Patents

Literature

53results about How to "Avoid production interruptions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Warning method, warning device and warning system for visual safety stock

ActiveCN101692300ARealize visualizationRealize automatic alarm functionAlarmsSimulationWarning system

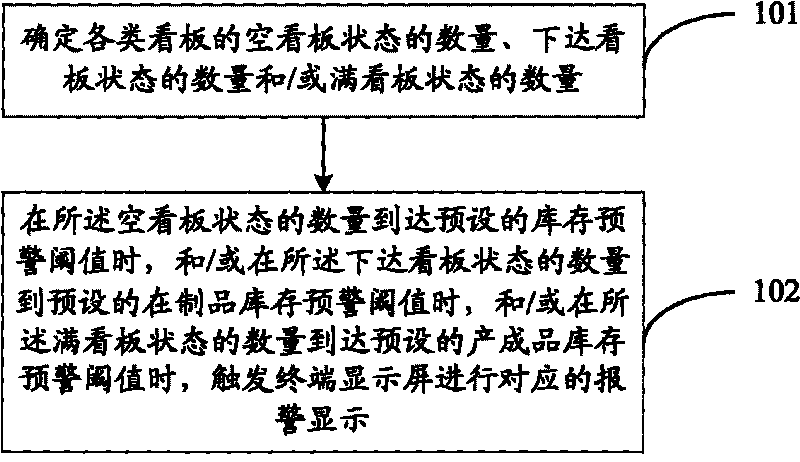

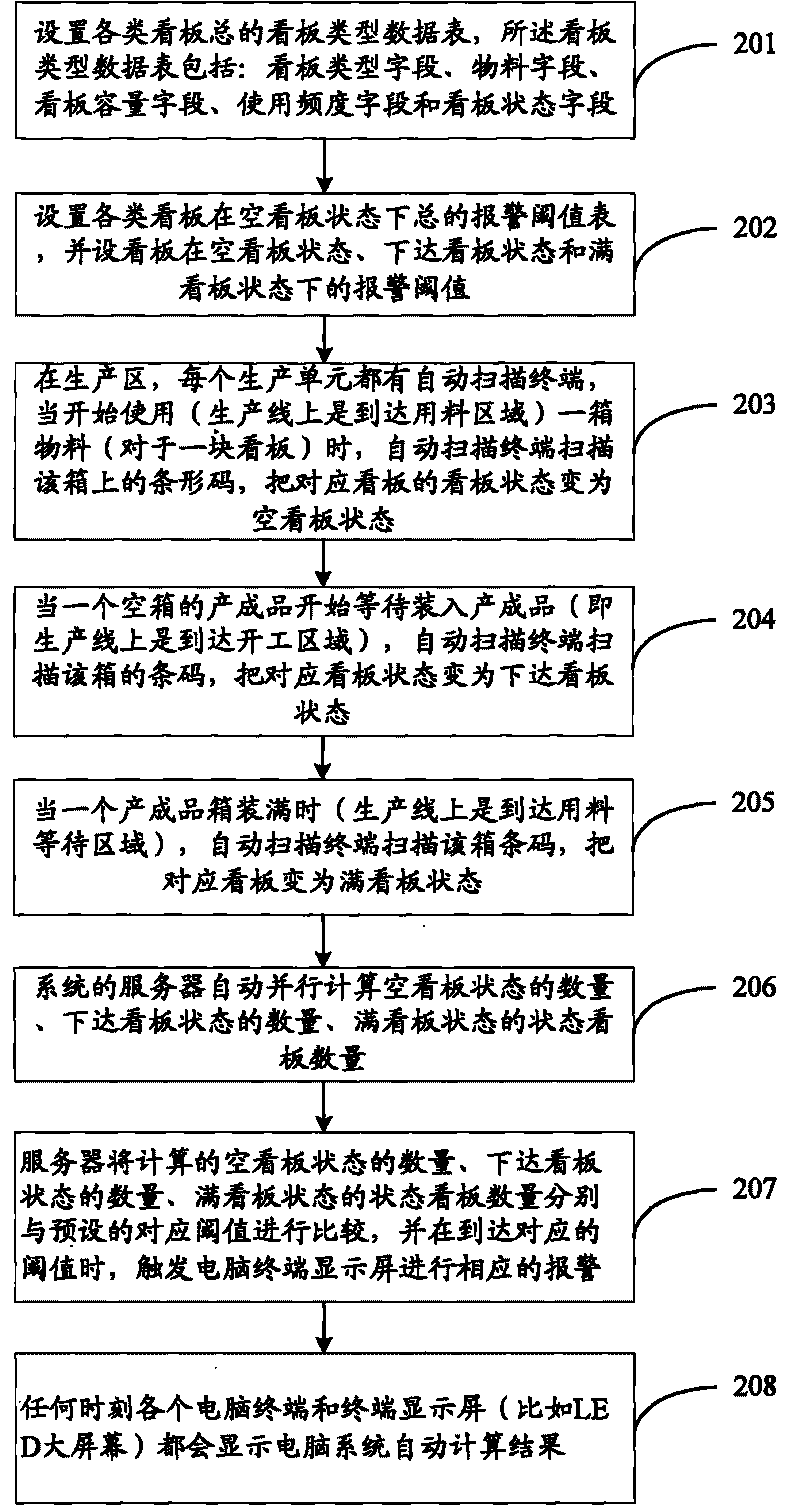

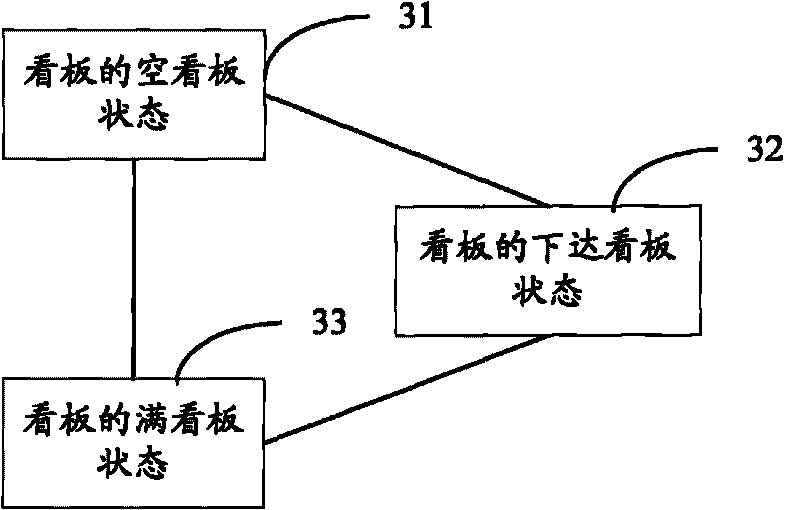

The invention relates to a warning method, a warning device and a warning system for visual safety stock. The method comprises the following steps: determining the number of empty billboard states, the number of release billboard states and / or the number of full billboard states of various billboards; when the number of the empty billboard states reaches a preset early warning threshold value of a stock, triggering a terminal display screen to carry out corresponding warning display; and / or when the number of the release billboard states reaches a preset early warning threshold value of a product stock, triggering the terminal display screen to carry out the corresponding warning display; and / or when the number of the full billboard states reaches a preset early warning threshold value of a finished product stock, triggering the terminal display screen to carry out the corresponding warning display. Through the preset warning threshold value, the stock data are visualized, and the warning display is automatically triggered so as to avoid production interruption and customer delivery period delay caused by stock shortage, and reduce the stock cost.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

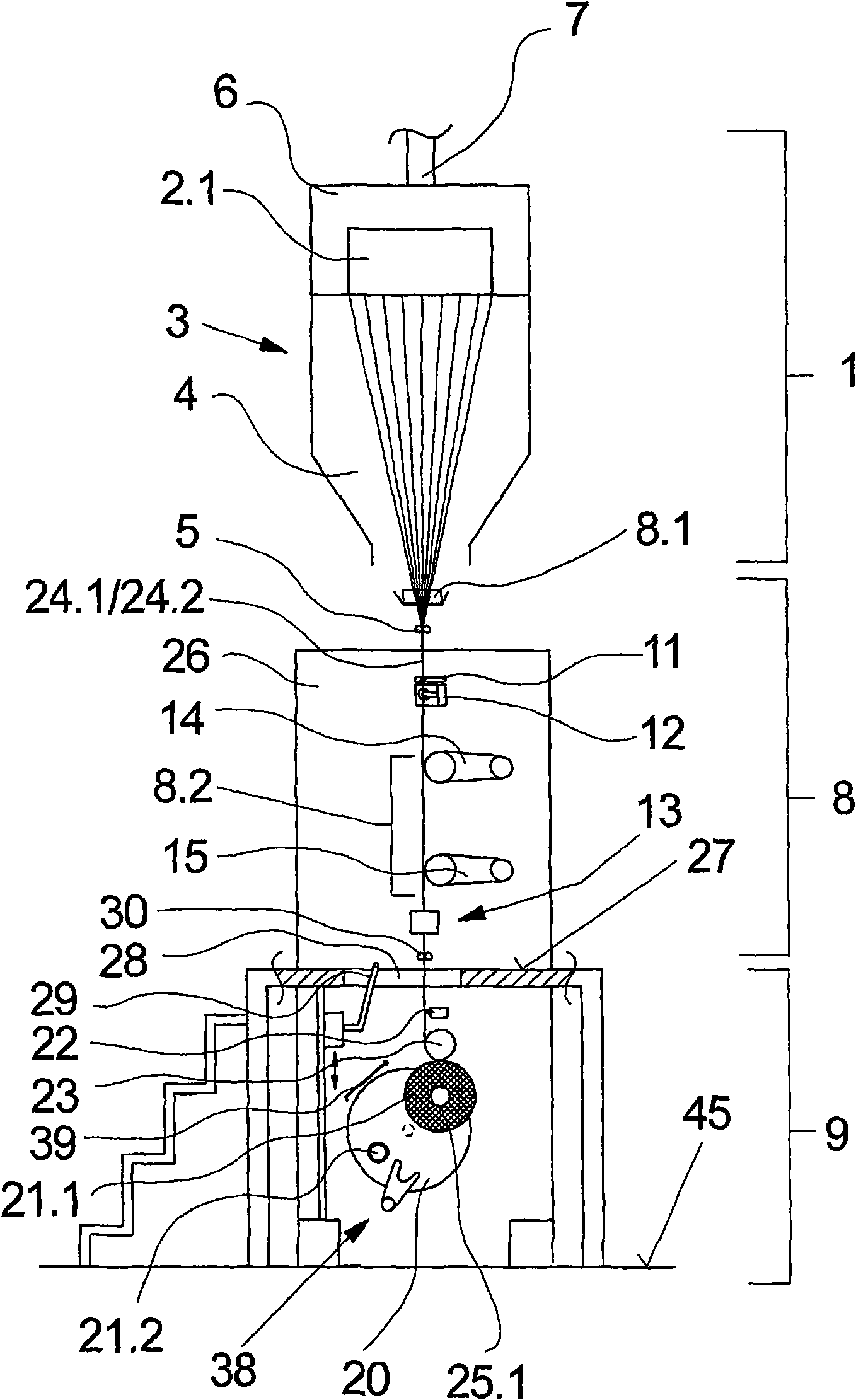

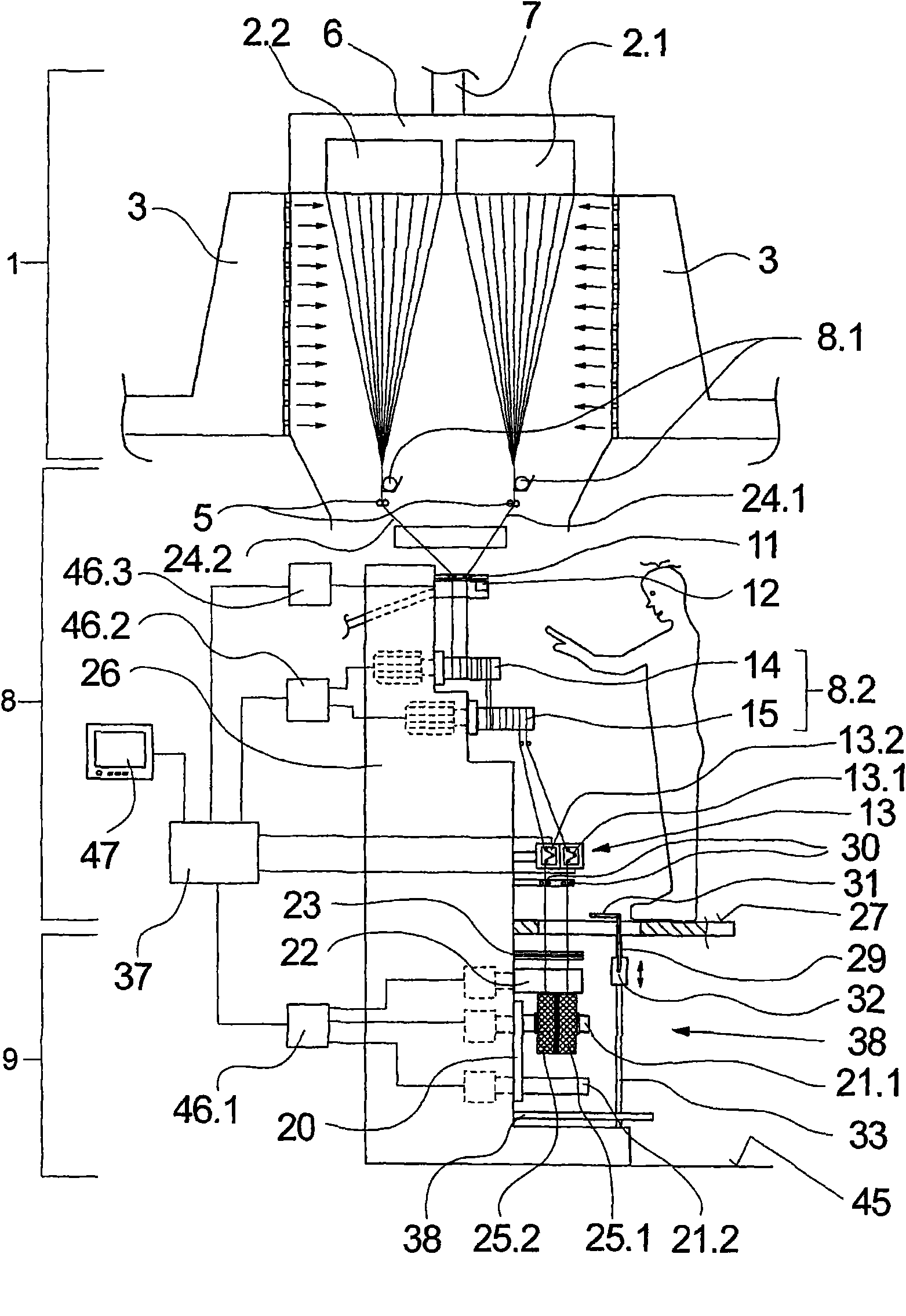

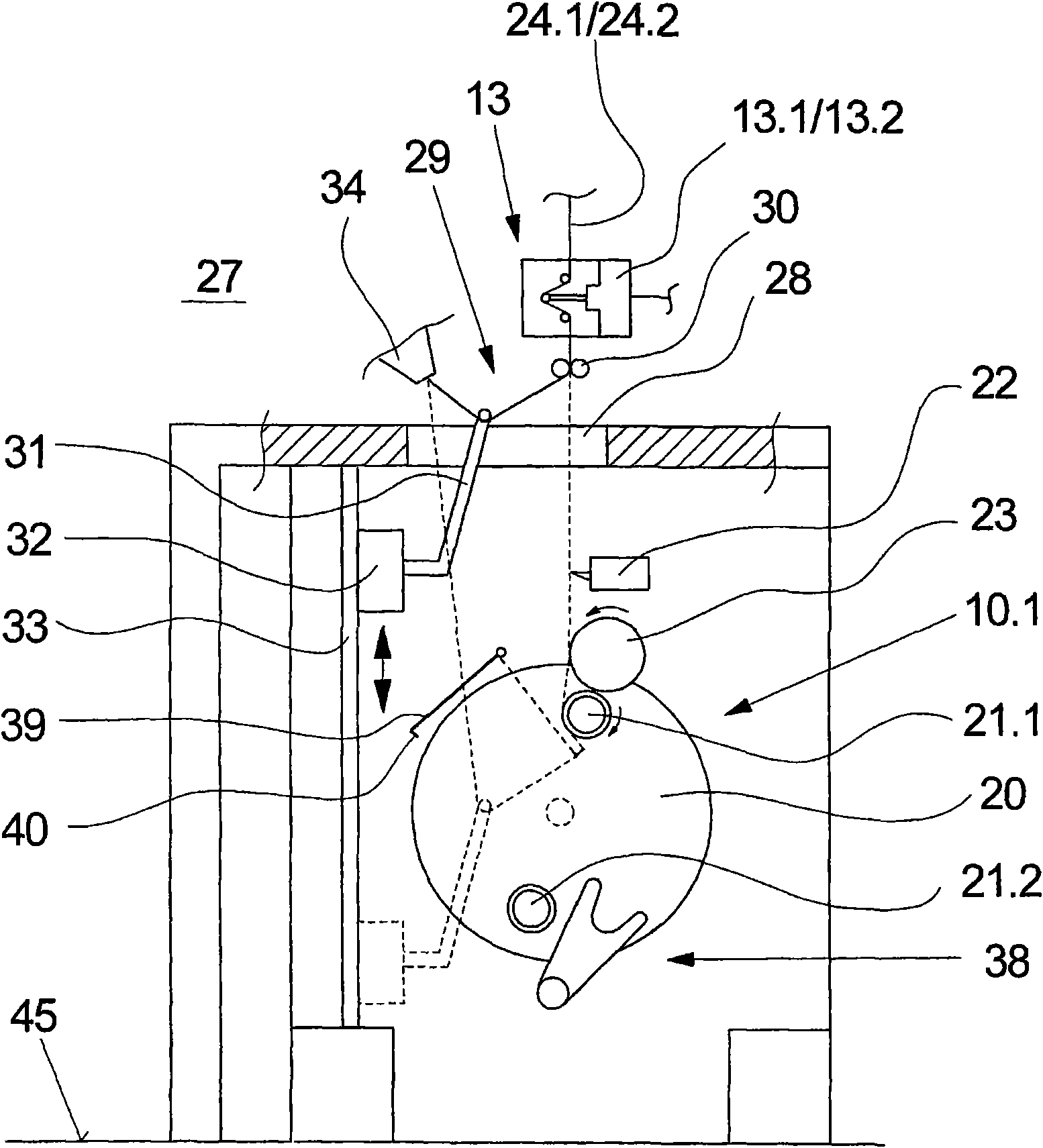

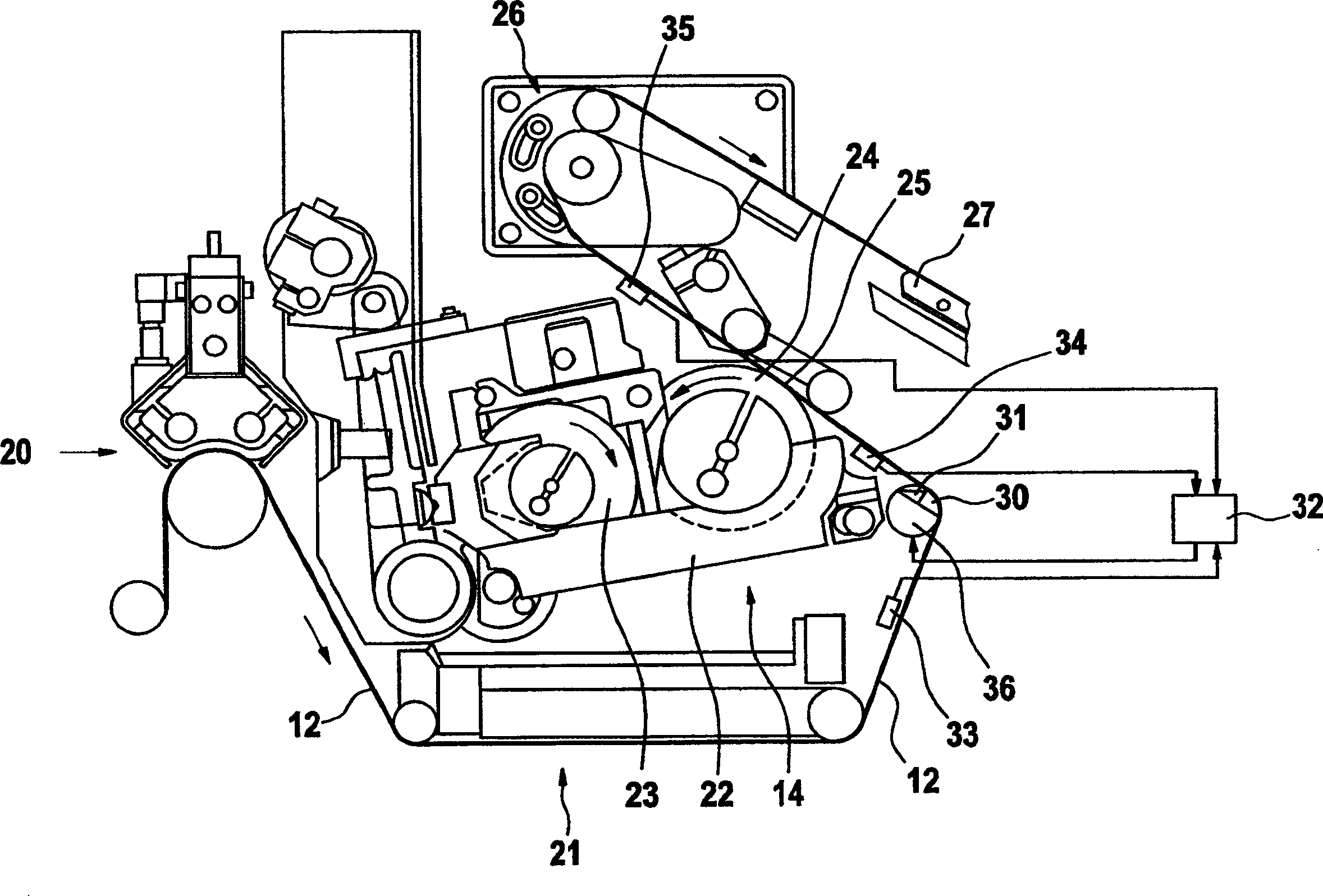

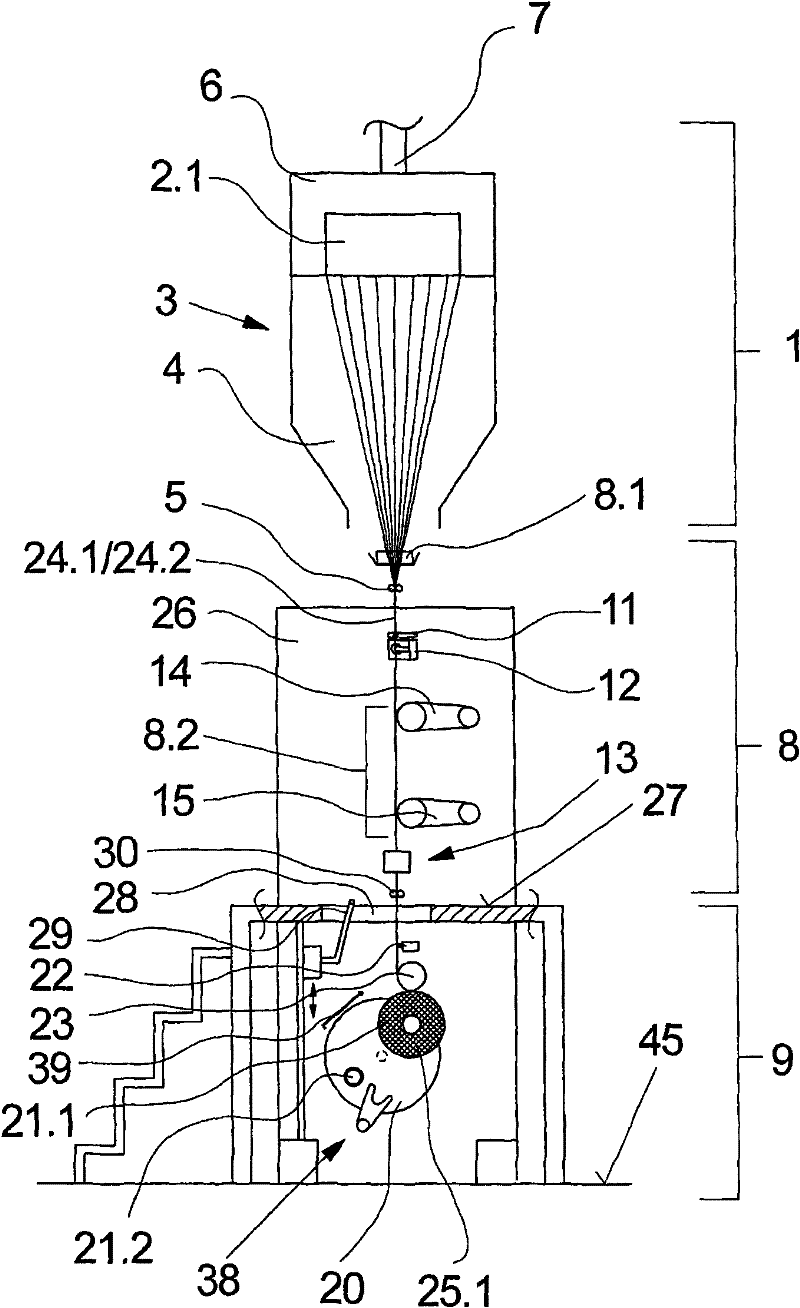

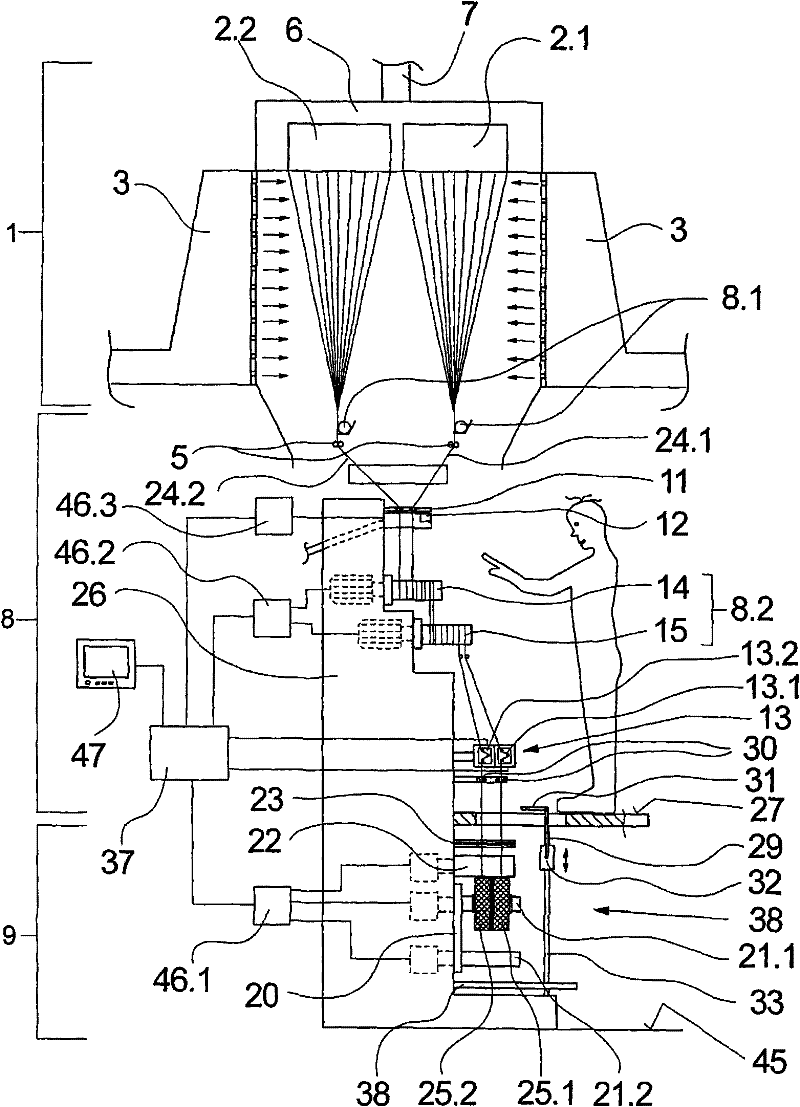

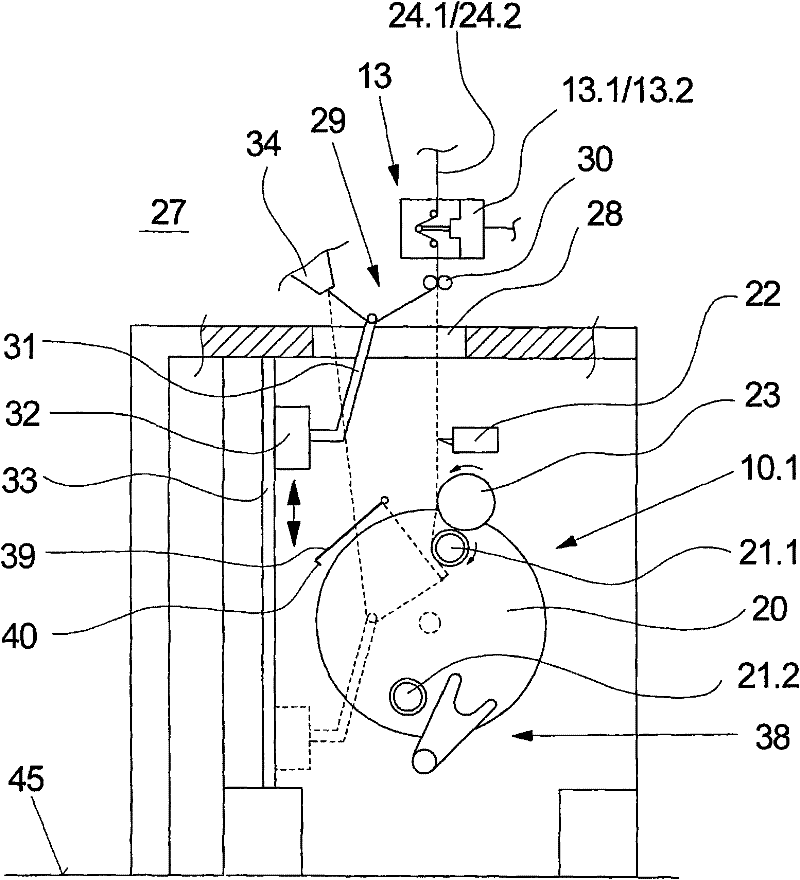

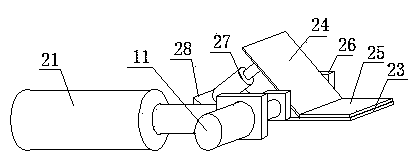

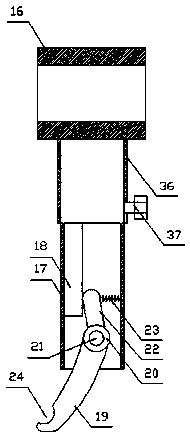

Method and device for melt spinning, treating and winding a synthetic thread

InactiveCN101646810AOperation without delayIdentify operabilityArtificial thread manufacturing machinesFilament handlingEngineeringConductor Coil

The invention relates to a method and a device for melt spinning, treating and winding a synthetic thread. The thread is pulled off, guided and treated after melt spinning by a treatment device and iswound onto a coil by a winding device. Said thread is guided vertically from the melt spinning process to the winding process over several levels. In order to maintain short operating times, in particular when the process is started or interrupted, the treatment device is operated from a first upper operational platform. The winding device is operated in a second lower operating platform. The thread is monitored in a transitional area between the treatment device and the winding device by means of a thread monitor.

