Detection method for avoiding misoperation of hydrogen analyzer

A detection method and analyzer technology, which is applied in the field of analysis systems, can solve problems such as non-conformity and product production interruption, and achieve the effect of avoiding production interruption and abnormal interlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

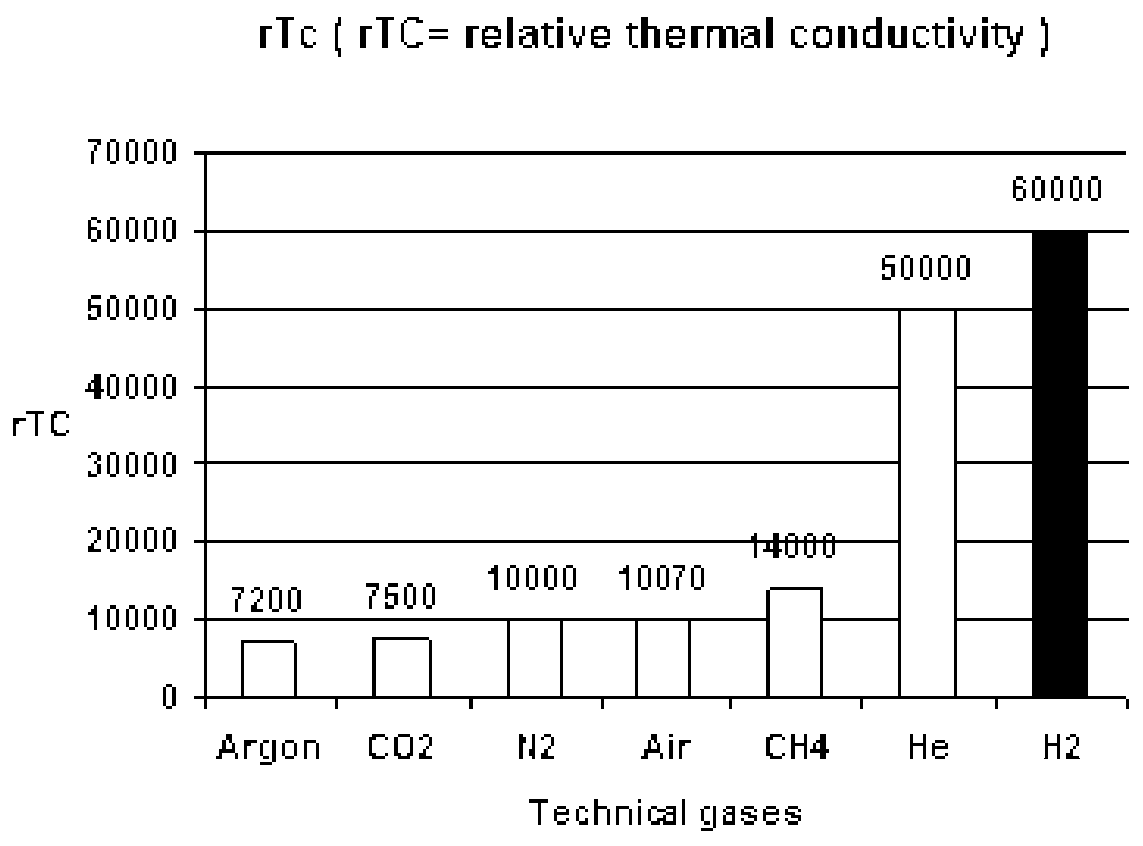

[0029] One: Determination of CH through a series of analogy methods 4 On the influence of the content of the hydrogen heat conductivity table in carbon monoxide, the relevant influence factors are obtained.

[0030] Equipment used:

