen and hydrogen gas in the titanium alloy through the oxygen, nitrogen and hydrogen analyzer; and (4) calculating mass percentage of oxygen, nitrogen and hydrogen in a test sample. According to the method disclosed by the invention, a self-made nickel particle fluxing agent with a relatively high blank value can be used to replace commercially available fluxing agents such as a nickel basket and nickel scraps, content of oxygen, nitrogen and hydrogen in the titanium alloy is measured through a pulse melting method, interference of the blank value can be remarkably reduced or eliminated by changing normal test steps and analysis conditions, and the same effects of the commercially available fluxing agents are achieved, so that detection cost is greatly reduced; and the method has the advantages of being simple, high in accuracy and the like, and meets the quick detecting requirements.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

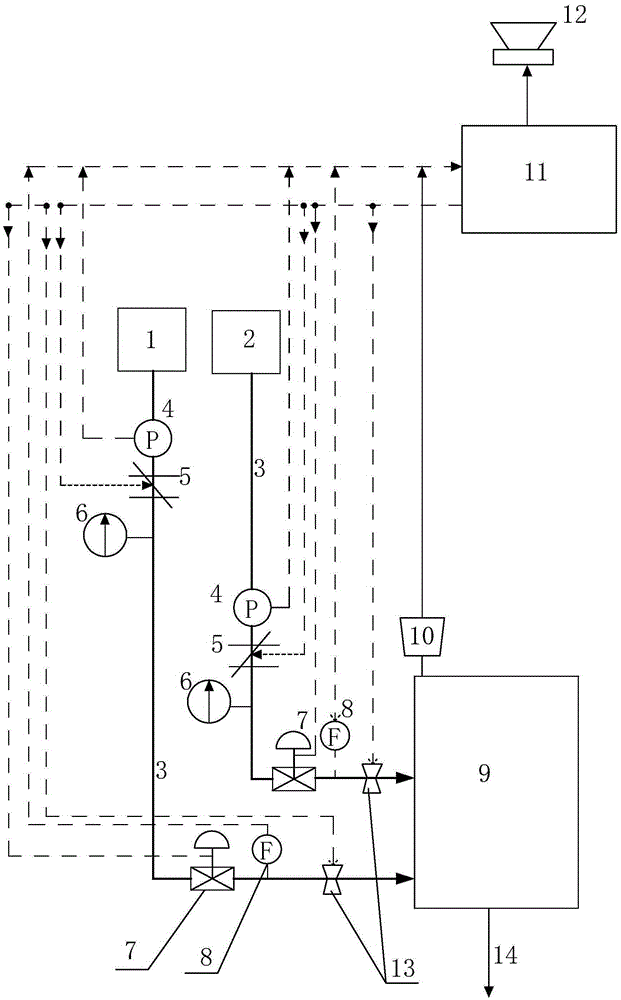

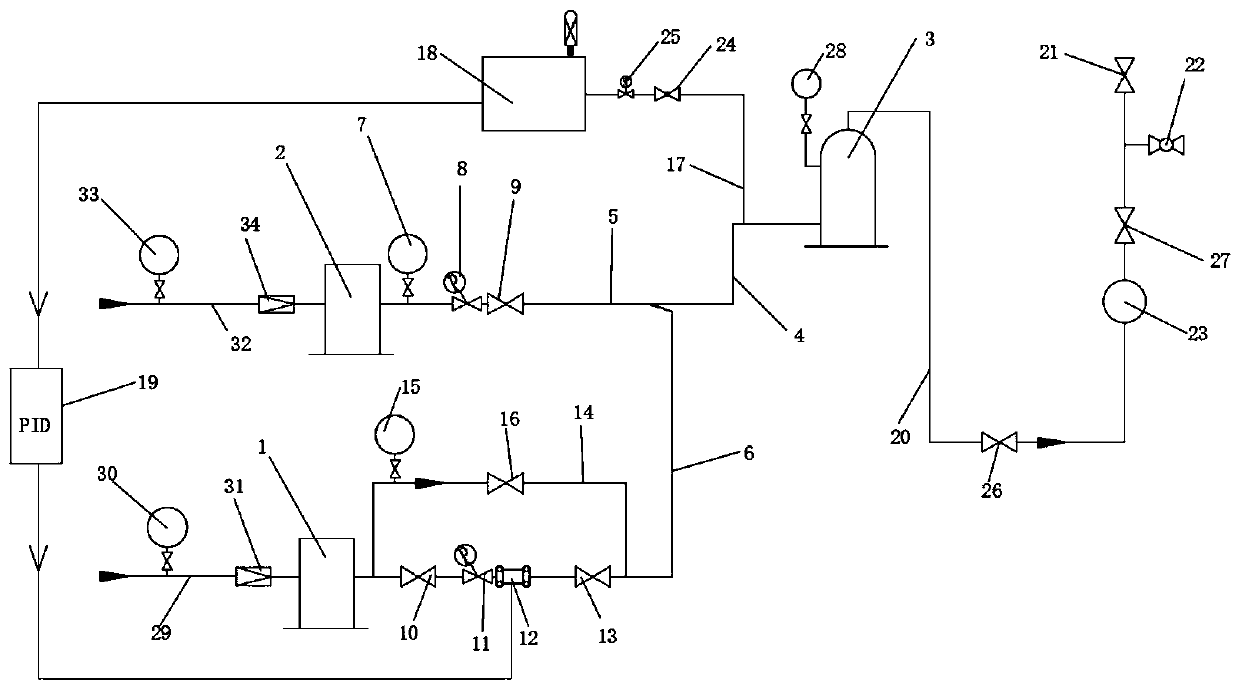

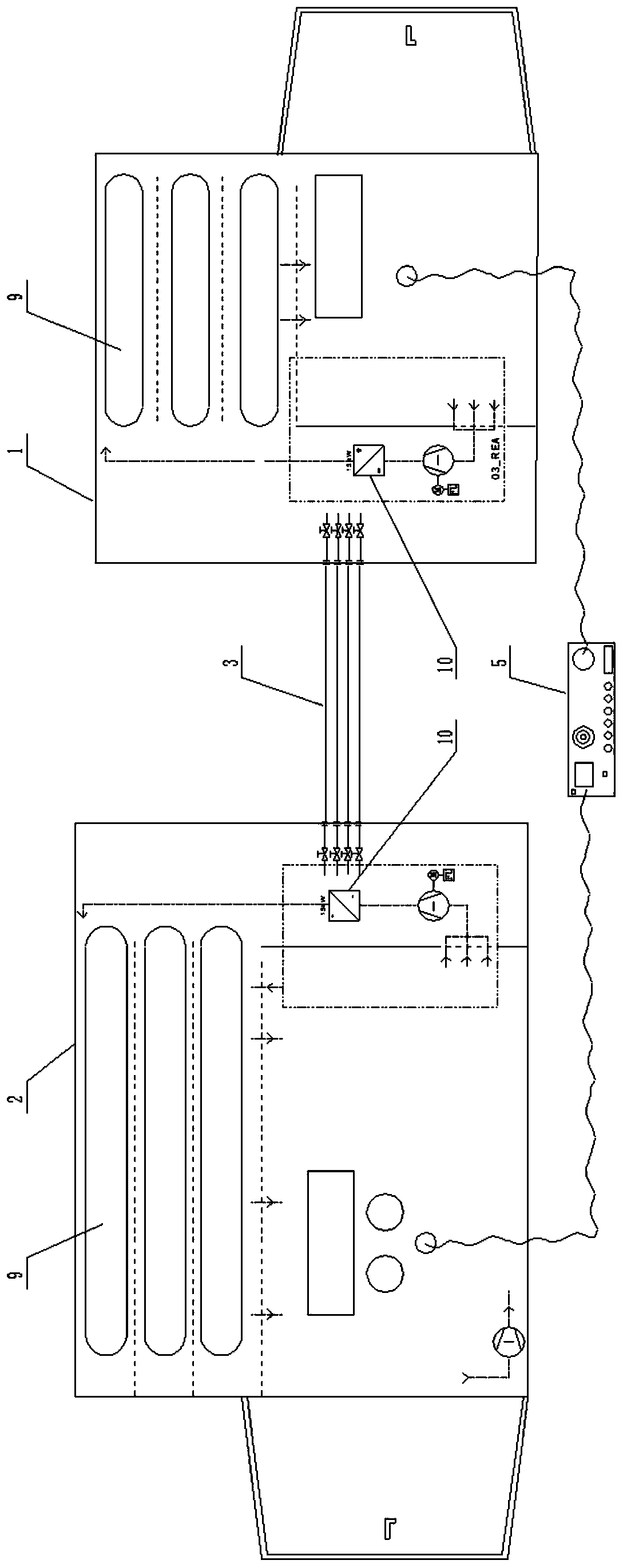

Protective gas monitoring system used for copper wire bonding processing

InactiveCN105334879AAccurate monitoringFast control responseControlling ratio of multiple fluid flowsCopper wireShielding gas

The invention discloses a protective gas monitoring system used for copper wire bonding processing. The protective gas monitoring system comprises a mixing tank, a hydrogen storage tank and a nitrogen storage tank. The hydrogen storage tank and the nitrogen storage tank are connected with an inlet of the mixing tank through conveying pipes. The protective gas monitoring system further comprises a DCS control system and a hydrogen analyzer. A pressure sensor, a pressure adjusting valve, a flow adjusting valve, a flow sensor and a flow meter are sequentially arranged on each conveying pipe. The pressure sensors and the flow sensors are connected with the signal input end of the DCS control system. The pressure adjusting valves, the flow adjusting valves and the flow meters are connected with the signal output end of the DCS control system. The collecting end of the hydrogen analyzer is connected with the mixing tank, and the output end of the hydrogen analyzer is connected with the signal input end of the DCS control system. The system can accurately monitor pressure, flow and a matching value of nitrogen and hydrogen protective gas needed in the copper wire bonding process, effectively increase the yield of products, and has the advantages of being accurate in detection, high in control response speed and sensitive in response.

Owner:GUILIN STRONG MICROELECTRONICS

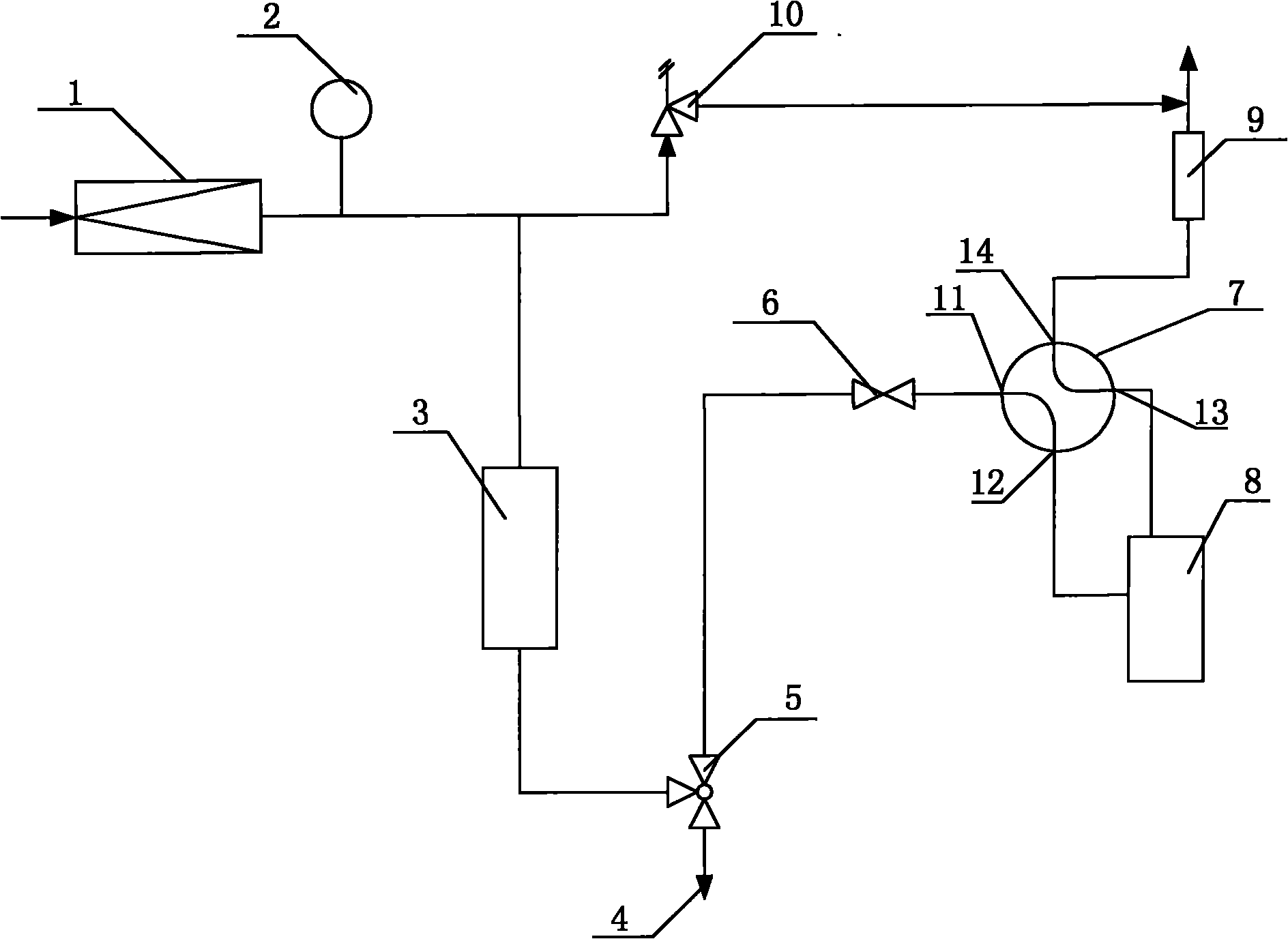

Device for desulfurizing electrolyzed water coal slurry to produce hydrogen

ActiveCN104327902AHigh purityAvoid secondary pollutionElectrolysis componentsMixersElectrolytic agentCo2 storage

The invention provides a device for desulfurizing electrolyzed water coal slurry to produce hydrogen, which has the advantages that the hydrogen is produced in a process of desulfurizing coal and the desulfurizing speed is high. The device comprises a material distribution system, an electrolysis system, a gas recycling system and a coal recycling system, wherein the material distribution system comprises a funnel feeding machine, a microwave drying machine, a belt conveyor, a powder mill, a material distribution funnel, a dry powder agitator and a slurry agitator; the electrolysis system comprises agitation tanks, an electrolysis tank, a direct-current pulse power supply cabinet, a microwave irradiation device, ultrasonic vibration rods, an electrode and a pipe net; a submerged pump is arranged in a separation plate between the two agitation tanks; the outlet of the pump is communicated with the pipe net at the bottom of the electrolysis tank by an electrolyte pipe; the electrode is vertically arranged at the center of the electrolysis tank and is of a closed square shape surrounded by four sets of electrode plates; the ultrasonic vibration rods are arranged on the two sides of the electrode in the electrolysis tank; and the gas recycling system comprises a carbon dioxide storage tank, a hydrogen storage tank, a pressure gauge, a flow meter, a check valve, a stop valve, a gate, a hydrogen analyzer, an emptying valve, a buffering tank and a boosting pump.

Owner:王号德

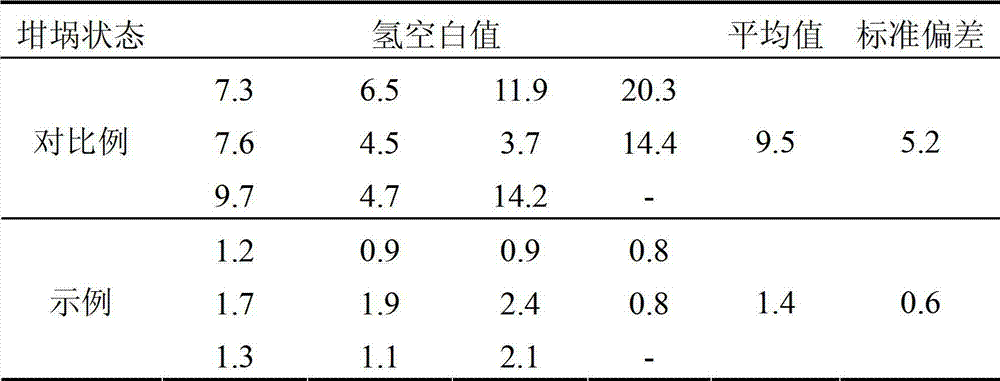

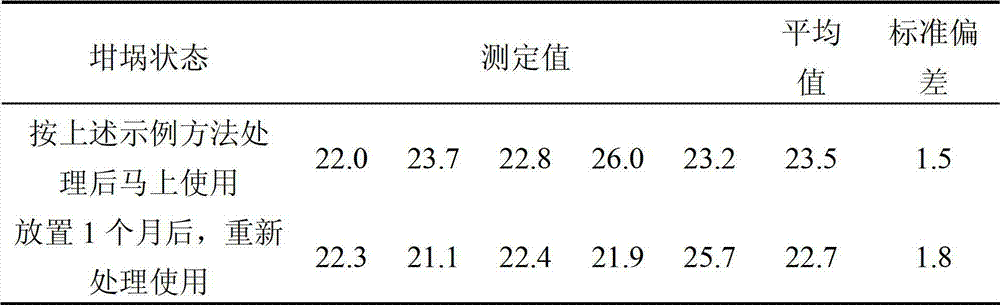

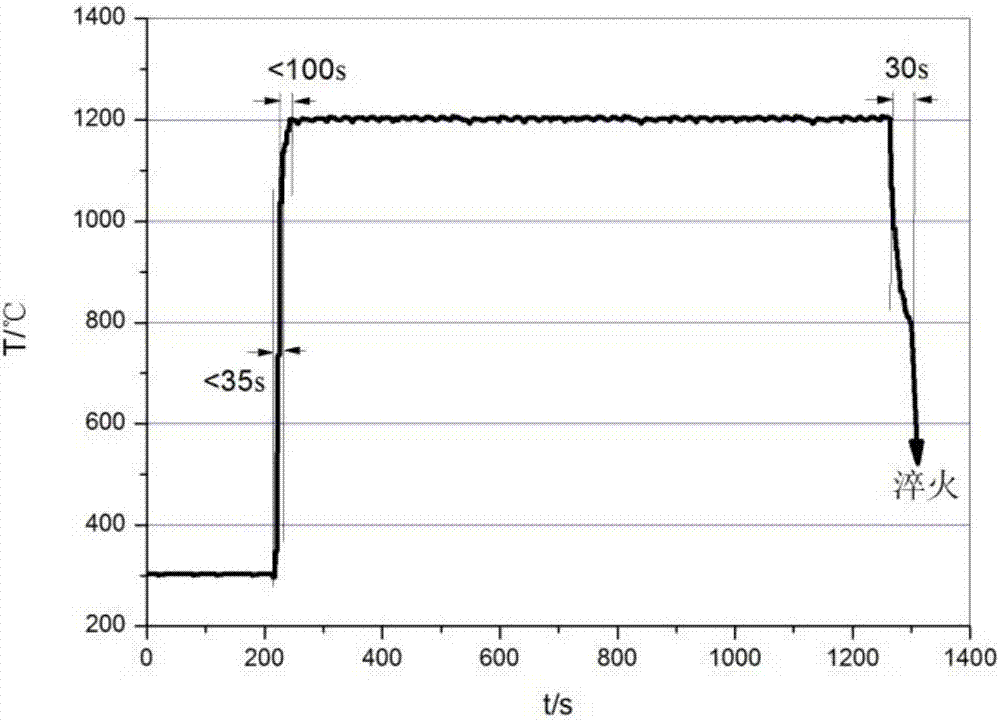

Method for improving precision and accuracy of hydrogen in oxygen-nitrogen-hydrogen combined determination of titanium or titanium alloy

ActiveCN102967619AReduce the hydrogen blank valueStable hydrogen blank valuePreparing sample for investigationMaterial thermal analysisFurnace temperatureNitrogen