Owner:OERLIKON TEXTILE GMBH & CO KG

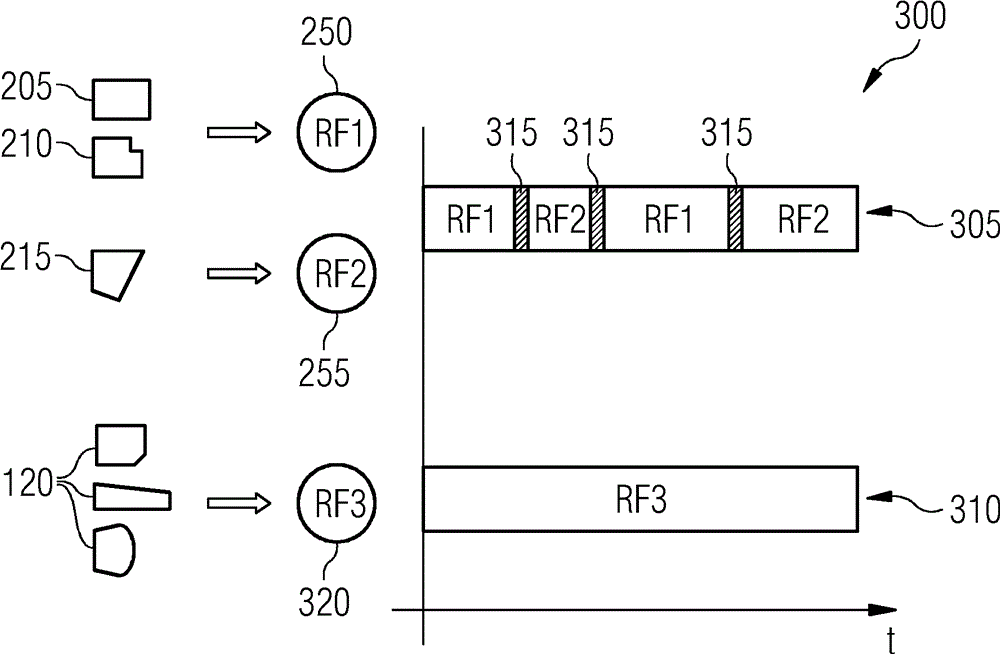

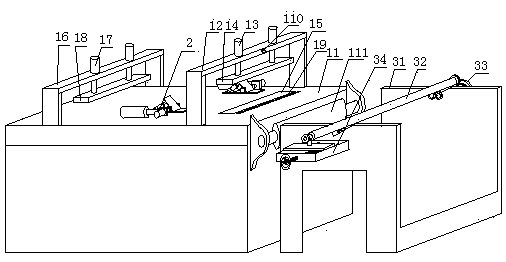

Formation of equipment families on fitting lines

ActiveCN104412284AReduce the numberTake advantage ofForecastingElectrical componentsElectronic componentComputer science

The invention concerns a fitting line which is arranged to fit printed circuit boards with electronic components. A method for determining equipment families for the fitting line comprises the following steps: initial forming of a number of equipment families, each having allocated printed circuit boards; selecting of one of the equipment families; and distributing of the printed circuit boards of the selected equipment family to the other equipment families by means of integral linear programming.

Owner:SIEMENS AG

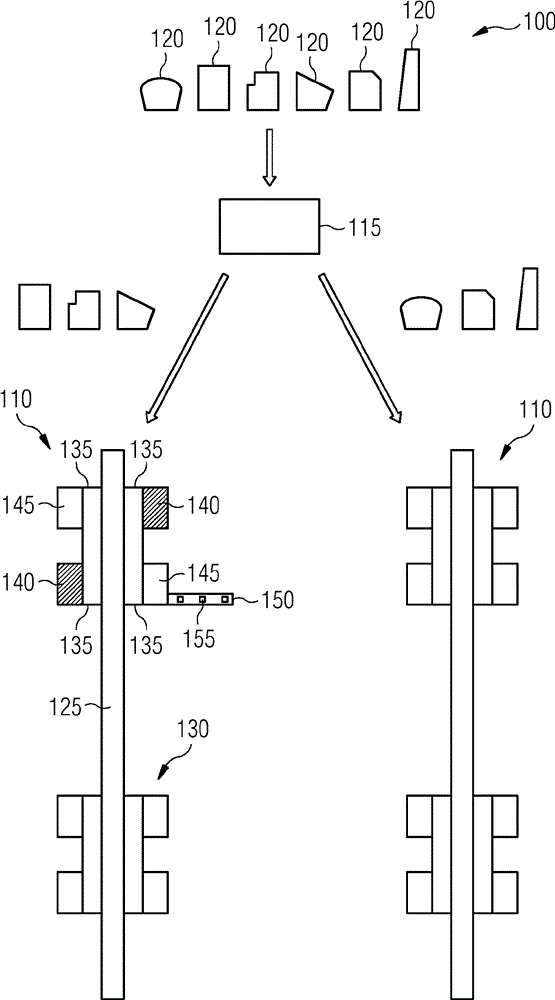

Part installation method of part assembly line

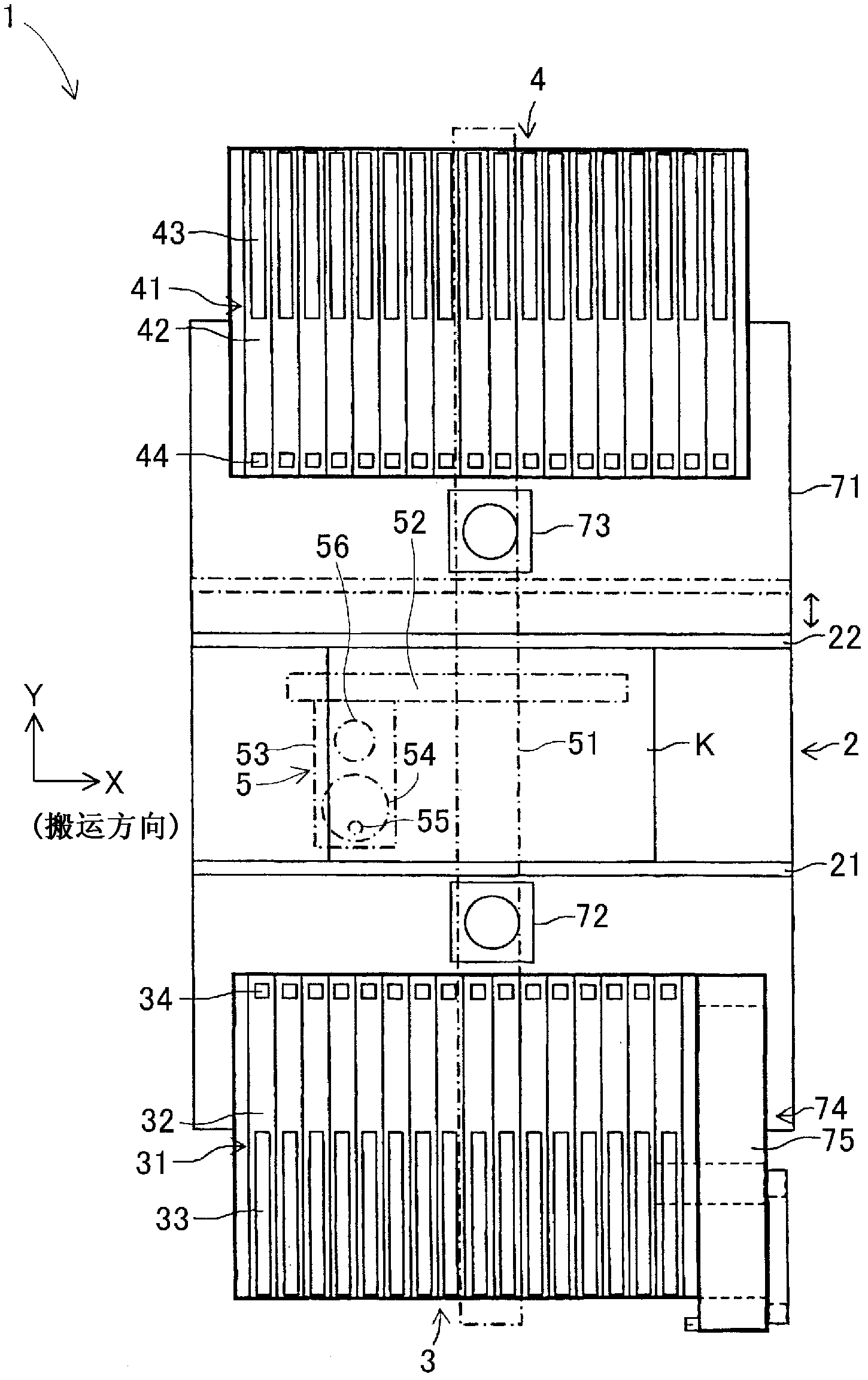

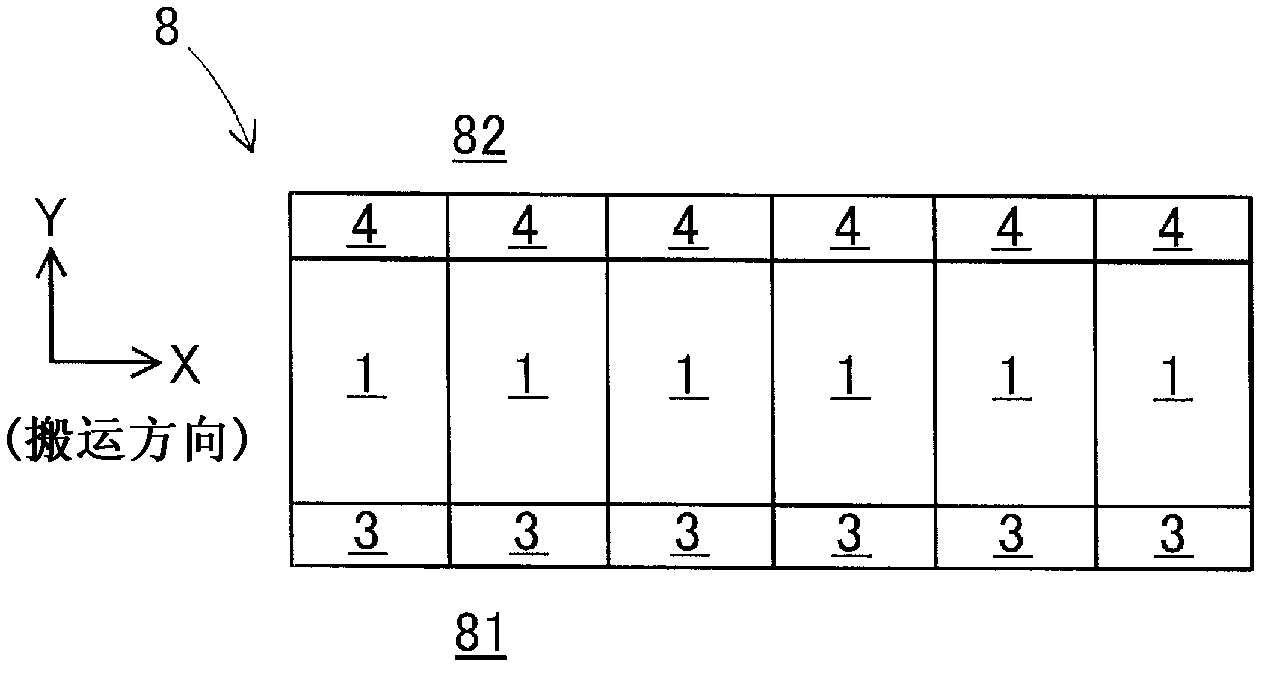

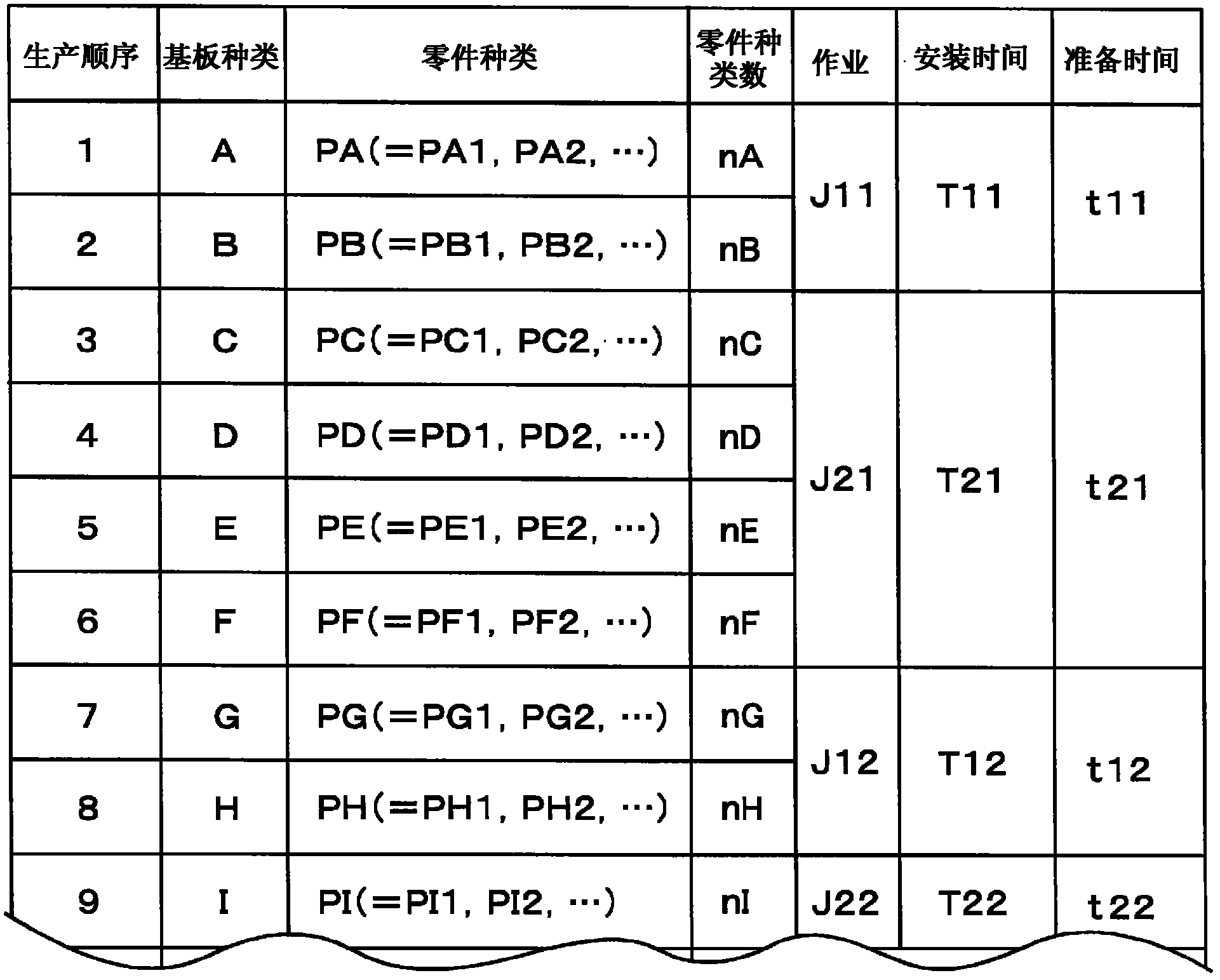

ActiveCN102762086AImprove work efficiencyNo production interruptionElectrical componentsSubstrate typeAssembly line

The invention provides a part installation method of a part assembly line. The part installation method realizes no overlapping of motion paths of operators performing part supply work related to types of substrates in production and part preparation work related to types of substrates to be produced, guarantees high operation efficiency and largely prevents production halts during the production of multi-operation production mode. In the part installation of the part assembly line with multiple stages of part installation machines arranged in parallel, the following steps are conducted in each stage of the part installation machines: the types of substrates produced according to the production order are distributed to substrate types on sides of first and second part feed devices alternatively; when a part transfer device selects parts from one of first and second part feed devices and installs the parts on substrates of the substrate types on the side of one part feed device, part receiving devices are disposed on the other part feed device; and the part receiving device are used for receiving parts being produced after production of the substrate types on the side of one part feed device and being of the types for the substrates of the substrate types on the side of the other part feed device.

