Patents

Literature

36 results about "Physical plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Physical plant, mechanical plant or industrial plant (and where context is given, often just plant) refers to the necessary infrastructure used in operation and maintenance of a given facility. The operation of these facilities, or the department of an organization which does so, is called "plant operations" or facility management. Industrial plant should not be confused with "manufacturing plant" in the sense of "a factory".

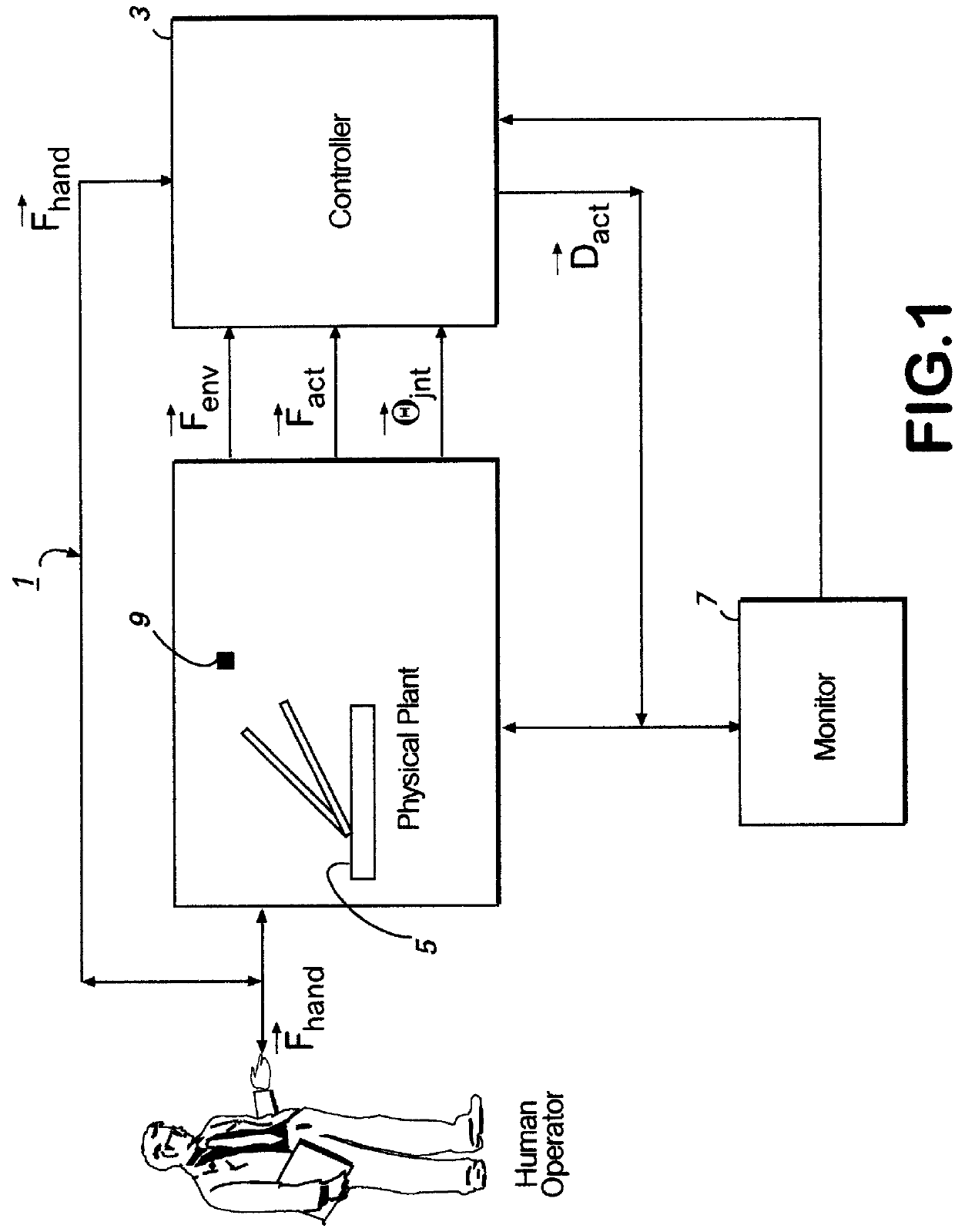

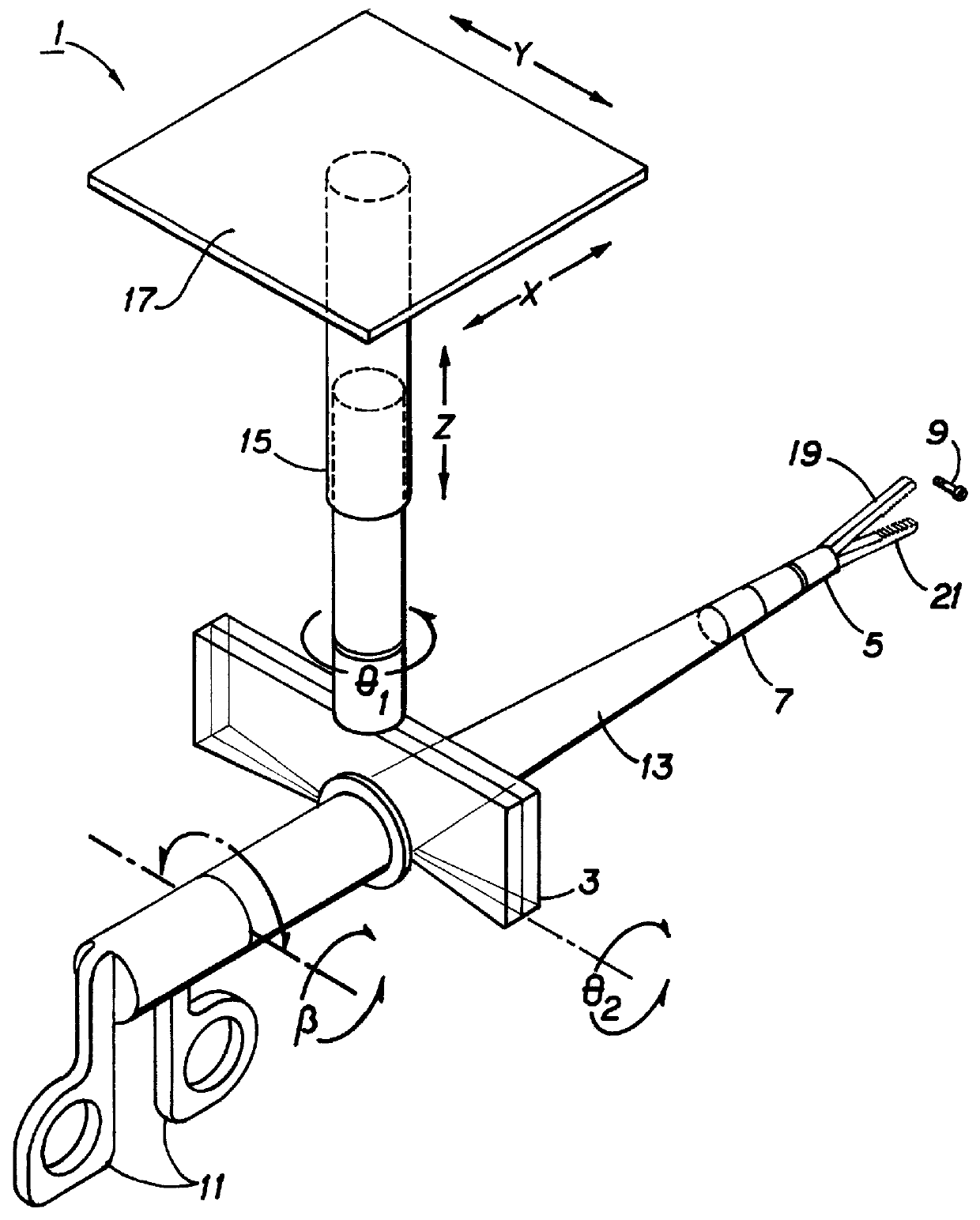

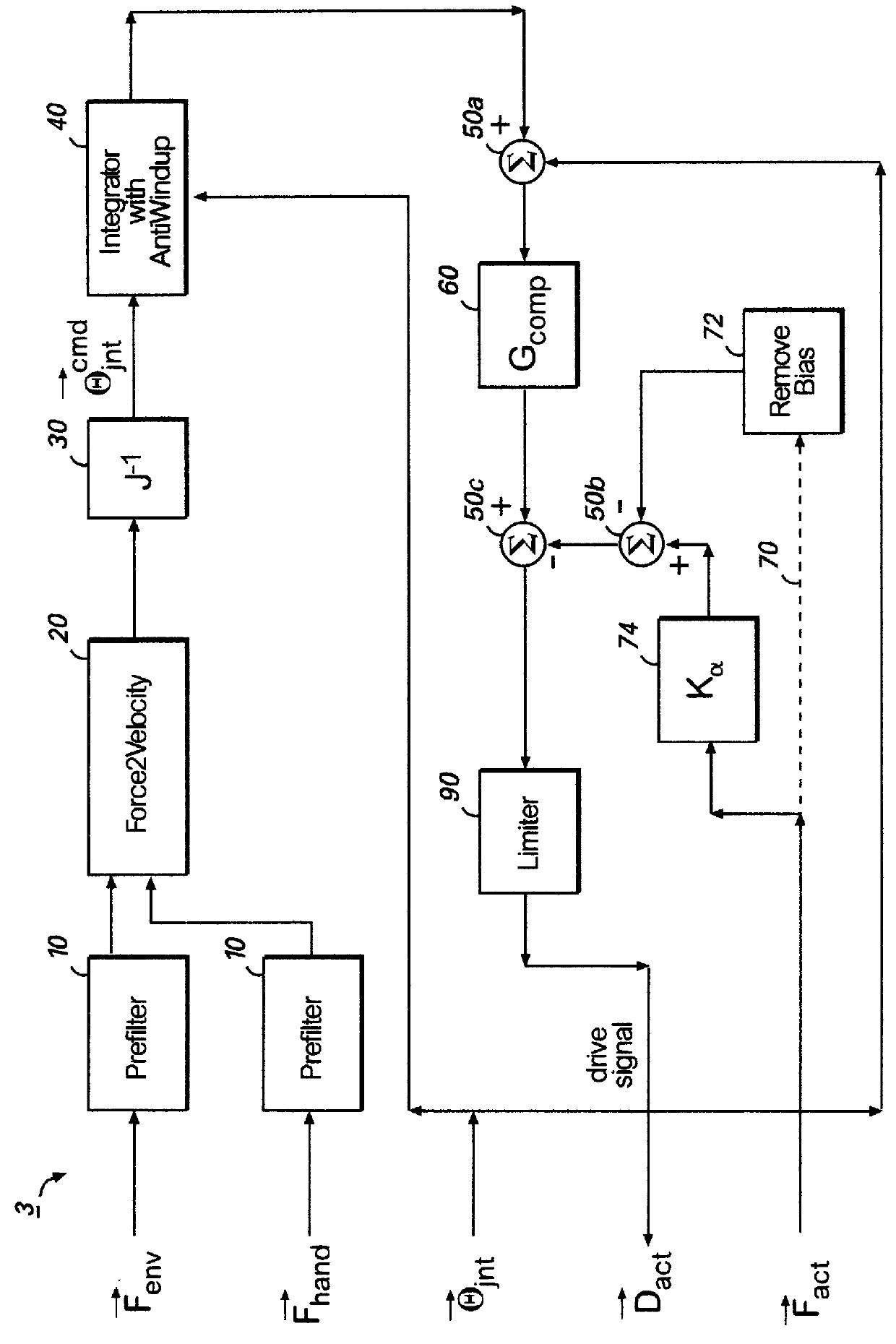

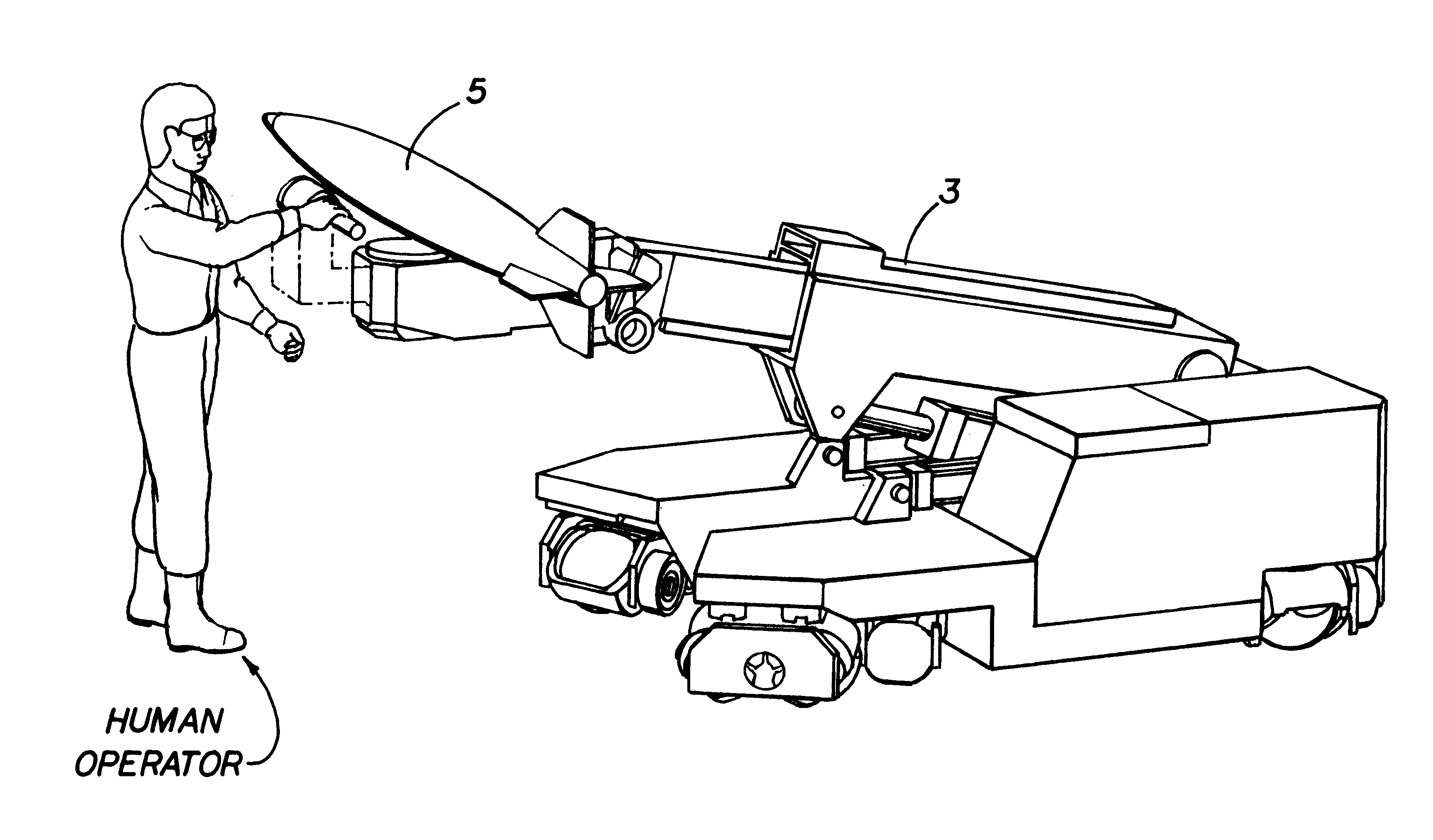

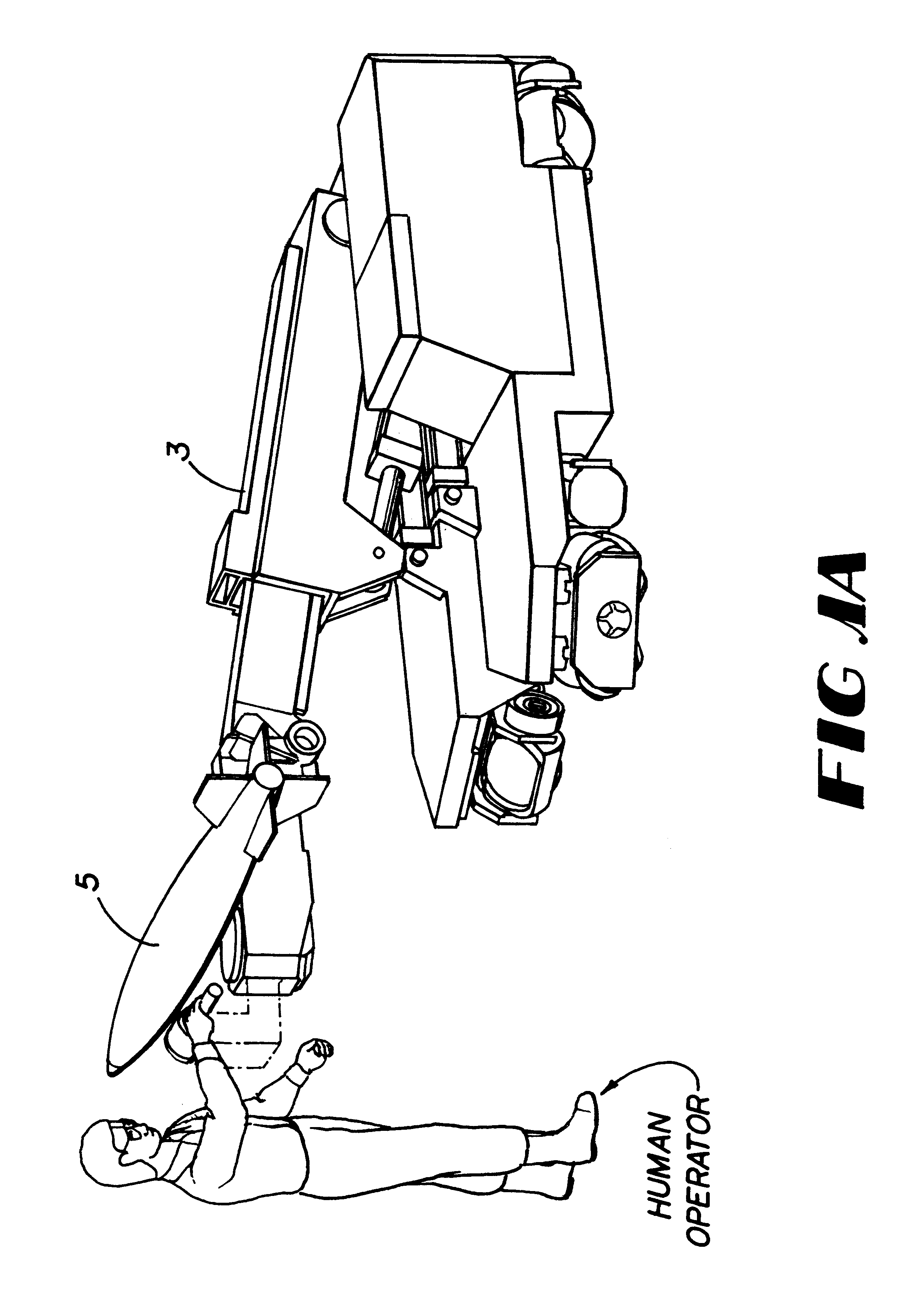

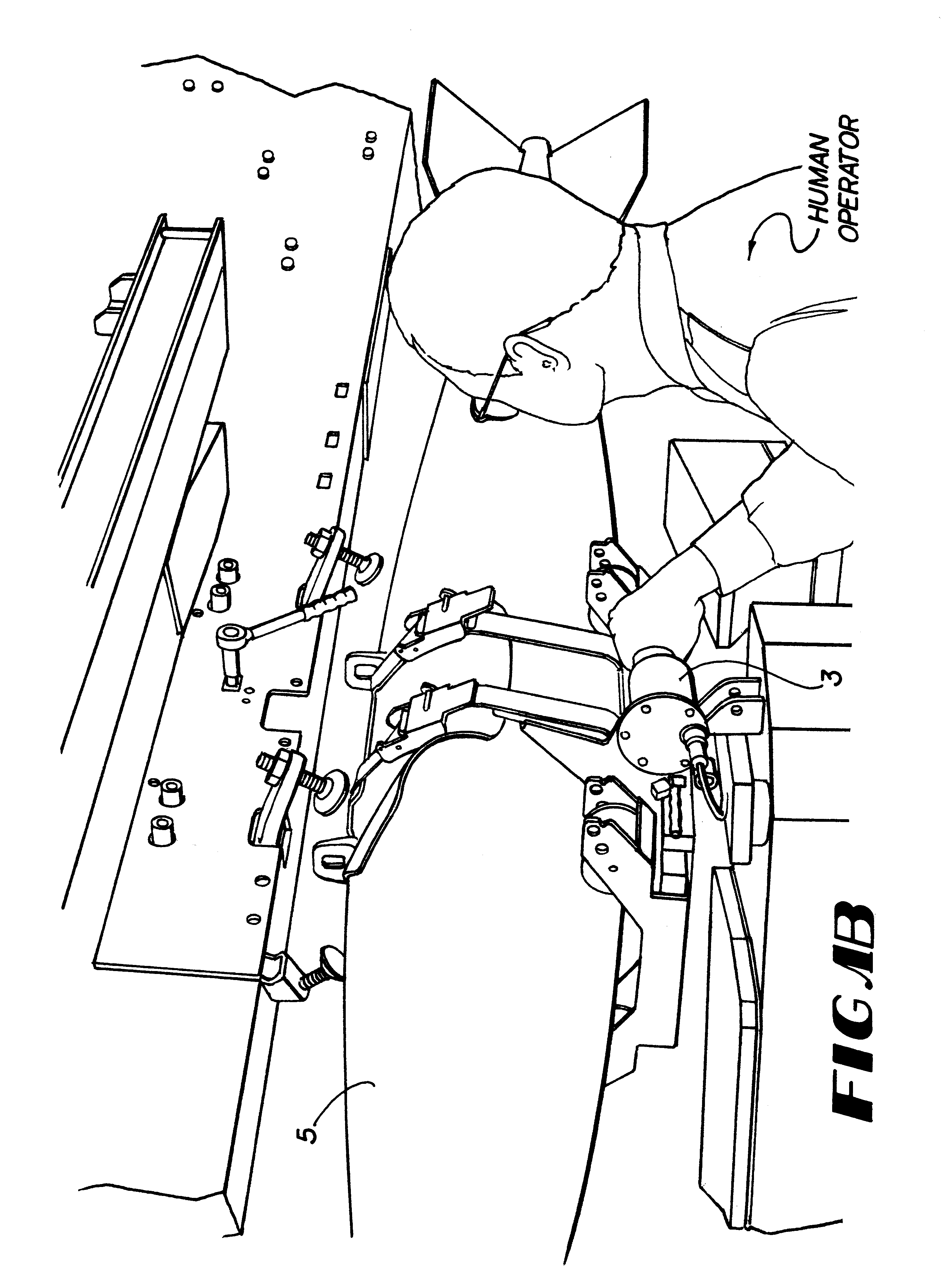

Apparatus and methods for a human de-amplifier system

InactiveUS6084371AProgramme-controlled manipulatorMicromanipulatorOperational systemAudio power amplifier

A human de-amplifier system for interfacing a human operator and a physical object through a physical plant, wherein the physical object has dimensions in the range of 1 micrometer to 1 mm. The human de-amplifier system uses an inner-feedback loop to increases the equivalent damping of the operating system to stabilize the system when it contacts with the environment and reduces the impact of the environment variation by utilizing a high feedback gain, determined by a root locus sketch. Because the stability of the human de-amplifier system of the present invention is greatly enhanced over that of the prior art, the de-amplifier system is able to manipulate the physical object has dimensions in the range of 1 micrometer to 1 mm with high stability and accuracy. The system also has a monitoring device to monitor the motion of the physical object under manipulation.