The invention provides a method for improving precision and accuracy of hydrogen in oxygen-nitrogen-hydrogen combined determination of titanium or a titanium alloy. The method comprises the following steps of: putting a graphite crucible into a high temperature furnace, filling inert gases into the high temperature furnace to discharge air in the furnace; carrying out heating, and maintaining temperature for more than 5h under a furnace temperature of 700 to 1000 DEG C; freely decreasing the temperature to the temperature of 400 to 500 DEG C, and then taking out the graphite crucible; then, mounting the graphite crucible into an electrode furnace of an oxygen-nitrogen-hydrogen analyzer, and carrying out degassing for 30-44 seconds under the temperature of 2300 to 2700 DEG C; and putting to-be-detected titanium or titanium alloy together with a nickel basket into the graphite crucible, and carrying out oxygen-nitrogen-hydrogen combined determination. According to the method provided by the invention, hydrogen baseline value of an oxygen-nitrogen-hydrogen combined determination system can be effectively reduced, and the obtained hydrogen baseline value is stable, so that the precision and the accuracy of the hydrogen in the oxygen-nitrogen-hydrogen combined determination of the titanium or the titanium alloy can be improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

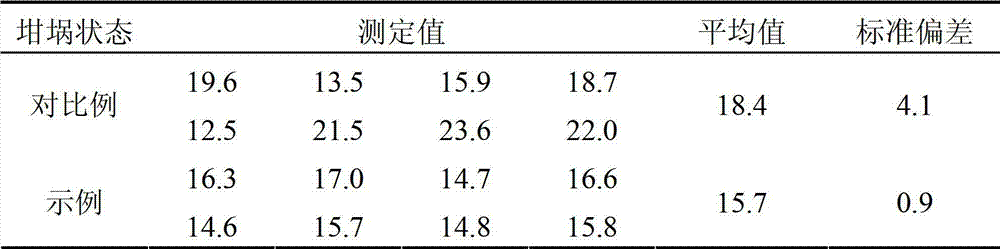

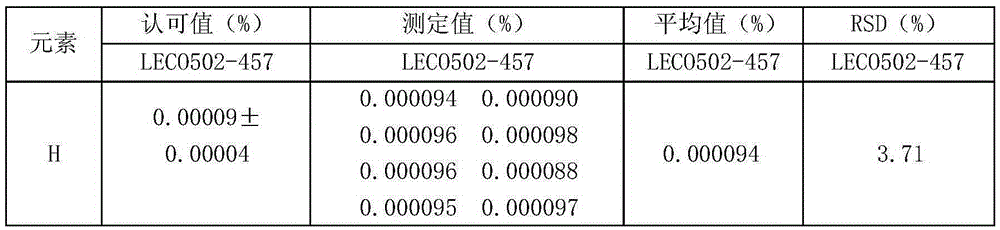

Method for measuring content of trace hydrogen in low alloy steel

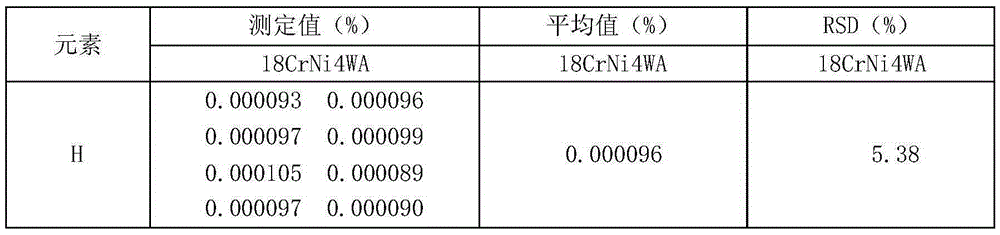

InactiveCN106568676AImprove accuracyLow and stable blank valueMaterial analysisHydrogen contentMaterials science

The invention relates to a method for measuring the content of trace hydrogen in low alloy steel. According to the method, a hydrogen analyzer is adopted, an inert gas pulse heating-thermal conductivity method is used to measure the content of trace hydrogen (less than 0.0002%) in low alloy steel, and the method comprises the following steps: preparing experiment conditions, preparing a sample, carrying out a blank experiment, calibrating a hydrogen analyzer, and measuring the hydrogen content of the sample. The provided method improves the accuracy of the measurement results and solves the problem that the content of trace hydrogen (less than 0.0002%) in low alloy steel is difficult to measure.

Owner:SHAANXI HONGYUAN AVIATION FORGING

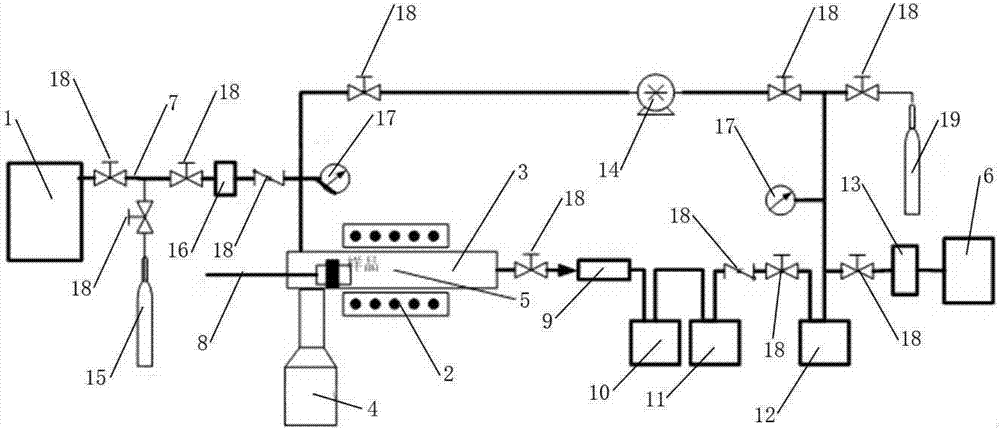

High-temperature steam oxidation quenching test device and method for reactor cladding material

ActiveCN107167488AImprove efficiencyEasy to controlMaterial thermal analysisSafety controlEngineering

The invention belongs to the technical field of nuclear safety control and relates to a high-temperature steam oxidation quenching test device and method for a reactor cladding material. The test device comprises a steam generator, an ordinary resistance furnace, a reaction chamber, a quenching tank, a thermocouple, a hydrogen analyzer and connecting pipes, wherein high-temperature steam provided by the steam generator enters the reaction chamber through the connecting pipe; the reaction chamber is used for accommodating a sample for a high-temperature steam oxidation quenching test; the reaction chamber is heated by a common resistance furnace outside the reaction chamber; the thermocouple is installed in the reaction chamber for measuring and controlling the temperature; the quenching tank is connected to the lower part of the reaction chamber for quenching the sample falling into the water in the quenching tank; the hydrogen analyzer is connected to the reaction chamber through the connecting pipe for analyzing content of hydrogen gas generated in the reaction chamber. With adoption of the test device and method, whether the reactor cladding material meets safety criteria can be evaluated easily and efficiently with the temperature accurately controlled and at a low cost.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

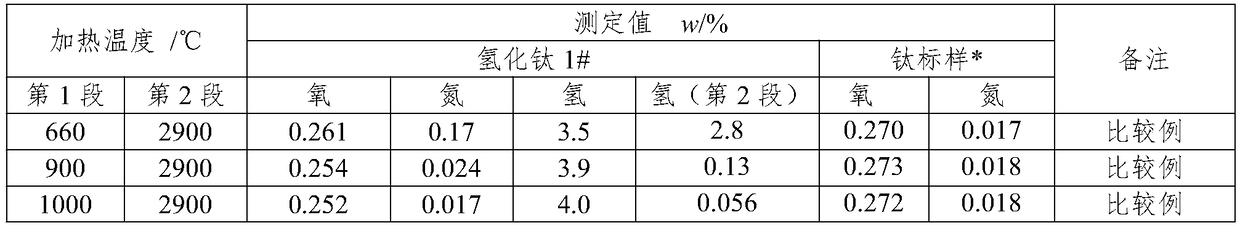

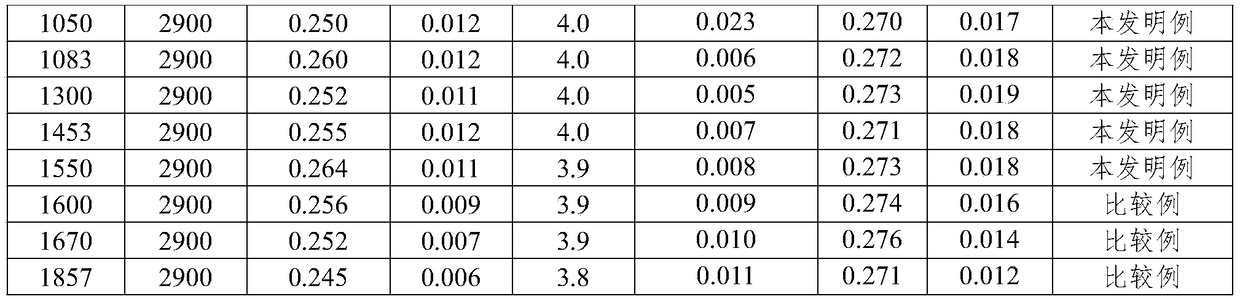

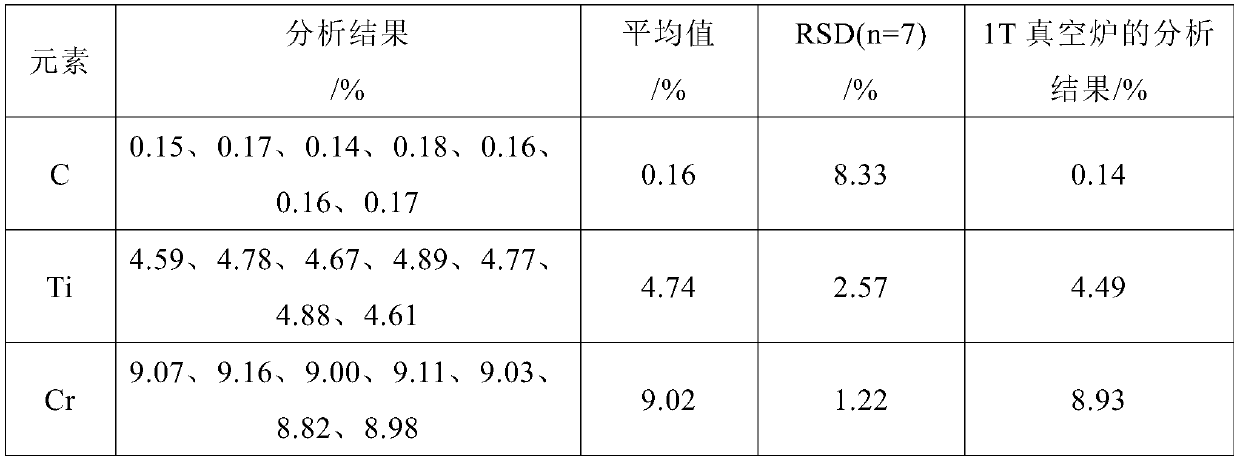

Method for simultaneously determining contents of oxygen, nitrogen, and hydrogen in titanium alloy

ActiveCN109342500AEliminate distractionsImprove work efficiencyMaterial heat developmentHydrogen contentNitrogen

The invention relates to a method for simultaneously determining the contents of oxygen, nitrogen, and hydrogen in titanium alloy, and belongs to the technical field of non-metallic impurity detectionfor the titanium alloy. The technical problem to be solved by the invention is to provide a method for simultaneously determining the contents of oxygen, nitrogen, and hydrogen in the titanium alloy.The technical scheme of the invention is as follows: the titanium alloy is put into an oxygen-nitrogen-hydrogen analyzer based on an inert gas fusion-infrared absorption and / or thermal conductivity method; the metal nickel is used as a fluxing agent; and a two-stage heating mode is adopted for the determination, wherein the first-stage heating temperature is 1050 DEG C to 1550 DEG C, and the second-stage heating temperature is 2700 DEG C to 3000 DEG C; and the hydrogen content in the titanium alloy is 0.030% to 4.1% (w / w). According to the method for simultaneously determining the contents ofoxygen, nitrogen, and hydrogen in the titanium alloy, the oxygen, nitrogen, and hydrogen in the titanium alloy are released in a segmented mode by adopting the two-stage heating mode, thereby eliminating the interference of high hydrogen content in nitrogen determination, and realizing the simultaneous determination of the three elements; and the detection result is accurate, and the result is consistent with the result determined step by step by a chemical method.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

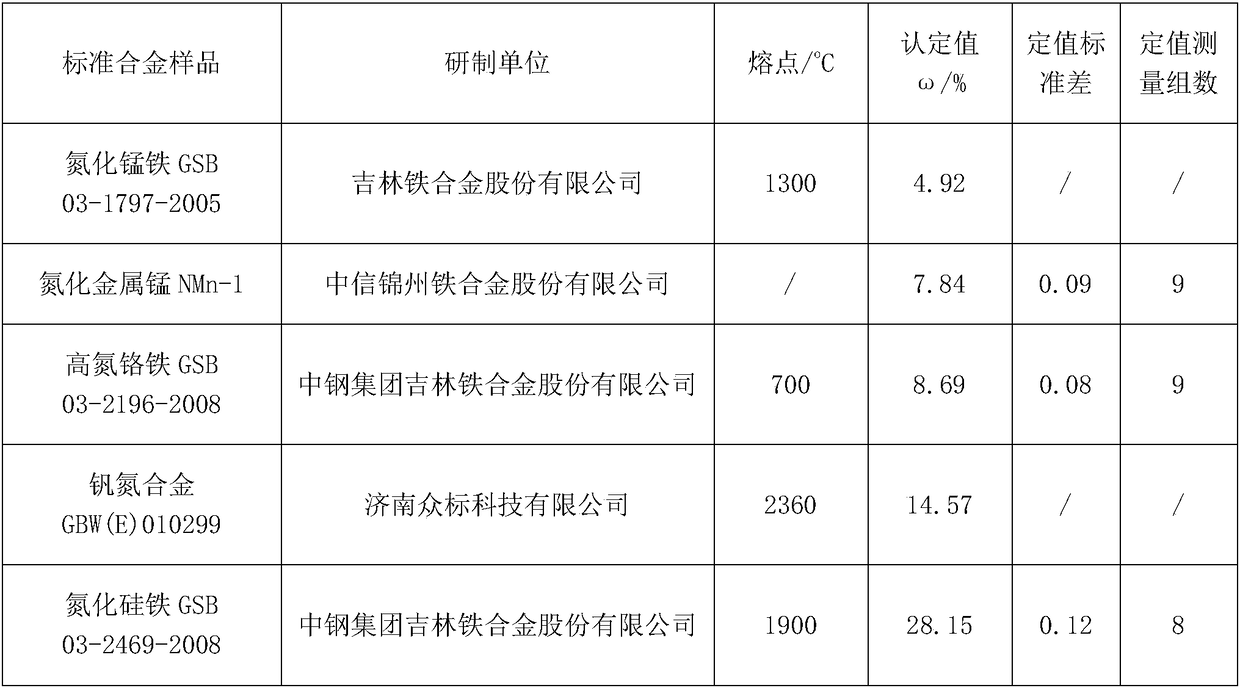

Rapid analysis method for major elements, minor elements and trace elements in alloy slag charge

InactiveCN110865168AImprove guidanceReduce testing costsPreparing sample for investigationTesting metal constituentsSlagFluorescence

The invention relates to a rapid analysis method for major elements, minor elements and trace elements in alloy slag charge. The rapid analysis method comprises the following steps: performing ultrasonic alkaline liquid cleaning on alloy slag charge, cleaning with pure water, performing ultrasonic cleaning with an organic reagent and blow-drying, preparing a cake-shaped sample by using the alloy slag charge, pressing the cake-shaped sample, grinding, polishing, cleaning with the organic reagent and blow-drying, and analyzing major elements, minor elements and trace elements in the cake-shapedsample by using at least one instrument of a carbon-sulfur analyzer, an oxygen-nitrogen-hydrogen analyzer, a spectrograph, an X ray fluorescent spectrograph and a mass spectrometer. The method provided by the invention can optimize a combination according to detectability and ranges of the instruments and perform analytical determination on the major elements, minor elements and trace elements, and determination cost is reduced; and the method has good guiding effect on high-temperature alloy slag charge remelting and smelting.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Control device for oxygenation intermittent coal gas preparation

InactiveCN101503635AReduce blowing heating timeIncrease gas production timeEnergy industryCombined combustion mitigationAir compressionControl system

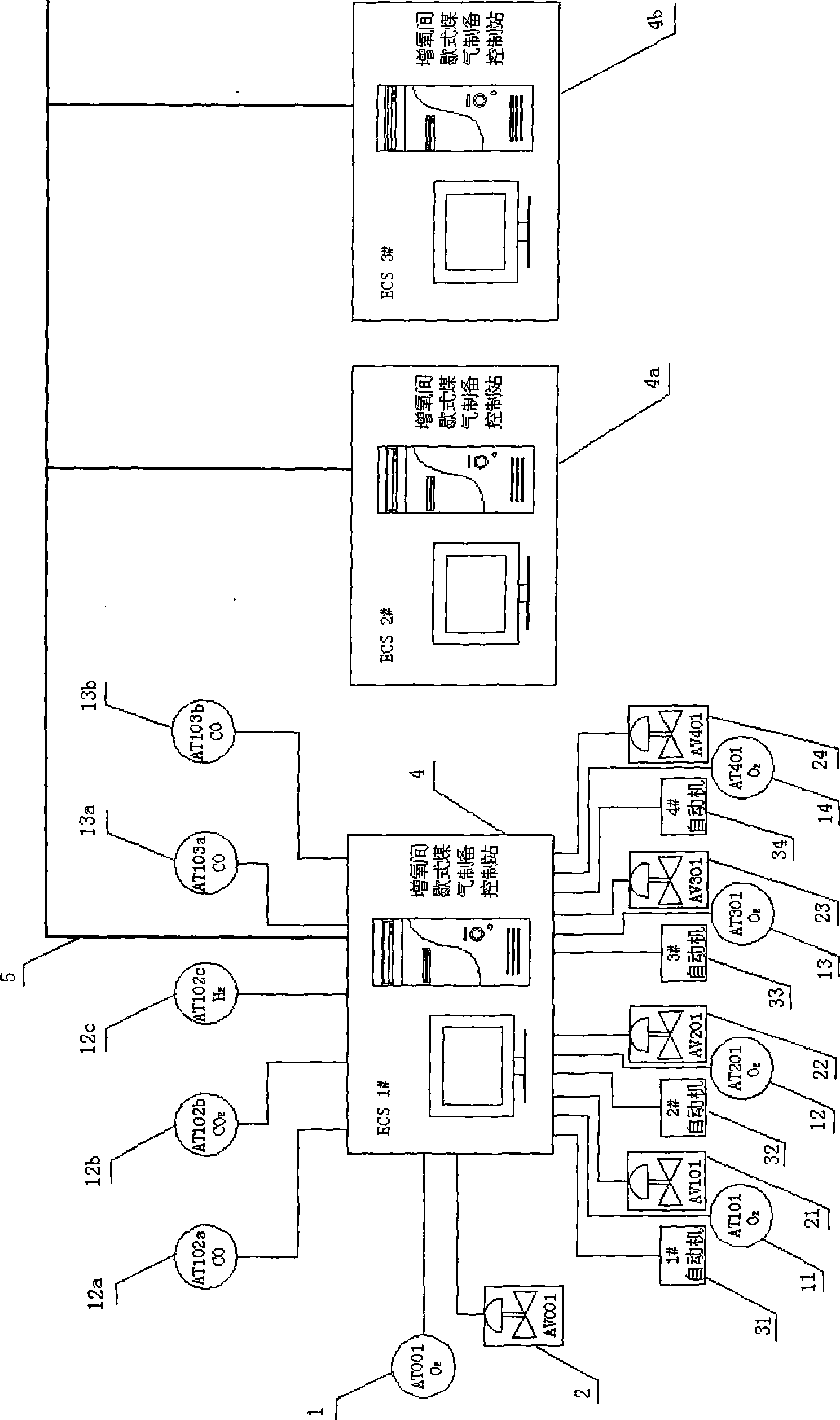

The invention discloses an oxygen enrichment intermittent coal gas preparation control device, which comprises an air compression tank, a coal gas producer and a control system. In the control system of the device, an embedded control station is connected with a magnetic oxygen analyzer, an infrared CO / CO2 analyzer, a thermal conductivity hydrogen analyzer, a pneumatic diaphragm control valve and an automaton respectively, and the magnetic oxygen analyzer, the infrared CO / CO2 analyzer and the thermal conductivity hydrogen analyzer are connected with the coal gas producer respectively. The device adopts a quality feedback principle to determine the oxygen concentration in oxygen-enriched air and the oxygen enrichment time according to reference elements such as compositions of blown gas or uplink and downlink coal gas, the producer temperature and the like, adopts a feedforward plus feedback algorithm and an adjustment link to ensure the adjustability and stability of oxygen enriched concentration, and realizes data communication by connecting the Ethernet with production local area networks inside enterprises in an OPC mode.