Owner:FUJI KK

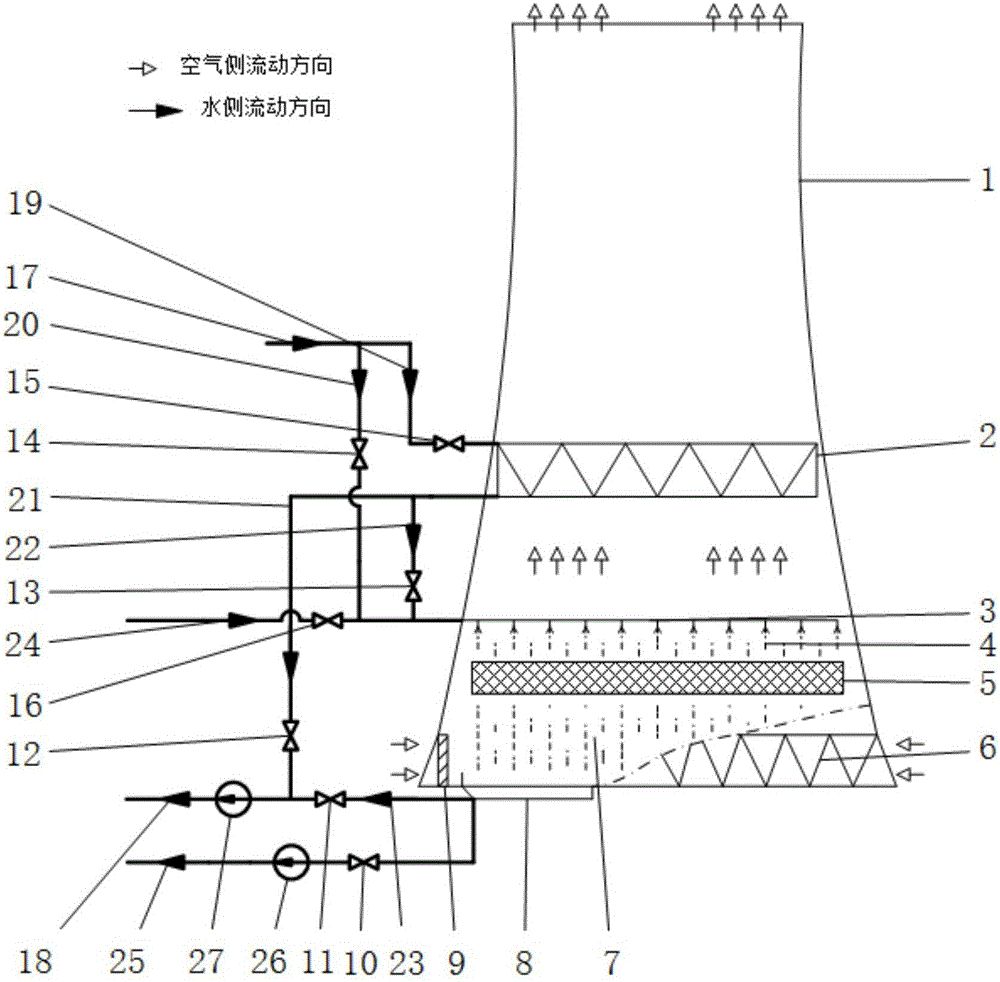

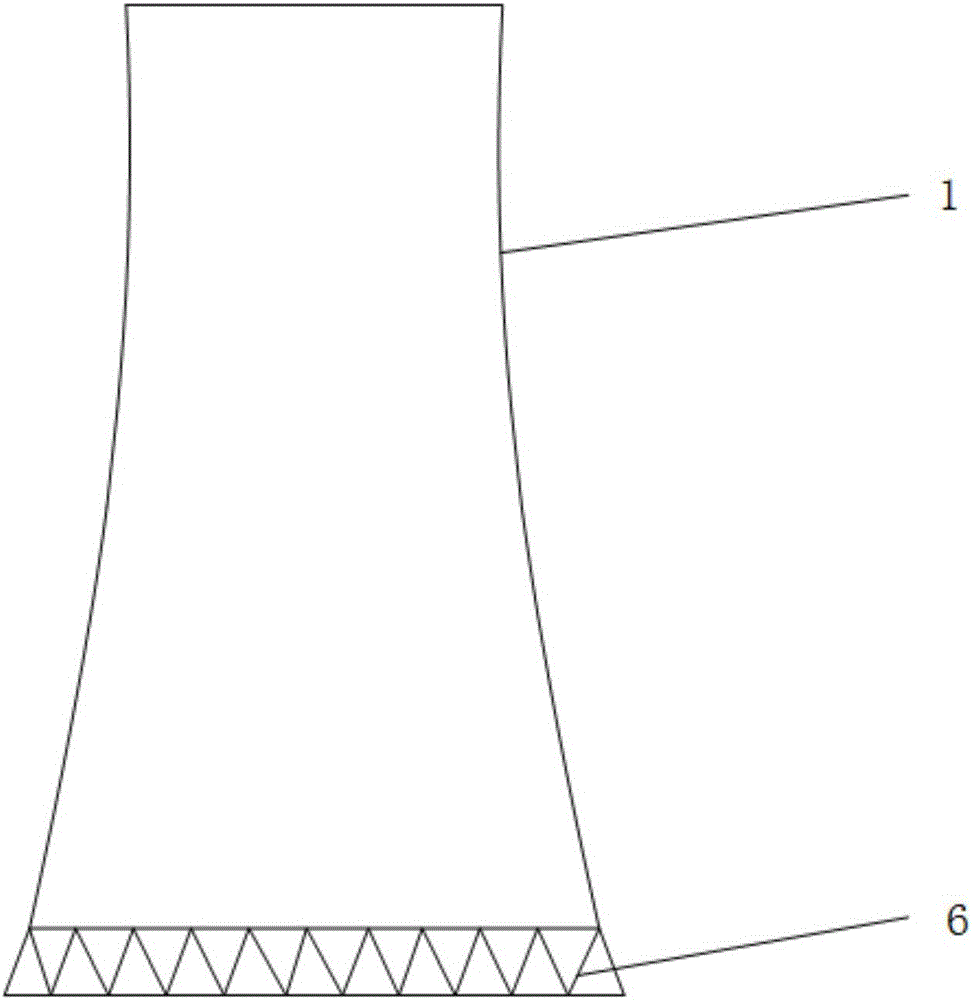

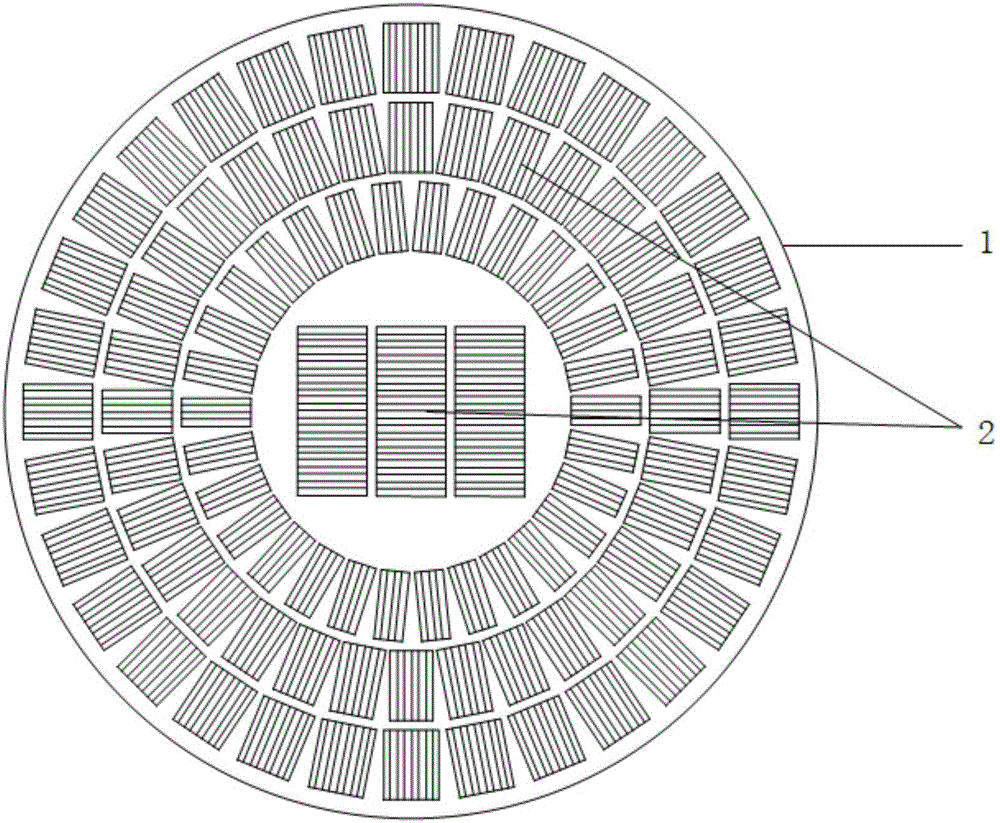

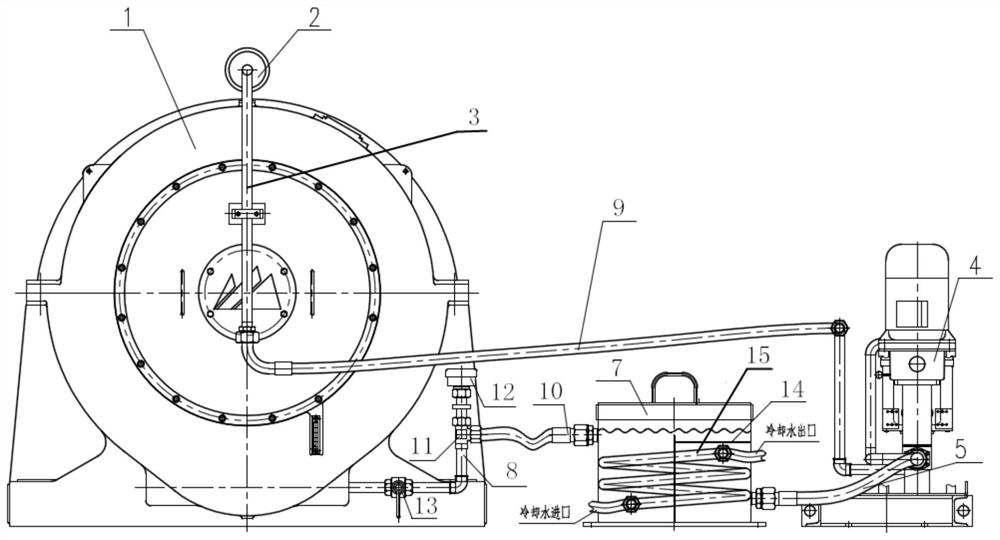

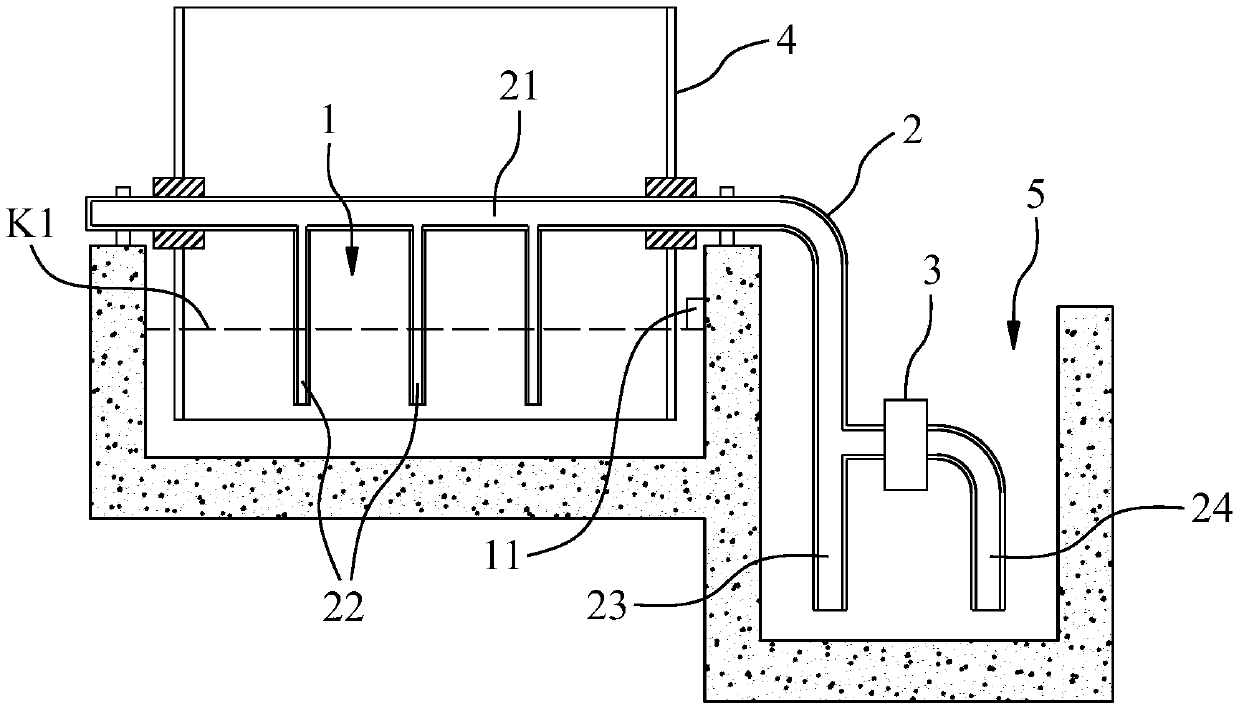

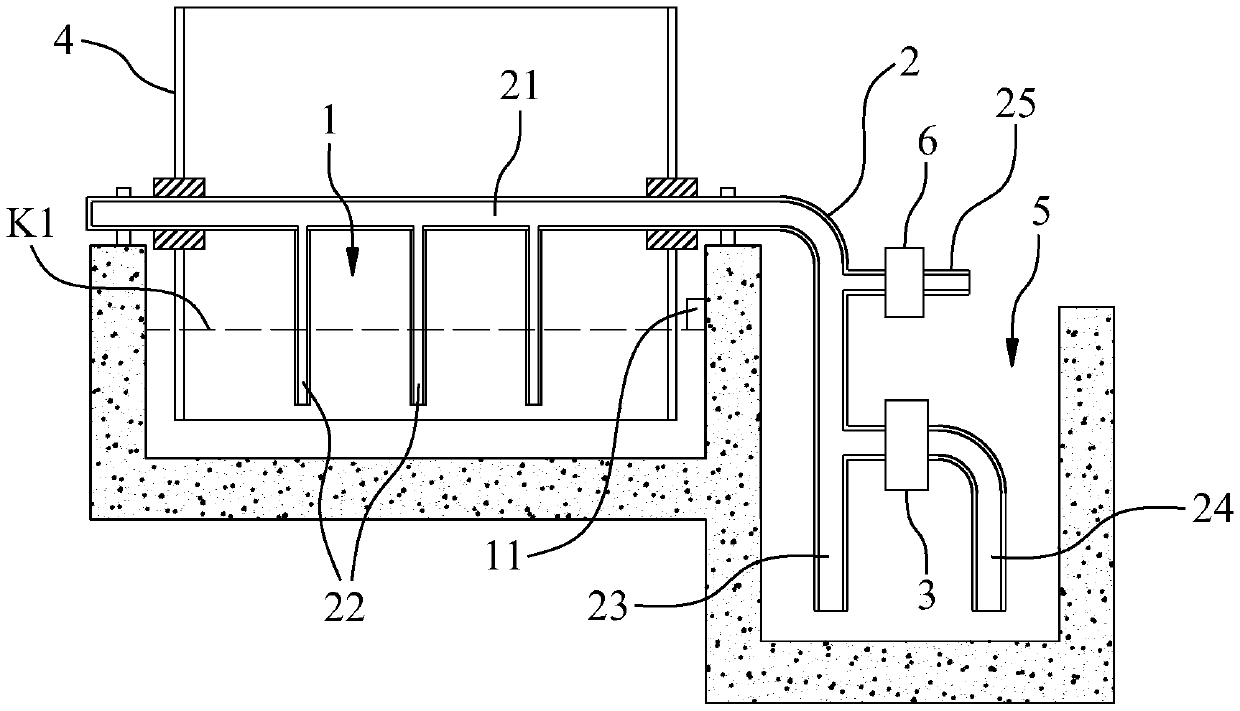

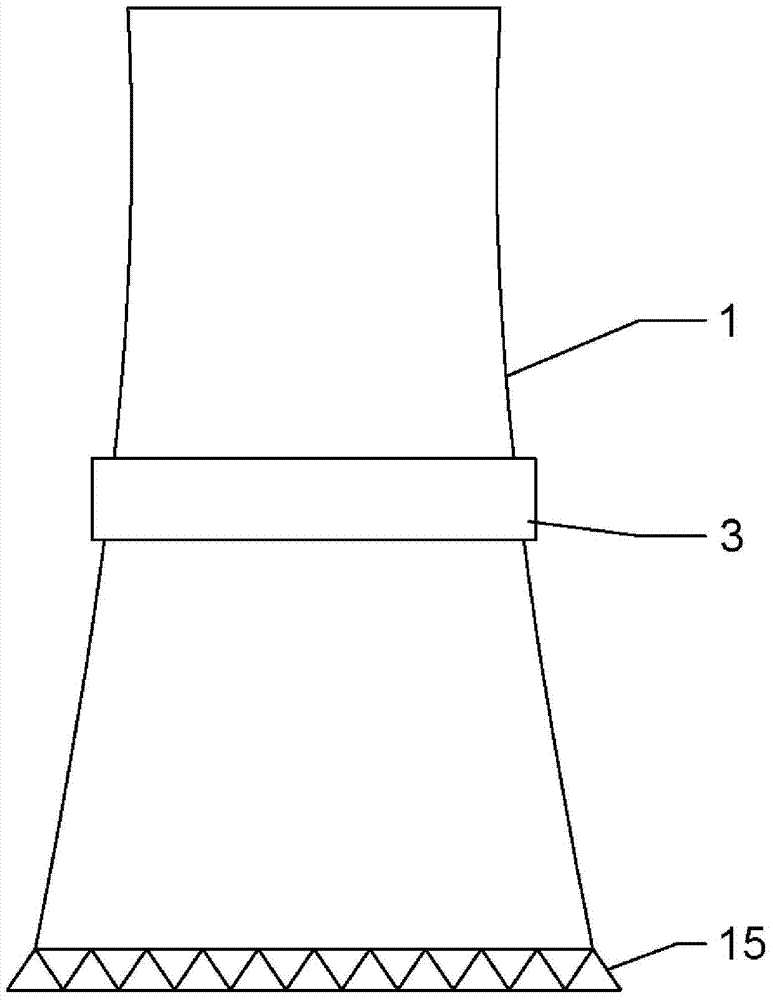

Natural ventilation dry-wet combined cooling tower with air precooling and winter freeze preventing functions

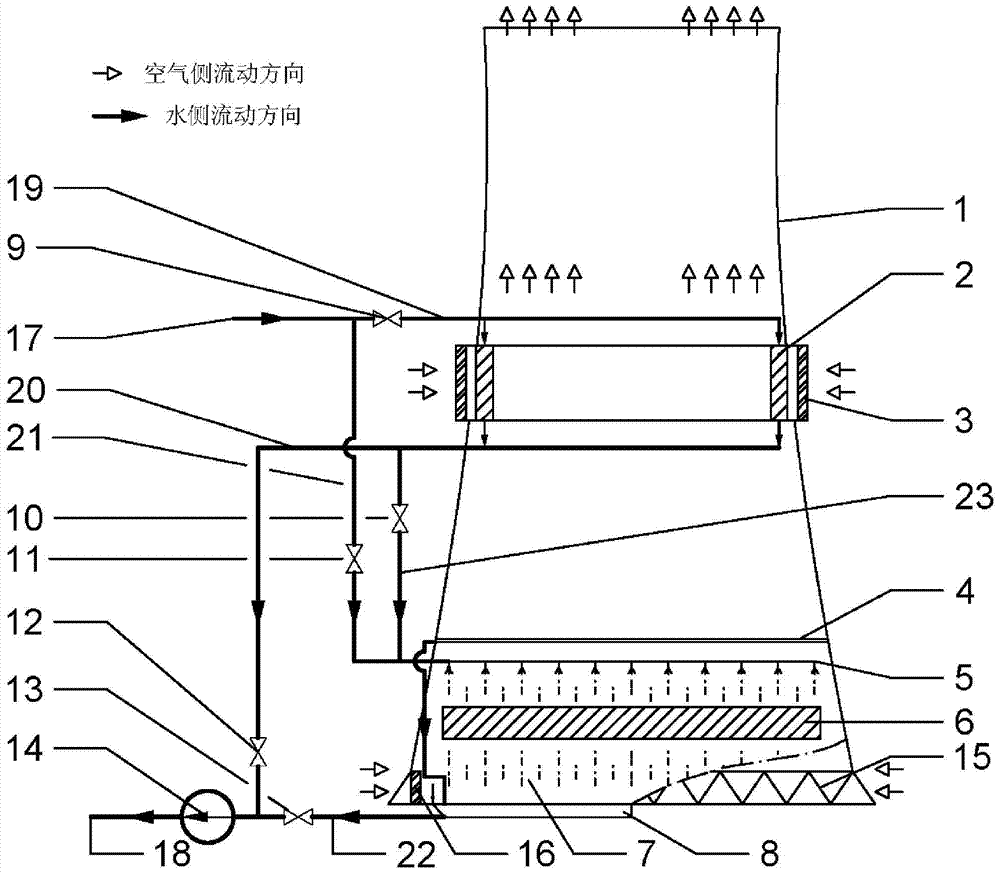

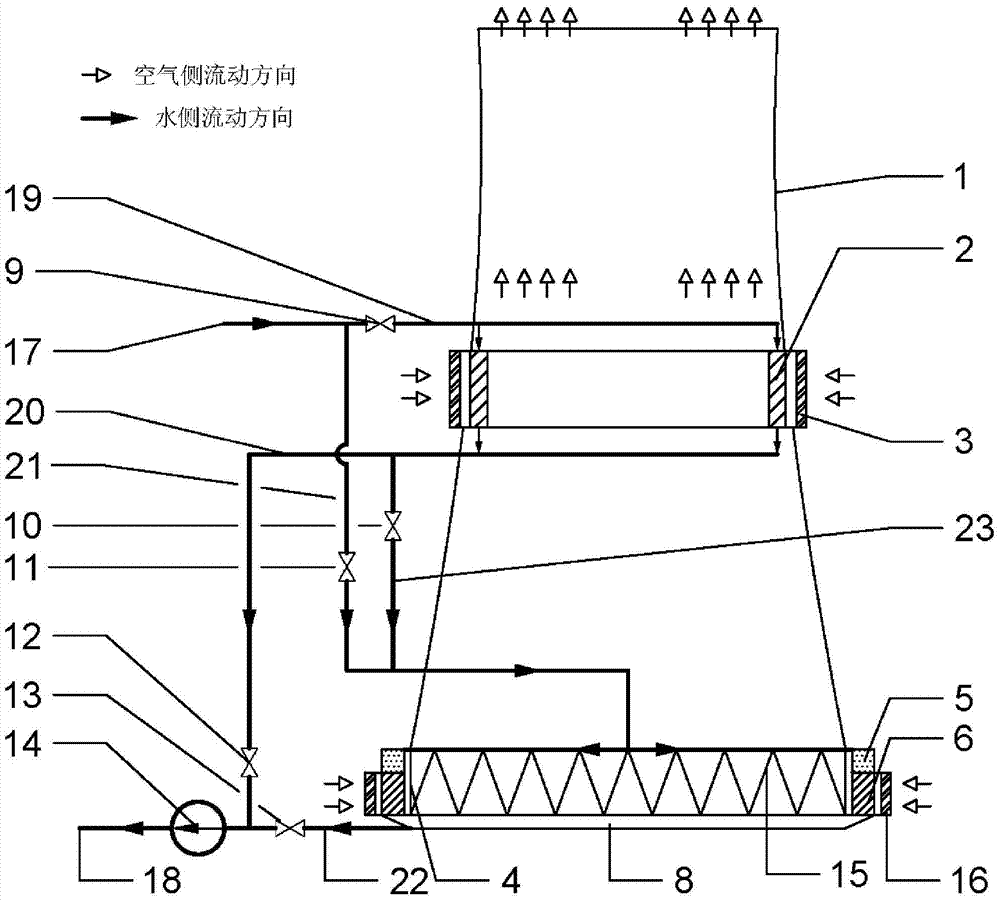

The invention relates to a natural ventilation dry-wet combined cooling tower with air precooling and winter freeze preventing functions. A dry-cooling section and a wet-cooling section are integrally arranged in the cooling tower in the perpendicular direction; the dry-cooling section comprises a dry-cooling unit, and a cooling triangle is arranged for wall-type heat exchange between air and circulating water; the wet-cooling section sequentially comprises a water distribution area, a packing area, a rain area and a water collecting tank from top to bottom, and an air-circulating water mixed heat exchange mode is adopted. A water side flowing system comprises a circulating water distribution system and a precooling system. According to the cooling tower, the operation modes including the single dry-cooling operation mode, the single wet-cooling operation mode, the dry-wet combined serial operation mode, the dry-wet combined parallel operation mode and the precooling dry-cooling operation mode of the cooling tower can be flexibly selected according to the actual conditions such as the local weather conditions and the on-site working conditions, therefore, continuous, safe and efficient operation of the cooling tower is guaranteed, water can be saved, the low tower outlet water temperature can be achieved at high temperature in summer, and the freeze problem of the dry-cooling unit can be effectively prevented in winter.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

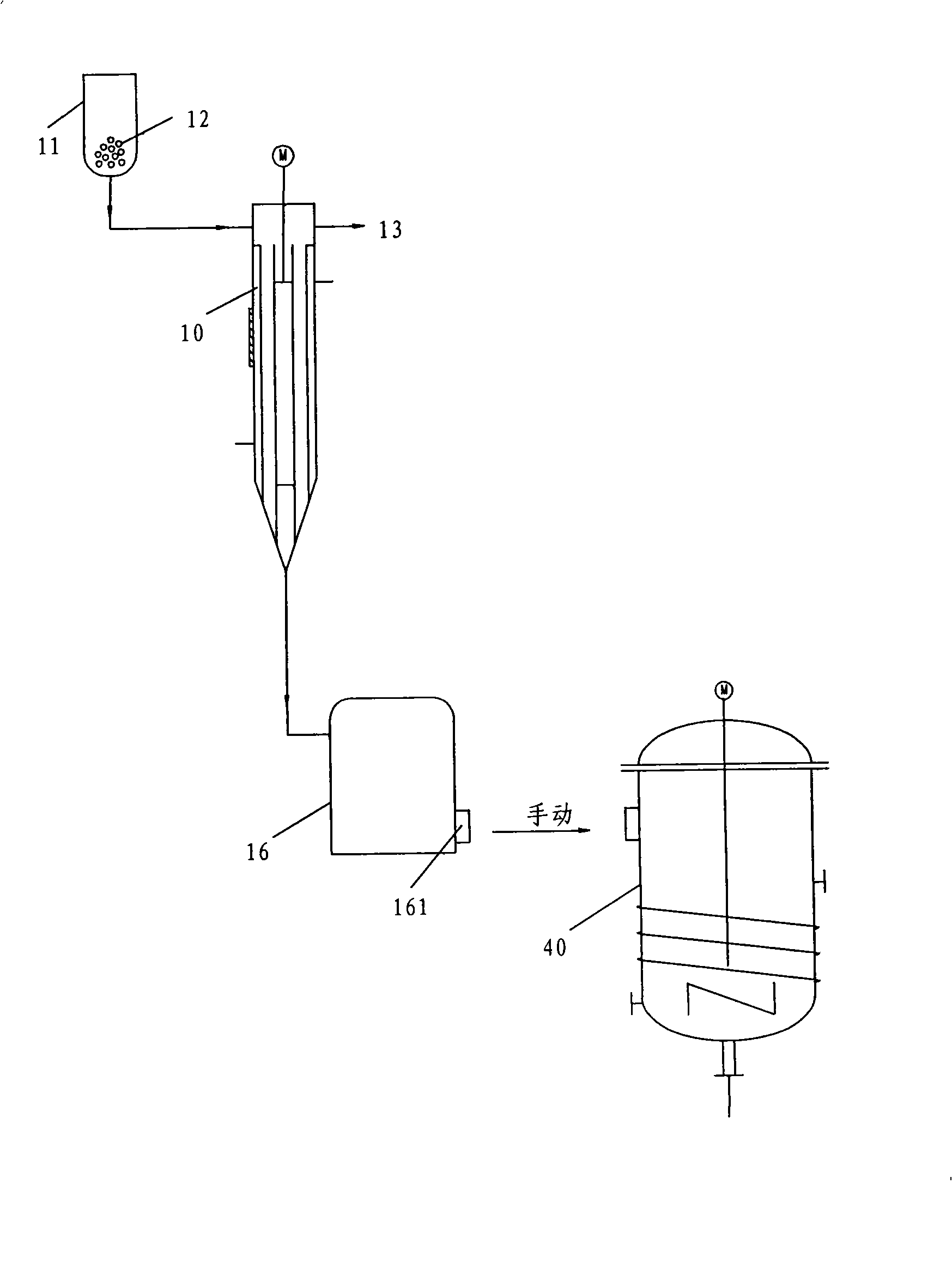

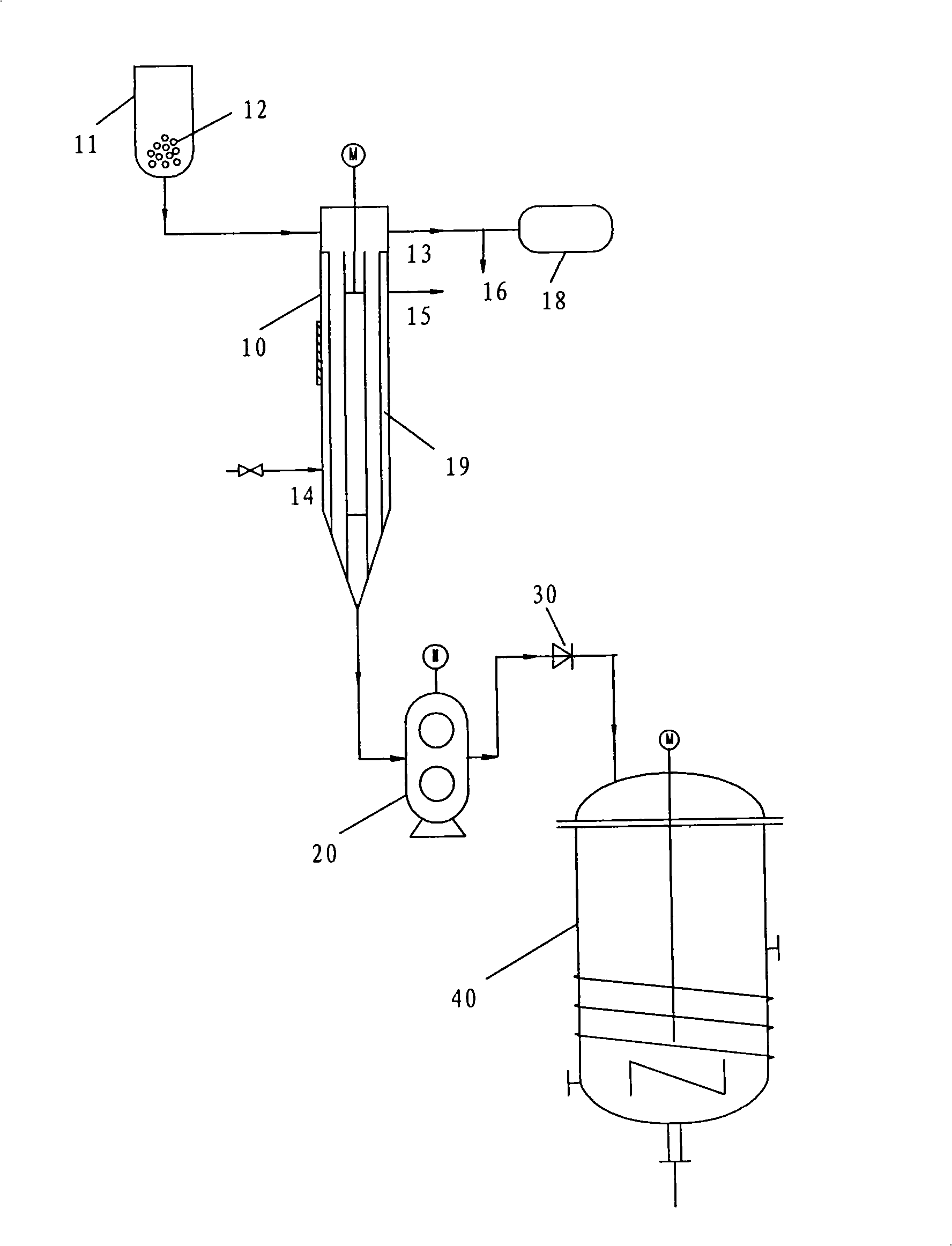

Auto discharging system for preparing light-coloured transparent alkyl glycoside

ActiveCN101333233ANo accumulationPrevent color burn-inSugar derivativesSugar derivatives preparationControl valvesGlucoside

The invention discloses an automatic discharging system which is used to prepare light-colored transparent alkyl glucoside and comprises a plate evaporator for evaporating the alkyl glucoside mixture, a discharging pump for outputting high-viscosity alkyl glucoside, a direction control valve for controlling the output of the high-viscosity alkyl glucoside, and a color drifting kettle for drifting the color of the high-viscosity alkyl glucoside. The technical proposal of the invention is that the invention has a discharging pump which can timely and directly outputs the high-viscosity alkyl glucoside inputted by the plate evaporator through the direction control valve to the color drifting kettle for color drifting so as to ensure continuous and automatic production to improve the production efficiency and save manpower and resources; besides, the discharging pump runs at all times so as to avoid the color deepening caused by local high temperature due to the large accumulation of alkyl glucoside; moreover, the discharging system is a closed system, so that the external air can not easily enter the system to avoid the alkyl glucoside color deepening as a result of air oxidation.