Owner:LOCKHEED MARTIN ENERGY SYST INC

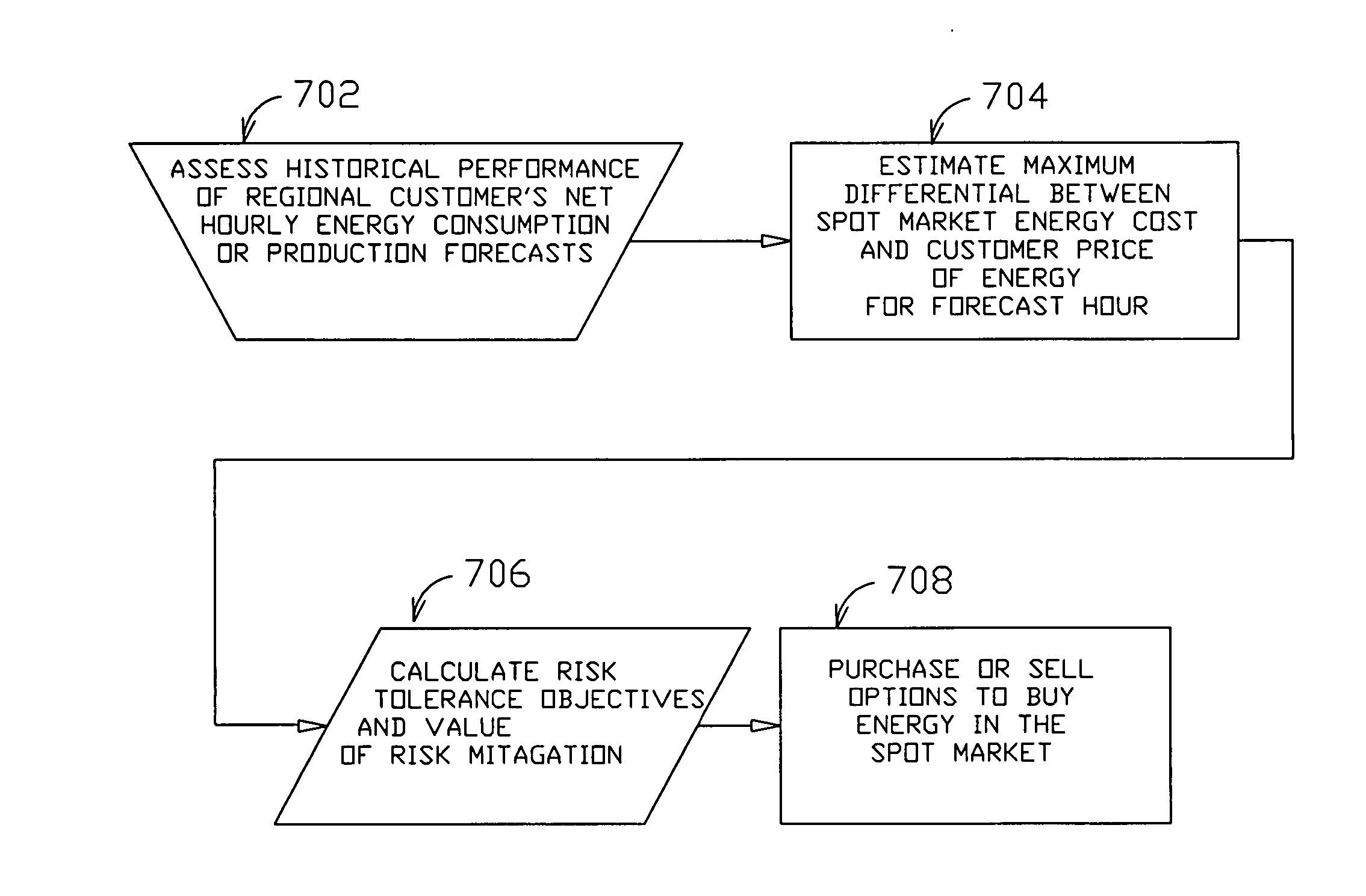

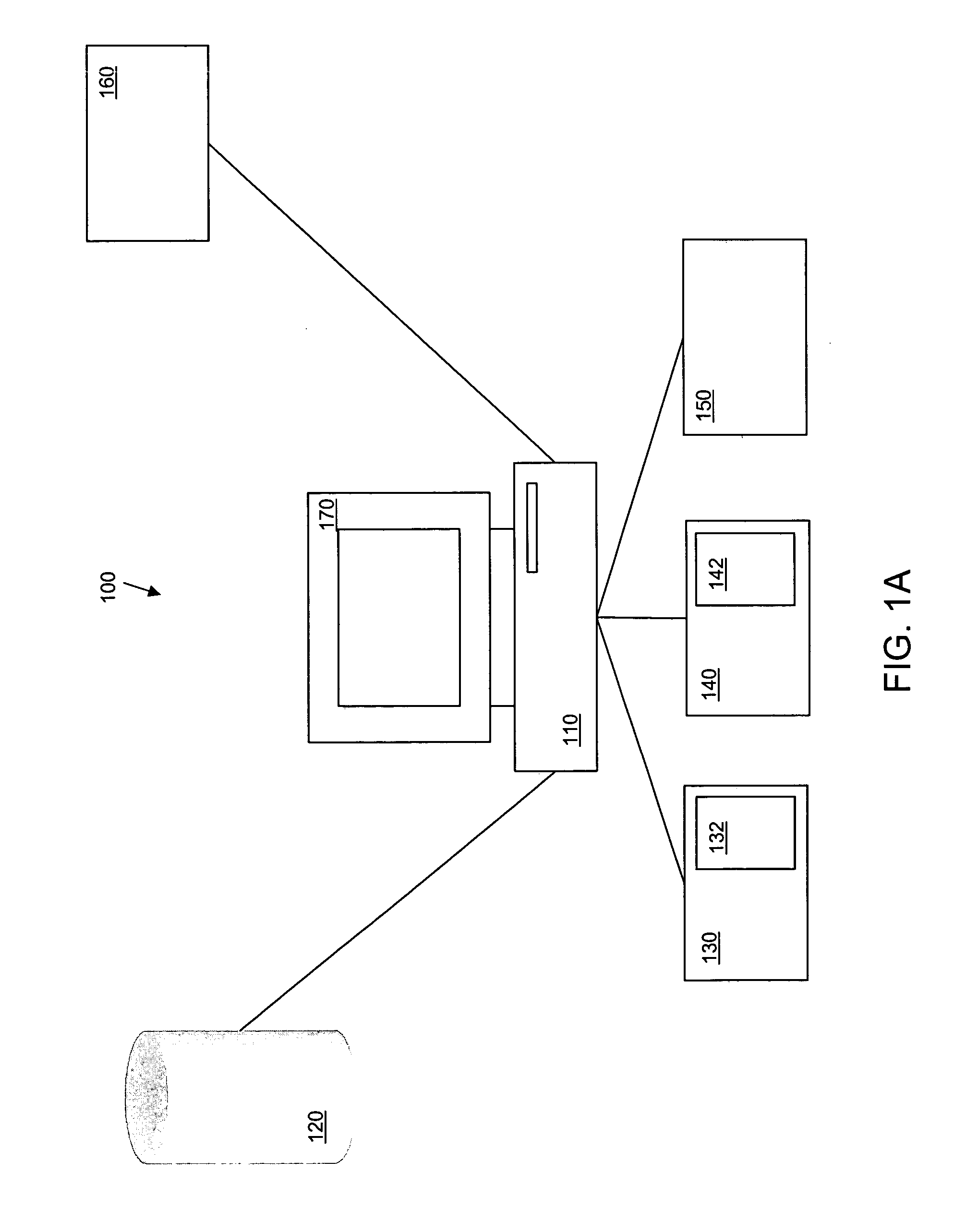

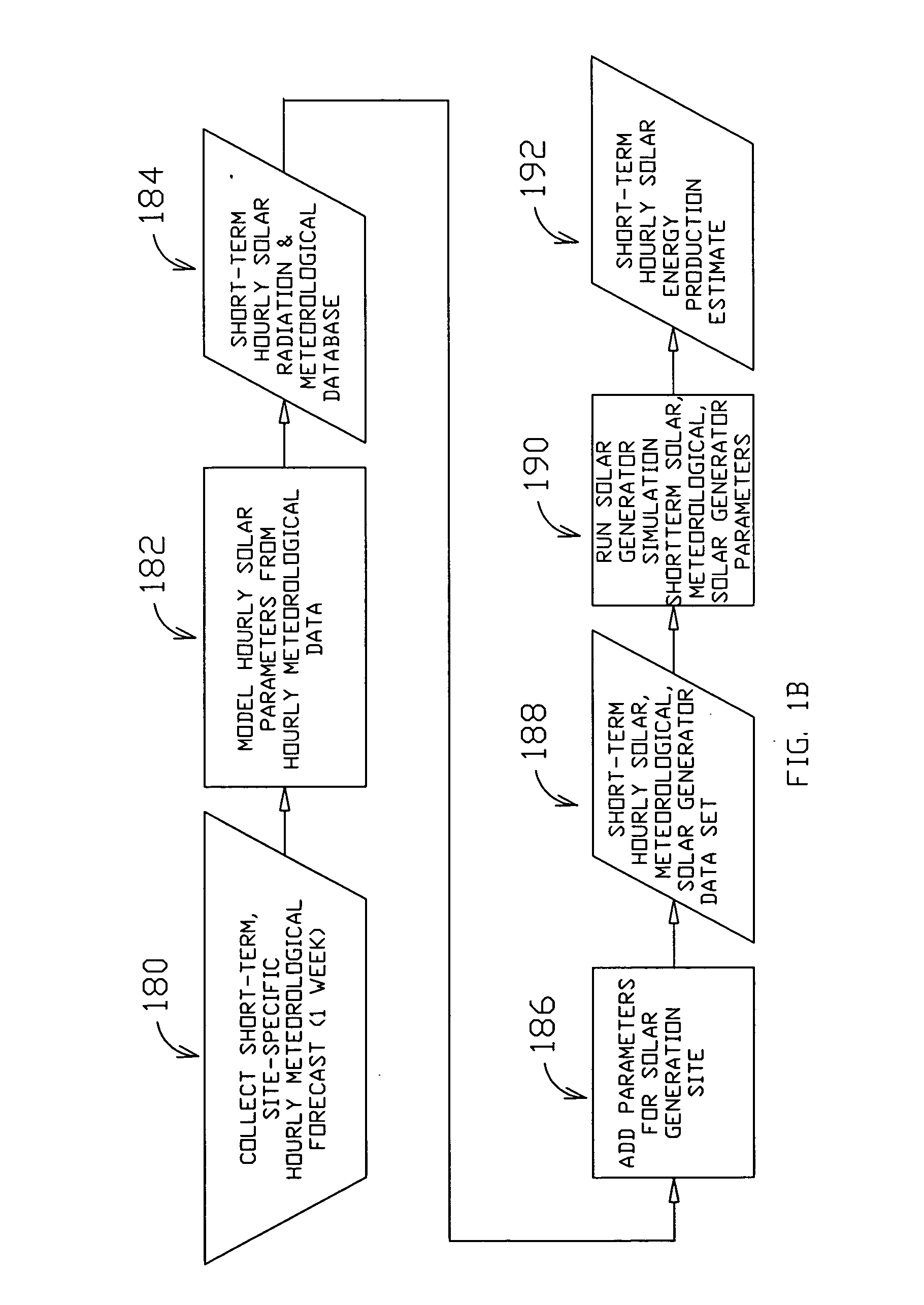

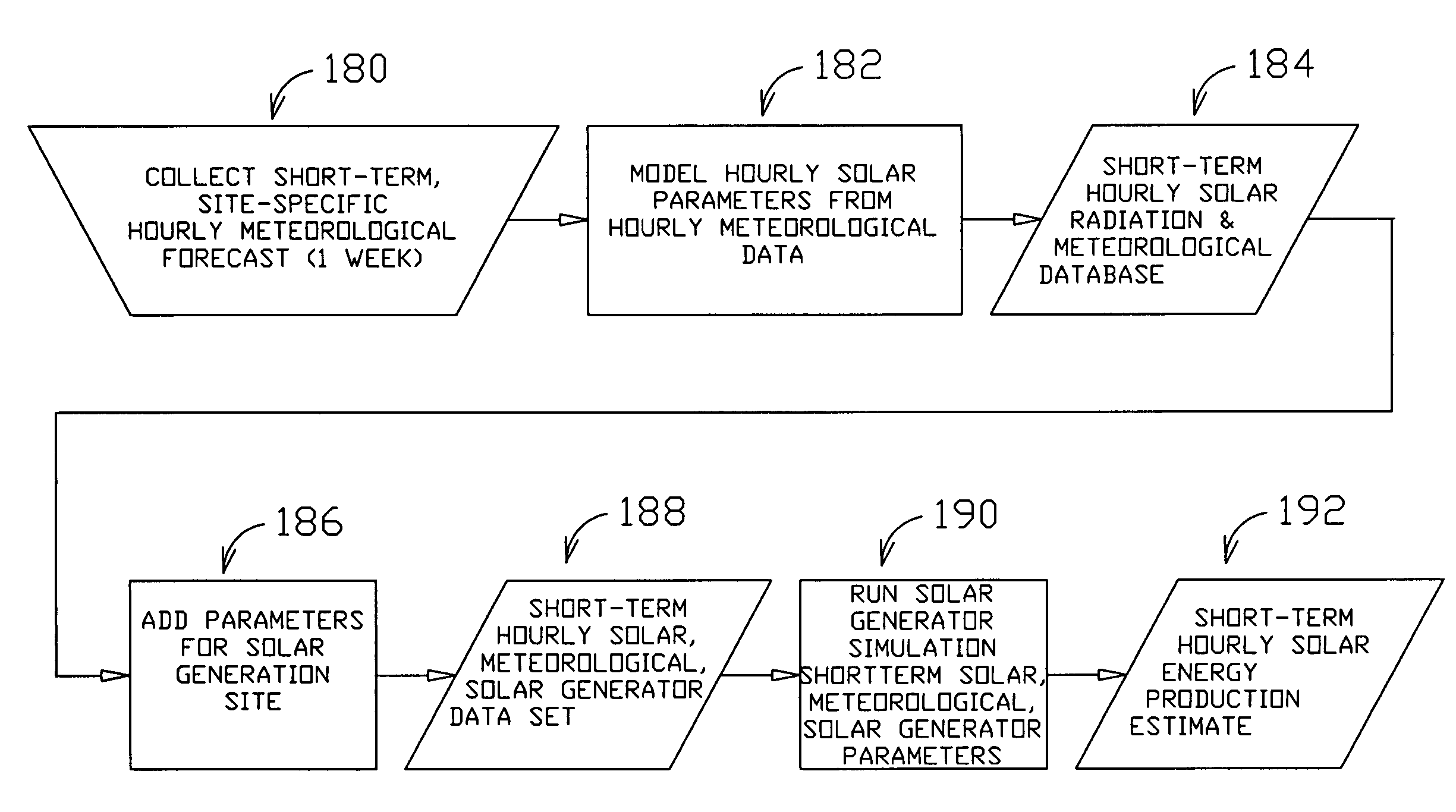

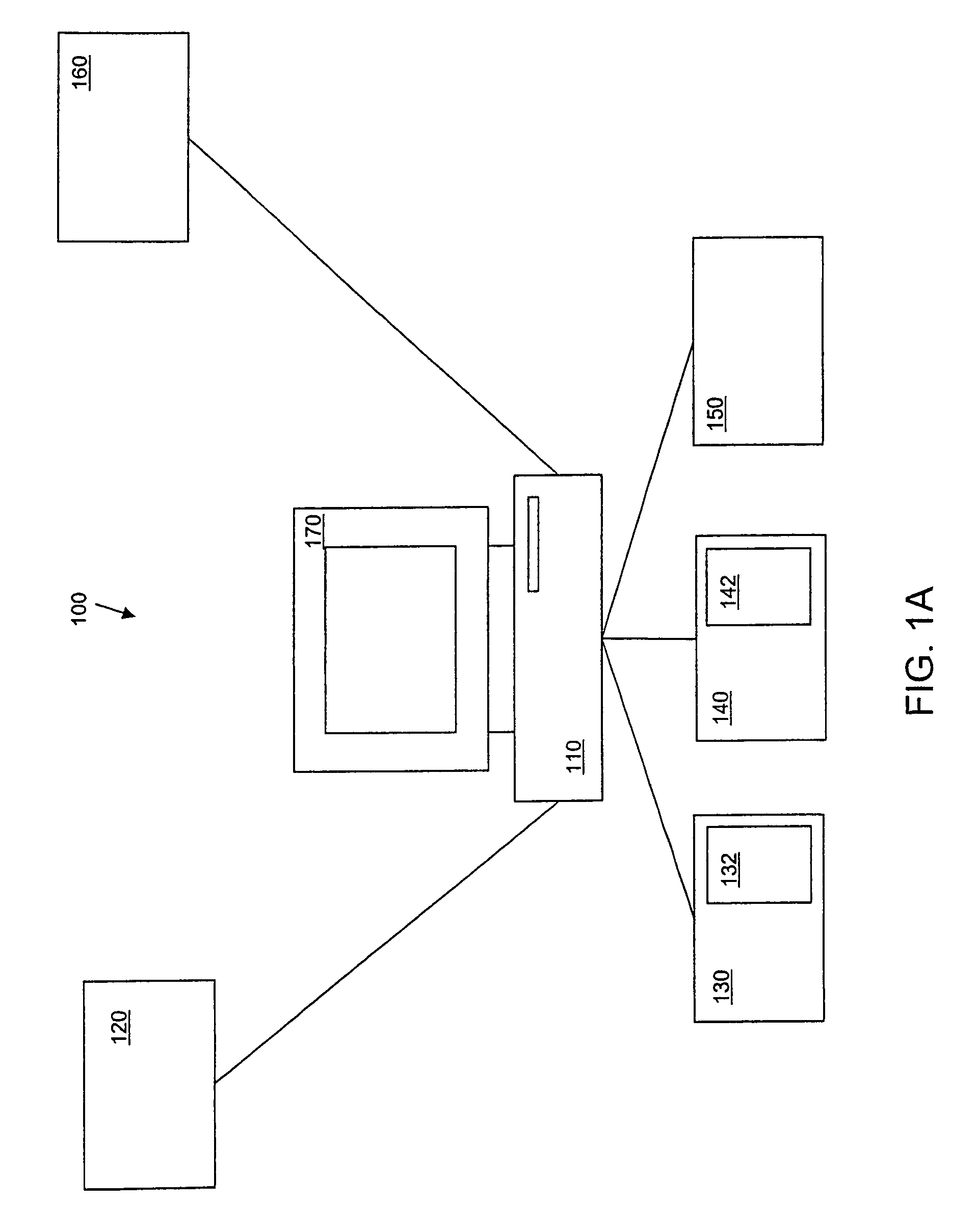

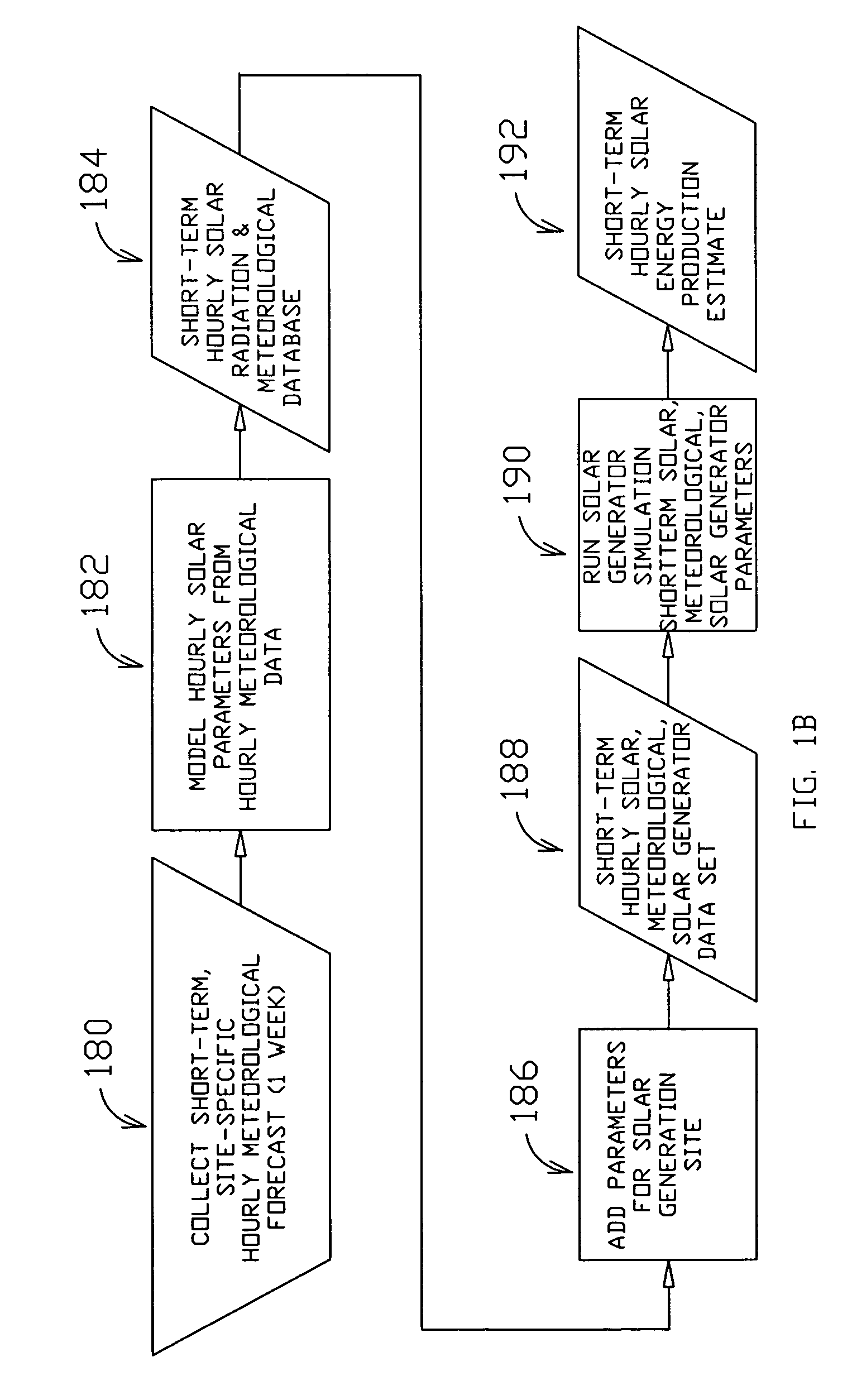

Method and system for predicting solar energy production

A system, method and computer program product to assist in managing the physical plant mechanisms and market finances for a deregulated electricity grid or regulated utility grid, populated with solar electric generation capacity. This system provides tools to assist grid operators in the scheduling and dispatch of generation resources in an electrical grid populated with solar electric generation capacity, a week in advance, on an hourly basis. It also provides tools to assist companies engaged in generation, distribution and energy marketing, in the electrical power industry, to manage their contractual supply obligations in the day-ahead hourly wholesale market and the spot market, in an electrical grid populated with solar electric generation capacity. This process can also be used to predict solar loading of building structures, using forecast irradiance data as inputs to common building energy modeling programs, a week in advance, on an hourly basis.

Owner:NEO VIRTUS ENG

Method and system for predicting solar energy production

ActiveUS7580817B2Financial riskGeneration forecast in ac networkFinanceSolar powerLoad following power plant

A system, method and computer program product to assist in managing the physical plant mechanisms and market finances for a deregulated electricity grid or regulated utility grid, populated with solar electric generation capacity. This system provides tools to assist grid operators in the scheduling and dispatch of generation resources in an electrical grid populated with solar electric generation capacity, a week in advance, on an hourly basis. It also provides tools to assist companies engaged in generation, distribution and energy marketing, in the electrical power industry, to manage their contractual supply obligations in the day-ahead hourly wholesale market and the spot market, in an electrical grid populated with solar electric generation capacity. This process can also be used to predict solar loading of building structures, using forecast irradiance data as inputs to common building energy modeling programs, a week in advance, on an hourly basis.

Owner:NEO VIRTUS ENG

Apparatus and methods for a human extender

A human extender controller for interface between a human operator and a physical object through a physical plant. The human extender controller uses an inner-feedback loop to increase the equivalent damping of the operating system to stabilize the system when it contacts with the environment and reduces the impact of the environment variation by utilizing a high feedback gain, determined by a root locus sketch. Because the stability of the human extender controller of the present invention is greatly enhanced over that of the prior art, the present invention is able to achieve a force reflection ratio 500 to 1 and capable of handling loads above the two (2) ton range.

Owner:LOCKHEED MARTIN ENERGY SYST INC

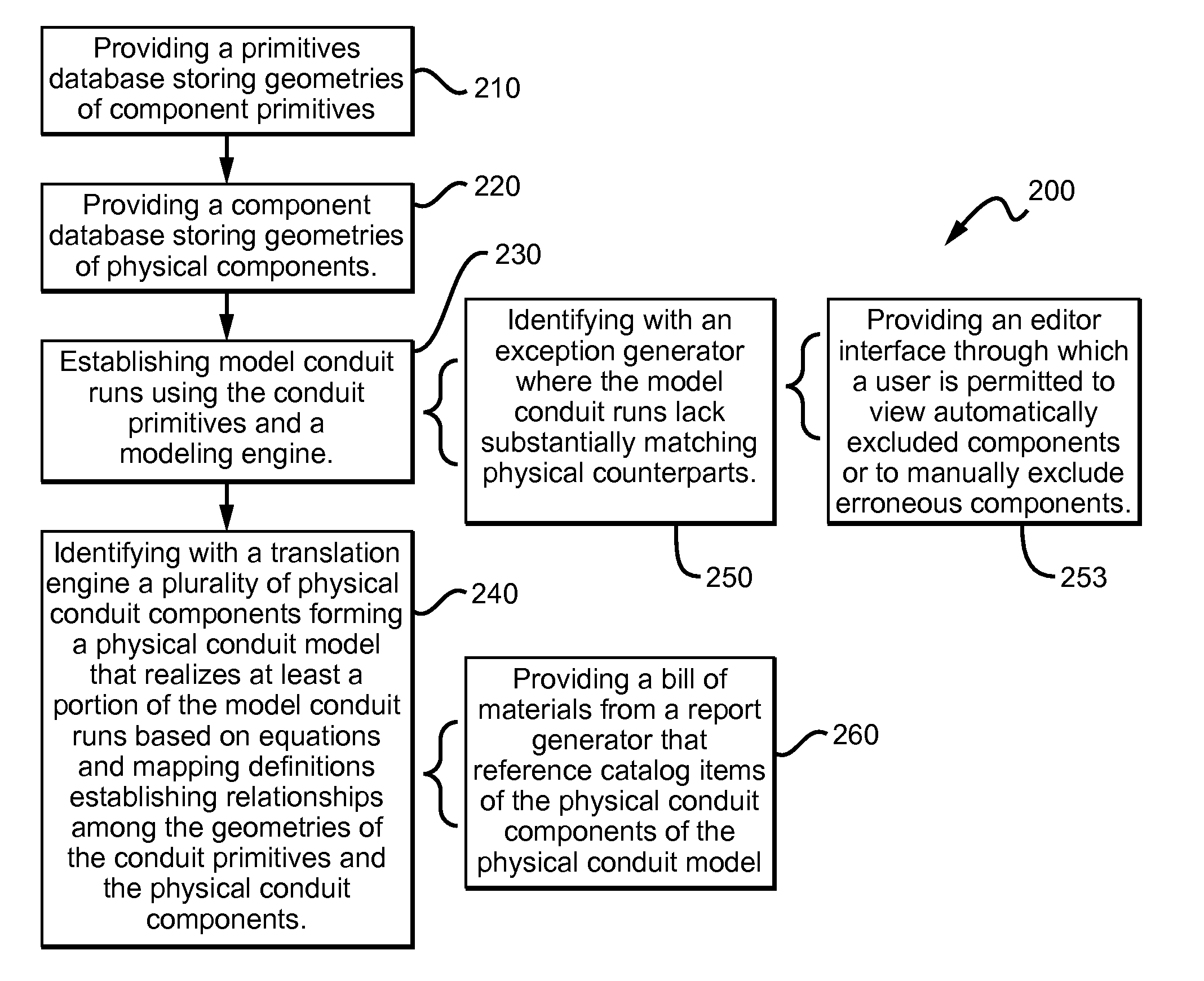

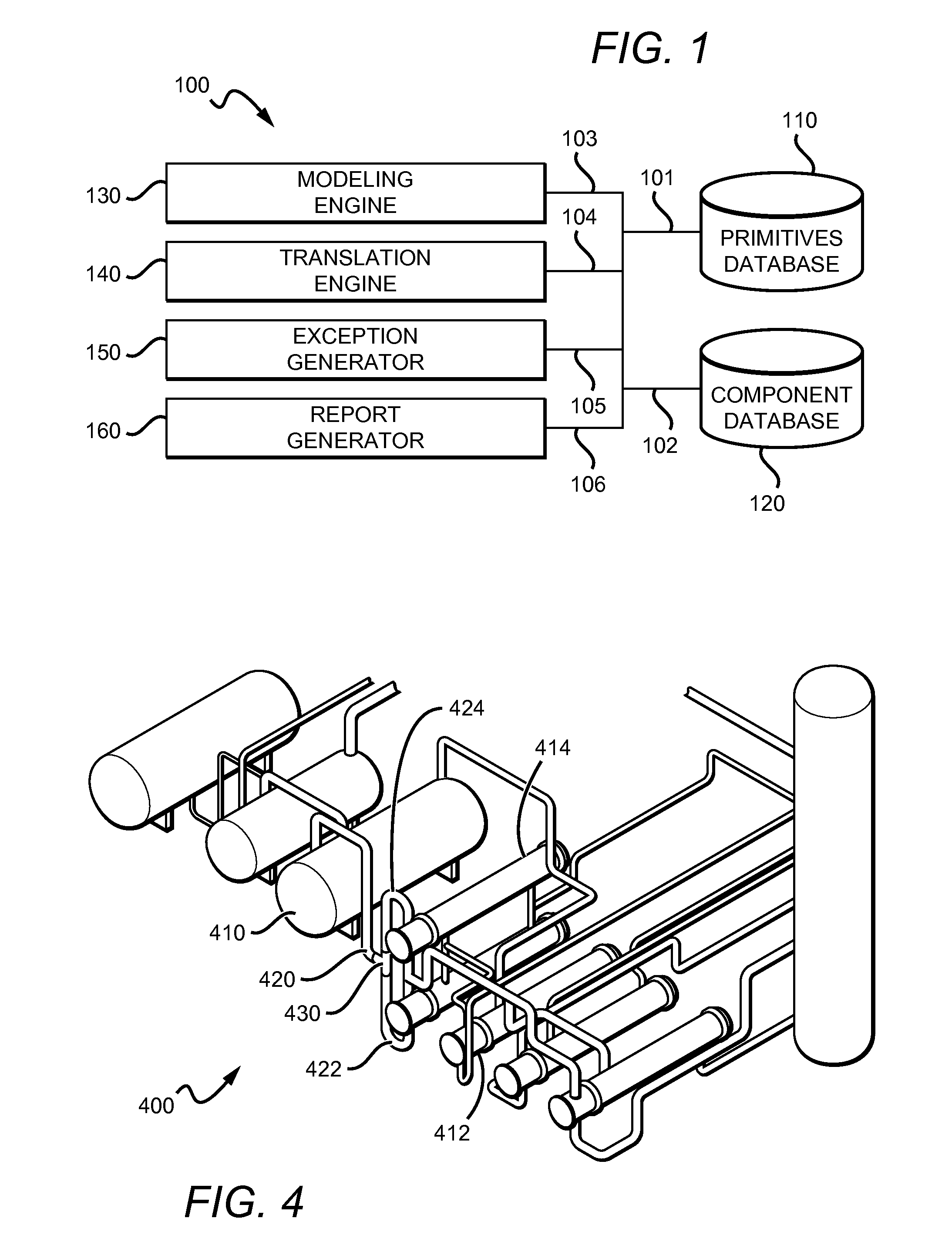

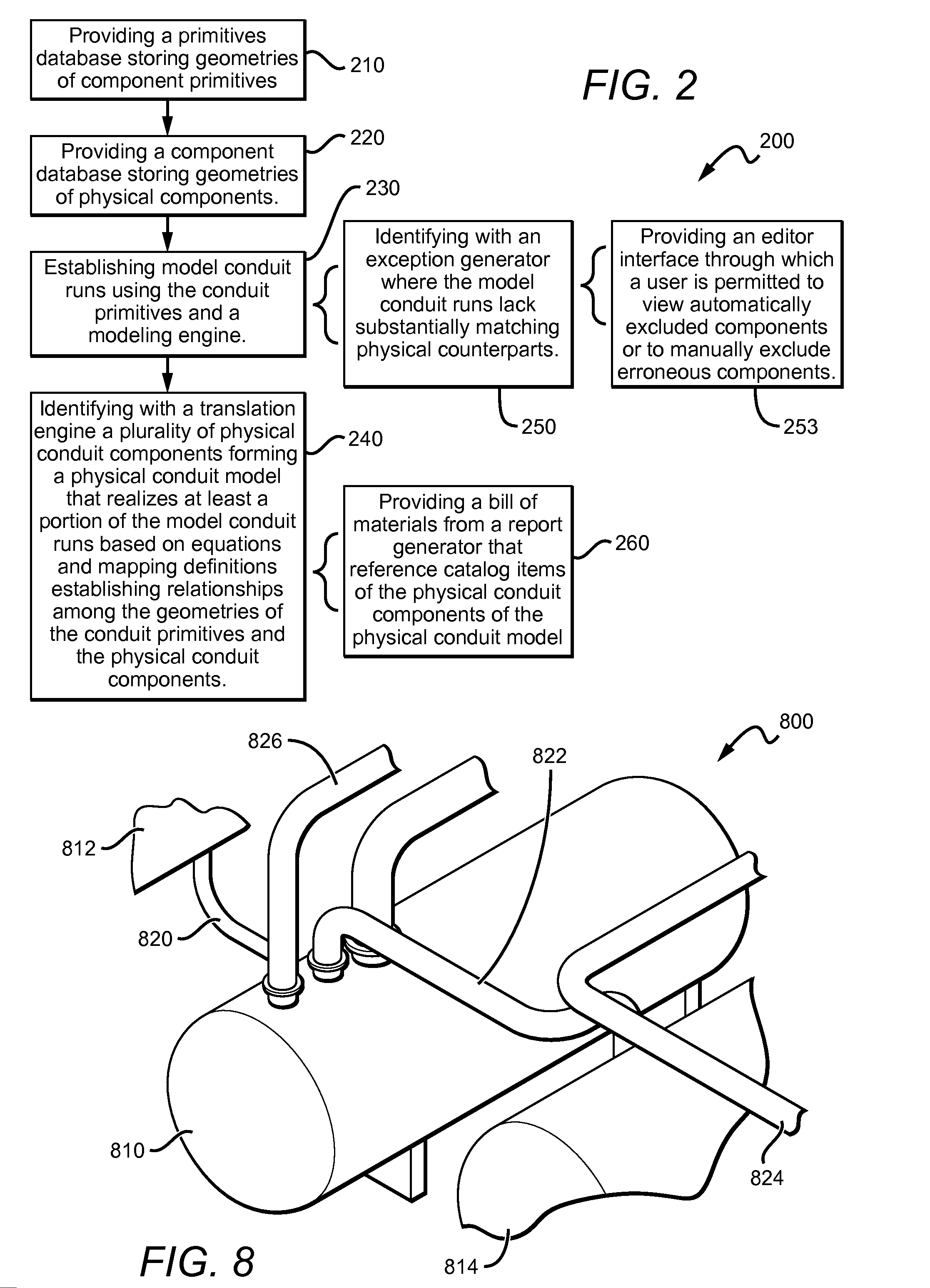

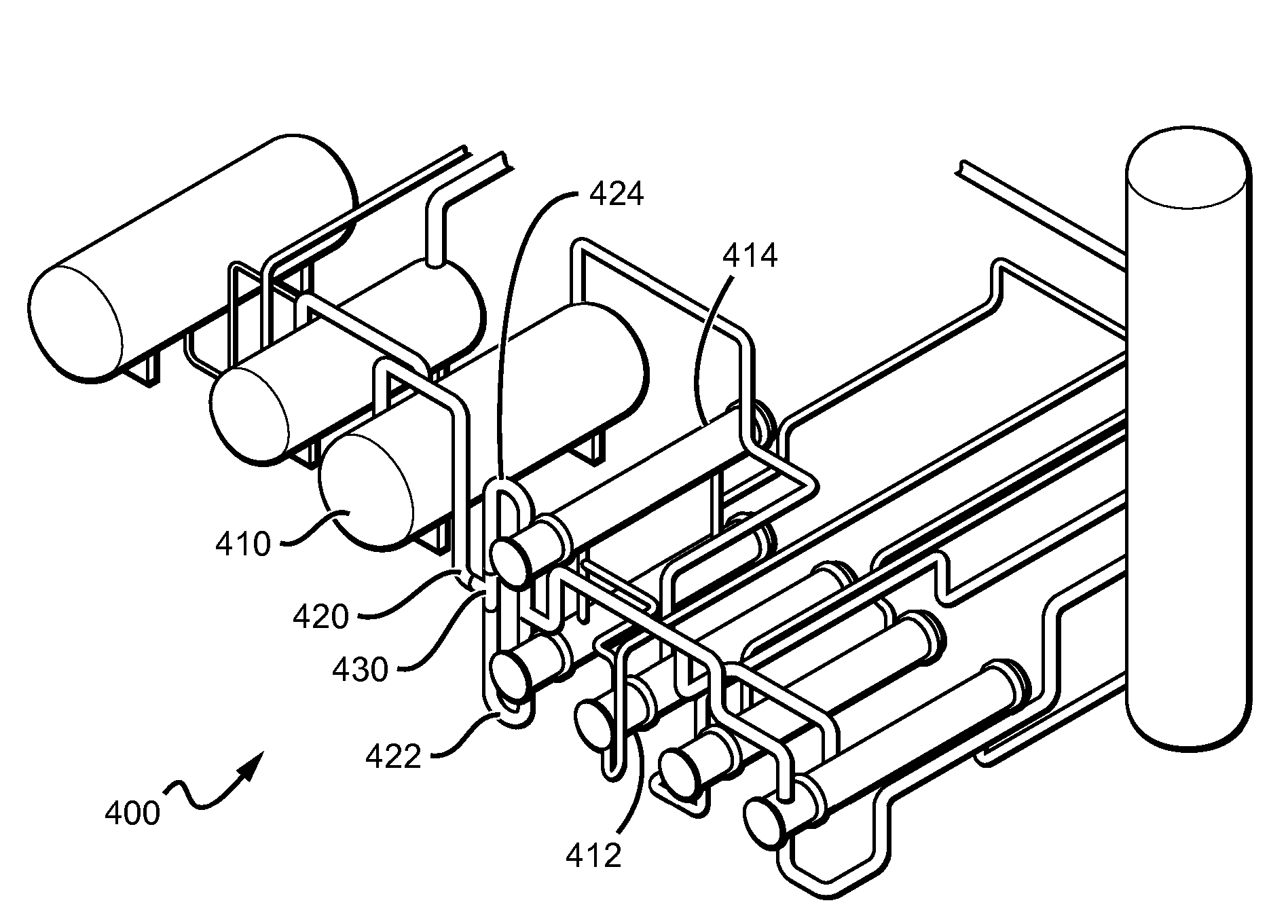

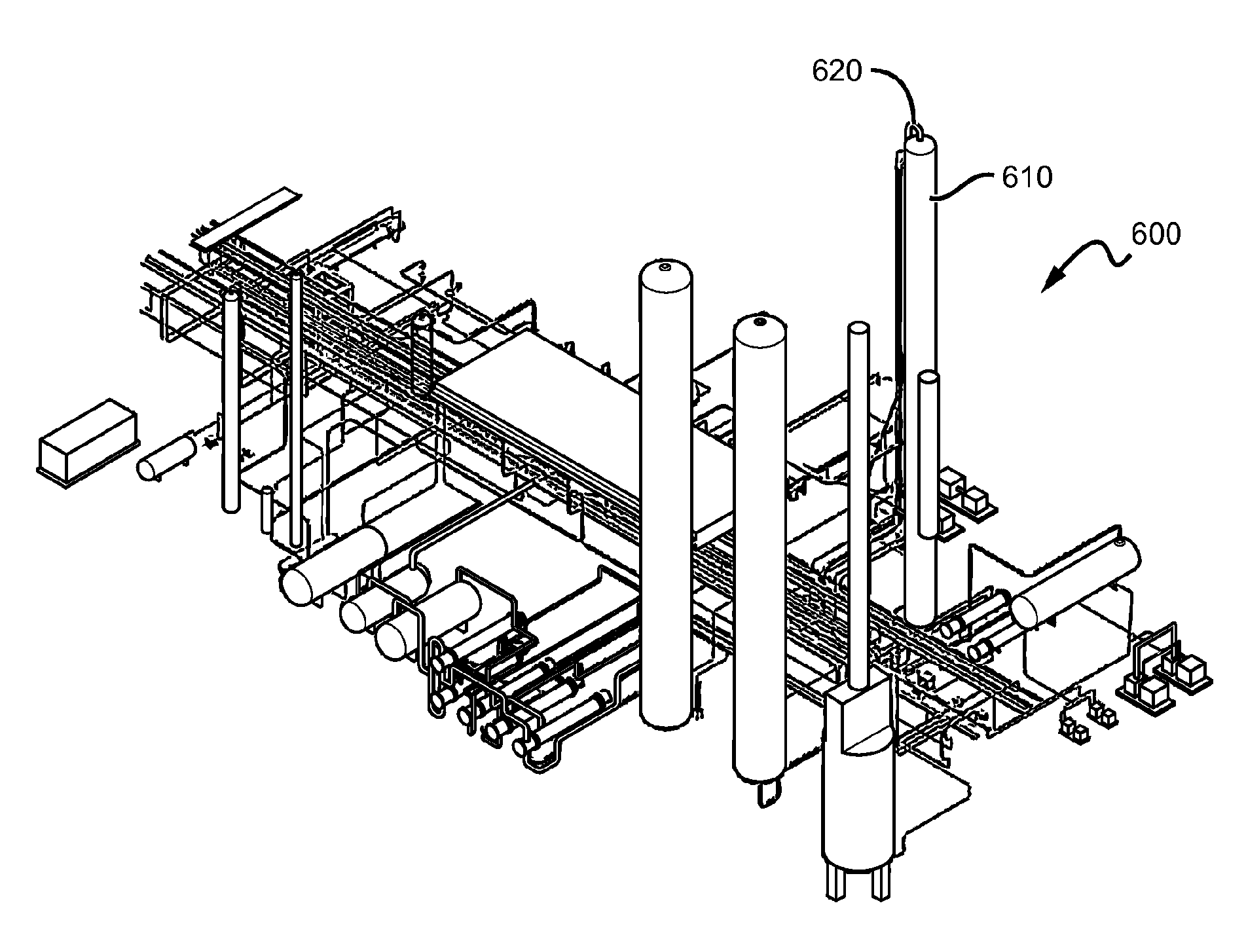

3D plant modeling systems and methods

InactiveUS20130035904A1Function can be ensuredGeometric CADConfiguration CADBill of materialsPlant models

Systems and methods for leveraging a preliminary plant model to create a detailed physical plant model are presented. The system stores instances of component primitives, and can utilize stored geometries of the component primitives to identify a plurality of physical components to form a physical plant model. The physical plant model can realize at least a portion of the component runs based on equations and mapping definitions that establish relationships among the geometries of the equipment and piping. The components of the physical plant model can be mapped to catalog items based on the geometries of the components. After translation, a bill of materials listing the physical plant model components can be produced.