Owner:武汉奥泰自动化工程有限责任公司

Method for analyzing and detecting content of nitrogen in alloy

The invention provides a method for analyzing and detecting the content of nitrogen in alloy. The method comprises the following steps: weighing an alloy sample to be detected, and grinding the alloysample to be detected to form powder; covering the alloy sample to be detected with a flux, and heating the alloy sample to be detected to melt the alloy sample to be detected in order to generate nitrogen; and introducing the generated nitrogen into an oxygen, nitrogen and hydrogen analyzer in order to obtain the content of nitrogen in the alloy sample to be detected. The method for analyzing anddetecting the content of nitrogen in alloy has the advantages of simplicity, fastness, small low detection limit, overcoming of complex sample treatment processes of a chemical method, high efficiency, energy saving, environmental protection, broad application prospect, and bringing of long-term economic and social benefits in future practical production.

Owner:TAIYUAN HEAVY IND

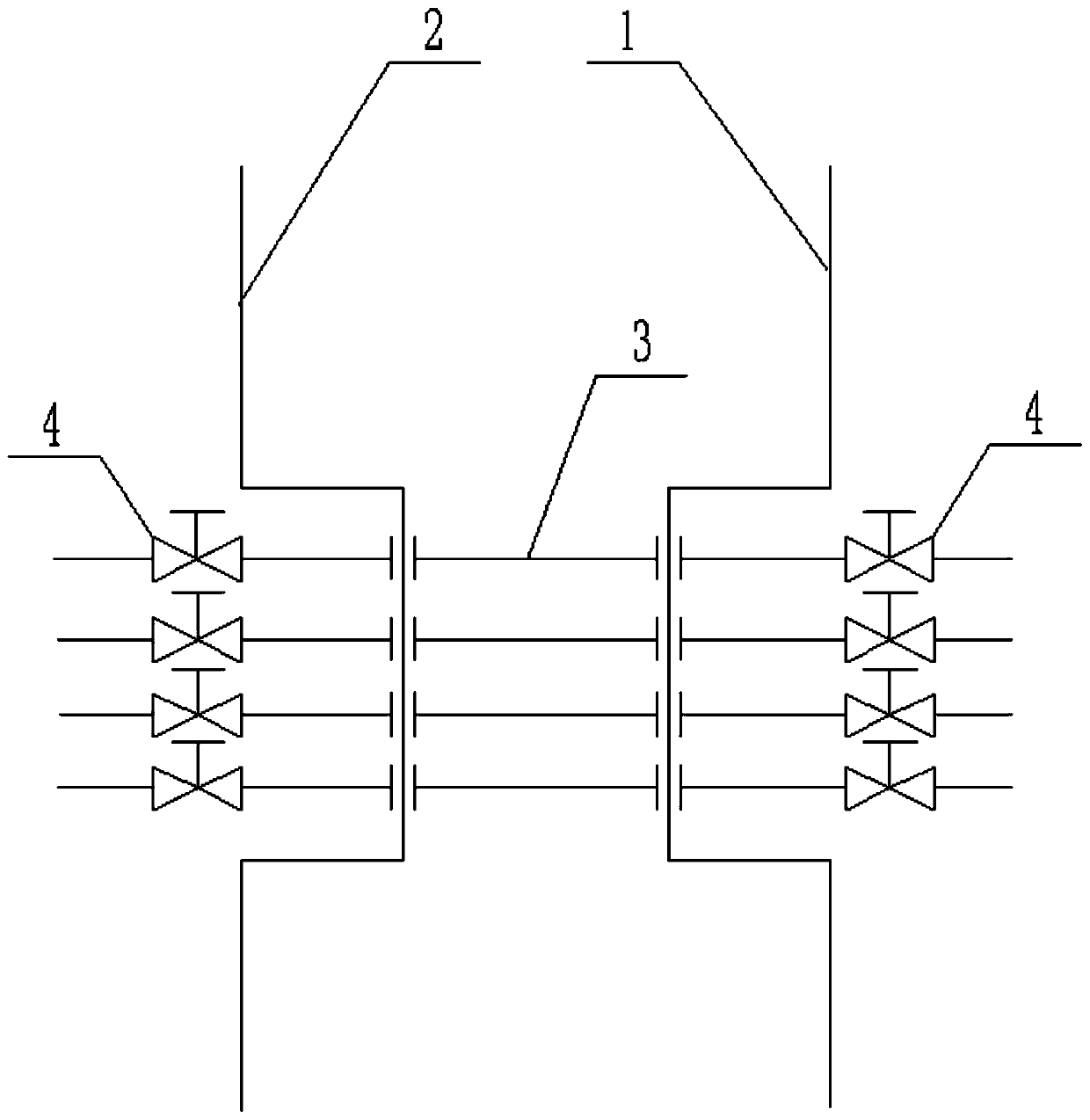

Online leakage detection method and device for non-oxidation furnace radiant tube containing shielding hydrogen gas

InactiveCN102879155ADoes not affect productionEasy to implementDetection of fluid at leakage pointPhysical chemistryEngineering

The invention discloses an online leakage detection method for non-oxidation furnace radiant tube containing shielding hydrogen gas. The online leakage detection method includes steps of 1), emptying gas in a non-oxidation furnace radiant tube and then closing the non-oxidation furnace radiant tube; 2), opening any one of joints of closed space and leading sampled gas in the closed space to be communicated with a hydrogen analyzer through the joint; 3), analyzing the sampled gas, determining that a leak point of the non-oxidation furnace radiant tube exists if the sampled gas contains hydrogen gas, and determining that no leak point of the non-oxidation furnace radiant tube exists if content of hydrogen gas in the sampled gas is zero. An online leakage detection device comprises a hydrogen analyzer, a gas inlet of the hydrogen analyzer is connected with one end of a gas sampling tube, the other end of the gas sampling tube is used for being connected with any joint, communicated with the outside, on the non-oxidation furnace radiant tube, and an exhaust outlet of the hydrogen analyzer is connected with an exhaust tube. By the online leakage detection method, online quick leakage-detection to the non-oxidation furnace radiant tube can be realized accurately, reliably, conveniently and quickly.

Owner:武钢集团有限公司

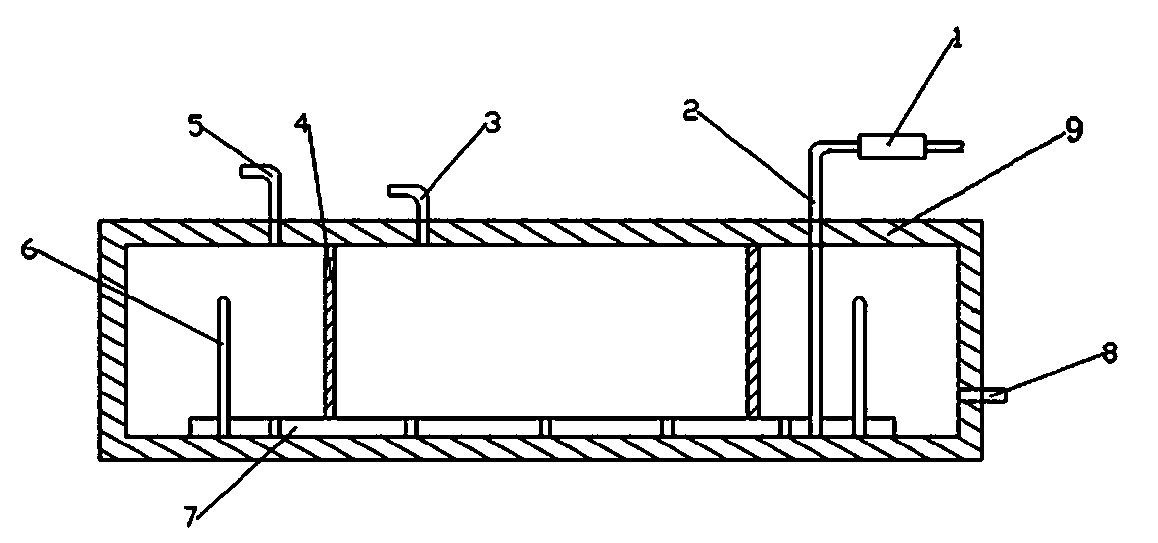

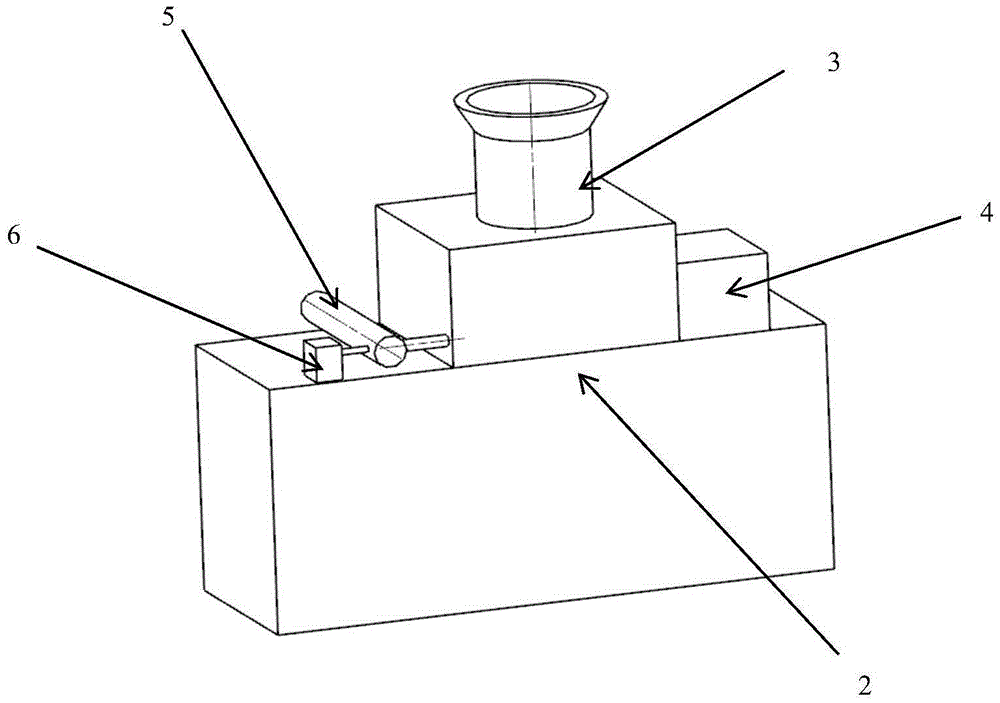

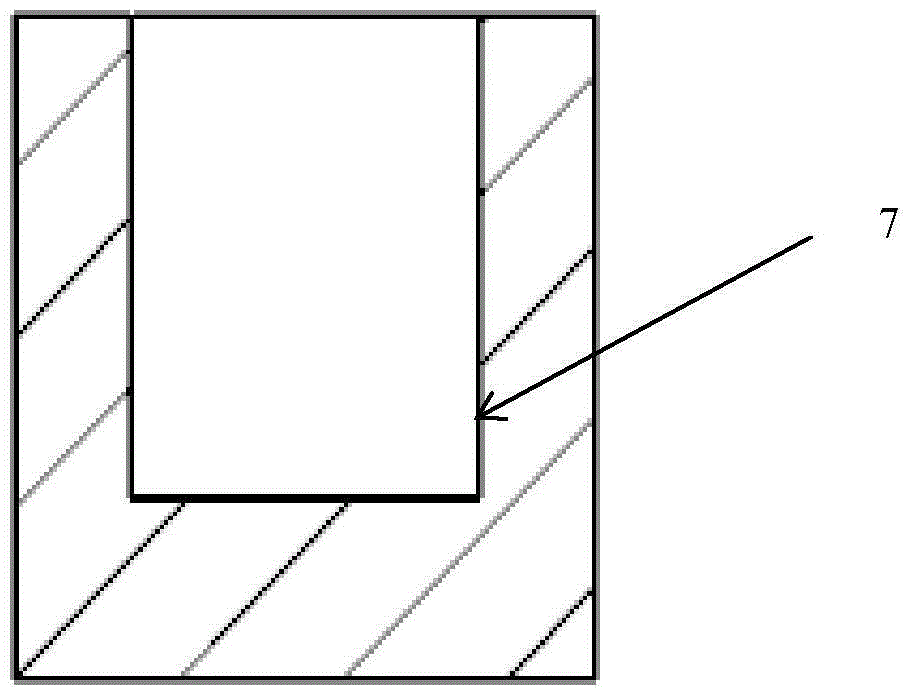

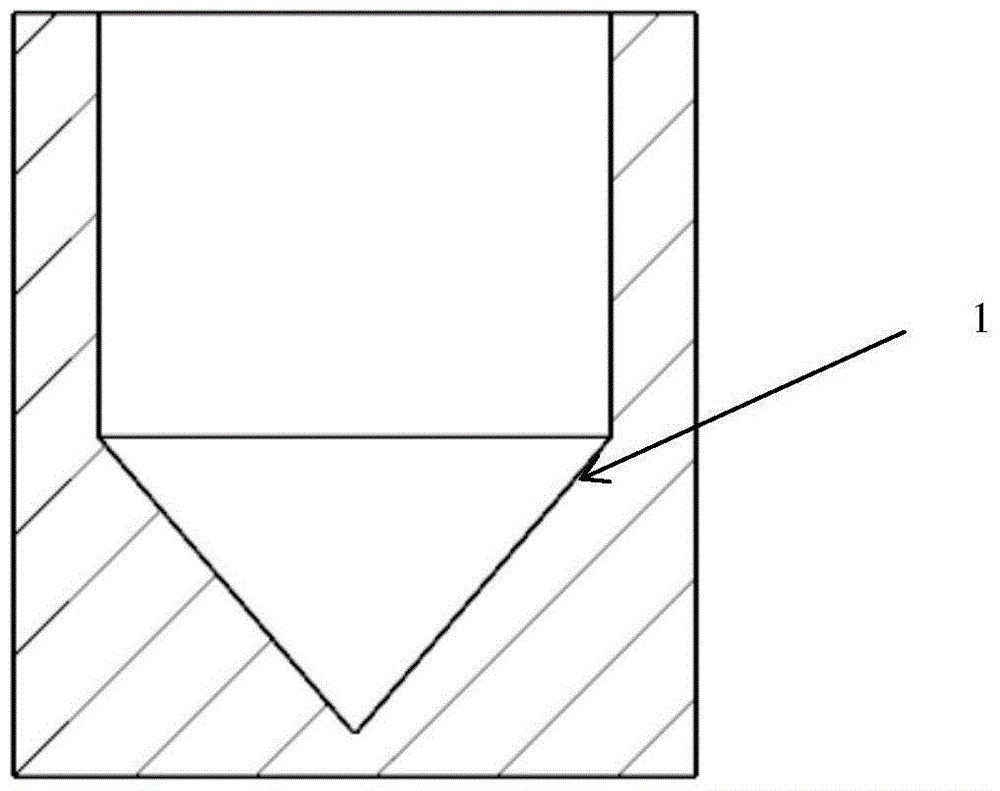

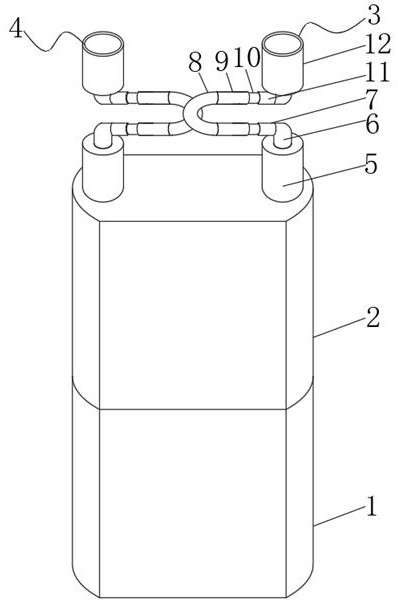

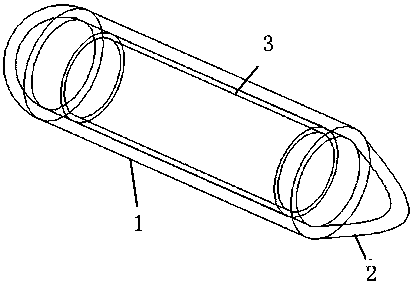

Carrier gas purification filter pipe for oxygen-nitrogen-hydrogen analyzer, furnace head and oxygen-nitrogen-hydrogen analyzer

ActiveCN105223135AHigh precisionReduce analysis costsMaterial heat developmentMaterial analysis by optical meansNitrogenGraphite

The invention relates to a carrier gas purification filter pipe for an oxygen-nitrogen-hydrogen analyzer, a furnace head and an oxygen-nitrogen-hydrogen analyzer, and belongs to the technical field of oxygen-nitrogen-hydrogen analysis. The carrier gas purification filter pipe for the oxygen-nitrogen-hydrogen analyzer comprises a filter pipe and a filtering material arranged in the filter pipe and used for filtering gas, as well as a linear displacement detector used for detecting the displacement of the filtering material. According to the carrier gas purification filter pipe for the oxygen-nitrogen-hydrogen analyzer, the linear displacement detector is used for precisely displaying the amount of graphite powder adsorbed by the filtering material in the filter pipe, and the filtering material can be timely replaced, so that the precision of an analysis result is improved, and the analysis cost is reduced.