Owner:SHANGHAI FINE CHEM CO LTD

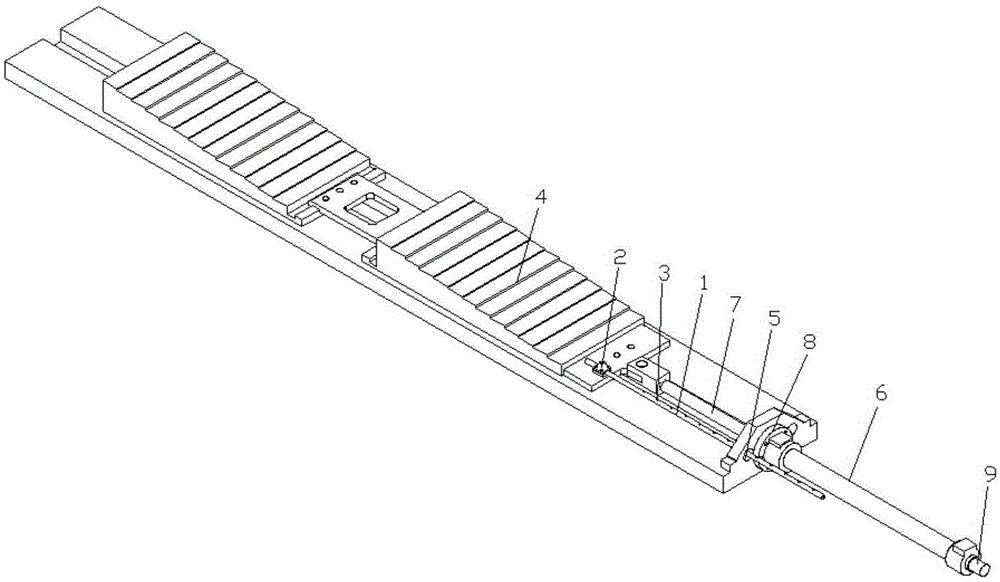

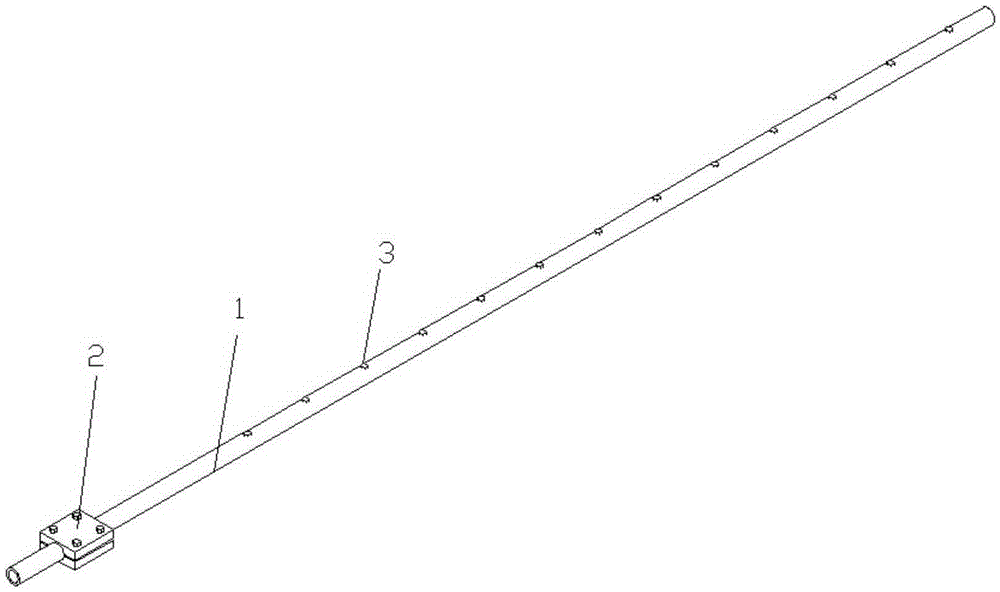

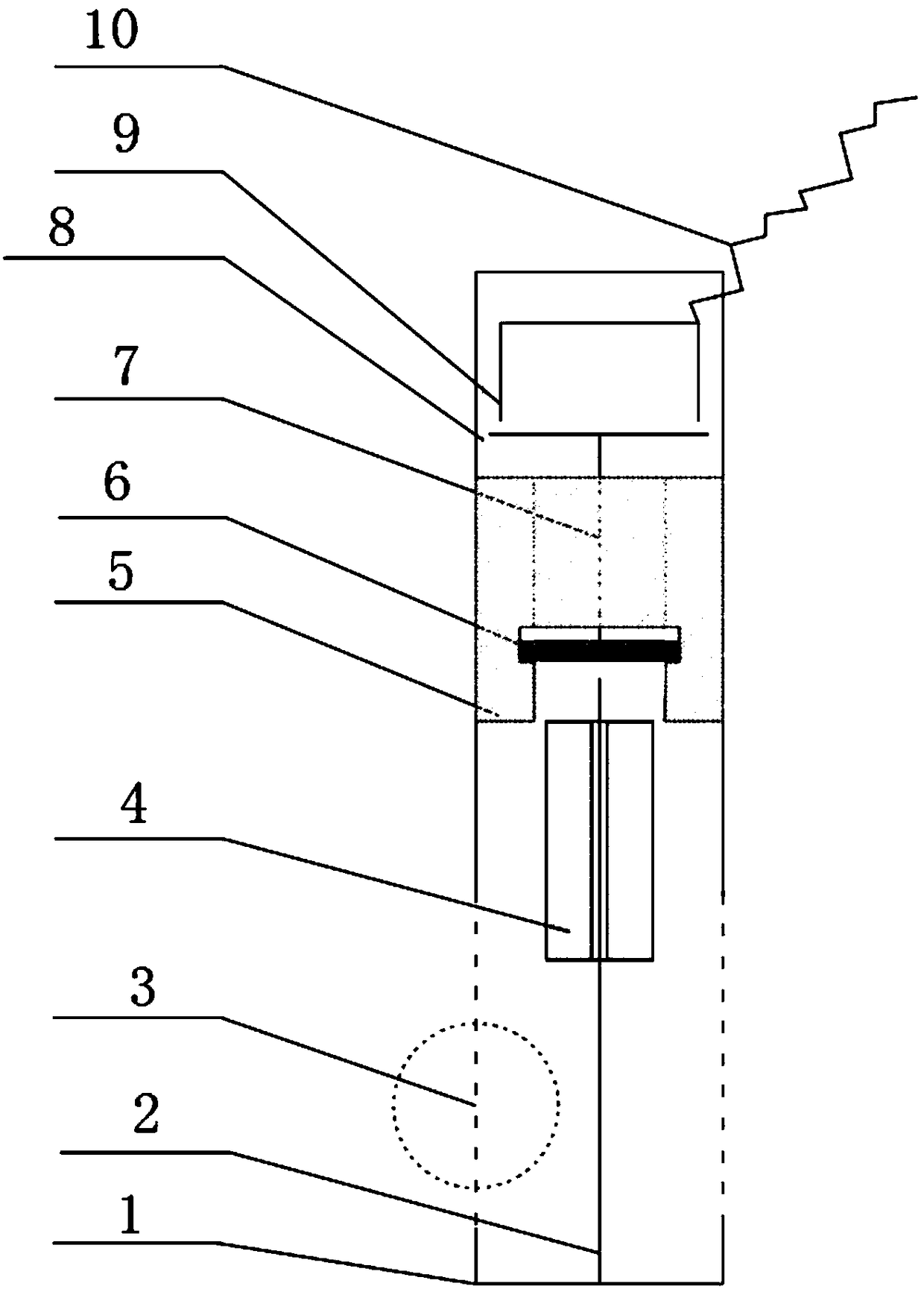

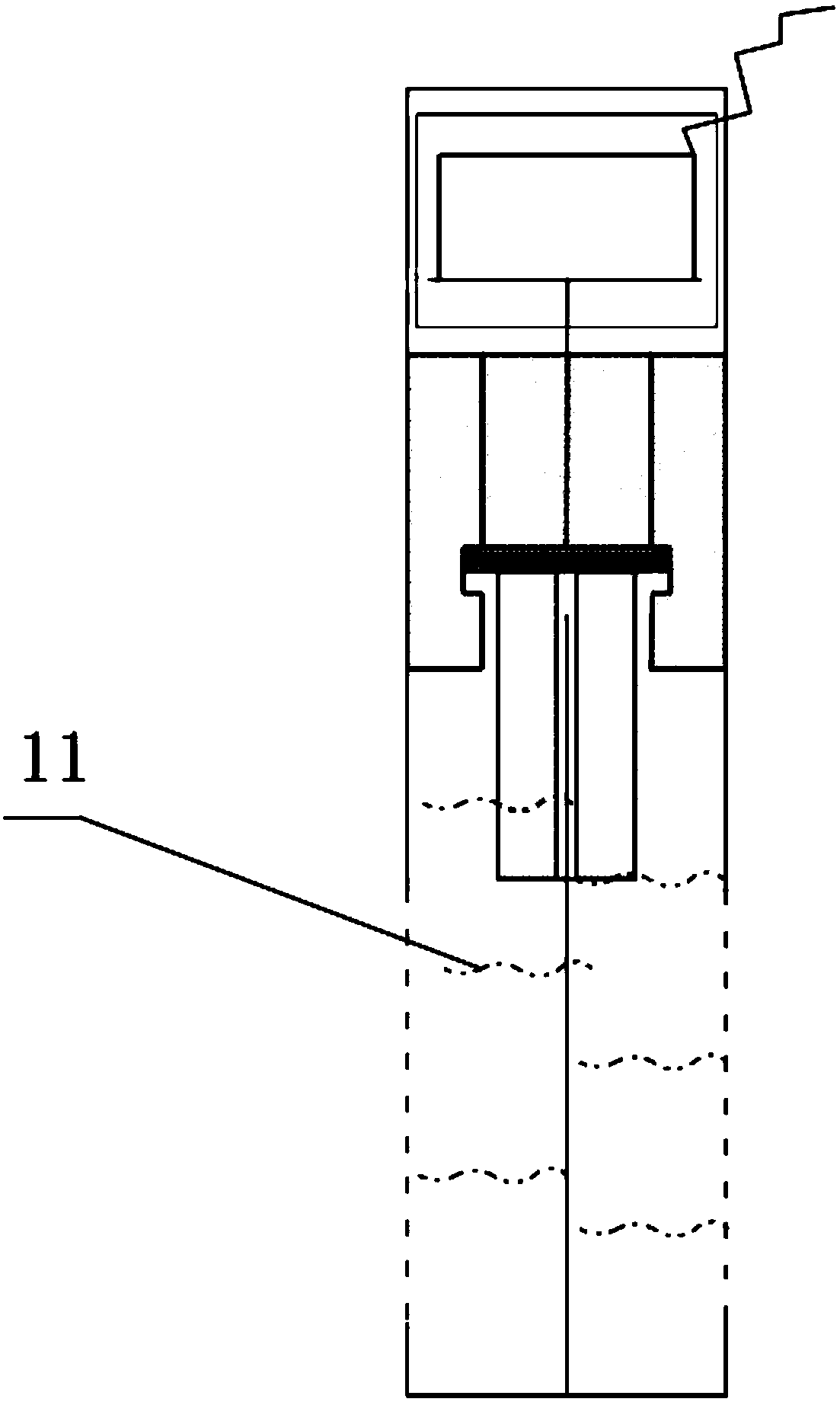

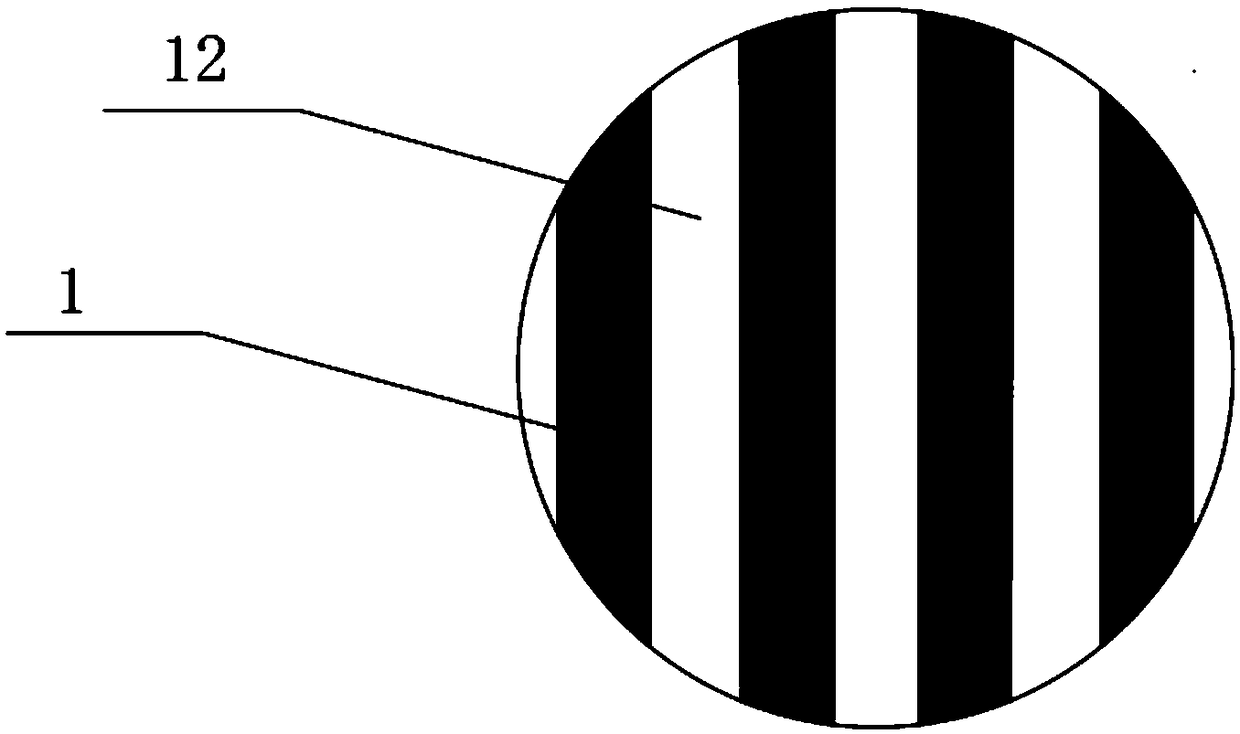

Fast detection device and method for position of lower step liner of rolling mill

ActiveCN105251785AReduce processing timeAvoid production interruptionsMeasuring devicesMetal rolling arrangementsIndustrial engineeringRolling mill

The invention provides a fast detection device and method for the position of a lower step liner of a rolling mill. The device comprises a ruler rod and a fixing pipe clamp, wherein the front end of the ruler rod is connected with the fixing pipe clamp, and a plurality of stage reading parts are uniformly arranged on the ruler rod at intervals; the number of the stage reading parts corresponds to the number of stages of the lower step liner, and the number of stages of the lower step liner is determined by observing the number of the stage reading parts. The fast detection device is low in manufacture cost, is suitable for the bad environment of sites, and is easily maintained and used. The method is easily popularized.

Owner:武汉钢铁有限公司

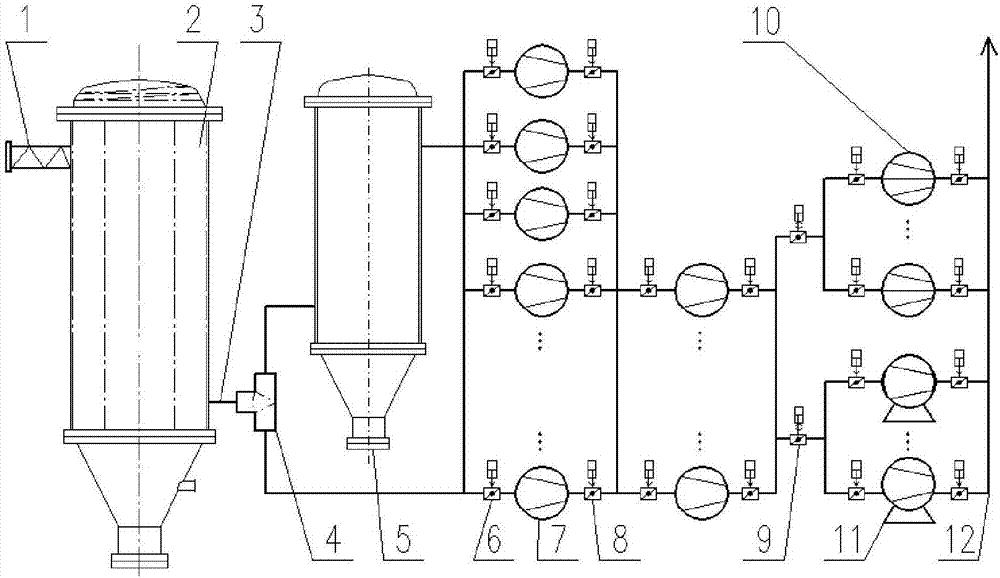

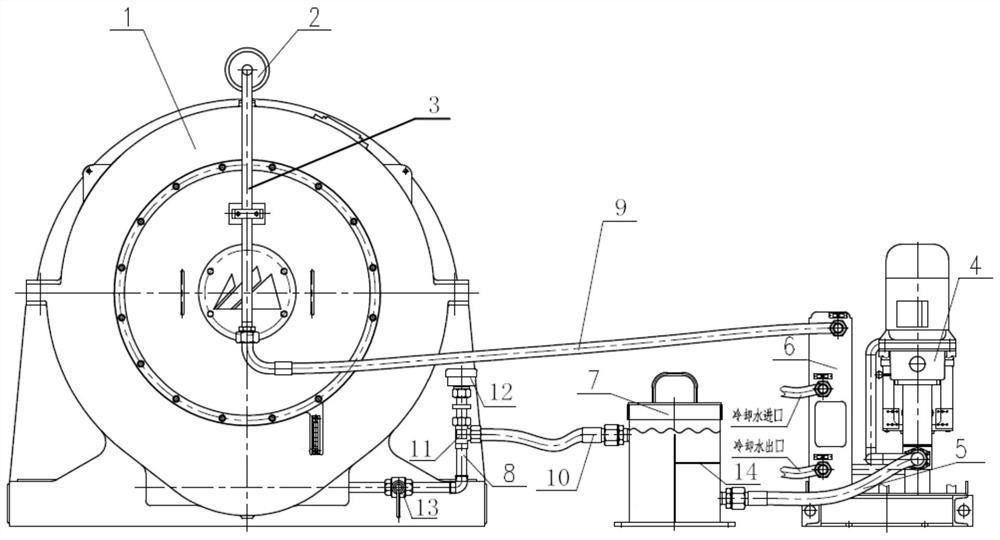

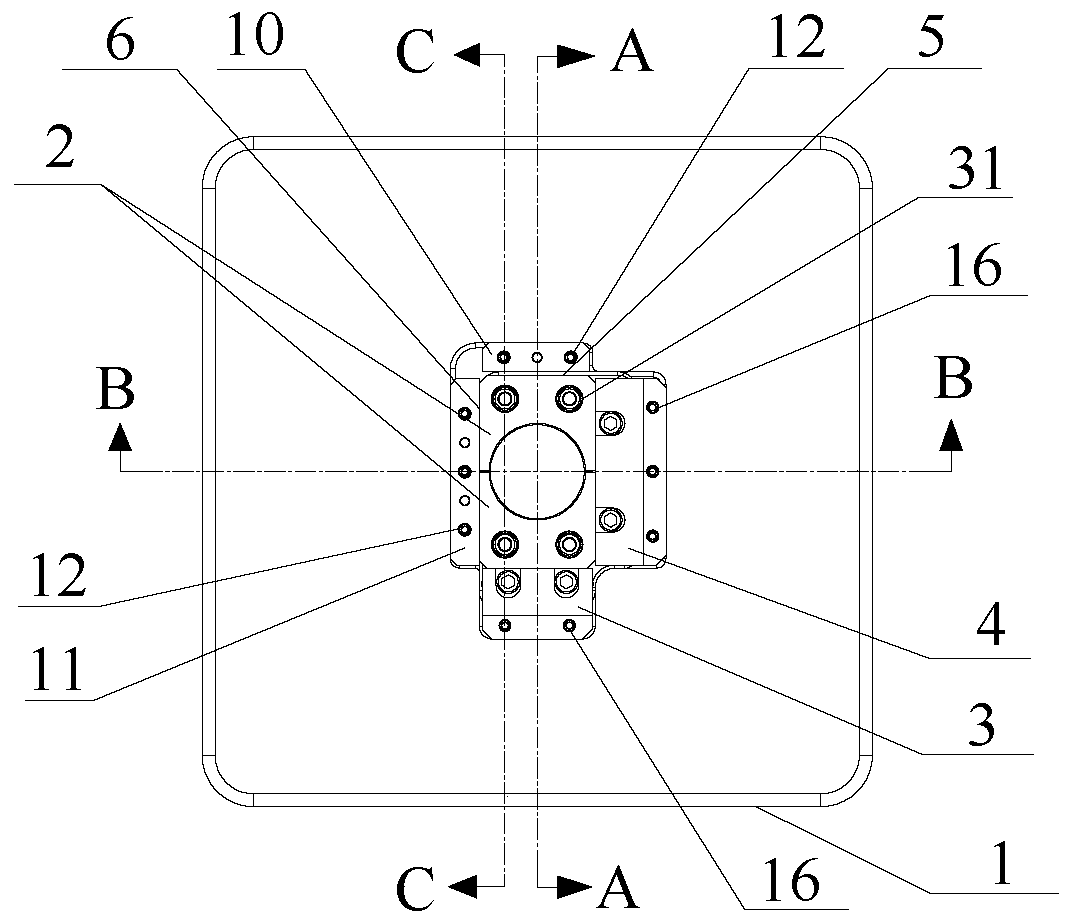

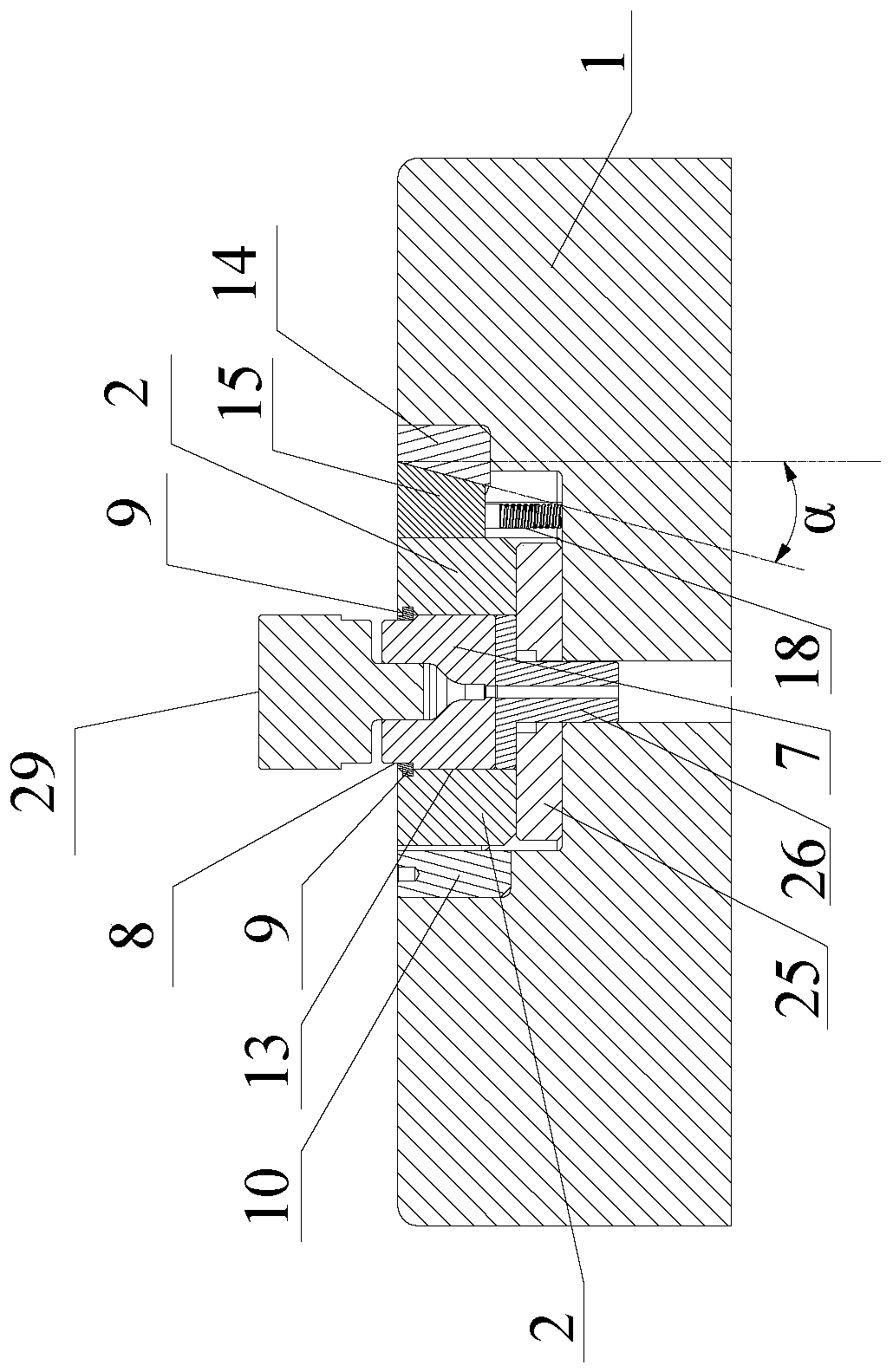

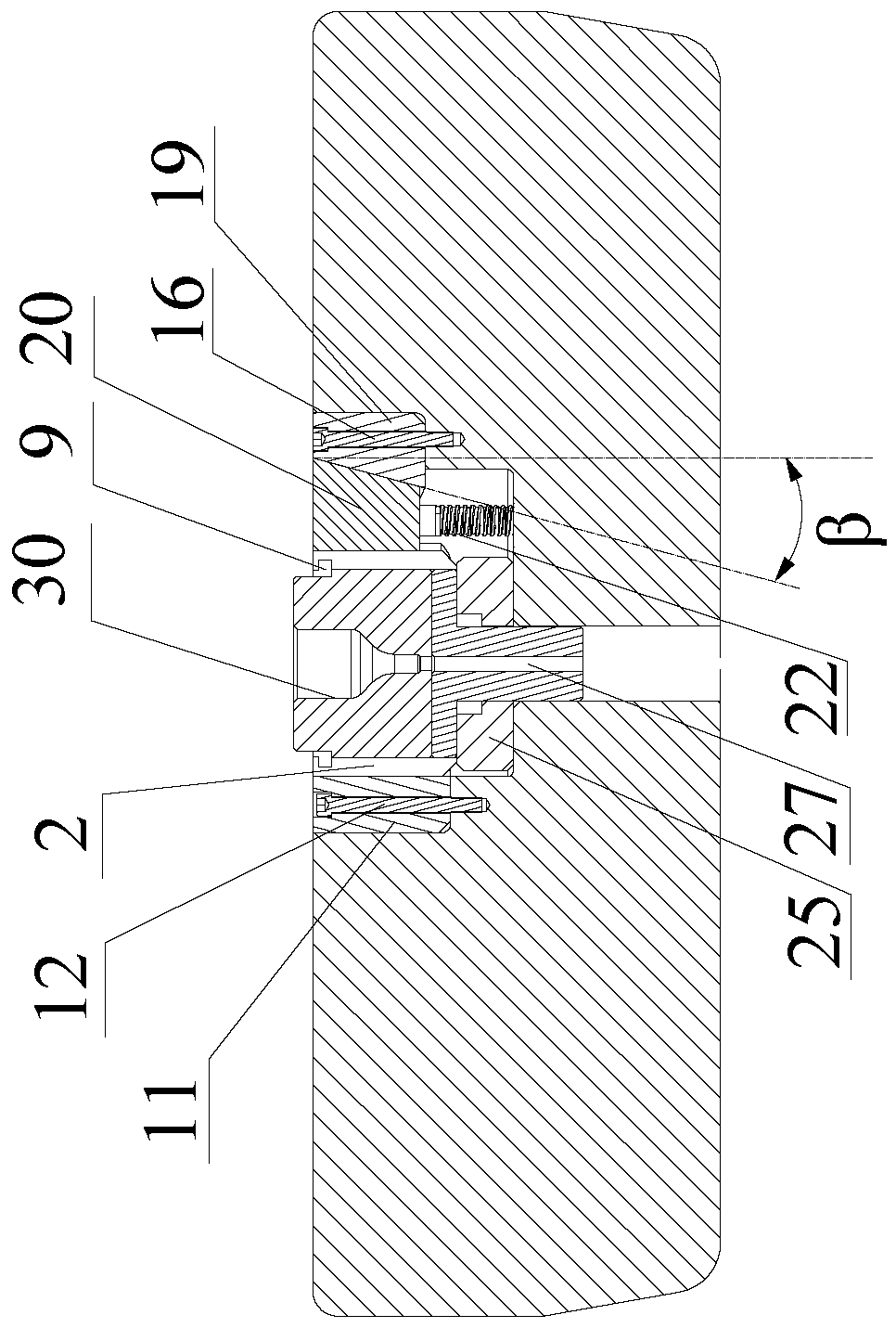

Switchable mechanical pump air-exhausting device for vacuum refining of molten steel

PendingCN107326151ASolve fever problemSolve efficiency problemsRotary/oscillating piston combinations for elastic fluidsMachines/enginesMolten steelLobe pump

The invention provides a switchable mechanical pump air-exhausting device for vacuum refining of molten steel and belongs to the technical field of external refining of steel-making furnaces. The switchable mechanical pump air-exhausting device comprises a water-cooled air exhausting pipe (1), an air cooler (2), an air exhausting pipe (3), a vacuum fast switching box (4), a high-temperature dust filter (5), a front pump valve (6), a lobe pump unit (7), a rear pump valve (8), a switching valve (9), a screw pump unit (10), a water ring pump unit (11) and an emptying pipeline (12). According to the switchable mechanical pump air-exhausting device, four different combination modes can be achieved through the vacuum fast switching box (4) and the switching valve (9) so as to adapt to different working conditions in the vacuum treatment process. The switchable mechanical pump air-exhausting device for vacuum refining of molten steel has the advantages that the air exhausting efficiency of a mechanical pump is high, the service life of equipment is long, and the operating cost is low.

Owner:BEIJING SHOUGANG INT ENG TECH

Orientated detection device for density of solution

PendingCN108918343AAvoid production interruptionsFully automatedMaterial analysis by measuring buoyant forcesInstabilityEngineering

The invention discloses an orientated detection device for the density of a solution. The device comprises a floating ball (4) capable of moving along a guiding rod (2), the floating ball (4) is placed in a cavity in a shell (1), a signal trigger (6) and a signal contactor (9) are sequentially arranged at one end, away from the guiding rod (2), in the shell (1), and the side surface (3) of the shell (1) is provided with a solution feeding and discharging opening (12) communicated with the cavity. The device solves the density detection problem of a concentrated solution, realizes continuous production, reduces the quality instability of the concentrated solution, and stably improves the economic value creation efficiency.