Owner:FLUOR TECH CORP

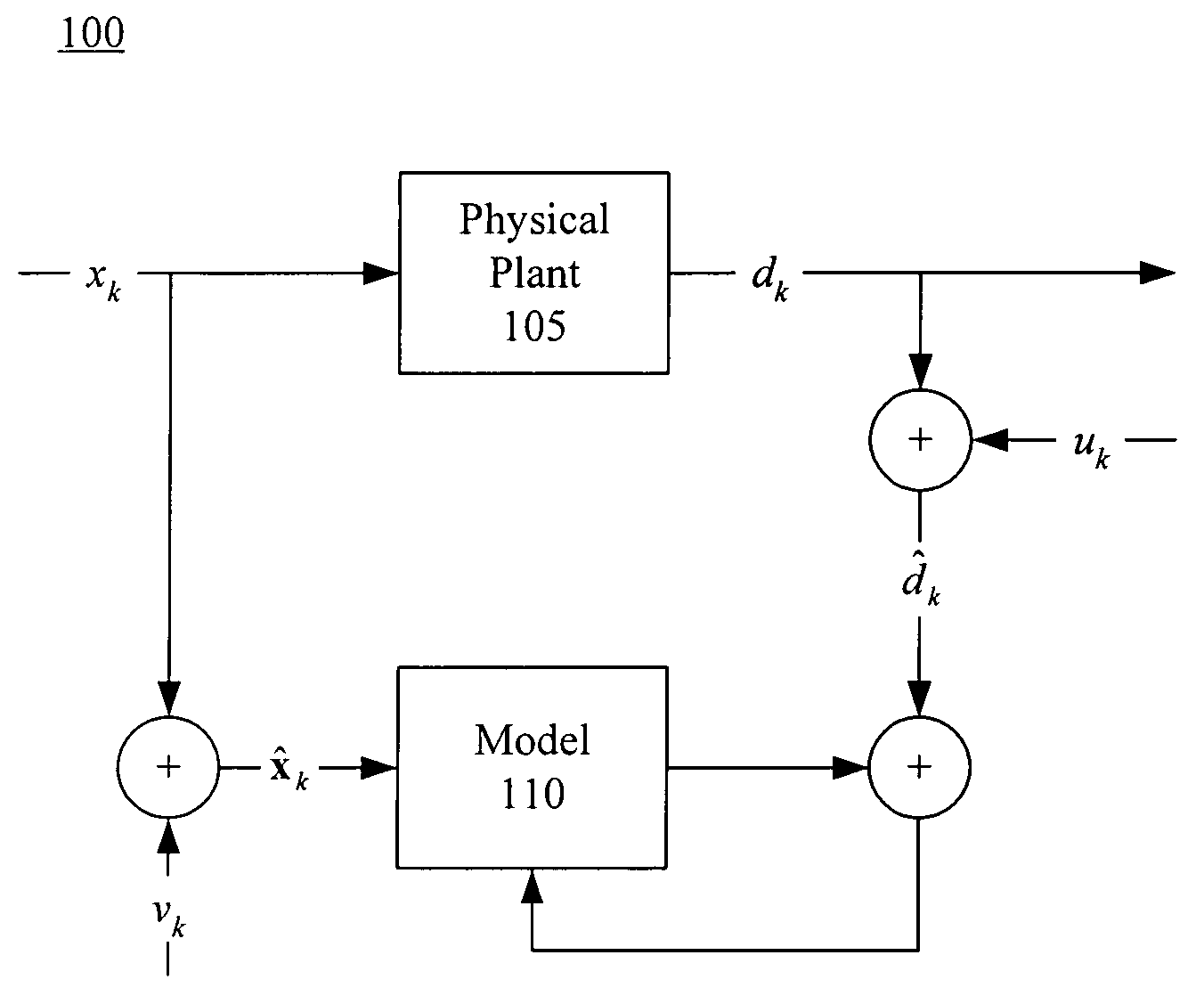

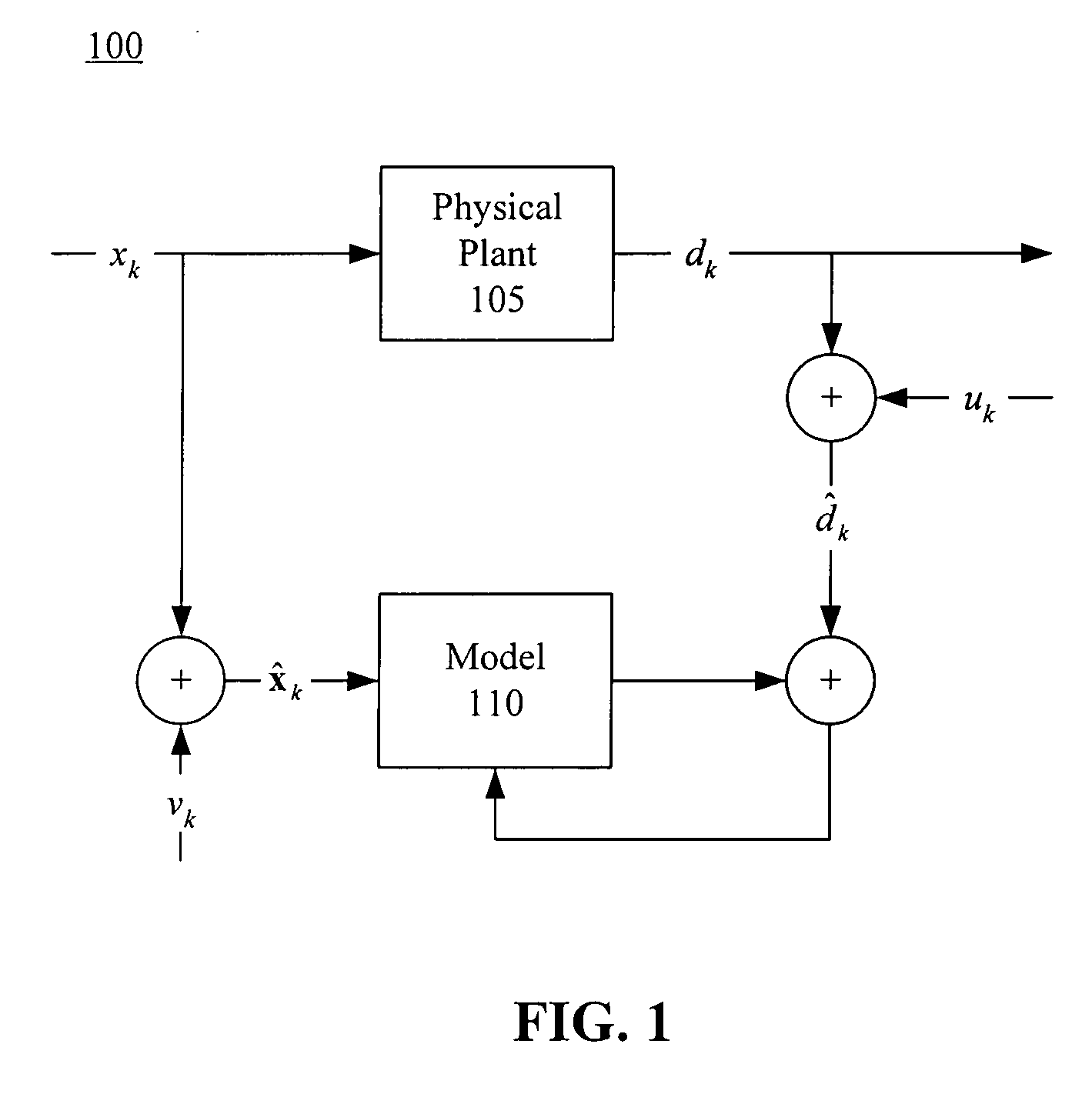

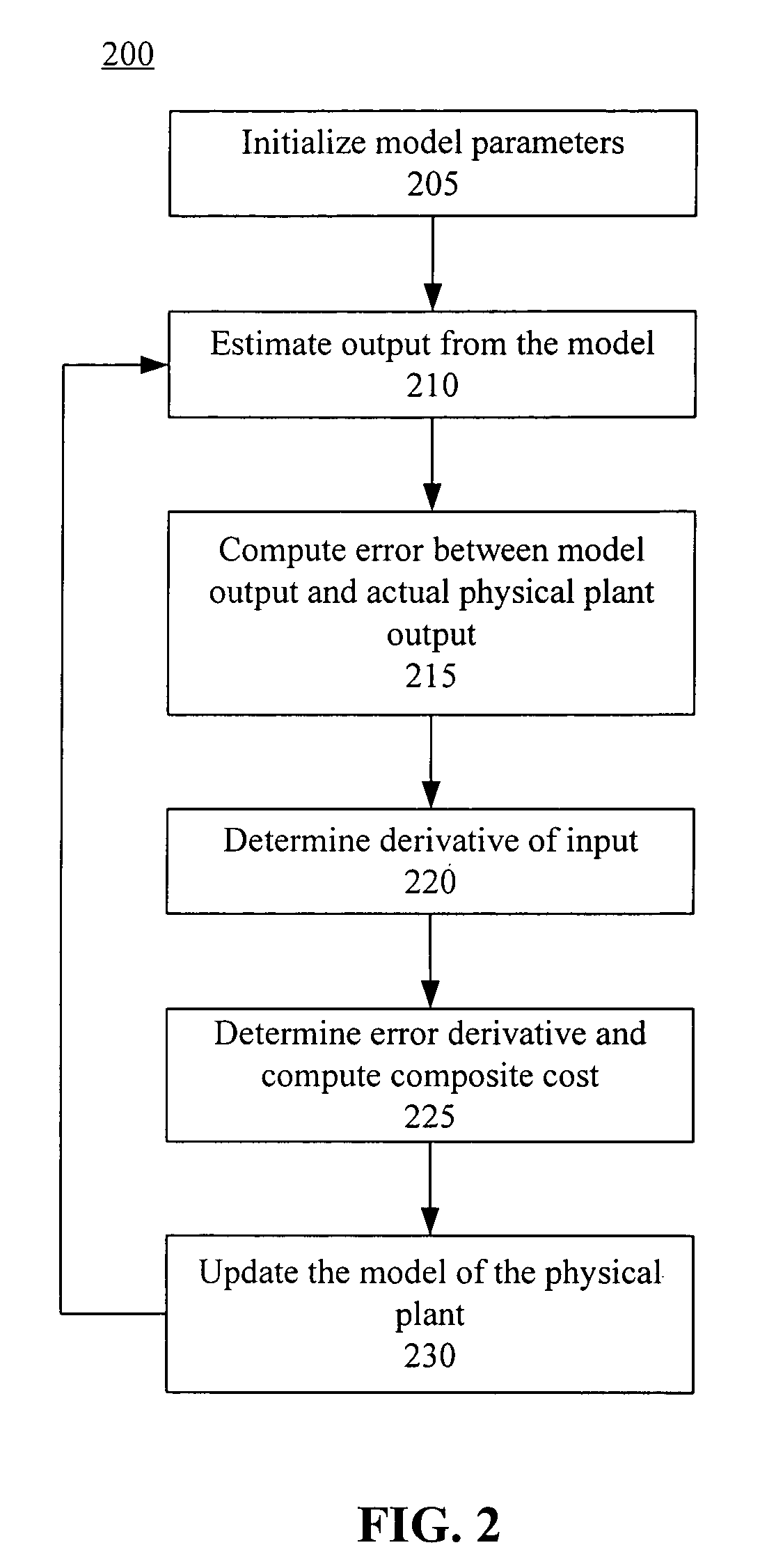

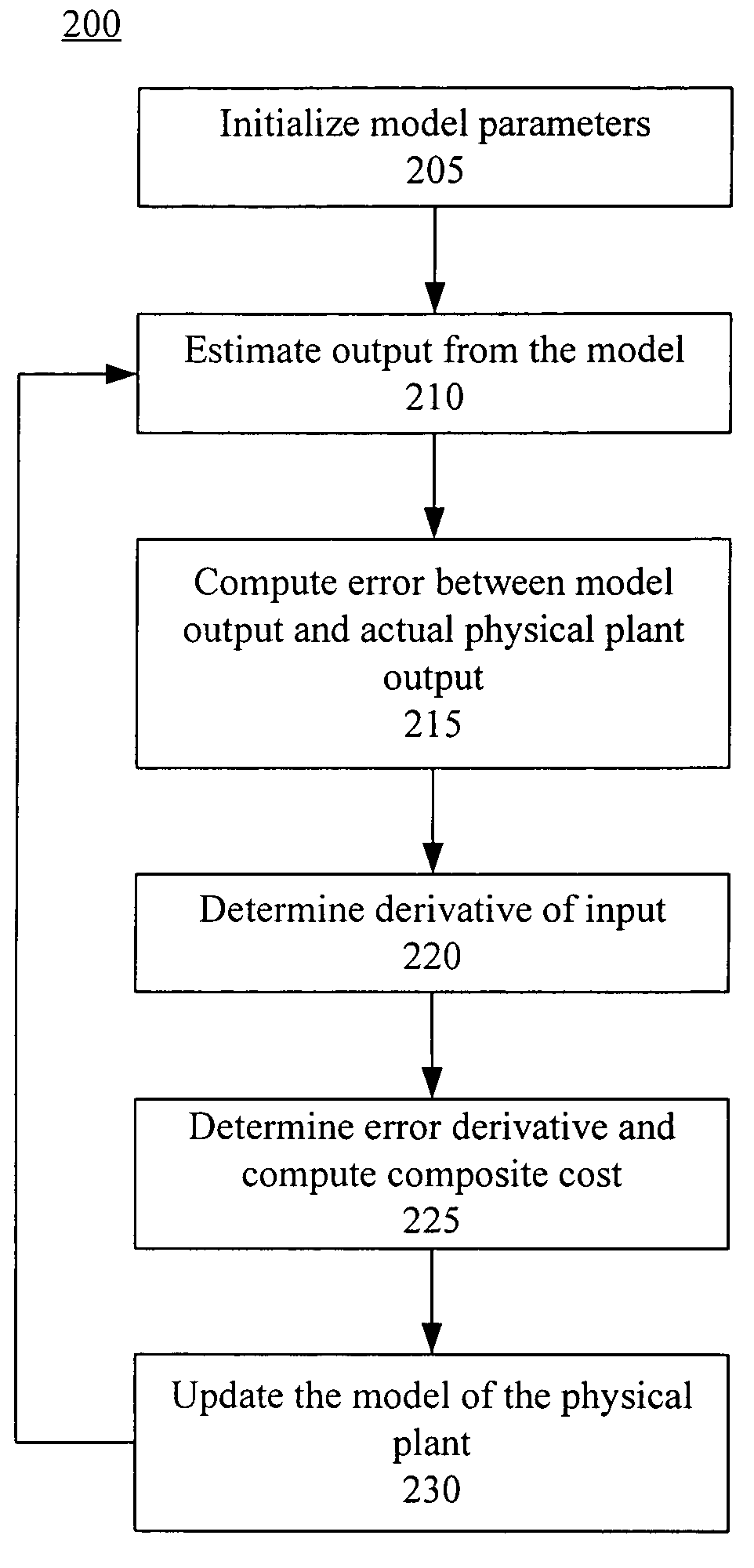

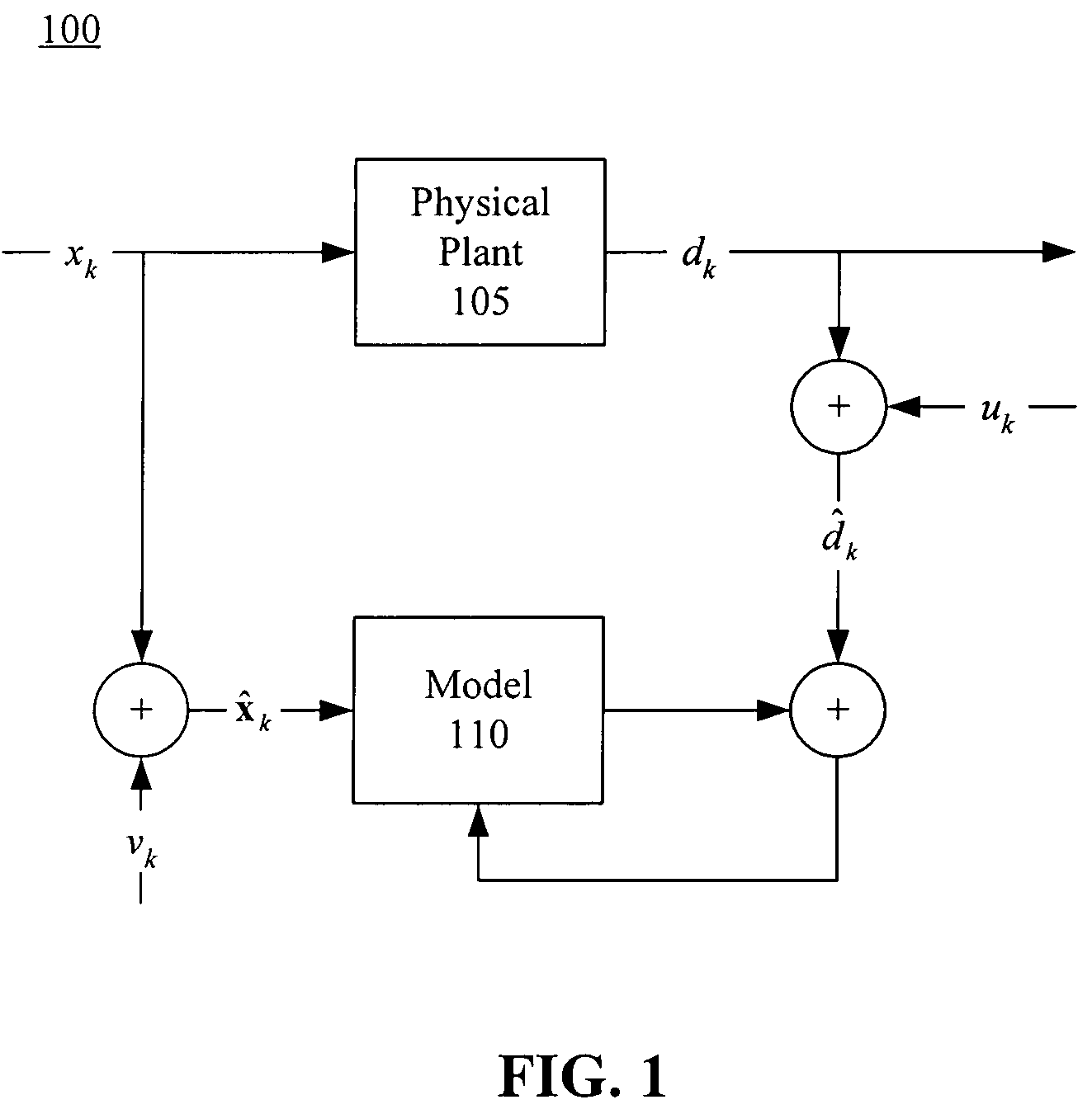

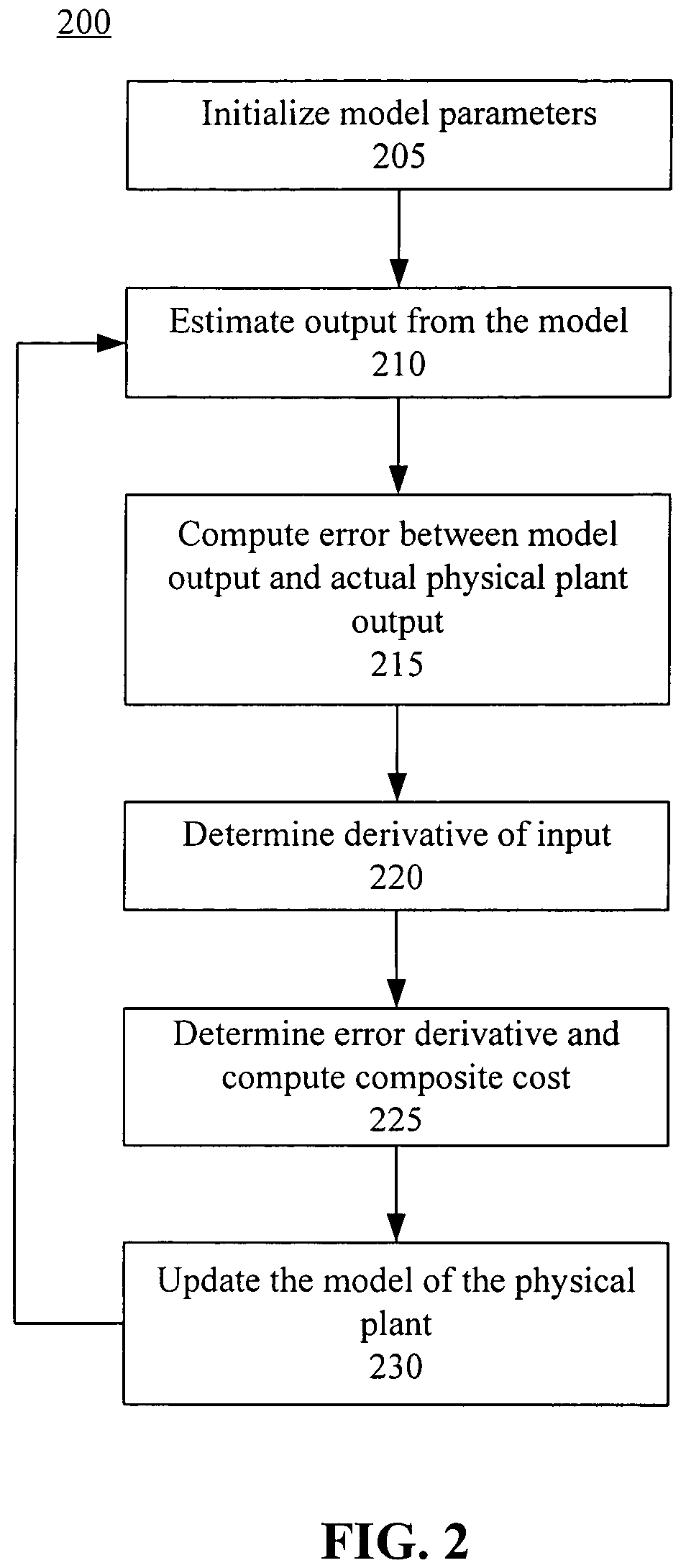

Accurate linear parameter estimation with noisy inputs

InactiveUS20050027494A1Reduce in quantityThe result is accurateEar treatmentComputation using non-denominational number representationErrors and residualsLinearity

A method of building a model for a physical plant in the presence of noise can include initializing the model of the physical plant, wherein the model is characterized by a parameter vector, estimating an output of the model, and computing a composite cost comprising a weighted average of an error between the estimated output from the model and an actual output of the physical plant, and a derivative of the error. The method further can include determining a step size and a model update direction. The model of the physical plant can be updated. The updating step can be dependent upon the step size. Another embodiment can include the steps of determining a Kalman gain and determining an error vector comprised of two entries weighted by a scalar parameter.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