Owner:LUOYANG PENGQI IND

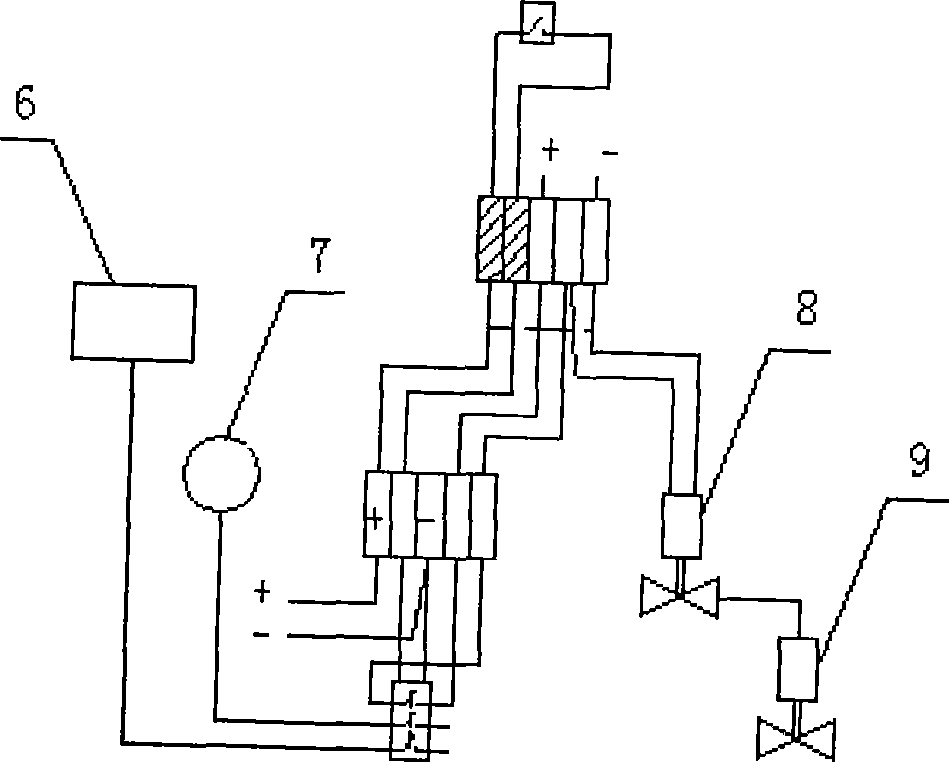

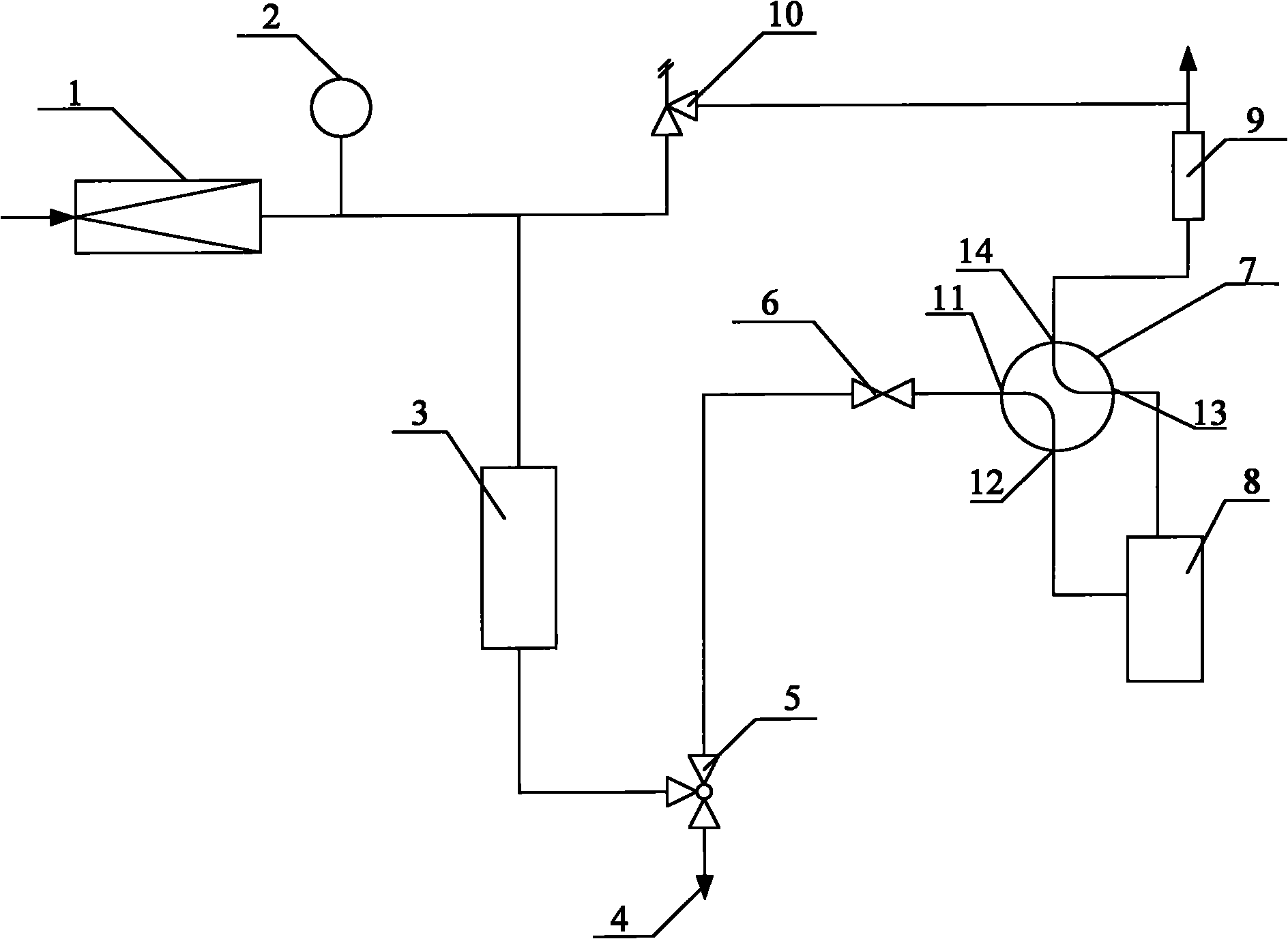

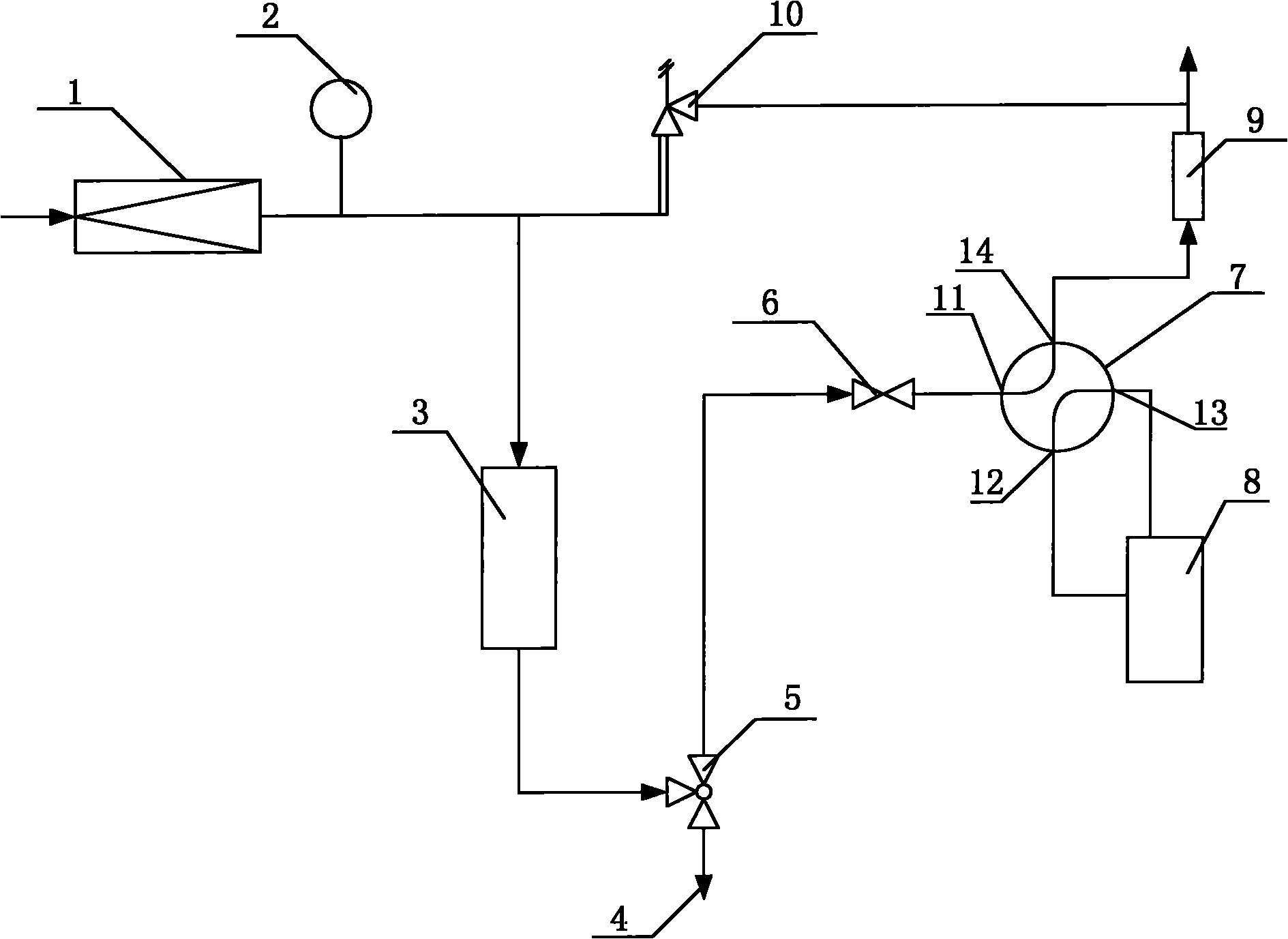

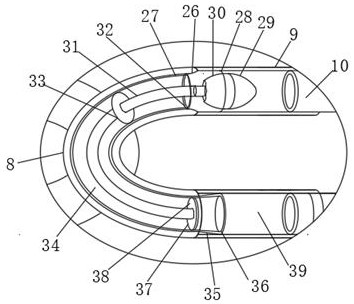

Multi-functional pretreatment device for water-electrolysis hydrogen production analyzer

InactiveCN102135529AAvoid damageReduce riskElectrolysis componentsPreparing sample for investigationFour-way valveProduct gas

The invention provides a multi-functional pretreatment device for water-electrolysis hydrogen production analyzer. The device comprises water-electrolysis hydrogen production equipment, the water-electrolysis hydrogen production equipment is connected with a pressure reducer, the pressure reducer is connected with a drier, the drier is connected with an entrance end of a two-position three-way valve, an exit end of the two-position three-way valve is externally connected to a manual sampling analysis pipeline and the other exit end of the two-position three-way valve is connected to a micrometering valve, the micrometering valve is connected to a first entrance end of a two-position four-way valve, a first exit end of the two-position four-way valve is connected with an analysis meter, the analysis meter is connected to a second entrance end of the two-position four-way valve, a second exit end of the two-position four-way valve is connected with a gas flow meter, the entrance end of the drier and the exit end of the gas flow meter are provided with pressure releasing pipelines, and the pressure releasing pipelines are provided with miniature safety valves. By the switching of a valve gate of the two-position four-way valve, damage to a probe of the analysis meter due to long term operation in the air and disqualified gas can be avoided, so that the analysis meter is prevented from damage, and the maintenance cost is saved.

Owner:SUZHOU JINGLI HYDROGEN MAKING EQUIP

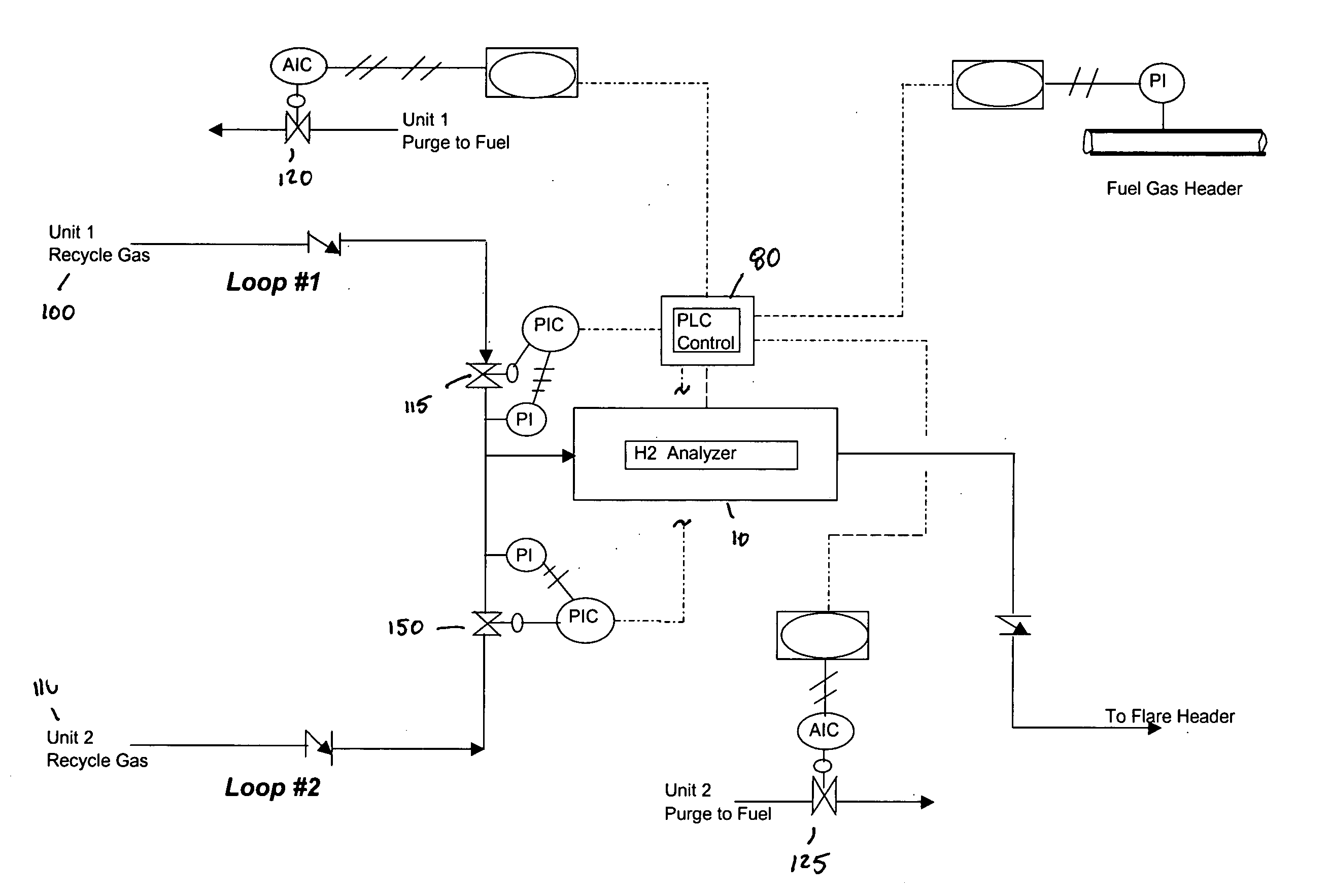

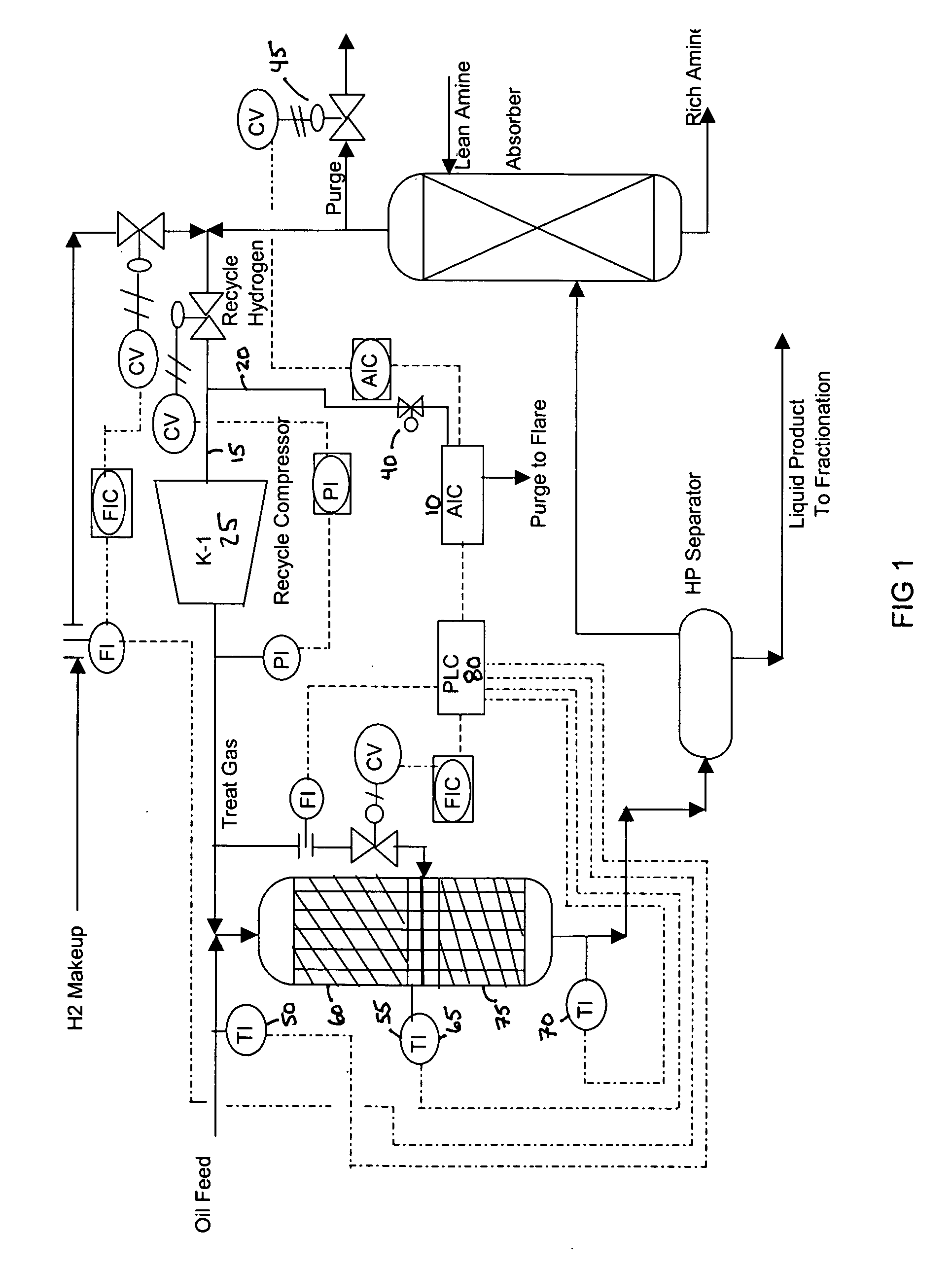

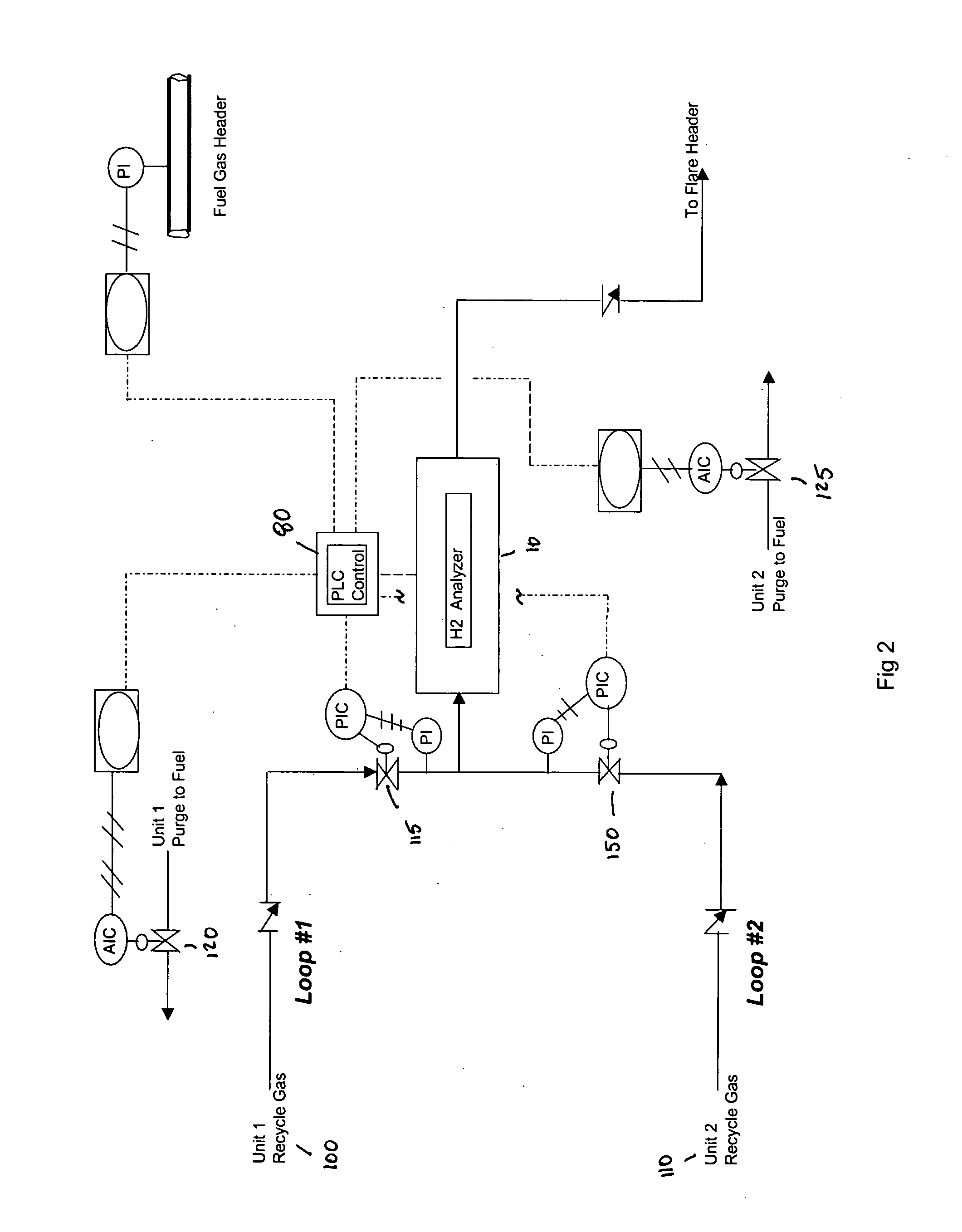

Process for controlling hydrogen partial pressure in single and multiple hydroprocessors

InactiveUS20060040399A1Long catalyst lifePrevent coke formationHydrocarbon oils treatment control/regulationMaterial analysis by optical meansHydrogen purityControl signal

A control scheme for controlling hydrogen partial pressure is provided that generally comprises a hydrogen purity analyzer that measures hydrogen purity on one or more hydroprocessing units. The hydrogen analyzer measures the purity of the treat gas, which is converted into a control signal and is transmitted to the appropriate hydroprocessing unit's purge gas controller. As hydrogen purity decreases in the hydroprocessing unit's recycle stream, the purge gas control valve opens and purges cracked gas contaminants. As hydrogen purity fluctuates, the purge gas control valve will open and close to maintain the desired purity setpoint. A programmable logic controller manages the inputs from the one or more hydroprocessing units and the signals that are transmitted to each unit's purge controller. The programmable logic controller may also be utilized to reactor hydrogen quench systems. The control of hydrogen partial pressure improves catalyst activity, hydrogen usage, and fuel efficiency.

