Steel hot rolling management and control system and method based on digital twinning

A technology of management and control system and hot-rolled pipe, applied in the field of simulation, can solve the problems of negligible R&D investment, lack of system simulation analysis and decision feedback mechanism, no investment in service and production application, etc., and achieve the effect of convenient decision-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

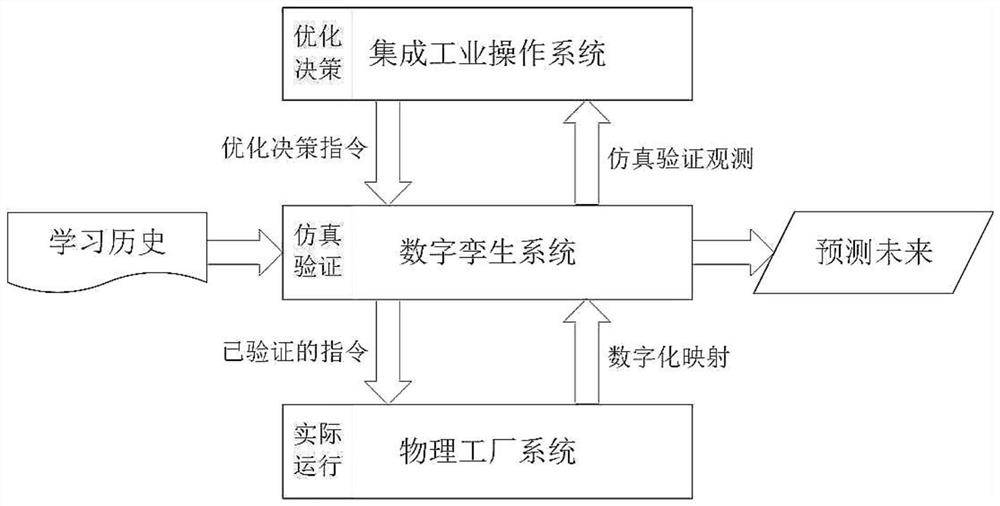

[0037] Such as figure 1 , the specific implementation system of the present invention comprises following 4 layers of structure:

[0038] Perception layer, which is used to perceive the environmental conditions of the physical factory, the operation status of equipment, and the quality attributes of hot-rolled slabs, etc., and simultaneously collect heterogeneous data and information fusion. It is the data source of digital twin information interaction, and the subsequent functions Both the implementation and the representation of the state will depend on these data.

[0039] The data layer, which is used to be the core link in the four levels, mainly includes data collection, data storage, data transmission and data analysis. Heterogeneous production equipment and material data is to provide real-time data of each data point in the form of OPCSERVER, and realize communication through TCP / UDP communication technology; the purpose of data storage is to transmit production plan...

Embodiment 2

[0047] According to the digital twin technology-based management and control system and method for steel hot rolling provided by the present invention, it mainly aims at the steel hot rolling process scene, constructs a virtual simulation scene equivalent to a physical factory, and drives the virtual simulation entity based on technologies such as digital twin and big data calculation Realize the accurate tracking of virtual twins of physical factory production, pre-simulation of historical and future production plans, monitoring and health prediction of key production equipment, and display business and production status through large-screen projection or mobile augmented reality in two-dimensional or Three-dimensional visualized data elements, thus gaining an immersive interactive experience of the factory. This embodiment mainly includes four levels: perception layer, data layer, presentation layer and control layer, and functions are mainly divided into precise tracking, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com