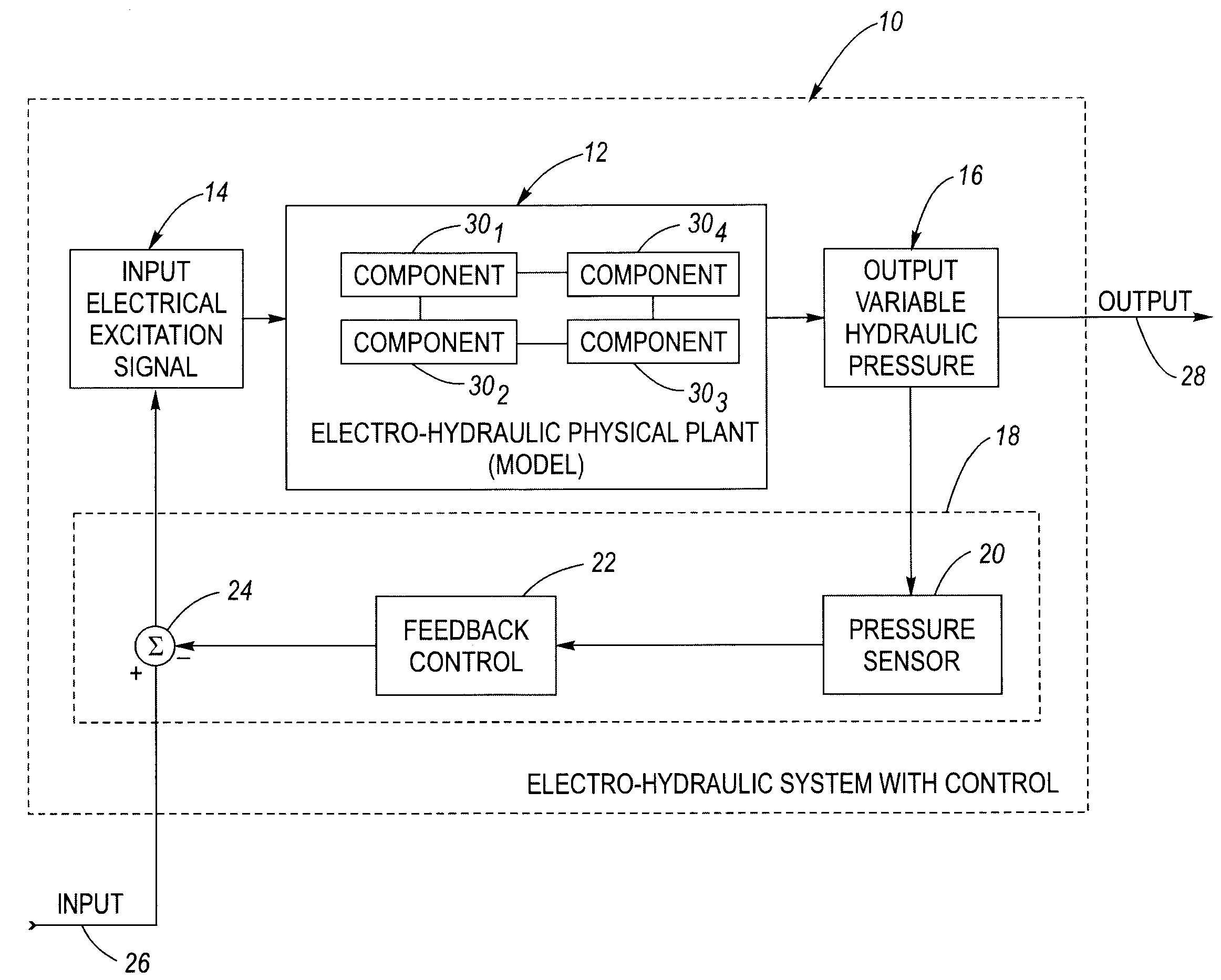

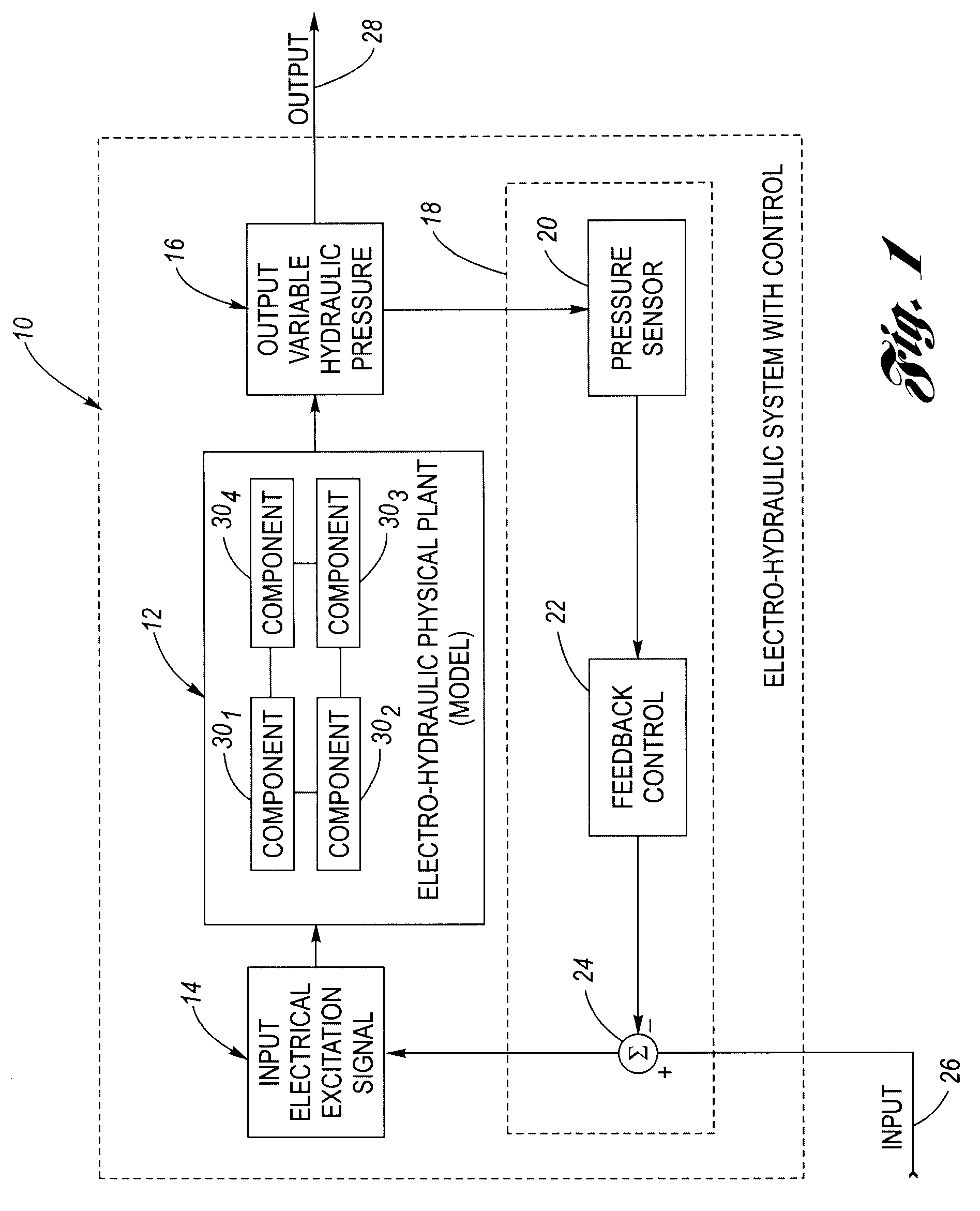

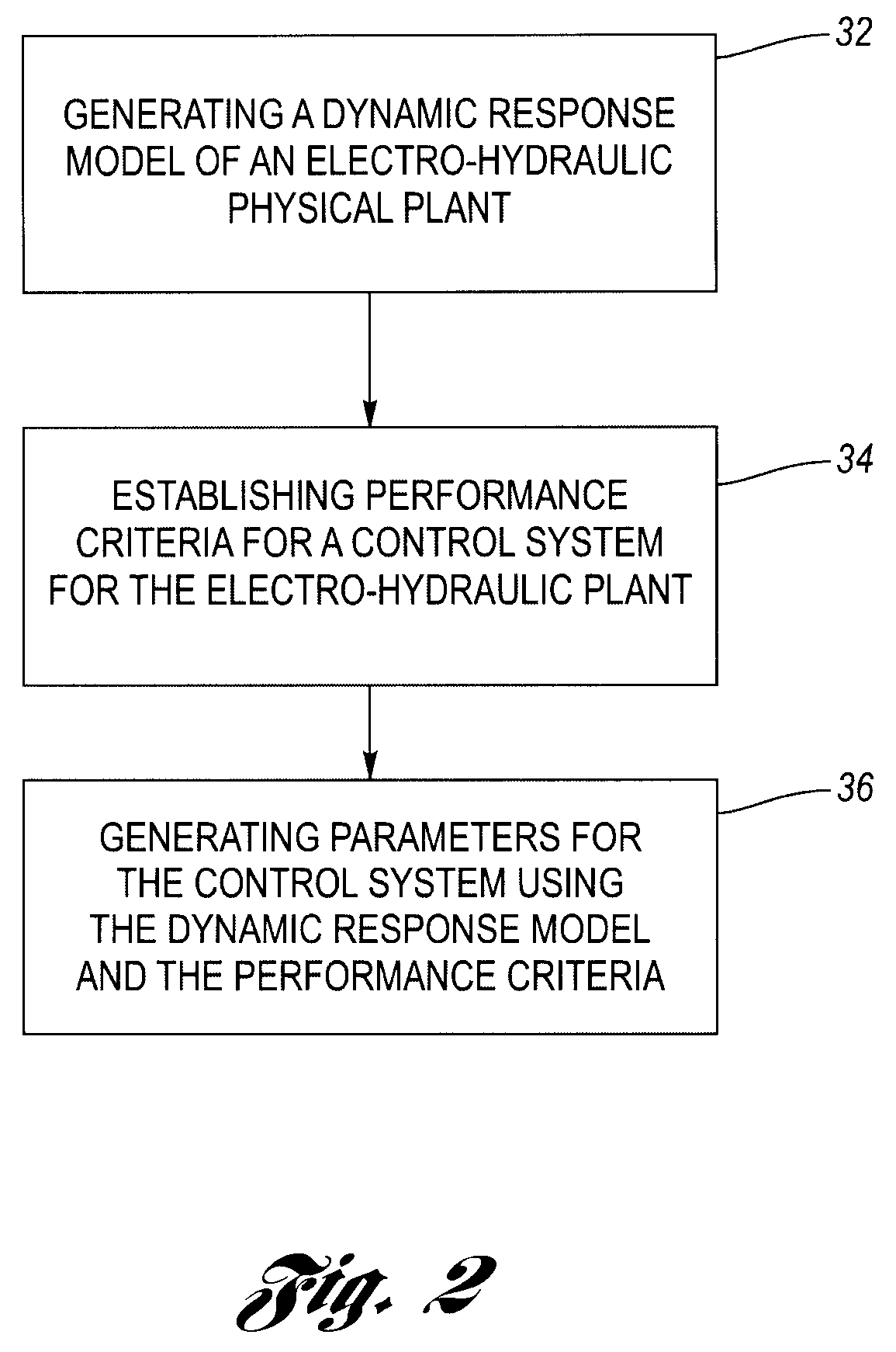

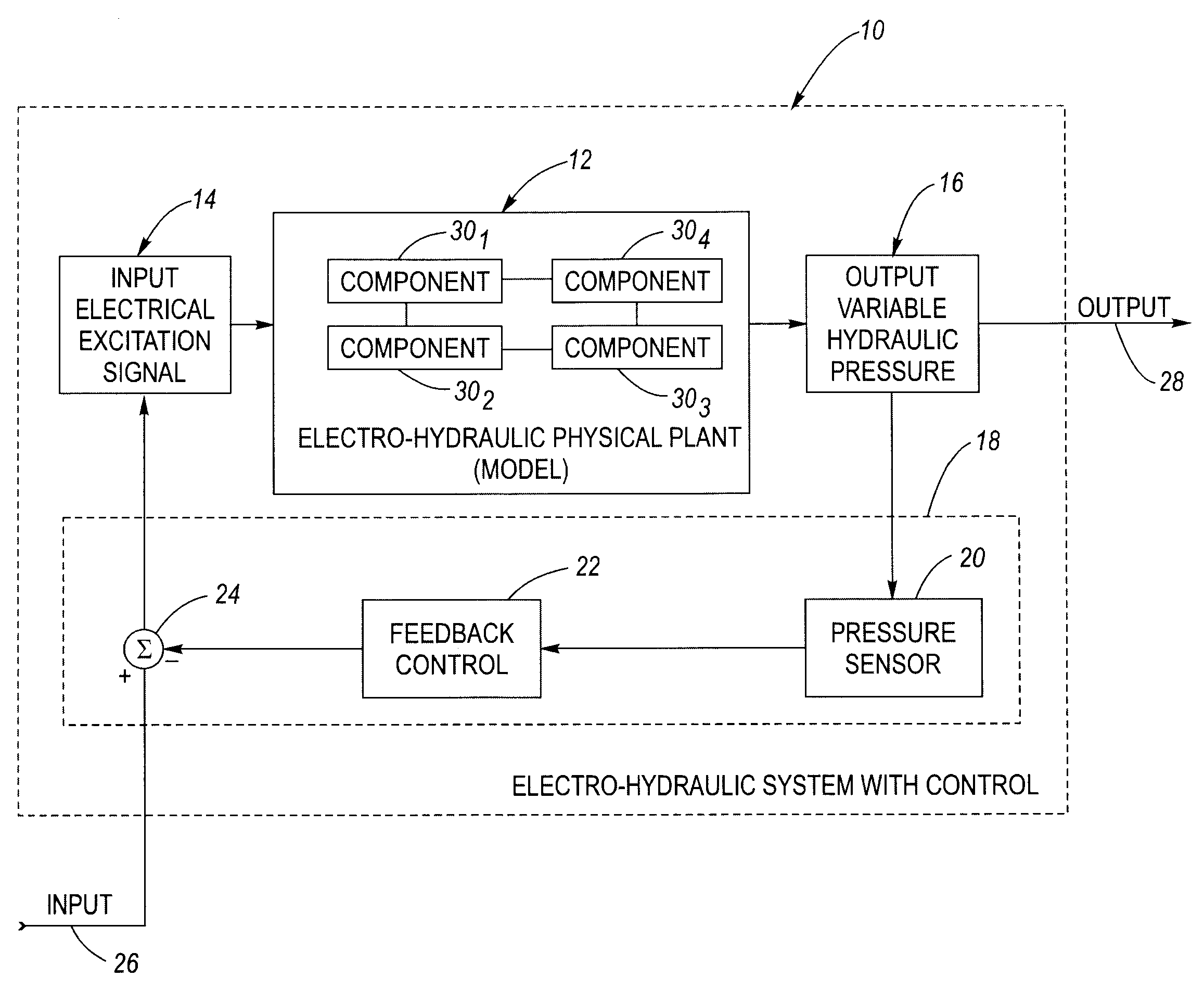

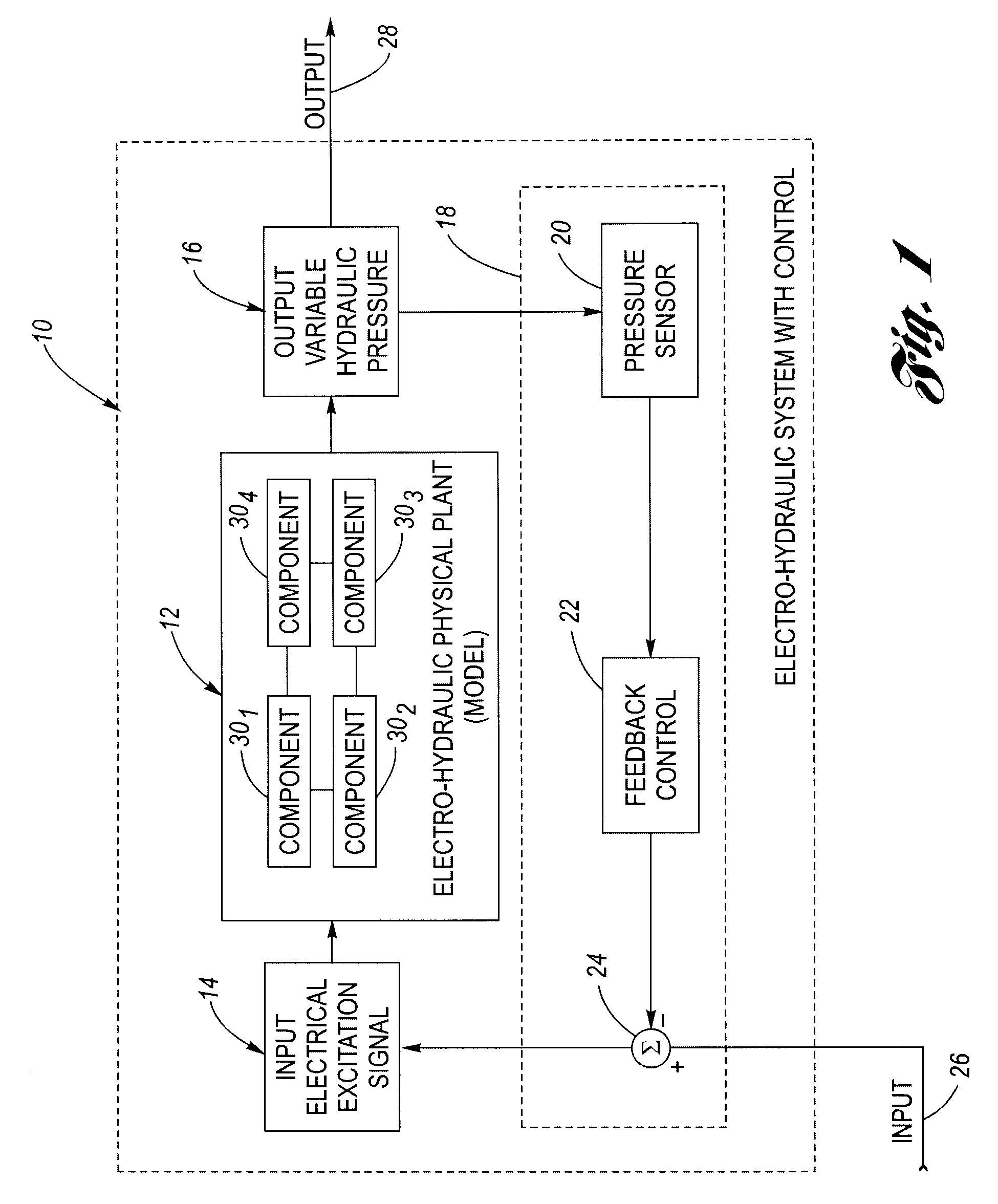

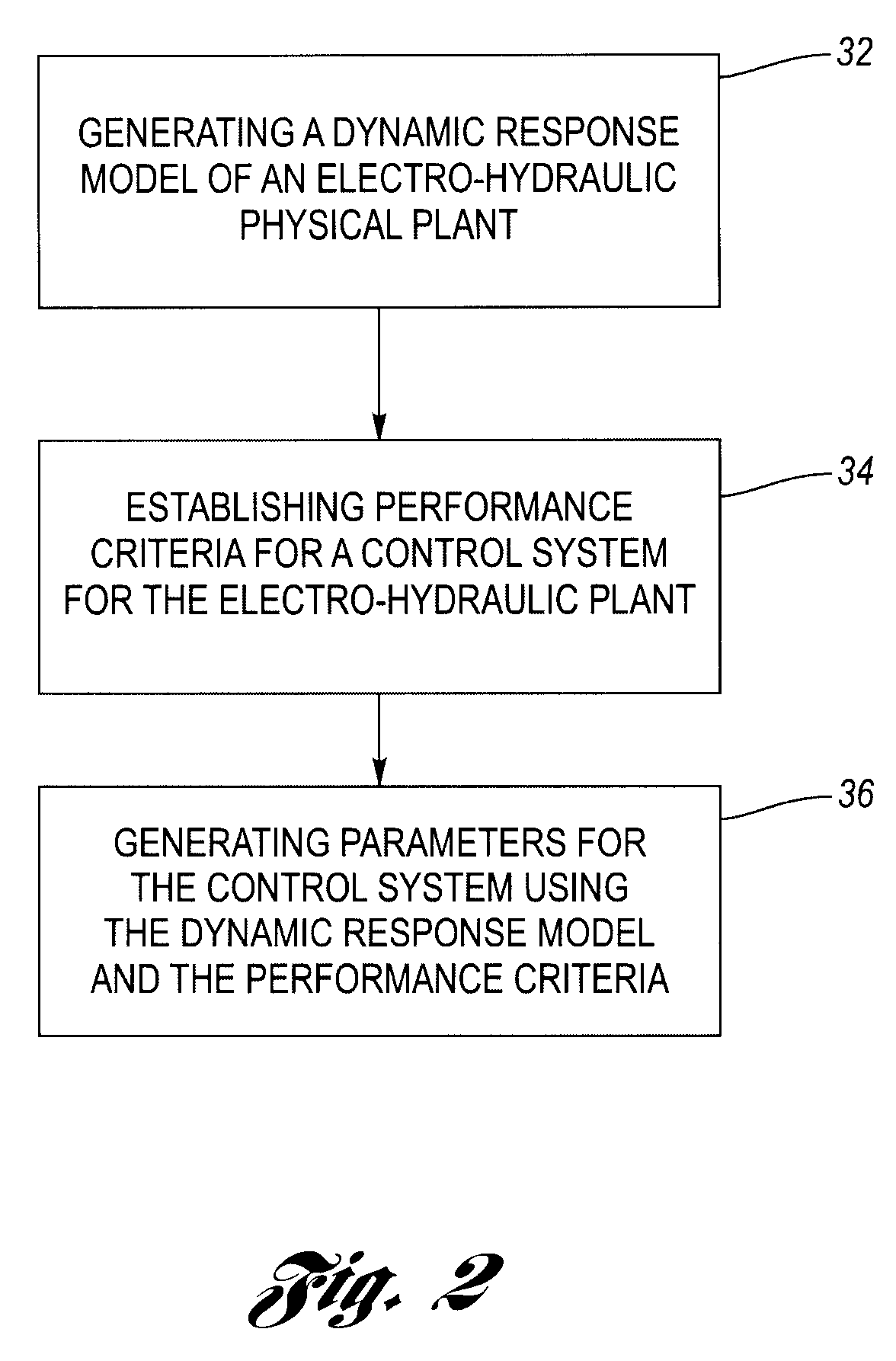

Method for generating an electro-hydraulic model for control design

ActiveUS7689309B2Shorten the development cycleSimulator controlAnalogue computers for nuclear physicsDamping factorOperating point

The dynamic response characteristics of an electro-hydraulic (EH) physical plant is represented by a model. The model includes a series of second order transfer functions, one for each operating point, of the EH physical plant. Command pressure, overshoot, rise time, damping coefficient, natural frequency and gain parameters are determined in developing each transfer function. The model can be used to advance the time in which the design and development of a control system for the EH physical plant can begin.

Owner:DELPHI TECH IP LTD

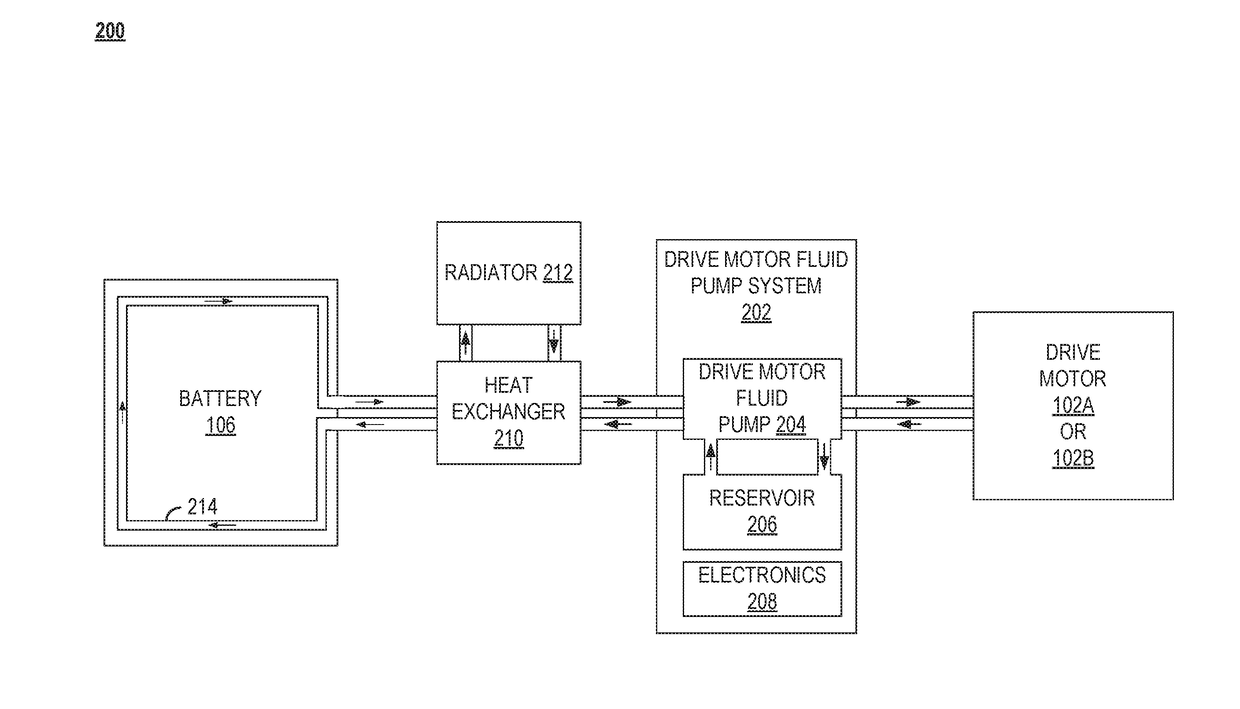

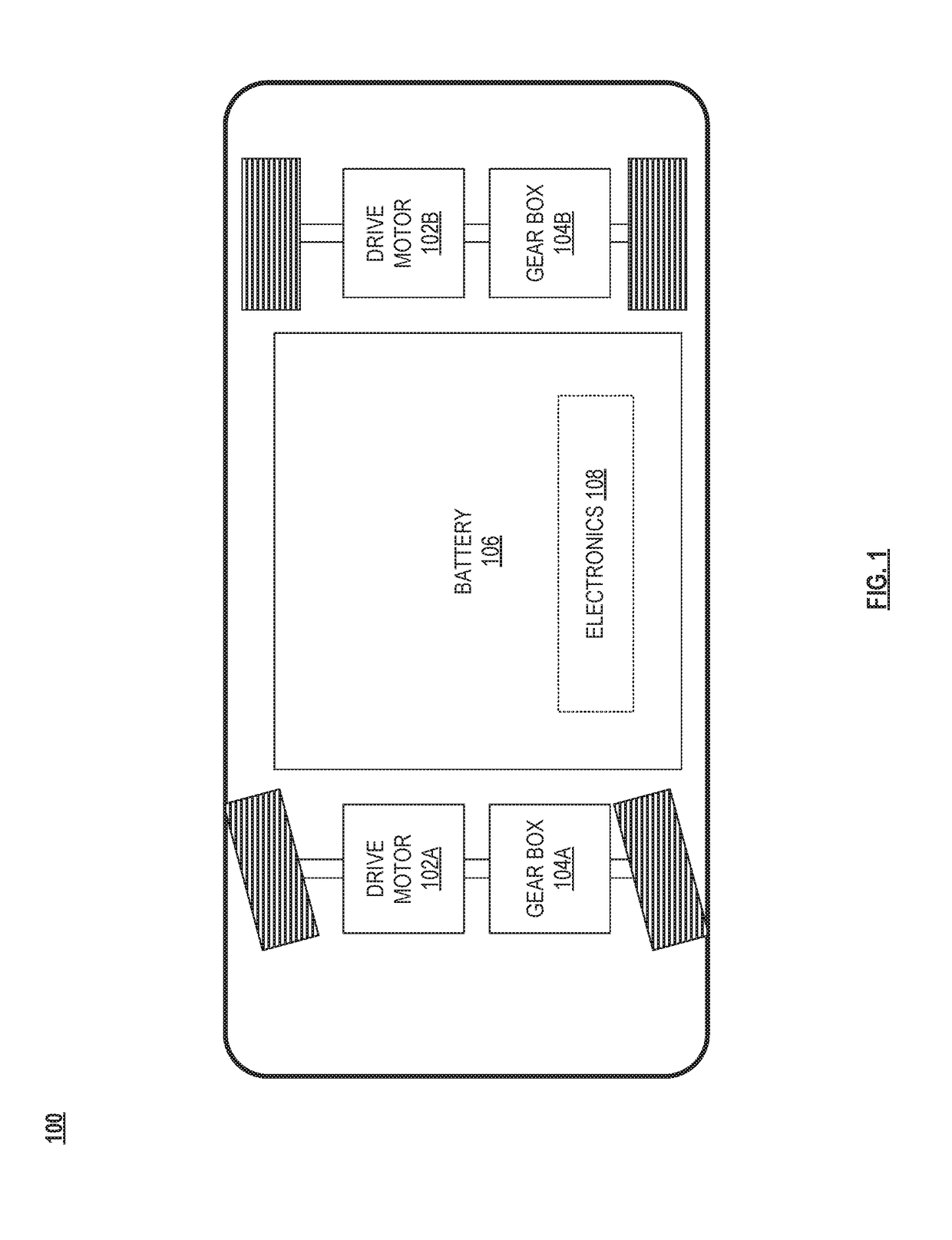

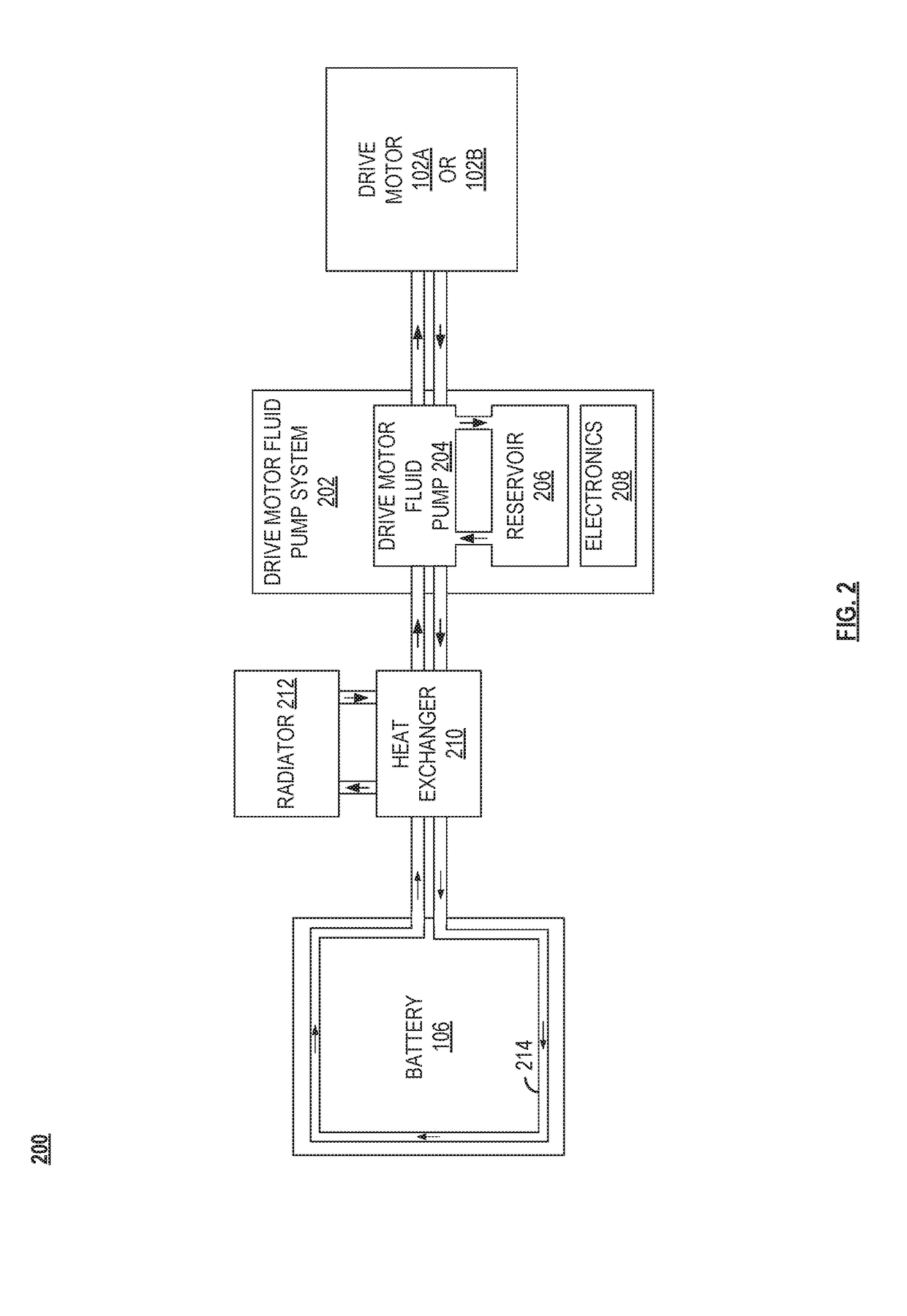

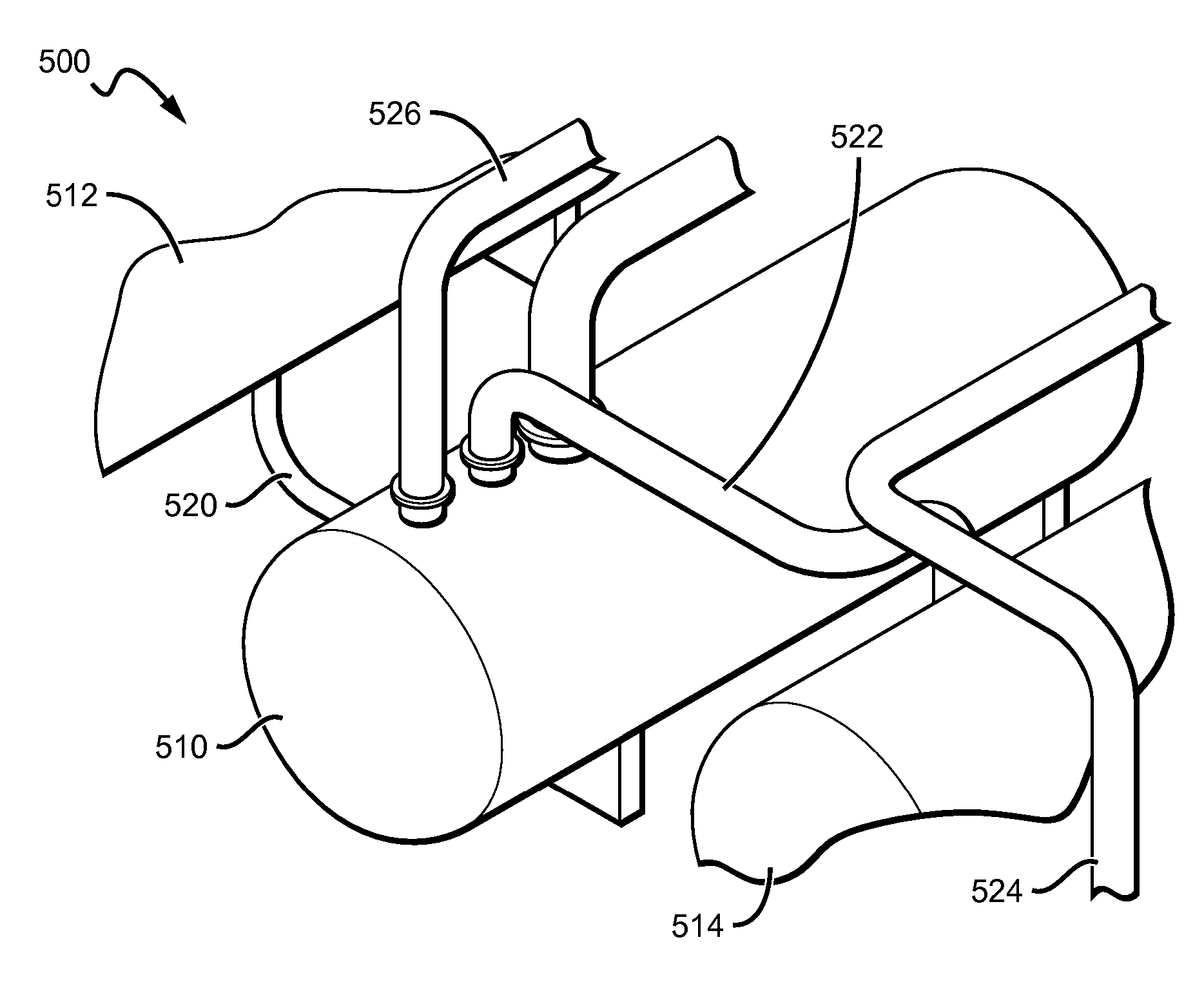

Integrated coolant bottle assembly

An integrated coolant bottle assembly includes a reservoir configured for use in a thermal system. Examples of such thermal systems include a cooling / heating system of a battery powered electric vehicle, electric power generators (e.g., motor-based systems), other physical plant installations, etc. Such a reservoir includes a first section and a second section. The second section is joined to the first section at a reservoir interface thereby forming the reservoir that is configured for storage and / or flow of a liquid medium. The first section may include an integrated channel that provides a pathway for the flow of the liquid medium. The reservoir may also include a component interface configured to facilitate connection of a component thereto (e.g., a pump, a battery pump, a powertrain pump, a chiller, a heater, a filter, an aerator, a valve, a connector, a fan, or a radiator).