Owner:HURT WILLIAM F

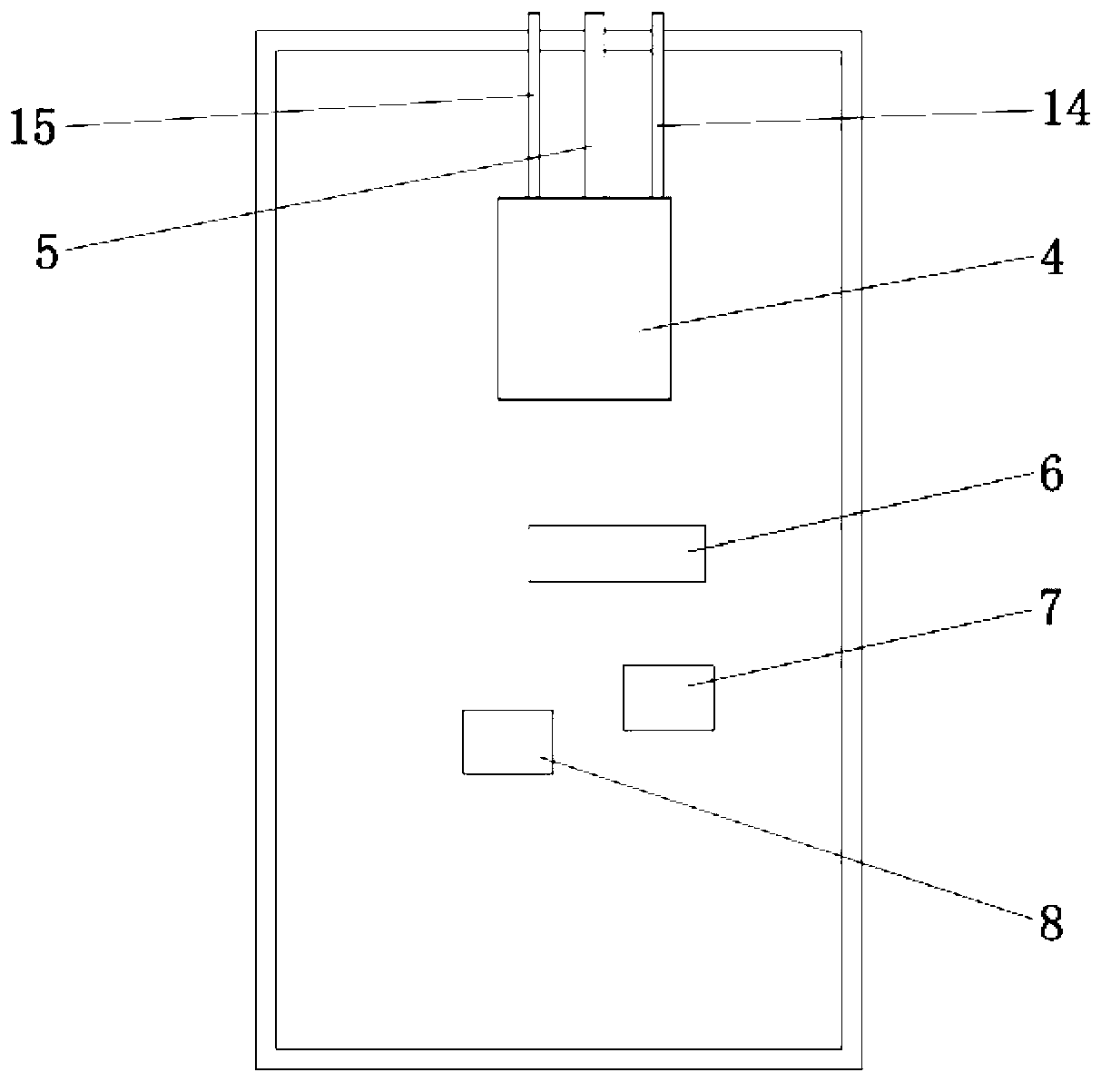

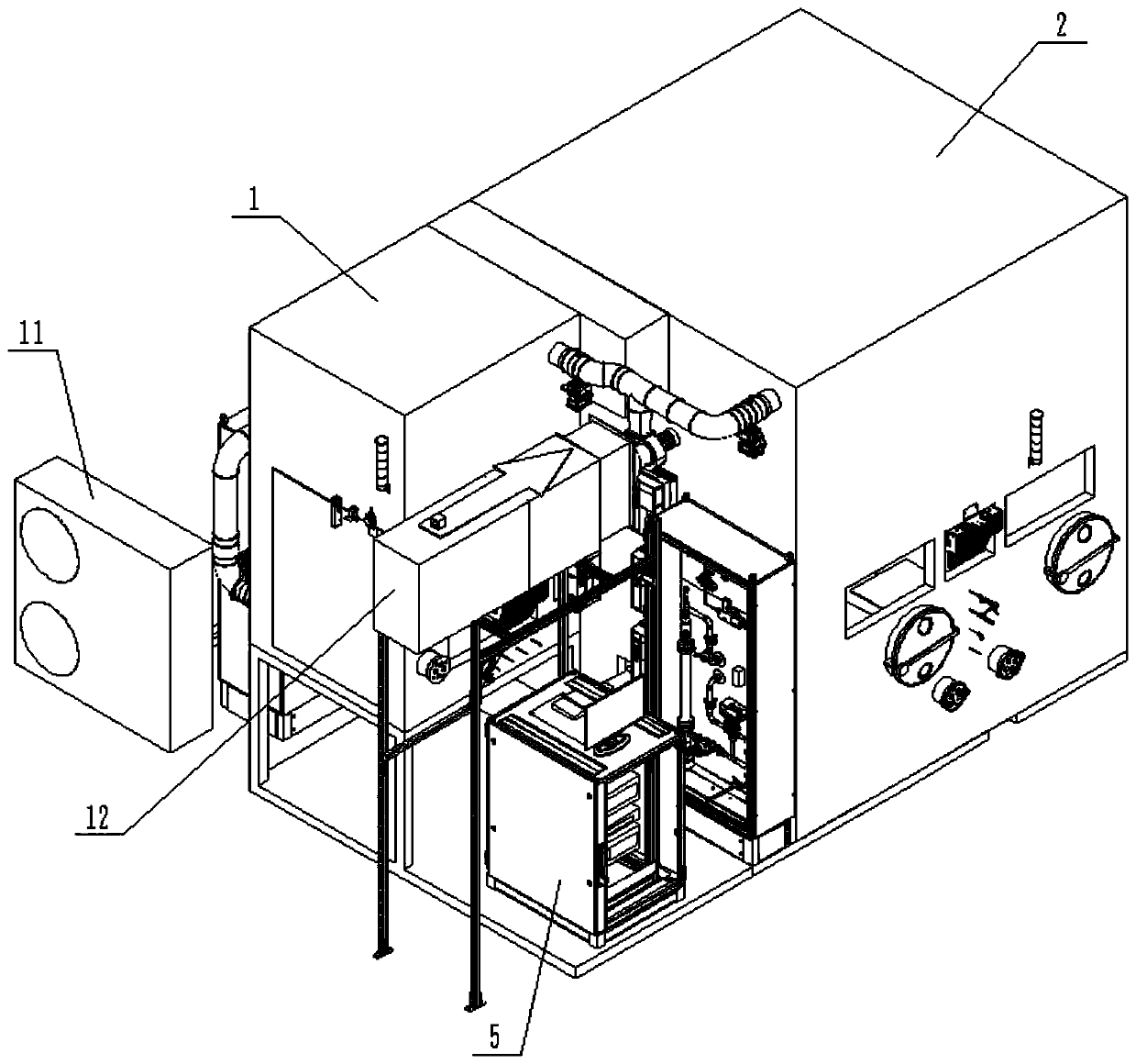

Dual-mode full-range oxygen-nitrogen-hydrogen analyzer

PendingCN114486797AHigh precisionSimple and elegant appearanceMaterial analysis by optical meansFluid pressure measurementAutomatic controlComputer printing