Owner:GUIZHOU KAILIN GRP CO LTD

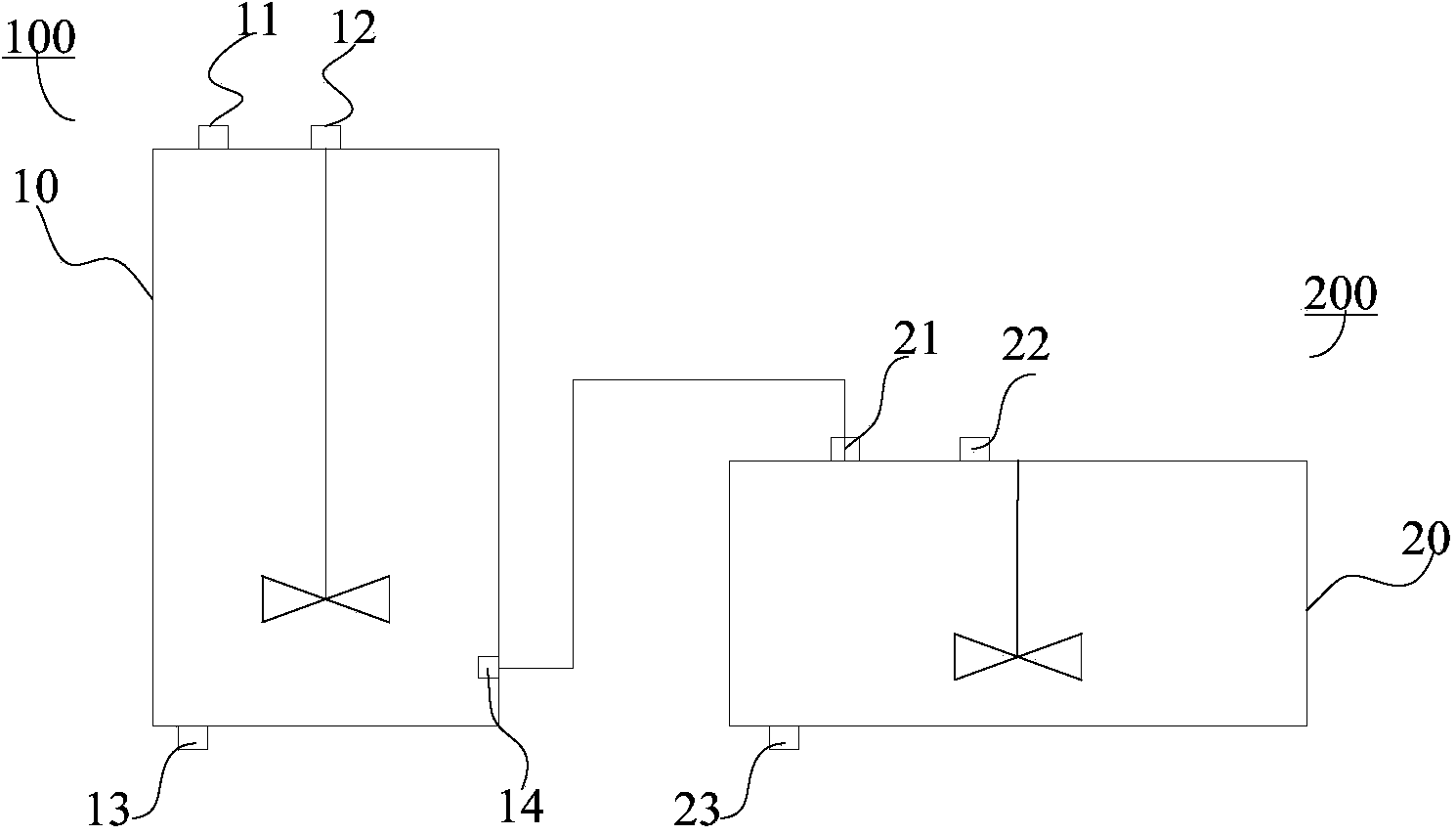

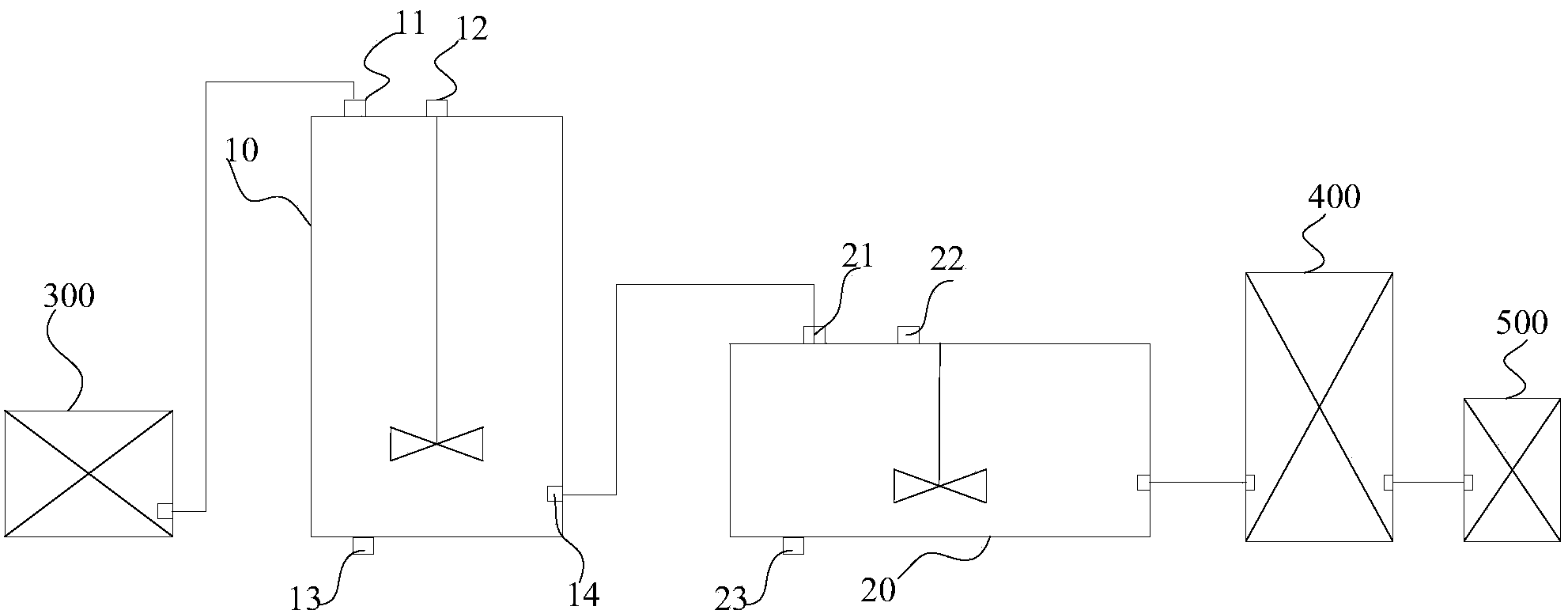

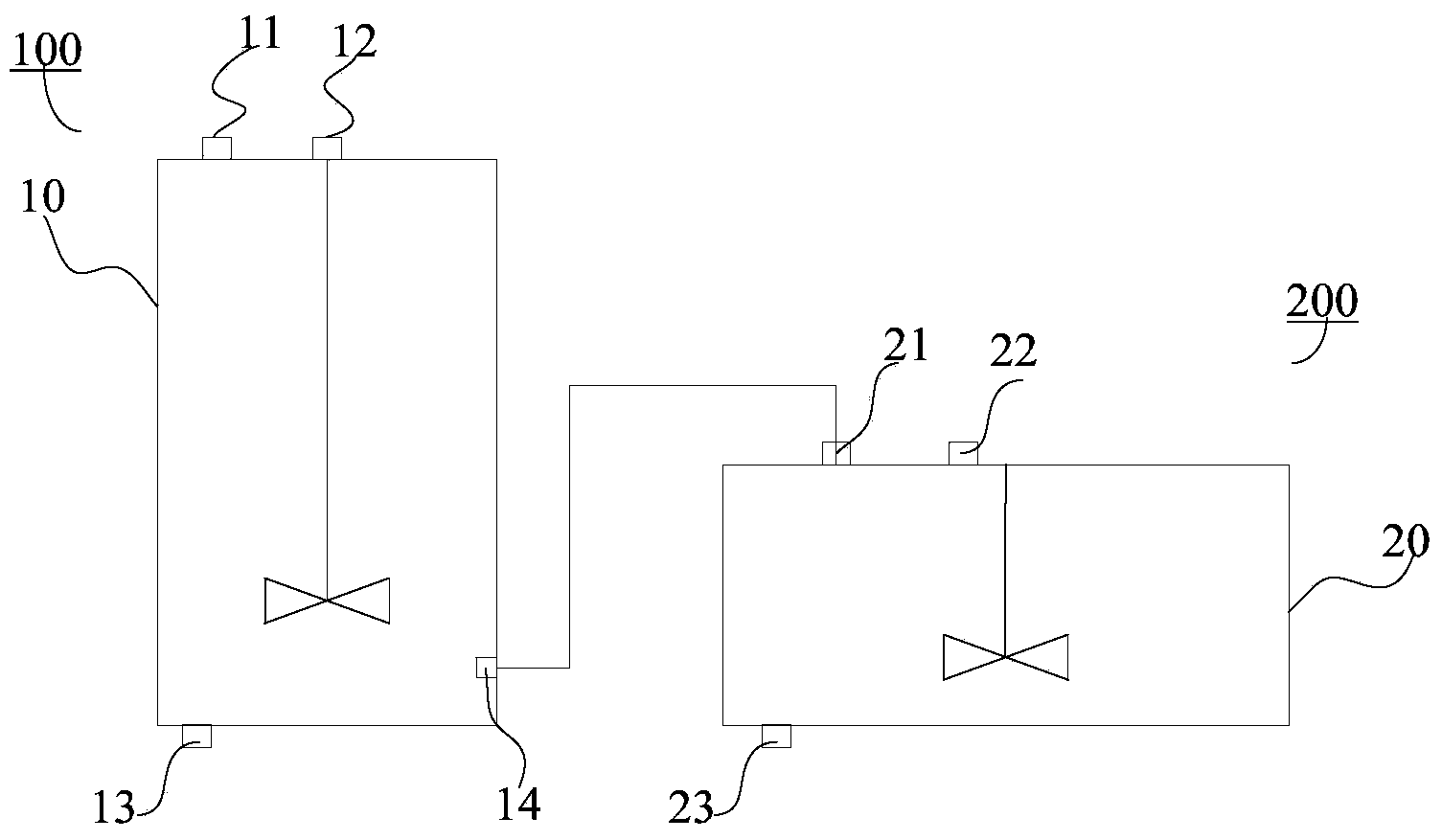

System for performing iron removal on iron-containing solution

ActiveCN104004914AHigh iron removal efficiencyImprove equipment utilizationProcess efficiency improvementIron removalProcess engineering

The invention discloses a system for performing iron removal on an iron-containing solution. The system comprises a vertical reaction kettle and a horizontal reaction kettle, wherein the vertical reaction kettle comprises a vertical reaction kettle body, an iron-containing solution feeding port, a first steam inlet and a first oxygen inlet; the horizontal reaction kettle comprises a horizontal reaction kettle body, a first iron-removed slurry feeding port, a second steam inlet and a second oxygen inlet; the iron-containing solution is an iron-containing sulfate solution, preferably, the iron-containing solution is at least one selected from a ferrous sulfate solution, an iron-containing nickel sulfate solution, an iron-containing cobalt sulfate solution and an iron-containing copper sulfate solution. According to the system for iron removal of the iron-containing solution disclosed by the embodiment of the invention, the vertical reaction kettle and the horizontal reaction kettle are combined for use so as to effectively solve the production interruption caused by the problems of scaling in the kettles in the iron removal process and ensure the continuous and stable operation of production, thereby significantly improving the iron removal efficiency and the equipment utilization rate.

Owner:CHINA ENFI ENGINEERING CORPORATION

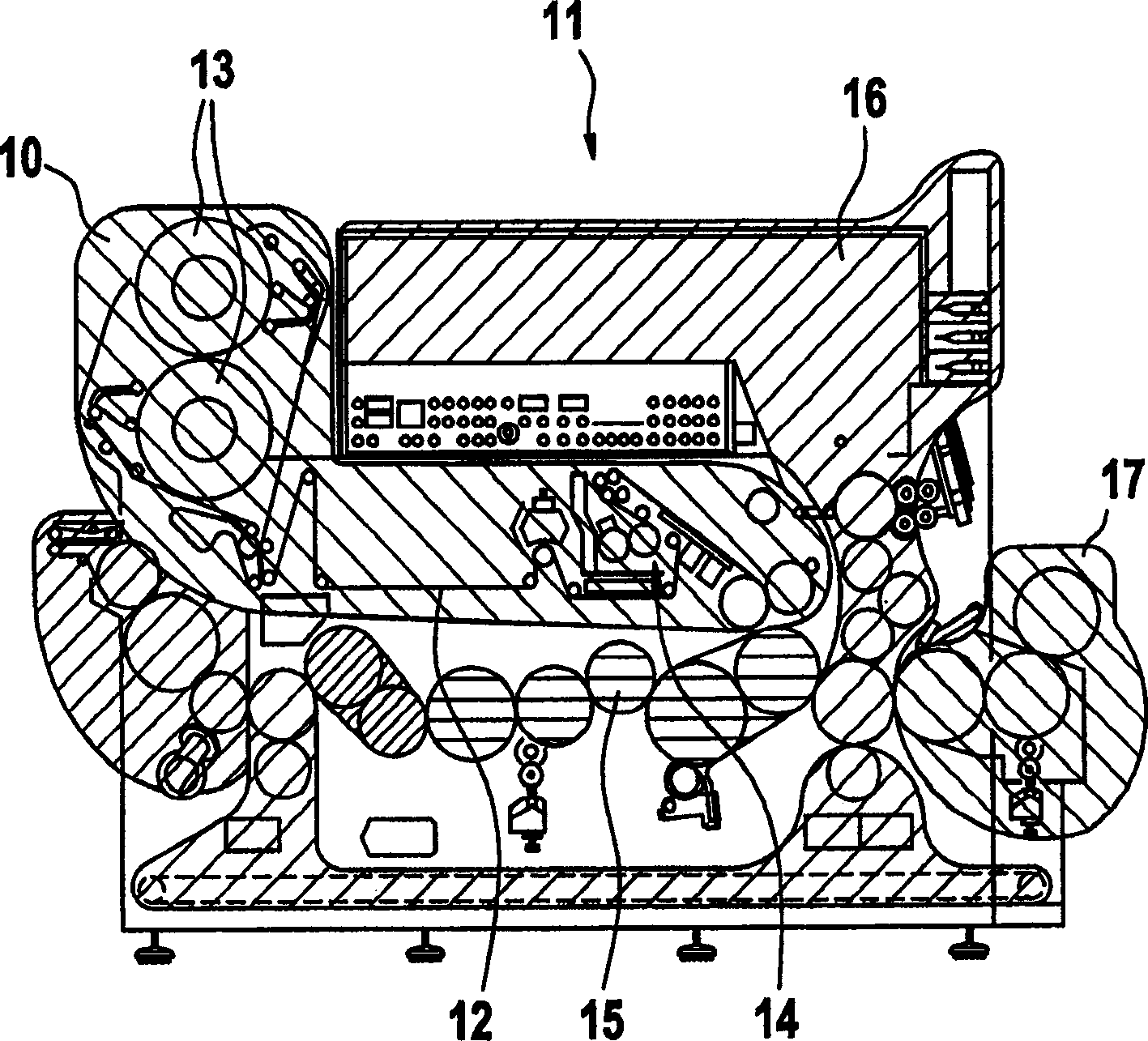

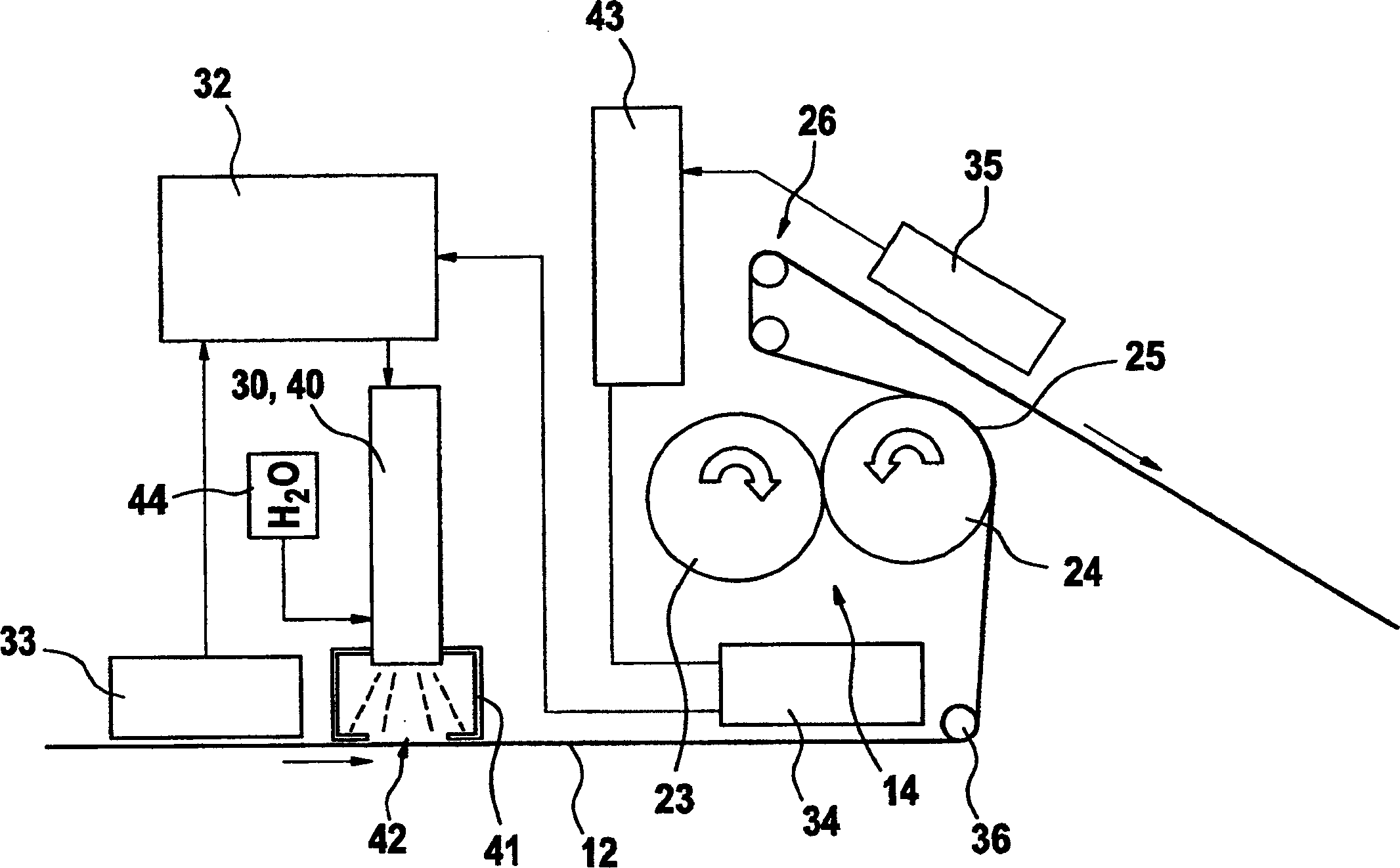

Machine of the tobacco-processing industry

InactiveCN1572160AHigh bonding strengthReduce downtimeCigarette manufacturePulp and paper industryEngineering

Provided is a machine of tobacco-processing industry, in the machine which has a paper delivery unit to deliver paper 12; 53 to a processing unit 15 to wrap a rod-shaped product with the paper 12; 53, wherein the machine has a gluing unit 14 for gluing the paper 12; 53 on a position 25 for gluing of paper travel. The machine has moistening devices 30; 58 for moistening the paper 12; 53, arranged before the gluing position 25 in a direction of travel of the paper 12; 53. The invention also relates to a method corresponding to the gluing of the paper.

Owner:HAUNI MASCHINENBAU AG

Cleaning method of clogging materials on RH lower groove and alloy feed opening

ActiveCN109576445AAvoid cloggingEasy to cleanHollow article cleaningChemical reactionGibbs free energy

The invention discloses a cleaning method of clogging materials on an RH lower groove and an alloy feed opening. In 20 min and within 20 min after RH production is ended, under the condition that thegroove temperature is higher than 1300 DEG C, an oxygen lance is adopted to blow oxygen to the lower groove; oxygen blowing is performed at three stages, namely the high stage, the middle stage and the low stage according to the distance between the muzzle of the oxygen lance and the bottom of the groove; the distance between the muzzle of the oxygen lance and the bottom of the groove at the highstage is larger than 5.5 m and smaller than 7.0 m, the distance between the muzzle of the oxygen lance and the bottom of the groove at the middle stage is larger than 5.0 m and smaller than 5.5 m, andthe distance between the muzzle of the oxygen lance and the bottom of the groove at the low stage is larger than 4.5 m and smaller than 5. 0 m; and the oxygen blowing speed is 1200-1500 Nm<3> / h. Theclogging materials on the lower groove and the alloy feed opening are melted by heat released by a chemical reaction between sufficient oxygen and Fe left on the inner wall of the groove and the alloyfeed opening; and by using the heat released by a Fe-O chemical reaction and combination with Gibbs free energy characteristics of FeO, Fe3O4 and Fe2O3, the clogging materials on the lower groove andthe alloy feed opening are melted, the refractory material damage is reduced, the condition that the alloy feed opening is blocked by the clogging materials is avoided, the production interruption caused by blockage of the clogging materials is avoided, and the service life of a refractory material in a vacuum tank is prolonged.

Owner:TANGSHAN IRON & STEEL GROUP +1

Method and device for melt spinning, treating and winding a synthetic thread

InactiveCN101646810BOperation without delayQuickly identify broken wiresArtificial thread manufacturing machinesFilament manufactureEngineeringMechanical engineering

The invention relates to a method and a device for melt spinning, treating and winding a synthetic thread. The thread is pulled off, guided and treated after melt spinning by a treatment device and is wound onto a coil by a winding device. Said thread is guided vertically from the melt spinning process to the winding process over several levels. In order to maintain short operating times, in particular when the process is started or interrupted, the treatment device is operated from an upper operational platform. The winding device is operated in a lower operating platform. The thread is monitored in a transitional area between the treatment device and the winding device by means of a thread monitor.

Owner:OERLIKON TEXTILE GMBH & CO KG

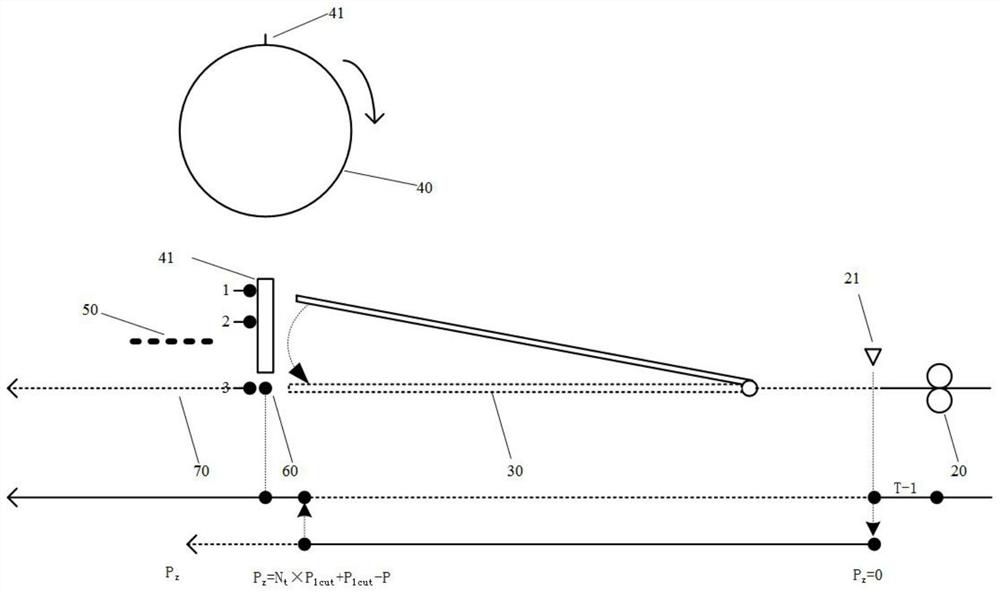

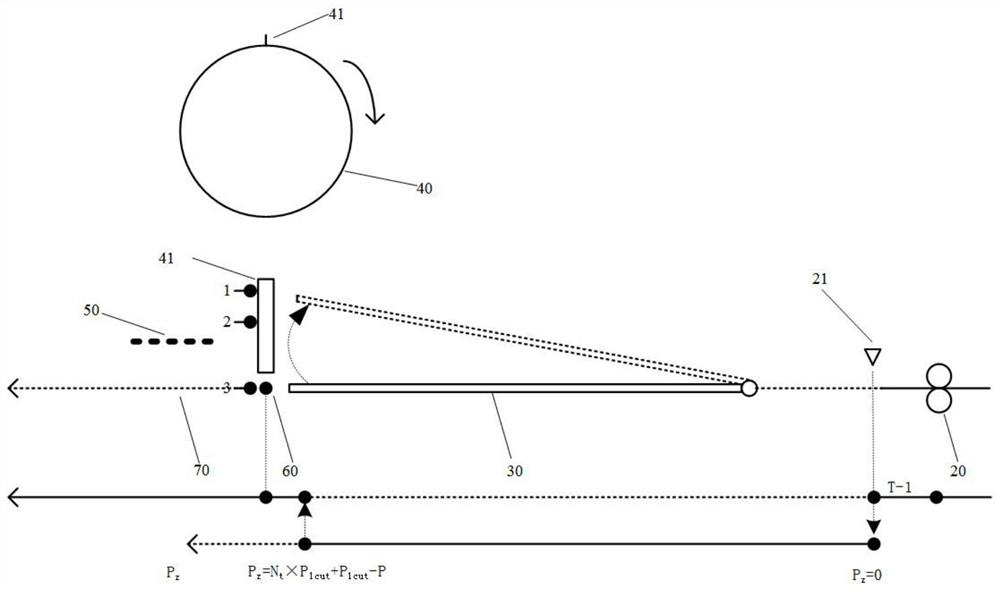

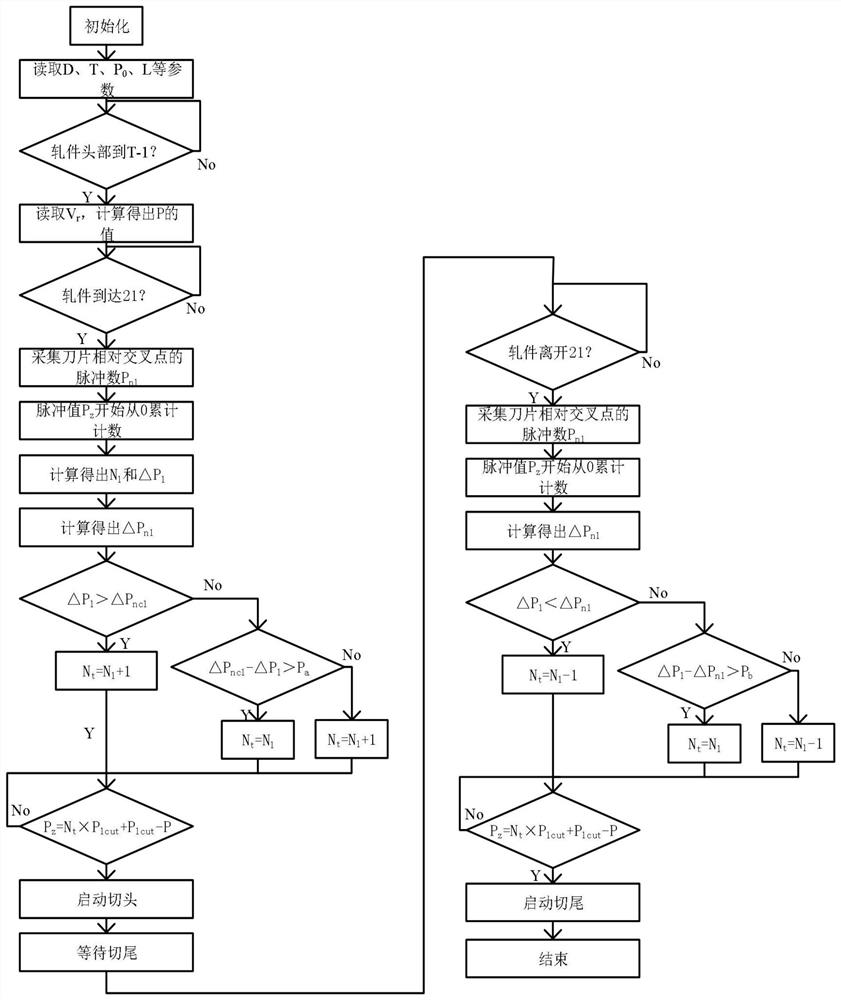

Method for controlling high-speed flying shear

ActiveCN111804736AReduce labor intensityEliminate unstable factors of high-speed flying shearRare end control deviceMetal rolling arrangementsClassical mechanicsKnife blades

The invention relates to a method for controlling a high-speed flying shear. The method comprises the steps that a first pulse value P of the starting of a steel poker is calculated; a third pulse value P1cut corresponding to the length between adjacent blades is calculated, and blade rotation pulses are accumulated and counted to obtain a fourth pulse value Pz; original blade rotating blade number N1 corresponding to the distance between rolled piece detection equipment and an intersection point, a fifth pulse value delta P1 corresponding to the remaining length, and a sixth pulse value deltaPn1 of the next blade reaching the intersection position are calculated; if the situation that the sixth pulse value delta Pn1 minus the fifth pulse value delta P1 is greater than the first pulse value P is satisfied, the actual blade rotating blade number Nt is equal to the original blade rotating blade number N1; otherwise, the actual blade rotating blade number Nt is equal to the original blade rotating blade number N1 plus 1; and the flying shear is started when the situation that the fourth pulse value Pz is equal to the actual blade rotation blade number Nt multiplied by the third pulsevalue P1cut plus the third pulse value P1cut minus the first pulse value P is satisfied. According to the method for controlling the high-speed flying shear, the accurate control of the steel poker can be achieved, so that the control precision of the high-speed flying shear is improved, the production interruption fault caused by the high-speed flying shear is eliminated, and the production efficiency is greatly improved.