Owner:TESLA INC

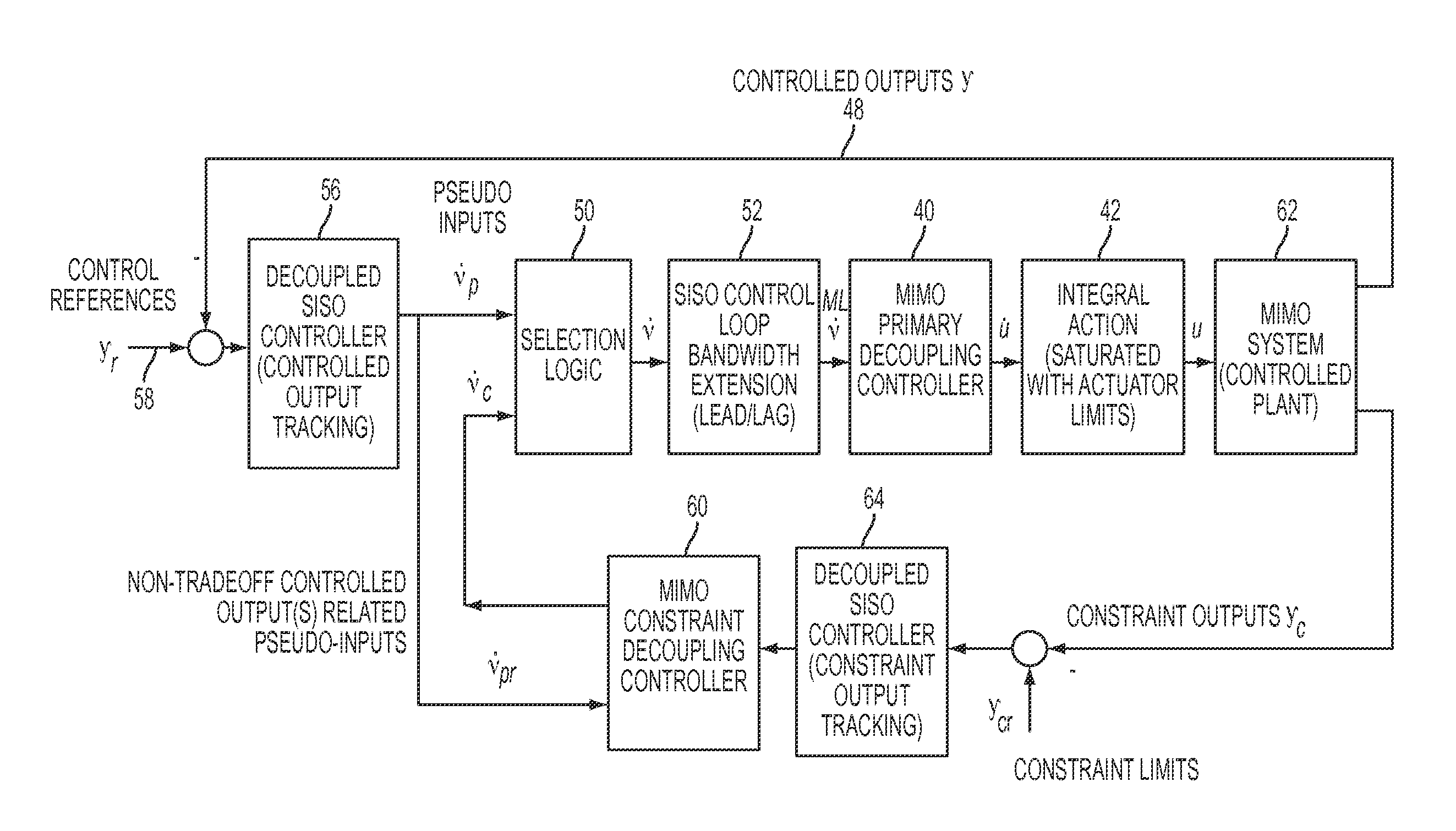

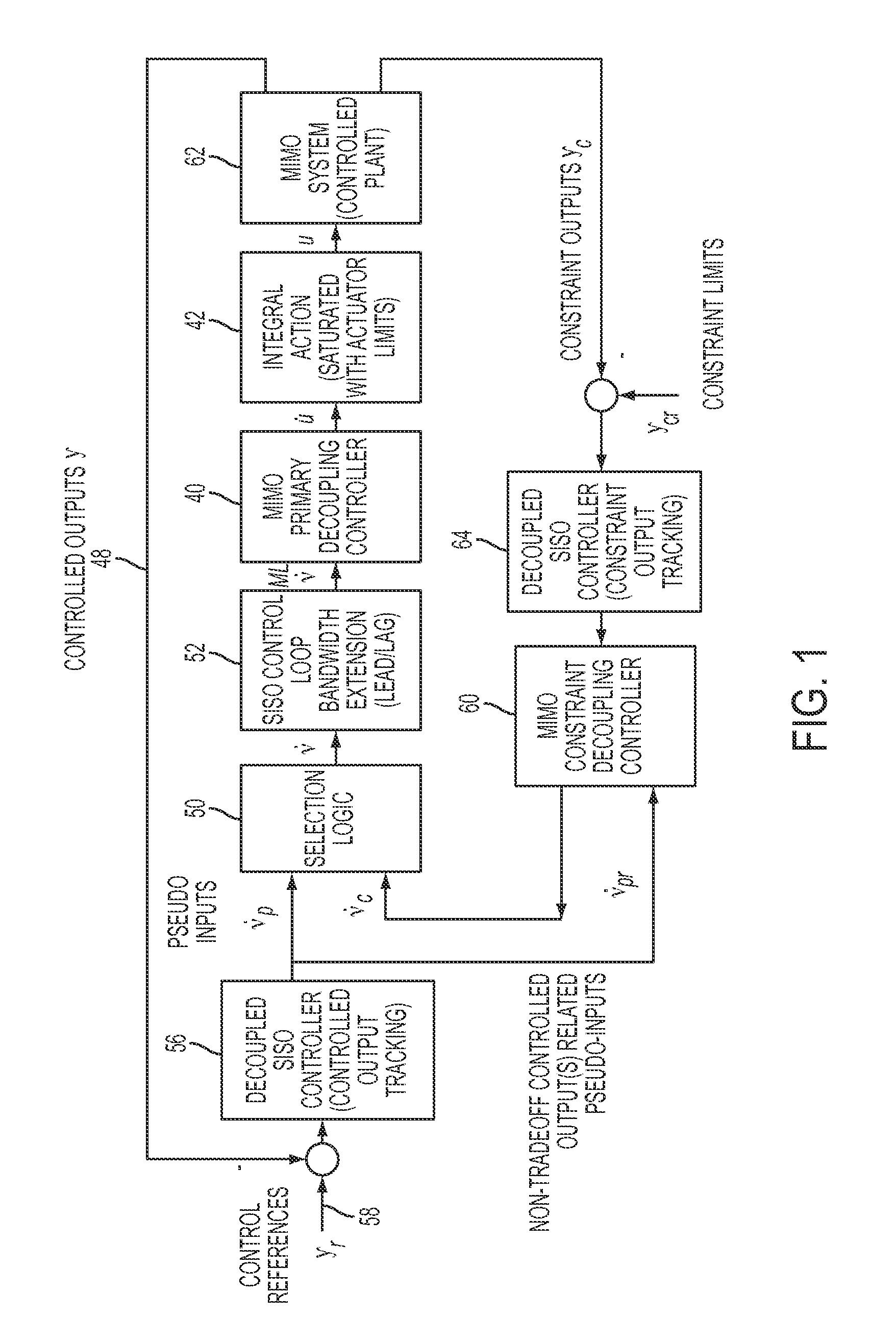

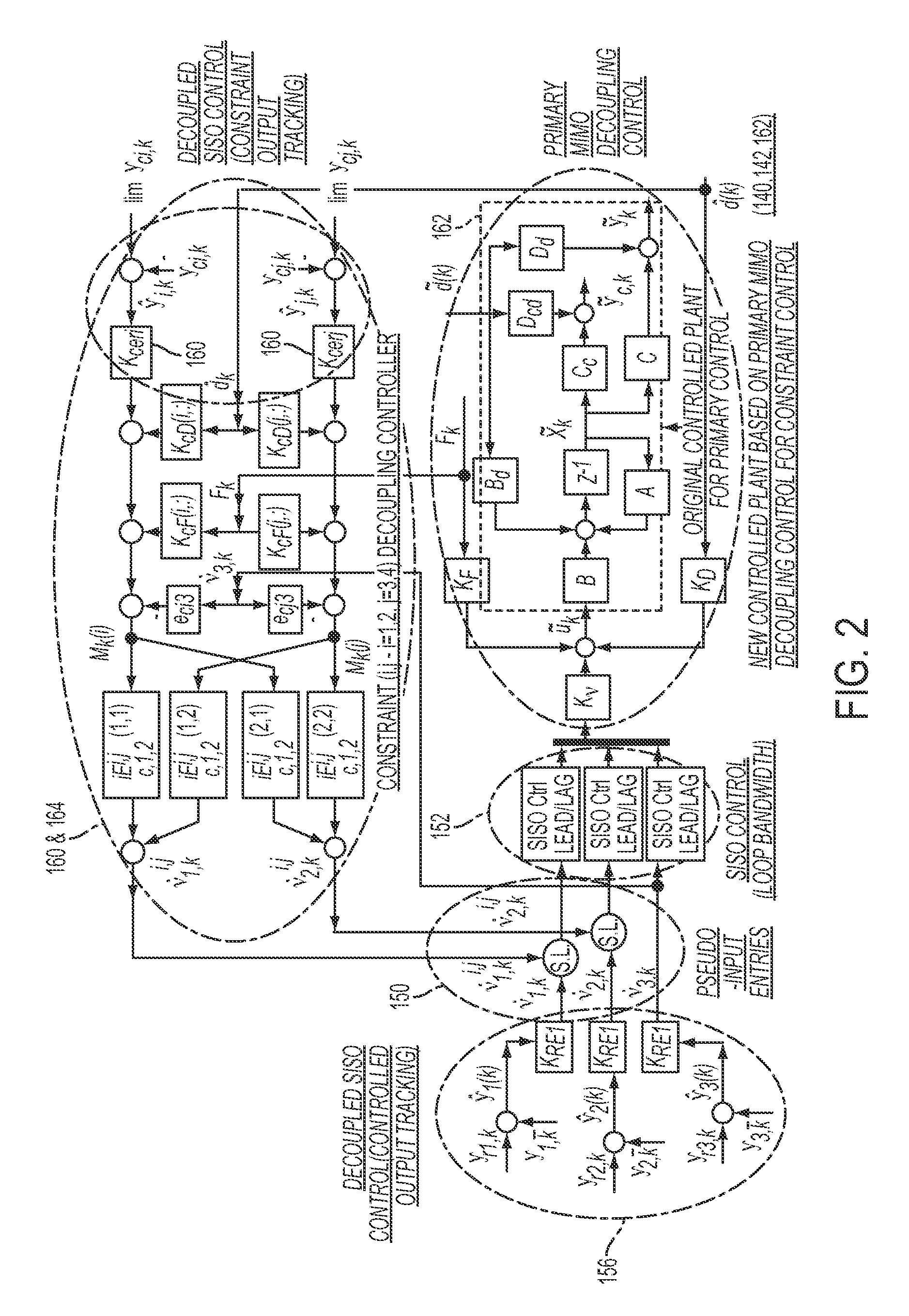

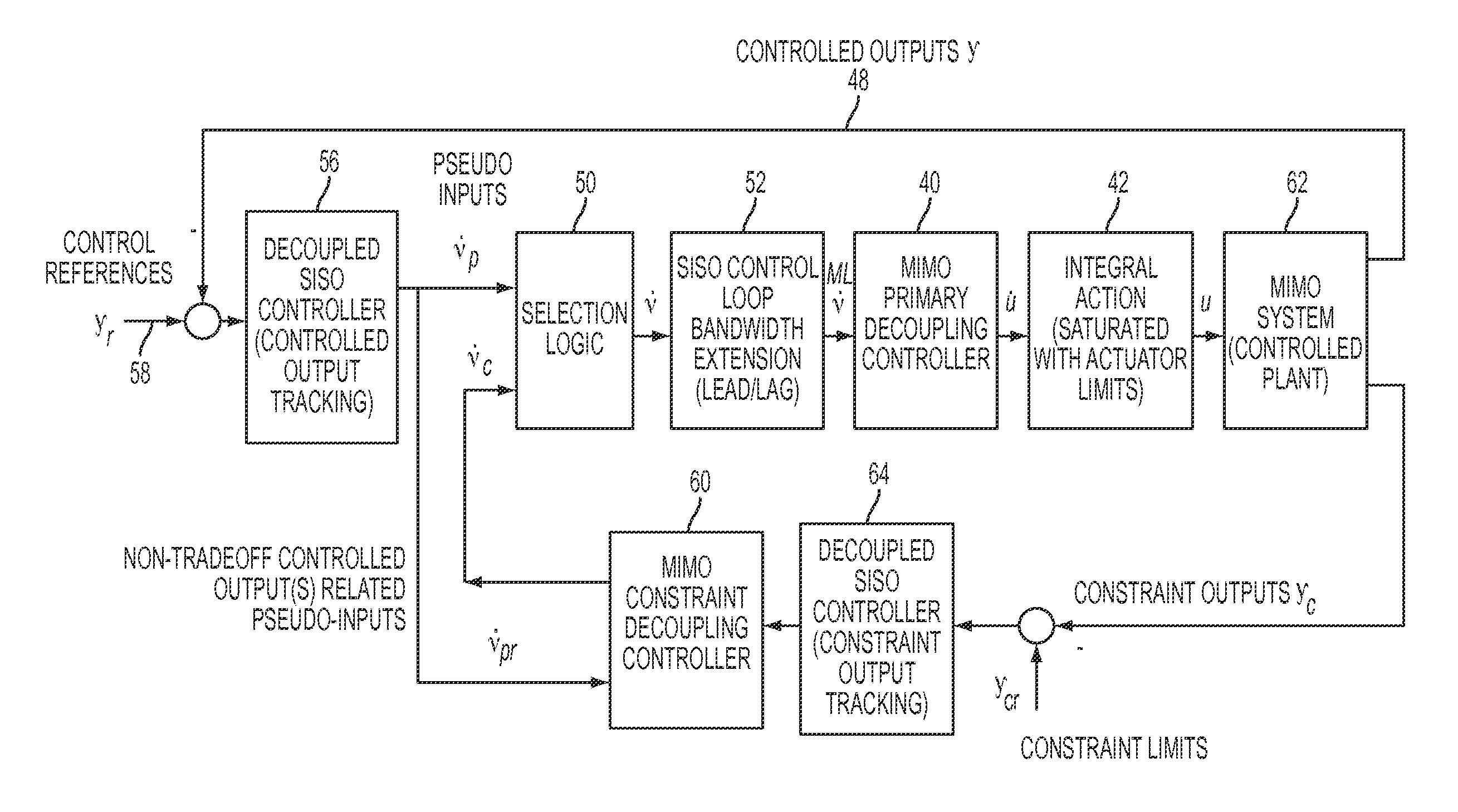

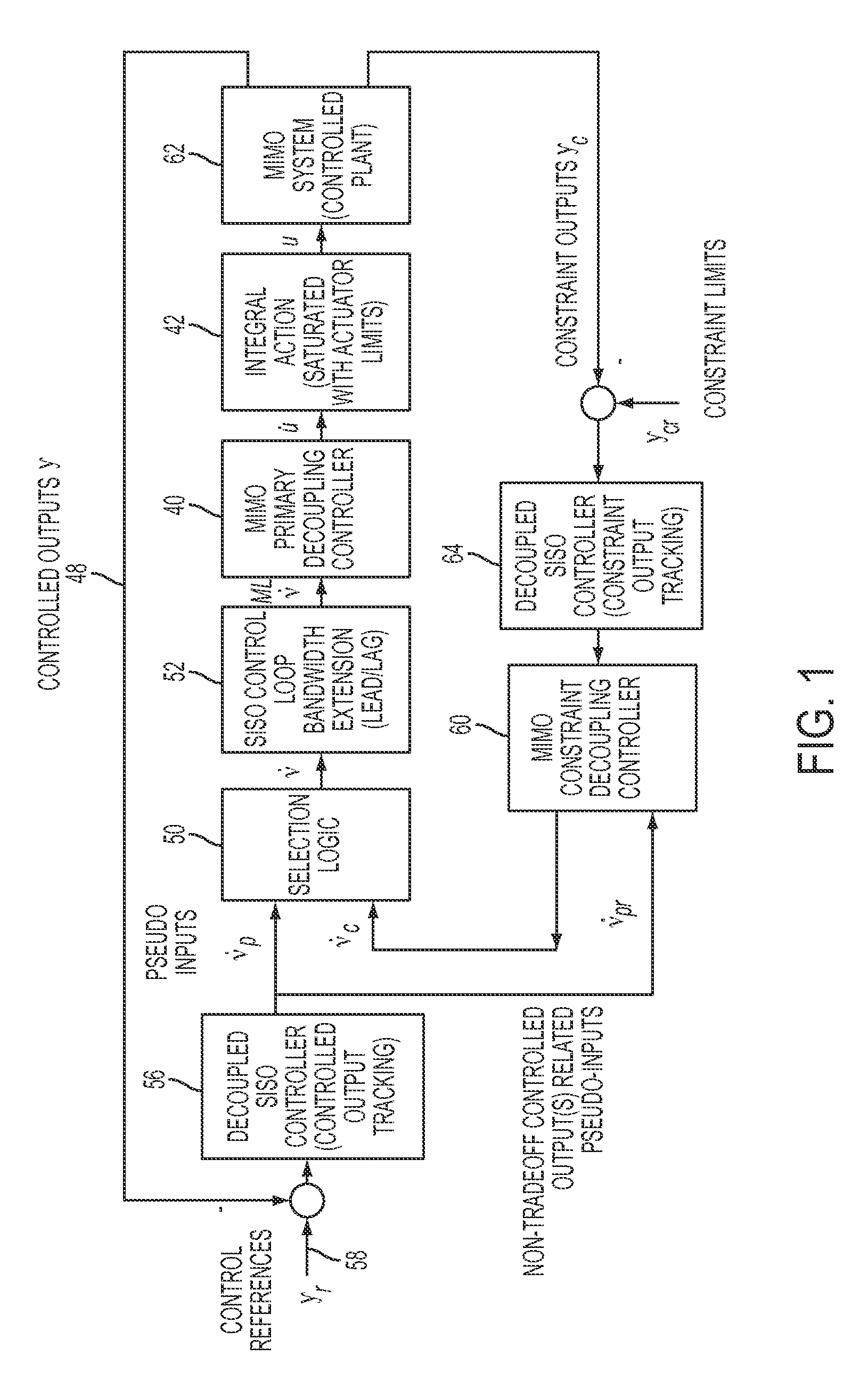

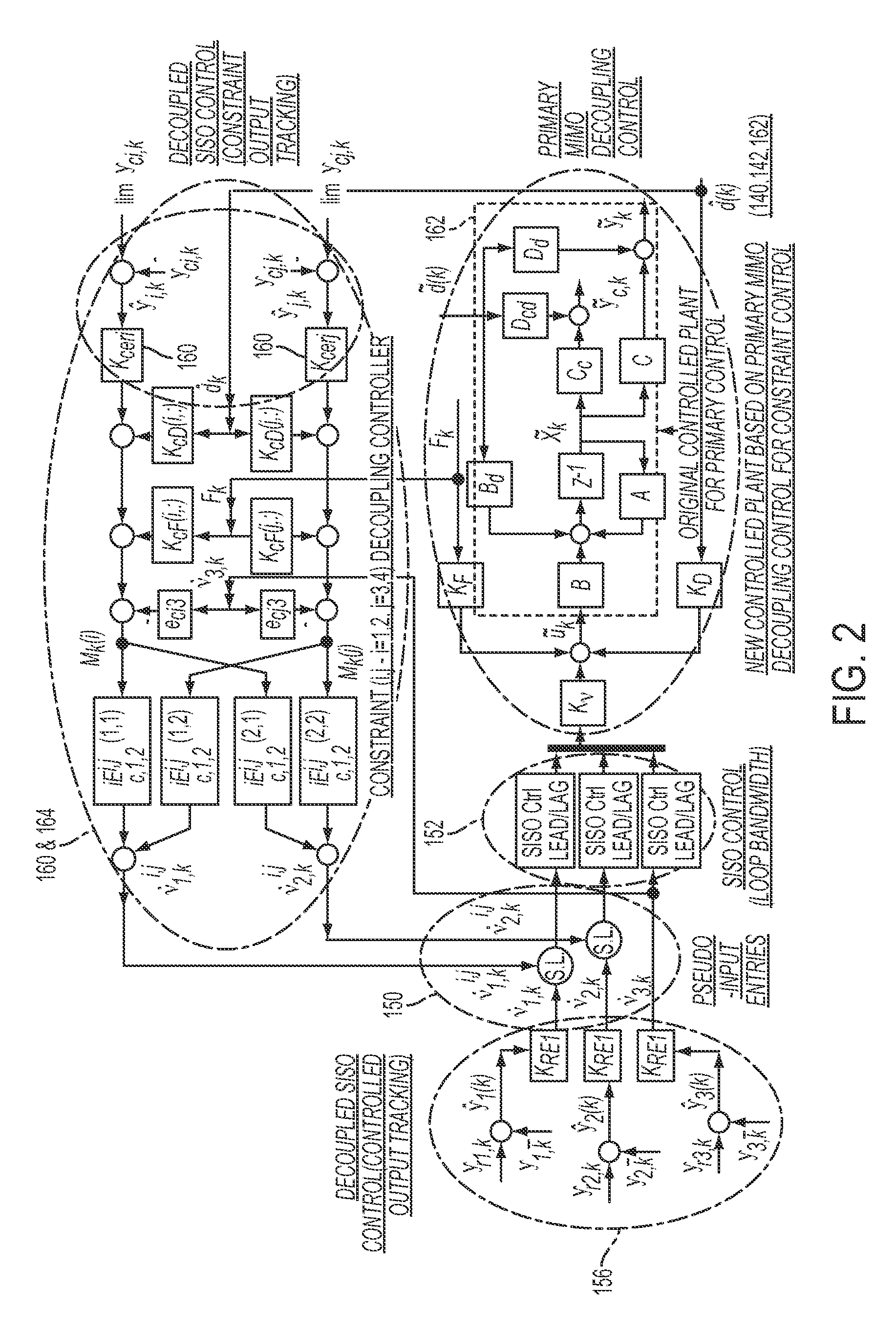

Methods and Apparatuses for Advanced Multiple Variable Control with High Dimension Multiple Constraints

ActiveUS20130211550A1Choose simpleImprove coordinationElectric controllersIgnition automatic controlConstraint controlTrade offs

A method and apparatus for multiple variable control of a physical plant with high dimension multiple constraints, includes: mathematically decoupling primary controlled outputs of a controlled physical plant from one another and shaping the pseudo inputs / controlled outputs desired plant dynamics; tracking primary control references and providing pseudo inputs generated by desired primary output tracking for selection; mathematically decoupling constraints from one another; mathematically decoupling constraints from non-traded off primary controlled outputs of the controlled physical plant; shaping the pseudo inputs / constraint outputs desired plant dynamics; tracking constraint control limits; providing pseudo inputs generated by desired constraint output tracking for selection; selecting the most limiting constraints and providing the smooth pseudo inputs for the decoupled primary control; and controlling the physical plant using the decoupled non-traded off primary controlled outputs and the decoupled selected most limiting constraints.

Owner:GENERAL ELECTRIC CO

Method for generating an electro-hydraulic model for control design

ActiveUS20090012772A1Reduce product development timeShorten the development cycleSimulator controlAnalogue computers for nuclear physicsDamping factorOperating point

The dynamic response characteristics of an electro-hydraulic (EH) physical plant is represented by a model. The model includes a series of second order transfer functions, one for each operating point, of the EH physical plant. Command pressure, overshoot, rise time, damping coefficient, natural frequency and gain parameters are determined in developing each transfer function. The model can be used to advance the time in which the design and development of a control system for the EH physical plant can begin.

Owner:DELPHI TECH IP LTD

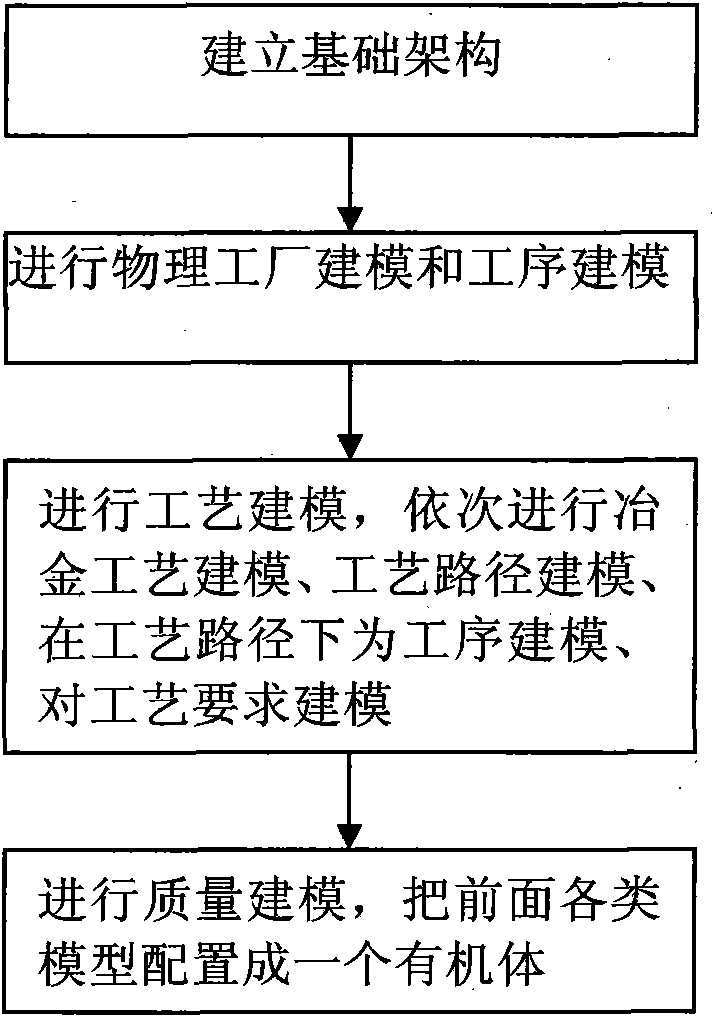

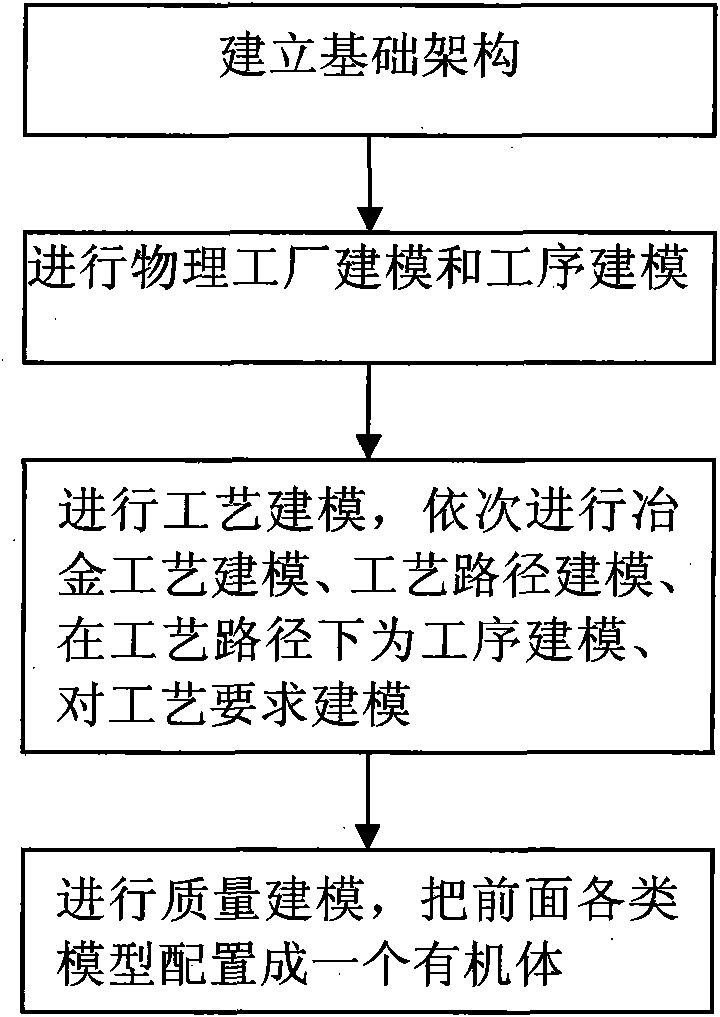

Metallurgical quality modeling method based on factory modeling

ActiveCN102314527AHighly configurableQuick and efficient design meansSpecial data processing applicationsPhysical plantOrder of accuracy

The invention discloses a metallurgical quality modeling method based on factory modeling. The method comprises the following steps of: configuring effective dynamic association, wherein an industrial base formed by a static model serves as a base; decomposing a metallurgical regulation directed to production to production guidance and quality monitoring of a full flow in various aspect, such as a physical factory, a process rule, a quality requirement and the like, in a way of hierarchy through a pre-defined physical factory model and a process model; establishing association relations between the transverse process model and a longitudinal procedure process requirements in a production process, wherein different process requirements exist under different process routes; and determining a set of requirements under the same product catalog, the same standard, the same mark and the same precision requirement under some process through characteristic attributes, namely index and sequence number. The invention discloses a metallurgical quality model generated by the metallurgical quality modeling method based on factory modeling, so the manufacturing process of a metallurgical product is public, controllable and configurable.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

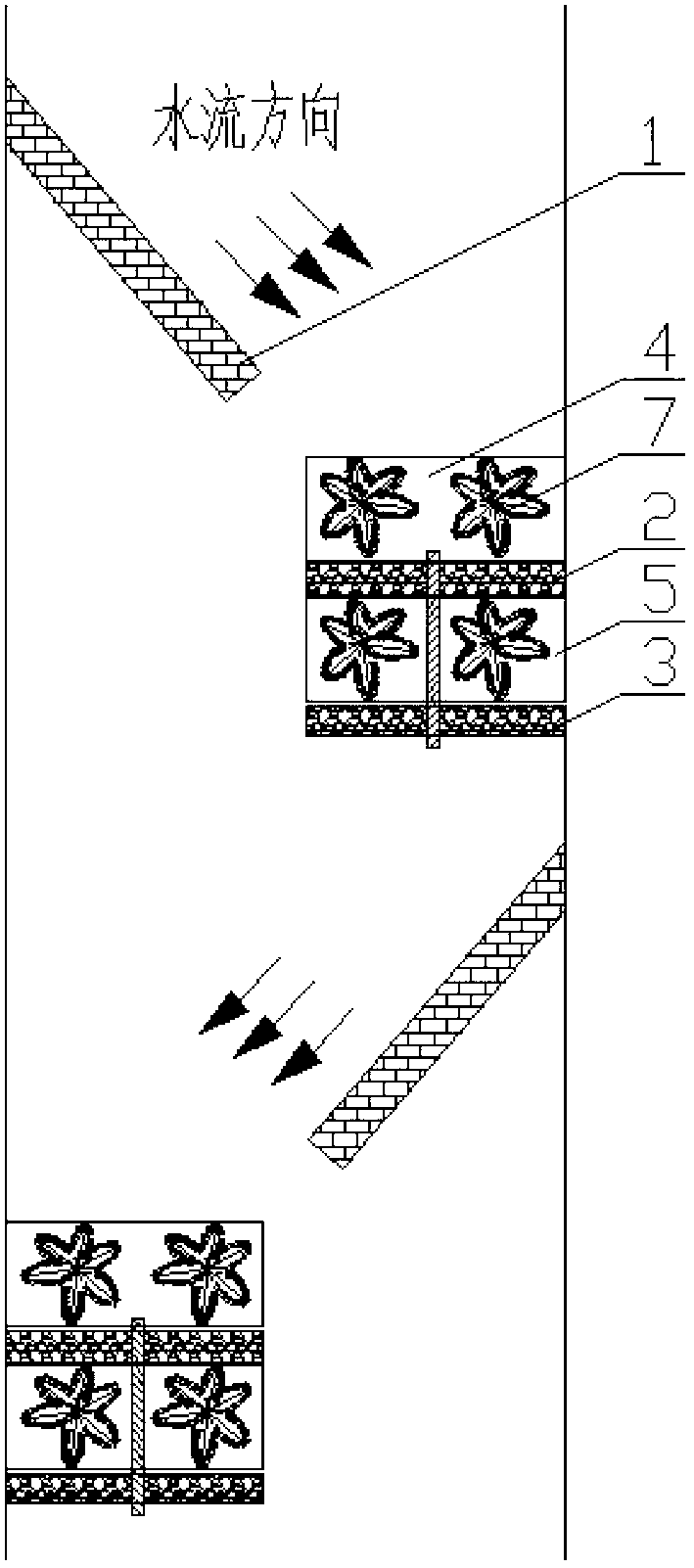

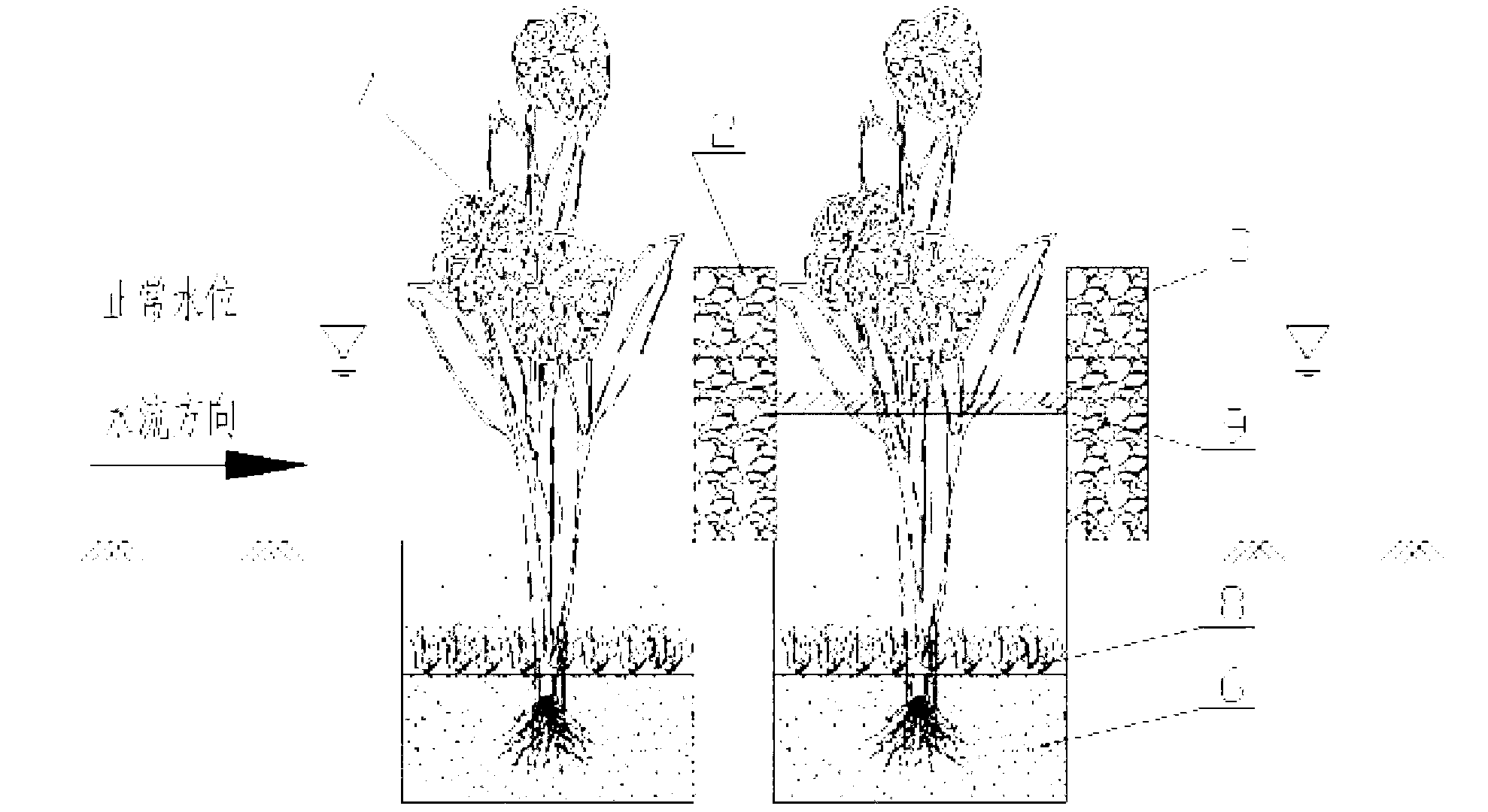

Backwash combination type farmland non-point source pollution cut-off purification system

InactiveCN103011497AProlong settling timeIncrease hydraulic retention timeBarrages/weirsClimate change adaptationTerrainEngineering

The invention discloses a backwash combination type farmland non-point source pollution cut-off purification system. Emergent aquatic plants and algae are arranged in gradient by virtue of structures such as guide downflow weir, backwash vertical filler, ecological settling pit which are constructed by using a part of canal (creek) beds, so that a physical-plant-microorganism ternary stereo purification system is formed, the hydraulic power condition in the canal (creek) can be greatly improved, the hydraulic power staying time can be prolonged, and the farmland non-point source pollutant can be effectively blocked and settled and finally decomposed and purified in the ecological settling pit in the synergic action of organisms; the backwash vertical filler is reversely placed regularly to automatically remove clogging, and the blocking effect can be in effect continuously, so that manual management operation can be reduced; and the purification system does not influence flood discharge of the canals (creeks) under a condition of heavy rain run-off or flood stage. The cut-off purification systems can be used in a mode of serial connection according to particular terrain and topography, so that the water body can be purified in multiple stages.