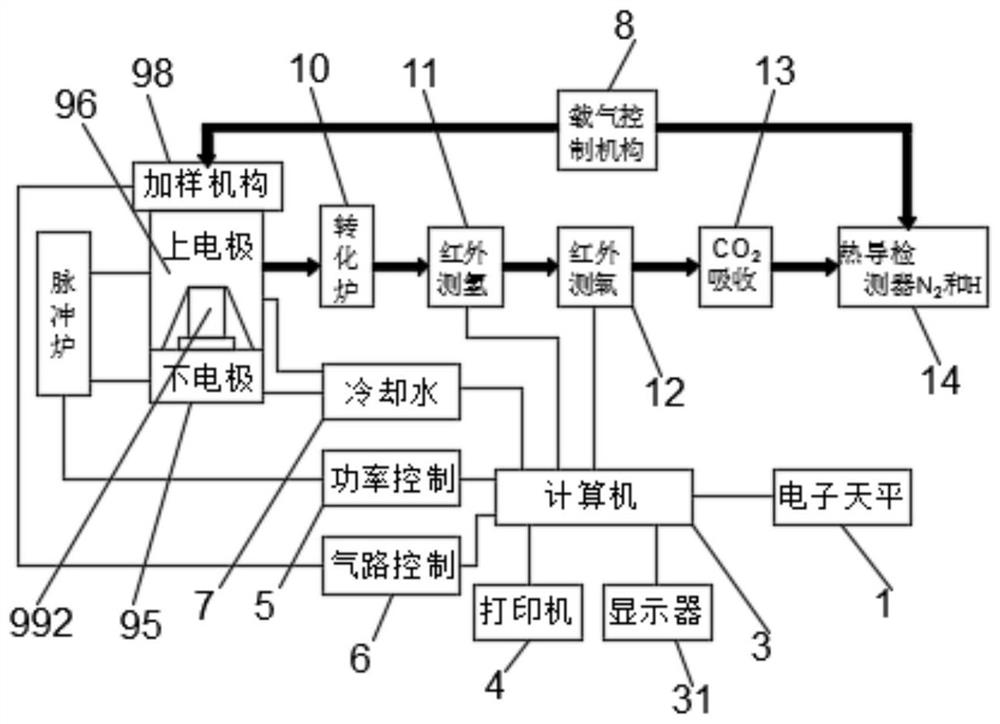

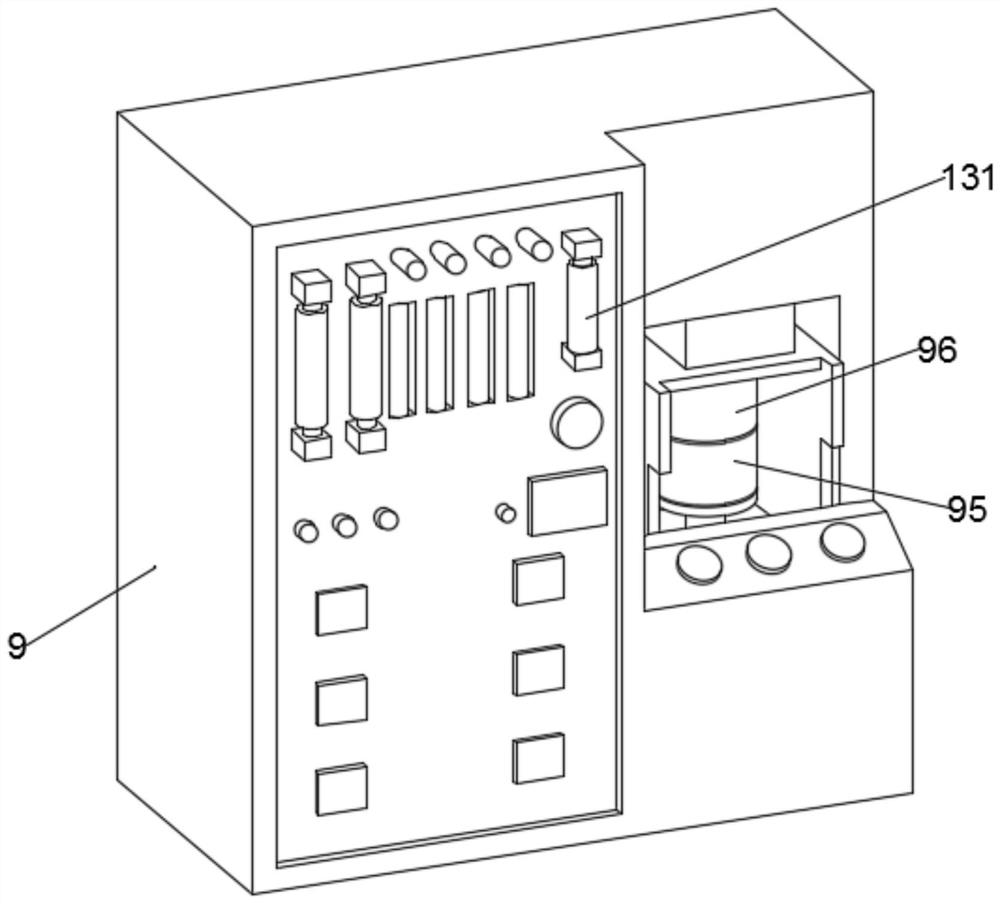

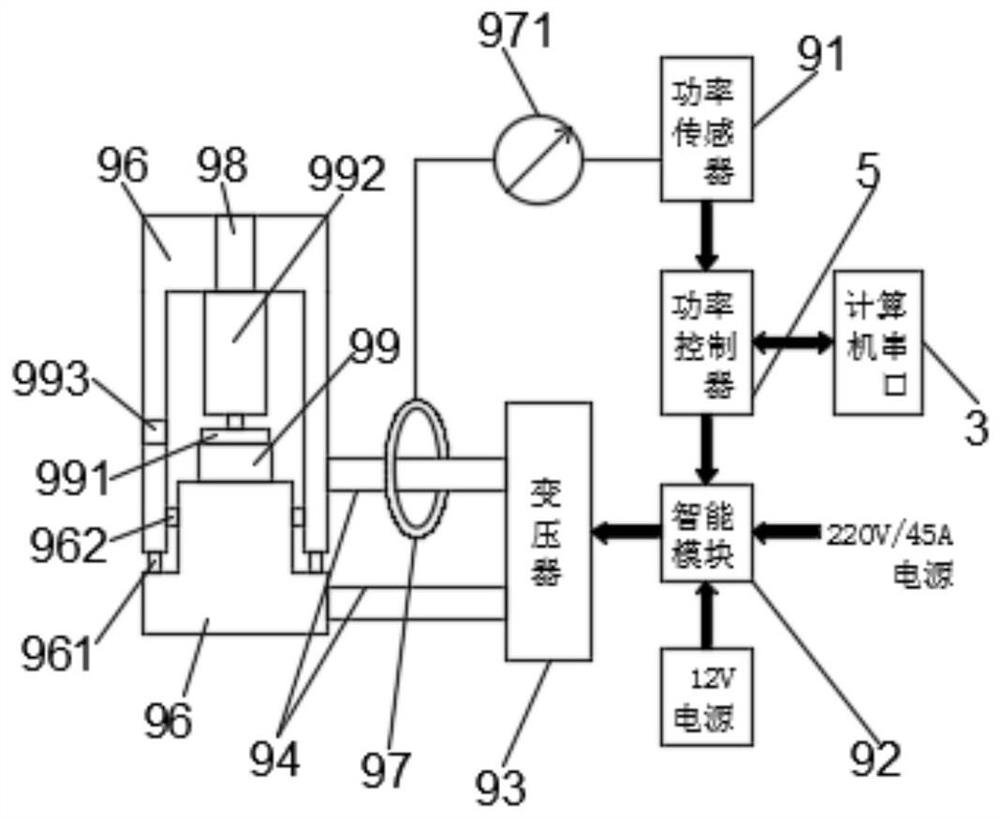

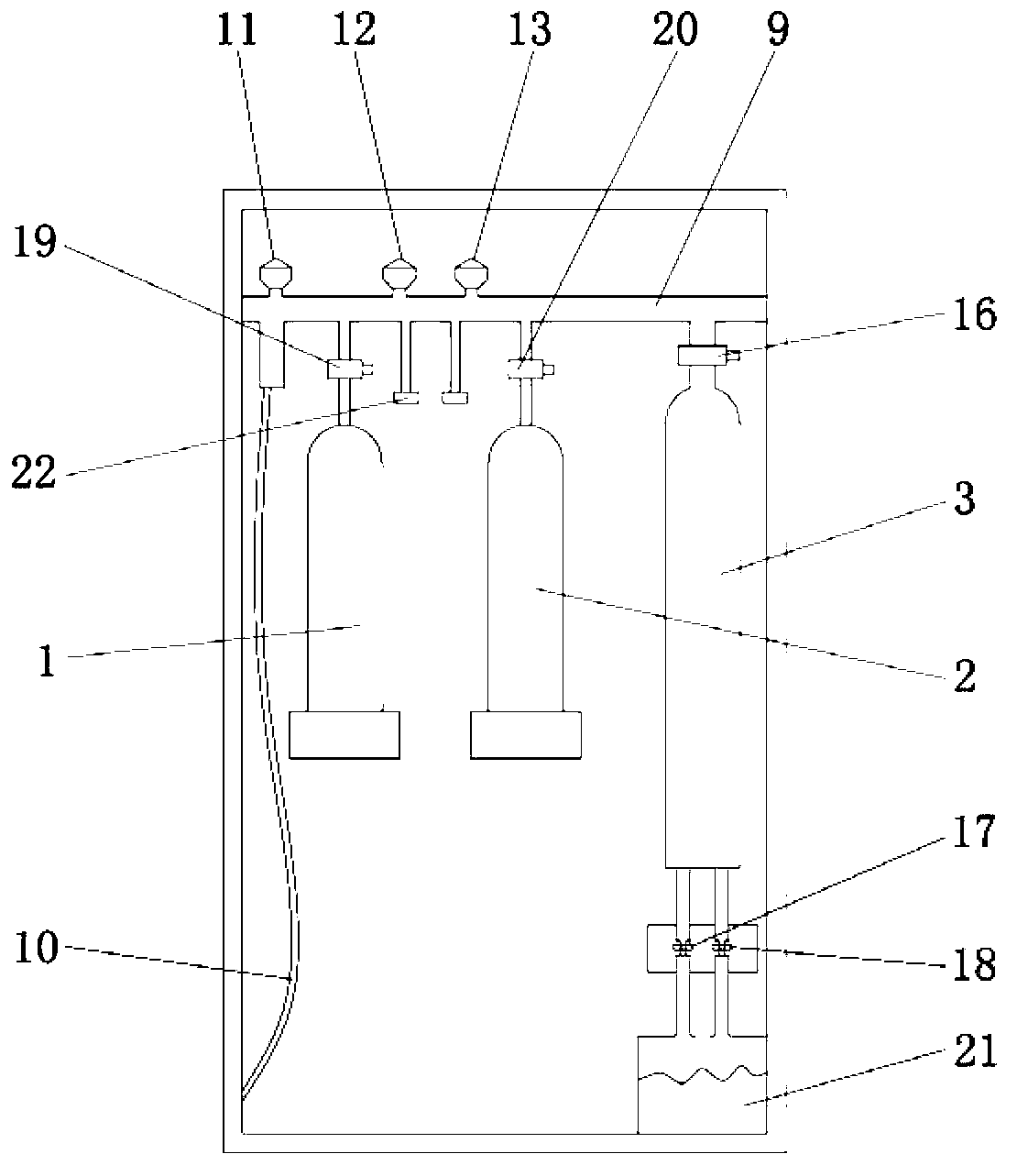

The invention provides a dual-mode full-range oxygen-nitrogen-hydrogen analyzer, relates to the technical field of oxygen-nitrogen-hydrogen analyzers, solves the problems of low automation degree and inaccurate analysis of the existing oxygen-nitrogen-hydrogen analyzer, and comprises an electronic balance, an analysis host, a computer and a printer, the analysis host is connected with the computer through a power controller and a gas circuit controller, the analysis host is connected with a cooling-water machine, and the cooling-water machine is controlled through the computer. According to the method, the temperature of a pulse furnace heating device reaches 2000-3000 DEG C, nitrogen in a sample is released, and the percentage content of oxygen and the percentage content of hydrogen in the detected sample are indirectly determined through an infrared hydrogen measurement analysis pool and an infrared oxygen measurement analysis pool respectively; finally, CO2 in the gas is filtered through a CO2 treatment device, the percentage content of nitrogen is determined through a thermal conductivity detection pool, and the analysis accuracy can be effectively improved through automatic control of a gas path system.

Owner:上海品彦光电科技有限公司

Oxy-hydrogen analyzer

The invention discloses an oxy-hydrogen analyzer, which consists of a hydrogen absorption bottle, an oxygen absorption bottle, a eudiometer, a copper tube, a heater and a control unit, wherein the heater is arranged on the back face of the instrument. The instrument has a simple structure, the detection step is simplified, the heating temperature is convenient to control, the analysis time is shortened, the analysis result has high accuracy and the operation is safe.

Owner:深圳华美板材有限公司

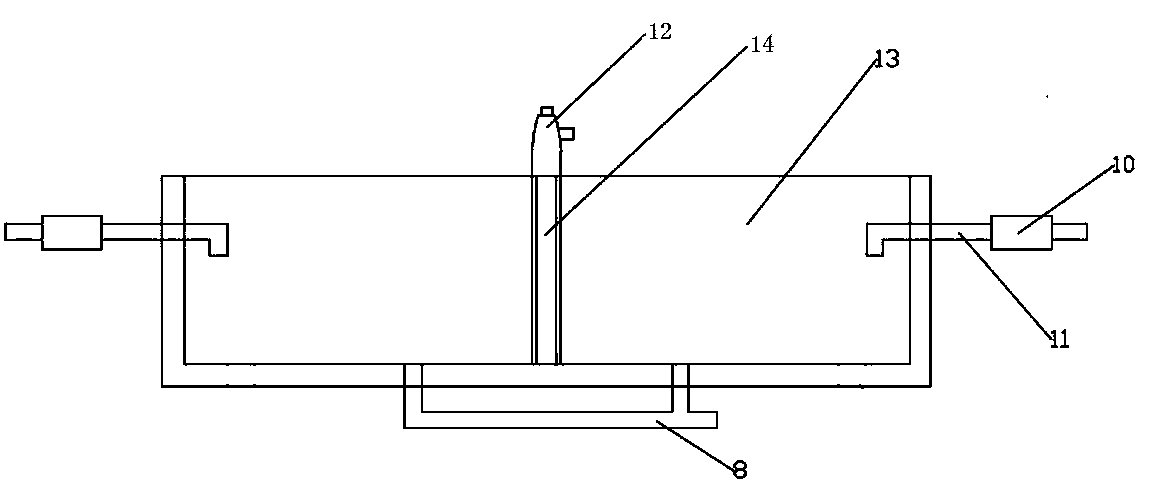

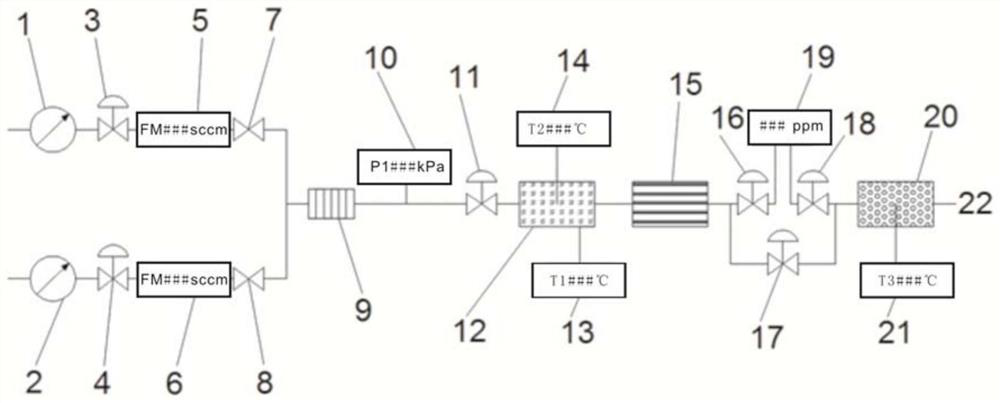

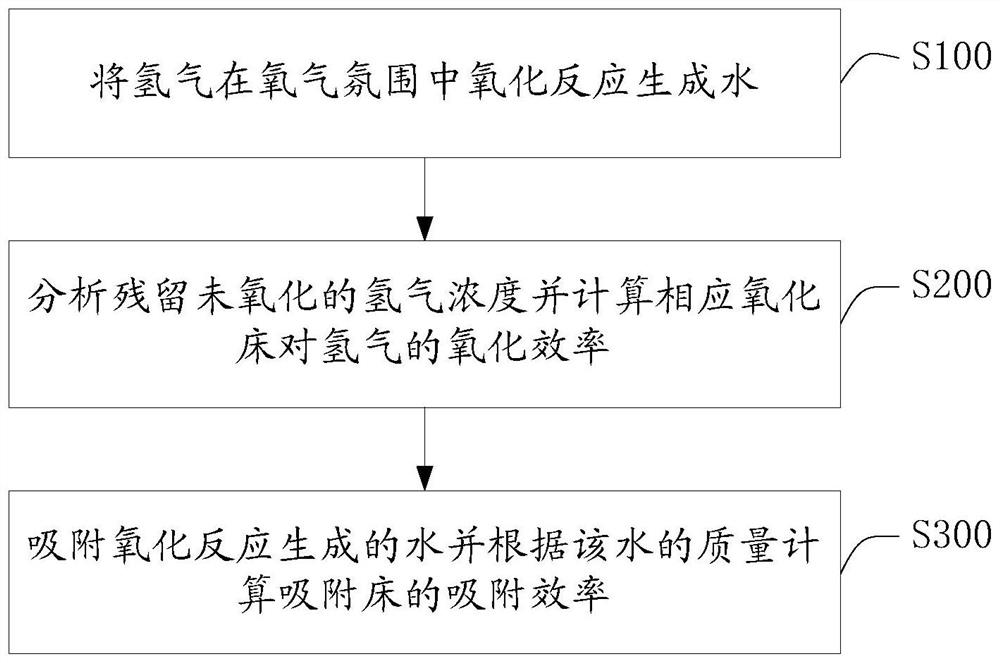

Oxidative adsorption experiment system and method for trace amount of hydrogen in oxygen atmosphere

ActiveCN111739673AImprove securityImprove the mixing effectNuclear energy generationNuclear monitoringPhysical chemistryAdsorption reaction

The invention relates to an oxidation adsorption experiment system and method for trace amount of hydrogen in an oxygen atmosphere. The system comprises an oxidation bed, a trace hydrogen analyzer andan adsorption bed which are connected in sequence; the gas source comprises a hydrogen source and an oxygen source which are connected to the inlet of the oxidation bed through a three-way valve to react to generate water; the trace hydrogen analyzer is used for analyzing the concentration of residual unoxidized hydrogen; the adsorption bed is used for adsorbing water generated by reaction. The method comprises the following steps: carrying out oxidation reaction on hydrogen in an oxygen atmosphere to generate water; analyzing the concentration of the residual unoxidized hydrogen and calculating the oxidation efficiency of the corresponding oxidation bed to the hydrogen; adsorbing water generated by the oxidation reaction, and calculating the adsorption efficiency of the adsorption bed according to the mass of the water. The experimental device has the beneficial effects that debugging, calibration, maintenance and the like of analysis equipment are the most time-consuming and labor-consuming steps of related experiments all the time; in the invention, the experimental device is only provided with one analysis device, namely the trace hydrogen analyzer, so that the experimental measurement device is simplified to a great extent under the condition that the precision is ensured.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

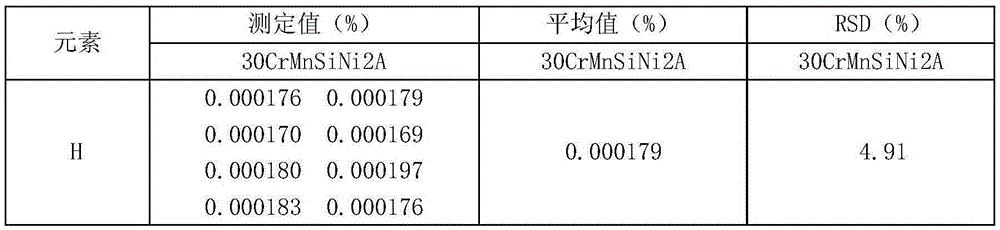

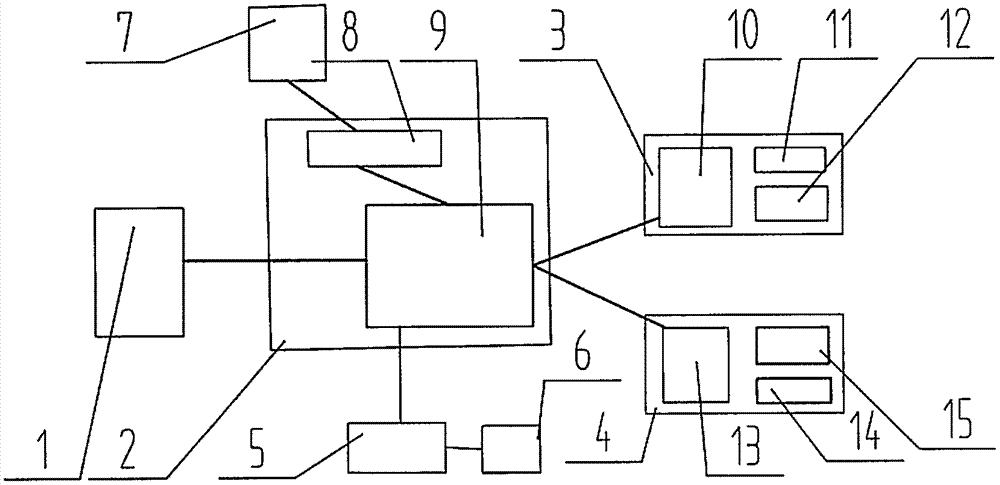

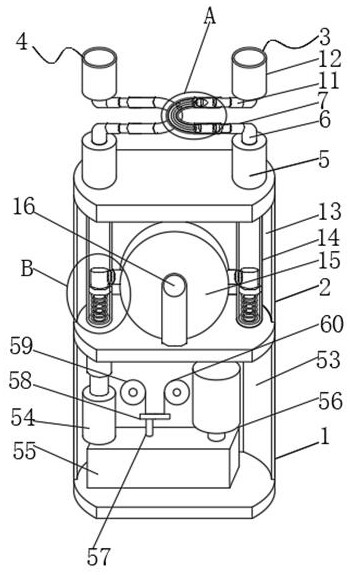

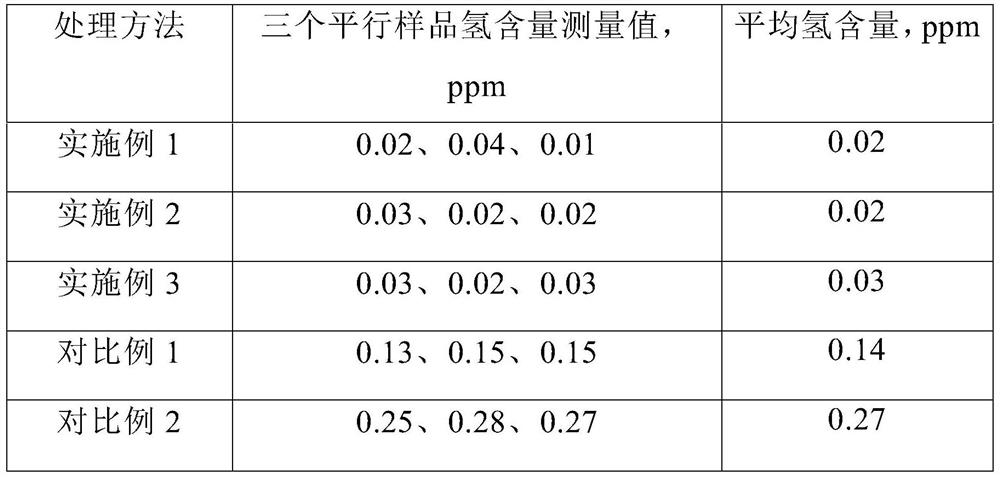

Analyser for intelligentized, rapid and highly-precise analysis of diffusible hydrogen in metal

InactiveCN107024379AConvenient and quick escapeStandard concentration curve fastMaterial heat developmentPreparing sample for investigationConcentration curveEngineering

The invention relates to an analyser for intelligentized, rapid and highly-precise analysis of diffusible hydrogen in a metal. According to the analyser, an electronic balance is connected to a main control board arranged in a thermal conductivity detection assembly, a hydrogen signal is connected to A / D acquisition and conversion arranged in the thermal conductivity detection assembly, the other end of the A / D acquisition and conversion is connected to the main control board, the other end of the main control board is divided into two paths, one path is connected to an infrared plate in an infrared extraction assembly, and the other path is connected to a sample injection control board of a standard gas injection assembly. Compared to the analyser in the prior art, the analyser of the present invention has the following characteristics that the standard concentration curve is established by using the standard gas injection assembly so as to calibrate the instrument, the sample is subjected to rapid constant temperature heating by using the infrared heat extraction assembly so as to make the diffusible hydrogen rapidly escape, the diffusible hydrogen can rapidly escape by performing infrared heat extraction on the sample and by performing the rapid constant temperature heating on the sample through the infrared heat extraction assembly, and the analyser has characteristics of simple structure, rapid analysis and standard concentration curve so as to provide the accuracy of the detection.

Owner:上海景瑞阳实业有限公司

Hydrogen sulfide analyzer

InactiveCN114280051ASmooth JingruControl volumeMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationWater vaporPhysical chemistry

The invention relates to the technical field of hydrogen sulfide analyzers, in particular to a hydrogen sulfide analyzer which comprises an analysis device, a content proportioning device is fixedly connected to the top of the analysis device, and a second gas inlet pipe device and a first gas inlet pipe device are arranged on the left side and the right side of the top of the content proportioning device respectively. When air pressure in a pressure adjusting pipe enters an inner cavity of the filtering device, the air pressure enters a hollow flow dividing groove through a pipeline mounting hole, and at the moment, air flow in the hollow flow dividing groove is dispersed into a plurality of second flow dividing grooves from an arc-shaped air outlet plate; in this way, the gas can be further filtered through adsorption carbon plates arranged on the multiple arc-shaped filter plates and the isolation plate, the matching pipe conveys external pure water vapor into the annular gas collection cavity, the detected sulfuration gas is mixed with the vapor, the humidity of the gas analyzed in the later period can be increased, and the detection accuracy is improved. And the hydrogen sulfide can be kept in a pure state, so that the detection accuracy can be improved.

Owner:陈佳玮

Verification device for nitriding furnace ammonia gas decomposition rate and verification method thereof

The invention discloses a verification device for nitriding furnace ammonia gas decomposition rate and a verification method thereof. Specifically, a nitriding furnace exhaust pipeline is equipped with a gas acquisition pipeline, the gas acquisition pipeline is connected to a verification body, the nitriding furnace exhaust pipeline is also connected to a hydrogen analyzer, wherein the verification body includes a communicating pipe, one end of the communicating pipe is communicated with the gas acquisition pipeline, and the other end is communicated with a measuring cylinder through a third valve. The top opening of the measuring cylinder is communicated with a water container through a first valve, and the bottom opening of the measuring cylinder is equipped with a second valve. The verification device and verification method provided by the invention can achieve rapid detection of ammonia gas decomposition rate and comparison with the hydrogen analyzer reading, and can monitor whether the hydrogen analyzer reading is correct in real time.

Owner:AECC AVIATION POWER CO LTD

Intelligent automatic hydrogen-nitrogen proportioning device

PendingCN110479123AIncrease or decrease flowEffective control of hydrogen concentrationTransportation and packagingMixer accessoriesHydrogen concentrationHydrogen pressure

The invention discloses an intelligent automatic hydrogen-nitrogen proportioning device which comprises a hydrogen pressure stabilizing tank, a nitrogen pressure stabilizing tank and a blending tank,wherein a gas mixing pipeline is arranged on the blending tank, the nitrogen pressure stabilizing tank is communicated with the gas mixing pipeline through a nitrogen conveying pipeline, the hydrogenpressure stabilizing tank is communicated with the gas mixing pipeline through a hydrogen conveying pipeline, a mixed gas detection pipeline is connected into the gas mixing pipeline, and the mixed gas detection pipeline comprises a hydrogen analyzer connected through a conveying pipe; the hydrogen analyzer is connected with a PID controller; the PID controller is connected with a regulating valveon the hydrogen conveying pipeline; wherein a gas outlet pipeline is arranged on the mixing tank, and an emptying valve and a mixed gas discharge valve, which are arranged in parallel, are arranged at the outer end part of the gas outlet pipeline. According to the invention, the gas demand of a special working condition that the pressure and the flow of a mixed gas use point are continuously changed is effectively improved; the frequency of hydrogen concentration change is reduced, the time and the frequency of manually correcting the hydrogenation amount are saved, and the utilization rate of the mixed gas is effectively improved.

