Protective gas monitoring system used for copper wire bonding processing

A shielding gas and monitoring system technology, applied in the direction of control/regulation system, multi-fluid ratio control, non-electric variable control, etc., can solve the problem that the shielding gas pressure, flow rate and mixing ratio are prone to deviation, and the shielding gas cannot accurately meet the requirements. Copper wire bonding packaging work, affecting product quality and other issues, to achieve the effect of sensitive response, fast control response speed, and improved yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in combination with specific embodiments and accompanying drawings.

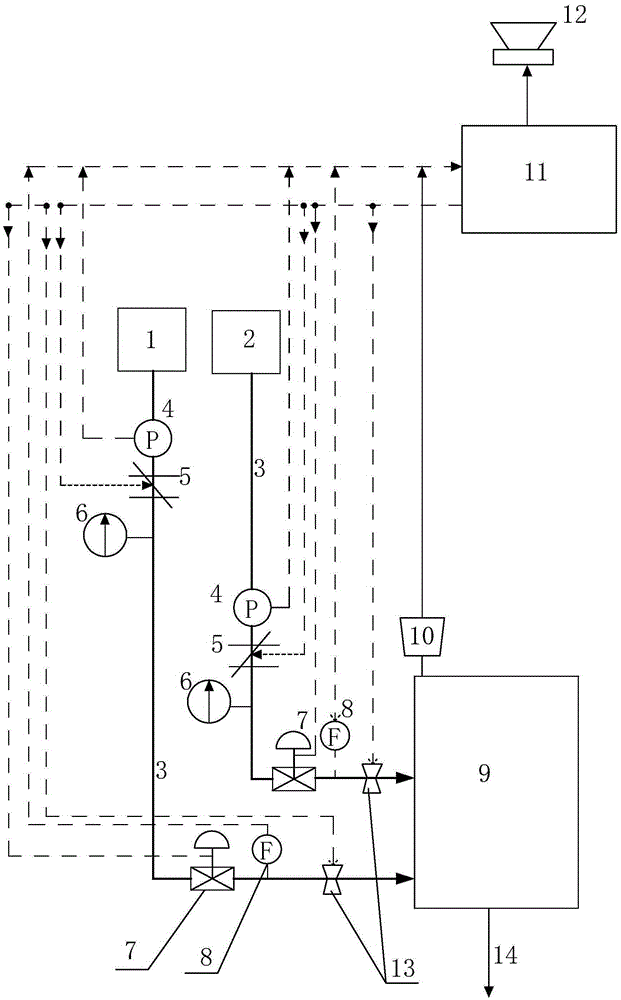

[0014] Such as figure 1 As shown, a shielding gas monitoring system for copper wire bonding processing includes a mixing tank 9, a hydrogen storage tank 1 and a nitrogen storage tank 2, and both the hydrogen storage tank 1 and the nitrogen storage tank 2 are connected to the mixing tank through a delivery pipe 3 9, the outlet of the mixing tank 9 is connected with a nitrogen-hydrogen protection gas output pipe 14, and also includes a DCS control system 11 and a hydrogen analyzer 10, and each delivery pipe 3 is sequentially provided with a pressure sensor 4, a pressure regulating valve 5, Flow regulating valve 7, flow sensor 8 and flow meter 13. An alarm device 12 is also connected to the DCS control system 11 .

[0015] The pressure sensor 4 and the flow sensor 8 are connected to the signal input end of the DCS control system 11 , and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com