Owner:TIANJIN UNIV

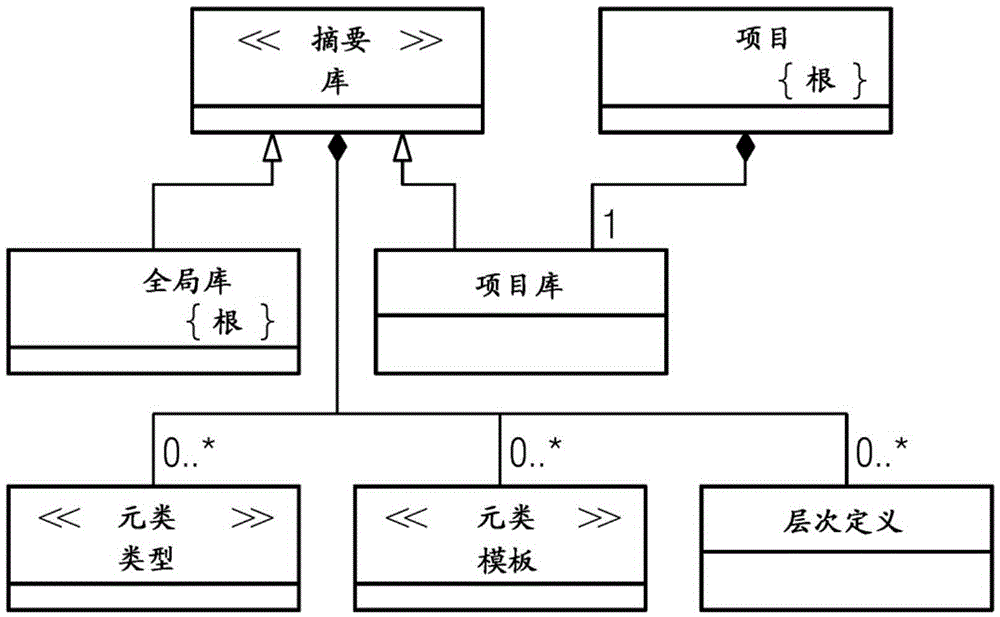

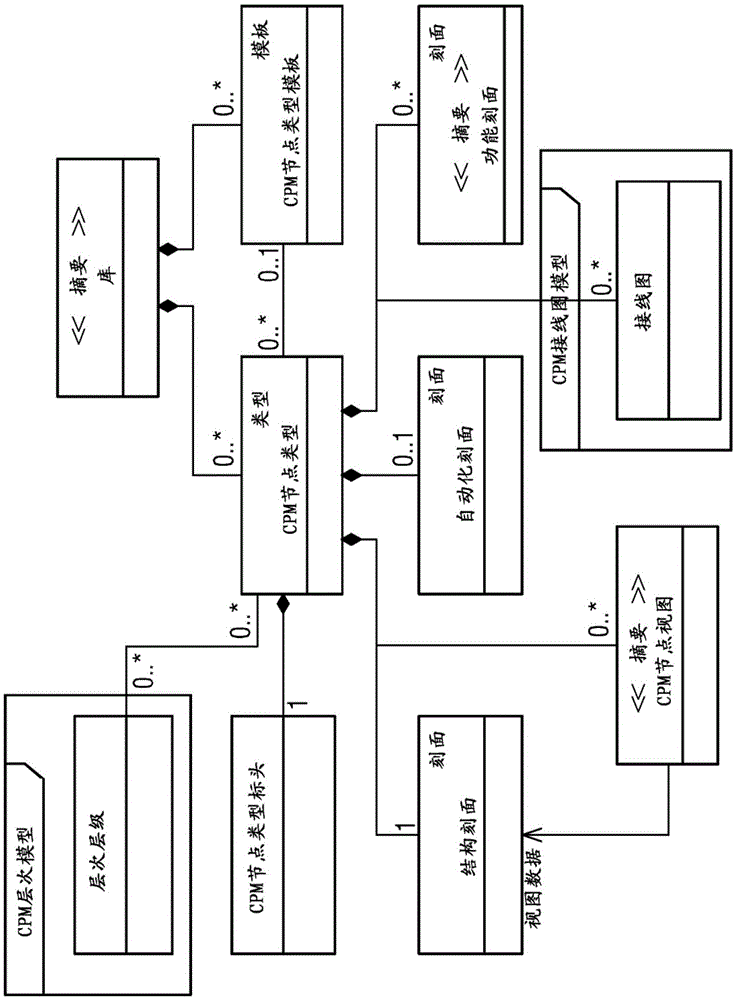

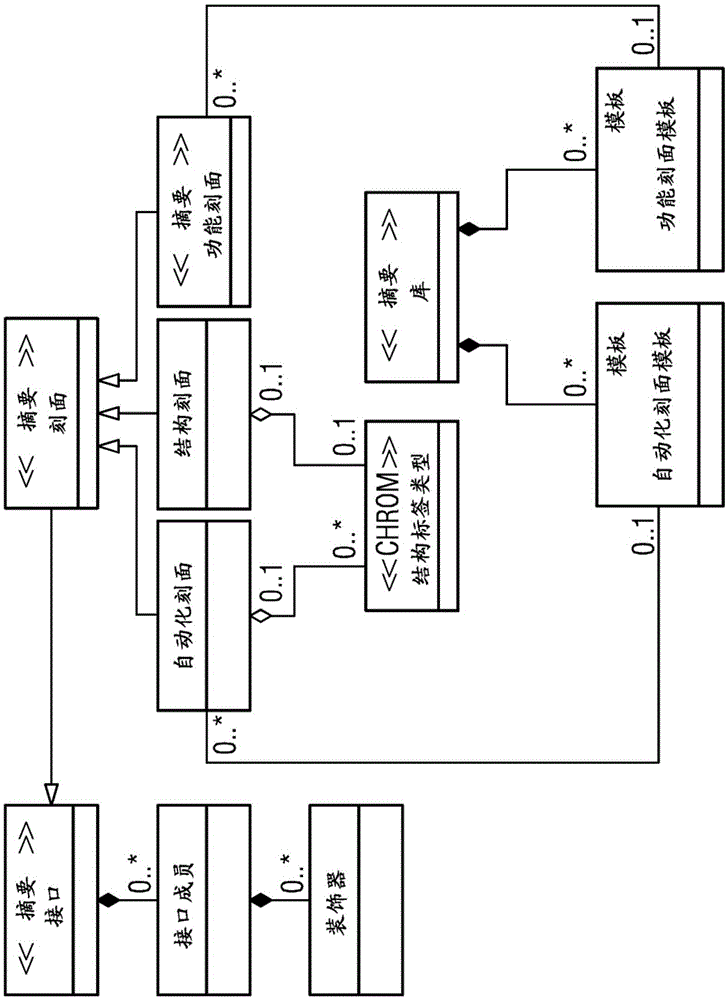

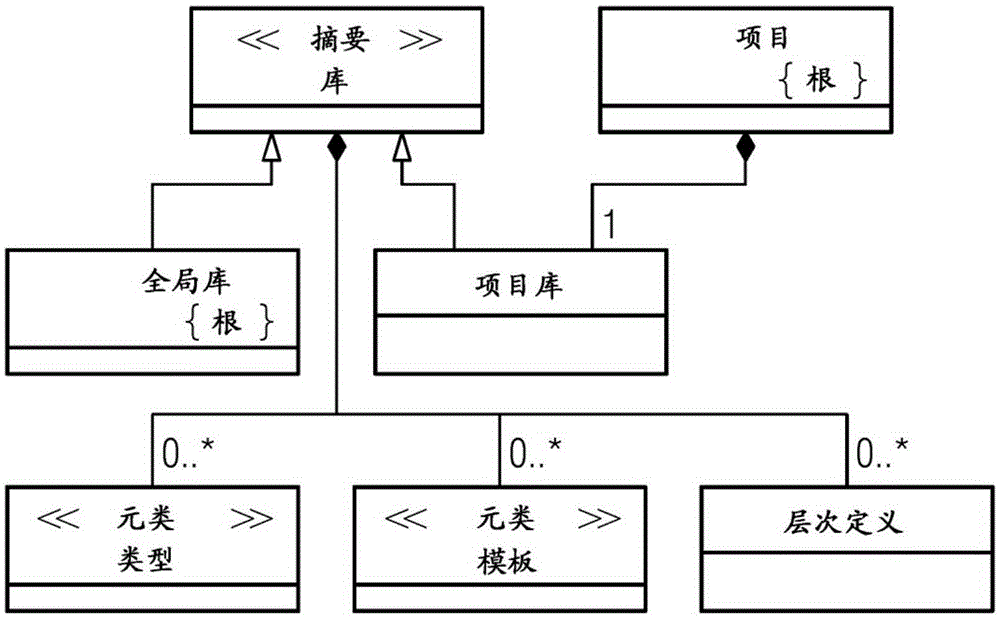

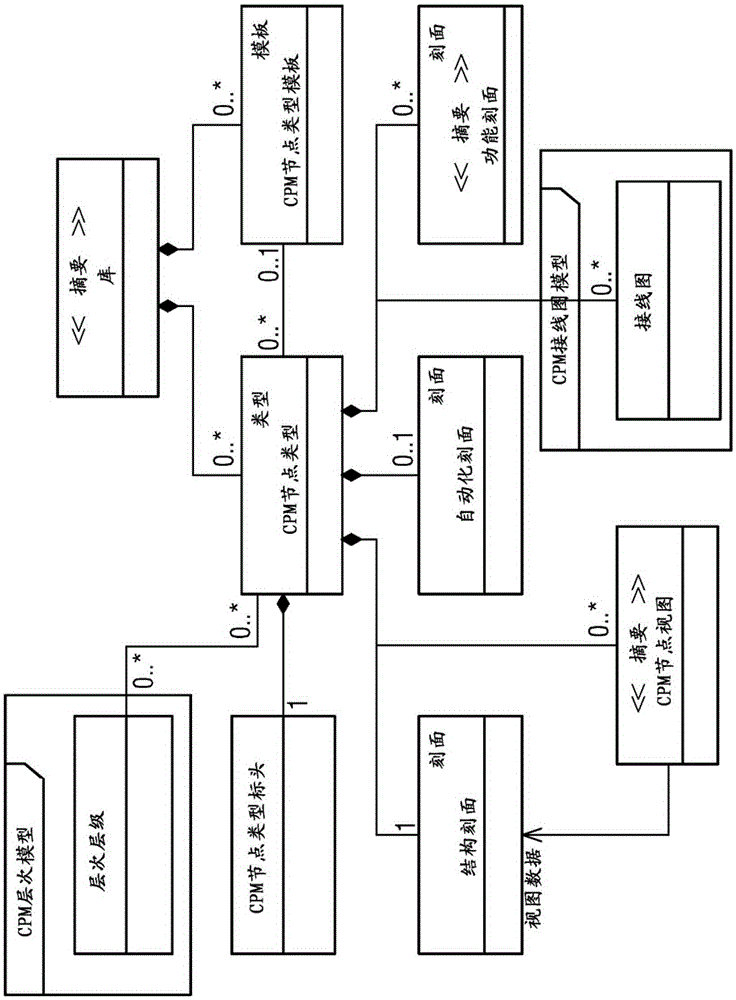

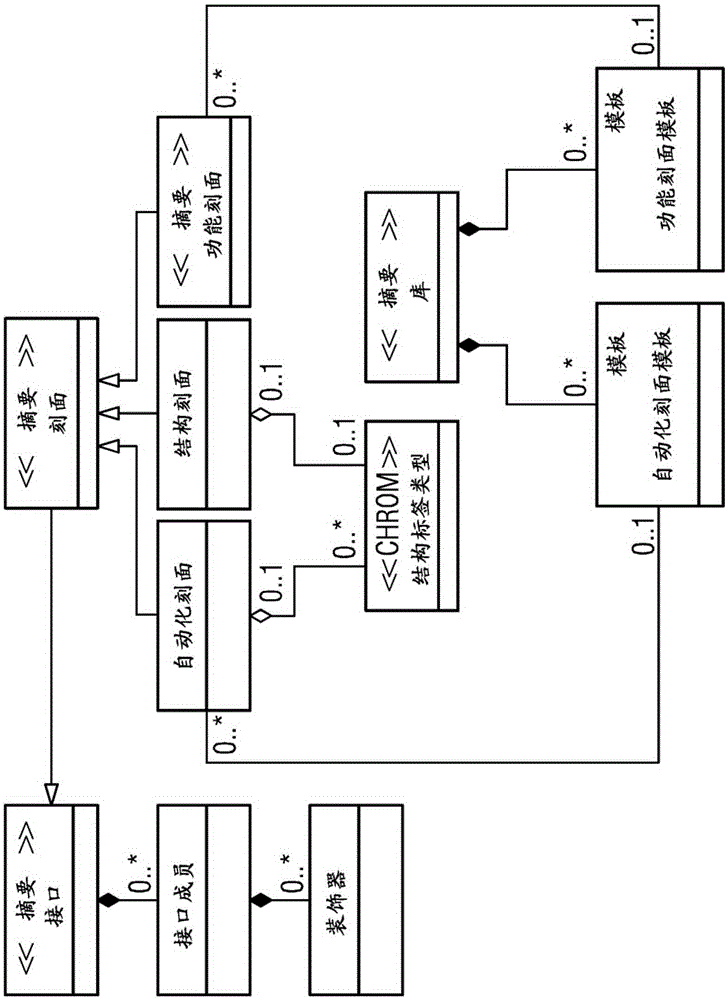

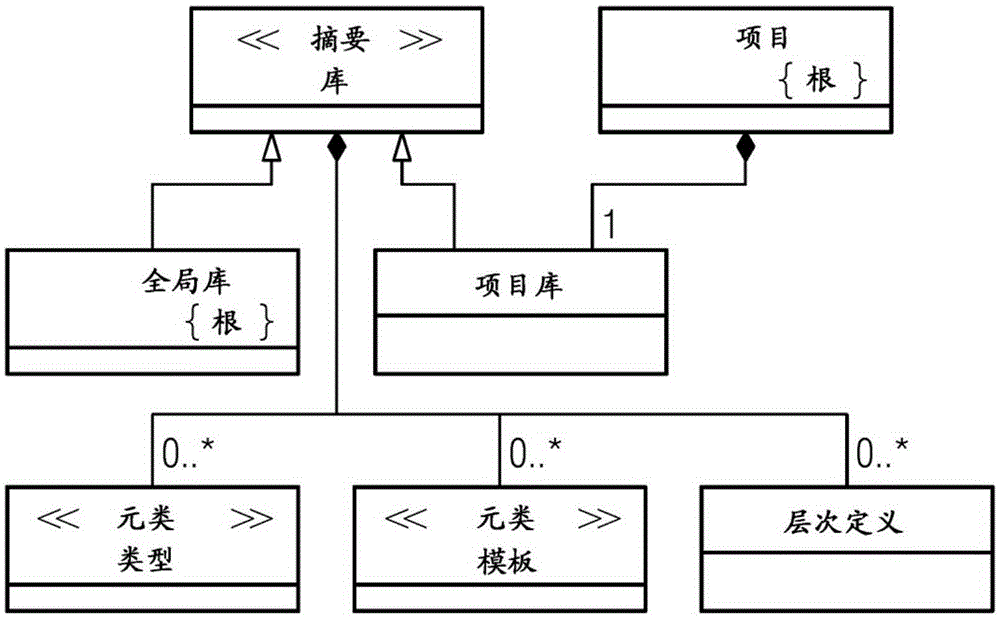

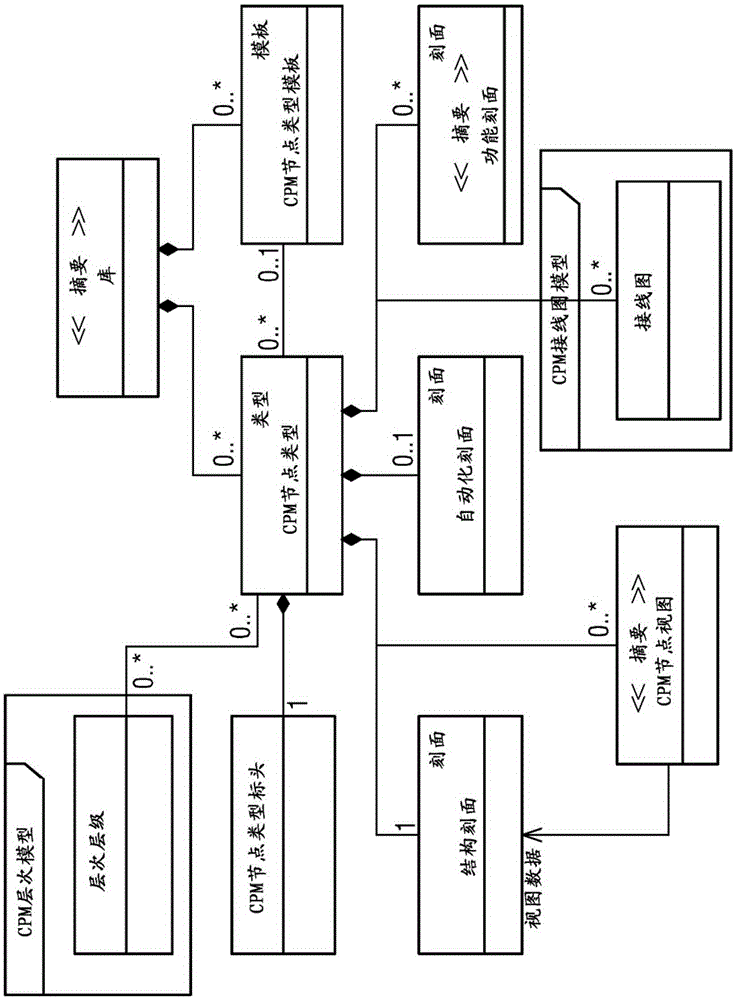

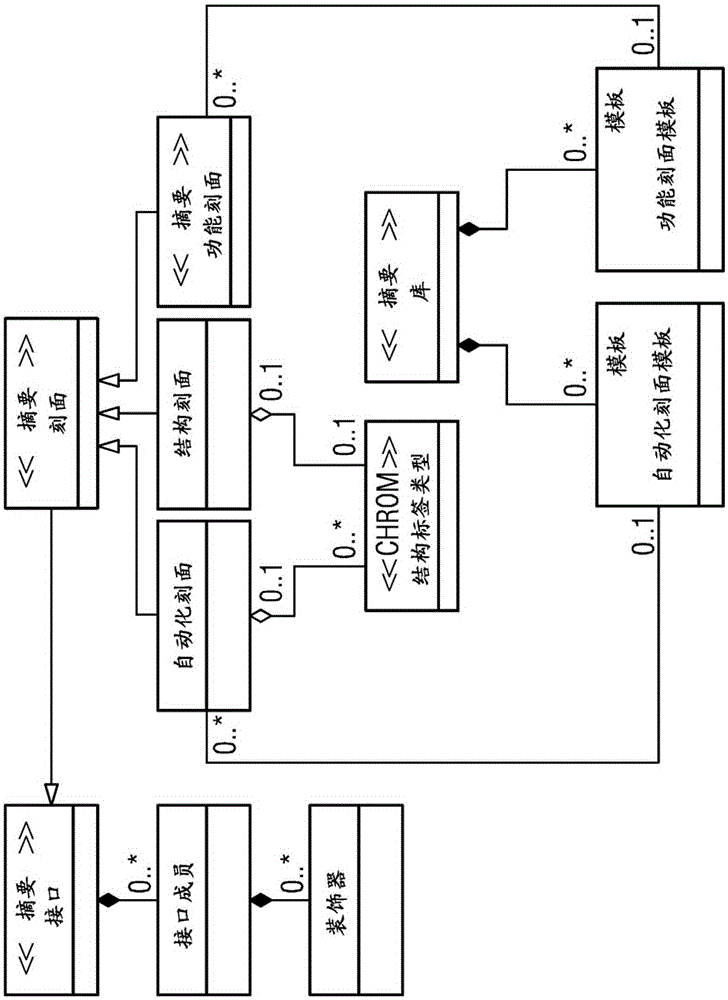

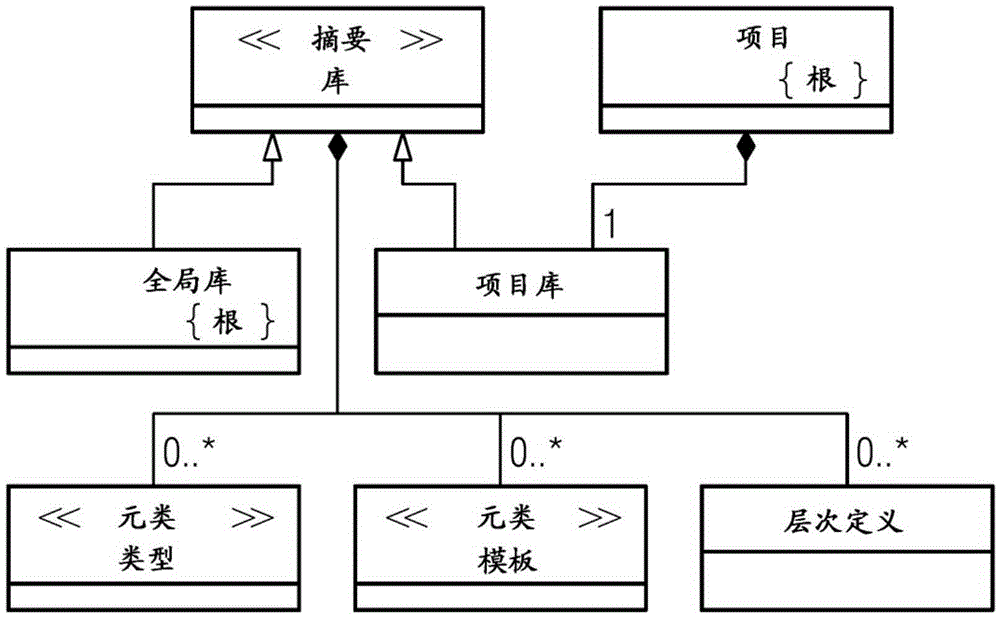

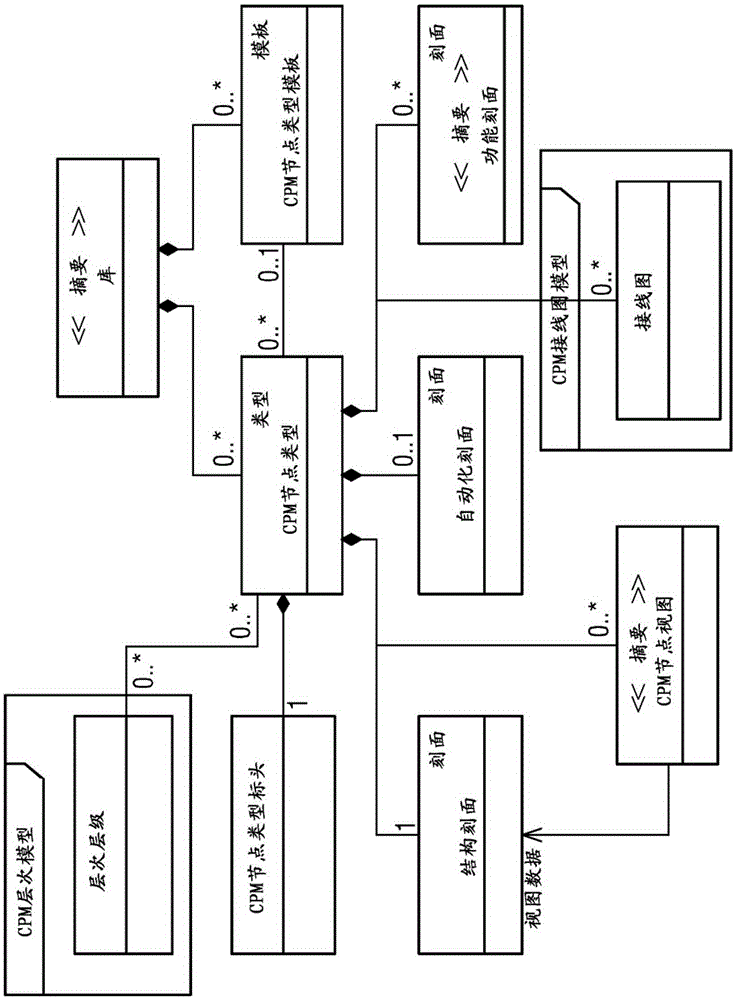

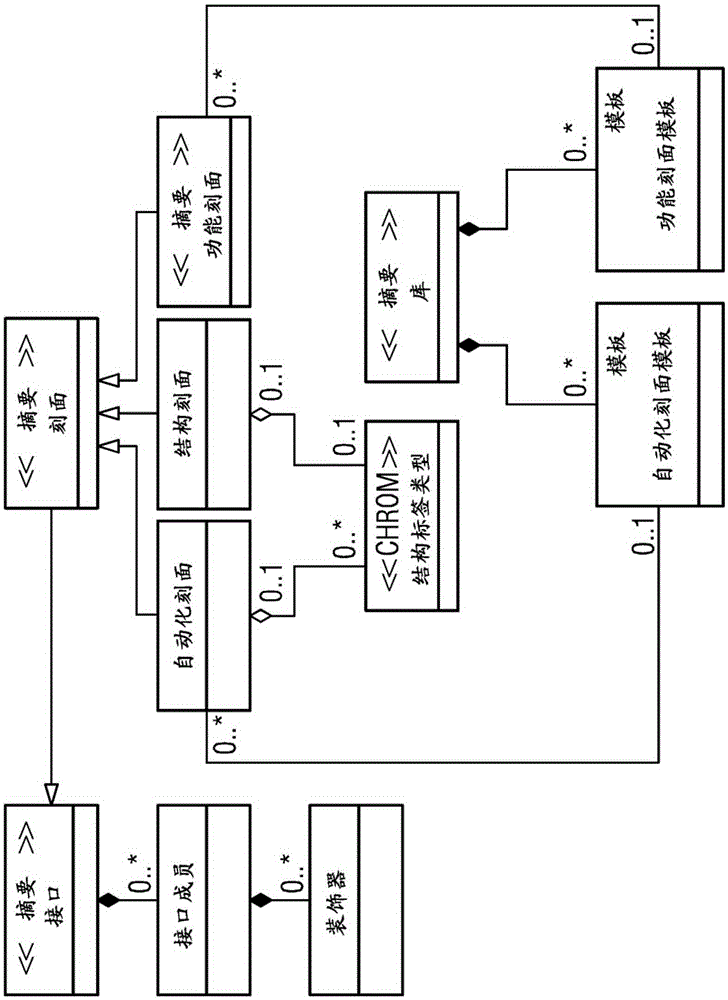

Common plant model for modelling of physical plant items of production plant

InactiveCN105654227ASimplify the linkProgramme controlGeometric CADPublic interfaceManufacturing execution system

The invention discloses a common plant model for modelling of physical plant items of a production plant within a manufacturing execution system having an engineering environment and a runtime environment, comprising: a) a node type model aggregating different aspects for the modelling of a single physical plant item involving public interface parameters as well as automation parameters; b) a number of nodes, each representing an instance of a node type; c) a library model comprising a project library and a global library, said libraries comprising the node type model, a facet model and a rule model as well as a hierarchy model, d) a graph model representing physical and / or logical connections between the nodes, e) a wiring chart model defining the interaction between interface members of different facets within the same node and / or among different nodes; and wherein each facet comprises at least one interface member and the logical link among the interface members is a virtual wire defining a connection used to propagate and align facet parameters which are linked to a specific node.

Owner:SIEMENS AG

Enhancing yields of harvested plant seeds by treating sowing seeds with selected doses of a physical plant stressor

Owner:HORIZON SEED TECH

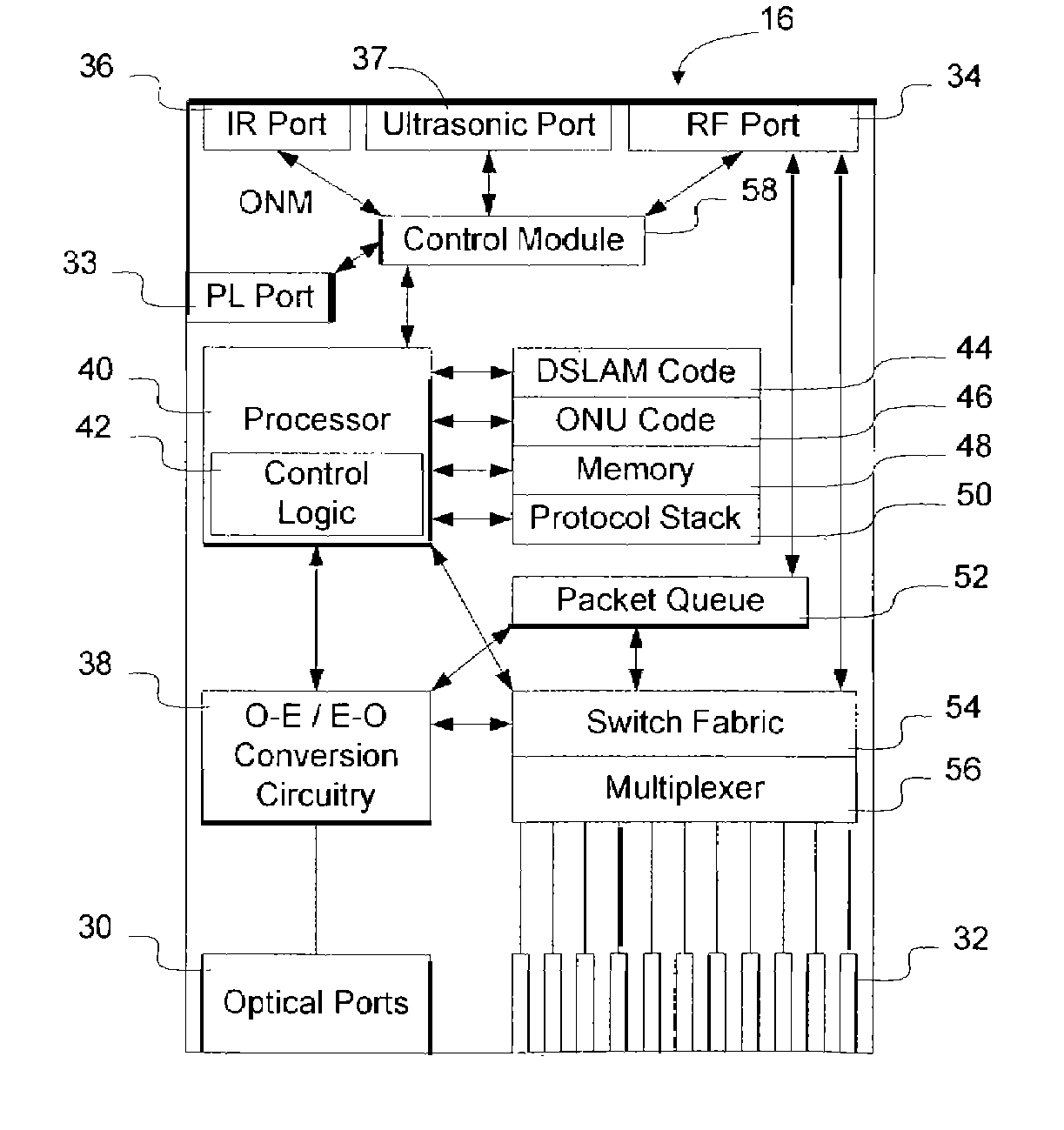

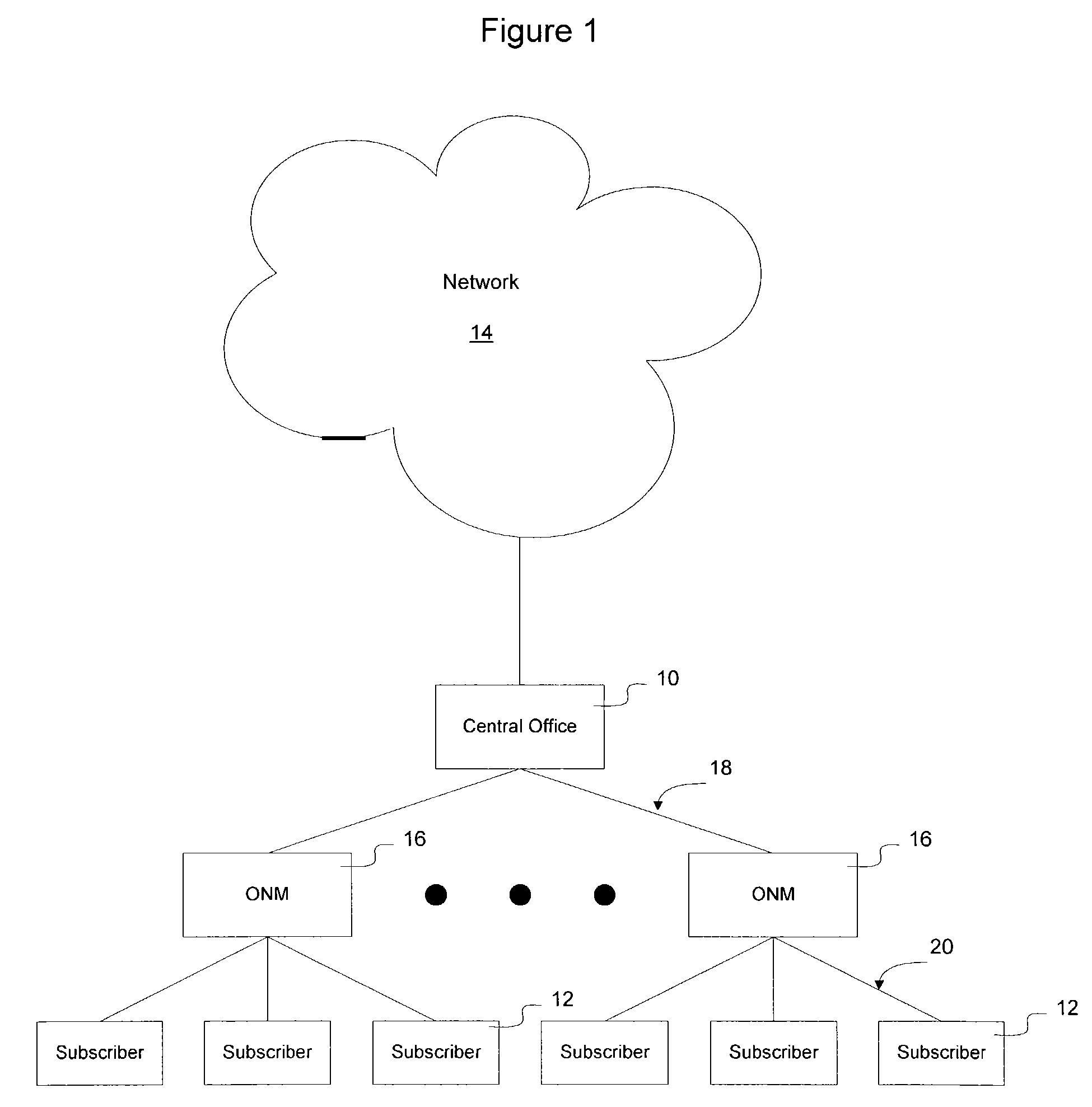

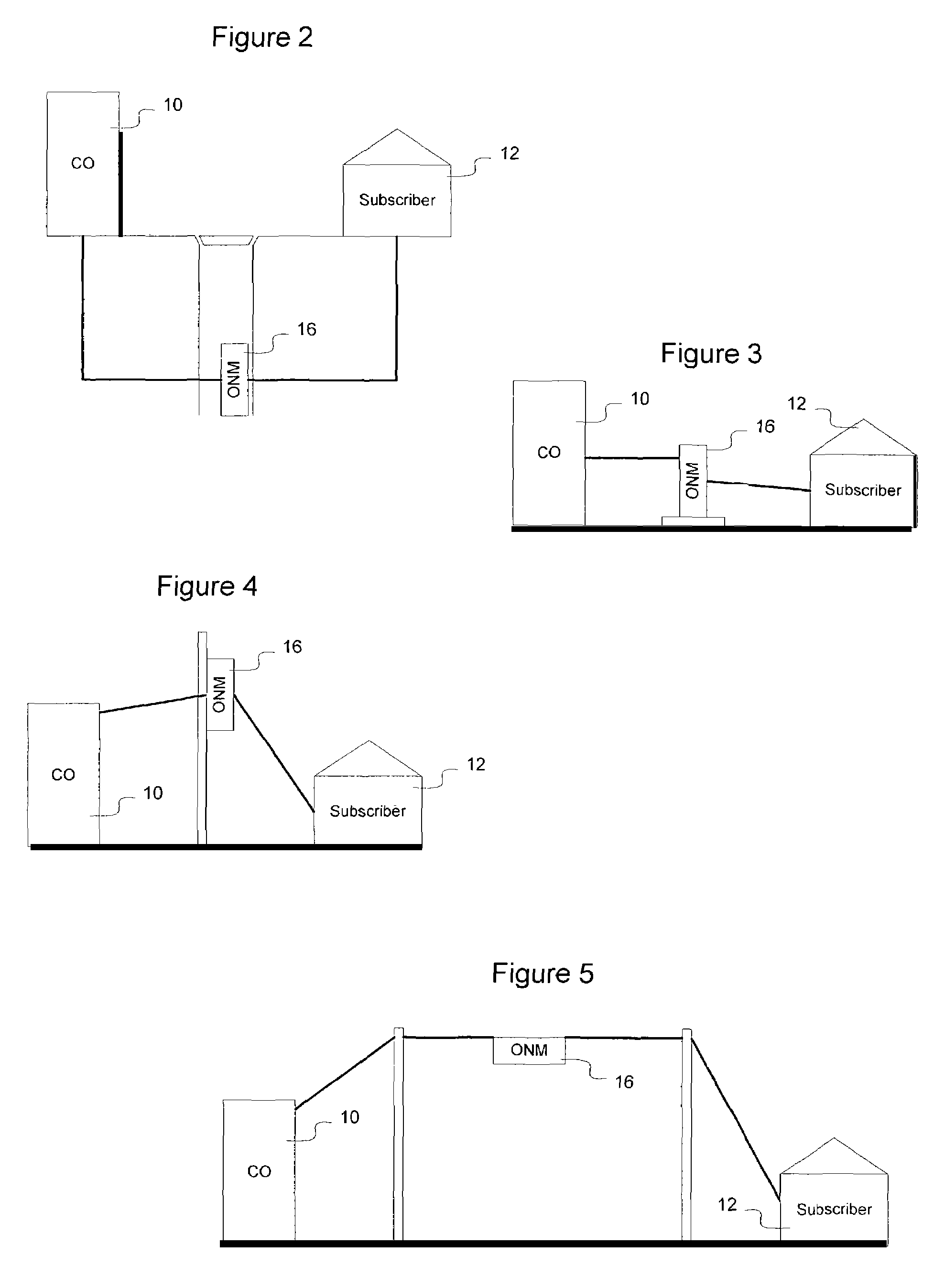

Remote interface for a network device in the physical plant

InactiveUS7450520B2Good flexibilityFacilitate transmissionError preventionTransmission systemsWireless transceiverTransceiver

A network device such as a combination ONU-DSLAM deployed outside the central office includes a wireless transceiver to enable a technician to interface with the network device over a wireless control channel. This allows the technician to monitor, interrogate, and control the network device to ascertain performance of the network or the network device and cause the network device to perform particular desired operations. Additionally, providing a wireless interface enables the network technician to fix specific perceived problems in the network device, such as by uploading new software to the network device, to enable the network device to have increased functionality or more reliable performance. Infra-red, wireless, powerline, or another technology may be used to interface with the network device. The wireless access port may also enable subscribers to access the network, for example by causing the network device to act as an 802.11 hot spot.