Owner:江苏宏博气体装备科技有限公司

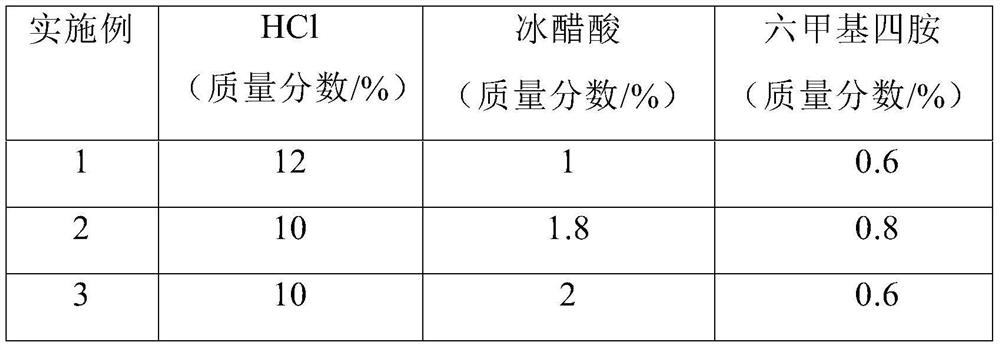

Method for obtaining hydrogen content of galvanized plate substrate

PendingCN113740142AAvoid corrosionAvoid enteringPreparing sample for investigationSurface cleaningHydrogen content

The invention discloses a method for acquiring the hydrogen content of a galvanized plate substrate. The method comprises the following steps of: S1, cleaning the surface of a galvanized plate, and storing the galvanized plate in liquid nitrogen for 24 hours; S2, soaking the galvanized plate treated in the step S1 in a pickling solution until a zinc layer completely disappears, taking out the galvanized plate, washing away the residual pickling solution on the surface, and placing the galvanized plate in acetone so as to carry out ultrasonic treatment, and blow-drying the galvanized plate; and S3, analyzing the hydrogen content in the galvanized plate substrate of the galvanized plate treated in the step S2 by using a TDS hydrogen analyzer. With the method adopted, the problem that the hydrogen content in the galvanized plate steel substrate cannot be accurately obtained is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Evaporative emission testing equipment for parts of automobile fuel system

PendingCN111458151AShorten the timeDouble the testing capacityInternal-combustion engine testingThermometers using electric/magnetic elementsFuel tankClosed chamber

The invention discloses evaporative emission testing equipment for parts of an automobile fuel system. The equipment comprises a first closed chamber and a second closed chamber, the first closed chamber is communicated with the second closed chamber through a plurality of communicating pipes, and the first closed chamber and the second closed chamber are connected with a same flame ion hydrocarbon analyzer through sampling pipes provided with valves respectively. The equipment has the beneficial effects that the evaporative emission values of a fuel tank and a carbon tank can be tested and obtained at the same time, a large amount of time is saved for a user, and due to the fact that a fuel system is tested in a regional mode, the equipment has very remarkable advantages in terms of search of standard-exceeding components in the development stage; and a user can simultaneously or respectively carry out two different tests on the basis of only inputting one flame ion hydrocarbon analyzer, so that the test capability is doubled, and the test cost is effectively saved.

Owner:法能环境模拟技术(北京)有限公司

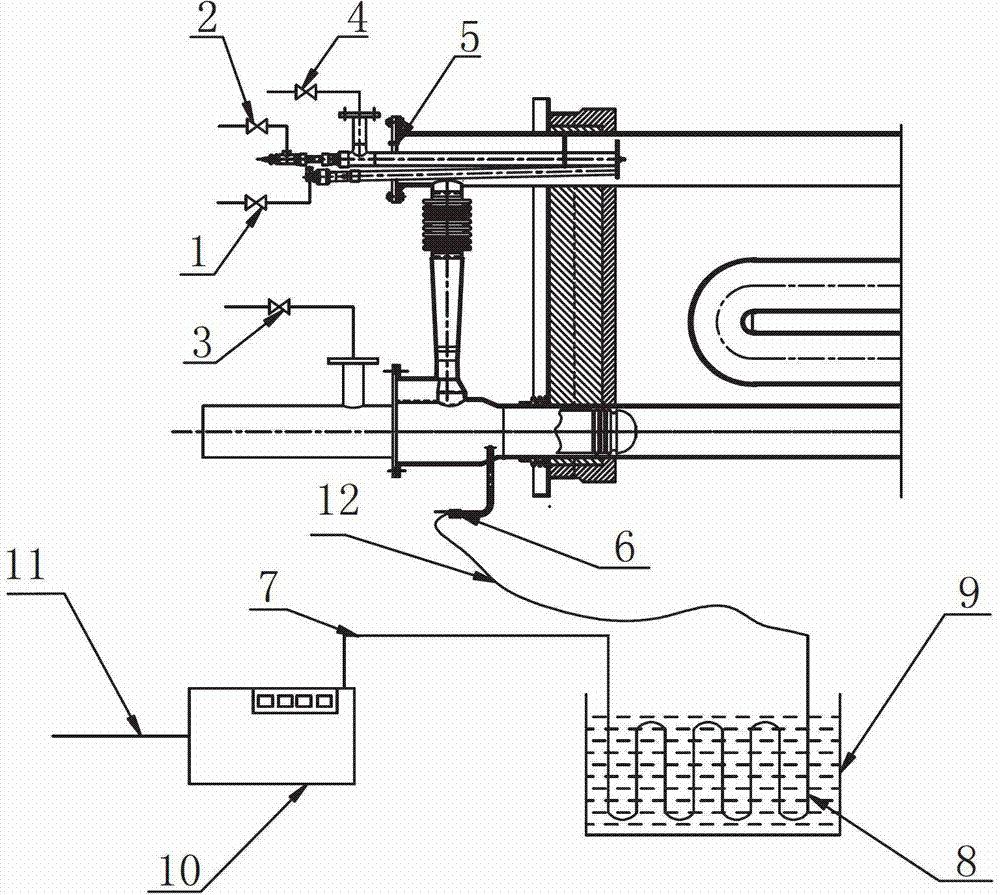

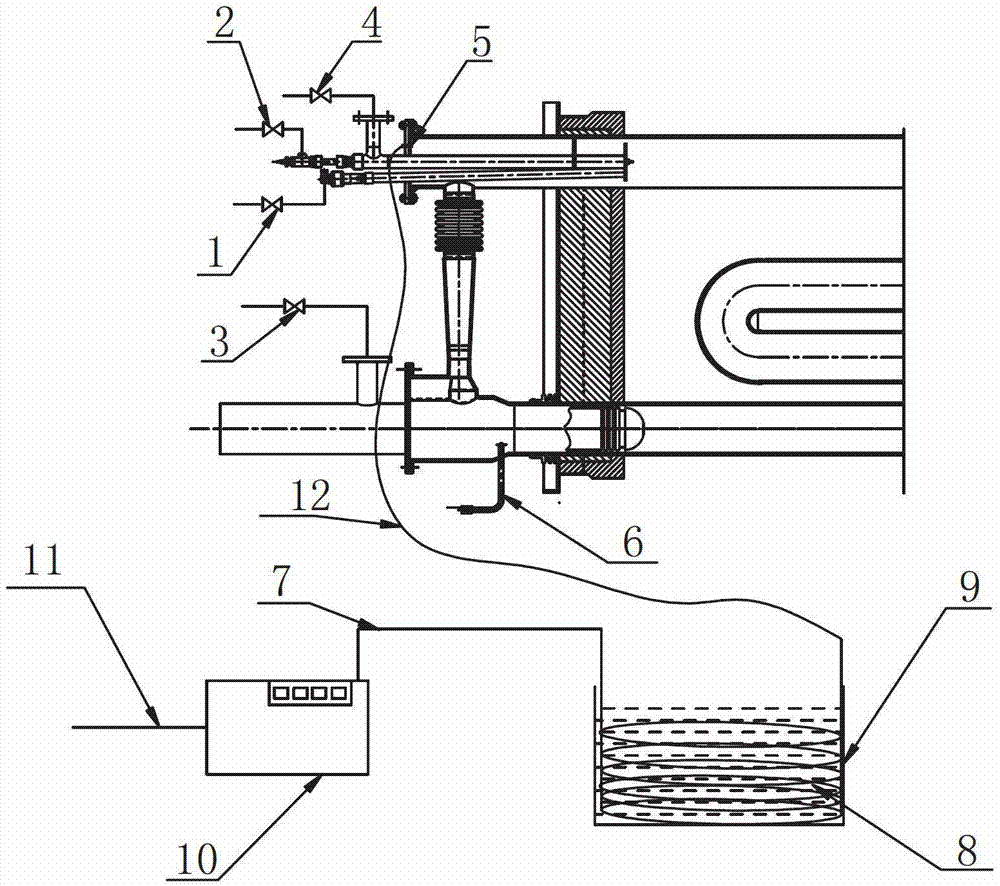

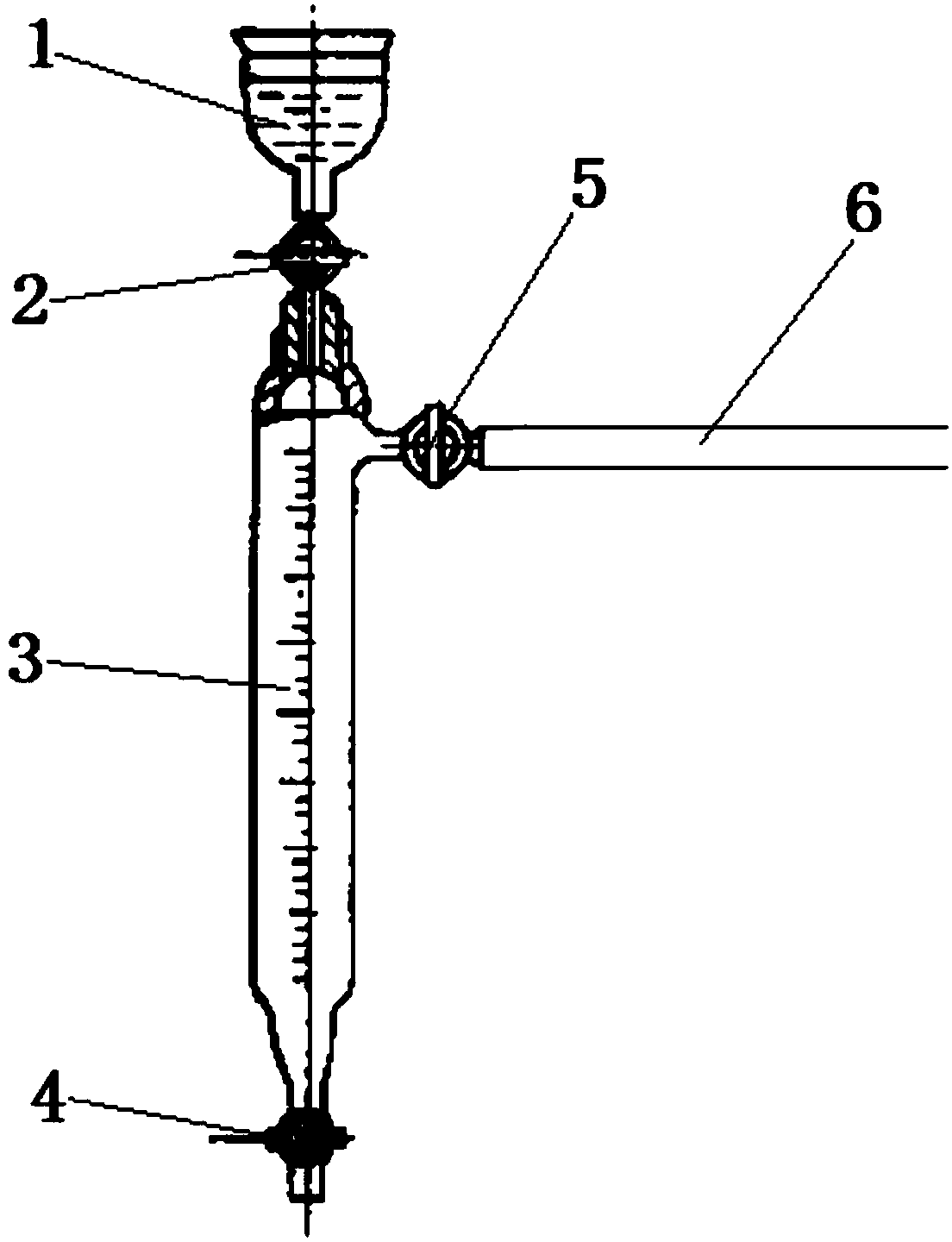

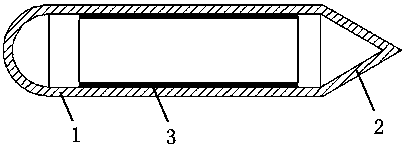

Sampling device and method for detecting nitrogen content of molten steel by oxygen, nitrogen and hydrogen analyzer

PendingCN107796666AReduce oxygen contentAvoid generatingWithdrawing sample devicesPreparing sample for investigationTest sampleNitrogen

The invention provides a sampling device and method for detecting the nitrogen content of molten steel by an oxygen, nitrogen and hydrogen analyzer and belongs to the technical field of molten steel sample detection tools and methods. The sampling device and method are used for rapidly sampling in the molten steel. According to the technical scheme, the sampling device comprises a glass containerand an aluminum foil, wherein the glass container is a long pipe; two ends of the glass container are sealed; a chamber of the glass container is vacuum; the aluminum foil is attached on the peripheryof an inner wall of the glass container; the front end of the glass container is a tapered head. In a sampling process, the tapered head of the glass container is immersed into the molten steel; thetapered head is molten under the action of high temperature of the molten steel; the molten steel is pumped into the glass container through the vacuum in the glass container; the molten steel and thealuminum foil attached on the inner wall of the glass container are subjected to aluminum deoxidation reaction, so that the oxygen content in the molten steel is reduced; the success rate of preparing a detection test sample can be improved. The sampling device provided by the invention is simple in structure, convenient to operate and rapid and efficient and can be used for rapidly preparing thequalified detection test sample under the condition that the oxygen content in the steel is relatively high; the detection efficiency is improved.

Owner:HEBEI IRON AND STEEL

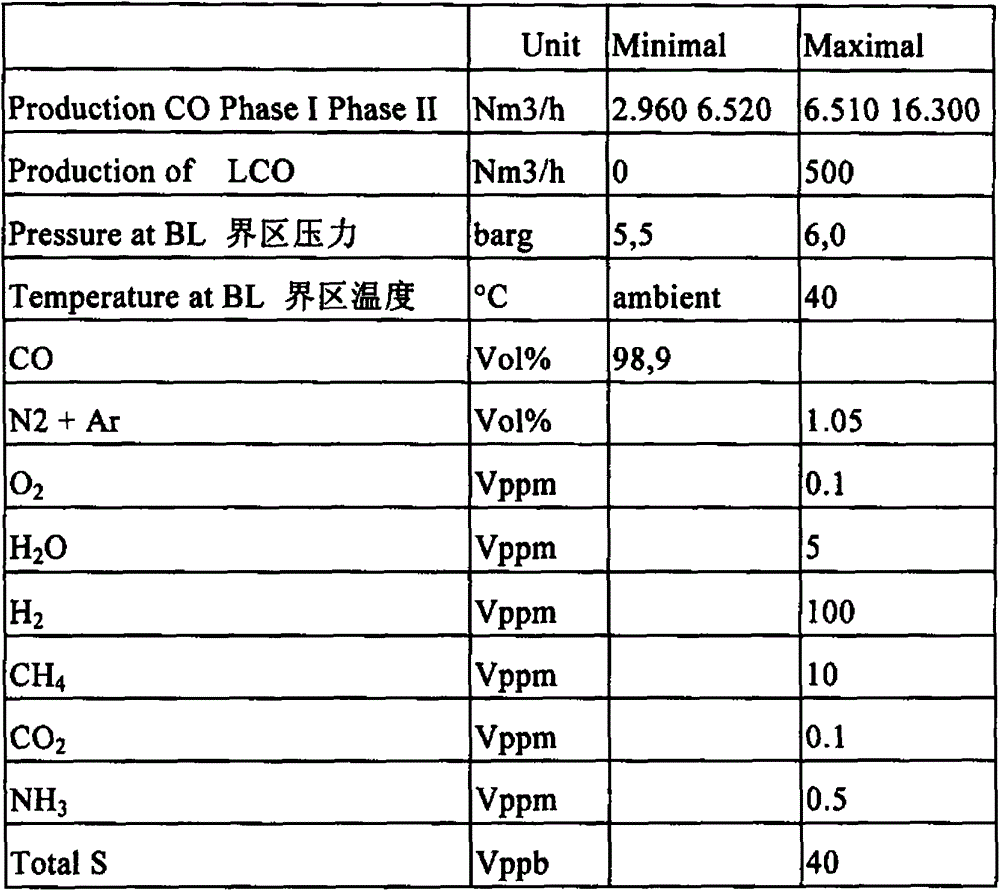

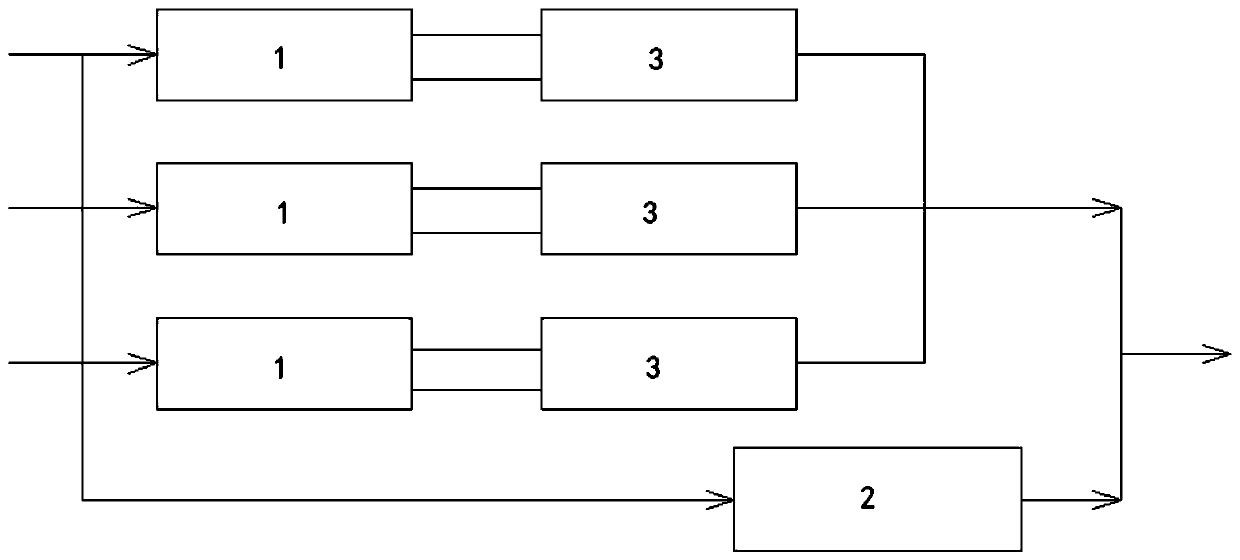

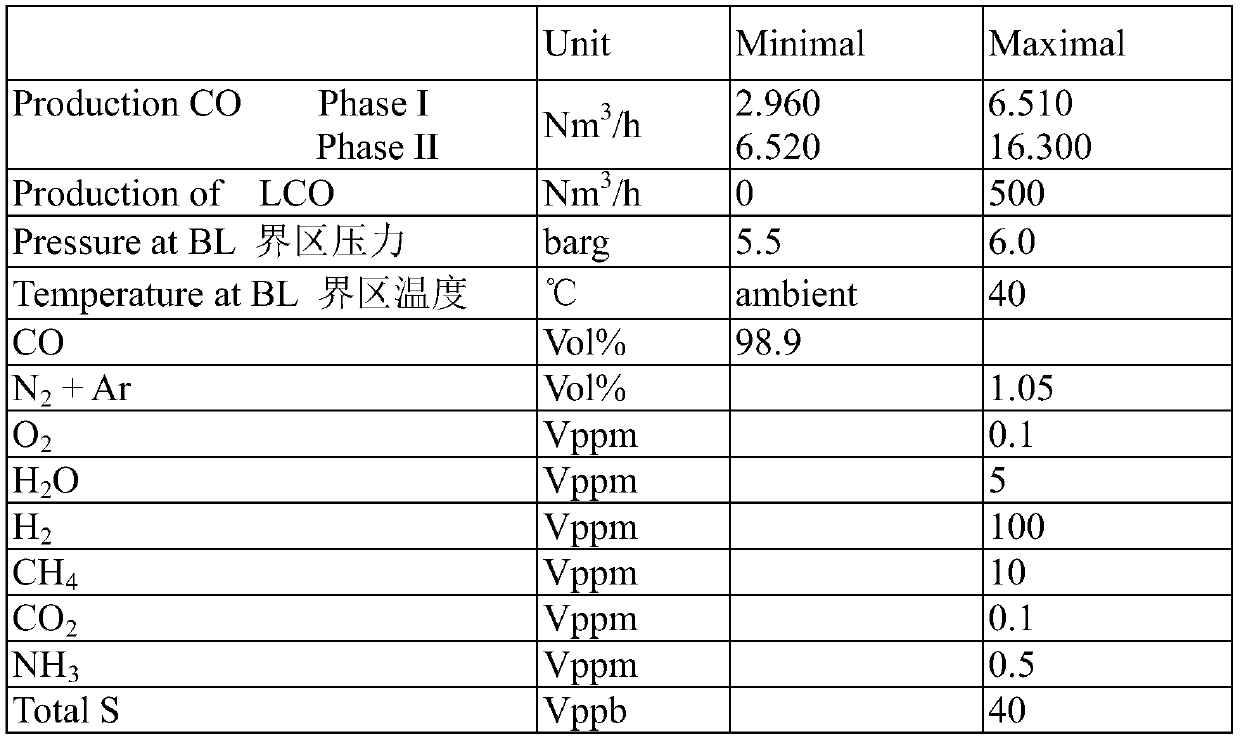

Method for increasing hydrogen analysis detection rate of hydrogen and carbon monoxide production apparatus

