Common plant model for modelling of physical plant items of production plant

A factory model and model technology, applied in data processing applications, special data processing applications, instruments, etc., can solve problems such as error-prone and difficult integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

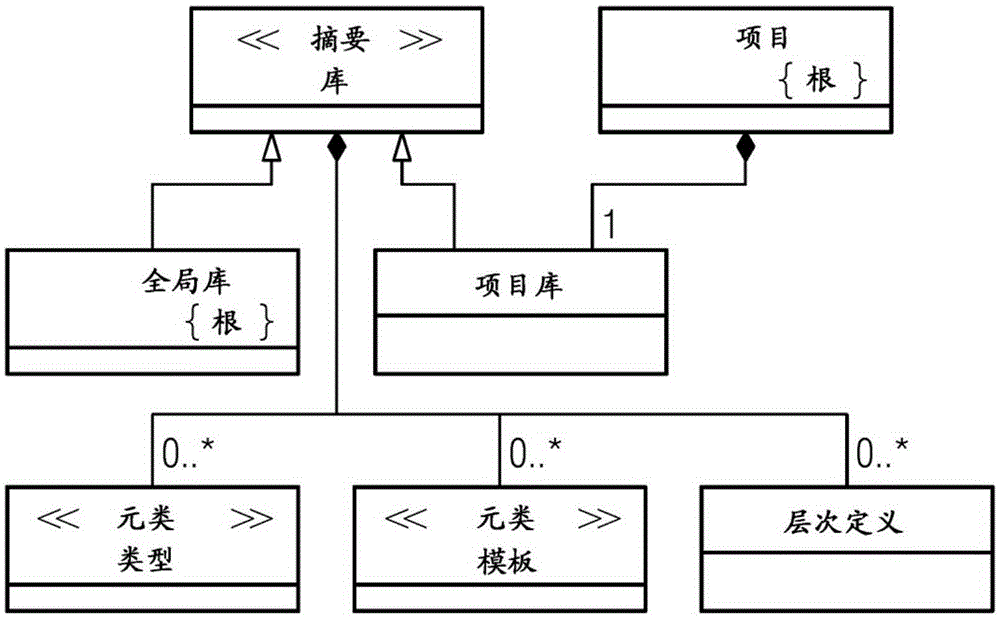

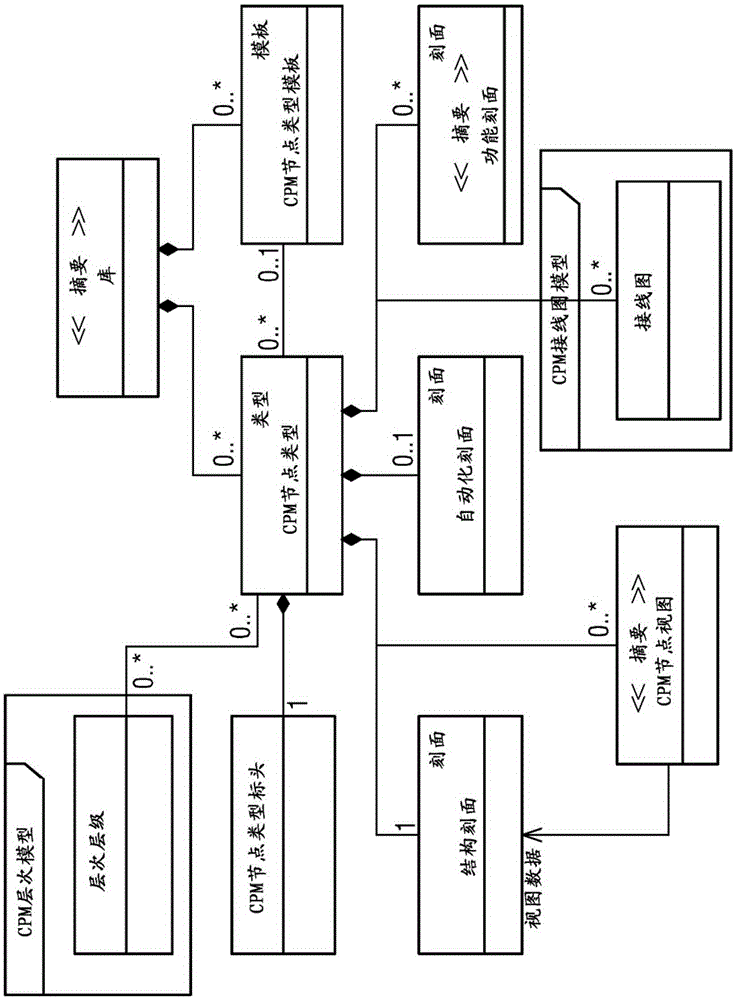

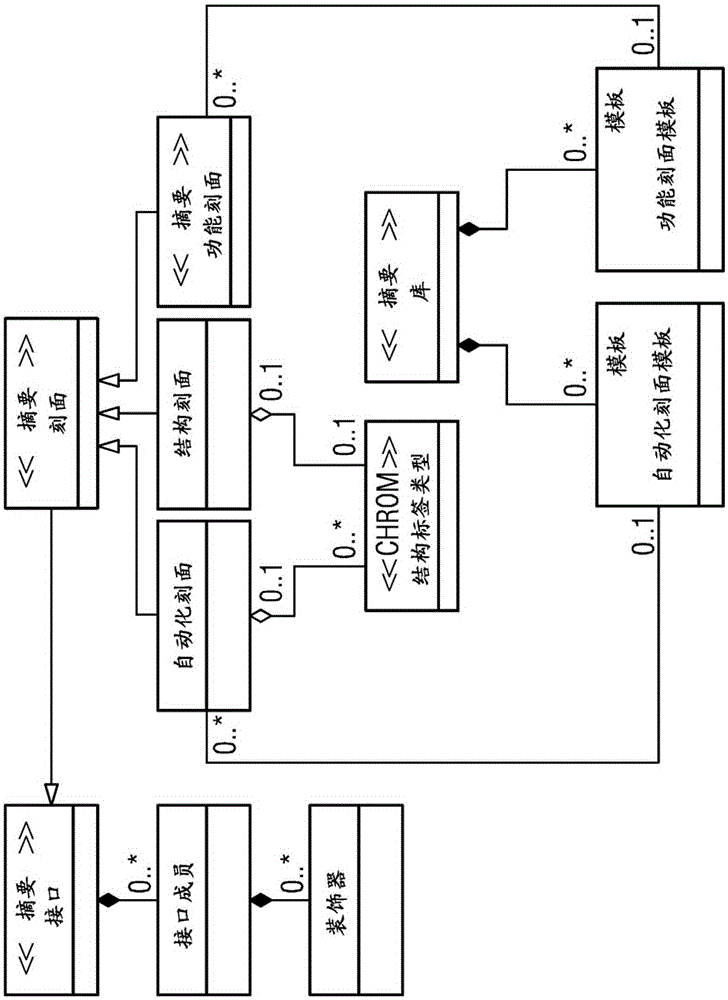

[0051] In the following, the object model of the Common Plant Model (hereinafter referred to as CPM) is described from an implementation-independent perspective. The general idea for the creation and application of the CPM is to employ a single software platform for the control and execution of the production process, where unique tasks are assigned to MES, SCADA and DCS+ systems. Customized software platforms are also referred to as projects in the following.

[0052] CPM is designed to model and organize every related item in a physical manufacturing plant. Physical plant items can represent fixed equipment, movable equipment, tools, assets, and so on. This specification uses the term "CPM node" for a physical plant item. The purpose of the CPM node is to aggregate different aspects for modeling a single plant entity element. This aggregation involves public interface parameters as well as automation parameters. All CPM nodes are characterized by a set of common paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com