Owner:RPX CLEARINGHOUSE

Methods and apparatuses for advanced multiple variable control with high dimension multiple constraints

ActiveUS9081378B2Improve coordinationImprove performanceElectric controllersAdaptive controlEngineeringConstraint control

Owner:GENERAL ELECTRIC CO

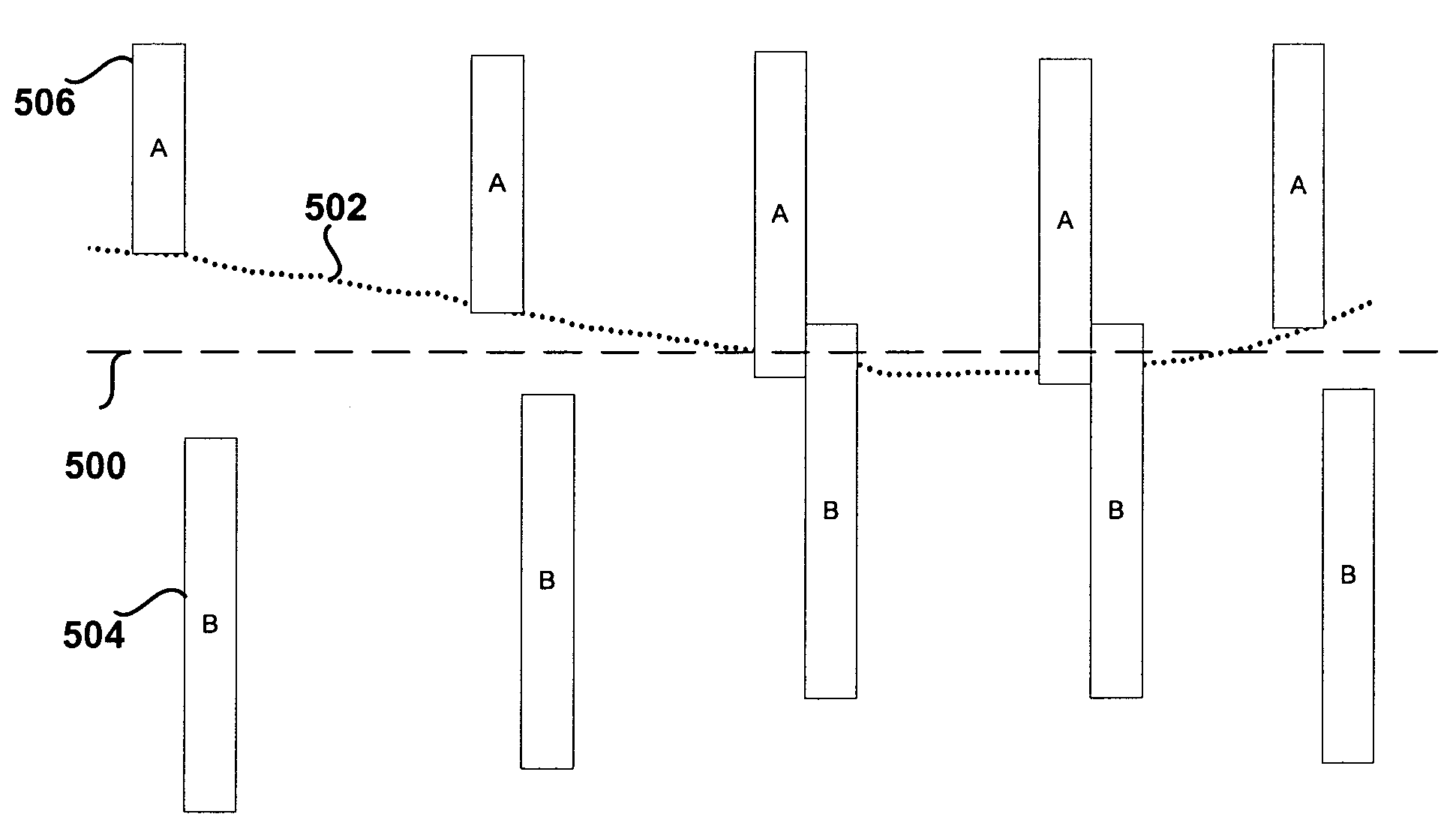

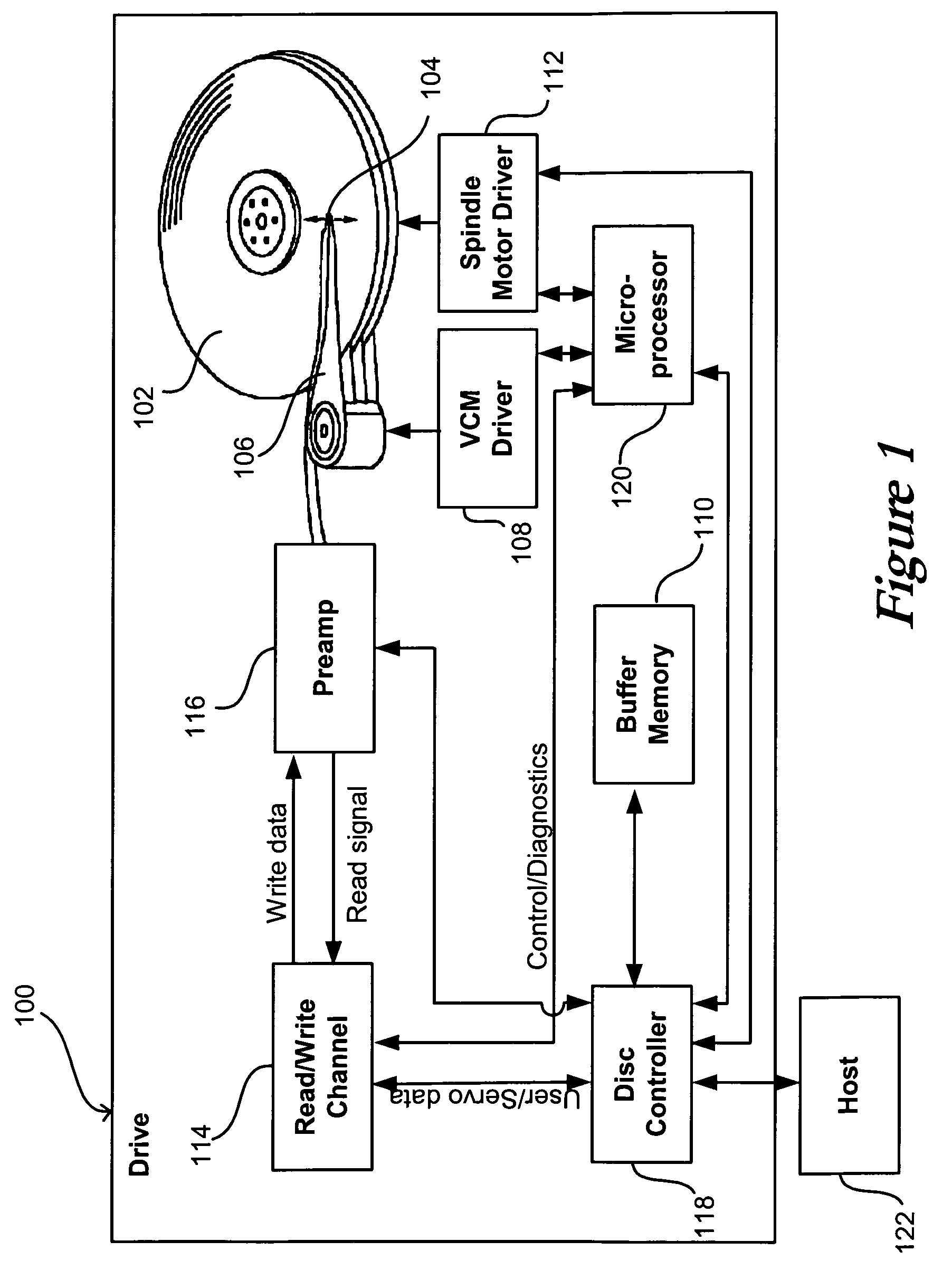

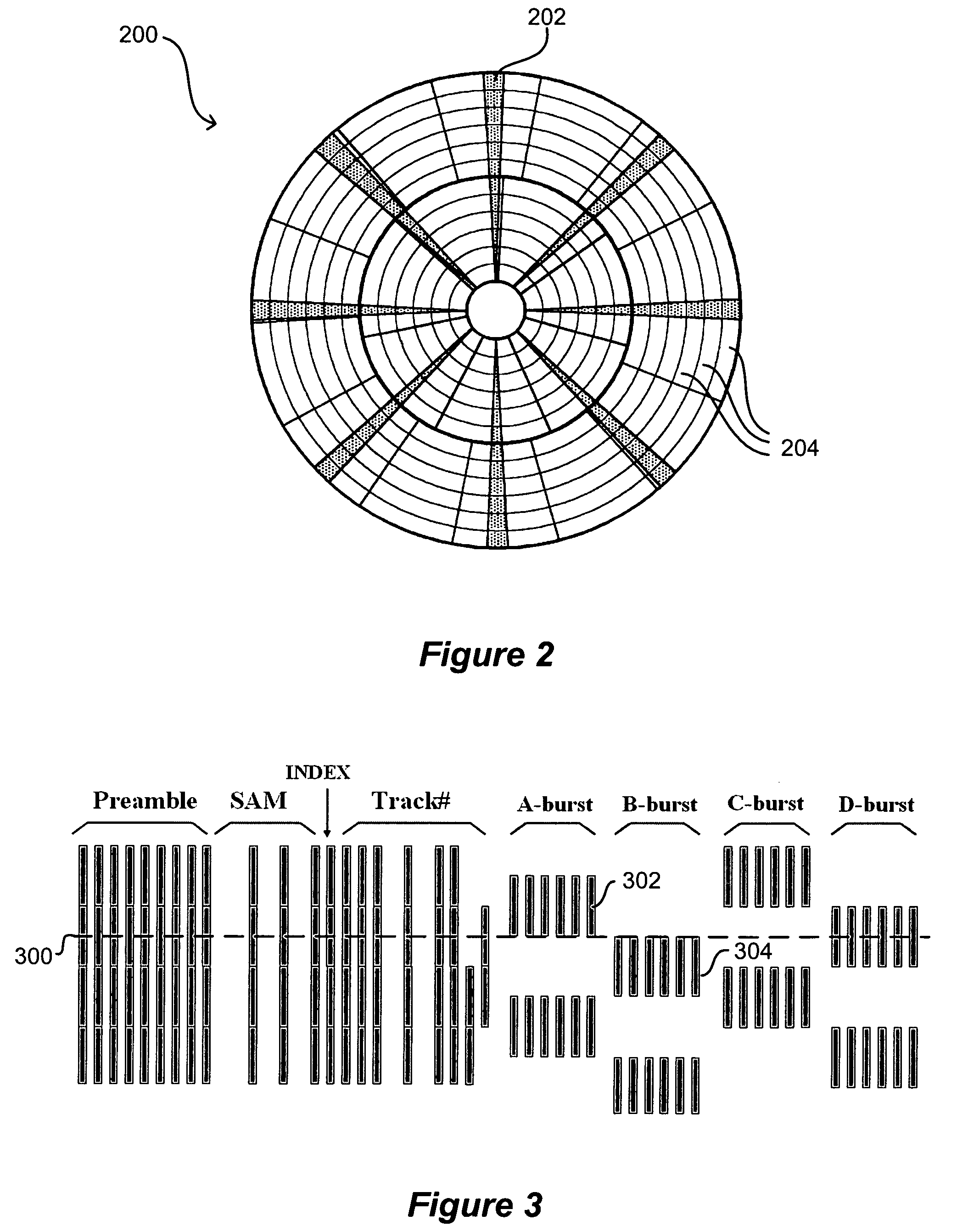

Systems and methods for conditional servowriting

Embodiments of the present invention determine the offset of a first burst of a burst pair from a centerline. This can be used to determine the desired offset position for a second burst of the burst pair. The target signal to provided the data storage unit for writing the second burst can take into account the transfer function of the controller and the physical plant so as to more accurately write at the desired offset position.

Owner:WESTERN DIGITAL TECH INC

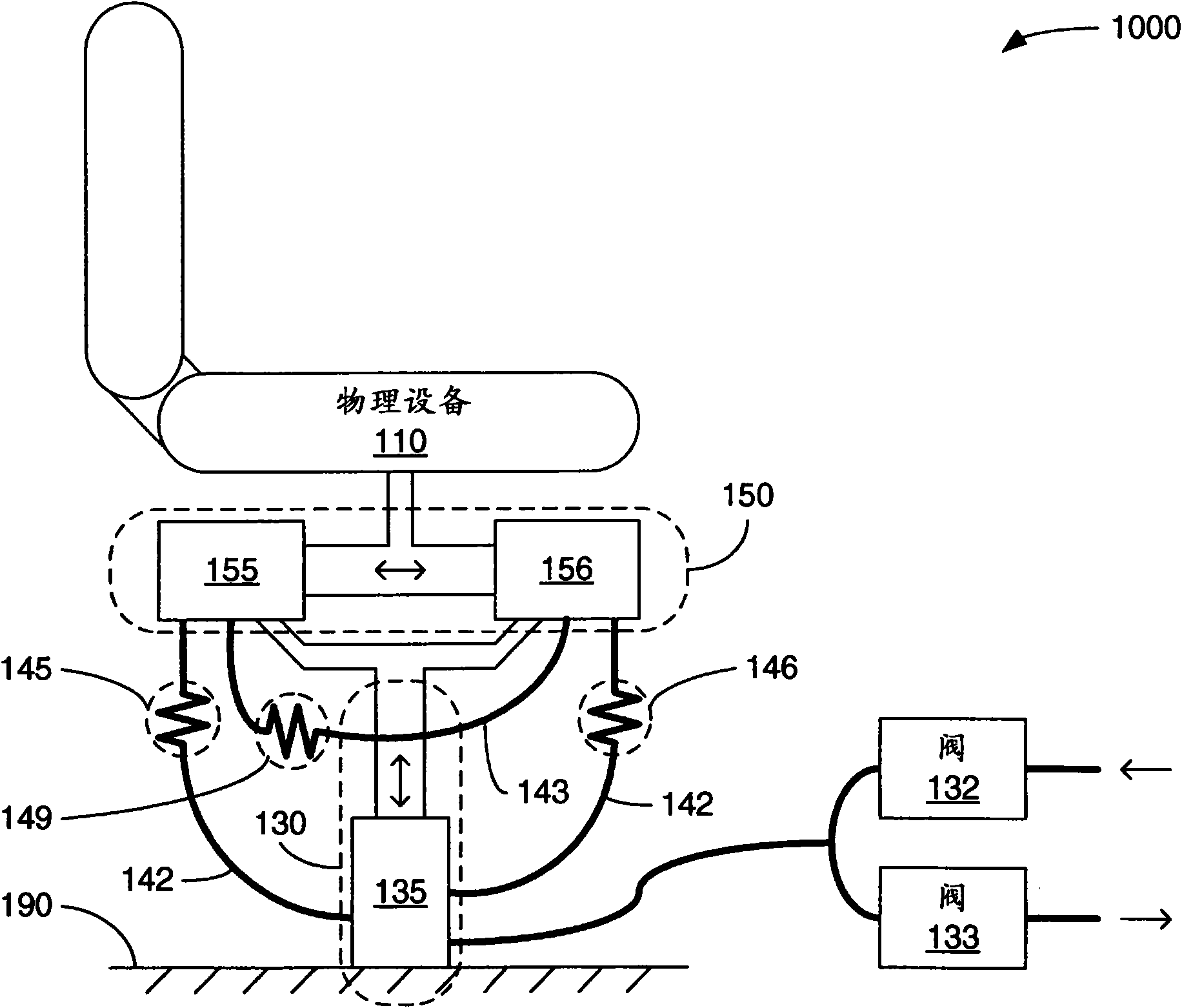

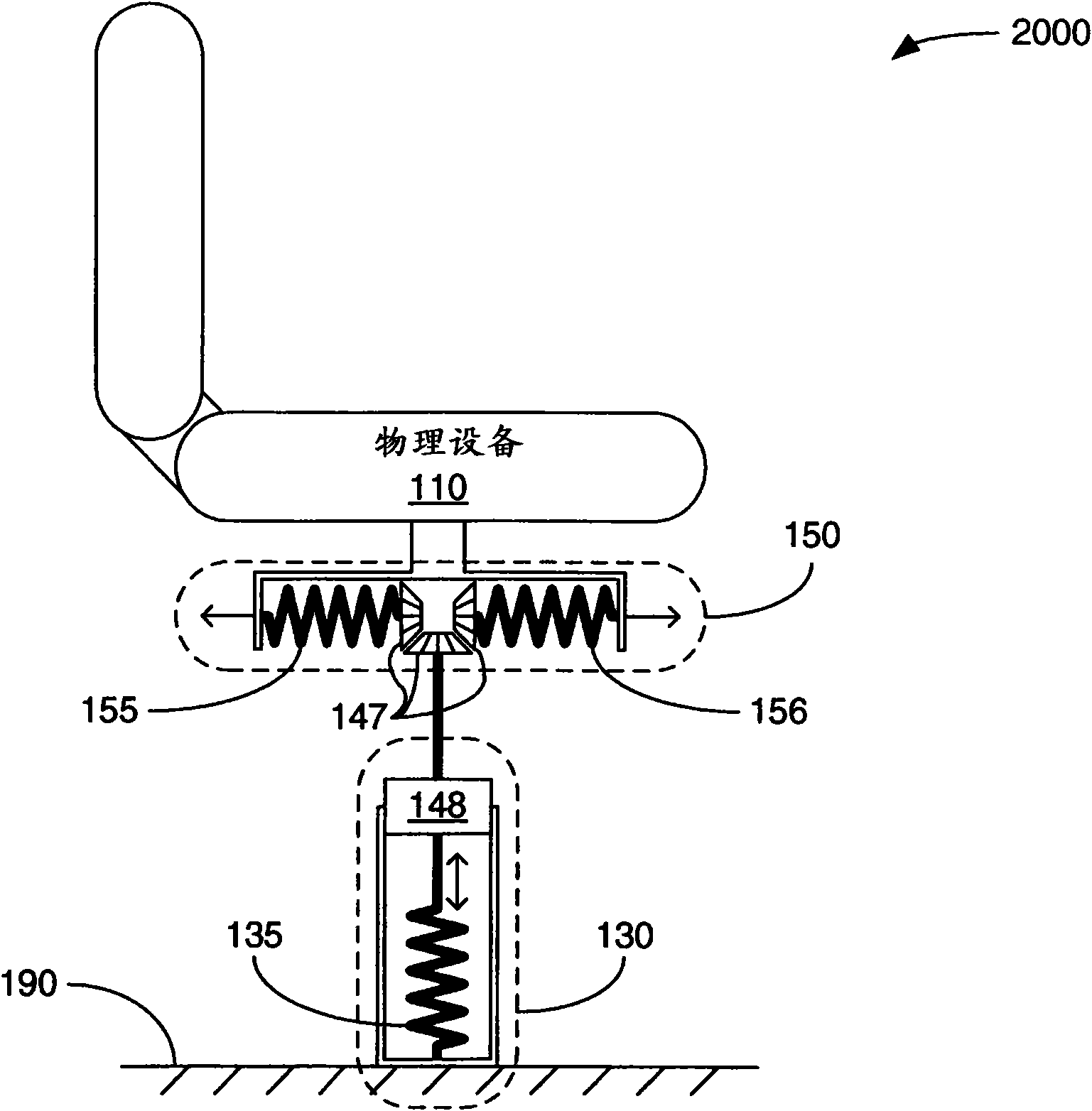

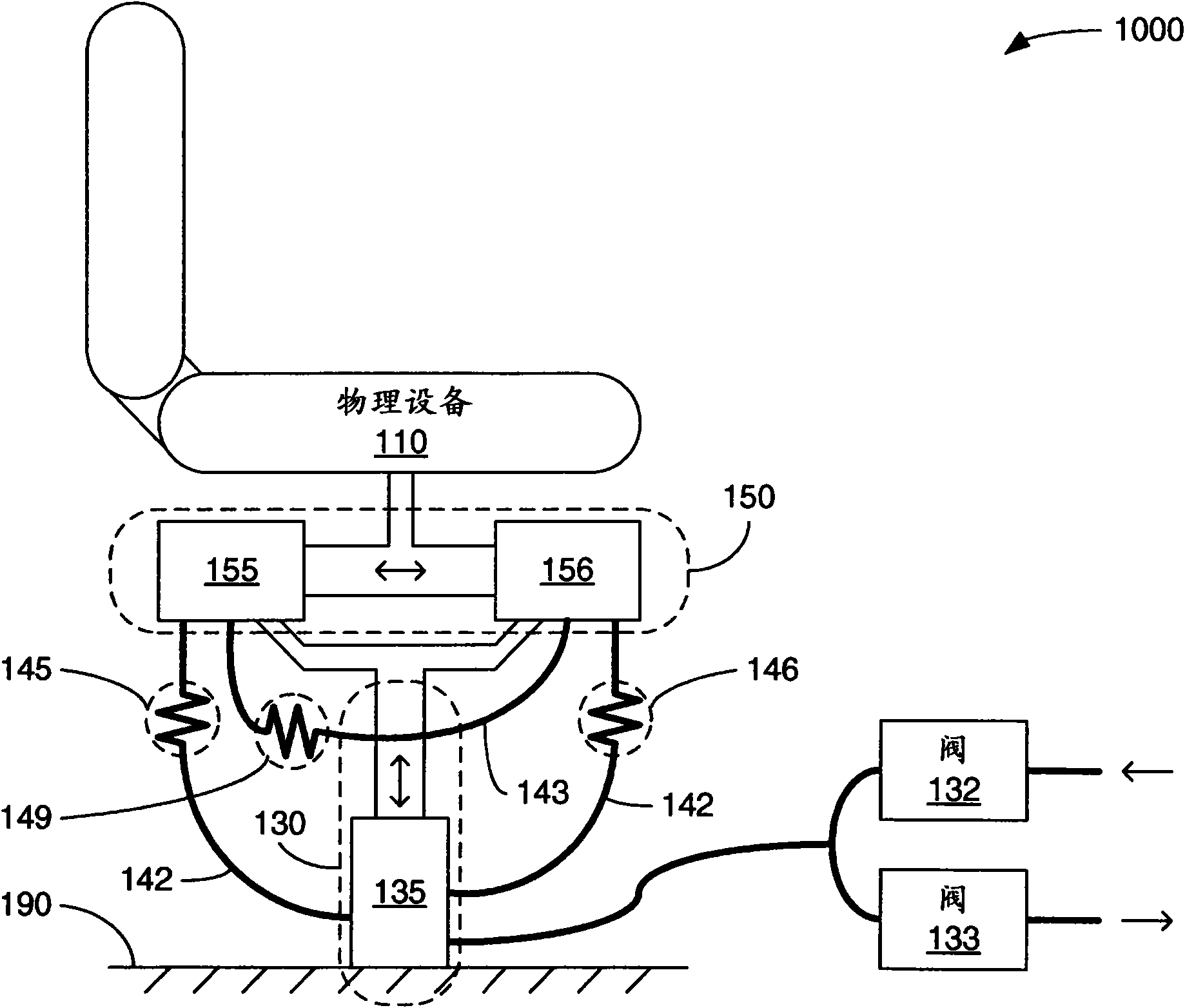

Plant suspension system with weight compensation

InactiveCN101945777AObvious featuresObvious advantagesSeat suspension devicesPhysical plantAutomotive engineering

An apparatus meant to be incorporated into a suspension system (1000, 2000) suspending a plant (i.e., an overall plant that includes a physical plant (110) and possibly a load that the physical plant supports) of a vehicle acts to alter the spring constant of at least one spring (155, 156) of the suspension system (1000, 2000) in response to changes in the weight of the plant so that a resonant frequency of the at least one spring (155, 156) isolating the plant from a jolt encountered by the vehicle during travel remains substantially unchanged despite changes to the weight of the plant.

Owner:BOSE CORP

Common plant model for modelling of physical plant items of production plant

The invention discloses a common plant model for modelling of physical plant items of a production plant, comprising: a) a node type model aggregating different aspects for the modelling of a single physical plant item involving public interface parameters as well as automation parameters; b) a number of nodes, each representing an instance of a node type; c) a library model comprising a project library and a global library, said libraries comprising a node type model, a facet model and a rule model as well as a hierarchy model, d) a wiring chart model defining the interaction between interface members of different facets of the nodes; and e) a graph model representing physical and / or logical connections between the nodes, wherein f) the graph model comprises a number of graphs being provided by a graph repository; g) each graph comprises a graph definition in terms of an unique identifier, a couple of nodes being linked via a graph connection link and optionally one or more graph attributes enriching the graph connection link.

Owner:SIEMENS AG

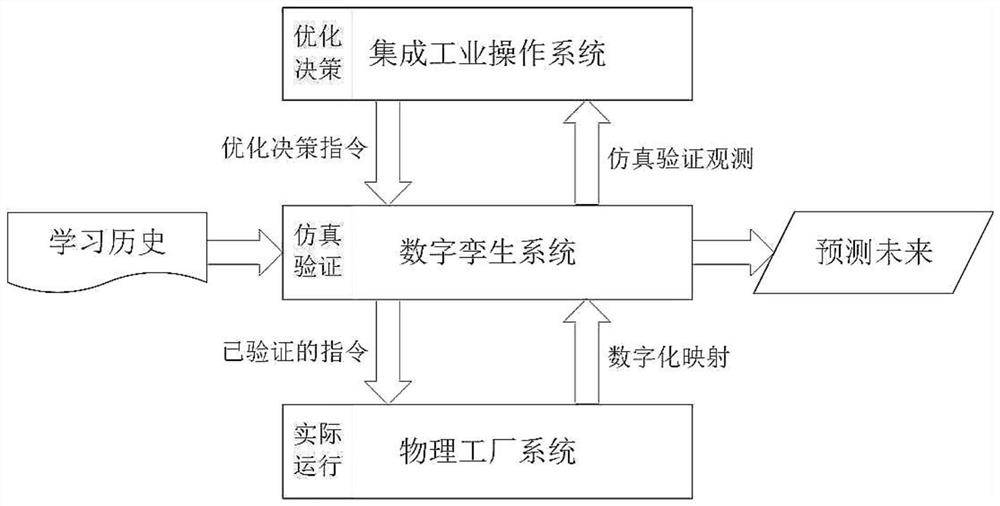

Steel hot rolling management and control system and method based on digital twinning

PendingCN114372341AInteractive humanizationFacilitate decision-makingImage enhancementImage analysisDecision controlData acquisition

The invention provides a steel hot rolling management and control system and method based on digital twinning. The system comprises a sensing module used for sensing the environment of a physical factory, the equipment operation condition and the quality attribute of a hot rolled slab; the data module is used for carrying out data acquisition, data storage, data fusion, data transmission and data analysis on the sensed environment, equipment and the hot rolled plate; the presentation module is used for representing the production condition of a real physical factory by adopting virtual twin images through three-dimensional graphic rendering and augmented reality technologies on the basis of the analyzed data; and the control module is used for forming decision control suggestions based on the fault knowledge base according to the control target and the corresponding control rule, and sending out a control instruction. According to the fault diagnosis method based on the multi-scale convolutional neural network, the operation state of the equipment is monitored, the abnormal condition of the equipment can be effectively judged, and a corresponding fault knowledge base is matched to give a repair suggestion.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Enhancing Yields of Harvested Plant Seeds by Treating Sowing Seeds with Selected Doses of a Physical Plant Stressor

The present invention relates to a method of enhancing the yield of harvested seed in plants by the application of selected doses of a physical plant stressor such as UV-C light (253.7 nm), X-rays, gamma ray, and electron beam irradiation to sowing seeds. This method can be used alone to enhance seed yield or in combination with standard seed treatments.

Owner:HORIZON SEED TECH

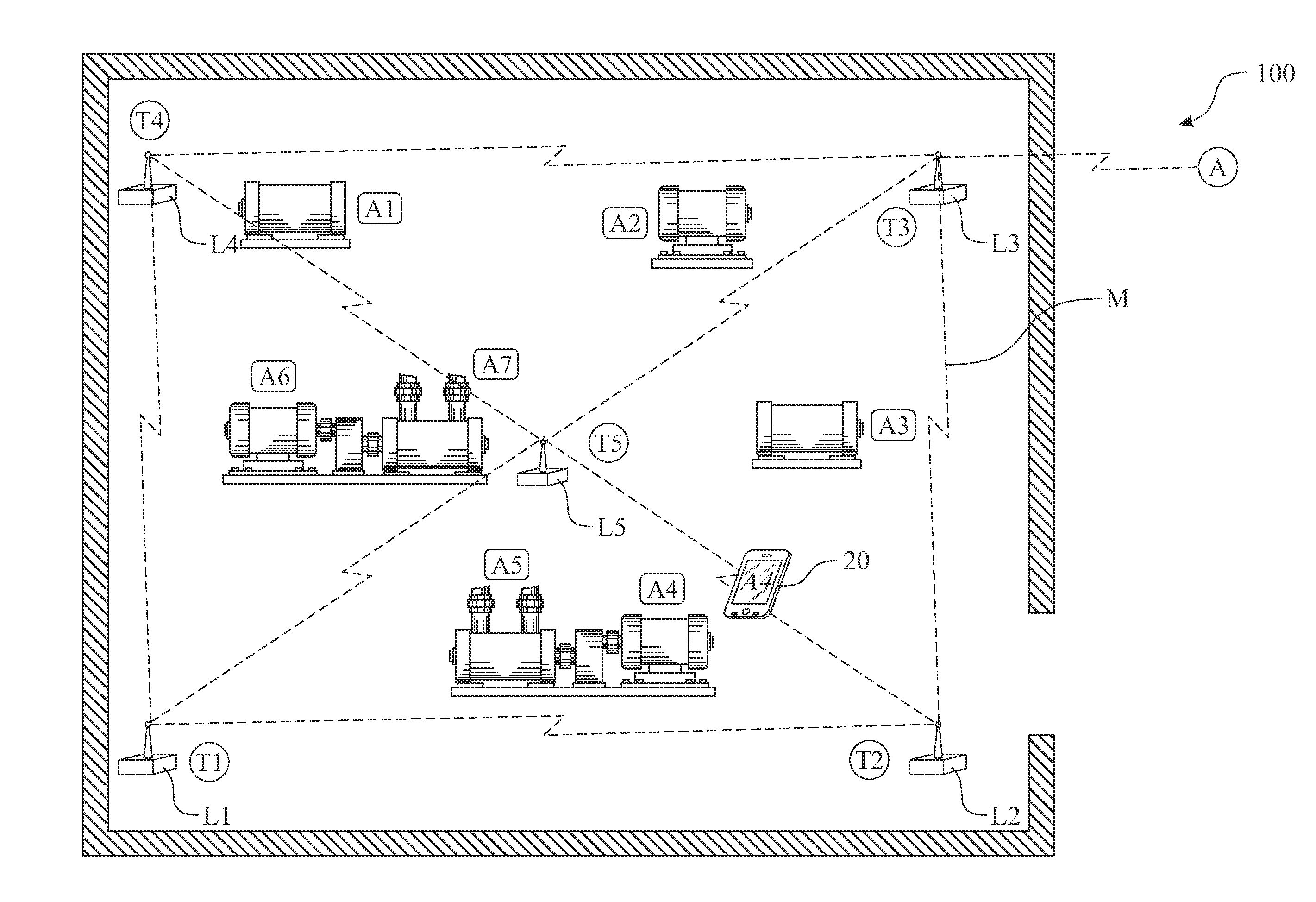

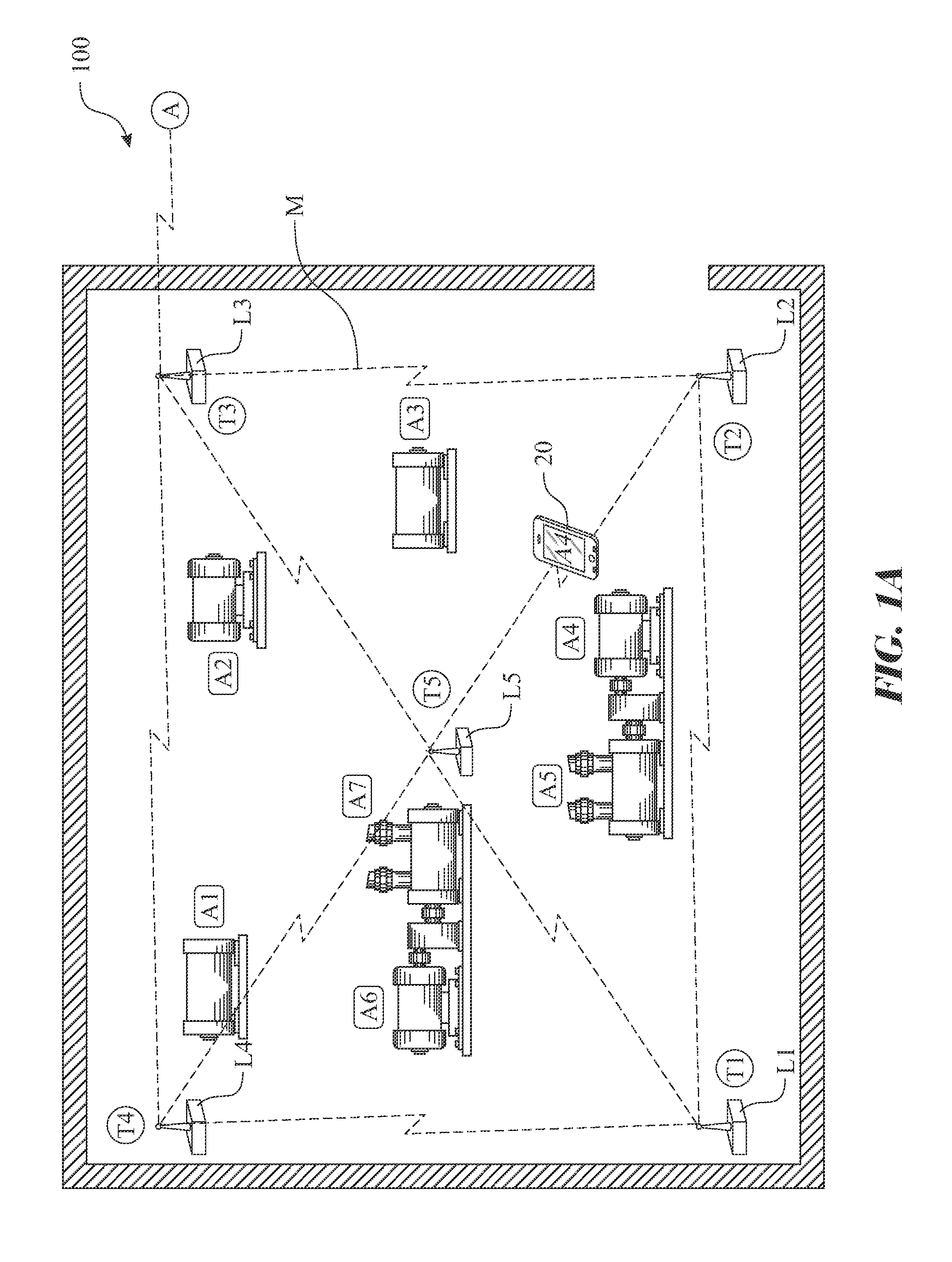

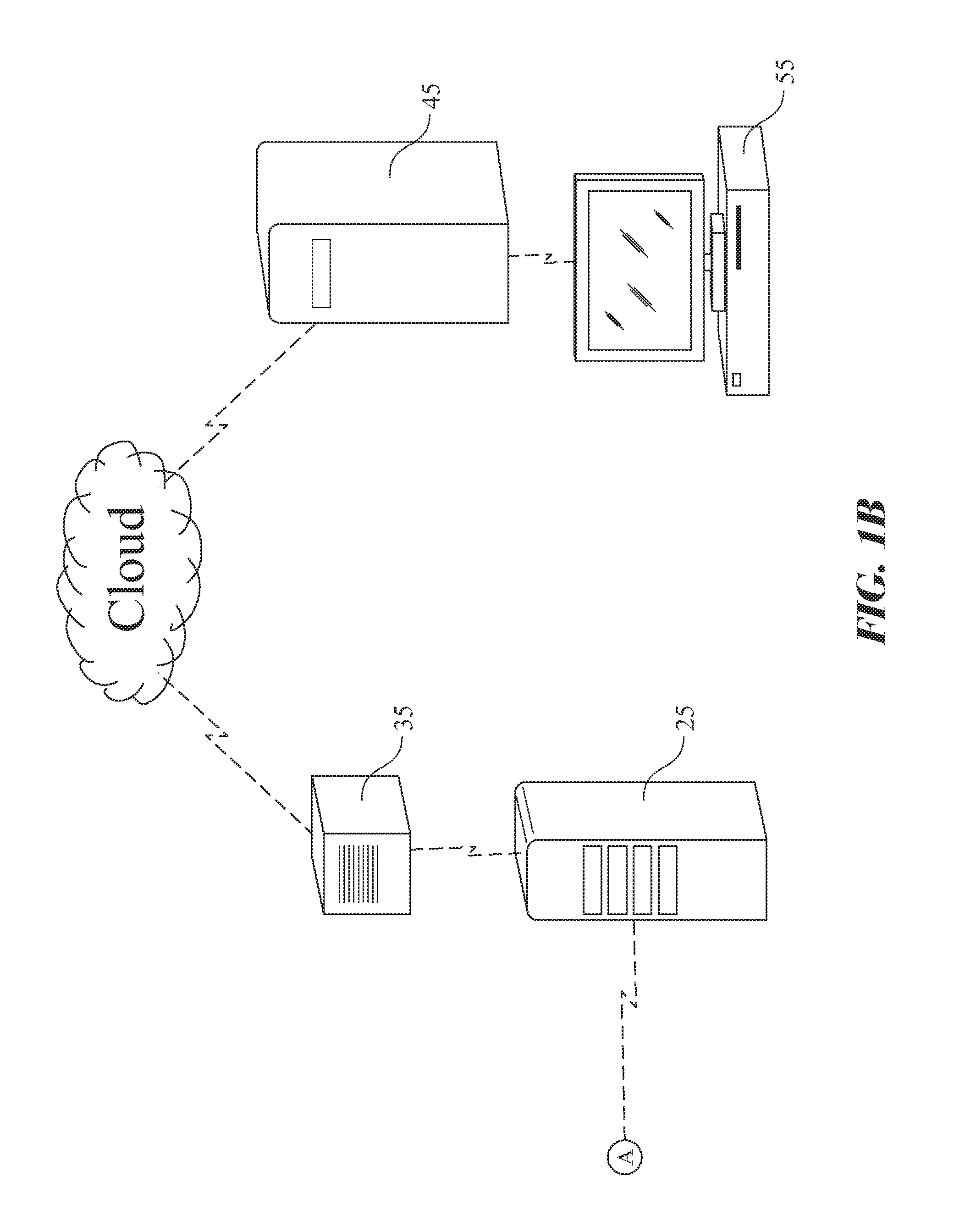

Method of operating a system for precisely locating an asset point in a physical plant