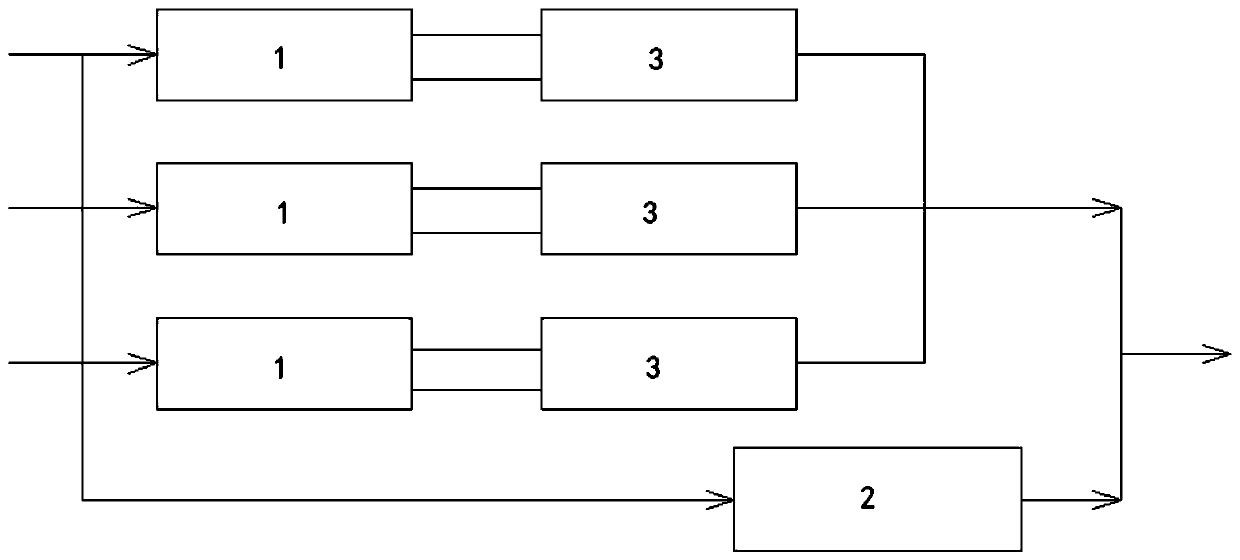

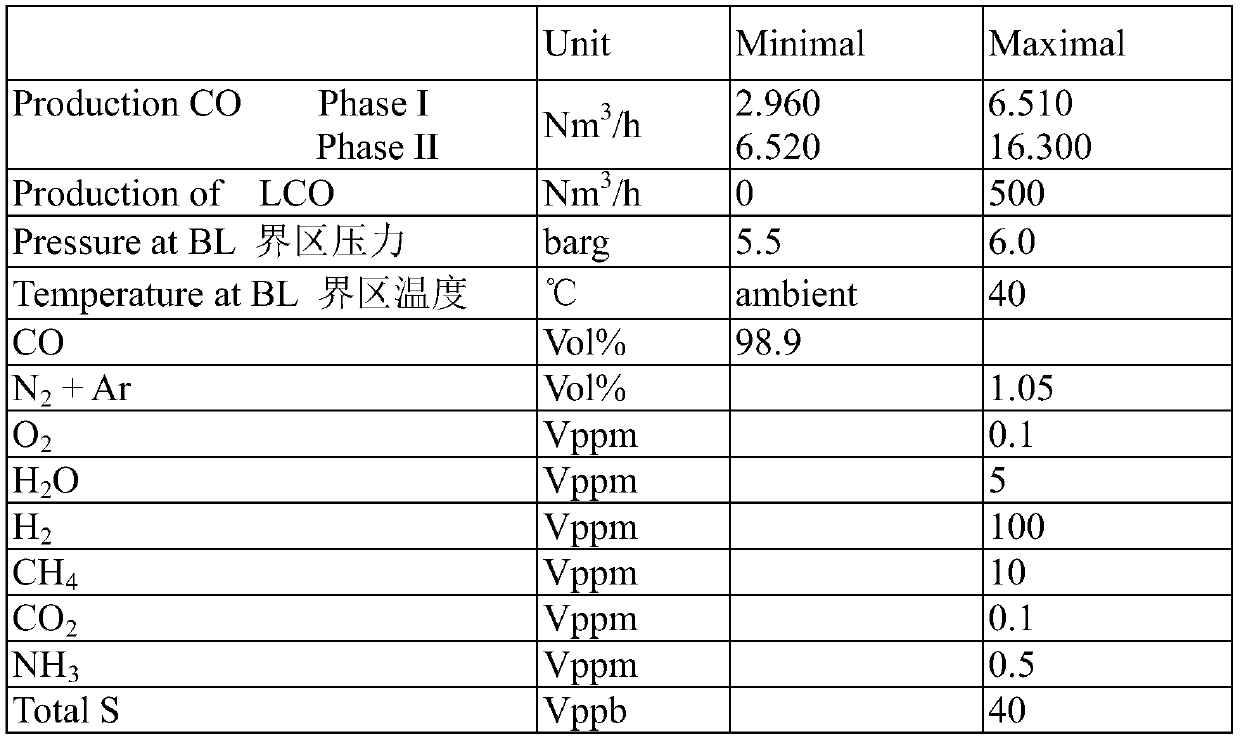

[0031] Hydrogen content analyzer in carbon monoxide products (3-1711AT050.01, ABB EL3060Caldos27, 0-12500ppm), hydrogen analyzer 1 in raw synthesis gas (1501AT072, CALOMAT 6F, 0-100%), carbon monoxide analyzer in raw synthesis gas ( 1501AT073, ULTRAMAT 6F, 0-100%), methane analyzer 2 in raw syngas (1501AT074, ULTRAMAT 6F, 0-0.5%).

[0032] Adoption steps:

[0033] 1. Equipped with standard gas with methane content of 1%, 3.7%, and 5.9% in carbon monoxide;

[0034] 2. At the same time, the analysis instruments 1501AT072, 1501AT073, 1501AT074, 3-1711AT050.01 analyze various standard gases to obtain the following data:

[0035]

[0036] 3. Concluded: methane content greater than 5.8% will cause chain of hydrogen in carbon monoxide

[0037] Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com