Owner:SGIS SONGSHAN CO LTD

Continuous production process of waterproof coiled material

InactiveCN105365339AContinuous feedingReturn to normal feedingLamination ancillary operationsLaminationEngineeringAsphalt

The invention provides a continuous production process of a waterproof coiled material. The process includes: sending a substrate into a covering component continuously by a winding temporary storage mechanism, coating the upper surface and lower surface of the substrate with asphalt respectively by the covering component, covering the upper surface of the substrate with a PET film, and covering the lower surface of the substrate with an isolating film; then letting the substrate covered with a film on the upper and lower surface respectively enter a rubber extrusion component continuously to conduct excess asphalt extrusion so as to obtain a waterproof coiled material, and passing the waterproof coiled material through a drying component, heating the inner layer asphalt to make the inner layer asphalt coated evenly, and subjecting the waterproof coiled material to cooling molding by a cooling component, thus obtaining the molded waterproof coiled material. The continuous production process of the waterproof coiled material can realize continuous feeding of the substrate, so that the covering component can achieve continuous production without interruption, thus ensuring production continuity and improving the processing efficiency.

Owner:安徽五星凯虹防水建材科技有限公司

Rotary kiln riding wheel bearing set lubricating device

PendingCN112728380AExtended service lifeLower oil temperatureConduits/junctionsCooling coilMetering pump

The invention relates to a rotary kiln riding wheel bearing set lubricating device. The device comprises an oil inlet hard pipe, an oil inlet hose, a metering pump, an oil tank, a first oil outlet hose, a second oil outlet hose, an oil outlet hard pipe, a tee joint and a ventilation cap. One end of the oil inlet hard pipe is connected with one end of the oil inlet hose, the other end of the oil inlet hose is connected with an oil outlet of the metering pump, an oil inlet of the metering pump is connected with one end of the first oil outlet hose, the other end of the first oil outlet hose is connected with an oil inlet of the oil tank, an oil outlet of the oil tank is connected with one end of the second oil outlet hose, and the other end of the second oil outlet hose, one end of the oil outlet hard pipe and the ventilation cap are respectively connected to three interfaces of the tee joint; a plurality of magnetic nets are further arranged in the oil tank; and the device further comprises an oil cooler connected in series between the oil inlet hose and the metering pump, or a cooling coil arranged in the oil tank. According to the rotary kiln riding wheel bearing set lubricating device, the oil temperature of the lubricating oil is remarkably reduced, the consumption of the lubricating oil is reduced, and the lubricating oil in a riding wheel bearing set can be kept at a lower oil temperature for a long time to ensure a good lubricating effect.

Owner:NANJING KISEN INT ENG

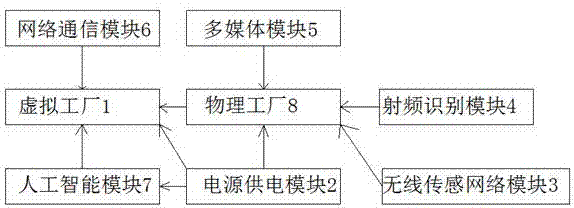

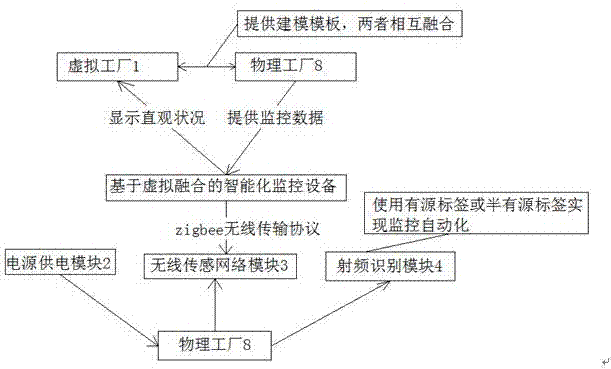

Intelligent monitoring device based on virtual fusion

PendingCN107992990AReduce operational burdenImprove operational efficiencyTransmission systemsNetwork topologiesRadio frequencyIndustrial site

The invention discloses an intelligent monitoring device based on virtual fusion and relates to the technical field of intelligent monitoring. The device comprises a virtual plant, a power supply module, a wireless sensing network module, a radio frequency identification module, a multimedia module, a network communication module and an artificial intelligence module, wherein the virtual plant isconnected with a physical plant; the wireless sensing network module, the radio frequency identification module and the multimedia module are all connected with the physical plant; the power supply module is connected with the physical plant and the virtual plant; and the artificial intelligence module and the network communication module are both connected with the virtual plant. The device is used for monitoring industrial site equipment and personnel in real time and realizing remote monitoring through high-reliability transmission, is flexile and diversified, has powerful functions, can beremotely managed through mobile equipment, a computer, etc. and has higher practicability.

Owner:CHANGZHOU INST OF TECH

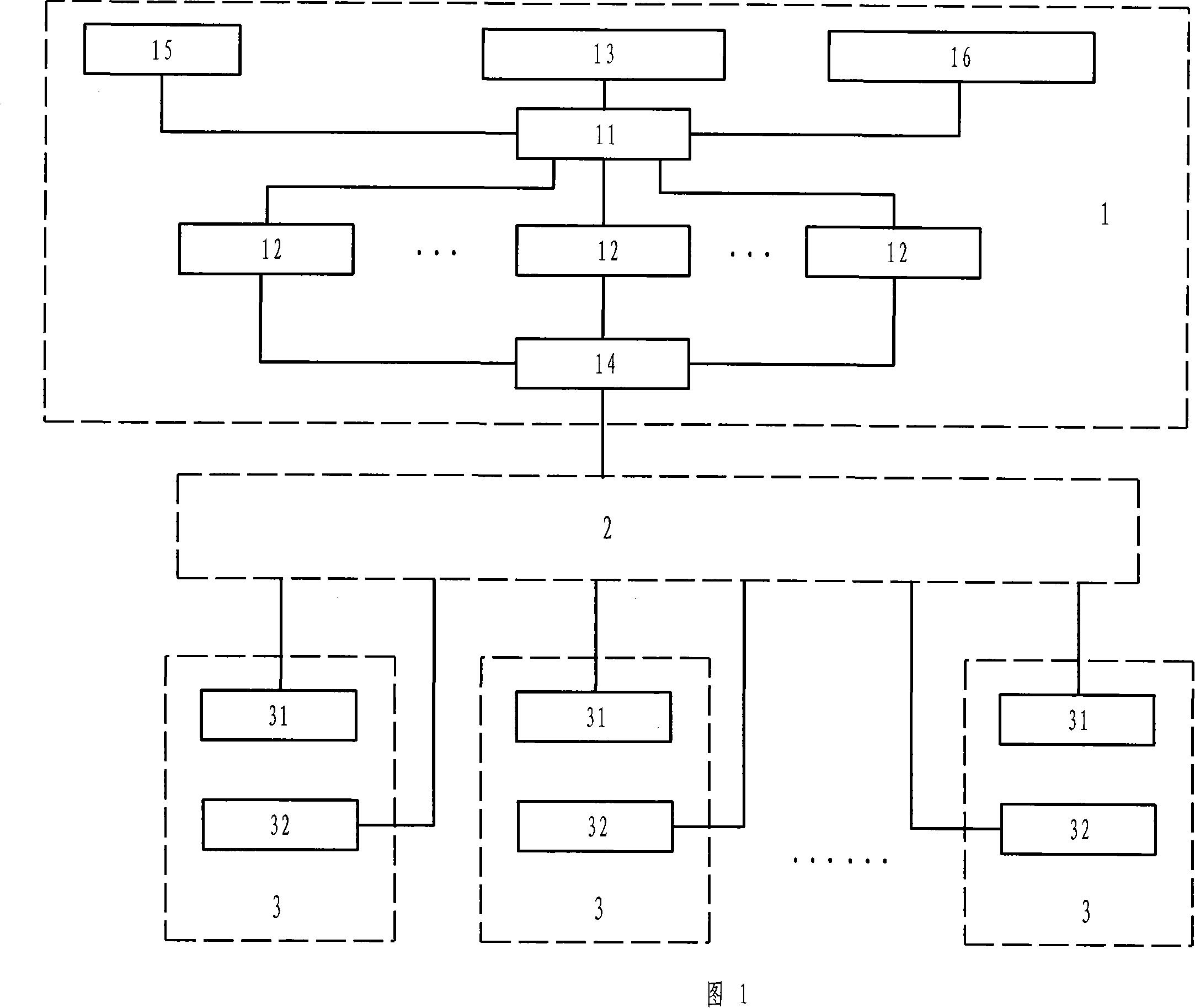

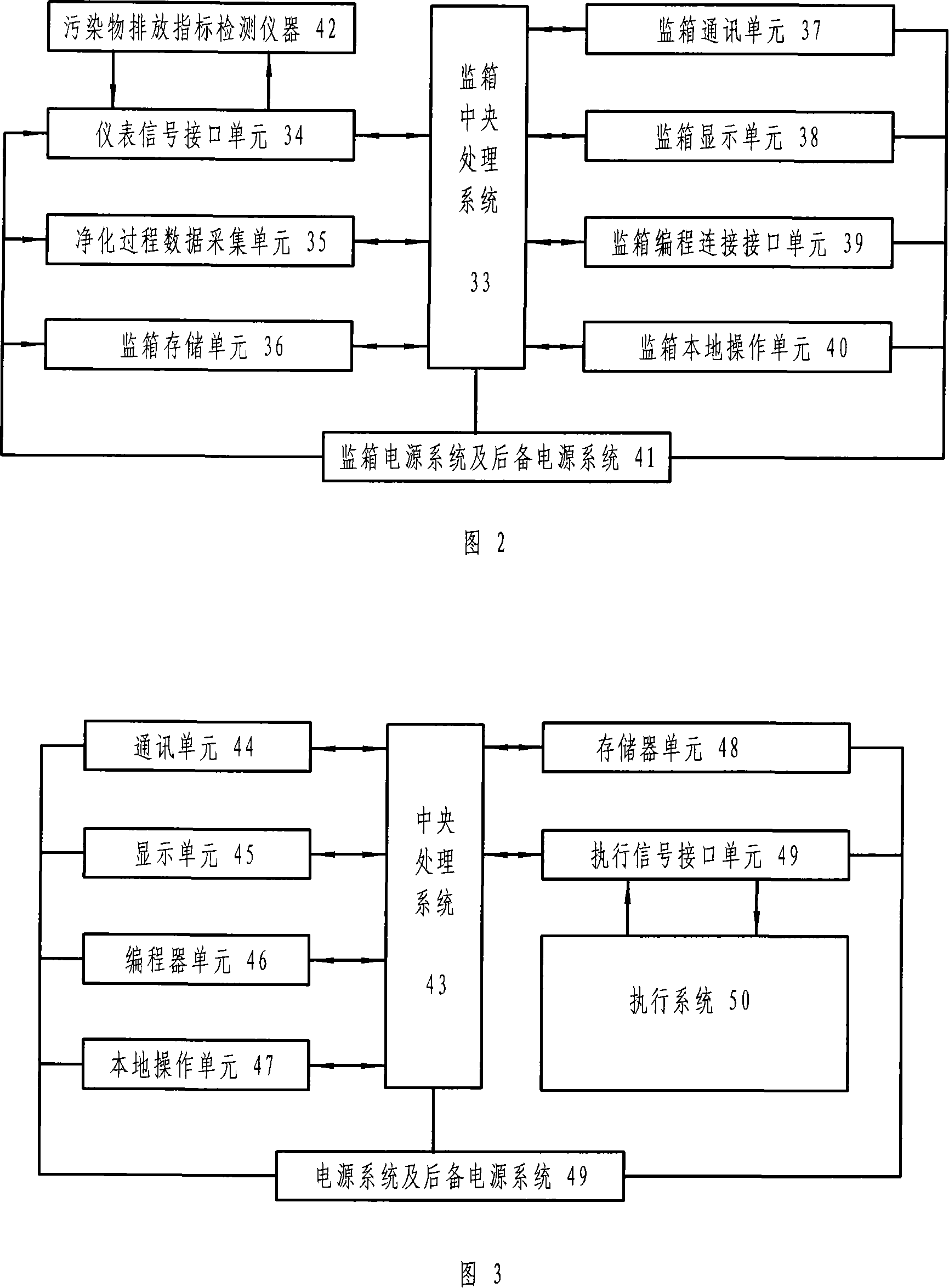

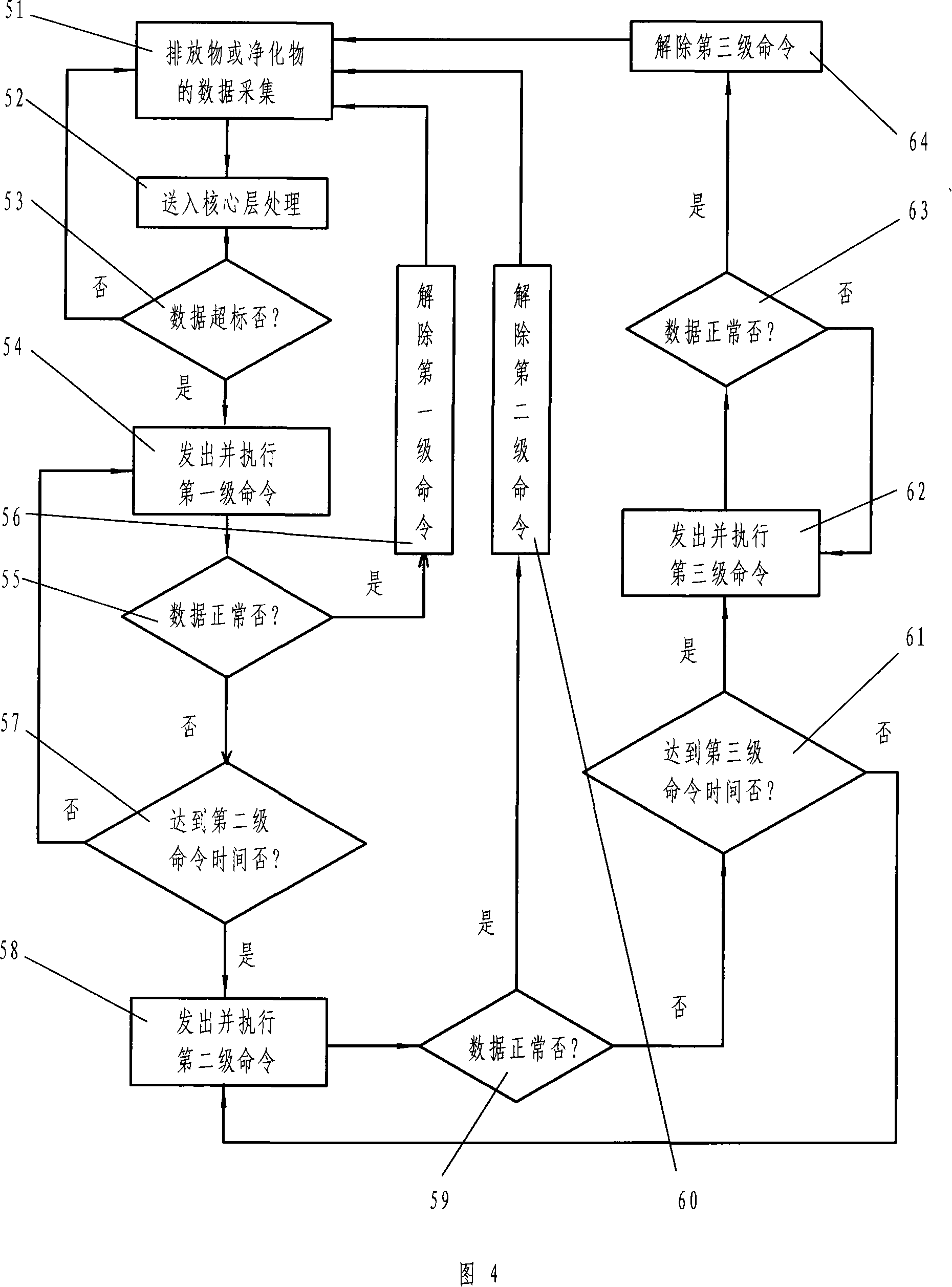

Contaminator and purification process real-time monitoring and delaminated control and execution system

ActiveCN101122796AAvoid production interruptionsImprove interrupt enforcementTotal factory controlProgramme total factory controlControl layerPollutant emissions

The invention discloses a real-time monitoring and hierarchical control execution system for discharge and purification process of pollutants, specifically relating to the real-time monitoring and hierarchical control execution system for discharge and purification process of pollutants. A technical problem that needs to be solved is to provide the real-time monitoring and hierarchical control execution system for discharge and purification process of pollutants, thus, making the discharge and purification process of pollutants monitored and controlled. Different execution methods can be adopted according to the different discharge and purification level. The adopted proposal comprises a core layer, a transmission layer and a centralized control layer. The system consists of a core layer, a transmission layer and a centralized control layer from top to bottom. The core layer has relative serves to form an Ethernet net. The transmission layer comprises transmission equipment and a network platform for network operators. The centralized control layer comprises an intelligent real-time monitoring box and an intelligent layering control box. The invention can be widely applicable to the factories that discharge pollutants and purification factories, which illustrates a good prospect of application.

Owner:SHANXI LIANHUA WEIYE TECH

Liquid discharge control method of bleaching pulp system

ActiveCN107938414BAvoid wastingAvoid production interruptionsWashing/displacing pulp-treating liquorsPulp de-wateringSiphonProcess engineering

The invention belongs to the technical field of papermaking equipment, and particularly relates to a liquid discharge control method of a bleaching slurry system. The liquid discharge control method comprises the following steps that A, a liquid level sensor is arranged on the groove wall of a slurry tank in a bleaching slurry system; the liquid level sensor is arranged at a place with a level height warning value of K1; and the place with the level height warning value of K1 is close to the tank opening of the slurry tank; and B, a liquid pumping device is arranged on a drainage pipeline usedfor discharging filtrate in the slurry tank; the liquid level sensor collects the water level height information in the slurry tank, so that the water level height in the slurry tank is monitored; when the water level height in the slurry tank is greater than K1, the pump liquid device is started and the liquid is discharged from the slurry tank to outside; and when the water level height in theslurry tank is lower than or equal to K1, the liquid pumping device is in a standby state. According to the invention, a siphon drainage liquid can be timely established when the water level in the slurry tank is suitable; when the slurry flow is too large, the liquid pumping device can be started in time to assist liquid discharging, so that the waste of raw material and the break off of production caused by overflow of the slurry from the slurry tank are avoided; the washing and the concentration effects of the slurry are effectively ensured, so that the quality of the bleaching slurry operation is ensured.

Owner:CHINA XUAN PAPER

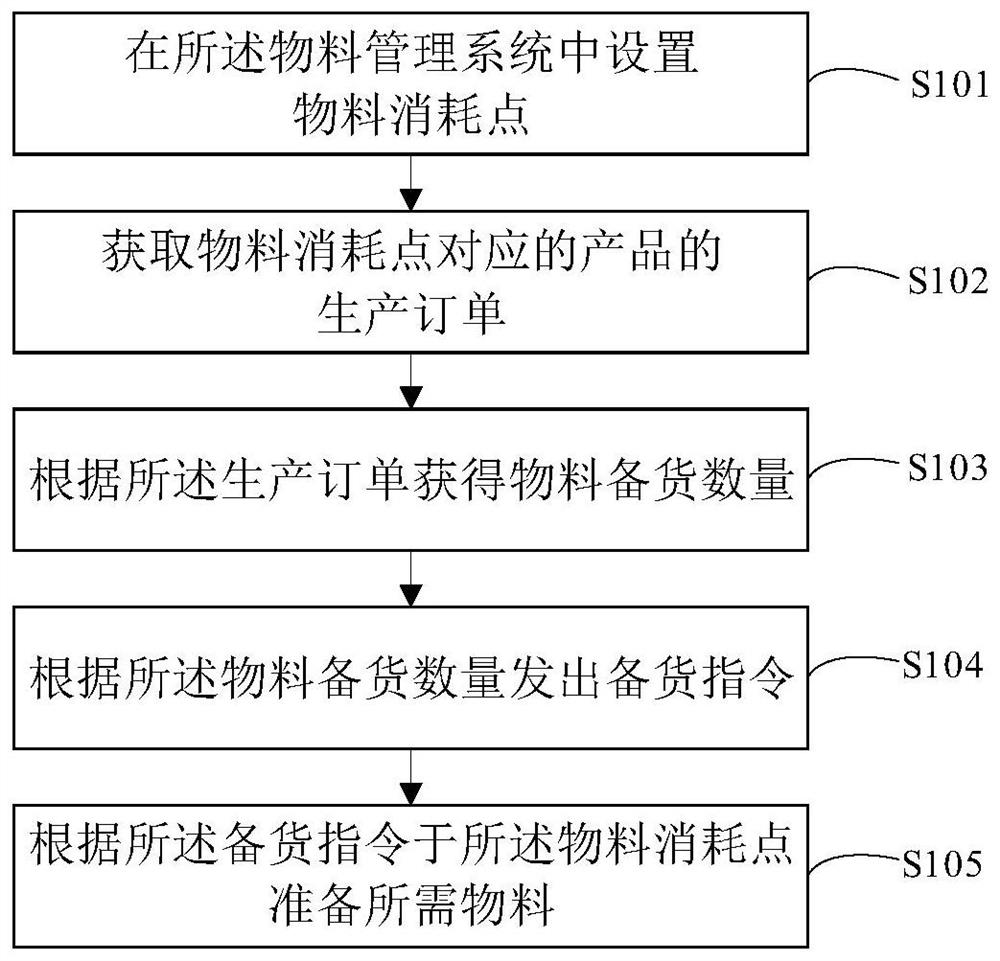

Material management method and system

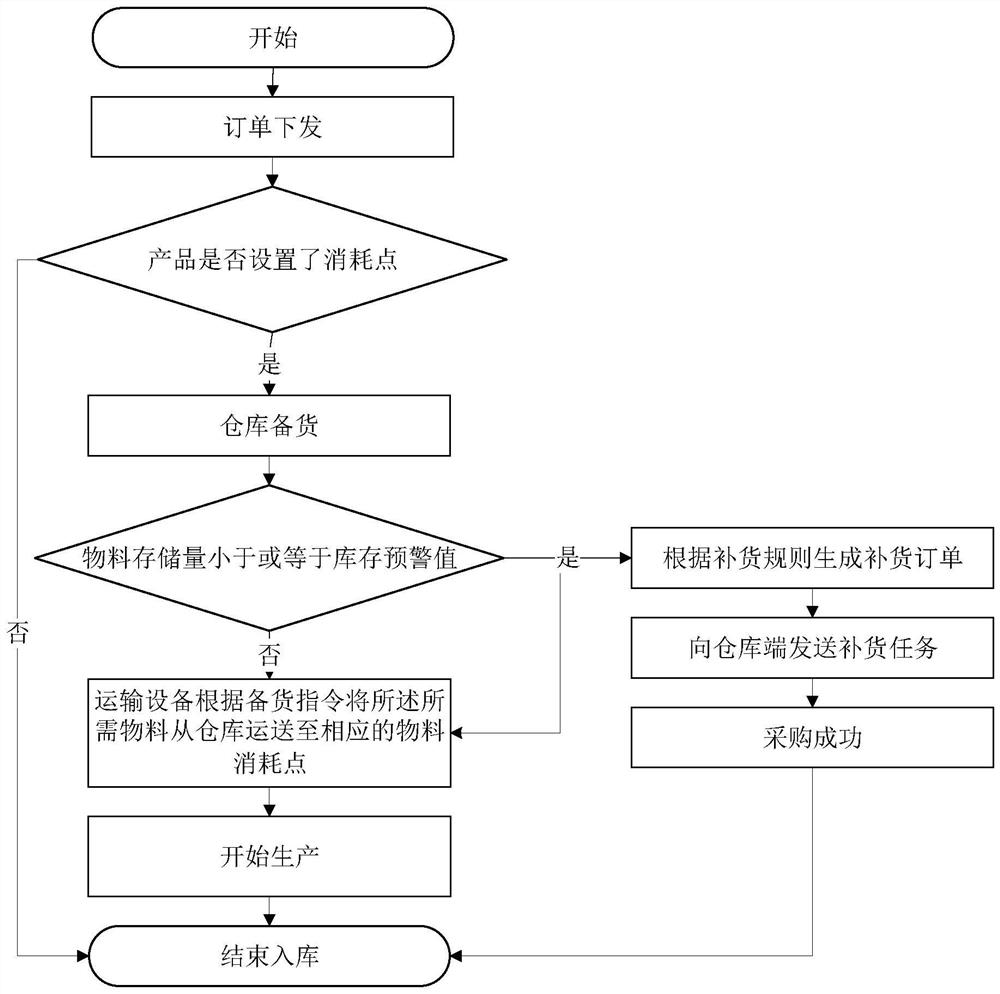

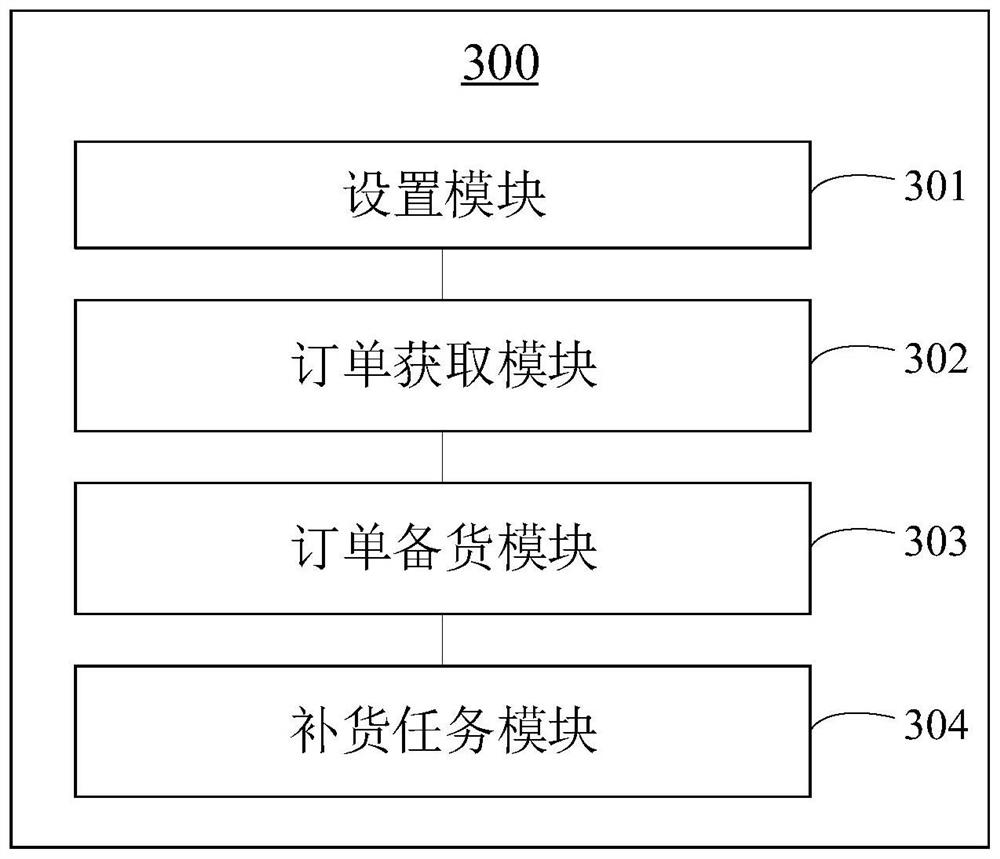

PendingCN114266521AAvoid production interruptionsGuaranteed continuityLogisticsManufacturing computing systemsMaterial consumptionProcess engineering

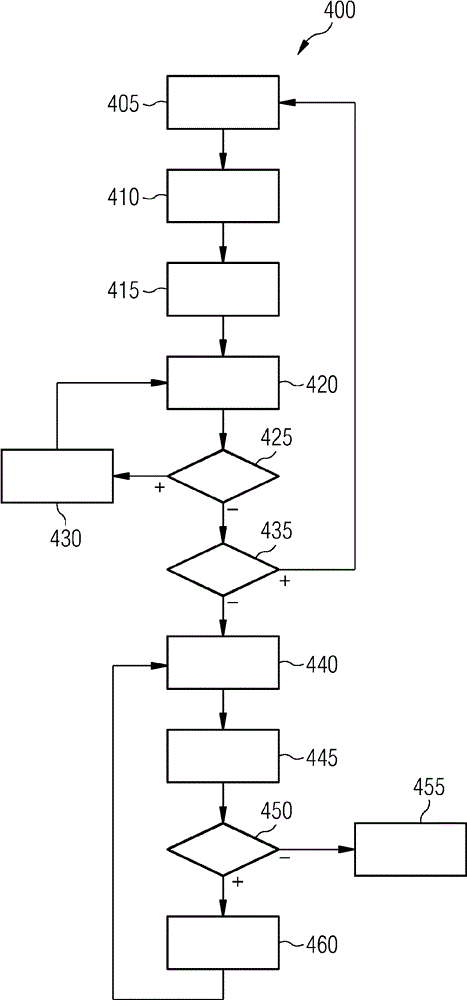

The invention provides a material management method and system, and the method is applied to a material management system which obtains materials according to a production order and produces products. The material management method comprises the following steps: setting a material consumption point in the material management system; obtaining a production order of a product corresponding to the material consumption point; obtaining a material stock number according to the production order; and sending a stock-up instruction according to the stock-up quantity of the materials, and preparing the required materials at the material consumption point according to the stock-up instruction. By adopting the method provided by the embodiment of the invention, different consumption points can be set, production interruption caused by material shortage of the station and unsmooth material turnover is avoided, and the production efficiency is improved.

