Female die fastening device of cylindrical closed forging die

A closed forging and fastening device technology, applied in the field of forging processing, can solve problems such as mold scrapping and production interruption, and achieve the effects of avoiding production interruption, ensuring processing quality, and solving the problem of mold wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

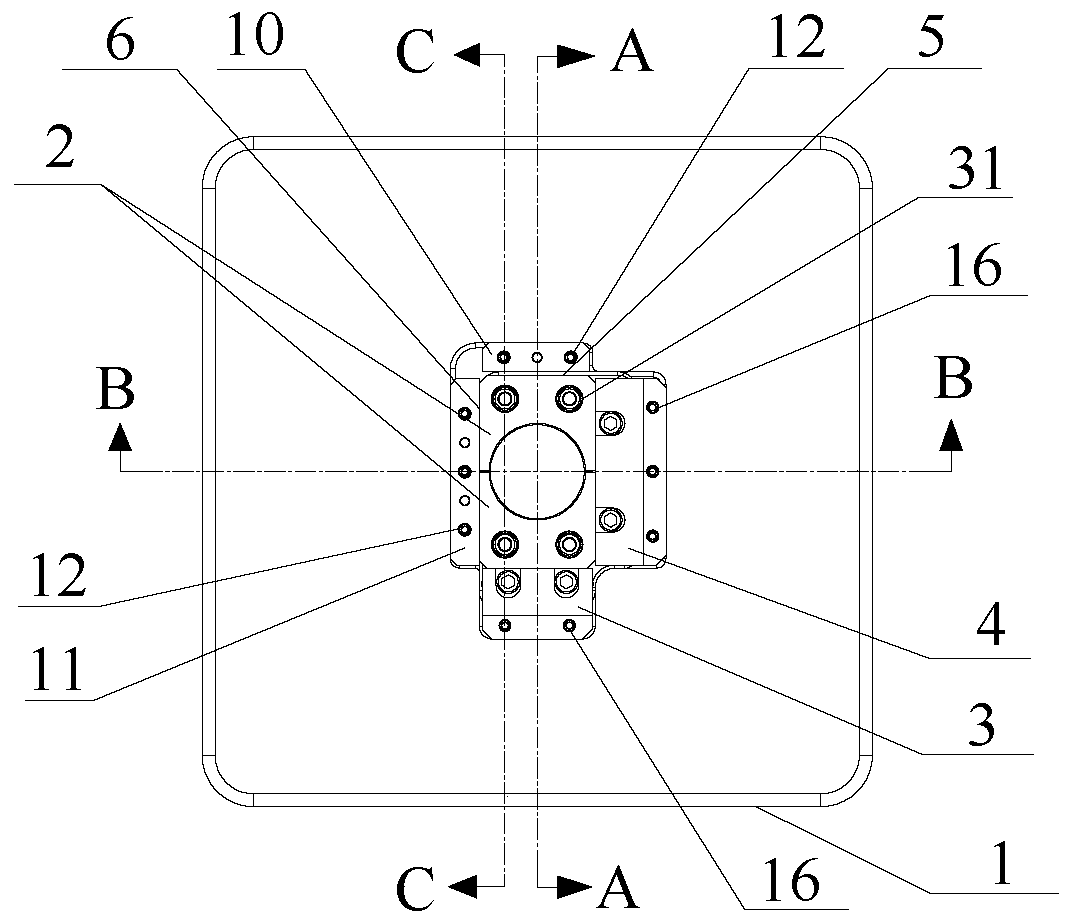

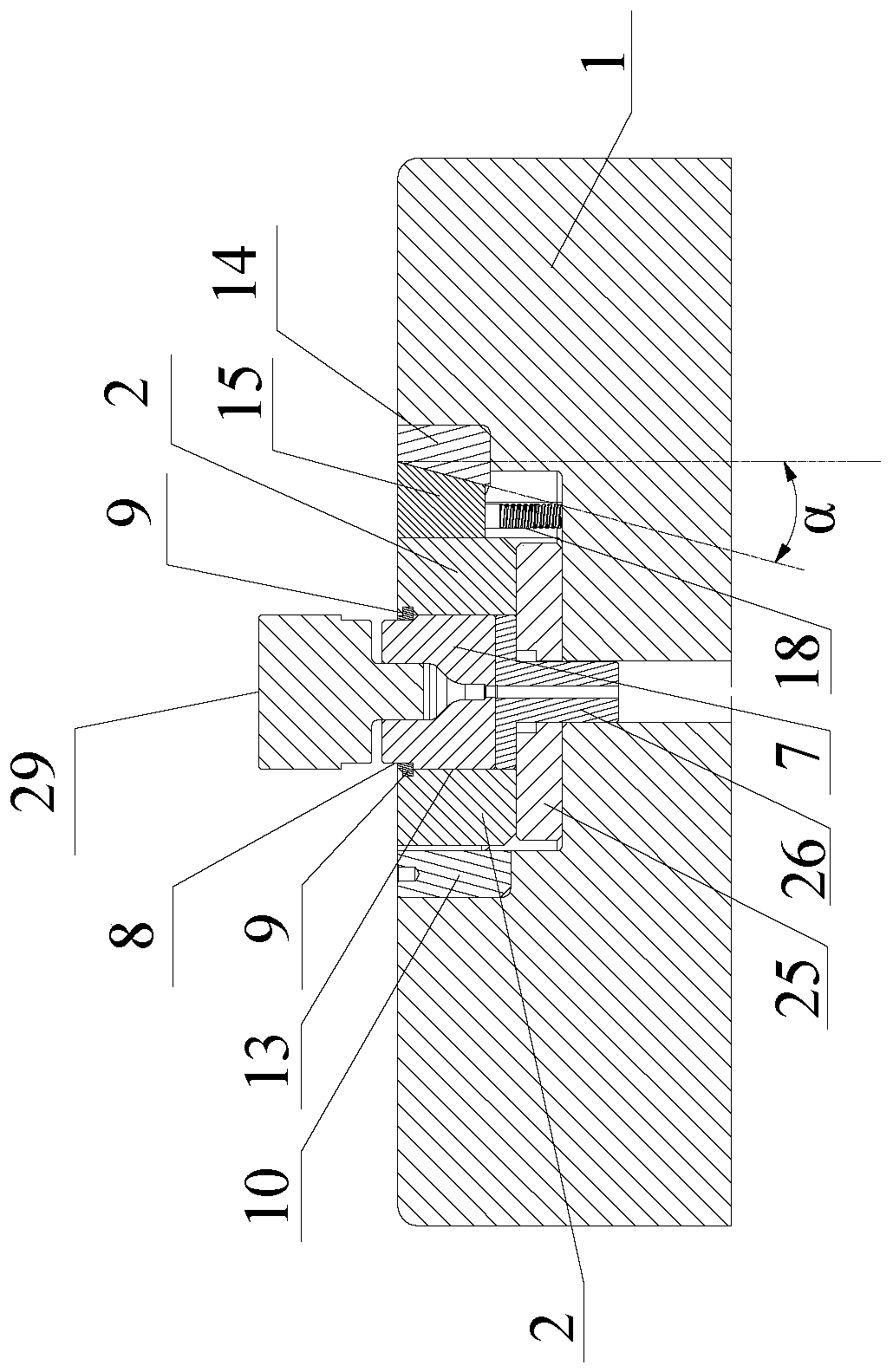

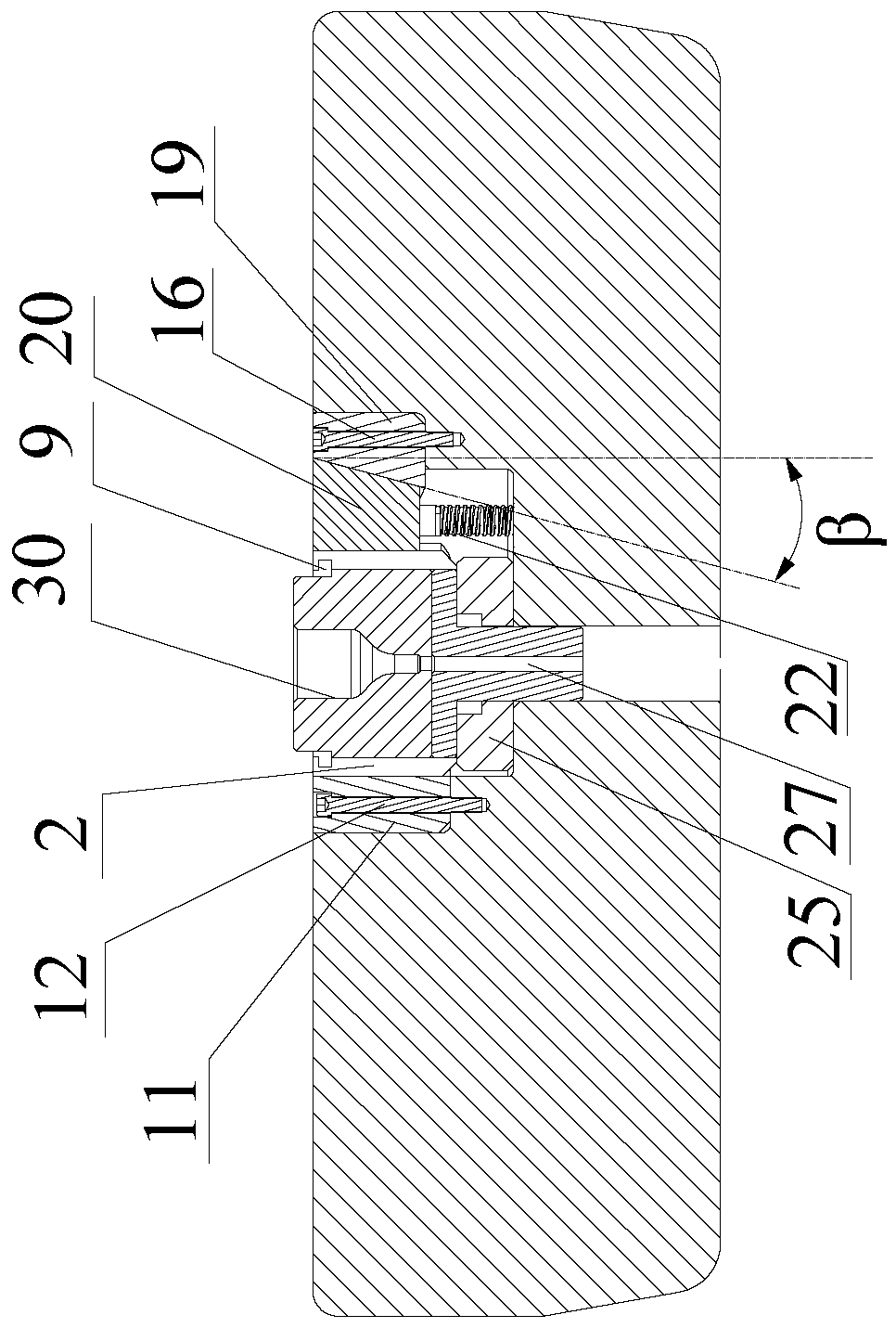

[0024] See Figure 1 to Figure 5 , a female die fastening device for a cylindrical closed forging die of the present invention, which includes a lower die base 1, a profiling piece, a transverse clamping assembly 3 and a longitudinal clamping assembly 4, and the lower die base 1 is provided with Horizontal datum plane and longitudinal datum plane, the shape of the profiling block is rectangular and its front side 5 and left side 6 are respectively attached to the transverse datum plane and the longitudinal datum plane; the profiling block consists of two symmetrically arranged clamping blocks 2 are assembled together, and the opposite sides of the two clamping blocks 2 are provided with arc-shaped through holes 13 through up and down. The radius of the arc-shaped through holes 13 is equal to the radius of the female mold 7, and the female mold 7 is arranged on two arc In the space surrounded by the shaped through hole 13, and the outer top surface of the female mold 7 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com