InactiveUS20150309159A1Accurate locationAccurate displayDirection finders using radio wavesPosition fixationOperational systemMeasurement point

A method of operating a system for precisely locating an asset or measurement point in a physical plant is provided. The steps of operating the system include providing a hand held device having an application disposed thereon; forming a wireless mesh with a plurality of transmitters located at known locations disposed throughout the physical plant; enabling the hand held device to triangulate to a precise location in the physical plant by virtue of the application and wireless mesh; overlaying the precise triangulated location on an asset map displayed on the hand held device, and displaying accurately both the particular asset and particular assets location by knowing its precise location overlaid onto the asset map.

Owner:AB SKF

Common plant model for modelling of physical plant items of production plant

The invention discloses a common plant model for modelling of physical plant items of a production plant within a manufacturing execution system having an engineering environment and a runtime environment, comprising: a) a node type model aggregating different aspects for the modelling of a single physical plant item comprising public interface parameters as well as automation parameters; b) a number of nodes, each representing an instance of one distinct node type; c) a library model comprising a project library and a global library, said libraries comprising the node type model, a facet model and a rule model as well as a hierarchy model, d) a wiring chart model defining the interaction between interface members of different facets of a node; and e) a graph model representing physical and / or logical connections between the nodes.

Owner:SIEMENS AG

Common plant model for modelling of physical plant items of production plant

The invention discloses a common plant model for modelling of physical plant items of a production plant, comprising: a) a node type model aggregating different aspects for the modelling of a single physical plant item involving public interface parameters as well as automation parameters; b) a number of nodes, each representing an instance of a node type; c) a library model comprising a project library and a global library, said libraries comprising a node type model, a facet model and a rule model as well as a hierarchy model, d) a wiring chart model defining the interaction between interface members of different facets of the nodes; e) a graph model representing physical and / or logical connections between the nodes, wherein f) the hierarchy model comprises a number of hierarchy definitions; g) each hierarchy definition comprises a number of hierarchy levels and optionally a number of hierarchy level constraints among those hierarchy levels; and h) each node is assigned to at least one of said hierarchy definitions and to at least one hierarchy level within the assigned hierarchy definition.

Owner:SIEMENS AG

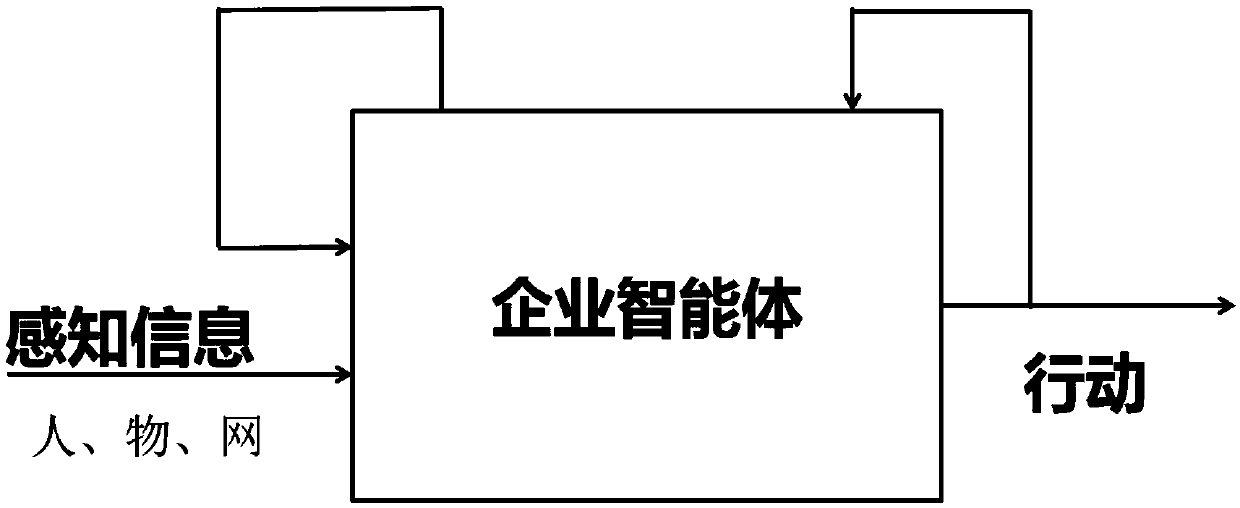

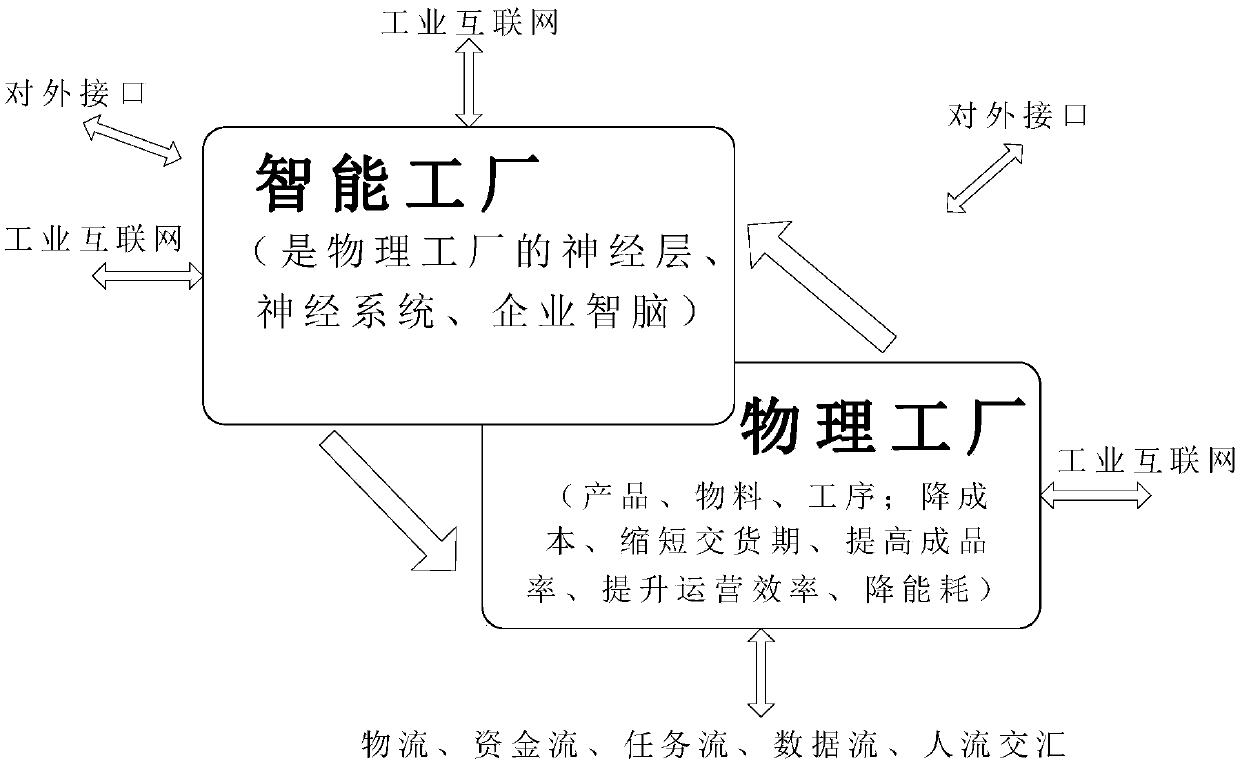

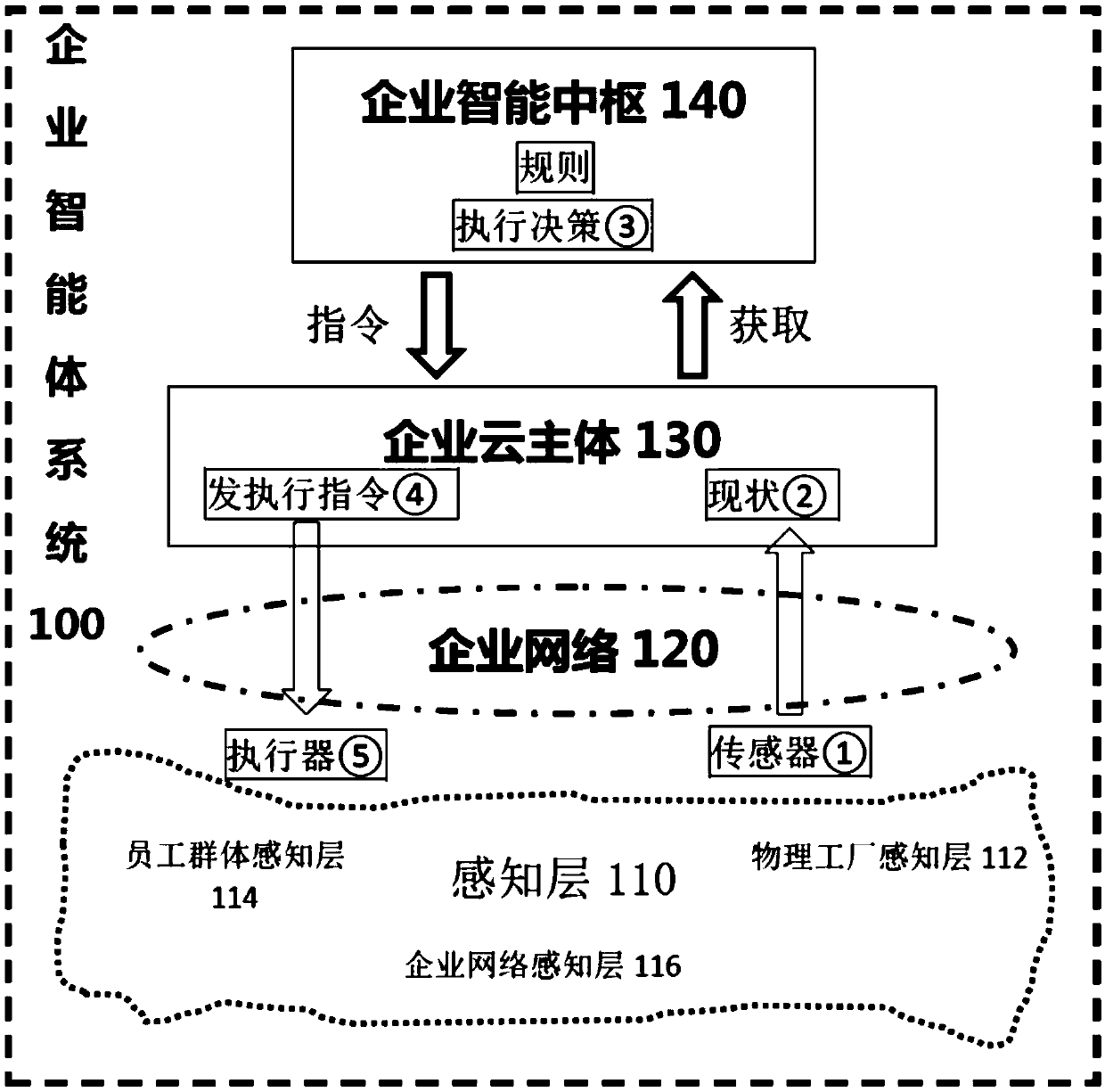

Enterprise agent system

The invention relates to an enterprise agent system. According to one embodiment, an enterprise agent system may include: a physical plant awareness layer disposed in a physical plant of an enterprisefor awareness of production data related to a production process of the physical plant; an employee group perception layer associated with employees of the enterprise and used for perceiving employeedata related to behaviors of the employee group of the enterprise; a network perception layer associated with the enterprise network and used for perceiving network data in the enterprise network; anenterprise cloud main body used for receiving the sensed production data, employee data and network data through an enterprise network and carrying out preliminary processing on the data to obtain enterprise big data; and an enterprise intelligent center used for generating an execution instruction based on the enterprise big data so as to schedule the operation of the enterprise.

Owner:CHINA INFORMATION COMM TECH GRP CORP

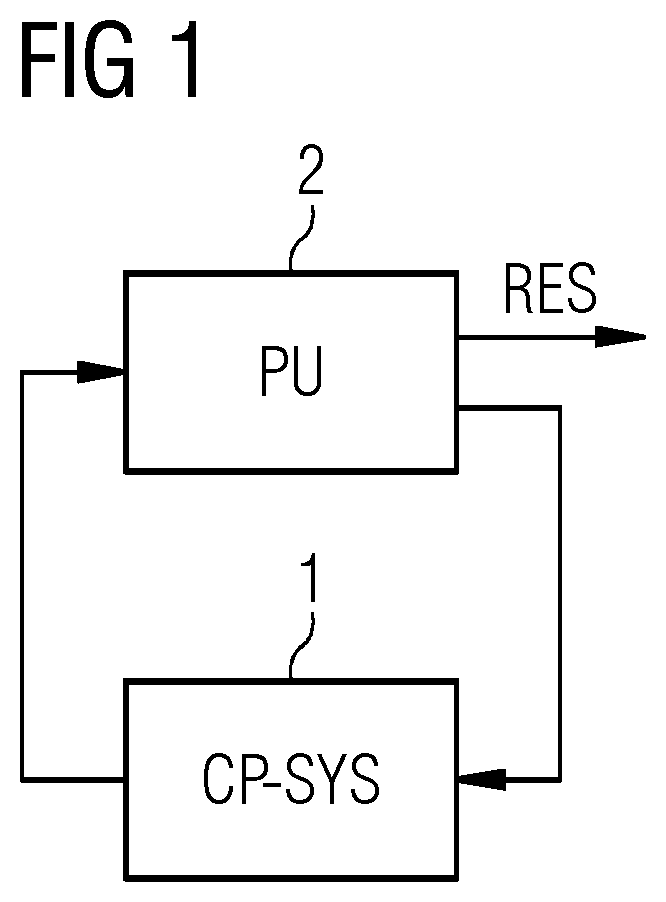

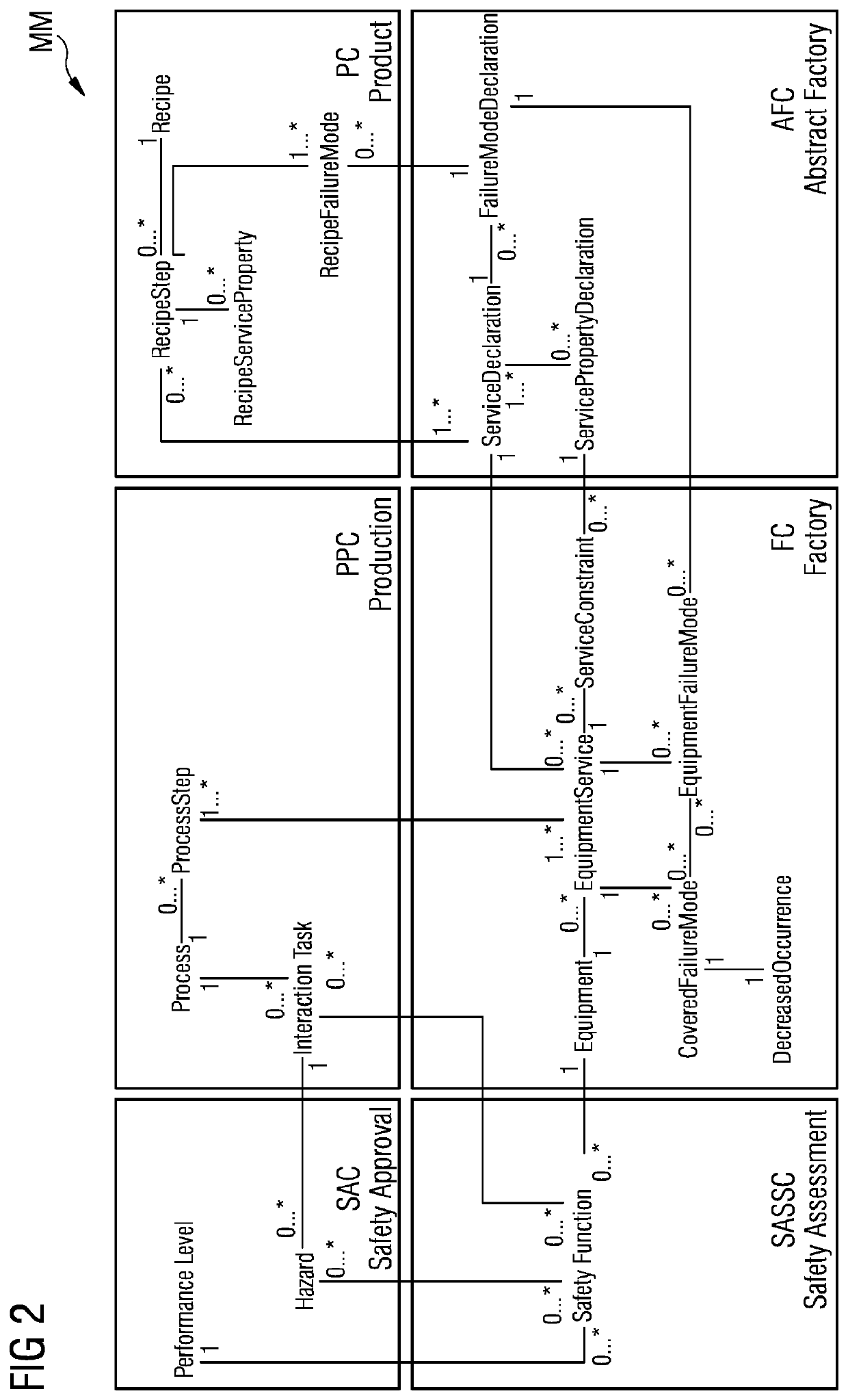

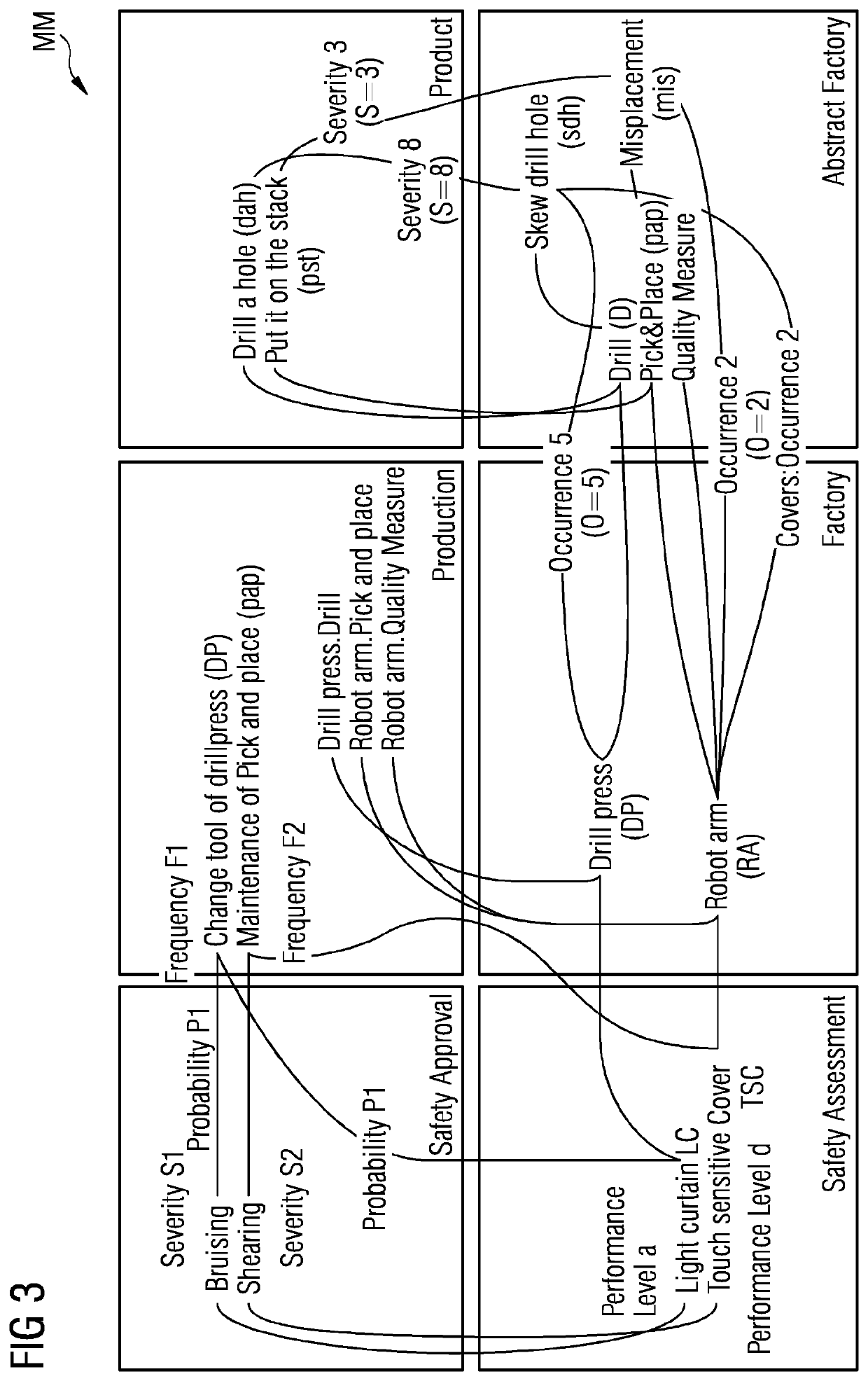

A method and system for determining machine safety and product quality for a flexible cyber-physical production system

PendingUS20220137589A1Quality improvementReliable and precise machine safety characteristicsProgramme controlComputer controlProcess engineeringComputer science

A computer-implemented method for determining automatically a machine safety and / or a product quality of a flexible cyber-physical production system with a configuration adaptable during a production process including production steps executed by machines forming equipment of a physical factory of the cyber-physical production system to produce a product according to a product recipe, wherein the machine safety and / or product quality are calculated during runtime of the flexible cyber-physical production system by processing a meta-model of the flexible cyber-physical production system stored in a computer readable storage medium, is provided.

Owner:SIEMENS AG

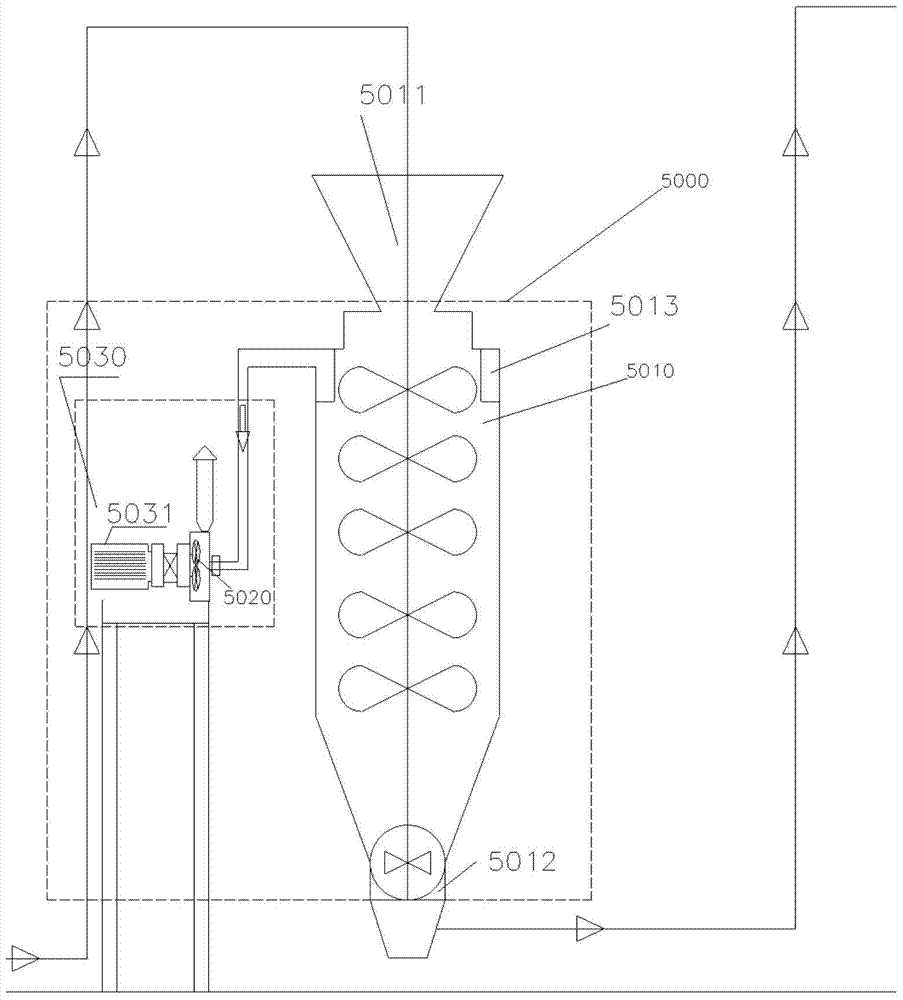

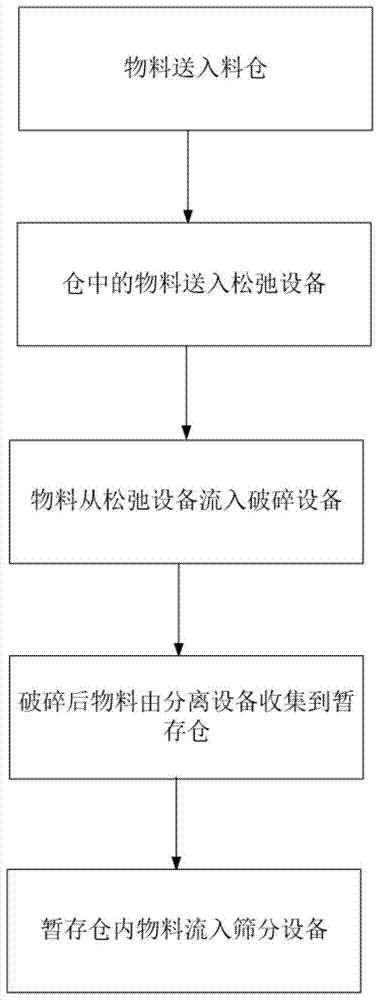

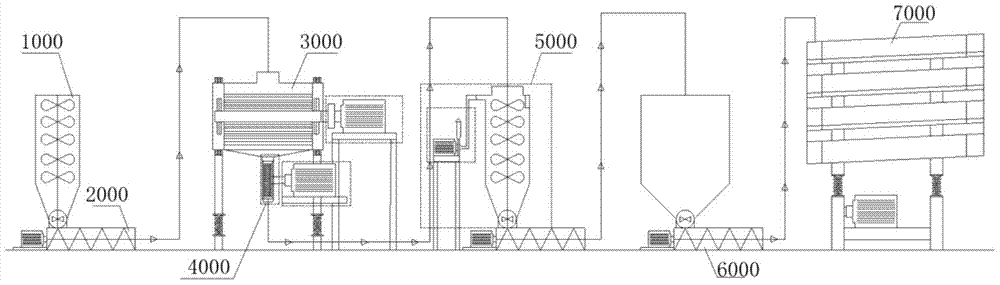

Equipment and method for selective crushing and separation of plant materials

The invention discloses a device and method for selective crushing and separation of plant materials. The selective crushing and separation device includes: a feeding hopper for containing materials to be processed; a relaxation device for realizing the particle structure of the material The release of the cohesive force between them; the crushing equipment, which realizes the separation of different cohesive forces in the material particles; the cyclone separation equipment, which collects all the crushed coarse and fine powder mixture materials into the temporary storage bin; screening device, the sieving device sieves the pulverized coarse and fine powder mixture into products of different particle size ranges and stores them separately. The equipment and method of the present invention realize the purpose of purely physical processing of plant materials, selective crushing and separation, and the equipment and method of the present invention can be used for all plant materials whose tissue structure properties are similar to jujube pulp particles containing skins and wheat bran , which will greatly improve the separation purity, material utilization rate and work efficiency of such raw materials.

Owner:连云港市赣榆区综合检验检测中心

Ecological interception repairing method of black and odorous riverway

PendingCN109896691AStrong targetingHigh implementabilityMultistage water/sewage treatmentAquatic animalEngineering

The invention aims to provide an ecological interception repairing method. To realize the aim, the invention is characterized in that firstly a riverway is segmented to be treating function areas, three interception areas of a physical plant interception area, a physical and biological interception area, and a comprehensive system interception area are arranged successively in the river direction,wherein the physical plant interception area comprises an interception filter screen, a cobblestone permeable dike and aquatic plants, the physical and biological interception area comprises a fibersubstrate permeable dike, aquatic plants and aquatic animals, and the comprehensive system interception area comprises a fiber substrate permeable dike, aquatic plants and animals, a artificial floating island and strains.

Owner:南京工大开元环保科技(滁州)有限公司 +1

3D plant modeling systems and methods

Systems and methods for leveraging a preliminary plant model to create a detailed physical plant model are presented. The system stores instances of component primitives, and can utilize stored geometries of the component primitives to identify a plurality of physical components to form a physical plant model. The physical plant model can realize at least a portion of the component runs based on equations and mapping definitions that establish relationships among the geometries of the component primitives and the physical plant model equipment and piping. The components of the physical plant model can be mapped to catalog items based on the geometries of the components. After translation, a bill of materials listing the physical plant model components can be produced.

Owner:FLUOR TECH CORP

Accurate linear parameter estimation with noisy inputs

InactiveUS7529651B2Reduce in quantityEar treatmentComputation using non-denominational number representationErrors and residualsComputer science

A method of building a model for a physical plant in the presence of noise can include initializing the model of the physical plant, wherein the model is characterized by a parameter vector, estimating an output of the model, and computing a composite cost comprising a weighted average of an error between the estimated output from the model and an actual output of the physical plant, and a derivative of the error. The method further can include determining a step size and a model update direction. The model of the physical plant can be updated. The updating step can be dependent upon the step size. Another embodiment can include the steps of determining a Kalman gain and determining an error vector comprised of two entries weighted by a scalar parameter.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com