The present invention relates to a method for increasing the hydrogen analysis detection rate of a hydrogen and carbon monoxide production apparatus, wherein the method is used for detecting the water content, the methane content, the hydrogen content and the carbon monoxide content in a CO product. According to the method, the output section of the detection apparatus is provided with a hydrogen analyzer, the hydrogen analyzer is connected with a sampling pipeline, the subsequent pipeline is provided with a rapid shut-off valve, the sampling pipeline is a sampling pipe with a diameter of 6 mm, testing is performed through the hydrogen analyzer after sampling is performed by using the sampling pipe, and the rapid shut-off valve on the subsequent pipeline is closed within 40 s when the detected hydrogen content achieves the alarm value. Compared with the method in the prior art, the method of the present invention has the following characteristics that: the response of the on-line analyzer can be increased by 4 times, the result action time is 26 s, the apparatus testing is smoothly passed through, and the on schedule gas supply is performed after the CO product customer approves.

Owner:SHANGHAI HUALIN IND GASES

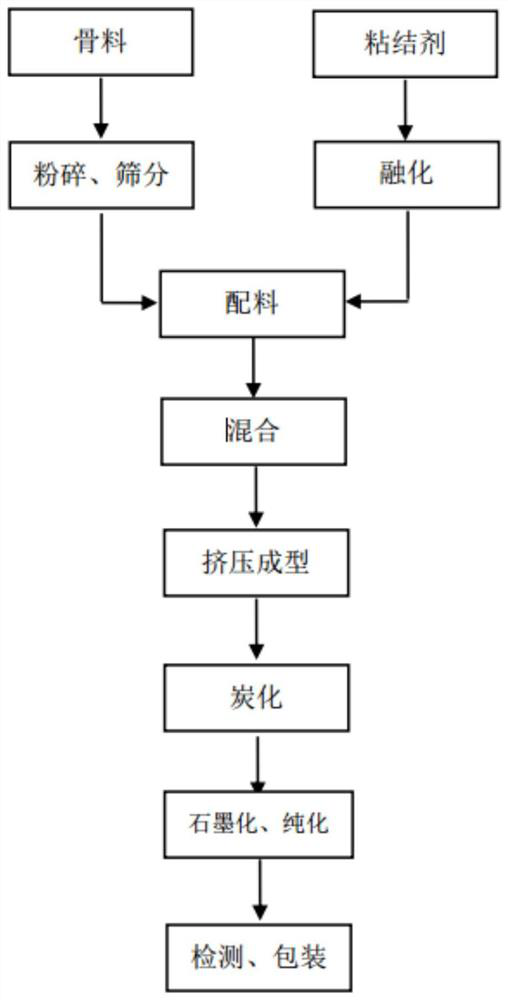

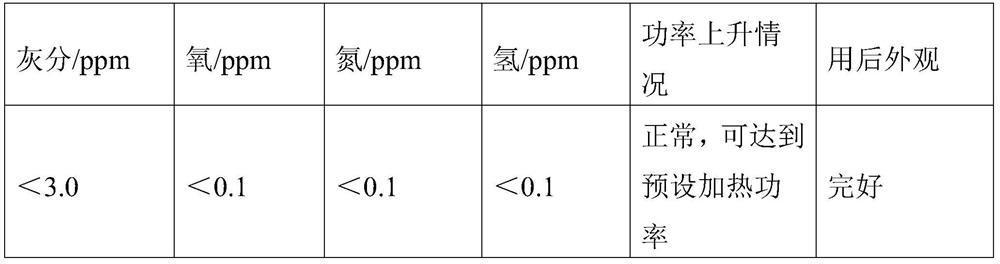

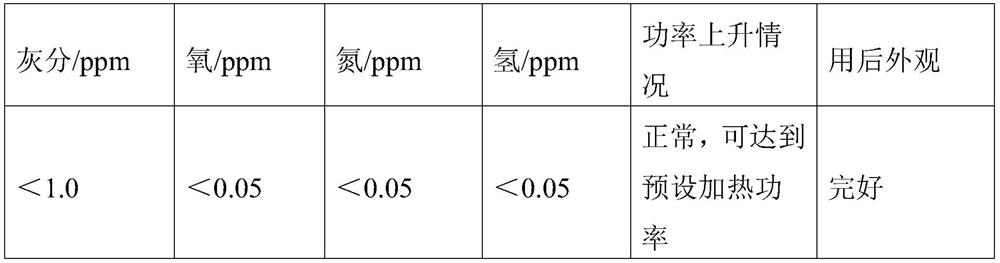

Preparation method of graphite material for oxygen-nitrogen-hydrogen analysis instrument

ActiveCN111751311AHigh degree of graphitizationImprove the lubrication effectMaterial analysis by optical meansCarbonizationGraphite

The invention discloses a preparation method of a graphite material for an oxygen-nitrogen-hydrogen analysis instrument. The preparation method comprises the following steps: 1) preparing a paste material; 2) extruding into a green body bar; 3) carbonizing to prepare a carbonized bar; and 4) purifying to obtain the high-purity graphite material for the oxygen-nitrogen-hydrogen analysis instrument.The low-nitrogen natural microcrystalline graphite is used as a main raw material so that compared with the existing production technology which generally adopts calcined petroleum coke and calcinedpitch coke as raw materials, the nitrogen content of the raw materials is remarkably reduced, and the production of the graphite material meeting the requirements of oxygen-nitrogen-hydrogen analysisinstruments is facilitated. The natural microcrystalline graphite has the advantages of high graphitization degree, good lubricity and the like so that the natural microcrystalline graphite is used asa raw material to be beneficial to reducing the resistance among materials during forming, and a product with a fine and compact structure and good uniformity is obtained; in the carbonization process, a specific heating system is adopted so that the product can be effectively prevented from cracking, the carbon residue rate of the binder is improved, and the density and strength of the product are further improved.

Owner:CENT SOUTH UNIV +1

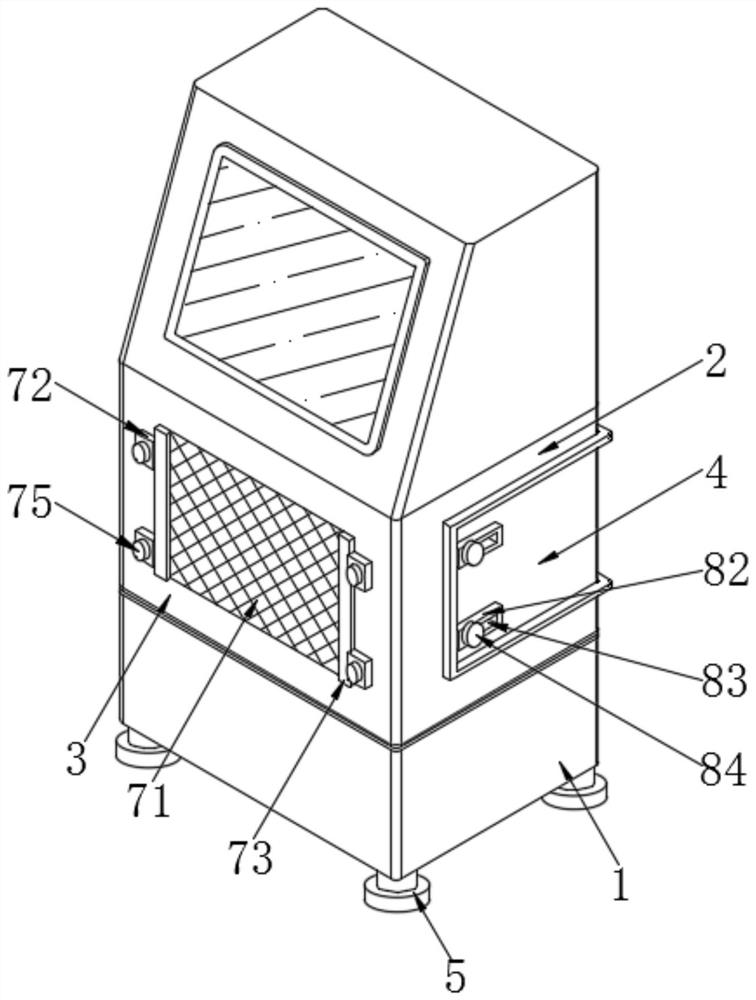

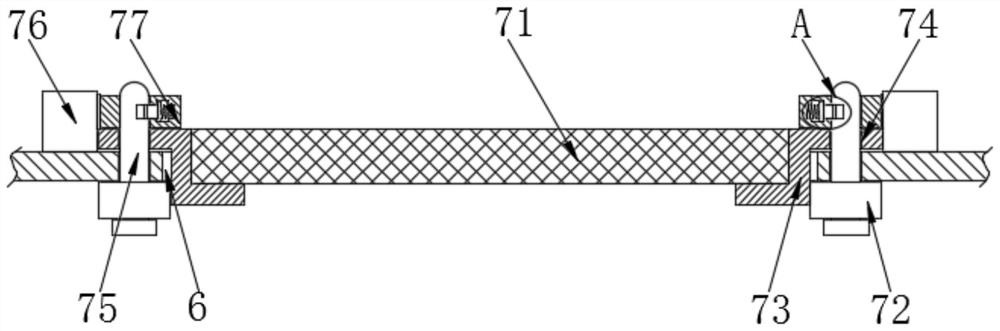

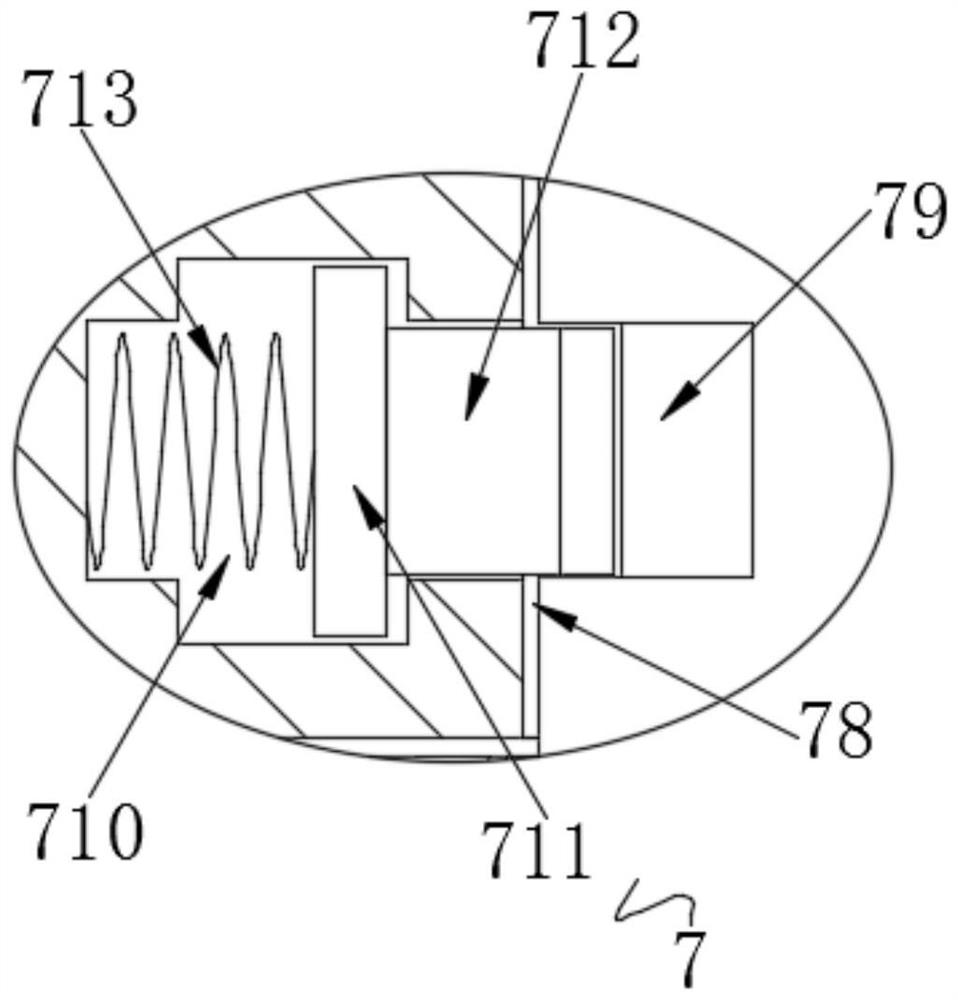

Full-automatic high-pressure hydrogen storage analyzer

PendingCN113853080AQuick releaseEasy to cleanDispersed particle filtrationClosed casingsStructural engineeringMechanical engineering

A full-automatic high-pressure hydrogen storage analyzer is disclosed in the invention, and comprises a supporting seat, a side plate, a ventilation plate and a maintenance plate, a base is fixedly connected to the periphery of the bottom of the supporting seat, a ventilation hole is formed in one side of the ventilation plate, filter screen assemblies are arranged at the positions, located on the two sides of the ventilation hole, of the back face of the ventilation plate, and a quick release assembly is arranged on one side of the side plate; and the filter screen assembly comprises a filter screen and four limiting blocks located on the front face, the filter screen is arranged at the ventilation holes, dust can be effectively blocked to prolong the service life of the filter screen assembly, the filter screen assembly is matched with a connecting plate in the filter screen assembly and limiting rods on the limiting blocks, and the relation between gradual change grooves in the limiting rods and protruding blocks is utilized to make the connecting plate quickly disassembled, so that the filter screen can be quickly disassembled, and the filter screen can be conveniently cleaned.

Owner:利晟(杭州)科技有限公司

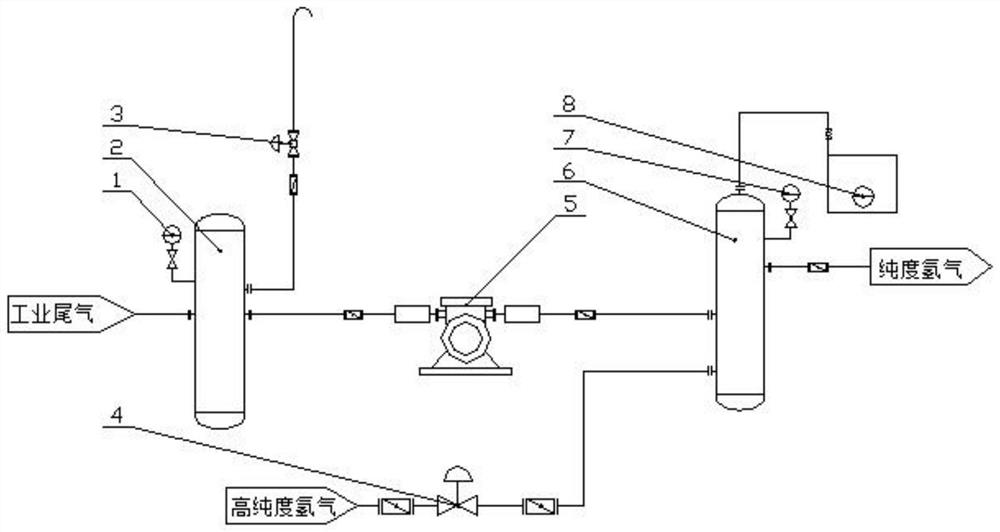

High-efficiency hydrogen recovery device and recovery method

PendingCN114413174AReduce volumeIngenious ideaPipeline systemsFluid handledHydrogen concentrationBuffer tank

The invention discloses a high-efficiency hydrogen recovery device and method.The recovery device comprises a front buffer tank, a draught fan and a rear buffer tank which are sequentially arranged and communicated together through a pipeline, the top of the rear buffer tank is connected with a hydrogen analyzer, and the bottom of the rear buffer tank is connected with a high-purity hydrogen supplementing pipeline; the hydrogen analyzer is electrically connected with the system controller; during hydrogen recovery operation, industrial tail gas is collected into the front buffer tank through the tail gas collecting pipeline and conveyed into the rear buffer tank through operation of the fan; and then, the hydrogen analyzer analyzes the purity of the gas in the rear buffer tank, and the hydrogen regulating valve is controlled to be opened and closed through the system controller, so that stable-purity hydrogen is obtained. According to the present invention, the concept is ingenious, the hydrogen concentration is rapidly adjusted by adding the hydrogen analyzer and the high-purity hydrogen supplementing pipeline, and the volume of the buffer tank is effectively reduced so as to save the occupied area of the device and reduce the manufacturing cost of the device.

Owner:LANGFANG GUANGHUI GAS EQUIP

Detection method for avoiding misoperation of hydrogen analyzer

InactiveCN109696456AAvoid production interruptionsAvoid improper interlockingMaterial thermal conductivityComponent separationHydrogen contentCo product

The invention relates to a detection method for avoiding misoperation of a hydrogen analyzer, which is used to judge the hydrogen content in a CO product gas. The detection method comprises the following specific steps: (1) a hydrogen analyzer (1) and a methane analyzer (2) in parallel with the hydrogen analyzer (1) are arranged in a CO transmission pipeline; 2) the CO product gas enters the hydrogen analyzer (1) and the methane analyzer (2) simultaneously, and if the hydrogen analyzer (1) outputs signals to indicate the hydrogen content meets the standard, the pipeline is unobstructed; and 3)if the output signals of the hydrogen analyzer (1) are abnormal, in combination of the signals transmitted by the methane analyzer (2), whether methane generates influences on the hydrogen analyzer (1) is further judged. In comparison with the prior art, through adding the methane analyzer and a PLC, interference of methane and argon to the hydrogen analyzer can be avoided.

Owner:SHANGHAI HUALIN IND GASES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com