Owner:瀚云科技有限公司

Dry-wet Combined Cooling Tower Using Natural Ventilation and Composite Operation Mode and Its Application

The invention belongs to the technical field of energy utilization and engineering thermophysics, and in particular relates to a combined dry-wet cooling tower adopting natural ventilation and combined operation mode and its application. The dry-wet combined cooling tower includes a tower body, a supporting structure, a dry cooling section, a wet cooling section and a flow distribution system; the tower body is in the form of a hyperbola, supported on the ground by a supporting structure; the dry cooling section and the wet cooling section are vertically Integrated in the same cooling tower; the dry-cooling section is located above the wet-cooling section; the dry-cooling section includes cooling triangles and dry-cooling section louvers; the wet-cooling section includes water eliminators, water distribution systems, filling areas, sumps and wet-cooling section louvers The flow distribution system includes the total inlet and outlet pipelines, the inlet and outlet pipelines of the dry cooling section, the inlet and outlet pipelines of the wet cooling section, valves and circulating pumps. The invention does not require fan power consumption, has high cooling efficiency, can provide lower water temperature out of the tower, and saves water resources.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

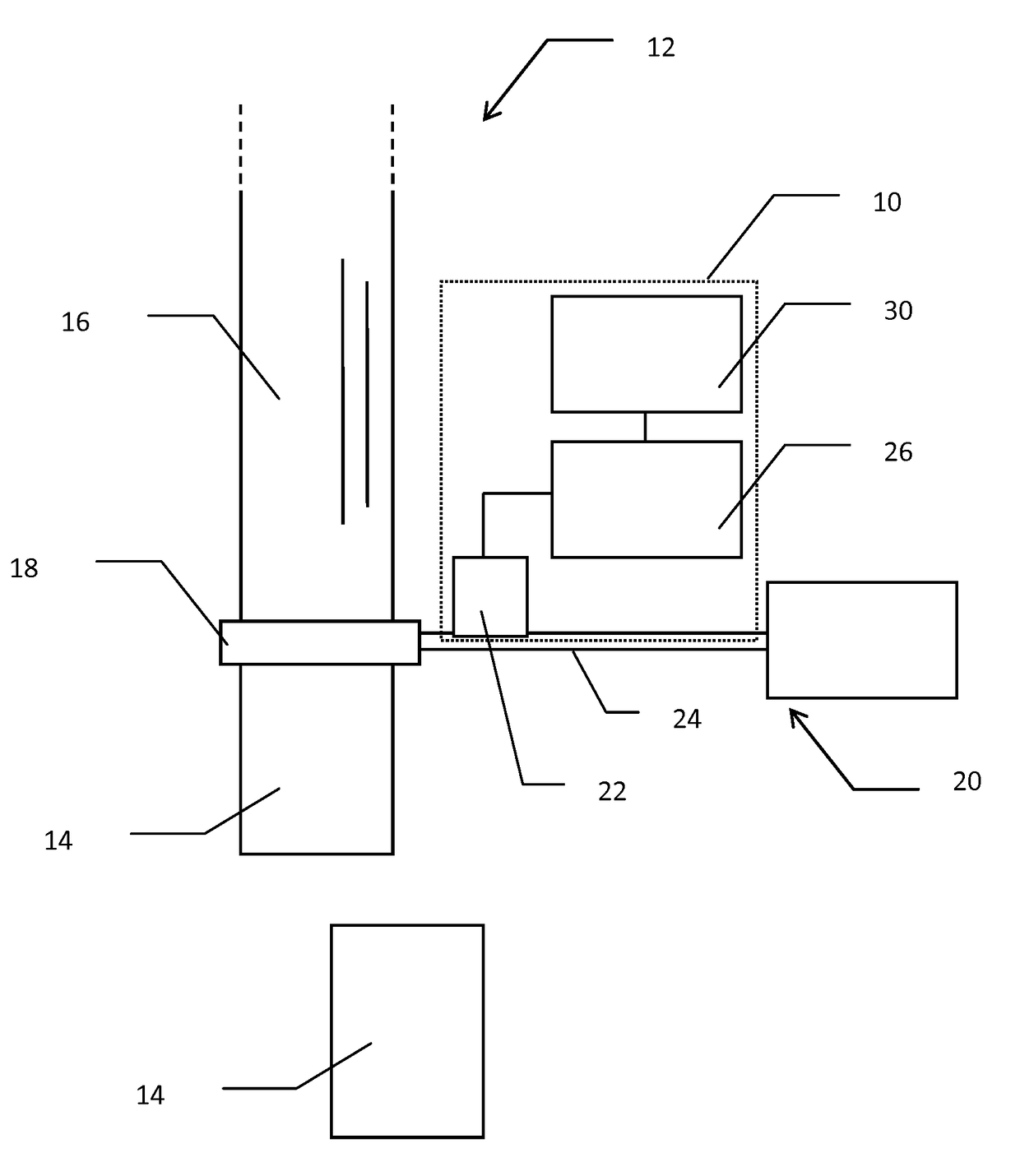

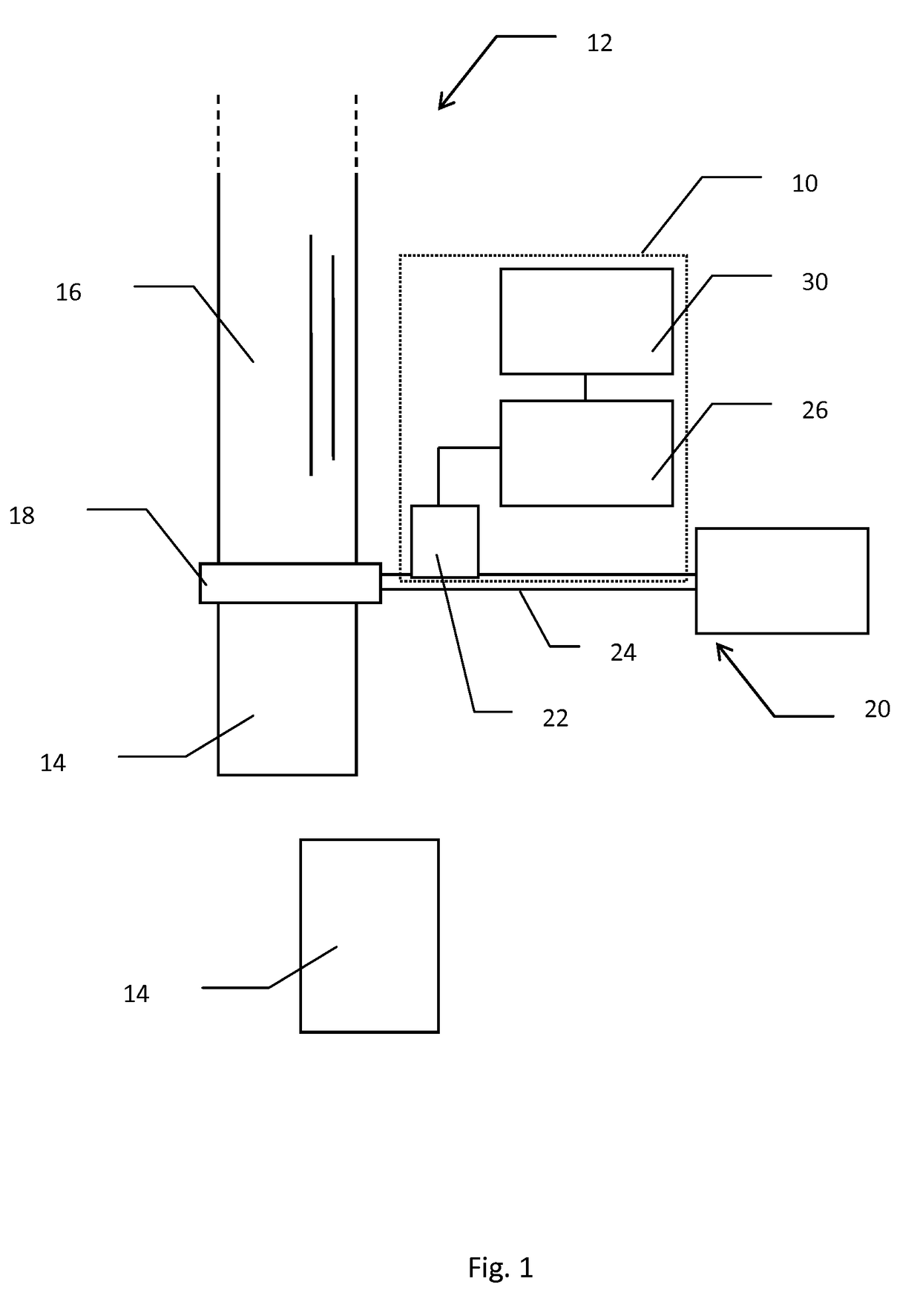

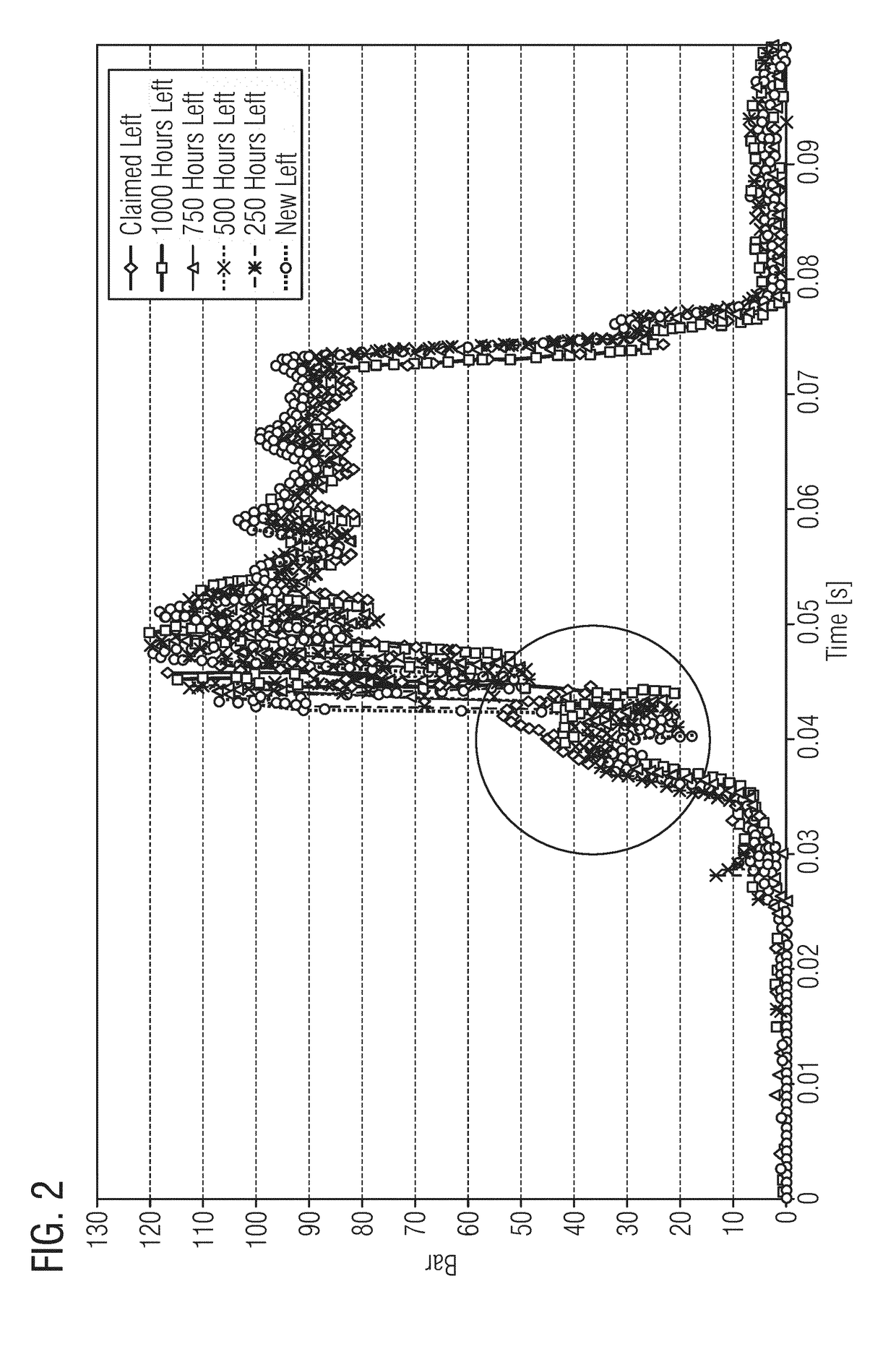

A cutting knife monitoring system for a filling machine

ActiveUS20180281219A1Avoid production interruptionsEasy to superviseMetal working apparatusSuccessive articlesMonitoring systemEngineering

The present invention relates to a tube cutting knife monitoring system for a filling machine for manufacturing packages from a tube, the filling machine comprising a tube cutting knife (18) and a hydraulic system (20) adapted to actuate the tube cutting knife, wherein the monitoring system comprises: a pressure sensor (22) adapted to detect hydraulic pressure of the hydraulic system when the tube cutting knife is cutting the tube; and a logging system (26) adapted to log the hydraulic pressure detected by the pressure sensor.

Owner:TETRA LAVAL HLDG & FINANCE SA

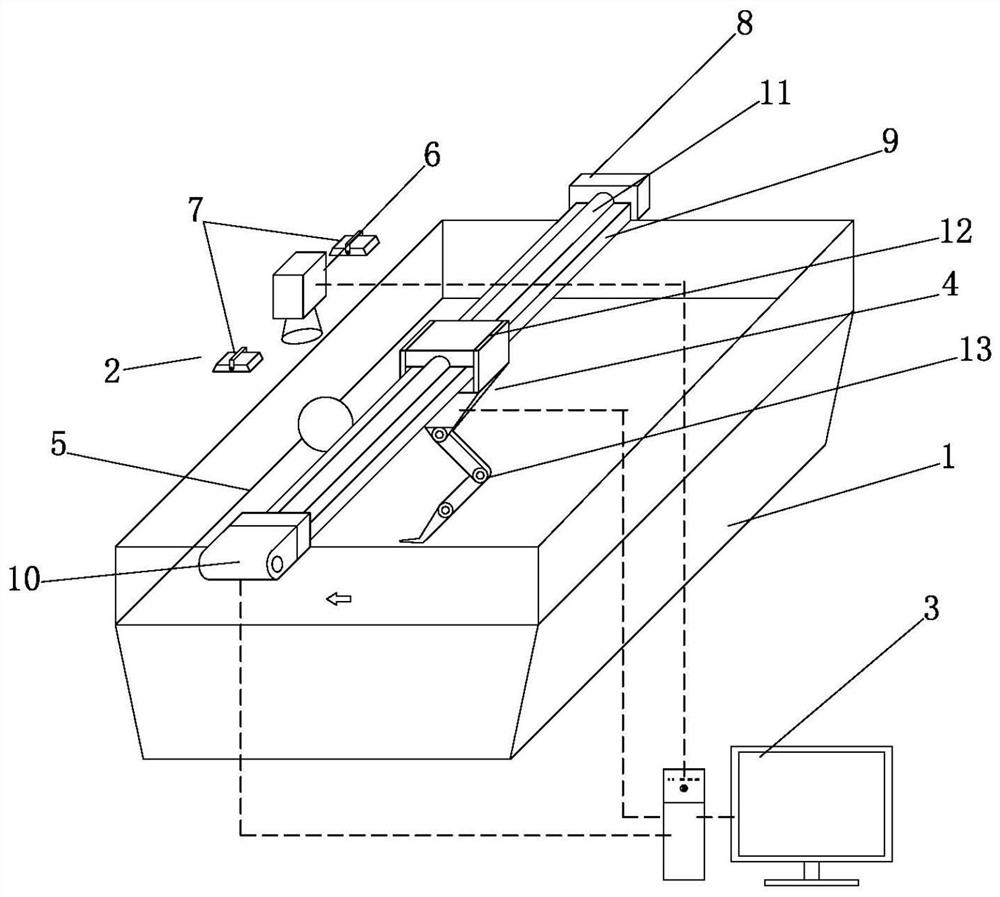

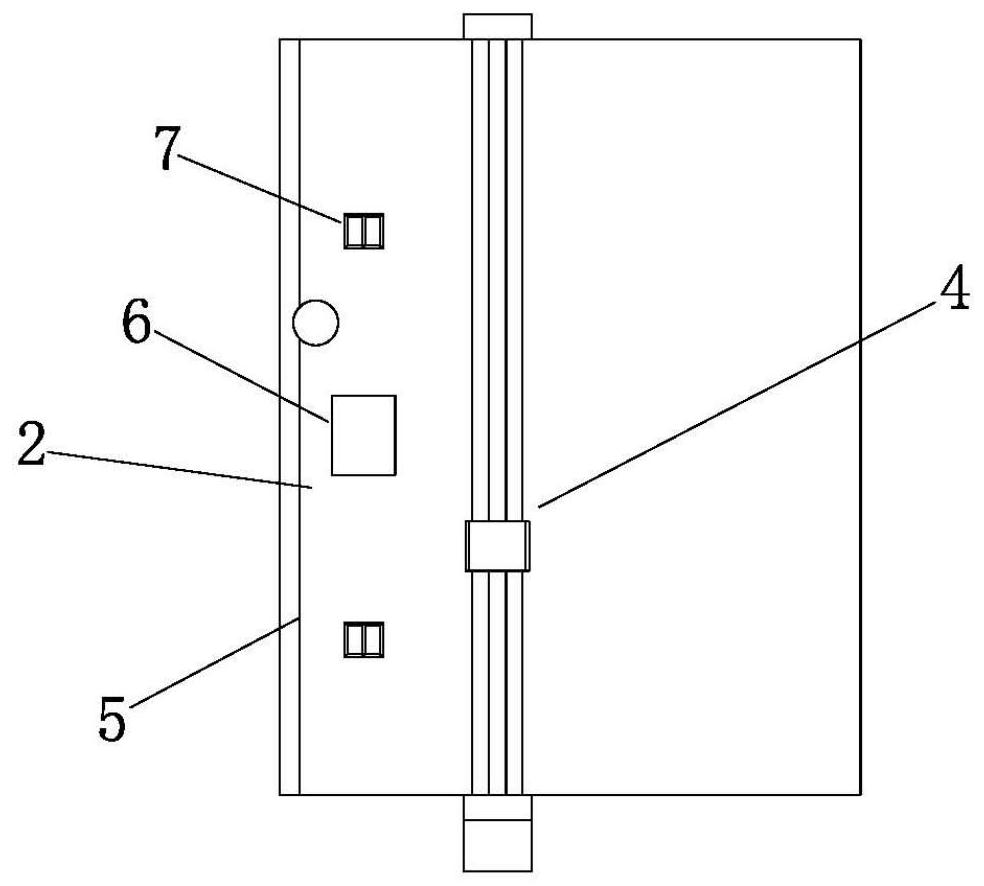

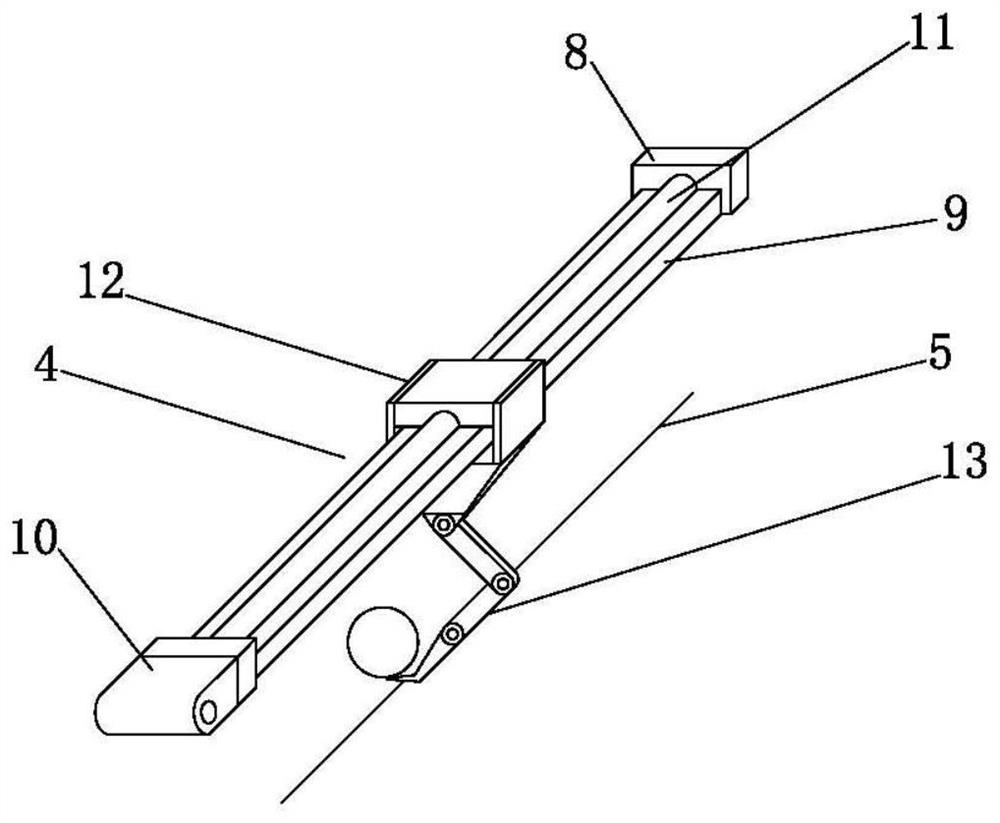

Dense medium shallow slot dredging device based on machine vision and control method

PendingCN113997265AReduce the burden onGuarantee the safety of lifeProgramme-controlled manipulatorWet separationCoal briquetteMechanical equipment

The invention provides a dense medium shallow slot dredging device based on machine vision and a control method. The dense medium shallow slot dredging device comprises a dense medium shallow slot, a visual detection assembly, a central processing unit and an overflow weir dredging device. The dense medium shallow slot is provided with an overflow weir, and the visual detection assembly is installed above the overflow weir; the overflow weir dredging device is installed in the dense medium shallow groove and located above the overflow weir, the visual detection assembly and the overflow weir dredging device are connected with a central processing unit, the visual detection assembly comprises an industrial camera and an LED light source, and the overflow weir dredging device comprises a support, a horizontal sliding rail, a rotating motor, a ball screw, a sliding block and a manipulator. The coal briquettes are recognized in a machine vision mode, the overflow weir is dredged through automatic mechanical equipment, the burden of field workers is relieved, accuracy is high, dredging operation is timely, heavy-medium shallow groove production abnormity can be avoided, and the sorting work efficiency can be improved.

Owner:CHINA UNIV OF MINING & TECH

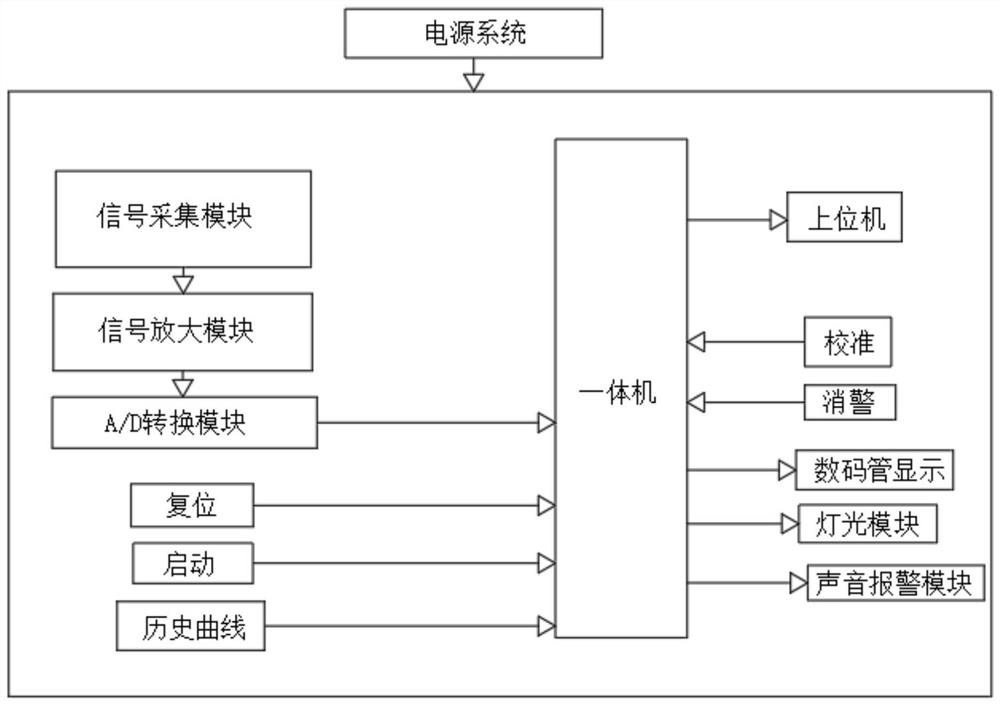

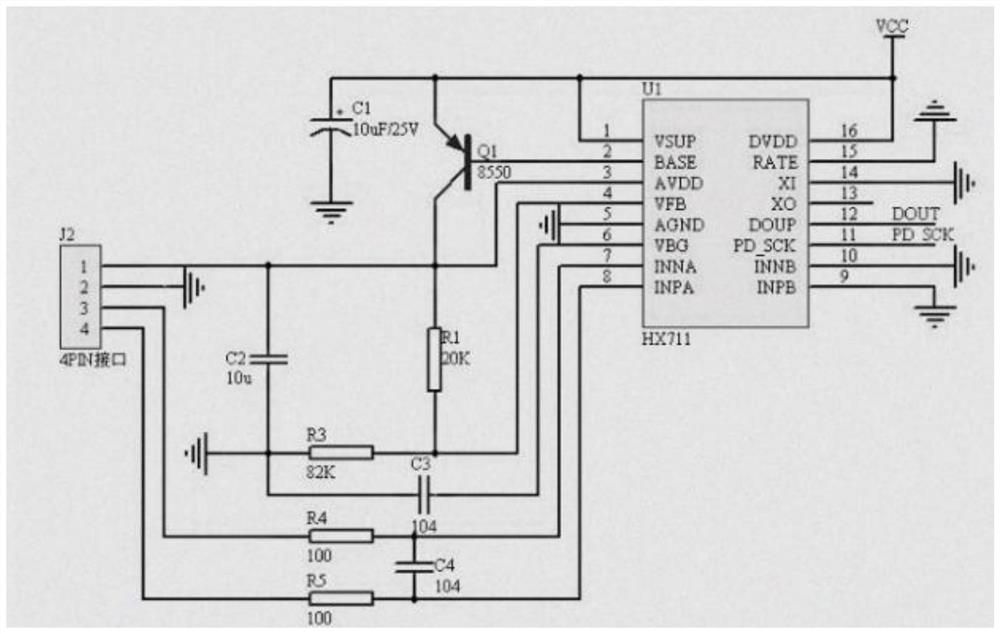

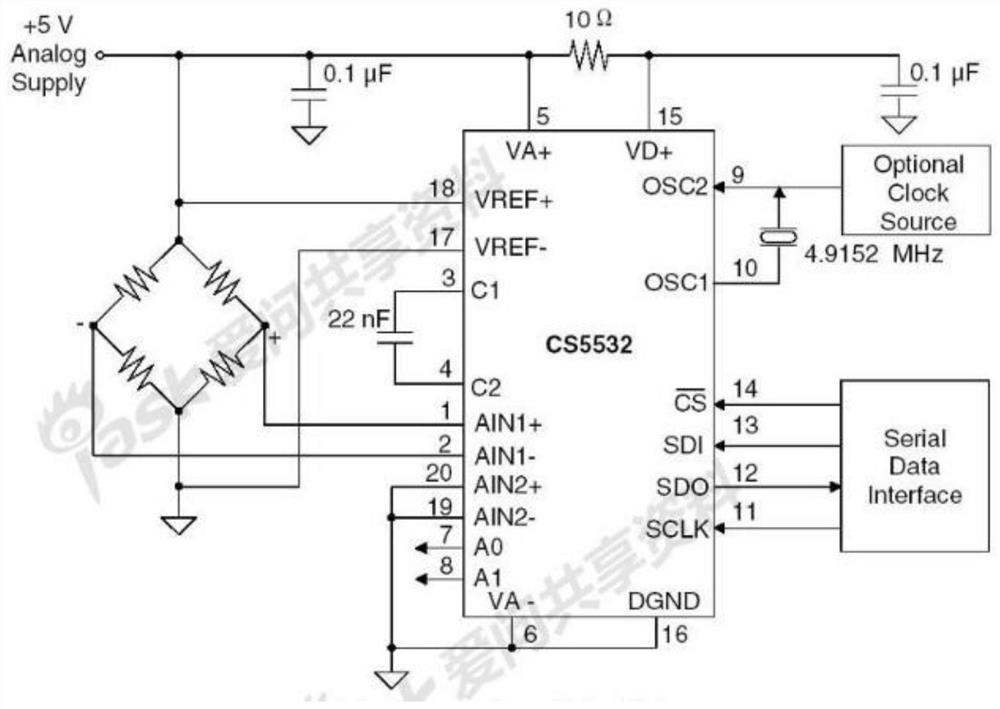

Automatic monoglyceride metering equipment and metering system

PendingCN113686419AImprove performanceHigh precisionWeighing indication devicesWeighing apparatus for materials with special property/formComputer hardwareMonoglyceride

The invention discloses automatic monoglyceridemetering equipment and an automatic monoglyceride metering system. The monoglyceride automatic metering equipment comprises a signal acquisition module, a signal amplification module, an A / D conversion module, an all-in-one machine, a light module, a sound alarm module and a power supply system, the signal acquisition module acquires weighing information through a weighing sensor, the signal acquisition module is in communication connection with the signal amplification module, the signal amplification module performs analog amplification on the information acquired by the weighing sensor and then transmits the information to the A / D conversion module, and the signal amplification module adopts an amplification circuit combined with an HX711 chip; and the A / D conversion module adopts a 24-bit A / D conversion chip and is in communication connection with the all-in-one machine and the signal amplification module. The monoglyceride automatic metering equipment and the metering system are more scientific and reasonable, can visually reflect the content of conveyed liquid in the product proportion, are accurate and digitized in process, and can timely give an early warning and make a timely reaction when input abnormity occurs in a metering pump system, so that the production process is prevented from being interrupted, and the safety is improved.

