Method for improving precision and accuracy of hydrogen in oxygen-nitrogen-hydrogen combined determination of titanium or titanium alloy

A titanium alloy, precision technology, applied in the field of graphite crucible pretreatment, can solve the problems of low hydrogen blank value, inconsistency, poor precision and accuracy, etc., to improve hydrogen precision and accuracy, stable hydrogen blank value, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the method for improving the precision and accuracy of hydrogen in joint measurement of oxygen, nitrogen and hydrogen of titanium or titanium alloy according to the present invention will be described in detail in combination with exemplary embodiments.

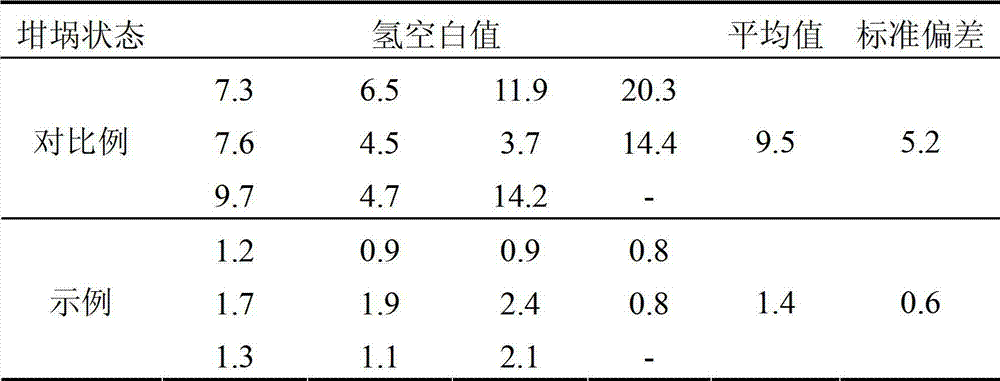

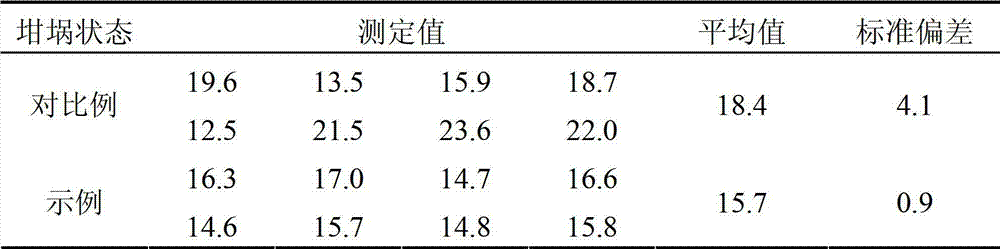

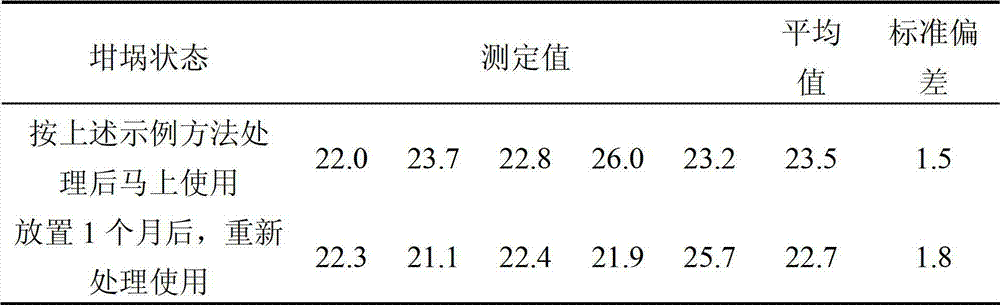

[0013] In an exemplary embodiment of the present invention, the method for improving the precision and accuracy of hydrogen in joint measurement of oxygen, nitrogen and hydrogen of titanium or titanium alloy comprises the following steps: placing the graphite crucible in a high temperature furnace, and then feeding Inert gas to drive out the air in the furnace; heat, and keep the furnace temperature at 700-1000°C for more than 5 hours; freely cool down to 400-500°C, then take out the graphite crucible and use it for the oxygen, nitrogen, and hydrogen analyzer; then, install the graphite crucible In the electrode furnace of the oxygen, nitrogen and hydrogen analyzer, degas at 2300°C-2700°C for 30-44s, prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com