Owner:上海缘缀包装材料有限公司

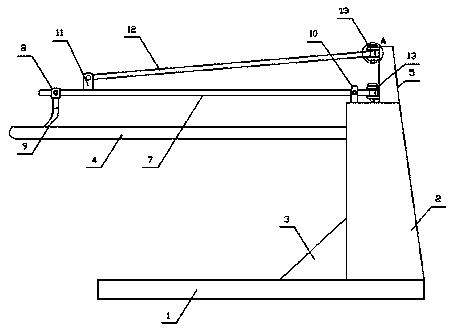

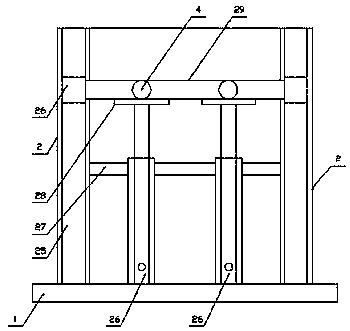

Unreeling device for galvanized steel wire production

The invention discloses an unreeling device for galvanized steel wire production. The unreeling device comprises a base, wherein a supporting frame is arranged on the base, and a horizontal supportingpipe is arranged on the supporting frame; and the unreeling device further comprises oil cylinders, wherein sliding grooves are formed in both sides of the supporting frame, first sliding blocks matched with each other are arranged in the sliding grooves, a horizontal support rod is connected with the first sliding blocks, a horizontal supporting pipe is connected with the horizontal support rod,a horizontal connecting rod is arranged above the horizontal supporting pipe, a check mechanism is arranged on the horizontal connecting rod, the lower surface of the horizontal supporting rod is connected with the upper surface of a horizontal supporting plate, the lower surface of the horizontal supporting plate is connected with the upper ends of the oil cylinders, and the lower ends of the oil cylinders are connected with the base. The oil cylinder disclosed by the invention can be used for adjusting the horizontal supporting rod, the horizontal supporting rod can slide up and down in thesliding grooves through the first sliding blocks to drive the horizontal supporting pipe to move up and down, a rebar coil is arranged on the horizontal supporting pipe in a hanging and sleeving manner, and the height of the horizontal supporting pipe is adjusted according to the size of the rebar coil to ensure the horizontal transportation of rebar, so that the unreeling quality and unreeling efficiency of the rebar is improved.

Owner:JIANGSU KAIWEI ADVANCED MATERIAL TECH CO LTD

Female die fastening device of cylindrical closed forging die

PendingCN110394413APrevent pulling outAvoid scrappingForging/hammering/pressing machinesEngineeringForging

The invention provides a female die fastening device of a cylindrical closed forging die. The device can solve the problem that a cylindrical female die body is frequently pulled out of a lower die base of an existing cylindrical closed forging die during puncher pin separating, production is interrupted, and the die is scrapped. The female die fastening device comprises a copying spliced block, atransverse clamping assembly and a longitudinal clamping assembly. The shape of the copying spliced block is rectangular, and the front side surface and the left side surface of the copying spliced block are attached to a transverse datum surface and a longitudinal datum surface on a lower die base correspondingly. Arc-shaped through holes are formed in the opposite side surfaces of the two clamping blocks of the copying spliced block correspondingly and penetrate through up and down. The radius of the arc-shaped through holes is equal to that of a female die body. An annular step is formed in the outer side of the top surface of the female die body. Lock inserts are fixed into the arc-shaped through holes in the circumferential direction of the arc-shaped through holes and axially pressthe step surface of the annular step. The transverse clamping assembly and the longitudinal clamping assembly can be movably mounted on the lower die base and used for pressing the rear side surface and the right side surface of the copying spliced block. The two clamping blocks are detachably fixed to the lower die base.

Owner:无锡航亚科技股份有限公司

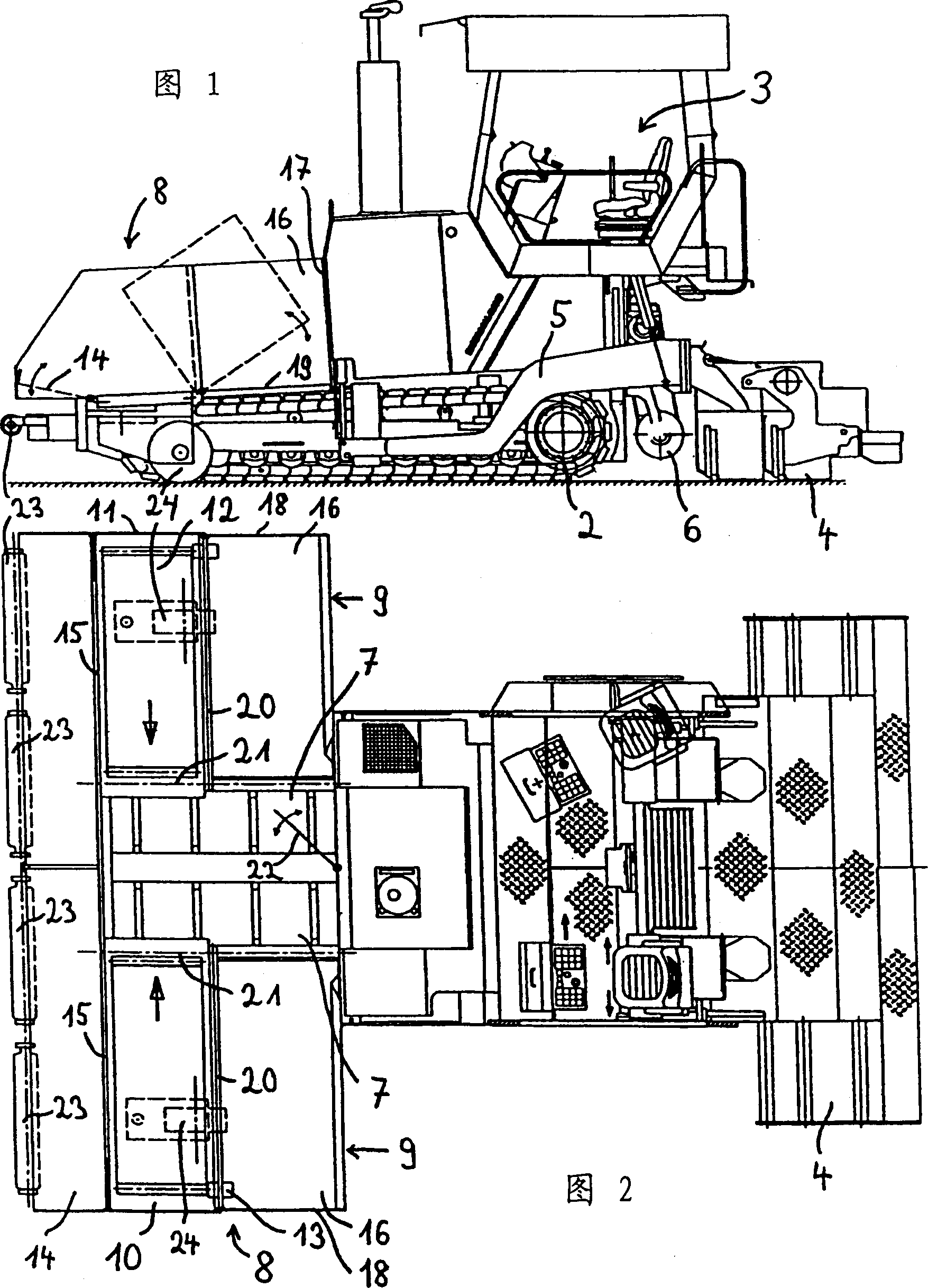

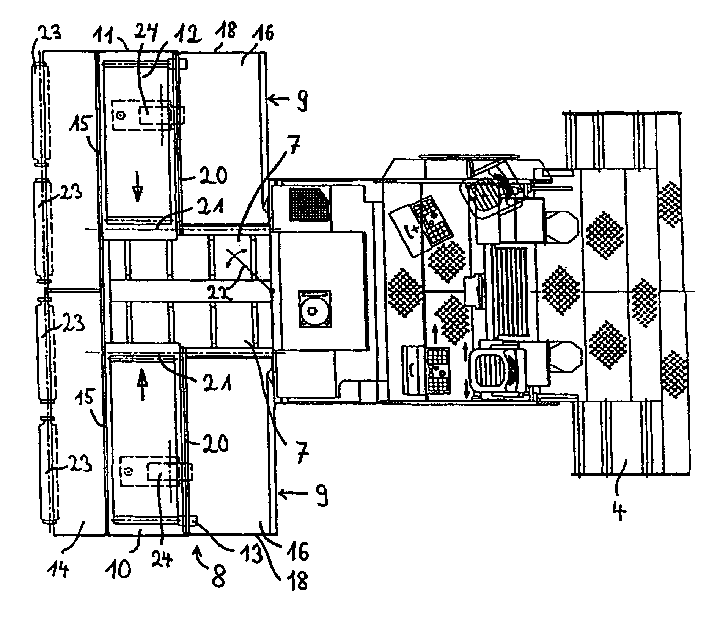

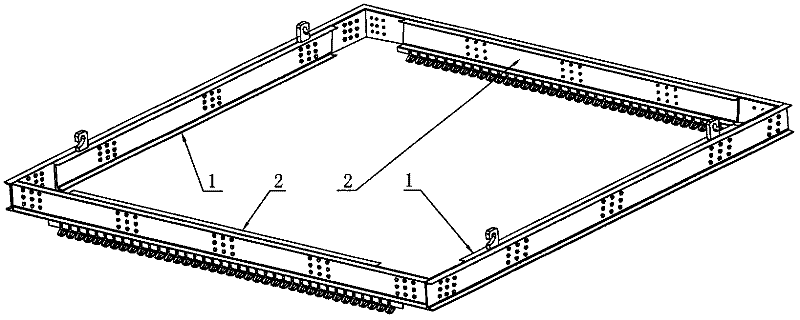

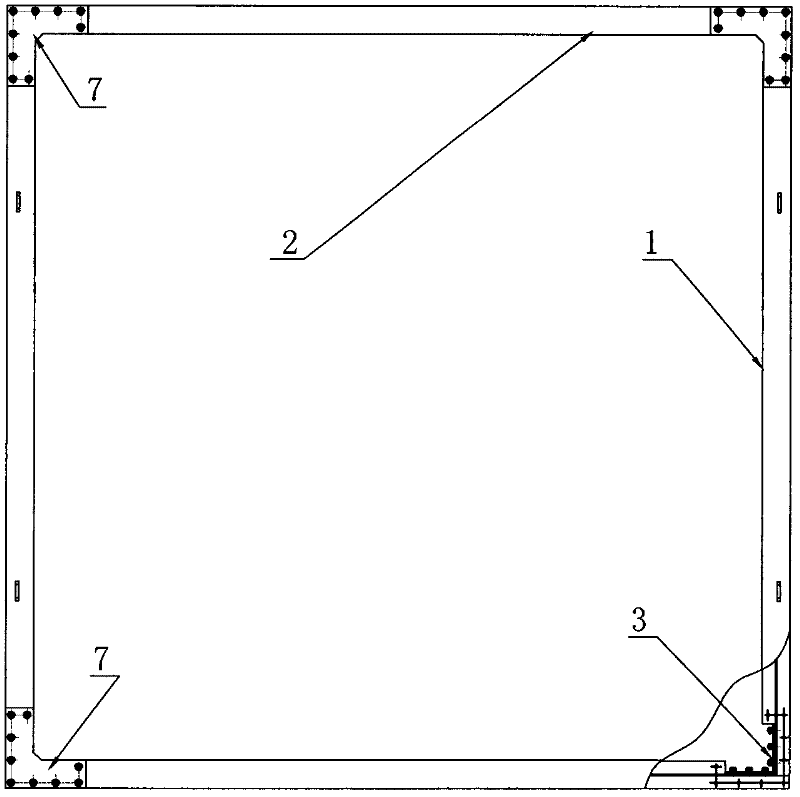

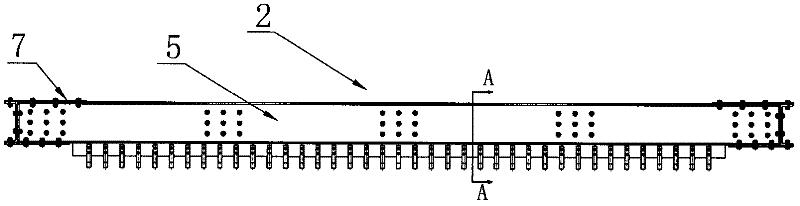

Paver and loader for same

A paver and a corresponding loader have a chassis which is provided, at the front in the paving direction, with a hopper for receiving material to be paved and, at the rear, with a floating screed, a longitudinal conveyor device being provided between the hopper and a distributor auger located in front of the screed in the paving direction, the hopper being open towards the longitudinal conveyor device and including two hopper halves which are each pivotable about an axis extending adjacently to the longitudinal conveyor device in the paving direction. Further, in each of the hopper halves is provided a lateral conveyor device which is drivable by a drive, is arranged on the bottom side and extends as far as the longitudinal conveyor device, those bottom portions of the hopper halves which remain with regard to the respective lateral conveyor device being tiltable relative to the lateral conveyor device.

Owner:ABG ALLG BAUMASCHINEN GMBH

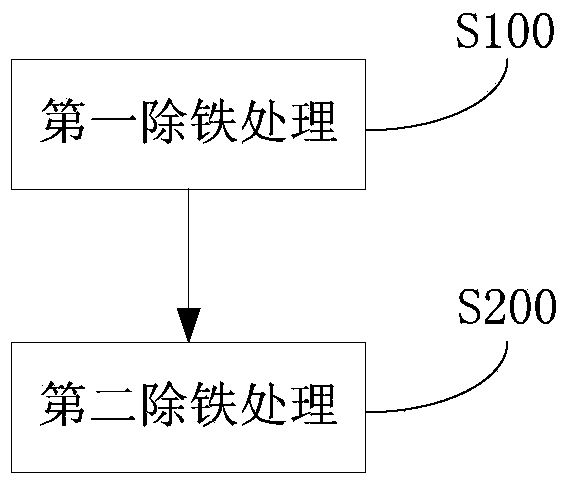

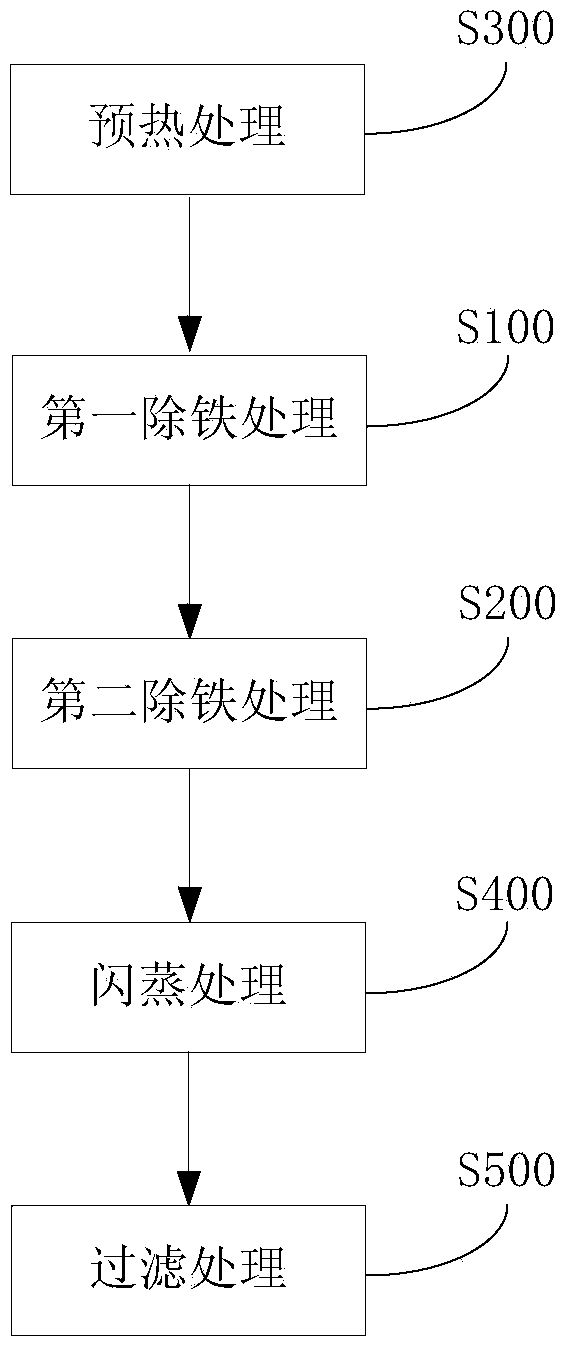

Method for removing iron from iron-containing zinc sulfate solution

ActiveCN104004913AHigh iron removal efficiencyImprove equipment utilizationProcess efficiency improvementSulfate zincIron removal

The invention discloses a method for removing iron from an iron-containing zinc sulfate solution. The method comprises the following steps: supplying the iron-containing zinc sulfate solution to a vertical reaction kettle, and introducing steam and oxygen into the vertical reaction kettle so as to perform primary iron removal treatment in the vertical reaction kettle to obtain first iron-removed slurry; supplying the first iron-removed slurry to a horizontal reaction kettle, and introducing steam and oxygen to the horizontal reaction kettle so as to perform secondary iron removal treatment in the horizontal reaction kettle to obtain second iron-removed slurry. According to the method of removing iron from the iron-containing zinc sulfate solution disclosed by the embodiment of the invention, the vertical reaction kettle and the horizontal reaction kettle are combined for use so as to effectively solve the production interruption caused by the problems of scaling in the kettles in the iron removal process and ensure the continuous and stable operation of production, thereby significantly improving the iron removal efficiency and the equipment utilization rate.

Owner:CHINA ENFI ENGINEERING CORPORATION

Short circuit device between electrolysis cell and electrowinning cell

The invention relates to a short circuit device between an electrolysis cell and an electrowinning cell, comprising a lifting beam and a current collection beam, wherein the lifting beam and the current collection beam form a rectangular frame and form a short circuit device, the lifting beam is provided with a conducting copper bar B, the current collection beam is provided with a conducing copper bar A, and the conducting copper bar A and the conducting copper bar B are connected into a conductive body by virtue of a copper connecting piece. The invention has the beneficial effect that: theproblem that the production is interrupted due to the outage of the whole electrolysis cell group as cathode plates and anode plates of several electrolysis cells slide outside the cells or a local electrolysis cell is required to be maintained can be effectively solved.

Owner:SANMEN SANYOU TECH CO LTD

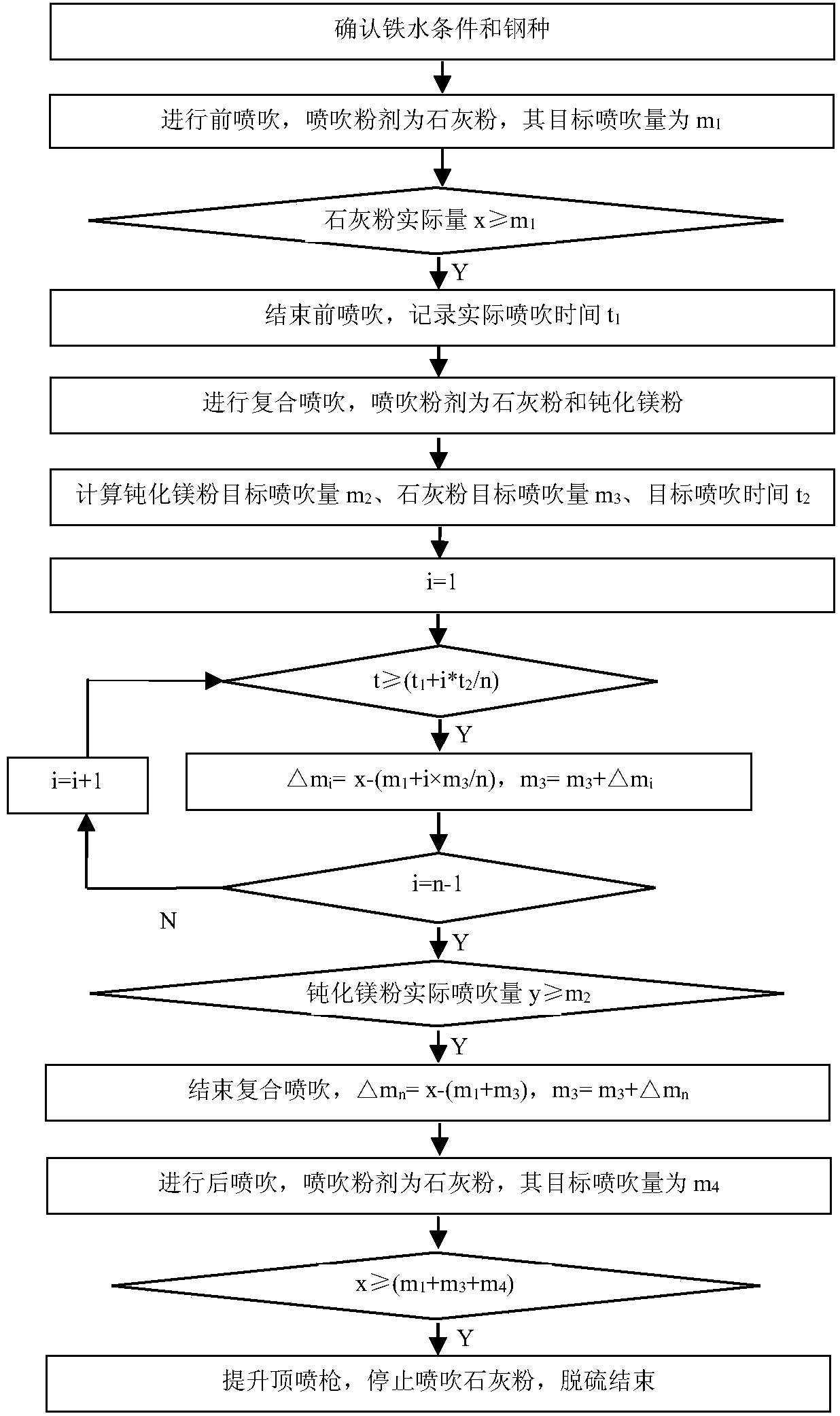

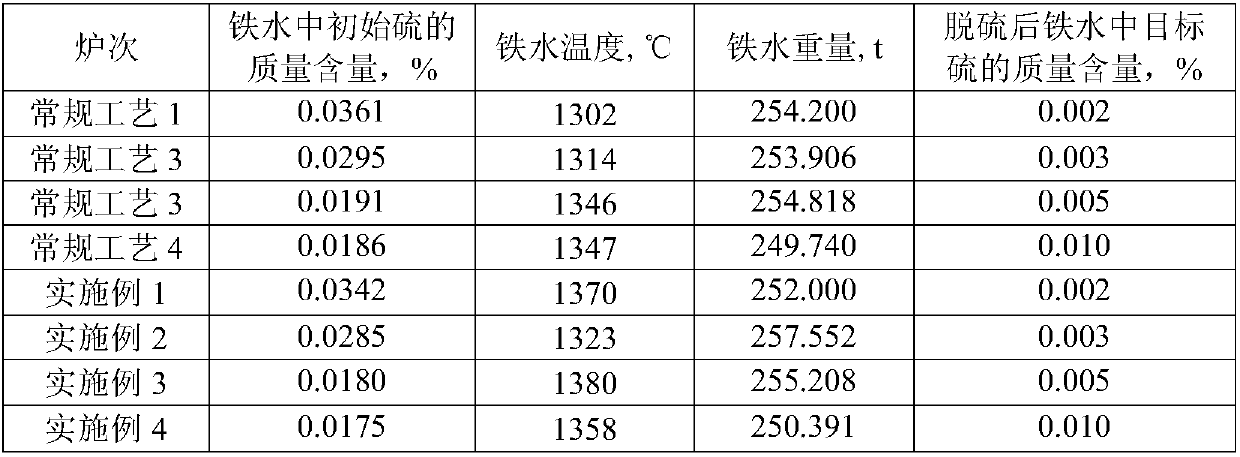

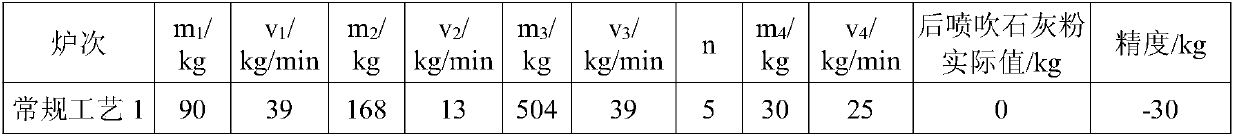

Method for controlling lime powder consumption in magnesium-based compound blowing molten iron desulfurization process

The invention discloses a method for controlling the lime powder consumption in a magnesium-based compound blowing molten iron desulfurization process, and mainly solves the technical problem that ina conventional compound blowing molten iron desulfurization process, the lime powder consumption control precision in the post-blowing stage is low. The method comprises the following steps: determining the molten iron condition and the steel type of heat with the desulfurization demand; carrying out pre-blowing; carrying out compound blowing, uniformly dividing the compound blowing stage into n sub-stages according to the principle that the passivation magnesium powder blowing time and the lime powder blowing time are the same, and acquiring the difference between the actual lime powder blowing amount with the target lime powder blowing amount through comparison when each sub-stage is finished; and carrying out post-blowing. The method disclosed by the invention has the advantages that the lime powder post-blowing amount can be consistent with the target value without manual monitoring and intervention; accordingly, not only can the operation be simplified, but also the circumstance that a blowing gun is blocked and the lime powder consumption is increased because the blowing process is finished in advance can be effectively prevented, and the production interruption is avoided; and through the application of the method, the lime powder post-blowing amount control precision can reach + / - 2 kg.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com